tow Citroen XSARA 2005 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA, Model: Citroen XSARA 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 162 of 462

![Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tens Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tens](/img/9/4138/w960_4138-161.png)

Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tension measuring instrument (SEEM) : 4122 -T

[3]Compression lever for dynamic tensioner: (-).0194.D

[4] Peg for dynamic tensioner roller of Ø 4 mm : (-) 0194.F

WARNING: (With or without air conditioning)

The auxiliaries drive belt cannot be re-used

with a manual tensioner roller.

The auxiliaries drive belt can be re-usedwith a dynamic tensioner roller.

Removing.

Raise and support the vehicle, front wheels hanging.

Disconnect the battery.

Remove the front RH wheel and the front RH splash-shield, using tool [1].

V

ehicle without air conditioning.Slacken bolts (2), screw (3)and the tensioning screw (1).

Push back the alternator towards the engine.

Remove the auxiliary equipment drive belt.

Refitting.

Refit the new auxiliary equipment drive belt.

Respect the following sequence: Crankshaft pinion, alternator pulley.

Position tool [2]on the belt.

Tighten the screw (1)to tension the belt to: 120 ± 4 SEEM units.

Tighten screw (3), bolts (2).

Remove tool [2].

Complete the refitting.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 156

Page 184 of 462

![Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusti Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusti](/img/9/4138/w960_4138-183.png)

Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusting square: (-).0188 J2

[2] Ø 4 mmpeg: (-).0188.Q1

[3] Ø 2 mmpeg: (-).0188.Q2

[4]Dynamic tensioner compression lever: (-).0188.Z

Removal.

Re-use of belt.

WARNING: Mark the direction the belt was fitted in case of re-use of the same belt.

Compress the tensioner roller (7)by moving it at «c»

(in anti-clockwise direction), tool [4].

Hold the tensioner roller (7) compressed and remove the belt.

No re-use of belt.

Compress the tensioner roller (7)by moving it at «c»

(in anti-clockwise direction), tool [4].

Peg using tool [2], at «d».

Loosen the screw (6).

Bring the eccentric roller (5)towards the rear.

Tighten the screw (6)by hand.

Remove the belt.

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 178

Page 206 of 462

![Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 200

ENGINE

200

CHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Peg the flywheel, using tool [1].

Position the tools [2a]and [2b].

Slacken the Citroen XSARA 2005 1.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 200

ENGINE

200

CHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Peg the flywheel, using tool [1].

Position the tools [2a]and [2b].

Slacken the](/img/9/4138/w960_4138-205.png)

Downloaded from www.Manualslib.com manuals search engine 200

ENGINE

200

CHECKING AND SETTING THE VALVE TIMING

Engine: NFU

Peg the flywheel, using tool [1].

Position the tools [2a]and [2b].

Slacken the tensioner roller.

Turn the dynamic tensioner roller so as to be able

to position the tool[4], with the aid of an Allen key

placed at «a».

Turn the tensioner roller towards the right to bring

it to the index «c»in position «b».

Peg the tensioner roller in this position in order to

slacken the timing belt to the maximum.

IMPERATIVE: Never make the dynamic tensioner

roller turn by a complete rotation.

Remove the timing belt (8).

Check that the rollers and the pump pulley turn

freely

(no tight spot).

