Citroen XSARA 2004 1.G Repair Manual

XSARA 2004 1.G

Citroen

Citroen

https://www.carmanualsonline.info/img/9/4135/w960_4135-0.png

Citroen XSARA 2004 1.G Repair Manual

Page 119 of 523

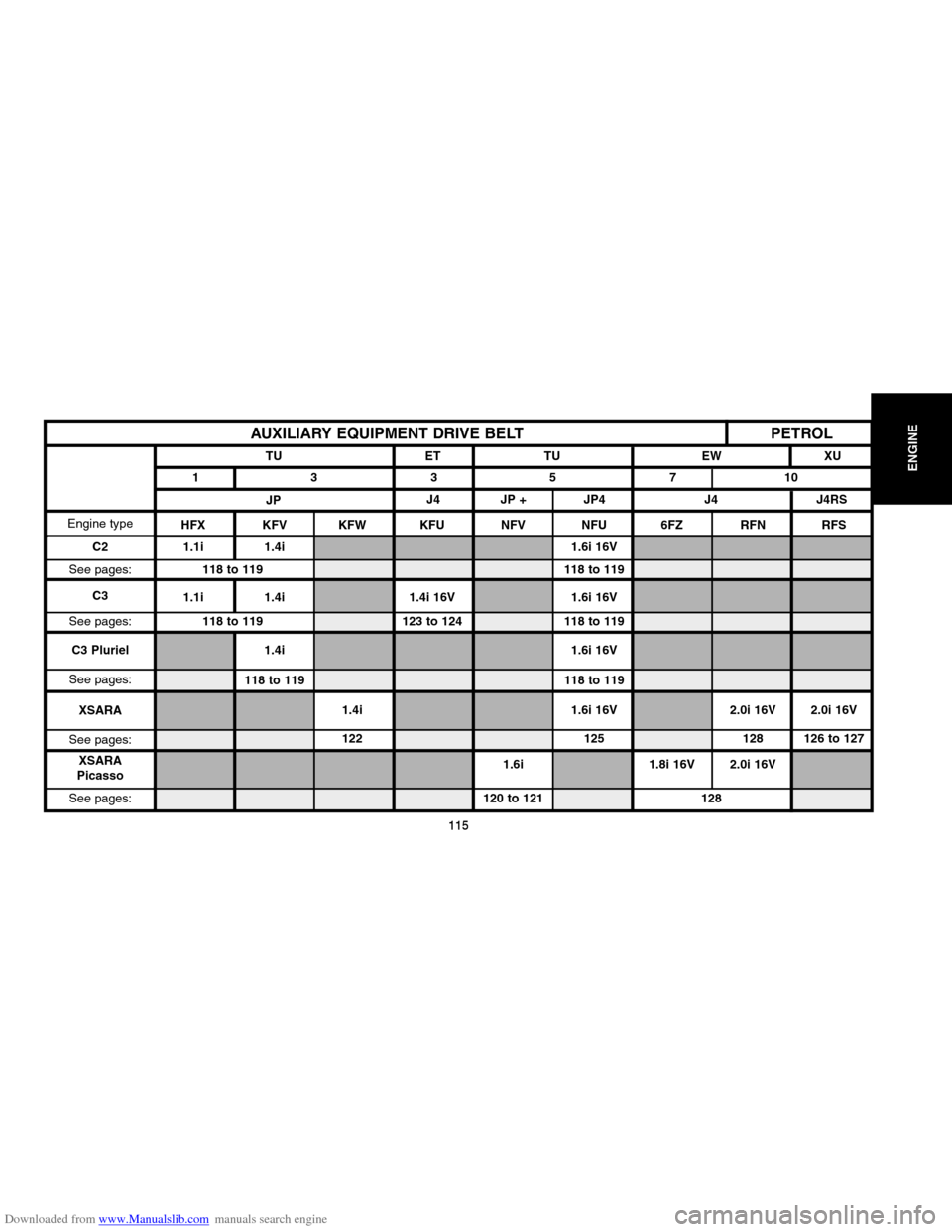

Downloaded from www.Manualslib.com manuals search engine 115

ENGINE

115

PETROL

A UXILIARY EQUIPMENT DRIVE BELT

TU

1

JP

3

JP +

J47

J410

J4RS ET EW

Engine type

C2

C3

C3 Pluriel

XSARA

See pages:

