ECU CITROEN DS4 2018 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2018, Model line: DS4, Model: CITROEN DS4 2018Pages: 296, PDF Size: 9.91 MB

Page 129 of 296

127

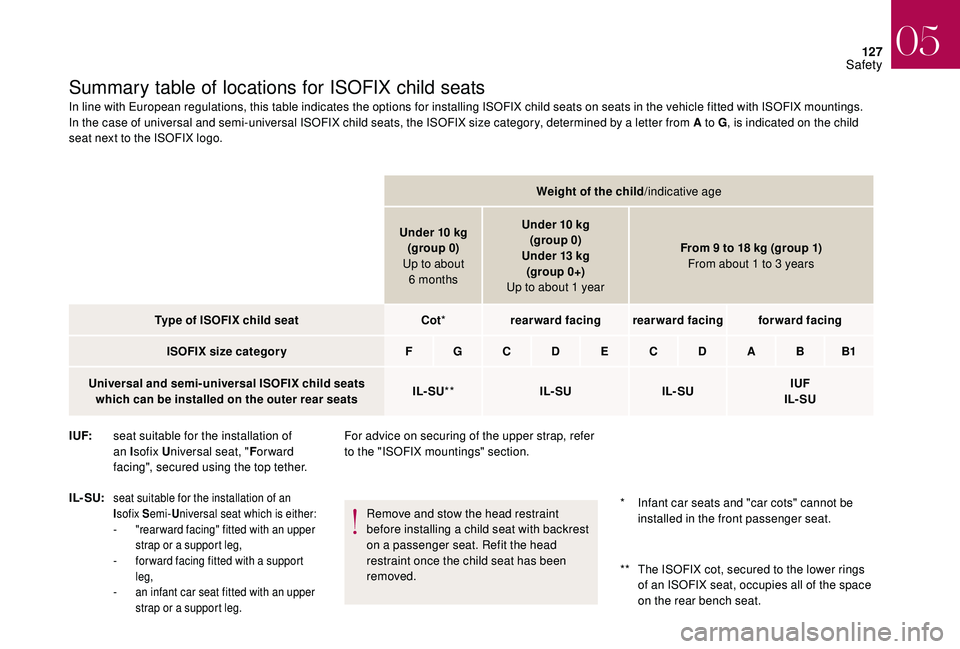

Summary table of locations for ISOFIX child seats

In line with European regulations, this table indicates the options for installing ISOFIX child seats on seats in the vehicle fitted with ISOFIX mountings.

In the case of universal and semi-universal ISOFIX child seats, the ISOFIX size category, determined by a letter from A to G, is indicated on the child

seat next to the ISOFIX logo.

Weight of the child/indicative age

Under 10 kg (group 0)

Up to about 6

monthsUnder 10 kg

(group 0)

Under 13 kg (group 0+)

Up to about 1 year From 9 to 18 kg (group 1)

From about 1 to 3 years

Type of ISOFIX child seat Cot* rearward facing rearward facing forward facing

ISOFIX size categor y F G C D E C D A B B1

Universal and semi-universal ISOFIX child seats which can be installed on the outer rear seats IL- SU

** IL- SU IL- SU IUF

IL- SU

I UF: seat suitable for the installation of

an Isofix U niversal seat, " For ward

facing", secured using the top tether.

IL- SU:

seat suitable for the installation of an

I sofix S emi-Universal seat which is either:

-

"

rear ward facing" fitted with an upper

strap or a support leg,

-

f

or ward facing fitted with a support

leg,

-

a

n infant car seat fitted with an upper

strap or a support leg.

For advice on securing of the upper strap, refer

to the "ISOFIX mountings" section.

Remove and stow the head restraint

before installing a child seat with backrest

on a passenger seat. Refit the head

restraint once the child seat has been

removed. *

I

nfant car seats and "car cots" cannot be

installed in the front passenger seat.

**

T

he ISOFIX cot, secured to the lower rings

of an ISOFIX seat, occupies all of the space

on the rear bench seat.

05

Safety

Page 130 of 296

128

The incorrect installation of a child seat in a

vehicle compromises the child's protection in

the event of an accident.

Ensure that there is no seat belt or seat belt

buckle under the child seat, as this could

destabilise it.

Remember to fasten the seat belts or the

child seat harnesses keeping the slack

relative to the child's body to a minimum,

even for short journeys.

