GEARBOX RATIO Citroen XSARA PICASSO 2005 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: XSARA PICASSO, Model: Citroen XSARA PICASSO 2005 1.GPages: 462, PDF Size: 10.48 MB

Page 5 of 462

Downloaded from www.Manualslib.com manuals search engine GENERAL

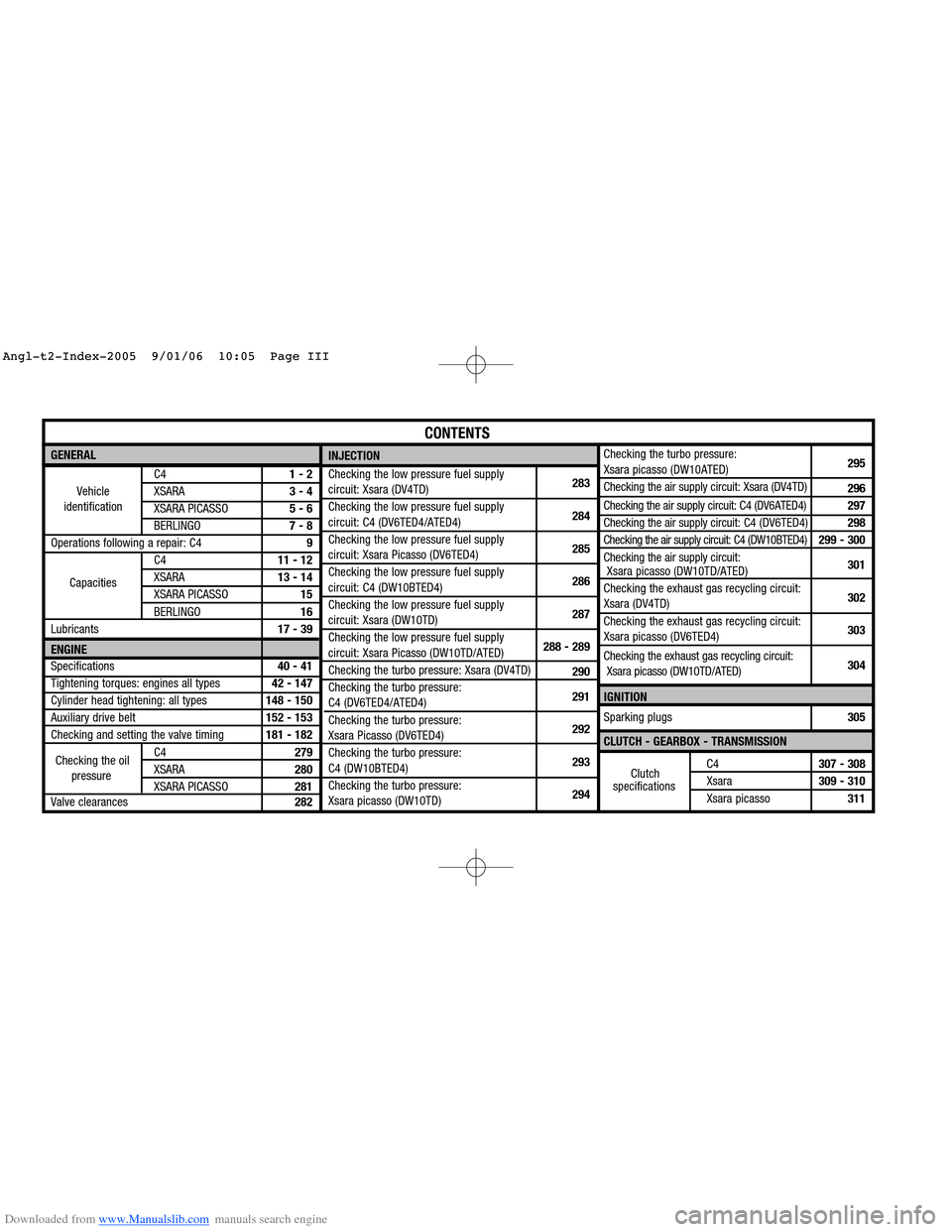

C41 - 2

XSARA3 - 4

XSARA PICASSO5 - 6

BERLINGO7 - 8

Operations following a repair: C49

C411 - 12

XSARA13 - 14

XSARA PICASSO15

BERLINGO16

Lubricants17 - 39

ENGINE

Specifications40 - 41

Tightening torques: engines all types42 - 147

Cylinder head tightening: all types148 - 150

Auxiliary drive belt152 - 153

Checking and setting the valve timing181 - 182

C4279

XSARA280

XSARA PICASSO281

Valve clearances282Checking the turbo pressure:

Xsara picasso (DW10ATED)295

Checking the air supply circuit: Xsara (DV4TD)

296

Checking the air supply circuit: C4 (DV6ATED4)297

Checking the air supply circuit: C4 (DV6TED4)298

Checking the air supply circuit: C4 (DW10BTED4)299 - 300

Checking the air supply circuit:

Xsara picasso (DW10TD/ATED)301

Checking the exhaust gas recycling circuit:

Xsara (DV4TD)302

Checking the exhaust gas recycling circuit:

Xsara picasso (DV6TED4)303

Checking the exhaust gas recycling circuit:

Xsara picasso (DW10TD/ATED)304

IGNITION

Sparking plugs305

CLUTCH - GEARBOX - TRANSMISSION

C4307 - 308

Xsara309 - 310

Xsara picasso311

CONTENTS

Vehicle

identification

Capacities

INJECTION

Checking the low pressure fuel supply

circuit: Xsara (DV4TD)283

Checking the low pressure fuel supply

circuit: C4 (DV6TED4/ATED4)284

Checking the low pressure fuel supply

circuit: Xsara Picasso (DV6TED4)285

Checking the low pressure fuel supply

circuit: C4 (DW10BTED4)286

Checking the low pressure fuel supply

circuit: Xsara (DW10TD)287

Checking the low pressure fuel supply

circuit: Xsara Picasso (DW10TD/ATED)288 - 289

Checking the turbo pressure: Xsara (DV4TD)

