sensor Citroen XSARA PICASSO 2005 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 86 of 462

Downloaded from www.Manualslib.com manuals search engine 80

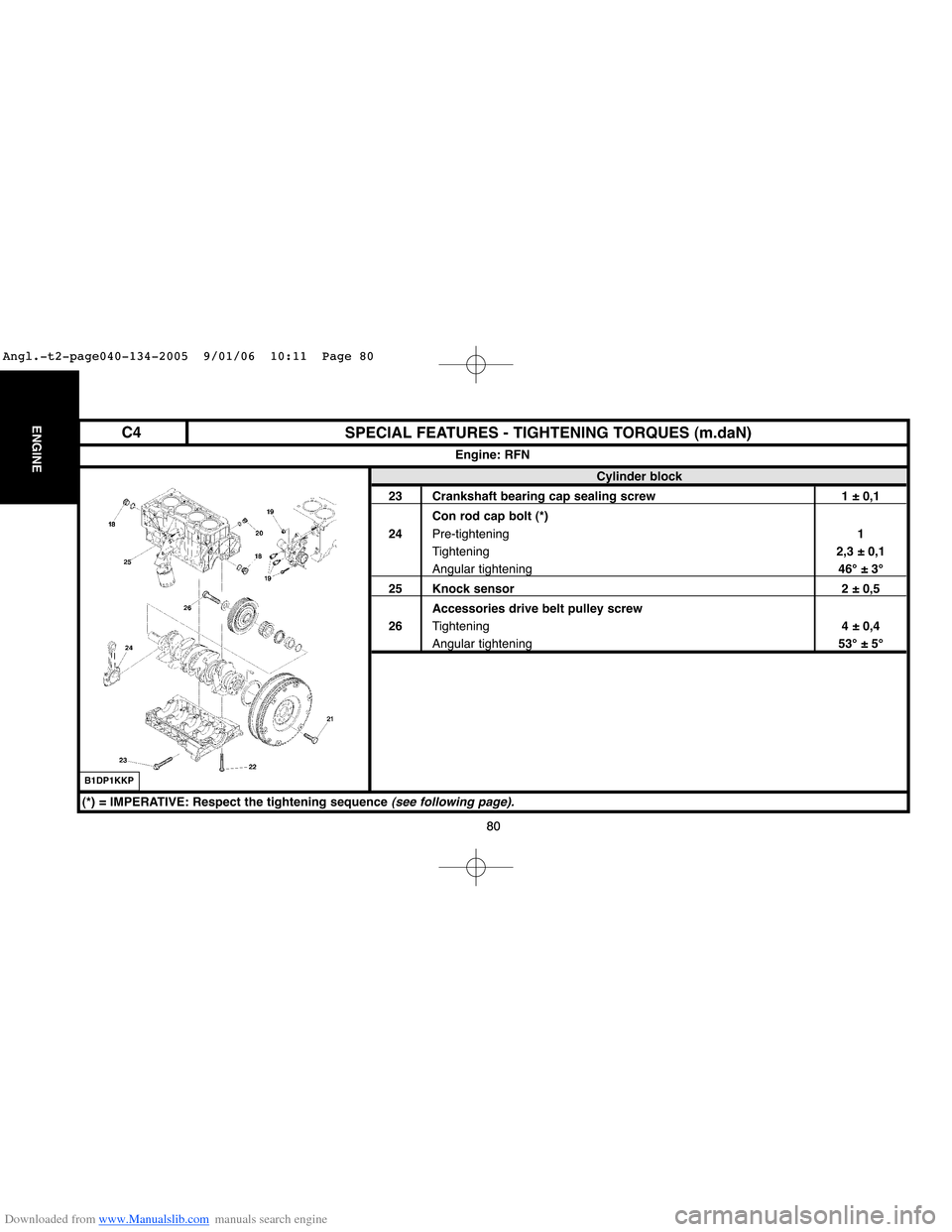

ENGINE

80

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder block

23 Crankshaft bearing cap sealing screw 1 ± 0,1

Con rod cap bolt (*)

24Pre-tightening1

Tightening2,3 ± 0,1

Angular tightening46°±3°

25 Knock sensor 2 ± 0,5

Accessories drive belt pulley screw

26Tightening4 ± 0,4

Angular tightening53°±5°

Engine: RFN

B1DP1KKP

(*) = IMPERATIVE: Respect the tightening sequence (see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 80

