engine coolant DACIA DUSTER 2009 1.G Heating And Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: DACIA, Model Year: 2009, Model line: DUSTER, Model: DACIA DUSTER 2009 1.GPages: 54, PDF Size: 1.16 MB

Page 19 of 54

Downloaded from www.Manualslib.com manuals search engine 61A-17

HEATING

Distribution unit: Removal - Refitting

61A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aLock the airbag computer (see Fault finding - Re-

placement of components) (88C, Airbags and pre-

tensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

a

aDrain the coolant circuit using the refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) .

aMove aside the engine compartment bulkhead

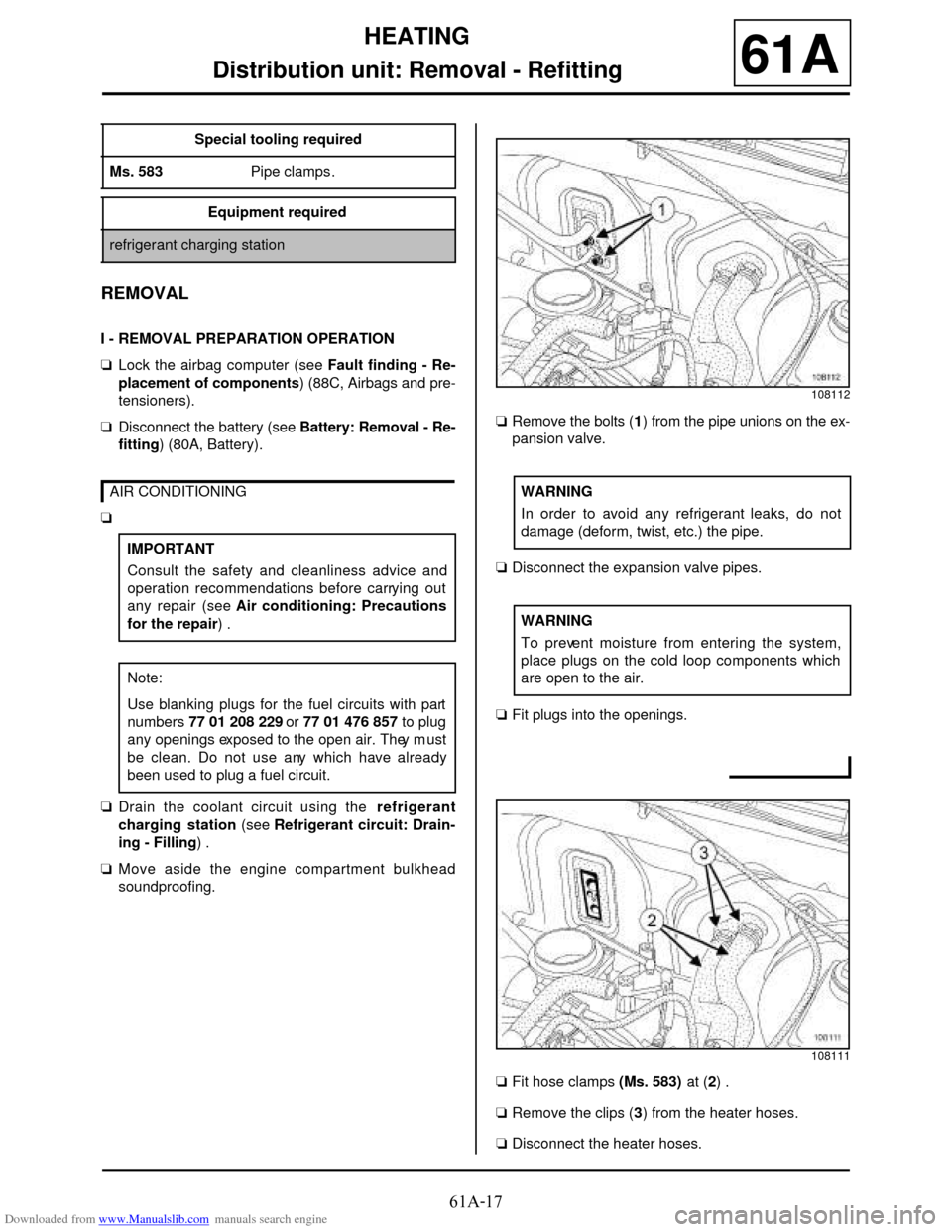

soundproofing.aRemove the bolts (1) from the pipe unions on the ex-

pansion valve.

aDisconnect the expansion valve pipes.

aFit plugs into the openings.