290

Checking the turbo pressure:

C4 (DV6TED4/ATED4)291

Checking the turbo pressure:

Xsara Picasso (DV6TED4)292

Checking the turbo pressure:

C4 (DW10BTED4)293

Checking the turbo pressure:

Xsara picasso (DW10TD)294

Checking the oil

pressureClutch

specifications

Angl-t2-Index-2005 9/01/06 10:05 Page III

Page 14 of 462

Downloaded from www.Manualslib.com manuals search engine 8

GENERAL

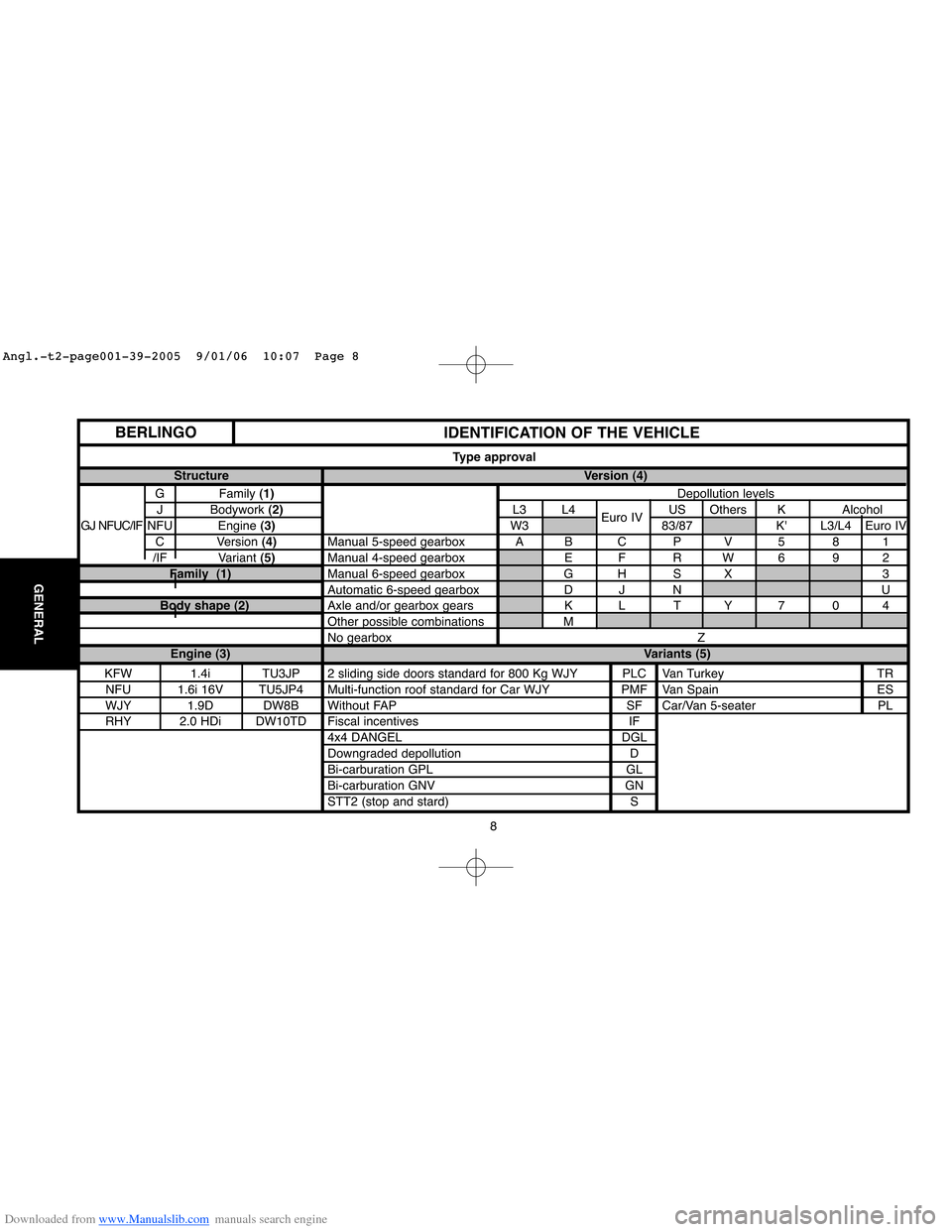

Structure Version (4)

G Family (1)Depollution levels

J Bodywork (2)L3 L4

Euro IVUS Others K Alcohol

GJ NFUC/IF N F UEngine (3)W3 83/87 K' L3/L4 Euro IV

C Version (4)Manual 5-speed gearbox A B C P V 5 8 1

/IF Variant (5)Manual 4-speed gearbox E F R W 6 9 2

Family (1)Manual 6-speed gearbox G H S X 3

Automatic 6-speed gearbox D J N U

Body shape (2)Axle and/or gearbox gears K L T Y 7 0 4

Other possible combinations M

No gearbox Z

Engine (3)Variants (5)

