wheel bolts Citroen GRAND C4 PICASSO RHD 2016 2.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2016, Model line: GRAND C4 PICASSO RHD, Model: Citroen GRAND C4 PICASSO RHD 2016 2.GPages: 523, PDF Size: 13.63 MB

Page 266 of 523

264

Accessories

A wide range of accessories and genuine parts is available from the CITROËN dealer network.

T hese accessories and parts are all suitable for your vehicle and benefit from CITROËN's recommendation and warranty.

"Comfort"

Door deflectors, sun blind, insulated module, coat hanger fixed to head restraint, mobile

r

eading lamp, mirror for caravan, front and rear

par

king

s

ensors,

p

rogrammable

a

dditional

h

eating, smoker's kit, solar film for rear door

w

indows, portable scented air freshener...

"Transport systems"

Boot carpet, boot liner, boot net, boot

spacers, transverse roof bars, ski carrier, roof

b

oxes, towbars, towbar wiring harnesses,

b

icycle carriers for towbar and roof bars,

t

owbars with fixed and detachable towball,

s

eparation net, sliding carrier, boot organiser

(

Grand C4 Picasso)...

If

a towbar and wiring harness are fitted

o

utside the CITROËN dealer network, the

i

nstallation must be done strictly in line with the

ma

nufacturer's

r

ecommendations.

If

your vehicle has a detachable towball, it is

r

ecommended that the ball be removed when

n

ot towing.

"Styling"

Gear lever knobs, aluminium foot rest, alloy wheels, door sill finishers, interior mirror

s

hells...

"Security and safety"

Anti-intrusion alarm, vehicle tracking system, c hild seats and booster cushions, breathalyser,

f

irst aid kit, fire extinguisher, warning triangle,

h

igh visibility vest, wheel security bolts, snow

c

hains, non-slip covers, winter tyres, foglamp

k

it, security film for front door windows, dog

g

uard, pet seat belt...

"Protection"

Mats*, seat covers compatible with lateral airbags, mud flaps, door protective mouldings,

b

umper protection strips, vehicle cover, boot

s

ill protector, door sill protectors, seat and boot

p

rotective covers for pets...

The

rear bodywork has been designed to avoid

s

p r ay.

*

T

o avoid any risk of jamming the pedals:

-

e

nsure that mats are correctly positioned

a

nd secured,

-

n

ever fit one mat on top of another.

Practical information

Page 291 of 523

289

Spare wheel

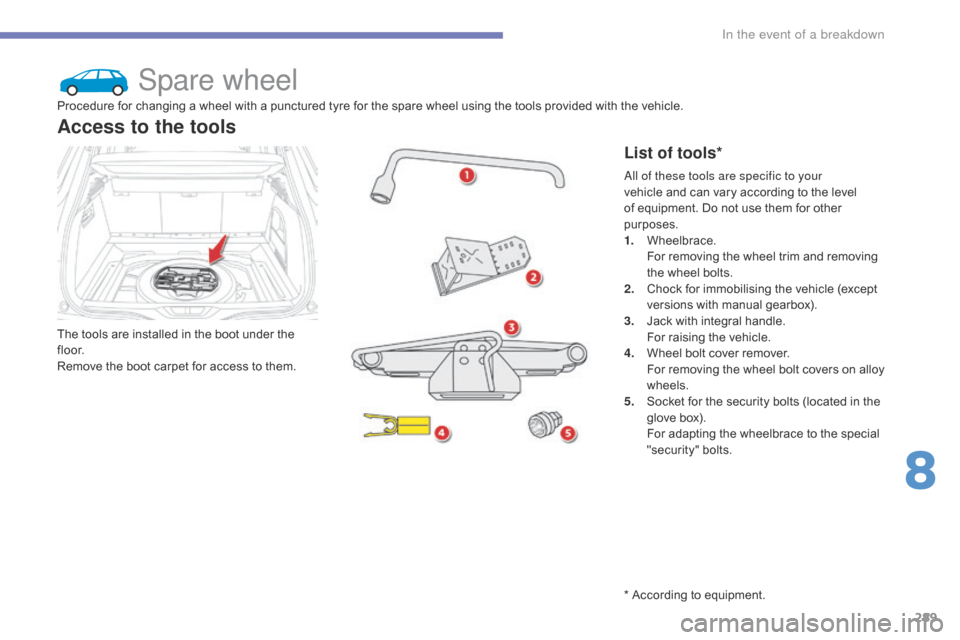

The tools are installed in the boot under the fl o o r.

Remove

the boot carpet for access to them.