Page 88 of 462

Downloaded from www.Manualslib.com manuals search engine 82

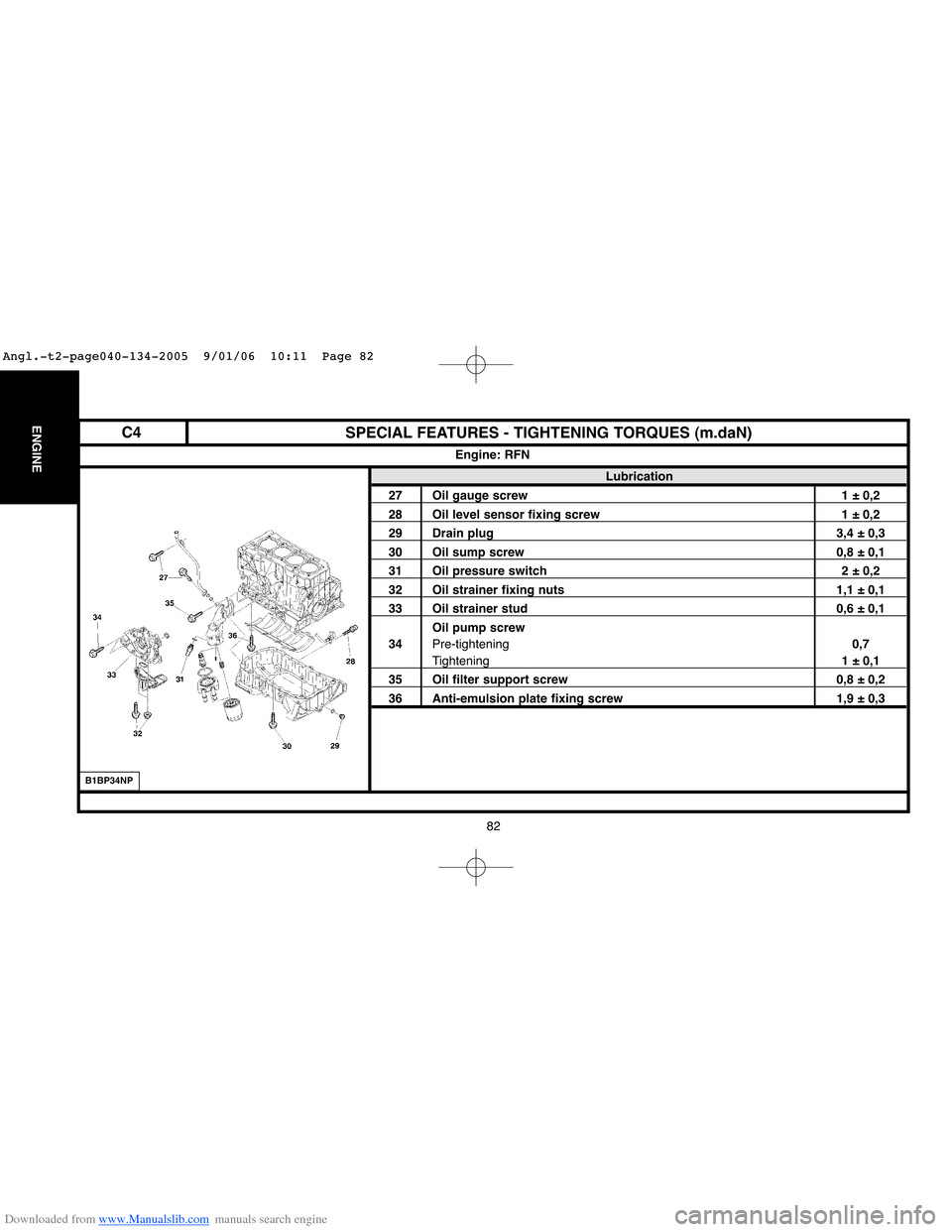

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

27 Oil gauge screw 1 ± 0,2

28 Oil level sensor fixing screw 1 ± 0,2

29 Drain plug 3,4 ± 0,3

30 Oil sump screw 0,8 ± 0,1

31 Oil pressure switch 2 ± 0,2

32 Oil strainer fixing nuts 1,1 ± 0,1

33 Oil strainer stud 0,6 ± 0,1

Oil pump screw

34Pre-tightening0,7

Tightening1 ± 0,1

35 Oil filter support screw 0,8 ± 0,2

36 Anti-emulsion plate fixing screw 1,9 ± 0,3

Engine: RFN

B1BP34NP

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 82

Page 92 of 462

Downloaded from www.Manualslib.com manuals search engine 86

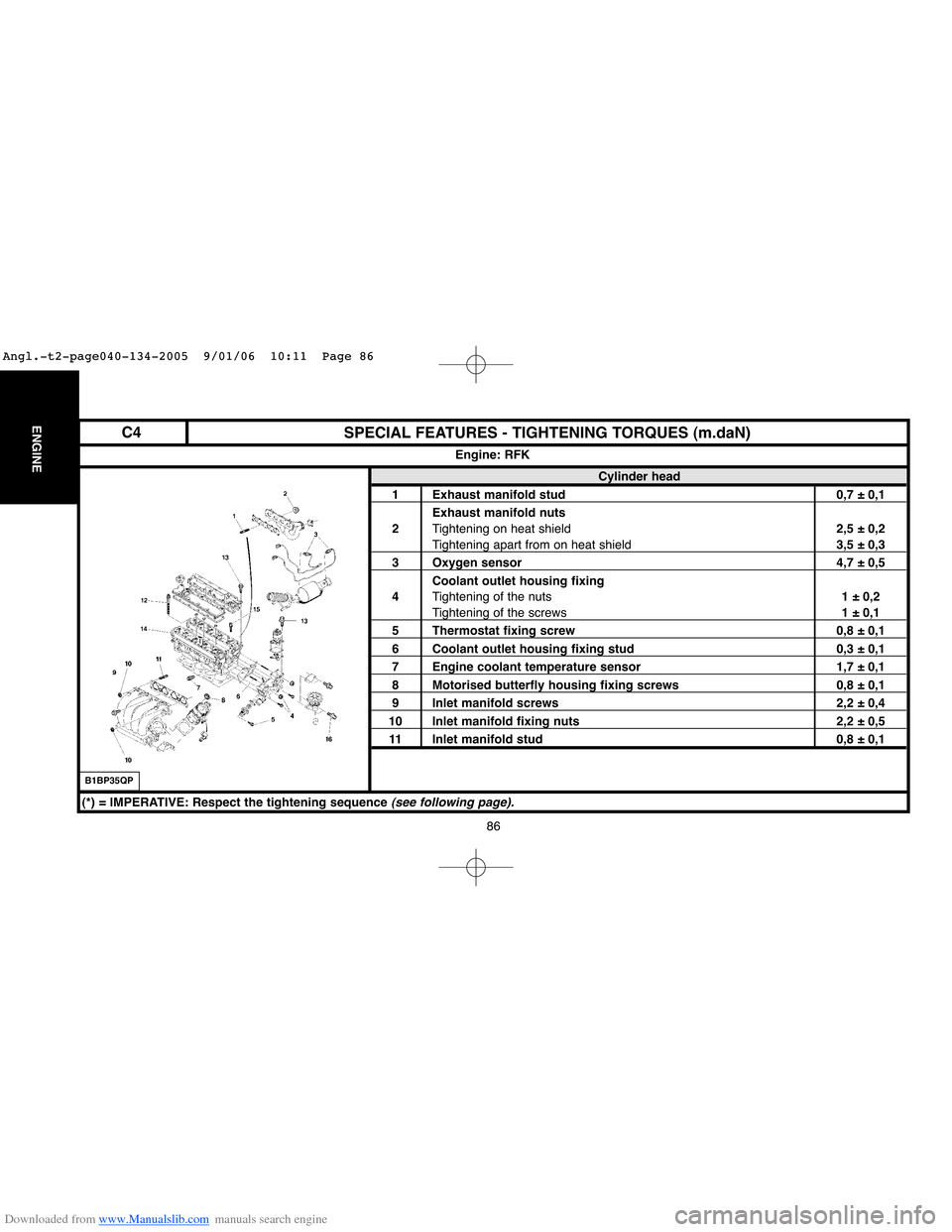

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder head

1 Exhaust manifold stud 0,7 ± 0,1

Exhaust manifold nuts

2Tightening on heat shield2,5 ± 0,2

Tightening apart from on heat shield3,5 ± 0,3

3 Oxygen sensor 4,7 ± 0,5

Coolant outlet housing fixing