B1BP2MBC

B1EP170C

B1EP18PC

B1EP18QC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 200

Page 261 of 462

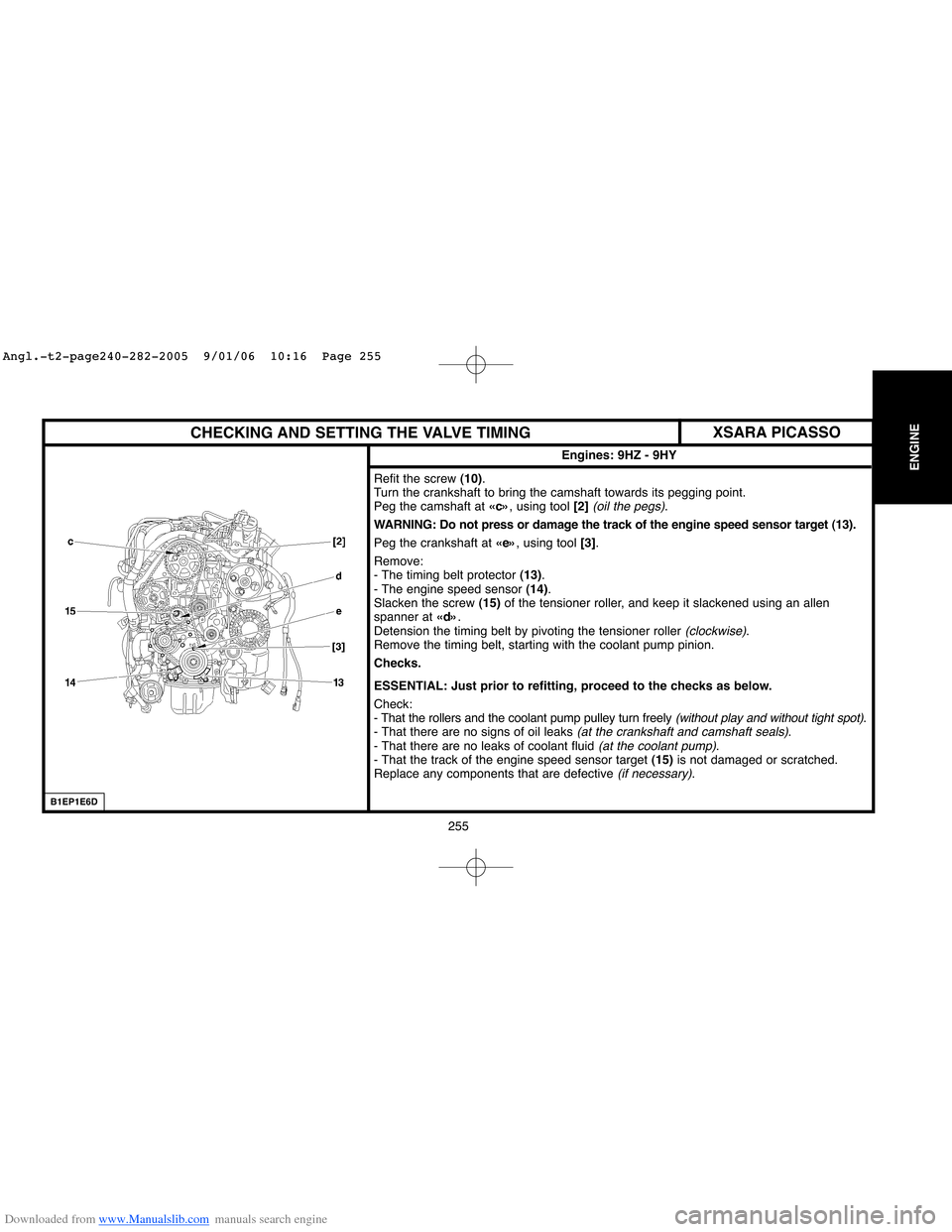

Downloaded from www.Manualslib.com manuals search engine 255

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

B1EP1E6D

Refit the screw (10).

Turn the crankshaft to bring the camshaft towards its pegging point.

Peg the camshaft at «c», using tool [2]

(oil the pegs).

WARNING: Do not press or damage the track of the engine speed sensor target (13).

Peg the crankshaft at «e», using tool [3].

Remove:

- The timing belt protector (13).

- The engine speed sensor (14).

Slacken the screw (15)of the tensioner roller, and keep it slackened using an allen

spanner at «d».

Detension the timing belt by pivoting the tensioner roller

(clockwise).

Remove the timing belt, starting with the coolant pump pinion.

Checks.

ESSENTIAL: Just prior to refitting, proceed to the checks as below.

Check:

- That the rollers and the coolant pump pulley turn freely

(without play and without tight spot).

- That there are no signs of oil leaks (at the crankshaft and camshaft seals).

- That there are no leaks of coolant fluid (at the coolant pump).

- That the track of the engine speed sensor target (15)is not damaged or scratched.

Replace any components that are defective

(if necessary).

XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 255

Page 399 of 462

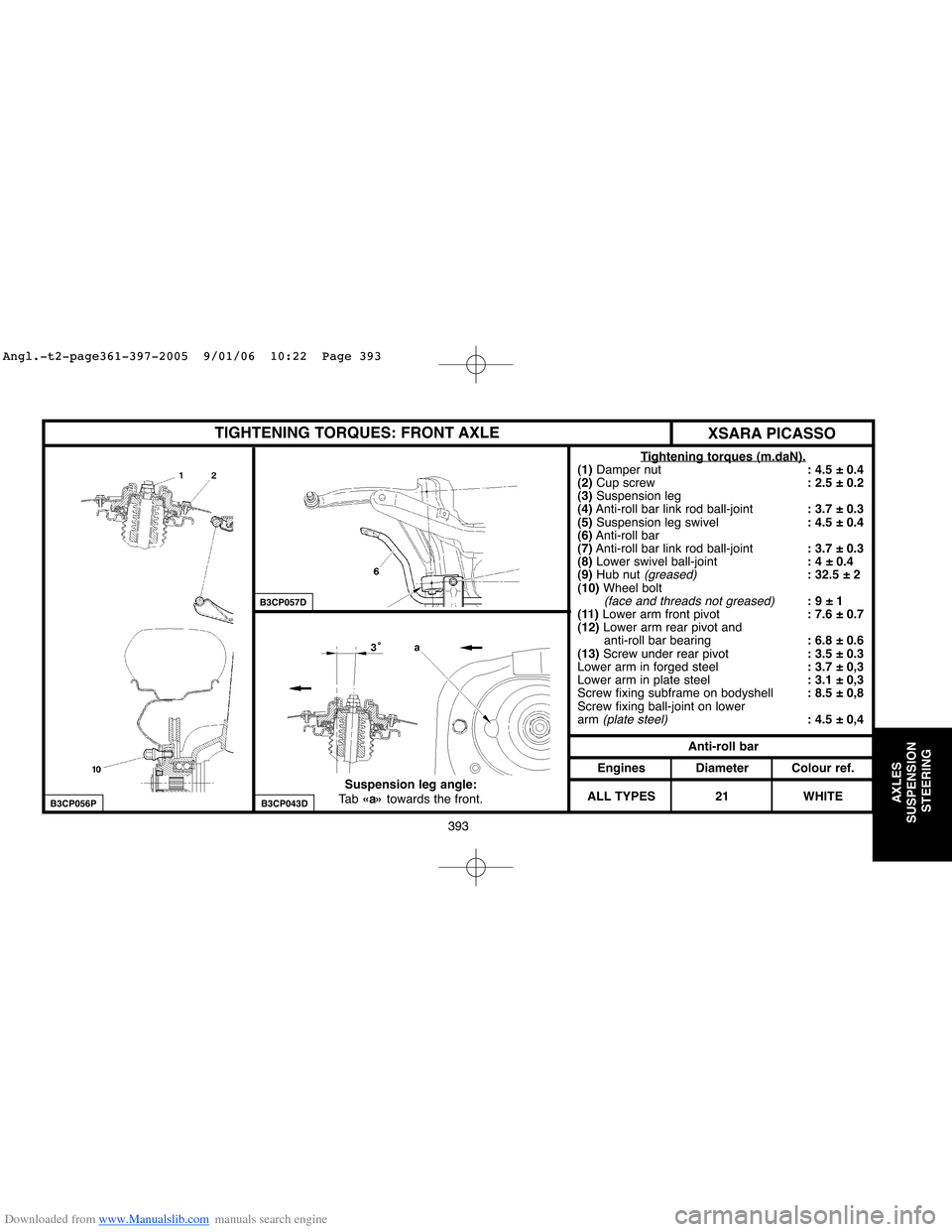

Downloaded from www.Manualslib.com manuals search engine 393

AXLES

SUSPENSION

STEERING

TIGHTENING TORQUES: FRONT AXLE

Tightening torques (m.daN).(1) Damper nut: 4.5 ± 0.4

(2)Cup screw: 2.5 ± 0.2

(3)Suspension leg

(4)Anti-roll bar link rod ball-joint: 3.7 ± 0.3

(5)Suspension leg swivel: 4.5 ± 0.4

(6)Anti-roll bar

(7)Anti-roll bar link rod ball-joint: 3.7 ± 0.3

(8)Lower swivel ball-joint: 4 ± 0.4

(9)Hub nut

(greased): 32.5 ± 2

(10)Wheel bolt

(face and threads not greased): 9 ± 1

(11) Lower arm front pivot: 7.6 ± 0.7

(12) Lower arm rear pivot and

anti-roll bar bearing: 6.8 ± 0.6

(13) Screw under rear pivot : 3.5 ± 0.3

Lower arm in forged steel : 3.7 ± 0,3

Lower arm in plate steel: 3.1 ± 0,3

Screw fixing subframe on bodyshell: 8.5 ± 0,8

Screw fixing ball-joint on lower

arm

(plate steel): 4.5 ± 0,4

Anti-roll bar

Engines

ALL TYPESDiameter

21Colour ref.

WHITE Suspension leg angle:

Ta b«a»towards the front.

