servicing CITROEN RELAY 2020 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2020, Model line: RELAY, Model: CITROEN RELAY 2020Pages: 196, PDF Size: 34.07 MB

Page 7 of 196

5

Eco-driving

Eco-driving

Eco-driving refers to a range of everyday

practices that allow the motorist to optimise their

fuel consumption and CO

2emissions.

Optimise your use of the gearbox

With a manual gearbox, move off gently and

change up promptly. While accelerating, change

up early.

The gear efficiency indicator prompts you to

engage the most suitable gear: whenever this

indication is displayed on the instrument panel,

follow it straight away.

Drive smoothly

Maintain a safe distance between vehicles, use

engine braking rather than the brake pedal and

press the accelerator gradually. These attitudes

help to save fuel, reduce CO

2 emissions and

decrease general traffic noise.

If the vehicle has the steering-mounted

"CRUISE" control, use cruise control at speeds

above 19 mph (30 km/h) when traffic is flowing

smoothly.

Use electrical equipment wisely

Before moving off, if the passenger compartment

is too warm, ventilate it by opening the windows

and air vents before using the air conditioning.

At speeds above 31 mph (50 km/h), close the

windows and leave the air vents open. Consider using equipment that can help keep

the temperature in the passenger compartment

down.

Unless automatically regulated, switch off the air

conditioning as soon as the desired temperature

has been reached.

Switch off the demisting and defrosting functions,

if they are not managed automatically.

Switch off the heated seat as soon as possible.

Switch off the headlamps and foglamps when

the visibility conditions do not require their use.

Avoid running the engine before moving off,

particularly in winter; your vehicle will warm up

much faster while driving.

As a passenger, avoid connecting your

multimedia devices (film, music, video game,

etc.) to help reduce consumption of electrical

energy, and hence fuel.

Disconnect all portable devices before leaving

the vehicle.

Limit the causes of excess consumption

Spread loads throughout the vehicle.

Limit the loads carried in the vehicle and

minimise wind resistance (roof bars, roof rack,

bicycle carrier, trailer, etc.). Preferably, use a

roof box.

Remove roof bars and roof racks after use.

At the end of winter, remove snow tyres and refit

summer tyres.

Comply with servicing instructions

Check tyre pressures regularly, with the tyres

cold, referring to the label in the door aperture on

the driver's side.

Carry out this check in particular:

– before a long journey.

– at each change of season.

– after a long period out of use.

Do not overlook the spare wheel and, where

applicable, the tyres on your trailer or caravan.

Have your vehicle serviced regularly (engine oil,

oil filter, air filter, passenger compartment filter,

etc.) and observe the schedule of operations in

the manufacturer's service schedule.

With a BlueHDi Diesel engine, if the SCR system

is faulty, your vehicle will emit pollution. Visit

a CITROËN dealer or a qualified workshop

as soon as possible to restore your vehicle’s

nitrogen oxide emissions to regulatory

compliance.

When filling the fuel tank, do not continue after

the third nozzle cut-out, to avoid overflow.

You will only see the fuel consumption of your

new vehicle settle down to a consistent average

after the first 1,900 miles (3,000 kilometres).

Page 12 of 196

10

Instruments

Be extra vigilant and avoid sudden braking.

Date / TimeFixed.

It is set via the “MODE” menu.

Beam heightFixed.

The headlamps are adjusted from position

0 to 3 depending on the load transported.

Adjust with the buttons on the MODE control

module.

Service spannerFixed.

Service is due.

Refer to the list of checks in the manufacturer's

service schedule then have the service carried

out.

Stop & StartFixed.

With the vehicle stationary (traffic lights,

stop sign, congestion, etc.), the Stop & Start

system puts the engine in STOP mode.

The indicator lamp goes off and the engine

restarts automatically in START mode, as soon

as you move off.

Flashing for a few seconds, then goes off.

STOP mode is temporarily unavailable.

Gear shift indicatorFixed.

The next higher gear may be engaged.

Speed limiterFixed.

The limiter is activated.

Fixed with "OFF".

The limiter is selected and not active.

Indicators

Service information

For a few seconds after the ignition is switched

on, the spanner symbolising service information

comes on: the screen informs you when the next

service is due, in accordance with the servicing

schedule indicated in the manufacturer's service

schedule.

This information is determined in relation to the

distance travelled since the previous service.

Engine oil level

Depending on the engine, the engine oil level is

then displayed, on a scale of 1 (Min) to 5 (Max).

