air condition Citroen XSARA PICASSO 2005 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 182 of 462

![Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 176

ENGINEXSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning

B1BP1YKD

Tools.

[1] Belt tension adj Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 176

ENGINEXSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning

B1BP1YKD

Tools.

[1] Belt tension adj](/img/9/4138/w960_4138-181.png)

Downloaded from www.Manualslib.com manuals search engine 176

ENGINEXSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning

B1BP1YKD

Tools.

[1] Belt tension adjusting square: (-).0188 J2

[2] Ø 4 mmpeg: (-).0188.Q1

[3] Ø 2 mmpeg: (-).0188.Q2

[4]Dynamic tensioner compression lever: (-).0188.Z

Removing.

Re-use of belt.

WARNING: Mark the direction the belt was fiited in case of re-use of the same belt.

Compress the tensioner roller (2)by action at «a»

(in anti-clockwise direction), tool [4].

Keep the tensioner roller (2)compressed and remove the belt.

No re-use of belt.

Compress the tensioner roller (2)by action at «a»

(in anti-clockwise direction), tool [4].

Peg using tool [2]at «b».

Keep the tensioner roller (2)compressed and remove the belt.

Loosen the screw (1).

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 176

Page 183 of 462

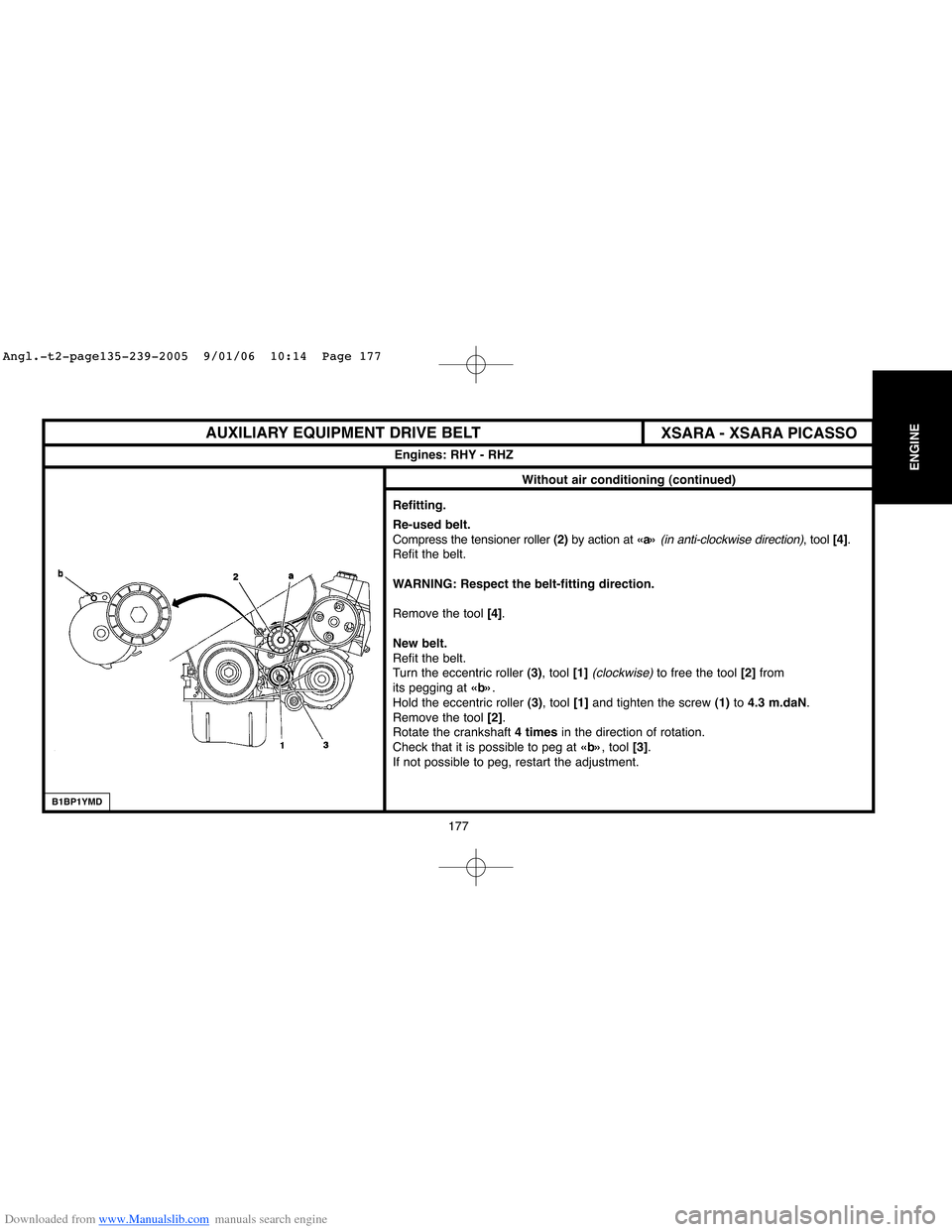

Downloaded from www.Manualslib.com manuals search engine 177

ENGINE

XSARA - XSARA PICASSO AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