KFW 1.4i TU3JP 2 sliding side doors standard for 800 Kg WJY PLC Van Turkey TR

NFU 1.6i 16V TU5JP4 Multi-function roof standard for Car WJY PMF Van Spain ES

WJY 1.9D DW8B Without FAP SF Car/Van 5-seater PL

RHY 2.0 HDi DW10TD Fiscal incentives IF

4x4 DANGEL DGL

Downgraded depollution D

Bi-carburation GPL GL

Bi-carburation GNV GN

STT2 (stop and stard) S

IDENTIFICATION OF THE VEHICLE

Type approval

BERLINGO

Angl.-t2-page001-39-2005 9/01/06 10:07 Page 8

Page 224 of 462

Downloaded from www.Manualslib.com manuals search engine 218

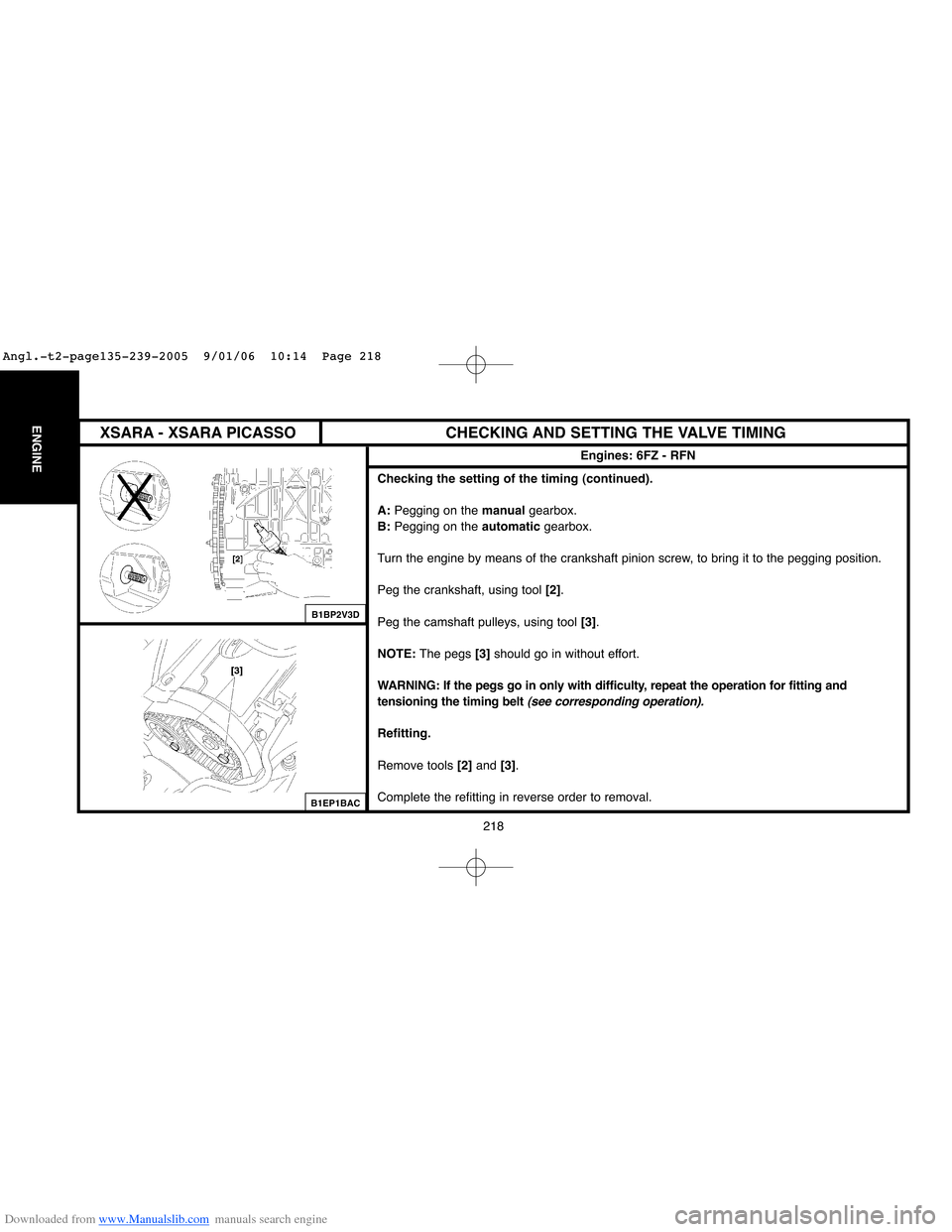

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 6FZ - RFN

Checking the setting of the timing (continued).

A:Pegging on the manualgearbox.

B:Pegging on the automaticgearbox.

Turn the engine by means of the crankshaft pinion screw, to bring it to the pegging position.

Peg the crankshaft, using tool [2].

Peg the camshaft pulleys, using tool [3].

NOTE:The pegs[3]should go in without effort.

WARNING: If the pegs go in only with difficulty, repeat the operation for fitting and

tensioning the timing belt

(see corresponding operation).

Refitting.

Remove tools [2]and [3].

Complete the refitting in reverse order to removal.