4Tightening of the nuts1 ± 0,2

Tightening of the screws1 ± 0,1

5 Thermostat fixing screw 0,8 ± 0,1

6 Coolant outlet housing fixing stud 0,3 ± 0,1

7 Engine coolant temperature sensor 1,7 ± 0,1

8 Motorised butterfly housing fixing screws 0,8 ± 0,1

9 Inlet manifold screws 2,2 ± 0,4

10 Inlet manifold fixing nuts 2,2 ± 0,5

11 Inlet manifold stud 0,8 ± 0,1

Engine: RFK

B1BP35QP

(*) = IMPERATIVE: Respect the tightening sequence(see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 86

Page 96 of 462

Downloaded from www.Manualslib.com manuals search engine 90

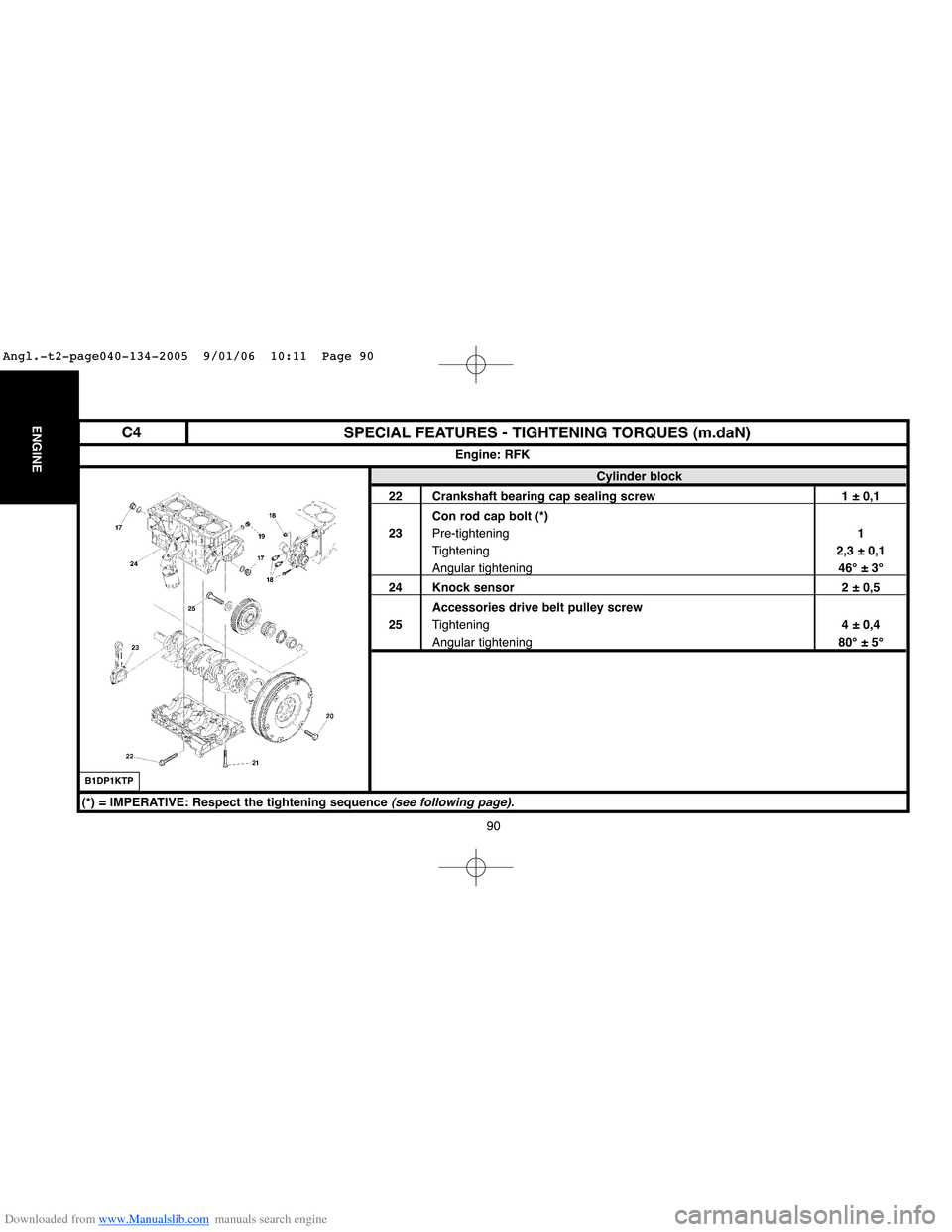

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder block

22 Crankshaft bearing cap sealing screw 1 ± 0,1

Con rod cap bolt (*)

23Pre-tightening1

Tightening2,3 ± 0,1

Angular tightening46°±3°

24 Knock sensor 2 ± 0,5

Accessories drive belt pulley screw

25Tightening4 ± 0,4

Angular tightening80°±5°

Engine: RFK

B1DP1KTP

(*) = IMPERATIVE: Respect the tightening sequence (see following page).

