ECU CITROEN RELAY 2020 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2020, Model line: RELAY, Model: CITROEN RELAY 2020Pages: 196, PDF Size: 34.07 MB

Page 66 of 196

64

Driving

Driving recommendations

► Observe the driving regulations and remain

vigilant whatever the traffic conditions.

► Monitor your environment and keep your

hands on the wheel to be able to react to

anything that may happen any time.

► Drive smoothly, anticipate the need for

braking and maintain a longer safety distance,

especially in bad weather.

► Stop the vehicle to carry out operations that

require close attention (such as adjustments).

► During long trips, take a break every two

hours.

Important!

Never leave the engine running in a

closed space without sufficient

ventilation. Internal combustion engines emit

toxic exhaust gases such as carbon

monoxide. Danger of poisoning and death!

In severe wintry conditions (temperature

below -23°C), let the engine run for 4

minutes before moving off, to ensure the

correct operation and durability of the

mechanical components of your vehicle

(engine and gearbox).

Never drive with the parking brake

applied . Risk of overheating and

damage to the braking system!

Do not park the vehicle or leave the

engine running on a flammable

surface (dry grass, dead leaves, etc.). The

exhaust system of your vehicle is very hot,

even several minutes after the engine stops.

Risk of fire!

Never leave a vehicle unattended with

the engine running. If you have to leave

your vehicle with the engine running, apply

the parking brake and put the gearbox into

neutral or position N or P (depending on the

type of gearbox).

Never leave children inside the vehicle

unsupervised.

To assure the durability of your vehicle and your safety, remember that certain precautions,

described hereafter, should be taken when

driving your vehicle :

Manoeuvre cautiously, at low speed

The dimensions of your vehicle differ from those

of a light vehicle, in width, in height, as well as in

length, and some obstacles will be more difficult

to notice.

Manoeuvre slowly.

Before turning, check that there are no obstacles

at mid-height along the sides.

Before reversing, check that there are no

obstacles, particularly at high level behind the

vehicle. Be aware of the external dimensions, if ladders

are fitted.

Load the vehicle correctly

With a load carried, the vehicle must remain

within the maximum authorised weight, the

Gross Vehicle Weight.

To avoid upsetting the balance of the vehicle,

the load should be centred and the heaviest part

placed on the floor in front of the rear wheels.

It is inadvisable to place heavy loads on a roof

rack.

Loading also implies adherence to the maximum

load of the roof bar anchor points. Adhere to

the maximum permissible weight, according to

CITROËN dealer specifications.

Loads must be securely lashed down.

A load that is not properly secured inside the

vehicle may affect vehicle handling and create a

risk of accident.

If your vehicle is fitted with a drop-side back, the

height and width of the load must remain within

the overall dimensions of the vehicle.

Drive the vehicle in a prudent and efficient

way

Take corners gently.

Anticipate the need to brake as the stopping

distance is increased, particularly on wet or icy

roads.

Be aware of the effect of side winds on the

vehicle.

Effective eco-driving saves fuel; accelerate

progressively, anticipate the need to slow down

and adapt your speed to suit the situation.

Indicate changes of direction well in advance so

that you are seen by other road users.

Take care

The tyres must be inflated to at least the

pressures indicated on the label, even over-

inflated by 0.2 to 0.3 bar for long journeys.

On flooded roads

We strongly advise against driving on flooded

roads, as this could cause serious damage to

the engine or gearbox, as well as to the electrical

systems of your vehicle.

If you are obliged to drive on a flooded road:

► check that the depth of water does not

exceed 15 cm, taking account of waves that

might be generated by other users,

► deactivate the Stop & Start function,

► drive as slowly as possible without stalling. In

all cases, do not exceed 6 mph (10 km/h),

► do not stop and do not switch off the engine.

Page 76 of 196

74

Driving

the whole manoeuvre, in particular using the

mirrors.

Radar

The operation of the radar as well as the

associated functions may be impaired through

the accumulation of dirt (mud, frost, etc.), in

certain difficult weather conditions (very heavy

rain, snow) or if the bumper is damaged.

If the front bumper is to be repainted, contact

a CITROËN dealer or a qualified workshop;

certain types of paint could interfere with the

operation of the radar.

Driving aids camera

This camera and its associated functions

may be impaired or not work if the windscreen

area in front of the camera is dirty, misty,

frosty, covered with snow, damaged or

masked by a sticker.