B1BP2V3D

B1EP1BAC

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 218

Page 312 of 462

Downloaded from www.Manualslib.com manuals search engine 306

CLUTCH

GEARBOX

TRANSMISSION

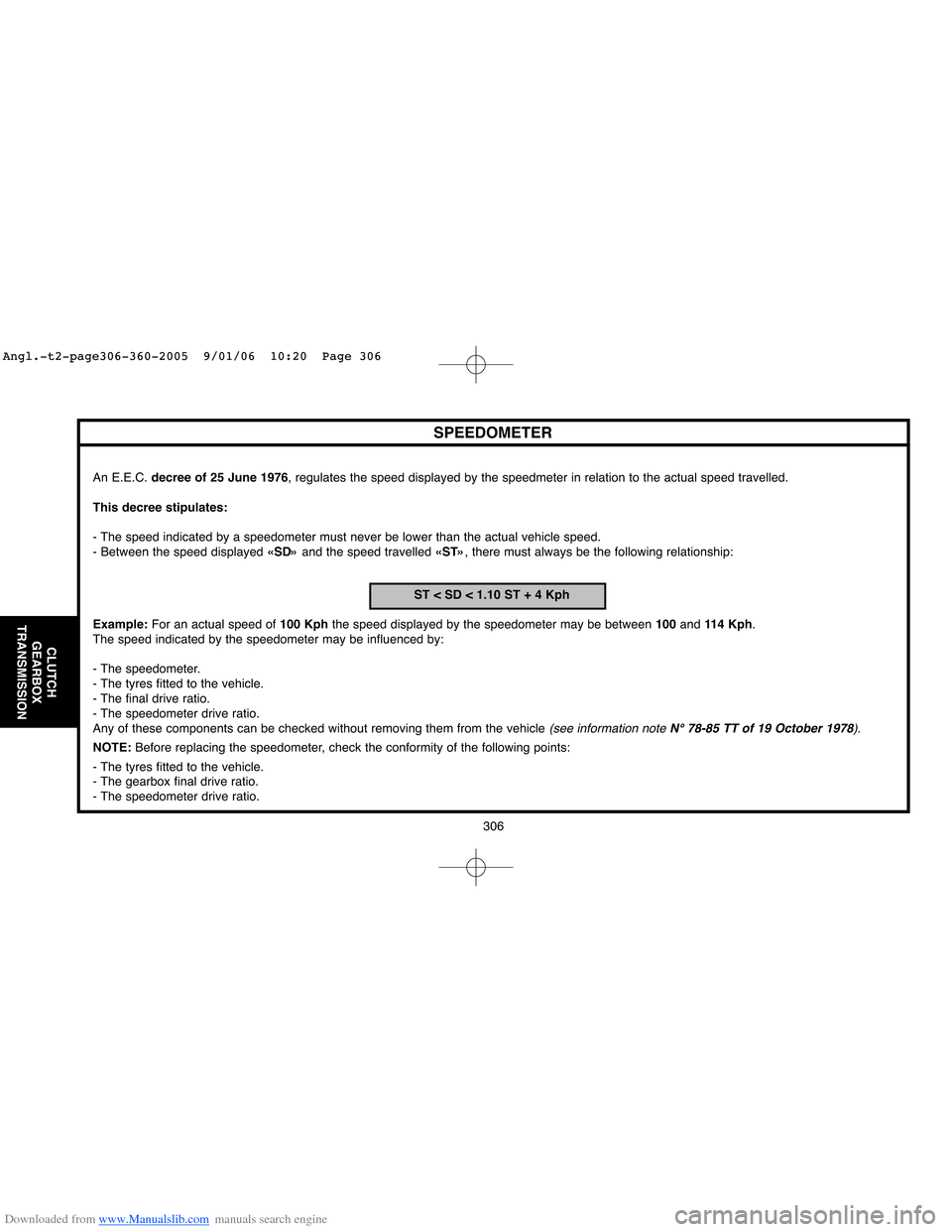

SPEEDOMETER

An E.E.C. decree of 25 June 1976, regulates the speed displayed by the speedmeter in relation to the actual speed travelled.

This decree stipulates:

- The speed indicated by a speedometer must never be lower than the actual vehicle speed.

- Between the speed displayed «SD»and the speed travelled «ST», there must always be the following relationship:

ST < SD < 1.10 ST + 4 Kph

Example:For an actual speed of 100 Kphthe speed displayed by the speedometer may be between 100and 114 Kph.

The speed indicated by the speedometer may be influenced by:

- The speedometer.

- The tyres fitted to the vehicle.

- The final drive ratio.

- The speedometer drive ratio.

Any of these components can be checked without removing them from the vehicle

(see information note N° 78-85 TT of 19 October 1978).

NOTE:Before replacing the speedometer, check the conformity of the following points:

- The tyres fitted to the vehicle.

- The gearbox final drive ratio.

- The speedometer drive ratio.