See pages:

See pages:

See pages:

HFX KFV KFW KFU NFV NFU 6FZ RFN RFS

1.1i 1.4i 1.6i 16V

118 to 119118 to 119

1.1i 1.4i 1.4i 16V 1.6i 16V

118 to 119 123 to 124 118 to 119

1.4i1.6i 16V

118 to 119 118 to 119

1.4i 1.6i 16V 2.0i 16V 2.0i 16V

122 125 128 126 to 127

1.6i1.8i 16V 2.0i 16V

120 to 121 128

TUXU

35

JP4

XSARA

Picasso

See pages:

Page 120 of 523

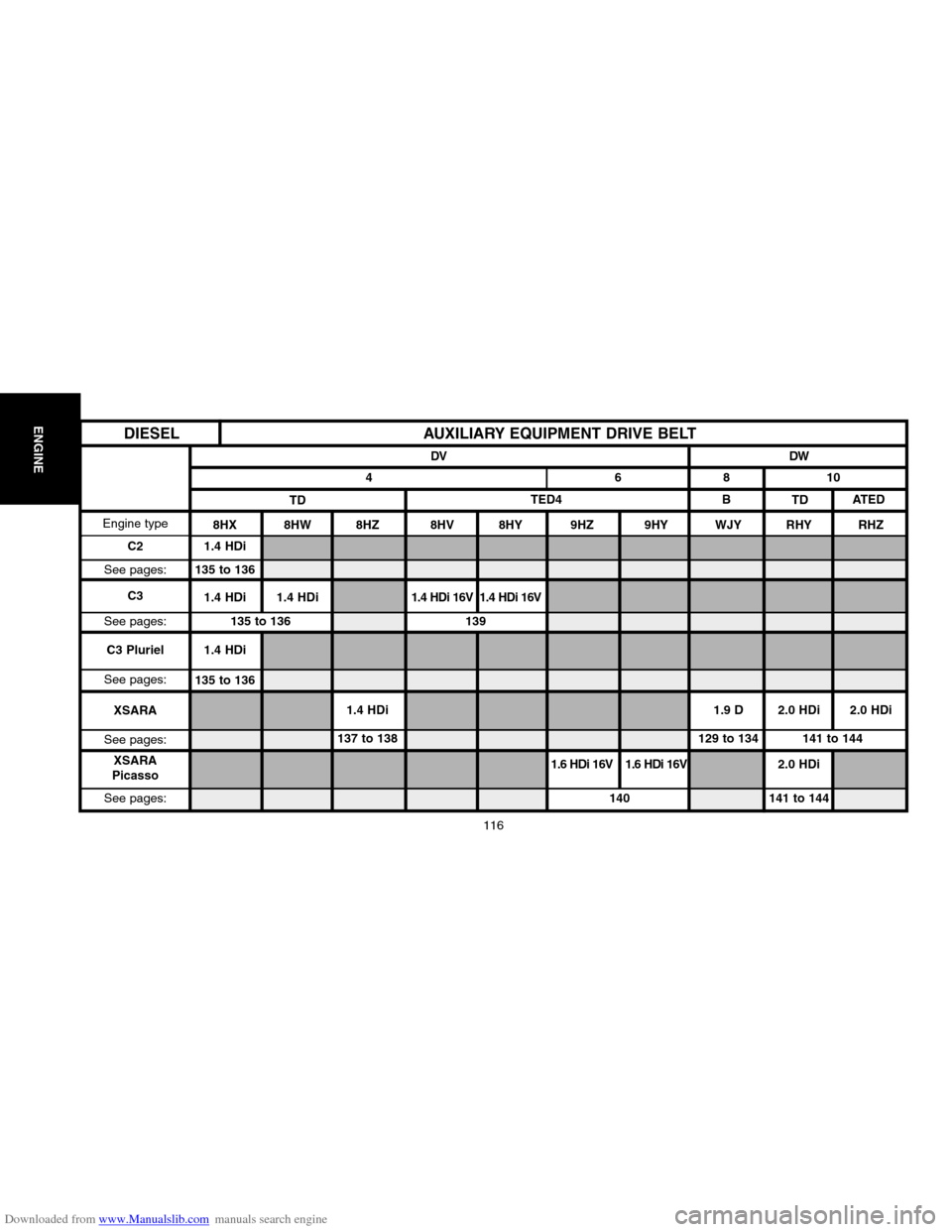

Downloaded from www.Manualslib.com manuals search engine 116

ENGINEDIESEL AUXILIARY EQUIPMENT DRIVE BELT

DV

TD

4

TED48

B10

ATED

Engine type

C2

C3

C3 Pluriel

XSARA

See pages:

See pages:

See pages:

See pages:

8HX 8HW 8HZ 8HV 8HY 9HZ 9HY WJY RHY RHZ

1.4 HDi

135 to 136

1.4 HDi 1.4 HDi 1.4 HDi 16V 1.4 HDi 16V

135 to 136 139

1.4 HDi

135 to 136

1.4 HDi 1.9 D 2.0 HDi 2.0 HDi

137 to 138 129 to 134 141 to 144

1.6 HDi 16V1.6 HDi 16V 2.0 HDi

140 141 to 144

DW

6

XSARA

Picasso

See pages:

TD

Page 124 of 523

Downloaded from www.Manualslib.com manuals search engine 120

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning.

Tools.

[1]Pliers for removing plastic pegs: 7504 –T

[2]Belt tension measuring instrument: 4122 –T

[3]TORX spanner

Remove.� Release the central screw (1),tool [3]� Detension the tensioner roller (2), (flat spanner 27 on flat).

� Remove the belt.

Refit.� Position the belt.

� Hold the belt in position using the tensioner roller (2).

� Pre�tension the belt 120 SEEM units, tool [2].