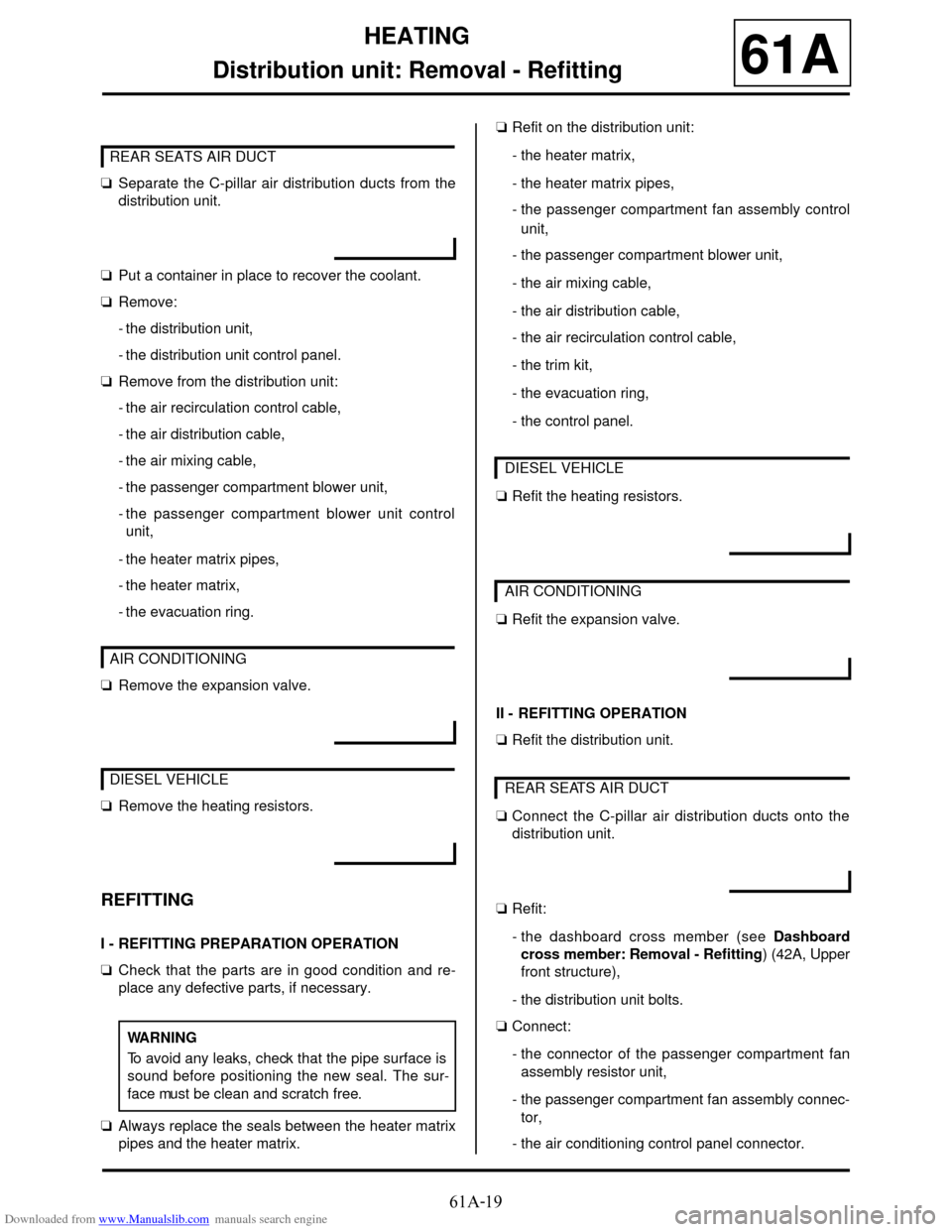

aFit hose clamps (Ms. 583) at (2) .

aRemove the clips (3) from the heater hoses.

aDisconnect the heater hoses. Special tooling required

Ms. 583Pipe clamps .