When installing a child seat using the seat

belt, ensure that the seat belt is tightened

correctly on the child seat and that it secures

the child seat firmly on the seat of your

vehicle. If your passenger seat is adjustable,

move it for wards if necessary.

At rear seating positions, always leave

sufficient space between the front seat and:

-

a r

ear ward facing child seat,

-

t

he child's feet for a child seat fitted

forward facing.

To do this, move the front seat for wards

and, if necessary, move its backrest into the

upright position.

For optimal installation of the forward facing

child seat, verify that its backrest is as close

as possible to the backrest of the vehicle

seat, if possible in contact with it.

Advice

The head restraint must be removed

before installing a child seat with a

backrest on a passenger seat.

Ensure that the head restraint is stored or

attached securely to prevent it from being

thrown around the vehicle in the event of

sharp braking. Refit the head restraint when

the child seat is removed.

Front seat belts

The legislation on carrying children on the

front passenger seat is specific to each

country. Refer to the legislation in force in

your country.

Deactivate the passenger's front airbag when

a rear ward facing child seat is installed on the

front passenger seat.

Otherwise, the child risks being seriously

injured or killed if the airbag is deployed.

Installing a booster seat

The chest part of the seat belt must be

positioned on the child's shoulder without

touching the neck.

Ensure that the lap part of the seat belt

passes correctly over the child's thighs. We recommend using a booster seat with

a backrest equipped with a belt guide at

shoulder level.

As a safety precaution, do not leave:

-

a c

hild or children alone and unattended in

a vehicle,

-

a c

hild or an animal in a vehicle under the

sun, with the windows closed,

-

t

he keys within the reach of children inside

the vehicle.

To prevent accidental opening of the doors

and rear windows, use the child lock.

Take care not to open the rear windows by

more than one third.

To protect young children from the rays of the

sun, fit side blinds on the rear windows.

05

Safety

Page 175 of 296

173

F Turn the key clockwise to lock the towball fixing mechanism.

F

A

lways remove the key and keep it in a safe

place.

If the key cannot be turned or removed,

this means that the towball is not fitted

correctly; start the procedure again.

If any locking step fails, start the

procedure again.

In all cases, if the marking remains red, do

not use the towball and contact the dealer

network or a qualified workshop.

F

A

ttach the trailer to the tow ball. F

A ttach the cable on the trailer to the security

eye located on the carrier.

F

L

ower the trailer harness socket carrier

by pulling down the eye visible below the

b u m p e r.

F

R

aise the protective cover on the socket

and connect the trailer plug.

Removing the towball

F Disconnect the trailer wiring harness from the socket on the carrier.

F

D

etach the trailer safety cable from the eye

on the carrier.

F

D

etach the trailer from the towball.

F

R

eturn the trailer harness connector carrier

to the folded position.