Access to the tools

List of tools*

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

A ll of these tools are specific to your

vehicle

and can vary according to the level

o

f equipment. Do not use them for other

p

urposes.

1.

W

heelbrace.

F

or removing the wheel trim and removing

t

he wheel bolts.

2.

C

hock for immobilising the vehicle (except

v

ersions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (located in the

g

love box).

F

or adapting the wheelbrace to the special

"s

ecurity"

b

olts.

*

According to equipment.

8

In the event of a breakdown

Page 293 of 523

291

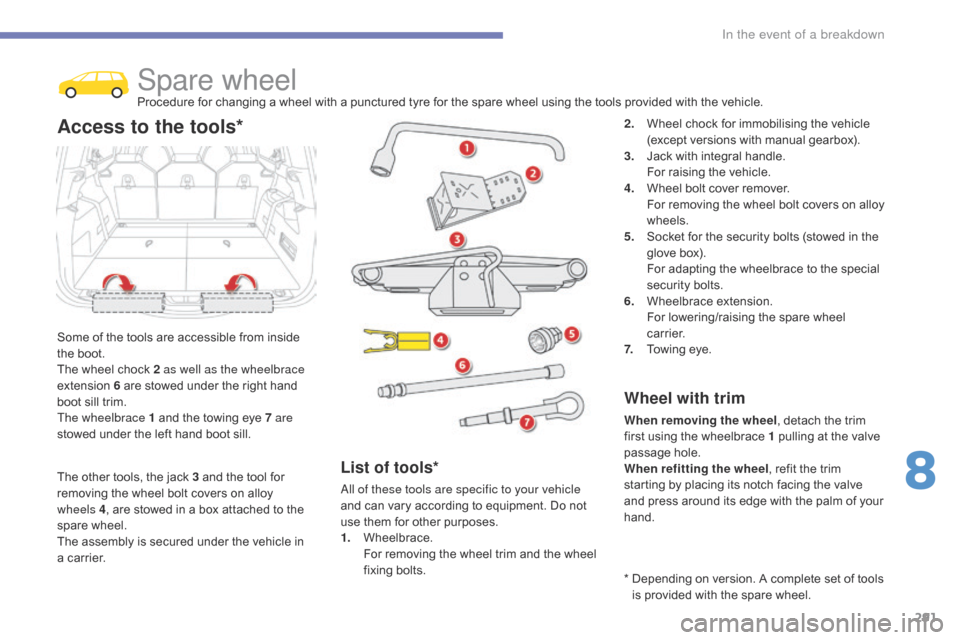

Spare wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

S

ome

of

the

tools are accessible from inside

t

he

boot.

The

wheel

chock 2 as well as the wheelbrace

extension

6

are stowed under the right hand

b

oot

sill

trim.

The wheelbrace 1

and the towing eye 7 are

stowed

under

the left hand boot sill.

Access to the tools*2. Wheel chock for immobilising the vehicle (

except versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (stowed in the

g

love box).

F

or adapting the wheelbrace to the special

s

ecurity bolts.

6.

W

heelbrace

e

xtension.

F

or lowering/raising the spare wheel

c

a r r i e r.

7.

T

owing eye.

Wheel with trim

When removing the wheel , detach the trim f

irst using the wheelbrace 1 pulling at the valve

p

assage hole.

When refitting the wheel ,

refit the trim

s

tarting by placing its notch facing the valve

a

nd press around its edge with the palm of your

han

d.

List of tools*

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

f

ixing

bol

ts. *

D

epending on version. A complete set of tools

i

s provided with the spare wheel.

The

other

tools,

the

jack

3

and

the

tool

for

r

emoving

the

wheel

bolt

covers

on

alloy

w

heels

4 ,

are

stowed

in

a

box

attached

to

the

spar

e

w

heel.

The

assembly

is

secured

under

the

vehicle

in

a

carrier.

8

In the event of a breakdown

Page 297 of 523

295

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not block traffic: the ground must be level,

s

table and not slippery.

Apply

the parking brake unless it has

b

een programmed to automatic mode,

s

witch off the ignition and engage first

g

ear* to block the wheels.

Check

that the braking warning lamp

a

nd the P warning lamp in the parking

b

rake control lever come on.

For

greater safety, place the chock 2

against

the wheel opposite to the one

b

eing

c

hanged.

The

occupants must get out of the

v

ehicle and wait where they are safe.

Never

go underneath a vehicle

s

upported by a jack; use an axle stand.

List of operations

F Remove the wheel bolt cover(s) using the t

ool 4 (depending on equipment).

F

F

it the security socket 5 on the

wheelbrace

1 to slacken the security bolt

(

if fitted).