In humid and cold weather, demist the

windscreen regularly.

Poor visibility (inadequate street lighting,

heavy rain, thick fog, snowfall), dazzle

(headlamps of an oncoming vehicle, low sun,

reflections on a damp road, leaving a tunnel,

alternating shade and light) can also impair

detection performance.

In the event of a windscreen replacement,

contact a CITROËN dealer or a qualified

workshop to recalibrate the camera;

otherwise, the operation of the associated

driving aids may be disrupted.

Other cameras

The images from the camera(s)

displayed on the touch screen or on the

instrument panel may be distorted by the

relief.

In the presence of areas in shade, or in

conditions of bright sunlight or inadequate

lighting, the image may be darkened and with

lower contrast.

Obstacles may appear further away than they

actually are.

Sensors

The operation of the sensors as well as

the associated functions may be disturbed

by sound interference such as that emitted

by noisy vehicles and machinery (e.g. lorries,

pneumatic drills), by the accumulation of

snow or dead leaves on the road or in the

event of damaged bumpers and mirrors.

When reverse gear is engaged, an audible

signal (long beep) indicates that the sensors

may be dirty.

A front or rear impact to the vehicle can

upset the sensors’ settings, which is not

always detected by the system: distance

measurements may be distorted.

The sensors do not systematically detect

obstacles that are too low (pavements, studs)

or too thin (trees, posts, wire fences).

Certain obstacles located in the sensors’ blind

spots may not be detected or may no longer

be detected during the manoeuvre.

Certain materials (fabrics) absorb sound

waves: pedestrians may not be detected.

Maintenance

Clean the bumpers and door mirrors and

the field of vision of the cameras regularly.

When washing your vehicle at high pressure,

direct the spray from at least 30 cm away

from the radar, sensors and cameras.

Mats

The use of mats not approved by

CITROËN may interfere with the operation of

the speed limiter or cruise control.

To avoid any risk of jamming the pedals:

► ensure that the mat is secured correctly,

► never fit one mat on top of another.

Units of speed

Ensure that the units of speed displayed

on the instrument panel (mph or km/h) are

those for the country you are driving in.

If this is not the case, when the vehicle is

stationary, set the display to the required

units of speed so that it complies with what is

authorised locally.

In case of doubt, contact a CITROËN dealer

or a qualified workshop.

Speed Limit recognition

and recommendation

Refer to the General recommendations on the

use of driving and manoeuvring aids .

Using the camera located at the top of the

windscreen, this system detects the following

types of signs and displays the corresponding

information on the instrument panel:

– the maximum authorised speed,

– no overtaking,

– the end of the previous limitations /

restrictions.

Page 99 of 196

97

Practical information

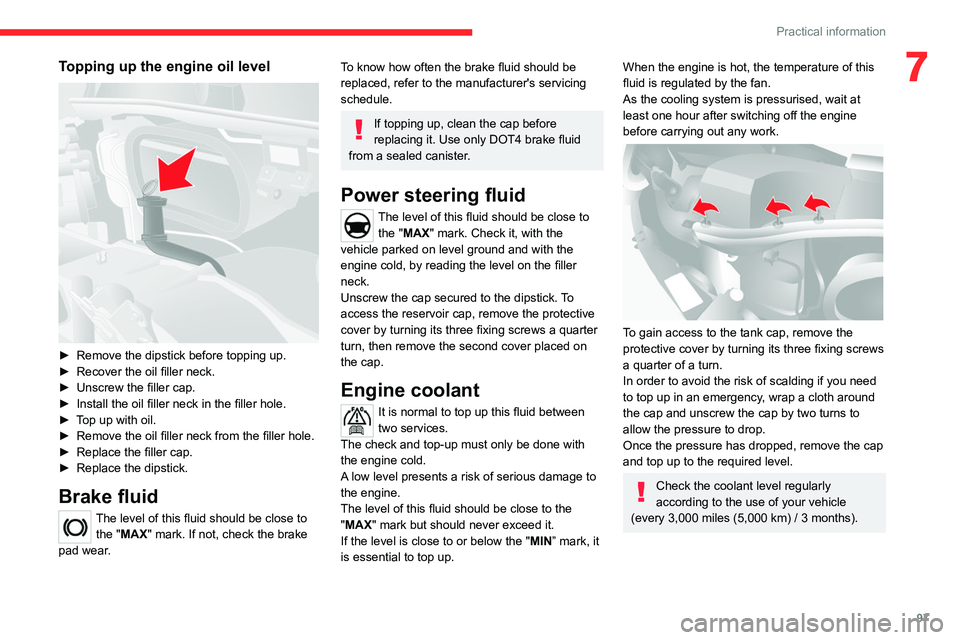

7Topping up the engine oil level

► Remove the dipstick before topping up.