� Lock the central screw (1),tool [3].

� Remove the tool [2].

� Rotate the crankshaft 2to 4times.

� Check the tension, 120 SEEM units.

� If not, restart the operation.

Page 125 of 523

Downloaded from www.Manualslib.com manuals search engine 121

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

With air conditioning.

XSARA PICASSO

B1BP235C

Tools.

[1]

Pliers for removing plastic pegs: 7504 –T

[2] Belt tension measuring instrument: 4122 –T

[3] 10 mm square (drain spanner)[4] TORX spanner

Remove.� Detension the automatic tensioner, tool[3].� Place aØ 6 mm peg at(a) to immobilise the automatic tensioner.

� Remove the belt.

Refit.� Position the belt

� Detension the automatic tensioner, tool[3].� Remove theØ 6 mm peg.

� Release the automatic tensioner.

� Remove the tool

[3].

Page 126 of 523

Downloaded from www.Manualslib.com manuals search engine 122

ENGINE

[1]Belt tension measuring instrument:4122�T

� Tension the belt using the screw (2).

� Tension should be:

102 ± 7 SEEM units.

� Tighten the screws (1).

� New belt

100 SEEM units.

� Re�used belt

AUXILIARY EQUIPMENT DRIVE BELT 2002

Alternator

Power�assisted steering Power steering and air con.With air conditioning

[1]

Belt tension measuring instrument:4122�T

� Tension the belt using the screw (4).

� Tension should be:

102 ± 7 SEEM units.

� Tighten the screws

(3).

� New belt

100 SEEM units.

� Re�used belt75 SEEM units.