Without air conditioning (continued)

Refitting.

Re-used belt.

Compress the tensioner roller (2)by action at «a»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the belt-fitting direction.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (3), tool [1]

(clockwise)to free the tool [2]from

its pegging at «b».

Hold the eccentric roller (3), tool [1]and tighten the screw (1)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «b», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YMD

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 177

Page 184 of 462

![Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusti Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusti](/img/9/4138/w960_4138-183.png)

Downloaded from www.Manualslib.com manuals search engine 178

ENGINEXSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning

B1BP1YLD

Tools.

[1]Belt tension adjusting square: (-).0188 J2

[2] Ø 4 mmpeg: (-).0188.Q1

[3] Ø 2 mmpeg: (-).0188.Q2

[4]Dynamic tensioner compression lever: (-).0188.Z

Removal.

Re-use of belt.

WARNING: Mark the direction the belt was fitted in case of re-use of the same belt.

Compress the tensioner roller (7)by moving it at «c»

(in anti-clockwise direction), tool [4].

Hold the tensioner roller (7) compressed and remove the belt.

No re-use of belt.

Compress the tensioner roller (7)by moving it at «c»

(in anti-clockwise direction), tool [4].

Peg using tool [2], at «d».

Loosen the screw (6).

Bring the eccentric roller (5)towards the rear.

Tighten the screw (6)by hand.

Remove the belt.