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 306

Page 318 of 462

Downloaded from www.Manualslib.com manuals search engine 312

CLUTCH

GEARBOX

TRANSMISSION

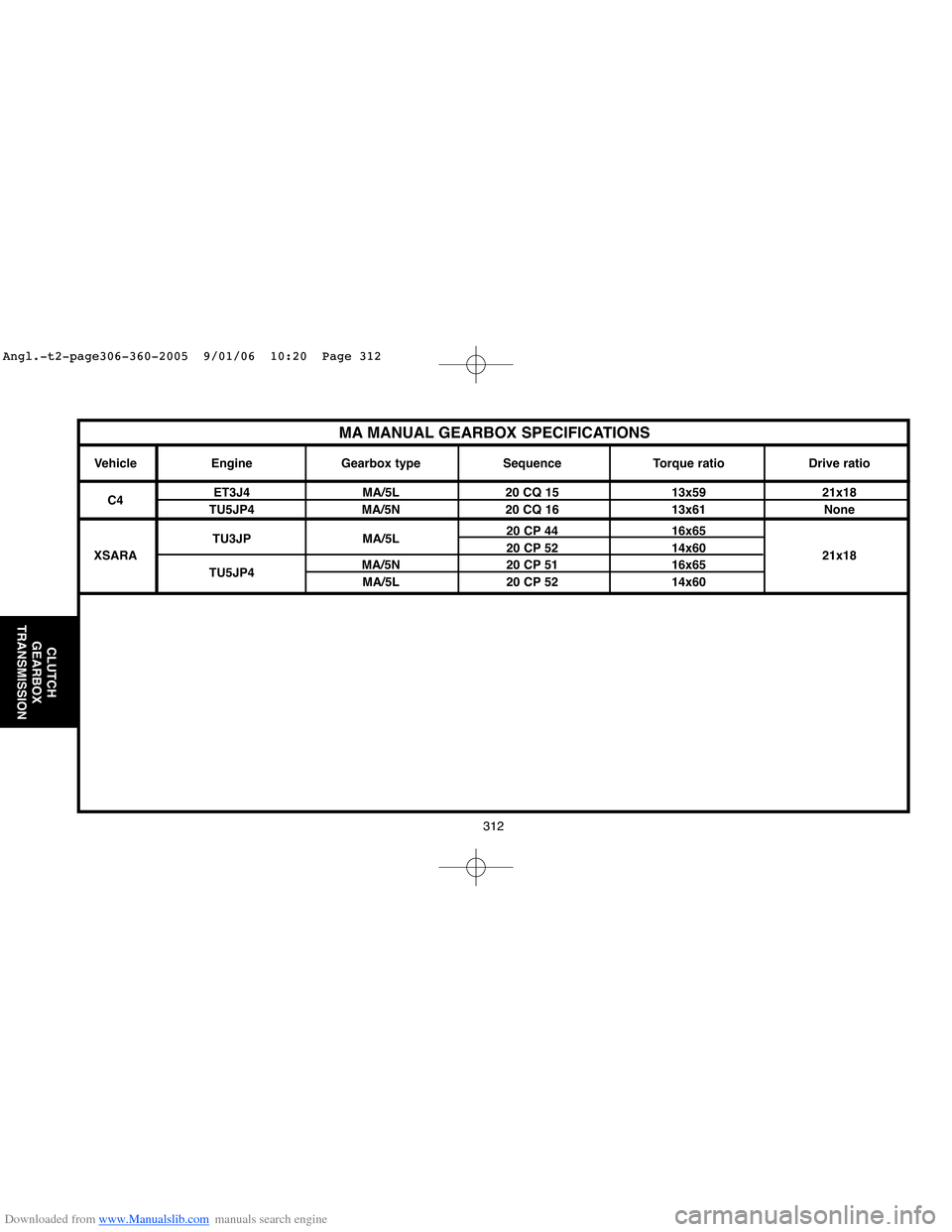

MA MANUAL GEARBOX SPECIFICATIONS

Vehicle Engine Gearbox type Sequence Torque ratio Drive ratio

C4ET3J4 MA/5L 20 CQ 15 13x59 21x18

TU5JP4 MA/5N 20 CQ 16 13x61 None

TU3JP MA/5L20 CP 44 16x65

XSARA20 CP 52 14x60

21x18

TU5JP4MA/5N 20 CP 51 16x65

MA/5L 20 CP 52 14x60

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 312

Page 319 of 462

Downloaded from www.Manualslib.com manuals search engine 313

CLUTCH

GEARBOX

TRANSMISSION

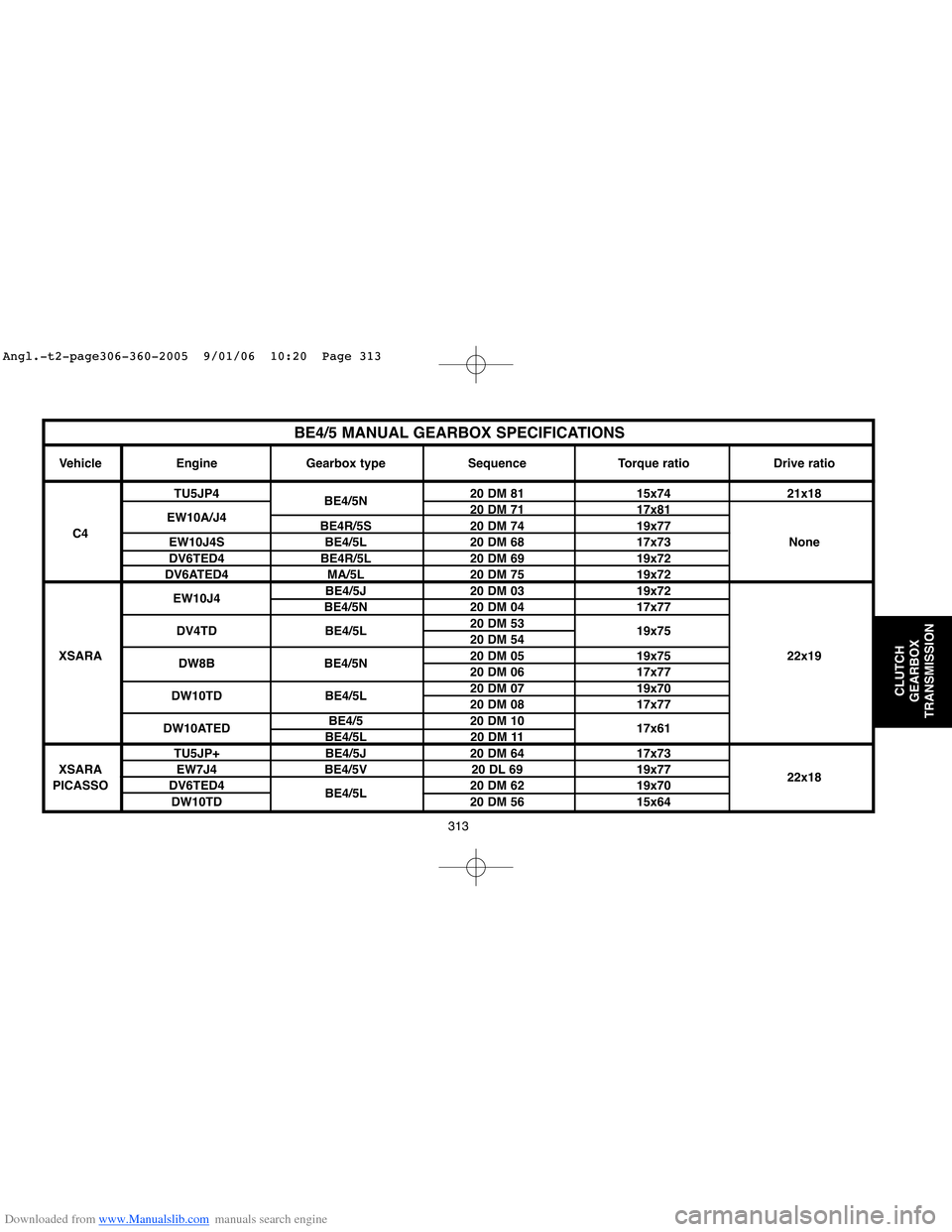

BE4/5 MANUAL GEARBOX SPECIFICATIONS

Vehicle Engine Gearbox type Sequence Torque ratio Drive ratio

TU5JP4

BE4/5N20 DM 81 15x74 21x18

EW10A/J420 DM 71 17x81

C4BE4R/5S 20 DM 74 19x77

EW10J4S BE4/5L 20 DM 68 17x73 None

DV6TED4 BE4R/5L 20 DM 69 19x72

DV6ATED4 MA/5L 20 DM 75 19x72

EW10J4BE4/5J 20 DM 03 19x72