B1BP1B3CB1BP124CB1BP1B2CB1BP122C

Engine: KFW

XSARA

Page 129 of 523

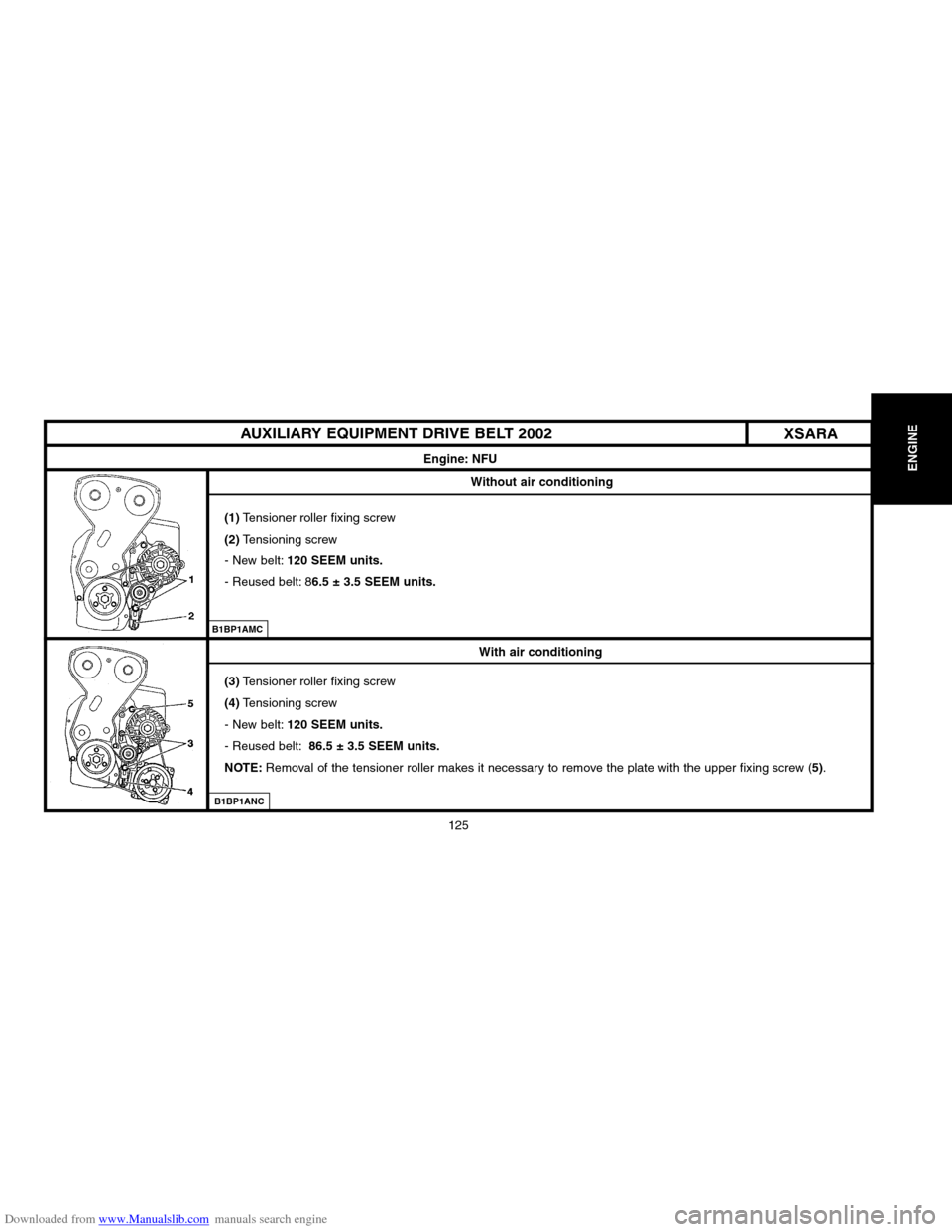

Downloaded from www.Manualslib.com manuals search engine 125

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002

XSARA

(1)Tensioner roller fixing screw

(2)Tensioning screw

� New belt:

120 SEEM units.

� Reused belt: 86.5 ± 3.5 SEEM units.

(3)

Tensioner roller fixing screw

(4)Tensioning screw

� New belt:

120 SEEM units.

� Reused belt:86.5 ± 3.5 SEEM units.

NOTE:

Removal of the tensioner roller makes it necessary to remove the plate with the upper fixing screw (5).