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 178

Page 185 of 462

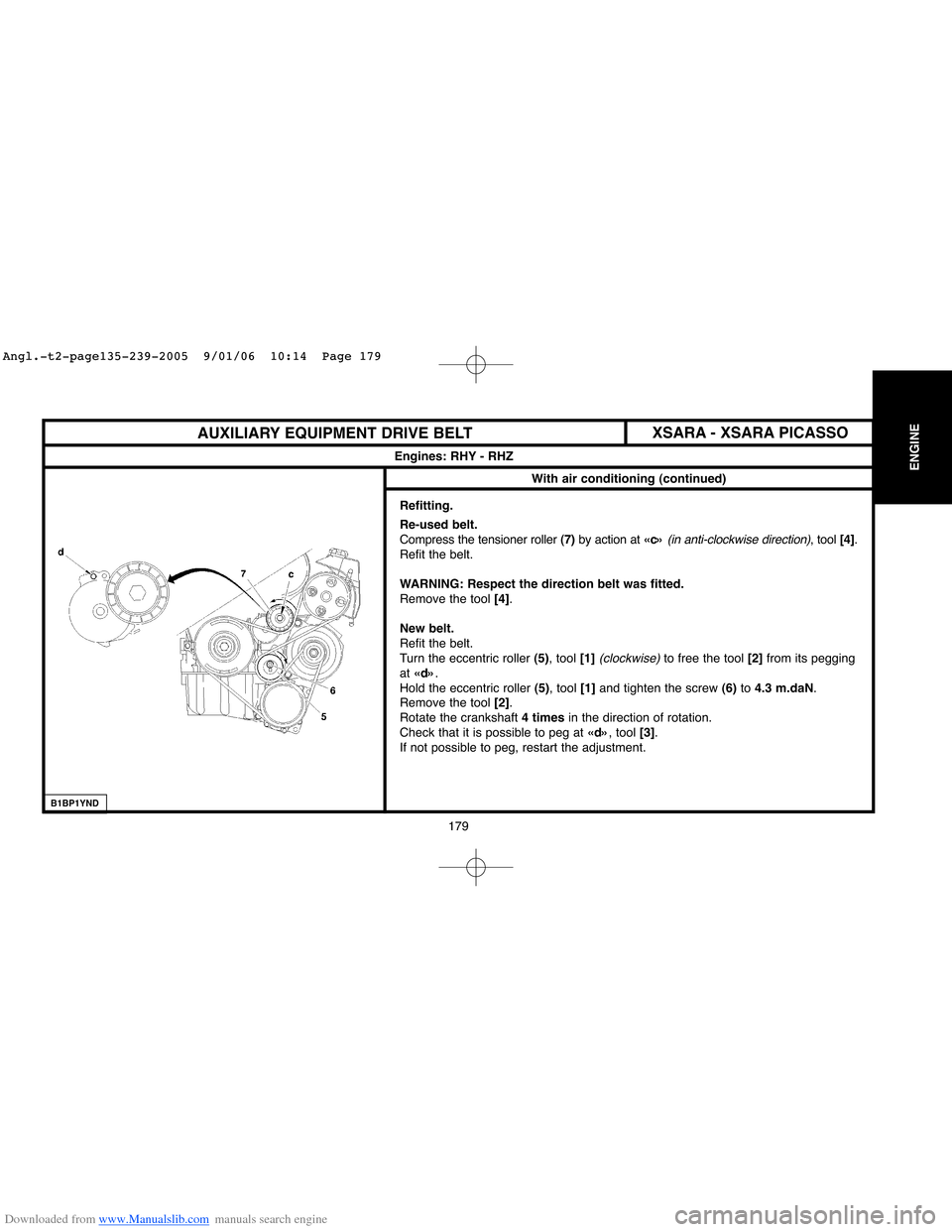

Downloaded from www.Manualslib.com manuals search engine 179

ENGINE

XSARA - XSARA PICASSO

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHY - RHZ

With air conditioning (continued)

Refitting.

Re-used belt.

Compress the tensioner roller (7)by action at «c»

(in anti-clockwise direction), tool [4].

Refit the belt.

WARNING: Respect the direction belt was fitted.

Remove the tool [4].

New belt.

Refit the belt.

Turn the eccentric roller (5), tool[1]

(clockwise)to free the tool [2]from its pegging

at «d».

Hold the eccentric roller (5), tool [1]and tighten the screw (6)to 4.3 m.daN.

Remove the tool [2].

Rotate the crankshaft 4 timesin the direction of rotation.

Check that it is possible to peg at «d», tool [3].

If not possible to peg, restart the adjustment.

B1BP1YND

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 179

Page 186 of 462

![Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten Citroen XSARA PICASSO 2005 1.G Owners Manual Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten](/img/9/4138/w960_4138-185.png)

Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic tensioner roller retaining peg Ø 4 mm : (-).0188.Q1

Removing.

Remove the splash-shield, under-engine sound-deadening, front RH wheel.

WARNING: Mark the direction of fitting of the auxiliaries drive belt in the case of

re-use of the belt.

Compress the dynamic tensioner roller (1)by acting at «b»

(anti-clockwise), using tool [1].

Peg using tool [2]at «a».

IMPERATIVE : Check that the roller (1) turns freely

(without play and without tight

spots).

Refitting.

Refit the auxiliaries drive belt.