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 90

Page 98 of 462

Downloaded from www.Manualslib.com manuals search engine 92

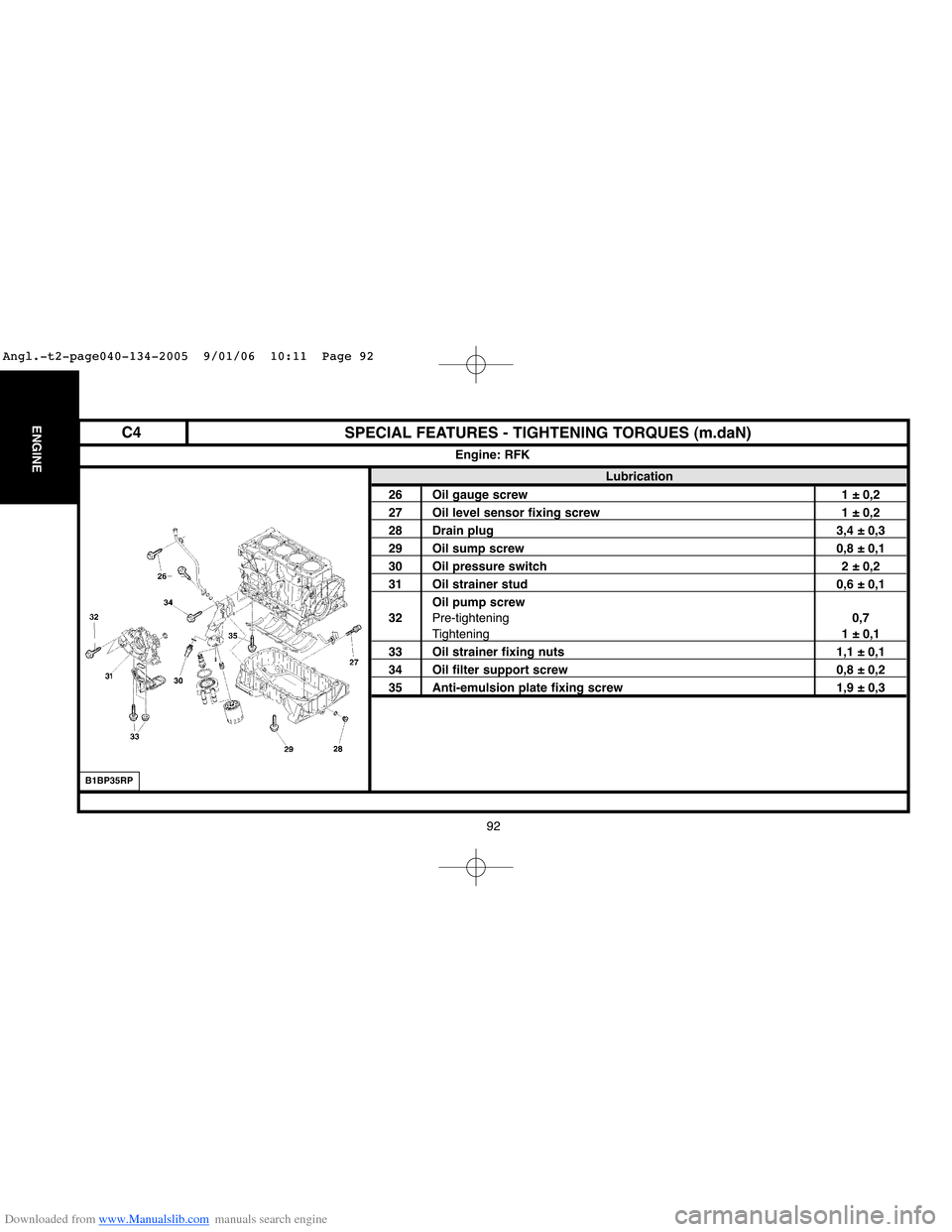

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

26 Oil gauge screw 1 ± 0,2

27 Oil level sensor fixing screw 1 ± 0,2

28 Drain plug 3,4 ± 0,3

29 Oil sump screw 0,8 ± 0,1

30 Oil pressure switch 2 ± 0,2

31 Oil strainer stud 0,6 ± 0,1

Oil pump screw

32Pre-tightening0,7

Tightening1 ± 0,1

33 Oil strainer fixing nuts 1,1 ± 0,1

34 Oil filter support screw 0,8 ± 0,2

35 Anti-emulsion plate fixing screw 1,9 ± 0,3

Engine: RFK

B1BP35RP