07

Practical information

Page 183 of 296

181

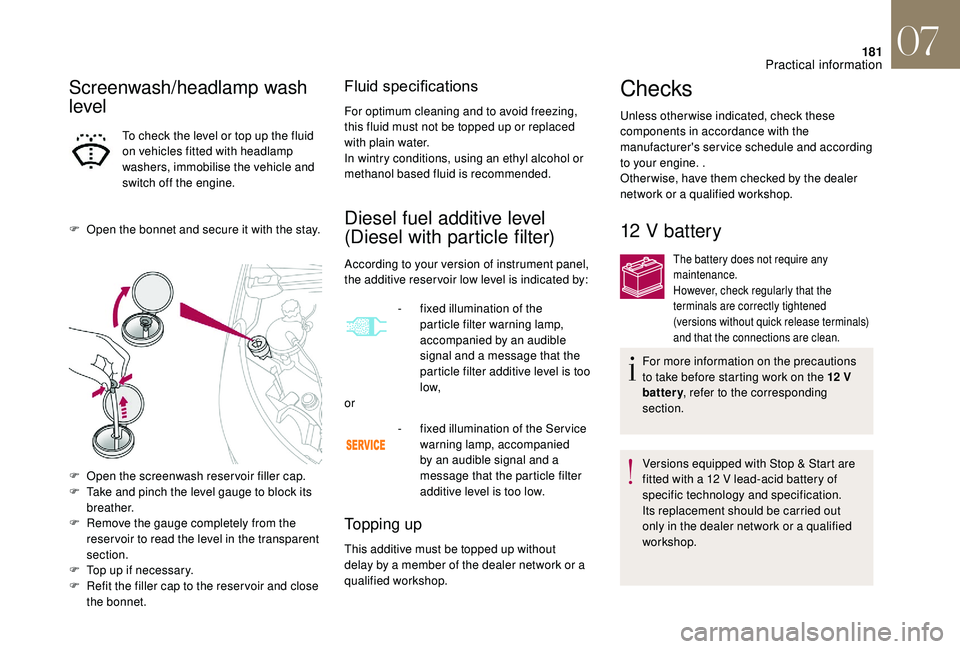

Screenwash/headlamp wash

level

To check the level or top up the fluid

on vehicles fitted with headlamp

washers, immobilise the vehicle and

switch off the engine.

F

O

pen the bonnet and secure it with the stay.

F

O

pen the screenwash reservoir filler cap.

F

T

ake and pinch the level gauge to block its

breather.

F

R

emove the gauge completely from the

reser voir to read the level in the transparent

section.

F

T

op up if necessary.

F

R

efit the filler cap to the reser voir and close

the bonnet.

Fluid specifications

For optimum cleaning and to avoid freezing,

this fluid must not be topped up or replaced

with plain water.

In wintry conditions, using an ethyl alcohol or

methanol based fluid is recommended.

Diesel fuel additive level

(Diesel with particle filter)

According to your version of instrument panel,

the additive reser voir low level is indicated by:

Topping up

This additive must be topped up without

delay by a member of the dealer network or a

qualified workshop. -

f

ixed illumination of the

particle filter warning lamp,

accompanied by an audible

signal and a message that the

particle filter additive level is too

low,

or

-

f

ixed illumination of the Ser vice

warning lamp, accompanied

by an audible signal and a

message that the particle filter

additive level is too low.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine. .

Otherwise, have them checked by the dealer

network or a qualified workshop.

12 V battery

The battery does not require any

maintenance.

However, check regularly that the

terminals are correctly tightened

(versions without quick release terminals)

and that the connections are clean.

For more information on the precautions

to take before starting work on the 12 V

battery , refer to the corresponding

section.

Versions equipped with Stop & Start are

fitted with a 12 V lead-acid battery of

specific technology and specification.

Its replacement should be carried out

only in the dealer network or a qualified

workshop.

07

Practical information

Page 187 of 296

185

Keep AdBlue® out of the reach of children,

in its original container or bottle.

Never transfer AdBlue

® to another

container: it would lose its purity.

Never dilute AdBlue

® with water.

Never pour AdBlue® into the Diesel fuel

tank. Containers or bottles are available from the

dealer network or a qualified workshop.

Never top up from an AdBlue

® dispenser

reserved for heavy goods vehicles.

Recommendations on storage

AdBlue® freezes below around -11°C and

deteriorates above 25°C. It is recommended

that bottles or containers be stored in a cool

place and protected from direct sunlight.

Under these conditions, the fluid can be kept

for at least a year.

If the additive has frozen, it can be used once it

has completely thawed out.

Never store bottles or containers of

AdBlue

® in your vehicle.