► Recover the oil filler neck.

► Unscrew the filler cap.

► Install the oil filler neck in the filler hole.

► Top up with oil.

► Remove the oil filler neck from the filler hole.

► Replace the filler cap.

► Replace the dipstick.

Brake fluid

The level of this fluid should be close to

the "MAX" mark. If not, check the brake

pad wear.

To know how often the brake fluid should be

replaced, refer to the manufacturer's servicing

schedule.

If topping up, clean the cap before

replacing it. Use only DOT4 brake fluid

from a sealed canister.

Power steering fluid

The level of this fluid should be close to the "MAX" mark. Check it, with the

vehicle parked on level ground and with the

engine cold, by reading the level on the filler

neck.

Unscrew the cap secured to the dipstick. To

access the reservoir cap, remove the protective

cover by turning its three fixing screws a quarter

turn, then remove the second cover placed on

the cap.

Engine coolant

It is normal to top up this fluid between

two services.

The check and top-up must only be done with

the engine cold.

A low level presents a risk of serious damage to

the engine.

The level of this fluid should be close to the

"MAX" mark but should never exceed it.

If the level is close to or below the " MIN” mark, it

is essential to top up.

When the engine is hot, the temperature of this

fluid is regulated by the fan.

As the cooling system is pressurised, wait at

least one hour after switching off the engine

before carrying out any work.

To gain access to the tank cap, remove the

protective cover by turning its three fixing screws

a quarter of a turn.

In order to avoid the risk of scalding if you need

to top up in an emergency, wrap a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Once the pressure has dropped, remove the cap

and top up to the required level.

Check the coolant level regularly

according to the use of your vehicle

(every 3,000 miles (5,000 km) / 3 months).

Page 107 of 196

105

In the event of a breakdown

8► Disconnect hose I and directly connect it

to the tyre valve; the cartridge will thereby be

connected to the compressor and the sealant will

not be injected.

If the tyre needs to be deflated, connect hose

I to the tyre valve and press the yellow button

located in the centre of the compressor switch.

Replacing the cartridge

To replace the sealant cartridge, proceed as

follows:

► Disconnect the hose I.

► Turn the cartridge to be replaced anti-

clockwise and lift it.

► Insert the new cartridge and turn it clockwise,

► Reconnect the hose I and connect pipe B to

its location.

The cartridge contains ethylene glycol, which is harmful if swallowed and irritates

the eyes.

It must be kept out of the reach of children.

After use, do not discard the cartridge in standard waste, take it to a

CITROËN dealer or an authorised waste

disposal site.

Spare wheel

Parking

► Park the vehicle where it does not block

traffic: the ground must be level, stable and

non-slippery.

► If the road is sloping or damaged, place an

object under the wheels to act as a chock.

► With a manual gearbox, engage first gear

then switch off the ignition to block the wheels.

► Apply the parking brake and check that the

warning lamp is on in the instrument panel.

► The passengers must get out of the vehicle

and wait where they are safe.

► Put on the high visibility vest and signal that

the vehicle is immobile by using the devices

envisaged by the legislation in force in the

country where you are driving (warning triangle,

hazard warning lamps, etc.).

► Equip yourself with the tools.

Special feature with pneumatic

suspension

If fitted to the vehicle, activate the vehicle lifting

mode before lifting the vehicle with a jack.

For right-hand drive vehicles, the buttons are

located on the right of the steering wheel.

► With the ignition on, press both buttons 1 and

2 simultaneously for at least 5 seconds.

Their indicator lamps light up, and remain fixed.

► To exit this mode, press buttons 1 and 2

simultaneously for an additional 5 seconds.

Their indicator lamps go out and the system

becomes fully operational again.

This mode is automatically deactivated if you

exceed the speed by about 3 mph (5 km/h).

Once the vehicle is well secured, proceed in the

following order:

1- Getting the tools.

2- Removing the spare wheel from its

housing.

3- Positioning the jack.

4- Replacing the wheel to be repaired.

5- Storing the wheel to be repaired.