Equipment required

refrigerant charging station

AIR CONDITIONING

IMPORTANT

Consult the safety and cleanliness advice and

operation recommendations before carrying out

any repair (see Air conditioning: Precautions

for the repair) .

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They m ust

be clean. Do not use any which have already

been used to plug a fuel circuit.

108112

WARNING

In order to avoid any refrigerant leaks, do not

damage (deform, twist, etc.) the pipe.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

108111

Page 21 of 54

Downloaded from www.Manualslib.com manuals search engine 61A-19

HEATING

Distribution unit: Removal - Refitting

61A

aSeparate the C-pillar air distribution ducts from the

distribution unit.

aPut a container in place to recover the coolant.

aRemove:

-the distribution unit,

-the distribution unit control panel.

aRemove from the distribution unit:

-the air recirculation control cable,

-the air distribution cable,

-the air mixing cable,

-the passenger compartment blower unit,

-the passenger compartment blower unit control

unit,

-the heater matrix pipes,

-the heater matrix,

-the evacuation ring.

aRemove the expansion valve.

aRemove the heating resistors.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the parts are in good condition and re-

place any defective parts, if necessary.

aAlways replace the seals between the heater matrix

pipes and the heater matrix.aRefit on the distribution unit:

-the heater matrix,

-the heater matrix pipes,

-the passenger compartment fan assembly control

unit,

-the passenger compartment blower unit,

-the air mixing cable,

-the air distribution cable,

-the air recirculation control cable,

-the trim kit,

-the evacuation ring,

-the control panel.

aRefit the heating resistors.

aRefit the expansion valve.

II - REFITTING OPERATION

aRefit the distribution unit.

aConnect the C-pillar air distribution ducts onto the

distribution unit.

aRefit:

-the dashboard cross member (see Dashboard

cross member: Removal - Refitting) (42A, Upper

front structure),

-the distribution unit bolts.

aConnect:

-the connector of the passenger compartment fan

assembly resistor unit,

-the passenger compartment fan assembly connec-

tor,

-the air conditioning control panel connector. REAR SEATS AIR DUCT

AIR CONDITIONING

DIESEL VEHICLE

WARNING

To avoid any leaks, check that the pipe surface is

sound before positioning the new seal. The sur-

face must be clean and scratch free.