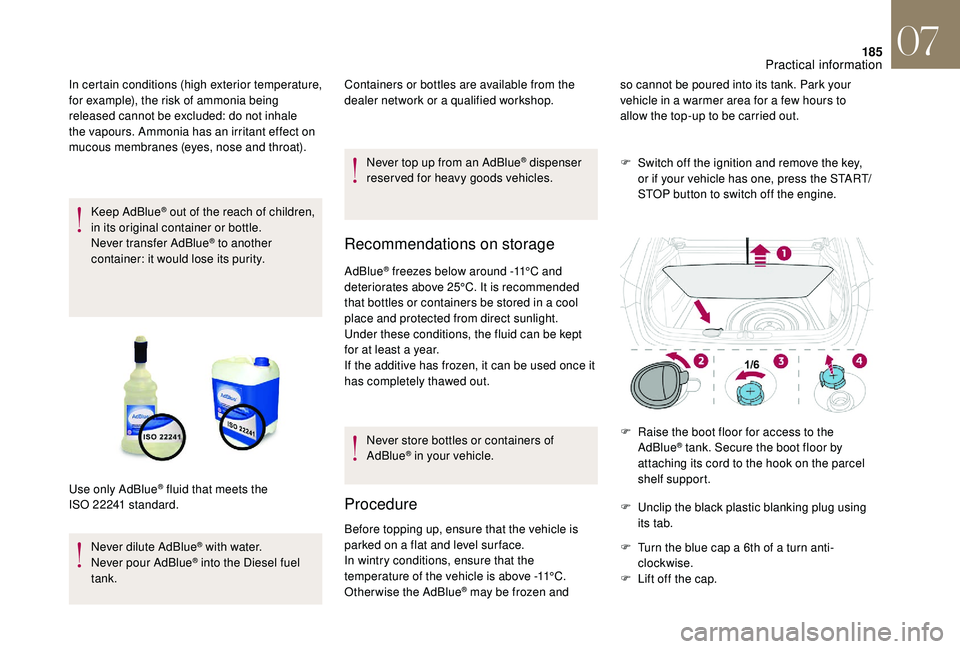

Procedure

Before topping up, ensure that the vehicle is

parked on a flat and level sur face.

In wintry conditions, ensure that the

temperature of the vehicle is above -11°C.

Otherwise the AdBlue

® may be frozen and F

S

witch off the ignition and remove the key,

or if your vehicle has one, press the START/

STOP button to switch off the engine.

F

R

aise the boot floor for access to the

AdBlue

® tank. Secure the boot floor by

attaching its cord to the hook on the parcel

shelf support.

F

U

nclip the black plastic blanking plug using

its tab.

F

T

urn the blue cap a 6th of a turn anti-

clockwise.

F

L

ift off the cap.

In certain conditions (high exterior temperature,

for example), the risk of ammonia being

released cannot be excluded: do not inhale

the vapours. Ammonia has an irritant effect on

mucous membranes (eyes, nose and throat).

Use only AdBlue

® fluid that meets the

ISO

22241 standard. so cannot be poured into its tank. Park your

vehicle in a warmer area for a few hours to

allow the top-up to be carried out.

07

Practical information

Page 192 of 296

190

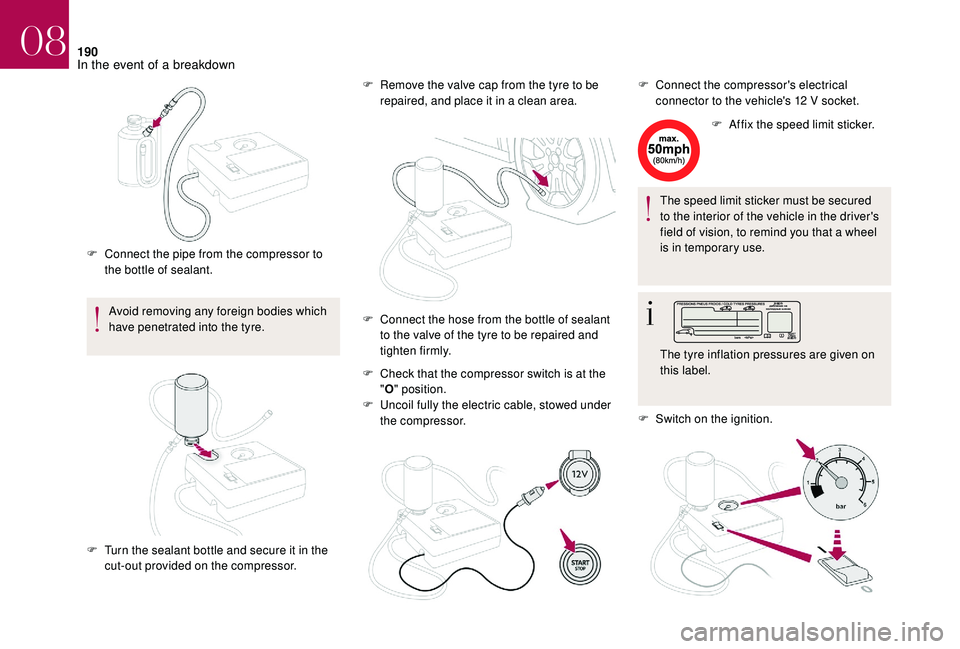

Avoid removing any foreign bodies which

have penetrated into the tyre.F

R

emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor. The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

F

C

onnect the pipe from the compressor to

the bottle of sealant.

F

T

urn the sealant bottle and secure it in the

cut-out provided on the compressor. F

C onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly. F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket.