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 92

Page 124 of 462

Downloaded from www.Manualslib.com manuals search engine 118

ENGINE

118

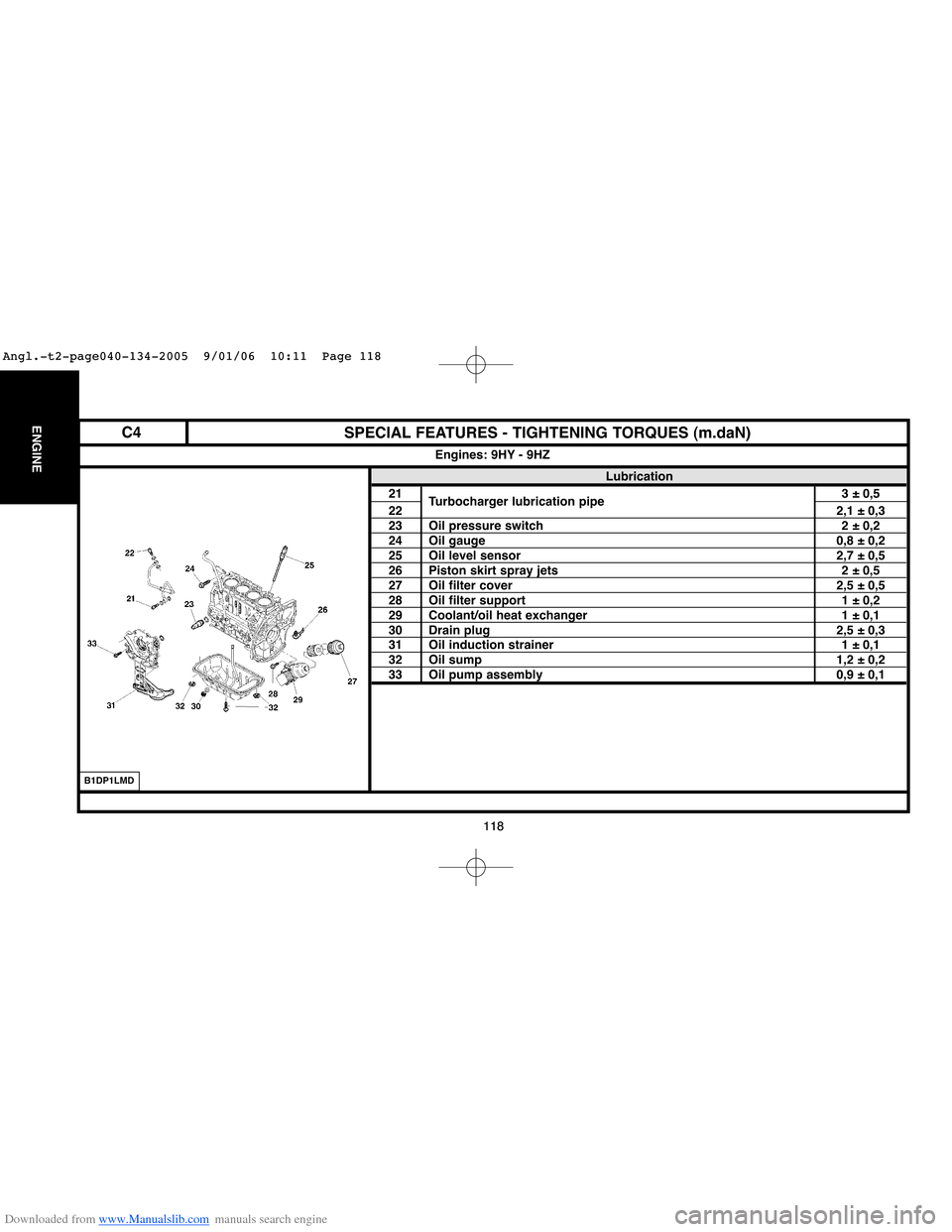

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Lubrication

21

Turbocharger lubrication pipe3 ± 0,5

222,1 ± 0,323 Oil pressure switch 2 ± 0,224 Oil gauge 0,8 ± 0,225 Oil level sensor 2,7 ± 0,526 Piston skirt spray jets 2 ± 0,527 Oil filter cover 2,5 ± 0,528 Oil filter support 1 ± 0,229 Coolant/oil heat exchanger 1 ± 0,130 Drain plug 2,5 ± 0,331 Oil induction strainer 1 ± 0,132 Oil sump 1,2 ± 0,233 Oil pump assembly 0,9 ± 0,1