F

S

lacken the other bolts (no more than a

1

/4 turn) using the wheelbrace 1

o

n l y.

* Position P

for

an

automatic

gearbox. Do

not use:

-

t

he jack for any purpose other than

l

ifting the vehicle,

-

a

ny other jack than the one

s

upplied by the manufacturer.F

P

lace the foot of the jack 3 on the ground

a

nd check that it is directly below the

f

ront A or rear B jacking point provided on

t

he underbody, whichever is closest to the w

heel to be changed.

Ensure that the jack is stable. If the

g

round is slippery or loose, the jack

m

ay slip or drop - Risk of injury!

Ensure

that the jack is positioned only

a

t one of the jacking points A or B

under

the vehicle, making sure that the

v

ehicle's contact sur face is centred on

t

he head of the jack. Other wise there is

a

risk of damage to the vehicle and/or of

t

he jack dropping - Risk of injury!

8

In the event of a breakdown

Page 298 of 523

296

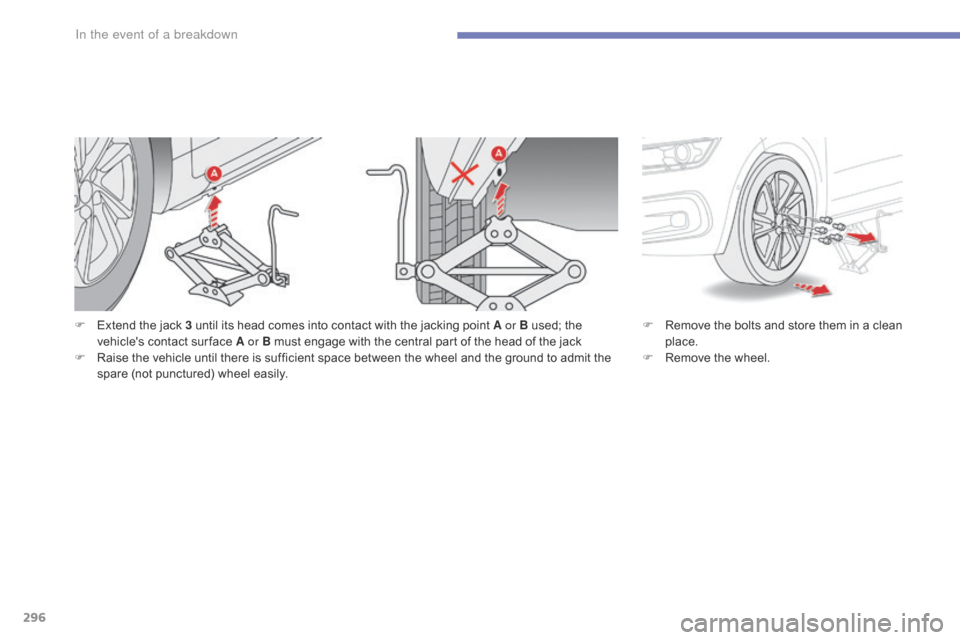

F Extend the jack 3 until its head comes into contact with the jacking point A or B used; the v

ehicle's contact sur face A or B must engage with the central part of the head of the jack

F

R

aise the vehicle until there is sufficient space between the wheel and the ground to admit the

s

pare (not punctured) wheel easily. F

R emove the bolts and store them in a clean p

lace.

F

R

emove the wheel.