The tyre inflation pressures are given on

this label.

F

S

witch on the ignition.F

A

ffix the speed limit sticker.

08

In the event of a breakdown

Page 194 of 296

192

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's electric plug to

the vehicle's 12 V socket.

F

S

witch on the ignition. F

S

witch on the compressor by moving the

switch to the position " I" and adjust the

pressure as shown on the vehicle tyre

pressure label. To deflate: press the black

button on the compressor hose by the valve

connector.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

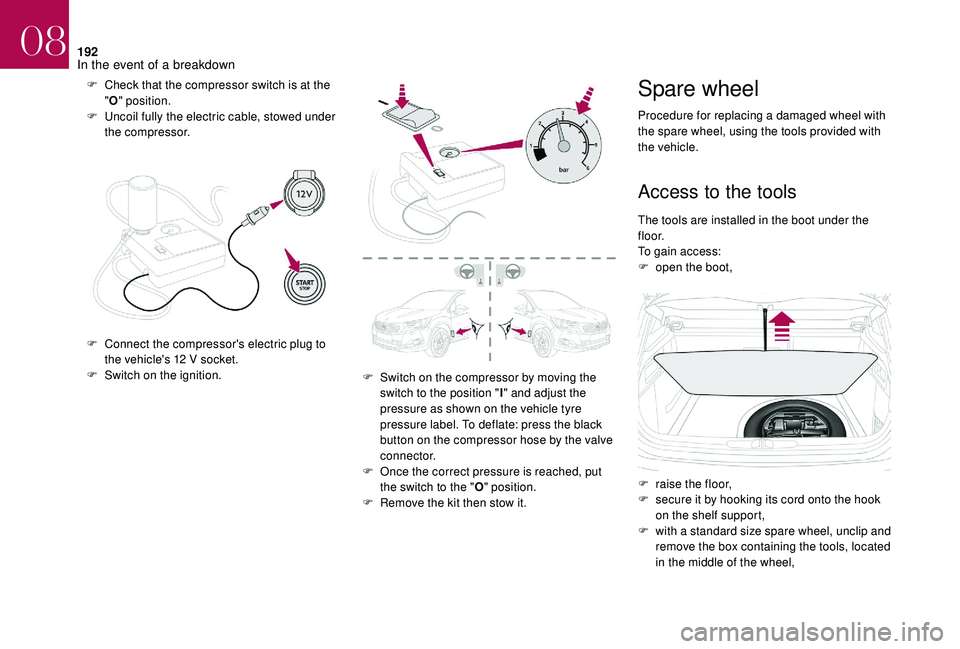

emove the kit then stow it.Spare wheel

Procedure for replacing a damaged wheel with

the spare wheel, using the tools provided with

the vehicle.

Access to the tools

The tools are installed in the boot under the

f l o o r.

To gain access:

F

o

pen the boot,

F

r

aise the floor,

F

s

ecure it by hooking its cord onto the hook

on the shelf support,

F

w

ith a standard size spare wheel, unclip and

remove the box containing the tools, located

in the middle of the wheel,

08

In the event of a breakdown

Page 195 of 296

193

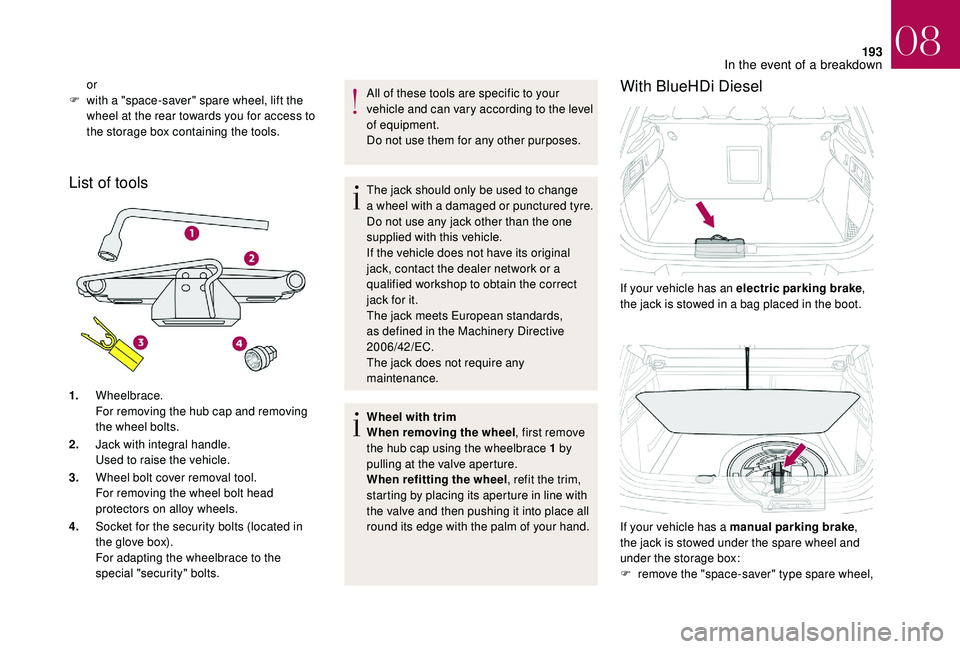

List of tools

1.Wheelbrace.

For removing the hub cap and removing

the wheel bolts.

2. Jack with integral handle.

Used to raise the vehicle.

3. Wheel bolt cover removal tool.

For removing the wheel bolt head

protectors on alloy wheels.

4. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the

special "security" bolts. All of these tools are specific to your

vehicle and can vary according to the level

of equipment.

Do not use them for any other purposes.

The jack should only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original

jack, contact the dealer network or a

qualified workshop to obtain the correct

jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

Wheel with trim

When removing the wheel

, first remove

the hub cap using the wheelbrace 1 by

pulling at the valve aperture.

When refitting the wheel , refit the trim,

starting by placing its aperture in line with

the valve and then pushing it into place all

round its edge with the palm of your hand.

With BlueHDi Diesel

If your vehicle has an electric parking brake ,

the jack is stowed in a bag placed in the boot.

or

F

w

ith a "space-saver" spare wheel, lift the

wheel at the rear towards you for access to

the storage box containing the tools.

If your vehicle has a manual parking brake,

the jack is stowed under the spare wheel and

under the storage box:

F

r

emove the "space-saver" type spare wheel,

08

In the event of a breakdown

Page 197 of 296

195

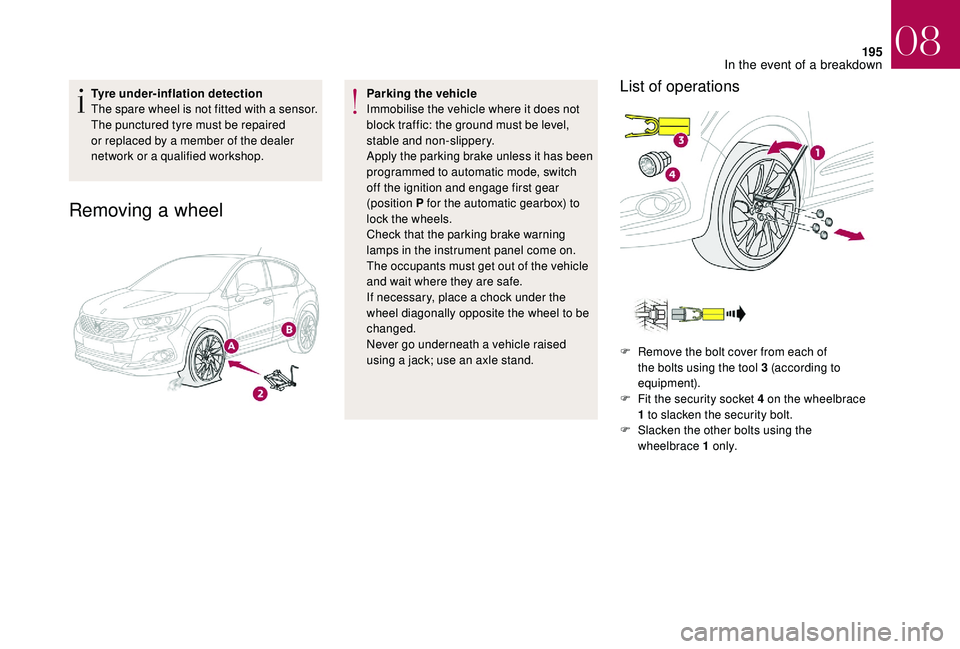

Tyre under-inflation detection

The spare wheel is not fitted with a sensor.