Engines: 9HY - 9HZ

B1DP1LMD

C4

Angl.-t2-page040-134-2005 9/01/06 10:11 Page 118

Page 240 of 462

Downloaded from www.Manualslib.com manuals search engine 234

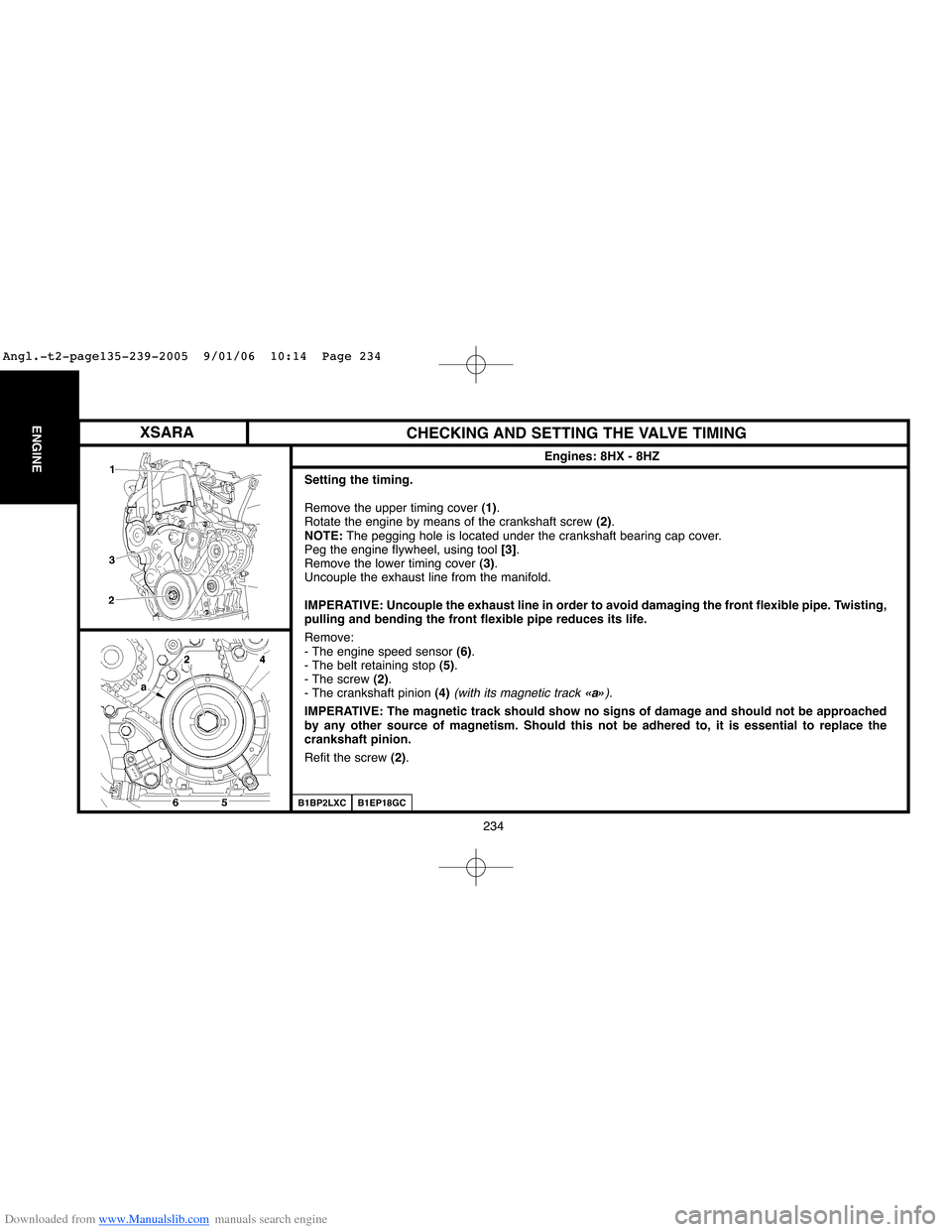

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 8HX - 8HZ

B1EP18GC

Setting the timing.

Remove the upper timing cover (1).

Rotate the engine by means of the crankshaft screw (2).

NOTE:The pegging hole is located under the crankshaft bearing cap cover.

Peg the engine flywheel, using tool [3].

Remove the lower timing cover (3).

Uncouple the exhaust line from the manifold.

IMPERATIVE: Uncouple the exhaust line in order to avoid damaging the front flexible pipe. Twisting,

pulling and bending the front flexible pipe reduces its life.

Remove:

- The engine speed sensor (6).

- The belt retaining stop (5).

- The screw (2).

- The crankshaft pinion (4)

(with its magnetic track «a»).

IMPERATIVE: The magnetic track should show no signs of damage and should not be approached

by any other source of magnetism. Should this not be adhered to, it is essential to replace the

crankshaft pinion.

Refit the screw (2).