In the event of a breakdown

Page 299 of 523

297

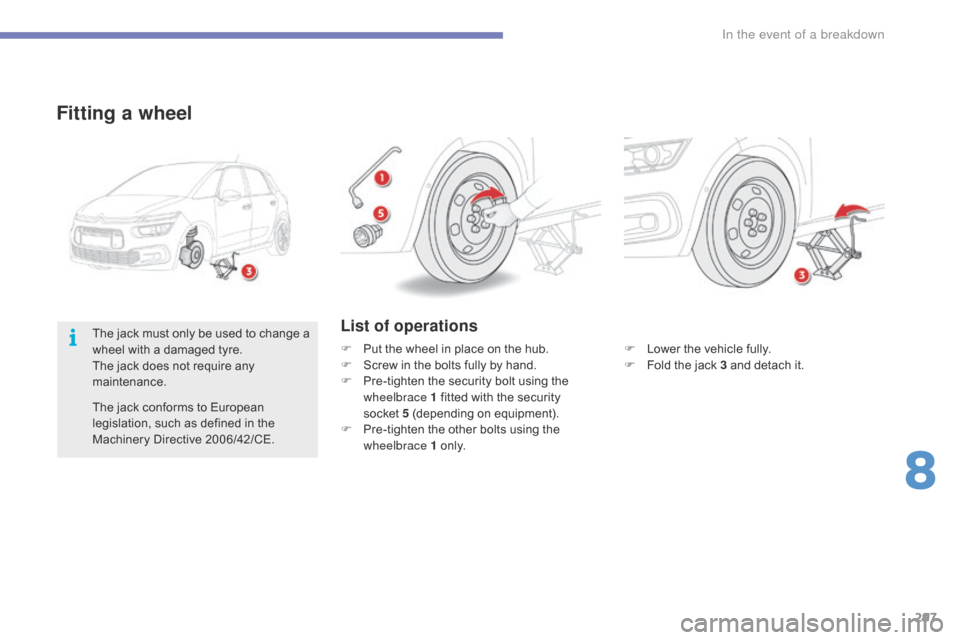

Fitting a wheel

F Lower the vehicle fully.

F F old the jack 3 and detach it.

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts fully by hand.

F

P

re-tighten the security bolt using the

w

heelbrace 1 fitted with the security

s

ocket 5

(depending on equipment).

F

P

re-tighten the other bolts using the

w

heelbrace 1

o

n l y.

The

jack

must

only

be

used

to

change

a

w

heel

with

a

damaged

tyre.

The

jack

does

not

require

any

m

aintenance.

The

jack

conforms

to

European

l

egislation,

such

as

defined

in

the

M

achinery

Directive

2006/42/CE.

8

In the event of a breakdown

Page 300 of 523

298

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels, when tightening the bolts on fitting, it

i

s normal to notice that the washers

d

o not come into contact with the

"

space-saver" spare wheel. The wheel

i

s secured by the conical sur face of

e

ach bolt.

After changing a wheel

To correctly store the punctured wheel in the boot ( not in the location for the

space-saver wheel ),

first remove the

c

entral cover.

When

using the "space-saver" type

s

pare wheel, do not exceed 50 mph

(

80 km/h).

Have

the tightening of the bolts and the

p

ressure of the spare wheel checked

b

y a CITROËN dealer or a qualified

w

orkshop without delay.

Have

the punctured wheel repaired

a

nd refitted to the vehicle as soon as

p

ossible.

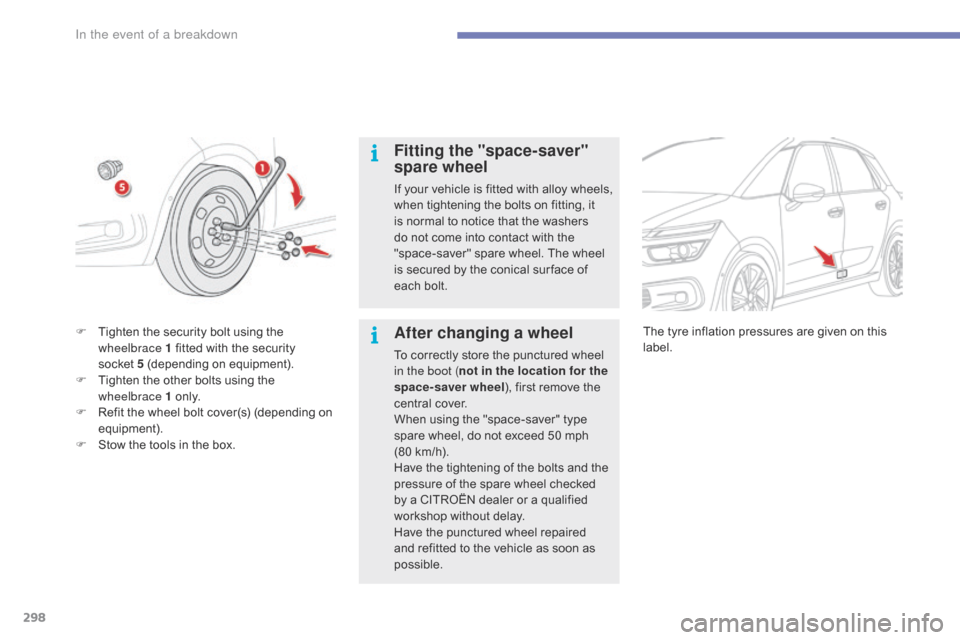

F

T

ighten

the

security

bolt

using

the

w

heelbrace 1

fitted

with

the

security

s

ocket 5

(depending

on

equipment).

F

T

ighten

the

other

bolts

using

the

w

heelbrace 1

o

n l y.

F

R

efit

the

wheel

bolt

cover(s)

(depending

on

e

quipment).

F

S

tow

the

tools

in

the

box. The

tyre inflation pressures are given on this lab

el.

In the event of a breakdown