The punctured tyre must be repaired

or replaced by a member of the dealer

network or a qualified workshop.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and non-slippery.

Apply the parking brake unless it has been

programmed to automatic mode, switch

off the ignition and engage first gear

(position P for the automatic gearbox) to

lock the wheels.

Check that the parking brake warning

lamps in the instrument panel come on.

The occupants must get out of the vehicle

and wait where they are safe.

If necessary, place a chock under the

wheel diagonally opposite the wheel to be

changed.

Never go underneath a vehicle raised

using a jack; use an axle stand.List of operations

F Remove the bolt cover from each of the bolts using the tool 3 (according to

equipment).

F

F

it the security socket 4 on the wheelbrace

1 to slacken the security bolt.

F

S

lacken the other bolts using the

wheelbrace 1 o n l y.

08

In the event of a breakdown

Page 199 of 296

197

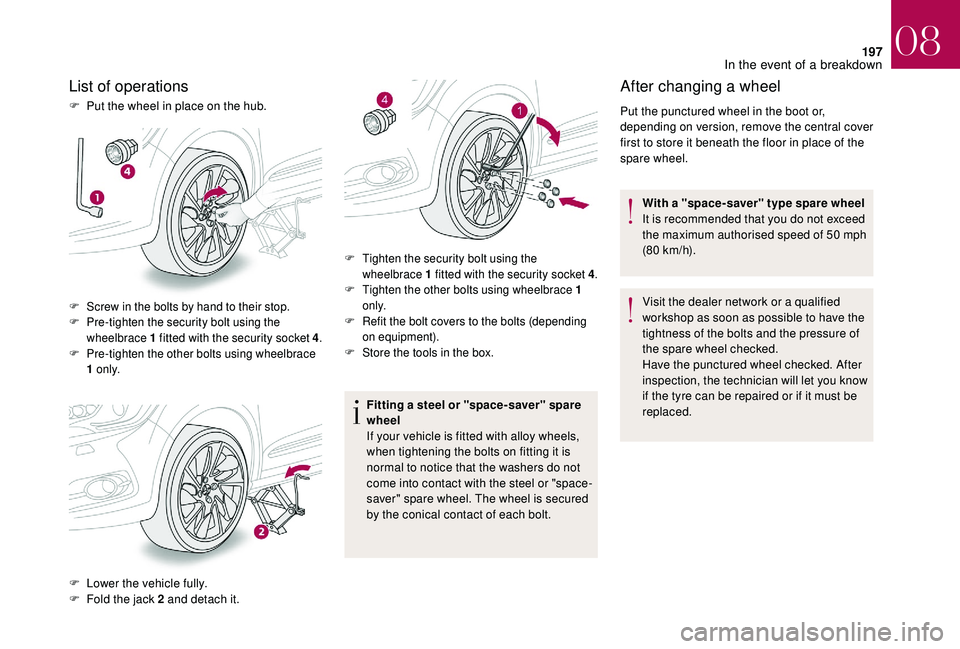

F Screw in the bolts by hand to their stop.

F P re-tighten the security bolt using the

wheelbrace 1 fitted with the security socket 4 .

F

P

re-tighten the other bolts using wheelbrace

1 o n l y.

F Lower the vehicle fully.

F F old the jack 2 and detach it.

F Tighten the security bolt using the wheelbrace 1 fitted with the security socket 4 .

F

T

ighten the other bolts using wheelbrace 1

o n l y.

F

R

efit the bolt covers to the bolts (depending

on equipment).

F

S

tore the tools in the box.

Fitting a steel or "space-saver" spare

wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting it is

normal to notice that the washers do not

come into contact with the steel or "space-

saver" spare wheel. The wheel is secured

by the conical contact of each bolt.

After changing a wheel

Put the punctured wheel in the boot or,

depending on version, remove the central cover

first to store it beneath the floor in place of the

spare wheel.With a "space-saver" type spare wheel

It is recommended that you do not exceed

the maximum authorised speed of 50 mph

(80 km/h).

Visit the dealer network or a qualified

workshop as soon as possible to have the

tightness of the bolts and the pressure of

the spare wheel checked.

Have the punctured wheel checked. After

inspection, the technician will let you know

if the tyre can be repaired or if it must be

replaced.

List of operations

F Put the wheel in place on the hub.

08

In the event of a breakdown