B3CP056P

B3CP057D

B3CP043D

XSARA PICASSO

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 393

Page 419 of 462

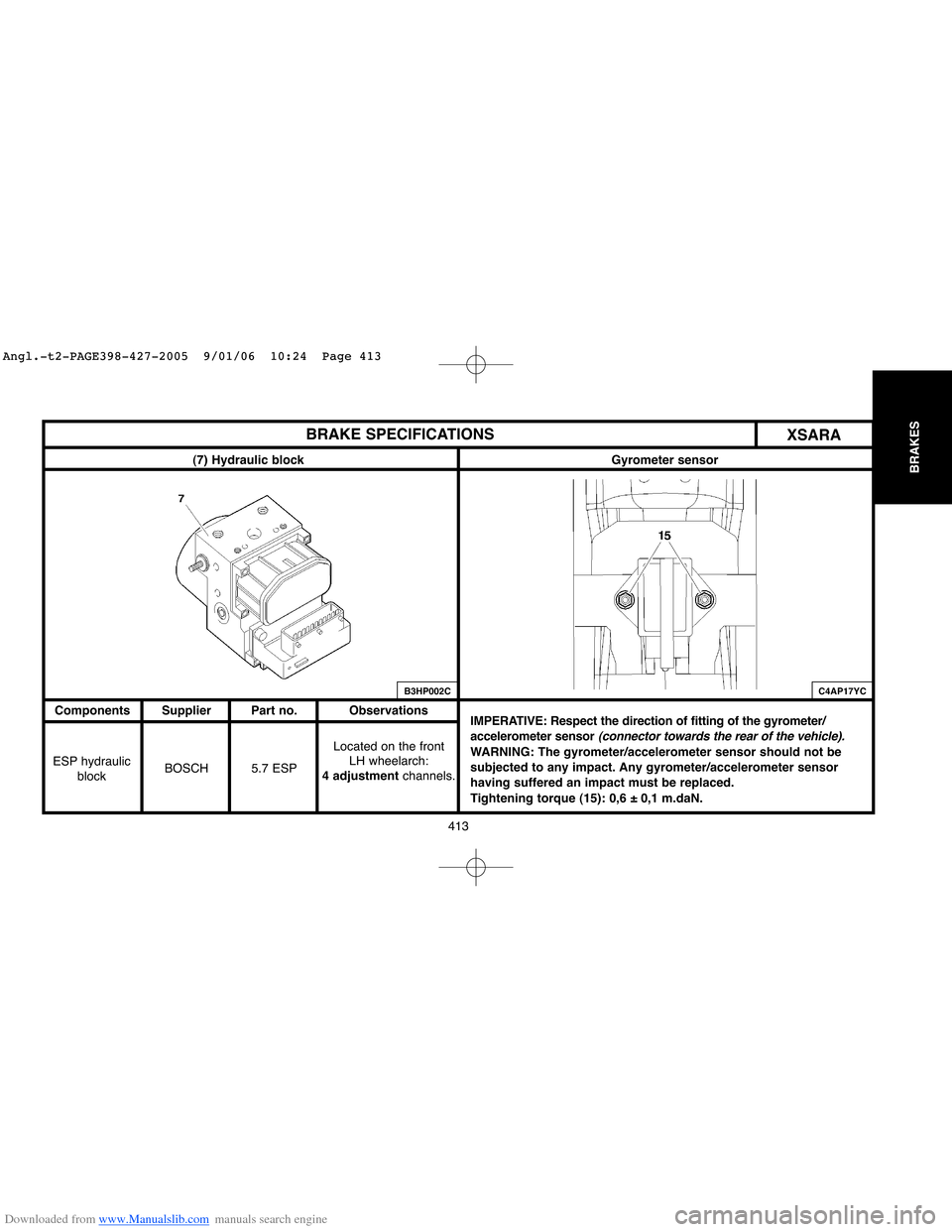

Downloaded from www.Manualslib.com manuals search engine 413

BRAKES

BRAKE SPECIFICATIONS

Gyrometer sensor (7) Hydraulic block

C4AP17YCB3HP002C

Observations Part no. Supplier Components

XSARA

ESP hydraulic

blockBOSCH 5.7 ESPLocated on the front

LH wheelarch:

4 adjustmentchannels.IMPERATIVE: Respect the direction of fitting of the gyrometer/

accelerometer sensor

(connector towards the rear of the vehicle).WARNING: The gyrometer/accelerometer sensor should not be

subjected to any impact. Any gyrometer/accelerometer sensor

having suffered an impact must be replaced.