If no scale is displayed, the oil level is

insufficient; it is essential to top it up to prevent

engine damage.

For the measurement of this level to be valid, the

vehicle must be parked on horizontal ground,

with the engine having been off for more than 30

minutes.

If in doubt, check the oil level using the

dipstick.

For more information on Checking levels,

refer to the corresponding section.

After a few seconds, the display returns to its

standard functions.

Engine oil quality

This warning lamp flashes and, if your vehicle is equipped with this function, a

message is displayed at each start: the system

has detected a deterioration of the engine oil. It

is essential to change the oil as soon as

possible.

This 2nd warning lamp, coupled with the

1st, lights up on the instrument panel if the

oil change has not been carried out, and the

degradation of the oil has exceeded a new

threshold. If this warning lamp comes on at

Page 13 of 196

11

Instruments

1regular intervals, the oil has to be changed as

soon as possible.

For 3.0 L HDi engines, the engine speed

is then limited to 3,000 rpm, then 1,500

rpm until the oil is changed. Change the

engine oil to prevent damage.

Resetting the service

indicator

A qualified workshop, equipped with the

diagnostic tool, will stop the permanent flashing

of the warning lamp after each service.

If you have serviced the vehicle yourself, reset

the service indicator as follows:

► Insert the key into the ignition switch.

► Turn it to the MAR - ON position.

► Simultaneously depress the brake and

accelerator pedals for more than 15 seconds.

Refer to the checklist in the

manufacturer's service schedule

provided on delivery of the vehicle.

Reminder of the servicing

information

To access the service indications at any

time, briefly press the MODE button.

Use the up/down arrows to view service intervals

and engine oil quality.

Pressing the MODE button again allows you to

return to the various display menus.

A long press allows you to return to the home

screen.

Menu... Select... Allows you

to...

Service Service

(miles/

km before

service) Display the

remaining

miles/

kilometres to

be travelled

before the

next service.

Oil change

(miles/km

before oil

change) Display the

remaining

miles/

kilometres to

be travelled

before the

next oil

change.

For more information on Vehicle

configuration (MODE) , refer to the

corresponding section.

Coolant temperature

If the needle is positioned between C (Cold)

and H (Hot): normal operation.

In arduous conditions of use or hot climatic

conditions, the needle may move close to the red

graduations.

If the needle enters the red zone or if the

warning lamp lights up:

► stop immediately, turn the ignition off. The

cooling fan may continue to run for a while, up to

approximately 10 minutes.

► wait for the engine to cool down to check the

level and if necessary, top it up.

In case of topping up

Be careful, the cooling circuit is under pressure!

To avoid any risk of burns, take a cloth and

unscrew the cap two turns to relieve the

pressure.

When the pressure has dropped, check the level

and remove the cap to top up.

If the needle remains in the red zone,

contact a CITROËN dealer or a qualified

workshop.

Page 99 of 196

97

Practical information

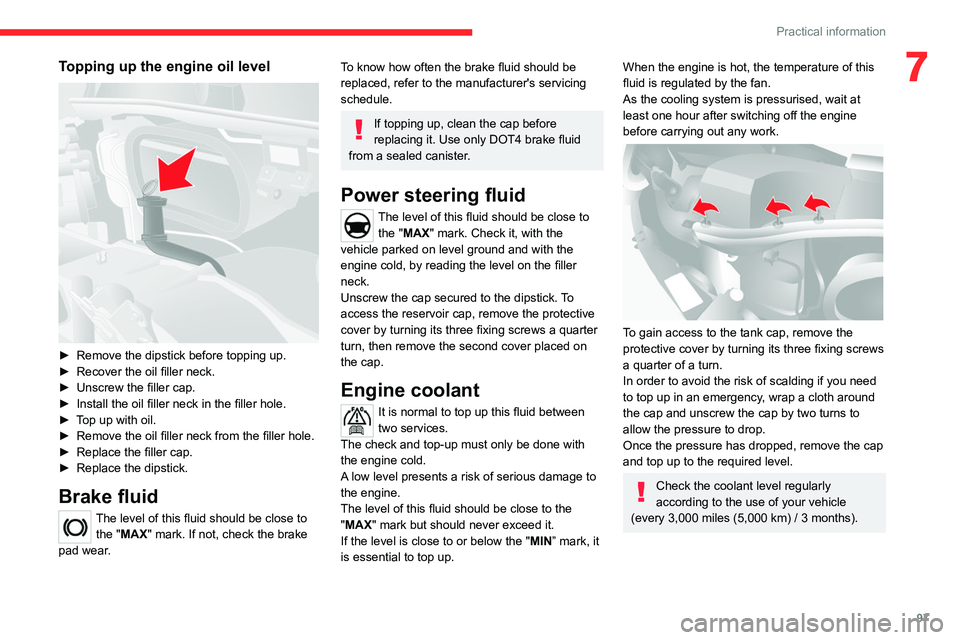

7Topping up the engine oil level

► Remove the dipstick before topping up.