BE4/5N 20 DM 04 17x77

DV4TD BE4/5L20 DM 53

19x75

20 DM 54

XSARA

DW8B BE4/5N20 DM 05 19x75 22x19

20 DM 06 17x77

DW10TD BE4/5L20 DM 07 19x70

20 DM 08 17x77

DW10ATEDBE4/5 20 DM 10

17x61

BE4/5L 20 DM 11

TU5JP+ BE4/5J 20 DM 64 17x73

XSARA EW7J4 BE4/5V 20 DL 69 19x77

22x18

PICASSO DV6TED4

BE4/5L20 DM 62 19x70

DW10TD 20 DM 56 15x64

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 313

Page 320 of 462

Downloaded from www.Manualslib.com manuals search engine 314

CLUTCH

GEARBOX

TRANSMISSION

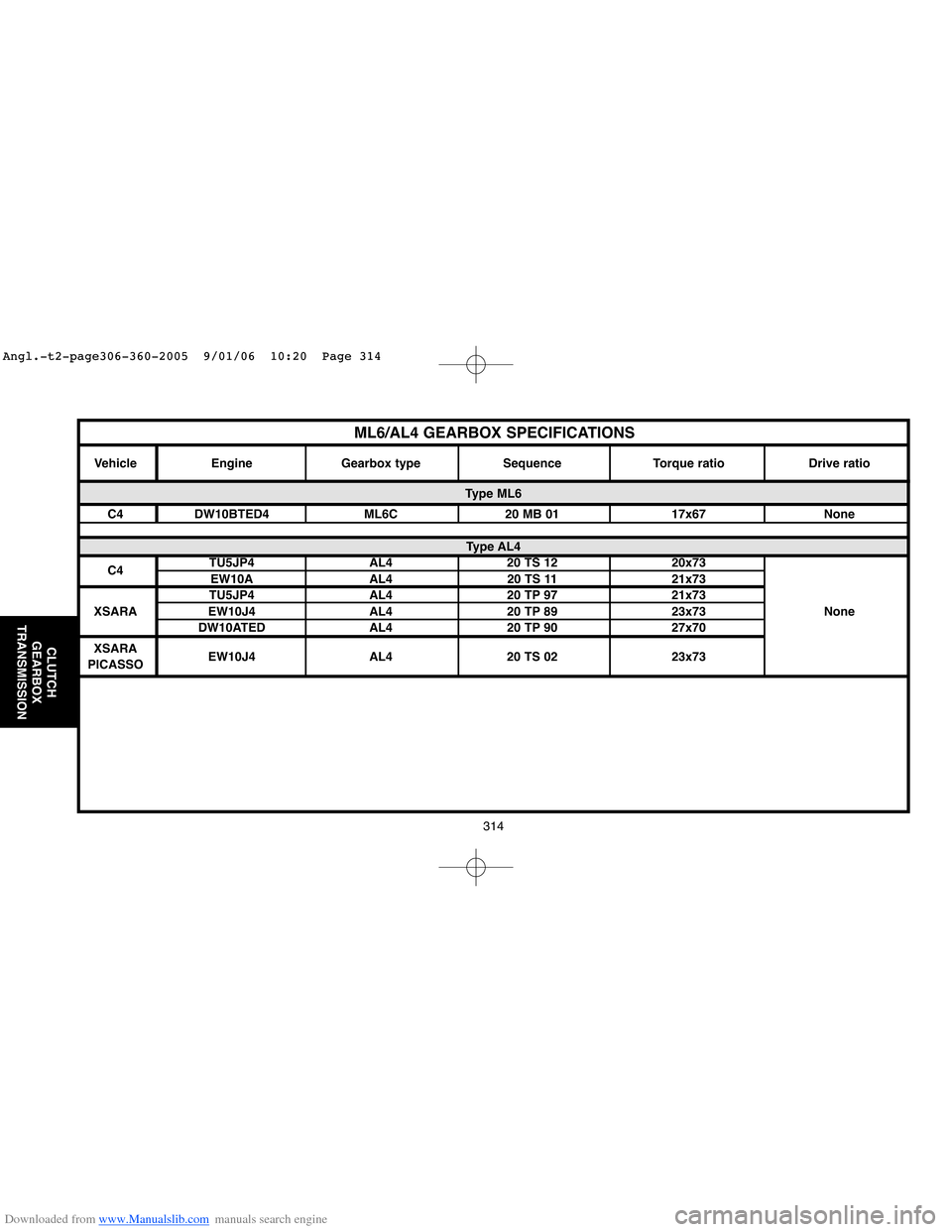

ML6/AL4 GEARBOX SPECIFICATIONS

Vehicle Engine Gearbox type Sequence Torque ratio Drive ratio

Type ML6

C4 DW10BTED4 ML6C 20 MB 01 17x67 None

Type AL4

C4TU5JP4 AL4 20 TS 12 20x73

EW10A AL4 20 TS 11 21x73

TU5JP4 AL4 20 TP 97 21x73

XSARA EW10J4 AL4 20 TP 89 23x73 None

DW10ATED AL4 20 TP 90 27x70

XSARA

PICASSOEW10J4 AL4 20 TS 02 23x73

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 314

Page 324 of 462