Tightening torque (15): 0,6 ± 0,1 m.daN.

Angl.-t2-PAGE398-427-2005 9/01/06 10:24 Page 413

Page 438 of 462

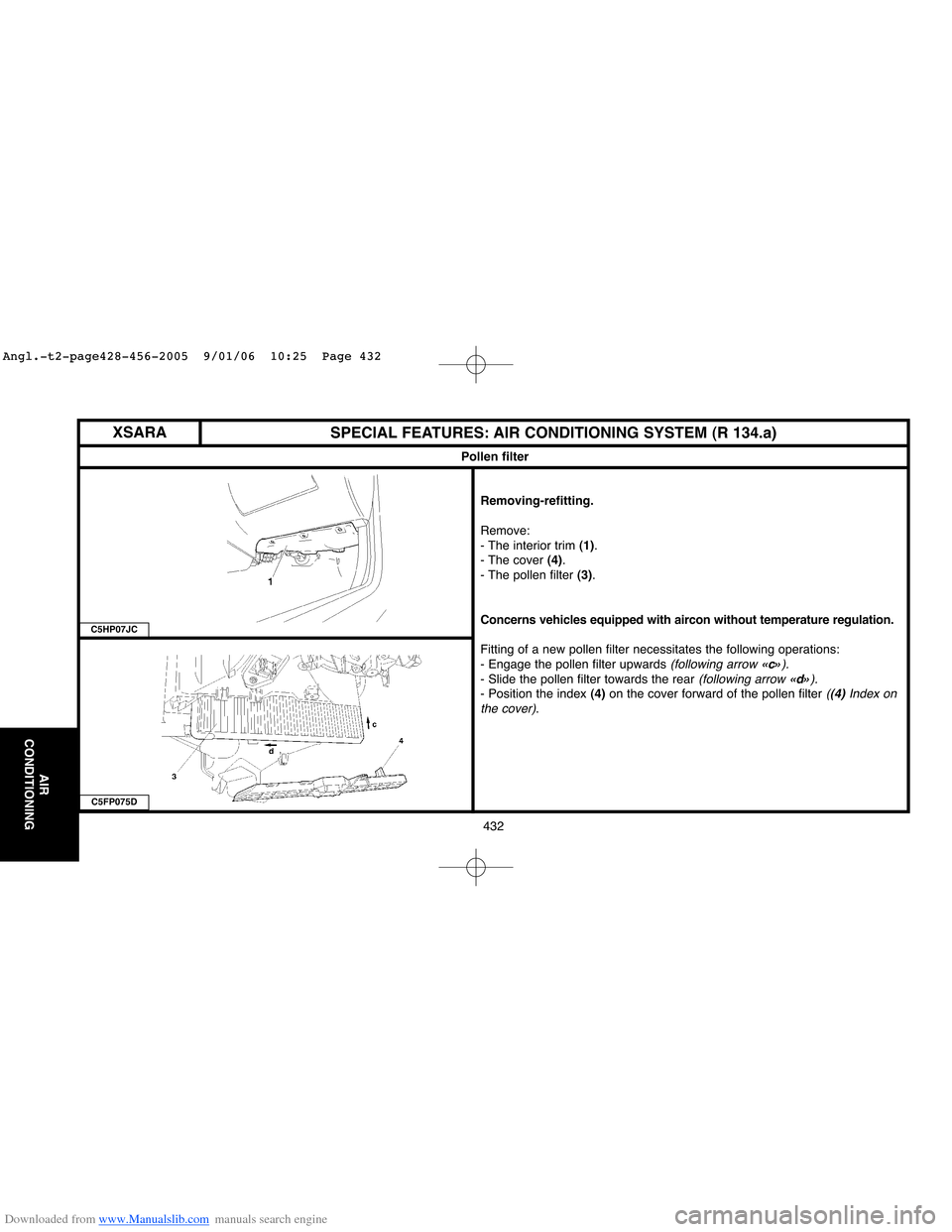

Downloaded from www.Manualslib.com manuals search engine 432

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Pollen filter

XSARA

Removing-refitting.

Remove:

- The interior trim (1).

- The cover (4).

- The pollen filter (3).

Concerns vehicles equipped with aircon without temperature regulation.

Fitting of a new pollen filter necessitates the following operations:

- Engage the pollen filter upwards

(following arrow «c»).- Slide the pollen filter towards the rear (following arrow «d»).- Position the index(4)on the cover forward of the pollen filter ((4)Index on

the cover).

C5HP07JC

C5FP075D

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 432