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in

the grooves of the various pulleys.

Compress the dynamic tensioner roller (1)by acting at «b», using tool [1].

Remove tool [2] at «a».

Complete the refitting.

JUMPER

Without air conditioning

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 180

Page 434 of 462

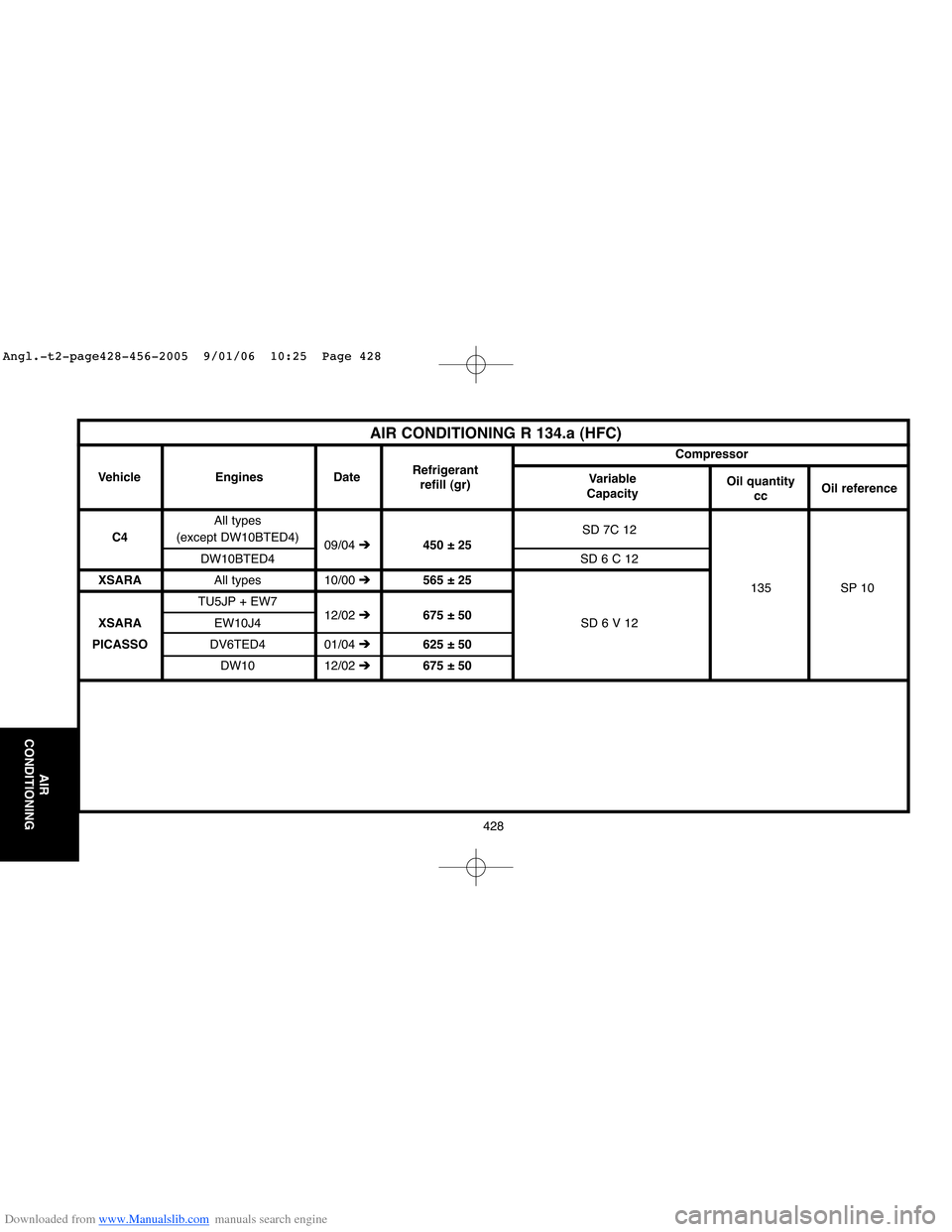

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING R 134.a (HFC)