Without air conditioning

With air conditioning

B1BP1ANC

B1BP1AMC

Engine: NFU

Page 130 of 523

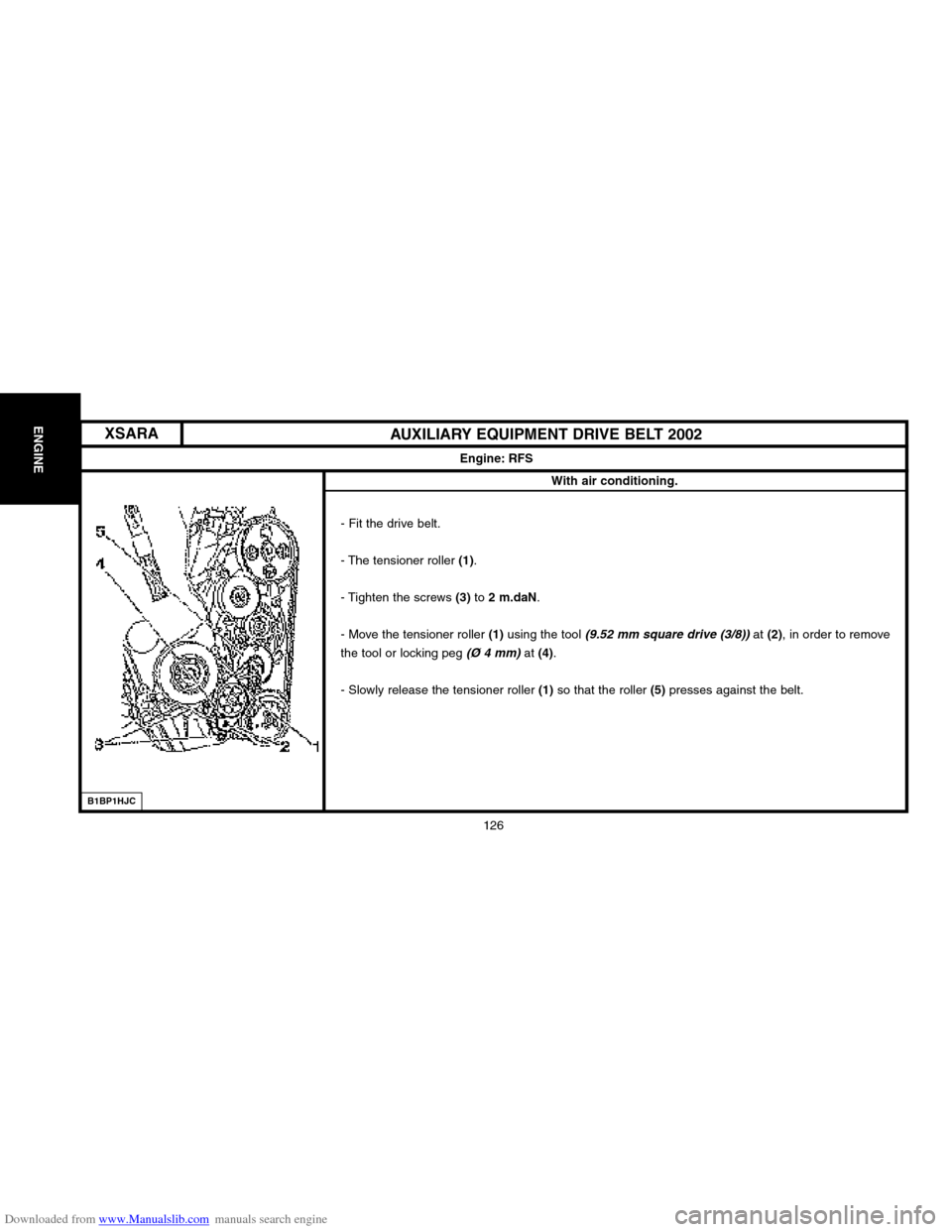

Downloaded from www.Manualslib.com manuals search engine 126

ENGINE

B1BP1HJC

XSARAAUXILIARY EQUIPMENT DRIVE BELT 2002

� Fit the drive belt.

� The tensioner roller

(1).

� Tighten the screws

(3)to 2 m.daN.

� Move the tensioner roller

(1)using the tool (9.52 mm square drive (3/8))at (2), in order to remove

the tool or locking peg

(Ø 4 mm)at (4).

� Slowly release the tensioner roller

(1)so that the roller (5)presses against the belt.

With air conditioning. Engine: RFS

Page 131 of 523

Downloaded from www.Manualslib.com manuals search engine 127

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002XSARA

Tools.

[1]

Belt tension measuring instrument :4122�T

� (1)

Tensioning screw.

� (2)Roller support fixing screw (3).