B1BP2LXC

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 234

Page 244 of 462

Downloaded from www.Manualslib.com manuals search engine 238

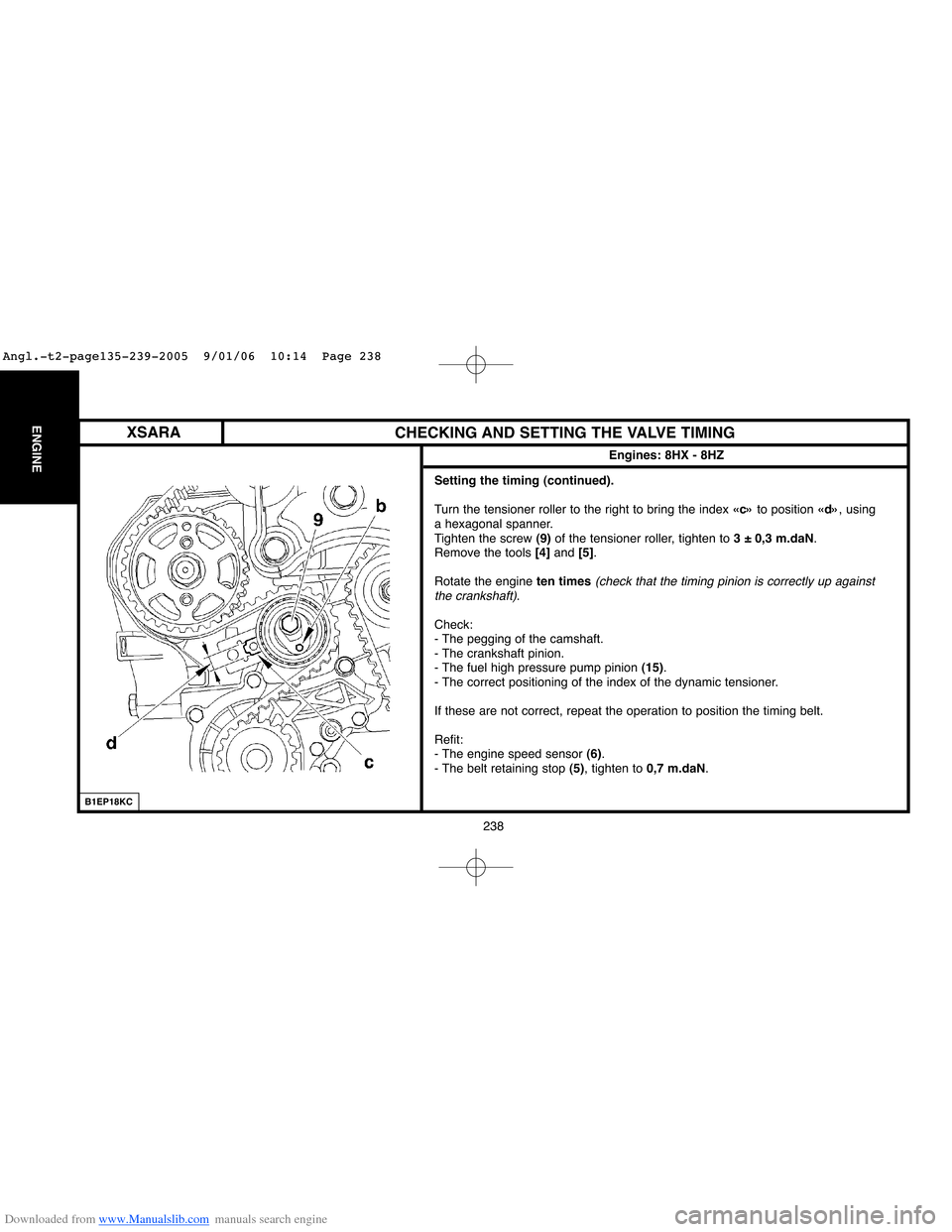

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 8HX - 8HZ

B1EP18KC

Setting the timing (continued).

Turn the tensioner roller to the right to bring the index «c»to position «d», using

a hexagonal spanner.

Tighten the screw (9)of the tensioner roller, tighten to 3 ± 0,3 m.daN.

Remove the tools [4]and [5].

Rotate the engine ten times

(check that the timing pinion is correctly up against

the crankshaft).

Check:

- The pegging of the camshaft.

- The crankshaft pinion.

- The fuel high pressure pump pinion (15).

- The correct positioning of the index of the dynamic tensioner.

If these are not correct, repeat the operation to position the timing belt.

Refit:

- The engine speed sensor (6).

- The belt retaining stop (5), tighten to 0,7 m.daN.

XSARA

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 238

Page 250 of 462

Downloaded from www.Manualslib.com manuals search engine 244

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

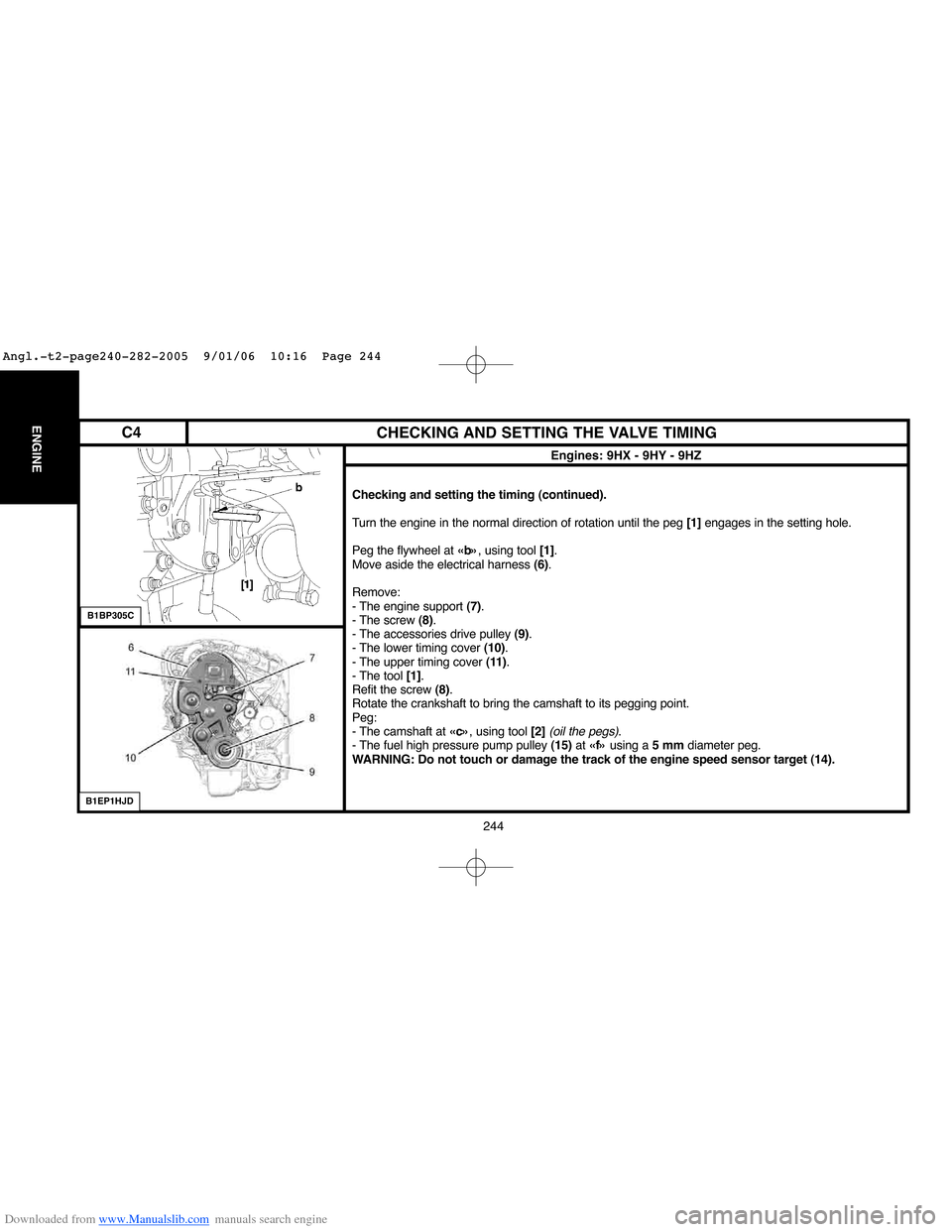

Checking and setting the timing (continued).