► Recover the oil filler neck.

► Unscrew the filler cap.

► Install the oil filler neck in the filler hole.

► Top up with oil.

► Remove the oil filler neck from the filler hole.

► Replace the filler cap.

► Replace the dipstick.

Brake fluid

The level of this fluid should be close to

the "MAX" mark. If not, check the brake

pad wear.

To know how often the brake fluid should be

replaced, refer to the manufacturer's servicing

schedule.

If topping up, clean the cap before

replacing it. Use only DOT4 brake fluid

from a sealed canister.

Power steering fluid

The level of this fluid should be close to the "MAX" mark. Check it, with the

vehicle parked on level ground and with the

engine cold, by reading the level on the filler

neck.

Unscrew the cap secured to the dipstick. To

access the reservoir cap, remove the protective

cover by turning its three fixing screws a quarter

turn, then remove the second cover placed on

the cap.

Engine coolant

It is normal to top up this fluid between

two services.

The check and top-up must only be done with

the engine cold.

A low level presents a risk of serious damage to

the engine.

The level of this fluid should be close to the

"MAX" mark but should never exceed it.

If the level is close to or below the " MIN” mark, it

is essential to top up.

When the engine is hot, the temperature of this

fluid is regulated by the fan.

As the cooling system is pressurised, wait at

least one hour after switching off the engine

before carrying out any work.

To gain access to the tank cap, remove the

protective cover by turning its three fixing screws

a quarter of a turn.

In order to avoid the risk of scalding if you need

to top up in an emergency, wrap a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Once the pressure has dropped, remove the cap

and top up to the required level.

Check the coolant level regularly

according to the use of your vehicle

(every 3,000 miles (5,000 km) / 3 months).

Page 136 of 196

134

Technical data

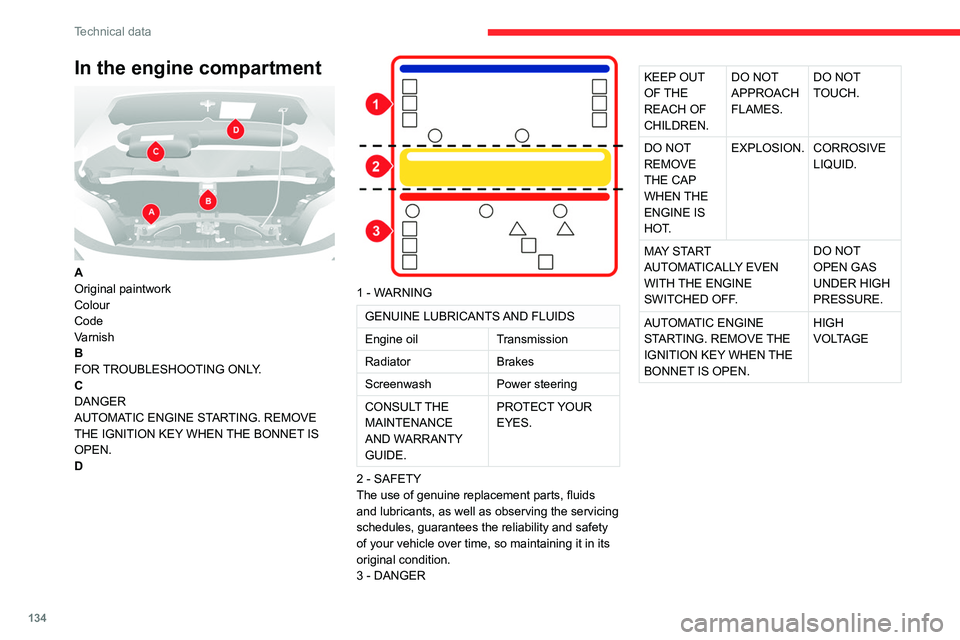

In the engine compartment

A

Original paintwork

Colour

Code

Varnish

B

FOR TROUBLESHOOTING ONLY.