� Lightly tighten the screws

(2).

� Place the tool

[1]on the belt.

� Tension the belt using the screw

(1).

• Reused belt

90 SEEM units.

• New belt

120 SEEM units.

� Tighten the screws

(2)to 2 m.daN.

� Remove the tool

[1].

� Rotate the crankshaft by 3 turns

(direction of rotation).

� Check the belt tension using the tool

[1], and adjust (if necessary).

Without air conditioning.

B1EP12YCB1EP12XC

Engine: RFS

Page 132 of 523

Downloaded from www.Manualslib.com manuals search engine 128

ENGINEAUXILIARY EQUIPMENT DRIVE BELT 2002

Engines: 6FZ � RFN

Without air conditioning.With air conditioning.

Tools.

[1]

Pliers for removing plastic pegs :7504�T

Remove the belt.

� Detension the belt (3)by turning the screw (2)of the tensioner roller (1)(anti�clockwise).

� The screw

(2) (WARNING: not left hand screw).

� Remove the belt (3), while keeping the tensioner roller (1)tight.

Refit the belt.� Refit the belt (3), while keeping the tensioner roller (1)tight.

� Release the tensioner roller (1).

B1BP23PCB1BP23QCB1BP23PCB1BP23RC

XSARA � XSARA PICASSO

Page 133 of 523

Downloaded from www.Manualslib.com manuals search engine 129

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002

Sans Power�assisted steering.

Tools.

[1]

Belt tension measuring instrument: 4122�T

Removal.

� Loosen the screws (2).

� Tighten the screw (1)until it is against its stop.

� Remove the belt.

Refitting.� Refit the belt.

� Fit the tool [1]on the belt at "d".

� Tighten the screw (1)to obtain:106 ±10 SEEM units.� Tighten the screws (2)to 2 m.daN.

� Remove the tool [1].

B1BP1SECB1BP1SDC

Engine: WJY

XSARA

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 120

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning.

Tools.

[1]Pliers for removing plastic peg Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 120

ENGINE

B1BP234C

XSARA PICASSOAUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

Without air conditioning.

Tools.

[1]Pliers for removing plastic peg](/img/9/4135/w960_4135-123.png)

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 121

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

With air conditioning.

XSARA PICASSO

B1BP235C

Tools.

[1]

Pliers for removing plastic peg Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 121

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT

Engine: NFV

With air conditioning.

XSARA PICASSO

B1BP235C

Tools.

[1]

Pliers for removing plastic peg](/img/9/4135/w960_4135-124.png)

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 122

ENGINE

[1]Belt tension measuring instrument:4122�T

� Tension the belt using the screw (2).

� Tension should be:

102 ± 7 SEEM units.

� Tigh Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 122

ENGINE

[1]Belt tension measuring instrument:4122�T

� Tension the belt using the screw (2).

� Tension should be:

102 ± 7 SEEM units.

� Tigh](/img/9/4135/w960_4135-125.png)

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 127

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002XSARA

Tools.

[1]

Belt tension measuring instrument :4122�T

� (1)

Tensioning screw.

� (2)Roller su Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 127

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002XSARA

Tools.

[1]

Belt tension measuring instrument :4122�T

� (1)

Tensioning screw.

� (2)Roller su](/img/9/4135/w960_4135-130.png)

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 128

ENGINEAUXILIARY EQUIPMENT DRIVE BELT 2002

Engines: 6FZ � RFN

Without air conditioning.With air conditioning.

Tools.

[1]

Pliers for removing Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 128

ENGINEAUXILIARY EQUIPMENT DRIVE BELT 2002

Engines: 6FZ � RFN

Without air conditioning.With air conditioning.

Tools.

[1]

Pliers for removing](/img/9/4135/w960_4135-131.png)

![Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 129

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002

Sans Power�assisted steering.

Tools.

[1]

Belt tension measuring instrument: 4122�T

Removal.

� Lo Citroen XSARA 2004 1.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 129

ENGINE

AUXILIARY EQUIPMENT DRIVE BELT 2002

Sans Power�assisted steering.

Tools.

[1]

Belt tension measuring instrument: 4122�T

Removal.

� Lo](/img/9/4135/w960_4135-132.png)