Downloaded from www.Manualslib.com manuals search engine 318

CLUTCH

GEARBOX

TRANSMISSION

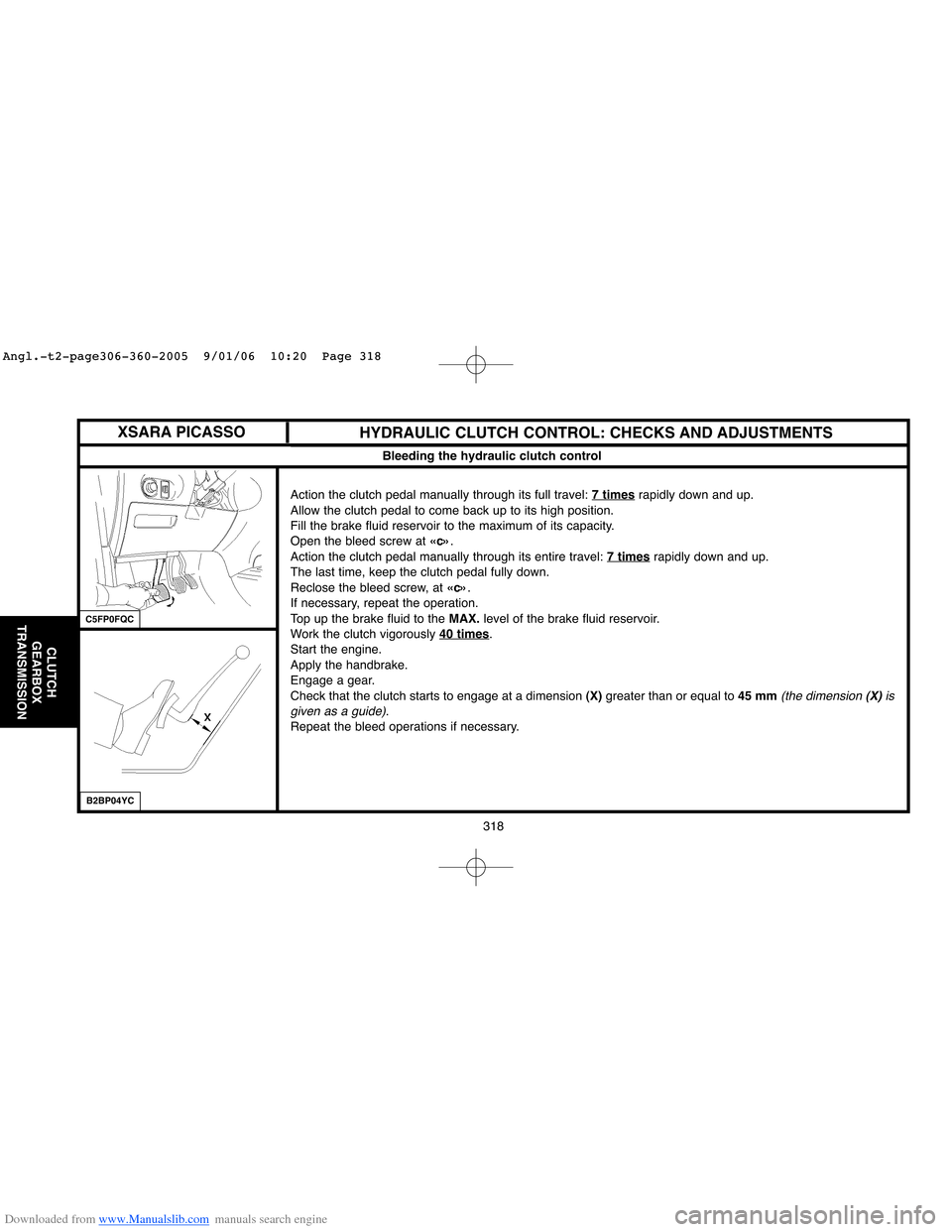

HYDRAULIC CLUTCH CONTROL: CHECKS AND ADJUSTMENTS

Bleeding the hydraulic clutch control

Action the clutch pedal manually through its full travel: 7 timesrapidly down and up.

Allow the clutch pedal to come back up to its high position.

Fill the brake fluid reservoir to the maximum of its capacity.

Open the bleed screw at «c».

Action the clutch pedal manually through its entire travel: 7 times

rapidly down and up.

The last time, keep the clutch pedal fully down.

Reclose the bleed screw, at «c».

If necessary, repeat the operation.

Top up the brake fluid to the MAX.level of the brake fluid reservoir.

Work the clutch vigorously 40 times

.

Start the engine.

Apply the handbrake.

Engage a gear.

Check that the clutch starts to engage at a dimension (X)greater than or equal to 45 mm

(the dimension (X)is

given as a guide).

Repeat the bleed operations if necessary.