Page 112 of 196

11 0

In the event of a breakdown

► Lightly tighten using wheelbrace D and wheel

bar B.

► Lower the vehicle using wheelbrace D and

wheel bar B, and then remove the jack.

► Tighten the bolts again using wheelbrace D

and wheel bar B.

Have the tightening of the bolts and the

pressure of the spare wheel checked by

the Manufacturer's dealer network or a

qualified workshop without delay.

Have the punctured wheel repaired and

refitted on the vehicle as soon as possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

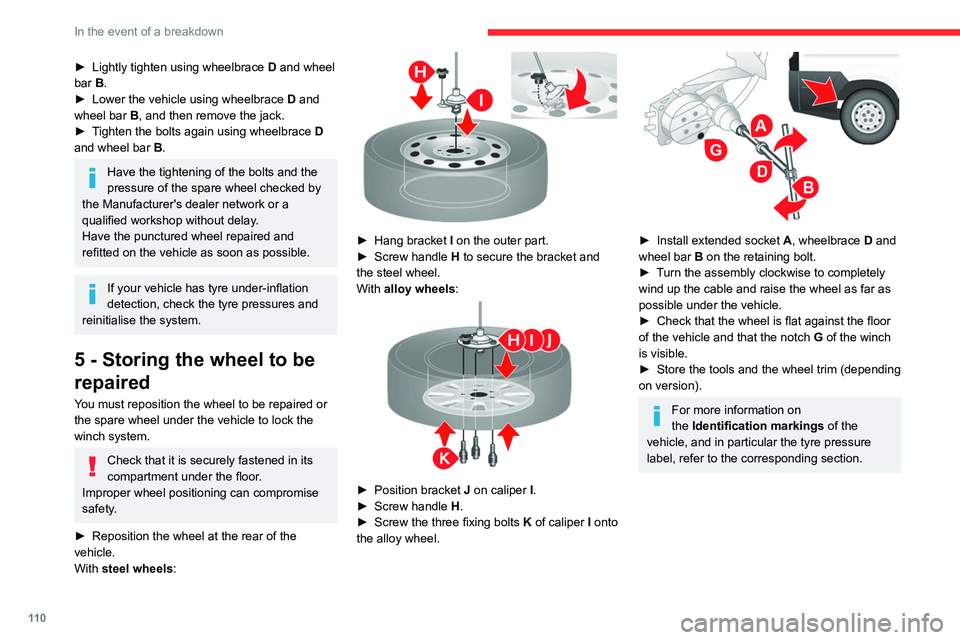

5 - Storing the wheel to be

repaired

You must reposition the wheel to be repaired or

the spare wheel under the vehicle to lock the

winch system.

Check that it is securely fastened in its

compartment under the floor.

Improper wheel positioning can compromise

safety.

► Reposition the wheel at the rear of the

vehicle.

With steel wheels:

► Hang bracket I on the outer part.

► Screw handle H to secure the bracket and

the steel wheel.

With alloy wheels:

► Position bracket J on caliper I.

► Screw handle H.

► Screw the three fixing bolts K of caliper I onto

the alloy wheel.

► Install extended socket A, wheelbrace D and

wheel bar B on the retaining bolt.

► Turn the assembly clockwise to completely

wind up the cable and raise the wheel as far as

possible under the vehicle.

► Check that the wheel is flat against the floor

of the vehicle and that the notch G of the winch

is visible.

► Store the tools and the wheel trim (depending

on version).

For more information on

the Identification markings of the

vehicle, and in particular the tyre pressure

label, refer to the corresponding section.

Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH

neutral product,

► when using a high pressure washer on

persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your

fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

Page 113 of 196

111

In the event of a breakdown

8Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

► do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

► use a sponge and soapy water or a pH

neutral product,

► when using a high pressure washer on

persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

► Do not touch the bulb directly with your

fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

disappears after the lamps have been on for a

few minutes.