C

DANGER

AUTOMATIC ENGINE STARTING. REMOVE

THE IGNITION KEY WHEN THE BONNET IS

OPEN.

D

1 - WARNING

GENUINE LUBRICANTS AND FLUIDS

Engine oil Transmission

Radiator Brakes

Screenwash Power steering

CONSULT THE

MAINTENANCE

AND WARRANTY

GUIDE. PROTECT YOUR

EYES.

2 - SAFETY

The use of genuine replacement parts, fluids

and lubricants, as well as observing the servicing

schedules, guarantees the reliability and safety

of your vehicle over time, so maintaining it in its

original condition.

3 - DANGER

KEEP OUT

OF THE

REACH OF

CHILDREN. DO NOT

APPROACH

FLAMES. DO NOT

TOUCH.

DO NOT

REMOVE

THE CAP

WHEN THE

ENGINE IS

HOT. EXPLOSION.

CORROSIVE

LIQUID.

MAY START

AUTOMATICALLY EVEN

WITH THE ENGINE

SWITCHED OFF. DO NOT

OPEN GAS

UNDER HIGH

PRESSURE.

AUTOMATIC ENGINE

STARTING. REMOVE THE

IGNITION KEY WHEN THE

BONNET IS OPEN. HIGH

VOLTAGEIn the fuel filler flap

DANGER REMOVE SLOWLY.

FUEL VAPOURS MAY CAUSE INJURY.

Page 150 of 196

148

Special features

– Never work under a tipper body that is not

supported,

– Switch off the power supply to the electro-

hydraulic unit using the circuit breaker,

– Vehicle stationary, engine off.

For safety reasons, we very strongly

advise against doing anything under the

tipper body while it is being operated or while

it is being serviced.

Maintenance

Reservoir

Regularly check and top up the engine oil level.

Change the oil once a year. If the oil contains

water, change it.

Regularly check the condition of the hose and

ensure the hydraulic system is properly sealed.

Pump and motor

No servicing required. The rolling elements are

permanently lubricated and the bearings are

lubricated by the pumped oil.

Lubrication

The pins of the tipper truck and the ram do not

contain lubricant. Regularly lubricate the hinges

and the grab handles of the side boards as well

as the retaining hooks of the rear board.

Sub-frame and tipper truck

For maximum service life, you are advised to

maintain your tipper truck by regularly washing it

using a power washer.

Carry out any required paint touch-ups quickly to

prevent the spread of rust.

After 8 months of use, check the tightening torque of the connection

between the chassis and the underbody (in

accordance with the manufacturer's

bodybuilding recommendations).

Cleaning the slide valve

► Loosen cap 244A, taking care with the ball

and retrieving it.

► Using a wide screwdriver, unscrew the banjo

bolt/piston assembly.

► Check that the piston slides freely and

remove any foreign bodies. Use a magnet to

remove any metal filings.

► Refit the assembly and make sure that the

piston slides freely. Retain the ball with a little

grease on the cap for refitting.

► Bleed the hydraulic unit.

Bleeding the hydraulic unit

► Unscrew hexagonal cap 257.

► Loosen internal screw 587 by half a turn,

using a 6 mm hex key.

► Operate the unit for a few seconds by

pressing the raise button.

The tipper truck does not rise or rises very

slowly. When the oil exits through this opening,

the unit is bled.

► Retighten screw 587 and replace cap 257.

Check that the tipper truck lowers correctly.

Detailed diagram of the UD2386 hydraulic

unit

Diagnostics

Symptoms ElectricHydraulic Verification/Check

The hydraulic unit does not work. XPower harness and unit relay.

X Control harness (control unit).

X Circuit-breaker.

Very noisy unit, rises slowly. XSuction strainer clogged or crushed at the bottom of the tank.

Very noisy new unit, rises quickly. XPump alignment, change the unit.

The ram lowers by itself. XLowering valve crushed or blocked.

The ram does not lower. XYes, check the slide valve and bleed.

Refer to the "Maintenance" section.

X No, check the coil and the electrical connections of the valve.

X No, replace the solenoid valve.

X No, check the alignment of the ram.

The unit works but its pressure does

not increase. X

Slide valve jammed if no solenoid valve on the unit.

Refer to the "Maintenance" section.

X Pressure relief device, setting, dirt.

X Pump seal out of service.

X Motor/pump coupling.

X Pump loose from its support.

The hydraulic unit does not work. XSolenoid valve blocked, replace it or retighten the nut behind the strainer .