C5FP0FQC

XSARA PICASSO

B2BP04YC

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 318

Page 349 of 462

Downloaded from www.Manualslib.com manuals search engine 343

CLUTCH

GEARBOX

TRANSMISSION

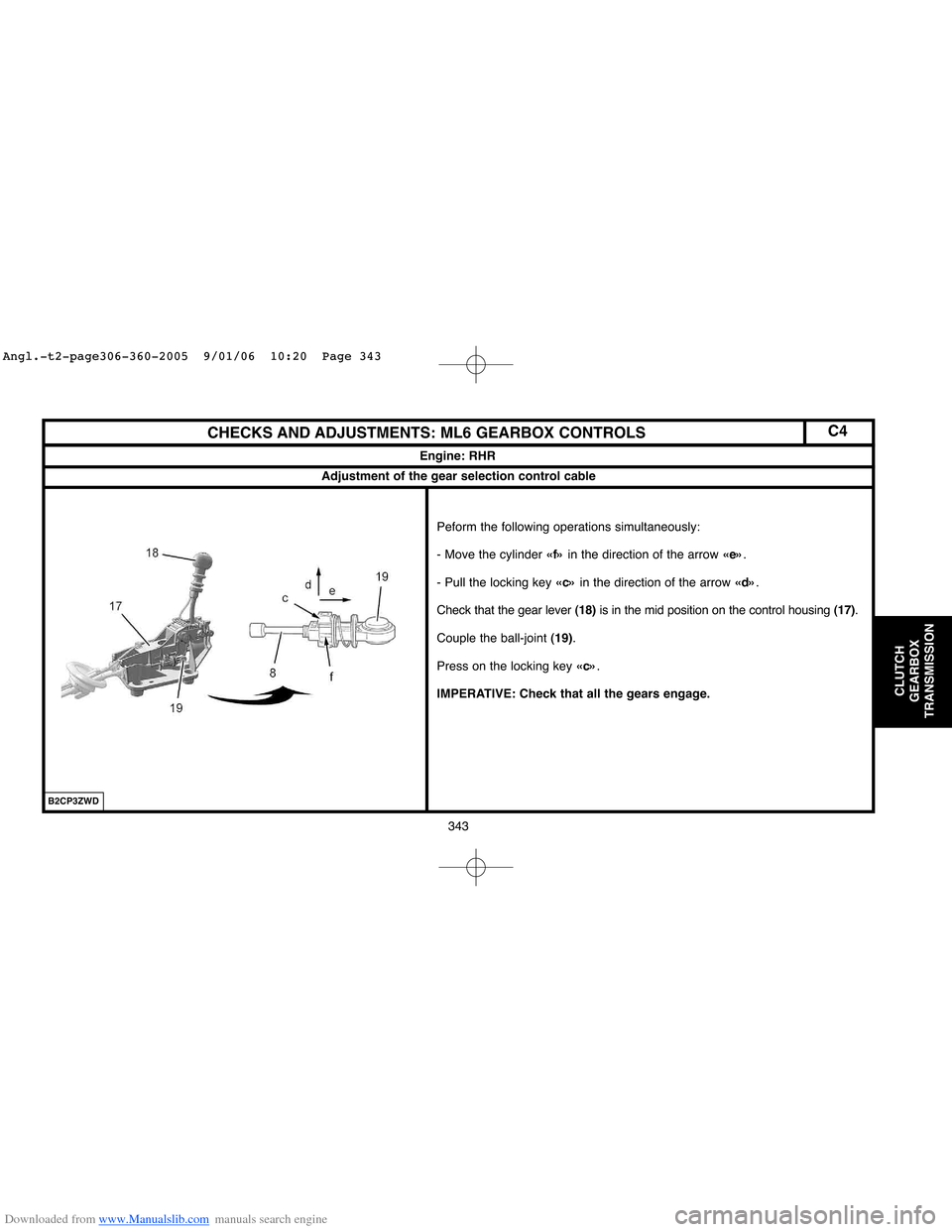

CHECKS AND ADJUSTMENTS: ML6 GEARBOX CONTROLS

Engine: RHR

Peform the following operations simultaneously:

- Move the cylinder «f»in the direction of the arrow «e».

- Pull the locking key «c»in the direction of the arrow «d».

Check that the gear lever (18)is in the mid position on the control housing (17).

Couple the ball-joint (19).

Press on the locking key «c».

IMPERATIVE: Check that all the gears engage.

B2CP3ZWD

Adjustment of the gear selection control cable

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 343

Page 351 of 462

Downloaded from www.Manualslib.com manuals search engine 345

CLUTCH

GEARBOX

TRANSMISSION

RECOMMENDATIONS/PRECAUTIONS : AL4 AUTOMATIC GEARBOX

Procedure to be followed prior to carrying out repairs on AL4 autoactive gearbox

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault:

- Gearbox in back-up mode with a replacement programme of

(the fault

values are taken in substitution).

- Gearbox in back-up mode with an emergency programme (3rd hydraulic).

WARNING: In the emergency programme, an impact is felt when

changing P/R, N/R and N/D.

Réception client.

Discuss with the customer, to find out all the malfunction symptoms.

Oil quality - Oil level.

Oil quality.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities: the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL: The gearbox must be replaced.Oil level

(see corresponding operation).

An excessive oil level can result in the following consequences:

- Excessive heating of the oil.

- Oil leaks.

An insufficent level causes the destruction of the gearbox.

Top up the level of oil in the gearbox

(if necessary).

Check using a diagnostic tool.

Read the fault codes

(engine and gearbox).

Absence of fault codes.

Carry out parameter measures, actuator tests and a road test.

Presence of fault codes.

Carry out the necessary repairs.

Delete the fault codes.

Carry out a road test to check the repair and, if need be, modify the

gearbox ECU parameters

(this is essential after an initialisation of the

ECU).

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 345