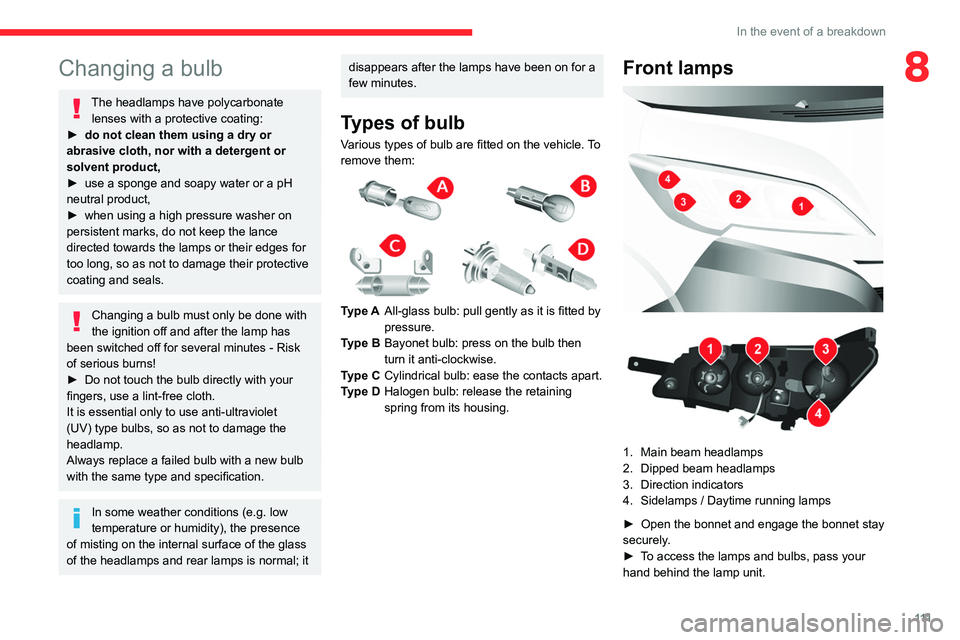

Types of bulb

Various types of bulb are fitted on the vehicle. To

remove them:

Type A All-glass bulb: pull gently as it is fitted by

pressure.

Type B Bayonet bulb: press on the bulb then

turn it anti-clockwise.

Type C Cylindrical bulb: ease the contacts apart.

Type D Halogen bulb: release the retaining

spring from its housing.

Front lamps

1. Main beam headlamps

2. Dipped beam headlamps

3. Direction indicators

4. Sidelamps / Daytime running lamps

► Open the bonnet and engage the bonnet stay

securely.

► To access the lamps and bulbs, pass your

hand behind the lamp unit.

Page 116 of 196

11 4

In the event of a breakdown

Front/Rear

► Press the points indicated by the arrows, then

remove the courtesy lamp.

► Open the protective flap.

► Remove the bulb by separating the two

contacts.

► Check that the new bulbs are securely held

between the two contacts.

► Close the protective flap.

► Fix the courtesy lamp in its housing and

make sure it is locked.

Rear lamps

1. Brake lamps

Type B, P21W - 21W

2. Brake lamps / Sidelamps

Type B, P21/5W - 21W et 5W

3. Direction indicators

Type B, PY21W - 21W

4. Reversing lamps

Type A, W16W - 16W

5. Foglamp

Type A, W16W - 16W

For more information on the Types of

bulbs , refer to the corresponding

section.

► Remove the faulty bulb, then open the rear

doors.

► Remove the corresponding access flap by

removing its seven fixing screws (van)

or

► Remove the corresponding access flap by

pulling its handle to unclip it (combi).

► Disconnect the electrical connector by

pressing on its central tab.

► Remove the two fixing nuts from the lens unit.

► From the outside, pull the lens unit.

► Remove the six fixing screws from the bulb

holder.

► Open the three retaining tabs and pull the

bulb holder out of its housing.

► Change the bulb.

► Carry out the operations in reverse order to

reposition each bulb.

Number plate lamps

Type C, C5W - 5W

Page 138 of 196

136

Special features

Crew cab

The crew cab, available on van

versions, consists of a bench

seat, seat belts, a storage

compartment and side windows.

It is separated from the loading area by a high-

resistance partition providing comfort and safety.

Rear bench seat

This ergonomic bench seat has four seats.

Storage space

A storage space is available under the bench

seat.

From the cab, tilt the seat cushion forwards to

access it.

Do not tilt the bench seat cushion during

transport.

Do not attach anything to the cab fixing

structure.

Do not exceed the number of passengers

indicated on the registration certificate.

In the rear, the loading area is intended

for carrying goods only.

You are advised to place the goods or heavy

objects as far forwards as possible in the

loading area (towards the cab) and to secure

them by means of straps using the stowing

rings on the floor.

Child seats

Do not install child seats, booster

cushions or carry-cots on the rear seats

of the cab.