Vehicle

All types

C4(except DW10BTED4)

09/04 ➔ ➔

450 ± 25SD 7C 12

DW10BTED4 SD 6 C 12

XSARAAll types 10/00 ➔ ➔

565 ± 25

135 SP 10

TU5JP + EW7

XSARAEW10J412/02 ➔ ➔

675 ± 50

SD 6 V 12

PICASSODV6TED4 01/04 ➔ ➔

625 ± 50

DW10 12/02 ➔ ➔

675 ± 50 Engines DateRefrigerant

refill (gr)Compressor

Variable

CapacityOil quantity

ccOil reference

428

AIR

CONDITIONING

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 428

Page 435 of 462

Downloaded from www.Manualslib.com manuals search engine 429

AIR

CONDITIONING

ESSENTIAL: The compressor lubricant is extremely hygroscopic; always use FRESH oil.

Checking the compressor oil level

There are three specific cases:

- 1/Repairs to a system without leaks.

- 2/Slow leak.

- 3/Fast leak.

1/ Repairing a system without leaks.

a) - Using draining/recovery equipment not fitted with an oil decanter.

- Drain the system as slowly as possible via the LOW PRESSUREvalve, so as not to lose any oil.

- No more oil should be added when filling the system with R 134.afluid.

b) - Using draining/filling equipment fitted with an oil decanter.

- Drain the R 134.afluid from the system in accordance with the instructions in the equipment handbook.

- Measure the amount of oil recovered.

- Add the same amount of NEWoil when filling the system with R 134.afluid.

c) - Replacing a compressor.

- Remove the old compressor, drain it and measure the oil quantity.

- Drain the new compressor

(supplied full), so that the same amount of NEWoil is left in the compressor as was in the old compressor.

- No more oil should be added when filling the system with R 134.a fluid.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Compressor lubricant

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 429

Page 436 of 462

Downloaded from www.Manualslib.com manuals search engine 430

AIR

CONDITIONING

Checking the compressor oil level (continued)

2/ Slow leak.

Slow leaks do not lead to oil loss, therefore the same procedure should be followed as if there was no leak at all.

3/ Fast leak.

This type of leak causes both oil loss as well as allowing air to enter the system.

It is therefore necessary to:

- Replace the dehydrator.

- Drain as much oil as possible

(when replacing the faulty component).

Either before or during filling of the system with R 134.afluid, introduce 80 ccof NEWoil into the circuit.

When changing one of the following components, add the quantity stated:

- A drying bottle : 15 ccof compressor oil.

- A condenser or an evaporator : 20 ccof compressor oil.

- High pressure or low pressure pipework : 5 ccof compressor oil.

- A drying cartridge : 15 ccof compressor oil.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 430

Page 437 of 462

Downloaded from www.Manualslib.com manuals search engine 431

AIR

CONDITIONING C5HP1C6C

Pollen filter

Note:The pollen filter is located in the engine compartment

on the RH side.

Removing.

Remove:

- The plastic pins (1).

- The plastic cover (2).

- The flap (3).

- The pollen filter (4).

Refitting.

Proceed in reverse order.

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

C5HP1C5CC5HP1C7C

C4

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 431

Page 438 of 462

Downloaded from www.Manualslib.com manuals search engine 432

AIR

CONDITIONING

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Pollen filter

XSARA

Removing-refitting.

Remove:

- The interior trim (1).

- The cover (4).

- The pollen filter (3).

Concerns vehicles equipped with aircon without temperature regulation.

Fitting of a new pollen filter necessitates the following operations:

- Engage the pollen filter upwards

(following arrow «c»).- Slide the pollen filter towards the rear (following arrow «d»).- Position the index(4)on the cover forward of the pollen filter ((4)Index on

the cover).

C5HP07JC

C5FP075D

Angl.-t2-page428-456-2005 9/01/06 10:25 Page 432