The control unit does not work. XCheck connection and contacts.

Emulsion in the tank. XIncorrectly positioned return pipe.

X Insufficient oil level.

Page 180 of 196

178

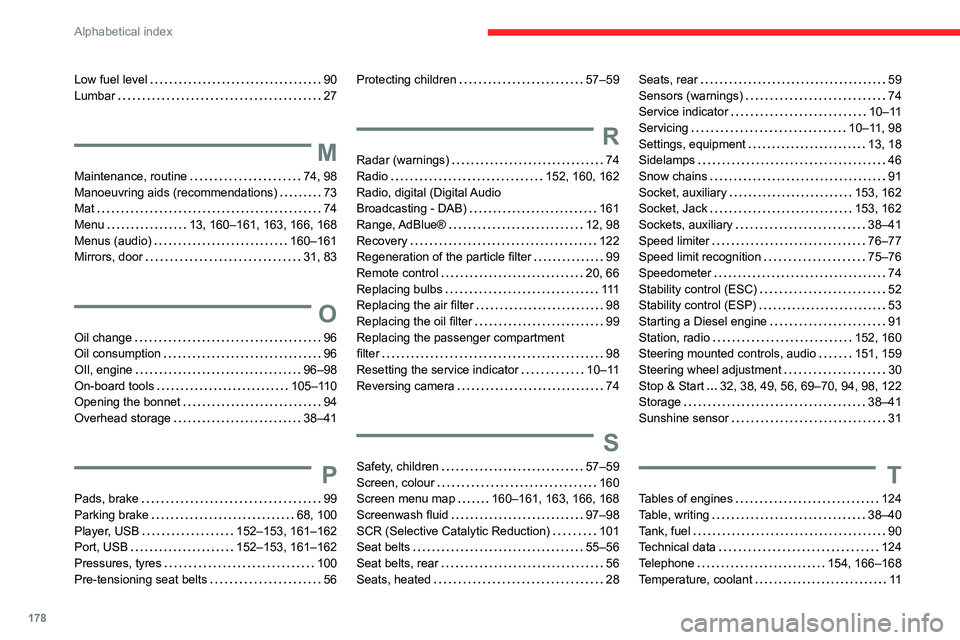

Alphabetical index

Low fuel level 90

Lumbar 27

M

Maintenance, routine 74, 98

Manoeuvring aids (recommendations) 73

Mat 74

Menu 13, 160–161, 163, 166, 168

Menus (audio) 160–161

Mirrors, door 31, 83

O

Oil change 96

Oil consumption 96

OIl, engine 96–98

On-board tools 105–110

Opening the bonnet 94

Overhead storage 38–41

P

Pads, brake 99

Parking brake 68, 100

Player, USB 152–153, 161–162

Port, USB 152–153, 161–162

Pressures, tyres 100

Pre-tensioning seat belts 56

Protecting children 57–59

R

Radar (warnings) 74

Radio 152, 160, 162

Radio, digital (Digital Audio

Broadcasting - DAB) 161

Range, AdBlue® 12, 98

Recovery 122

Regeneration of the particle filter 99

Remote control 20, 66

Replacing bulbs 111

Replacing the air filter 98

Replacing the oil filter 99

Replacing the passenger compartment

filter 98

Resetting the service indicator 10–11

Reversing camera 74

S

Safety, children 57–59

Screen, colour 160

Screen menu map 160–161, 163, 166, 168

Screenwash fluid 97–98

SCR (Selective Catalytic Reduction) 101

Seat belts 55–56

Seat belts, rear 56

Seats, heated 28

Seats, rear 59

Sensors (warnings) 74

Service indicator 10–11

Servicing 10–11, 98

Settings, equipment 13, 18

Sidelamps 46

Snow chains 91

Socket, auxiliary 153, 162

Socket, Jack 153, 162

Sockets, auxiliary 38–41

Speed limiter 76–77

Speed limit recognition 75–76

Speedometer 74

Stability control (ESC) 52

Stability control (ESP) 53

Starting a Diesel engine 91

Station, radio 152, 160

Steering mounted controls, audio 151, 159

Steering wheel adjustment 30

Stop & Start 32, 38, 49, 56, 69–70, 94, 98, 122

Storage 38–41

Sunshine sensor 31

T

Tables of engines 124

Table, writing 38–40

Tank, fuel 90

Technical data 124

Telephone 154, 166–168

Temperature, coolant 11