Chassis cab / Flatbed cab

The chassis cab and flatbed

cab versions are equipped with

a cab, fixed flatbed and specific

rear lamps.

These versions are also available with other

equipment:

– a double cab,

– a tipper truck.

For more information on all of its

equipment, refer to the corresponding

section.

Changing a bulb

For more information on Types of bulbs,

refer to the corresponding section.

Rear lamps

1. Direction indicators

Type B, PY21W - 21W

2. Brake lamps

Type B, P21W - 21W

3. Sidelamps

Type A, W5W - 5W

4. Reversing lamps

Type A, W16W - 16W

5. Foglamps

Type A, W16W - 16W

► Locate the faulty bulb.

Page 148 of 196

146

Special features

Specifications

EquipmentDetails

Tipper truck Tipper truck bed consisting of 2 high strength steel blanks, 2.5 mm thickness, zinc-coated, joined by central and

longitudinal laser welding.

Body-coloured tipper truck.

Structure of the tipper truck 2 main sidemembers in galvanised high strength steel.

1 ram-head crossmember made of steel tube.

Galvanised high strength steel crossmembers. Assembly protected against corrosion by the application of a

powder paint coating.

Sub-frame 2 “C”-shaped sidemembers in high strength steel, 2.5 mm thickness, secured internally by widened lower wing.

Mounted on base vehicle with high strength steel stamped brackets.

1 ram-foot crossmember made of steel and mechanically-welded tube, hot-dip galvanised.

1 rear hinge crossmember in galvanised steel.

Support stops on sidemember ends.

Rear lamp protection grille.

Truck side guards and wing supports in galvanised steel.

Boards High strength steel boards, 15/10 thickness, cold-formed and assembled by continuous laser welding.

Anti-corrosion protection guaranteed by a powder coating treatment.

Locking handles with reinforced zinc coating, integrated in the recess of the board.

Ladder-carrier Galvanised steel rails. Panels and crossmembers in lacquered steel with crimped bolts.

Electropump unit 12 Volts/2 kW.

Operating temperature: -20 to +70°C.

Hydraulic ram Expansion, nitride rod, 3 bodies, Diam: 107 mm.

Maximum pressure: 20 bar.

Hydraulic oil ISO HV 46 type mineral or equivalent.

Dimensions

This adaptation is available only on L2 single

cab; refer to the table below for the specifications

of the tipper truck.

Tipper truck (in mm)

Useable length 3,200

Overall length 3,248

Useable width 2,000

Overall width 2,100

Height of boards 350

Weight of the conversion (in

kg) 550

For the L2 chassis cab specifications,

refer to the Dimensions section of the

platform version.

Weights and towed loads

(kg)

The braked trailer weight with load transfer can

be increased, provided that the equivalent of this

load is removed from the vehicle so as not to

exceed the GTW. Warning! Towing using a lightly

loaded vehicle can adversely affect roadholding.

The kerb weight is equal to the unladen weight +

driver (75 kg) + tank full to 90%.

Page 149 of 196

147

Special features

10Dimensions

This adaptation is available only on L2 single

cab; refer to the table below for the specifications

of the tipper truck.

Tipper truck (in mm)

Useable length 3,200

Overall length 3,248

Useable width 2,000

Overall width 2,100

Height of boards 350

Weight of the conversion (in

kg) 550

For the L2 chassis cab specifications,

refer to the Dimensions section of the

platform version.

Weights and towed loads

(kg)

The braked trailer weight with load transfer can

be increased, provided that the equivalent of this

load is removed from the vehicle so as not to

exceed the GTW. Warning! Towing using a lightly

loaded vehicle can adversely affect roadholding.

The kerb weight is equal to the unladen weight +

driver (75 kg) + tank full to 90%.

Before towing a trailer, check that:

– the vertical force exerted on the towball is

not greater than the value (S) indicated on the

trailer’s tare plate;

– the Towed Weight (TW) is less than the value

indicated on the trailer’s tare plate and the Gross Vehicle Weight (GVW) does not exceed the

value indicated on the vehicle’s tare plate.

– in the case of a self-supporting trailer, the

Gross Train Weight (GTW) must not exceed the

value indicated on the vehicle's tare plate.

Hydraulic system

These precautions are mandatory for any

work on the hydraulic system.

– When carrying out maintenance work under

the tipper body, place the tipper body in the

safety position secured with its stay (position

indicated by a red arrow under the back of the

tipper body),