Turn the engine in the normal direction of rotation until the peg [1]engages in the setting hole.

Peg the flywheel at «b», using tool [1].

Move aside the electrical harness (6).

Remove:

- The engine support (7).

- The screw (8).

- The accessories drive pulley (9).

- The lower timing cover (10).

- The upper timing cover (11).

- The tool [1].

Refit the screw (8).

Rotate the crankshaft to bring the camshaft to its pegging point.

Peg:

- The camshaft at «c», using tool [2]

(oil the pegs).

- The fuel high pressure pump pulley (15)at «f»using a 5 mmdiameter peg.

WARNING: Do not touch or damage the track of the engine speed sensor target (14).

B1BP305C

B1EP1HJD

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 244

Page 251 of 462

Downloaded from www.Manualslib.com manuals search engine 245

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HX - 9HY - 9HZ

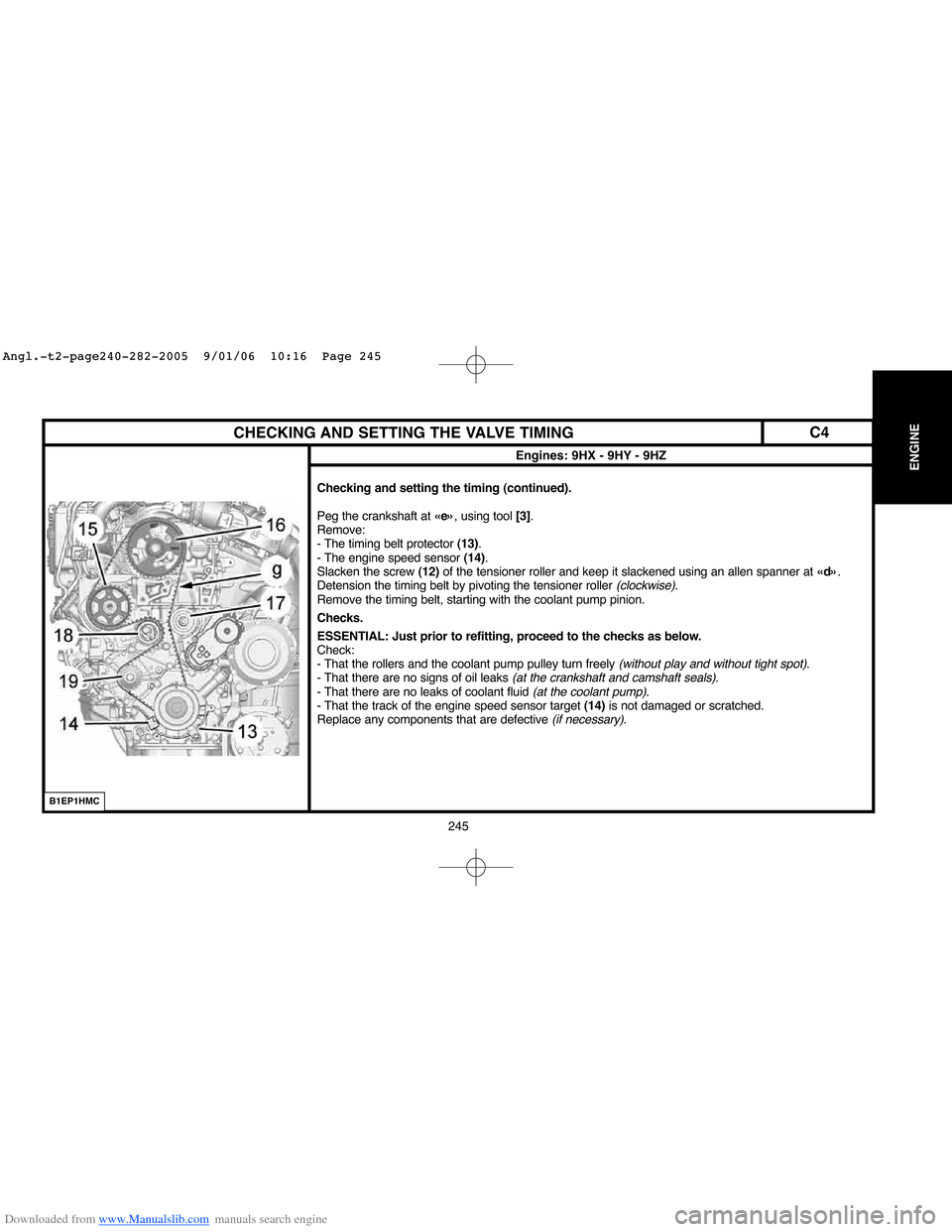

Checking and setting the timing (continued).

Peg the crankshaft at «e», using tool [3].

Remove:

- The timing belt protector (13).

- The engine speed sensor (14).

Slacken the screw (12)of the tensioner roller and keep it slackened using an allen spanner at «d».

Detension the timing belt by pivoting the tensioner roller

(clockwise).

Remove the timing belt, starting with the coolant pump pinion.

Checks.

ESSENTIAL: Just prior to refitting, proceed to the checks as below.

Check:

- That the rollers and the coolant pump pulley turn freely

(without play and without tight spot).

- That there are no signs of oil leaks (at the crankshaft and camshaft seals).

- That there are no leaks of coolant fluid (at the coolant pump).

- That the track of the engine speed sensor target (14)is not damaged or scratched.

Replace any components that are defective

(if necessary).

B1EP1HMC

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 245