DIESEL VEHICLE

AIR CONDITIONING

REAR SEATS AIR DUCT

Page 24 of 54

Downloaded from www.Manualslib.com manuals search engine 61A-22

HEATING

Heater matrix: Removal - Refitting

LEFT-HAND DRIVE

61A

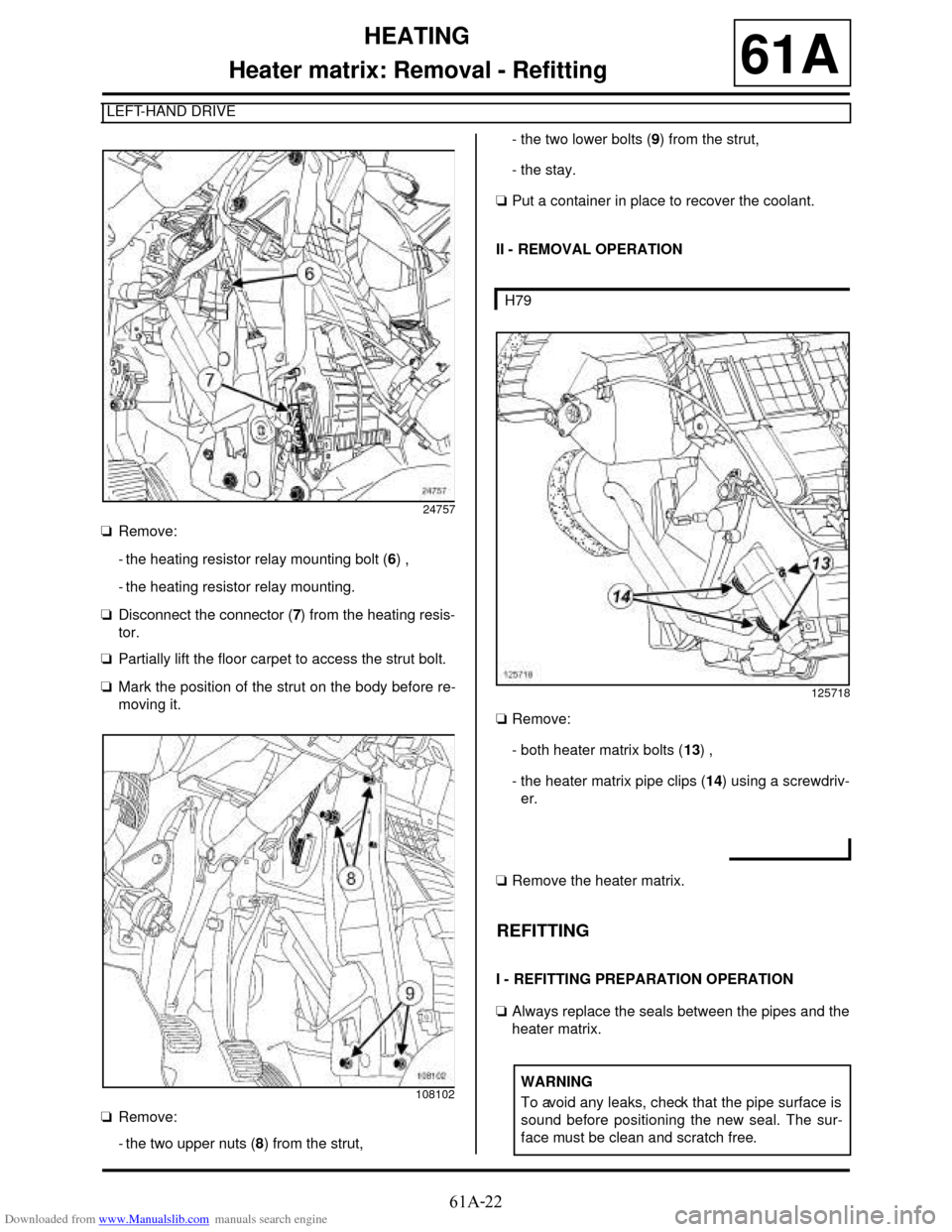

aRemove:

-the heating resistor relay mounting bolt (6) ,

-the heating resistor relay mounting.

aDisconnect the connector (7) from the heating resis-

tor.

aPartially lift the floor carpet to access the strut bolt.

aMark the position of the strut on the body before re-

moving it.

aRemove:

-the two upper nuts (8) from the strut,-the two lower bolts (9) from the strut,

-the stay.

aPut a container in place to recover the coolant.

II - REMOVAL OPERATION

aRemove:

-both heater matrix bolts (13) ,

-the heater matrix pipe clips (14) using a screwdriv-

er.

aRemove the heater matrix.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the seals between the pipes and the

heater matrix.

24757

108102

H79

125718

WARNING

To avoid any leaks, check that the pipe surface is

sound before positioning the new seal. The sur-

face must be clean and scratch free.

Page 41 of 54

Downloaded from www.Manualslib.com manuals search engine 62A-10

AIR CONDITIONING

Condenser: Removal - Refitting

AIR CONDITIONING

62A

Location and specifications (tightening torques, parts

always to be replaced, etc.) (see 62A, Air condition-

ing, Air conditioning: List and location of compo-

nents, page 62A-1) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the coolant circuit using the refrigerant

charging station.

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the front bumper (see Front bumper as-

sembly: Exploded view) and (see Exterior body

front trim assembly: Exploded view) (55A, Exteri-

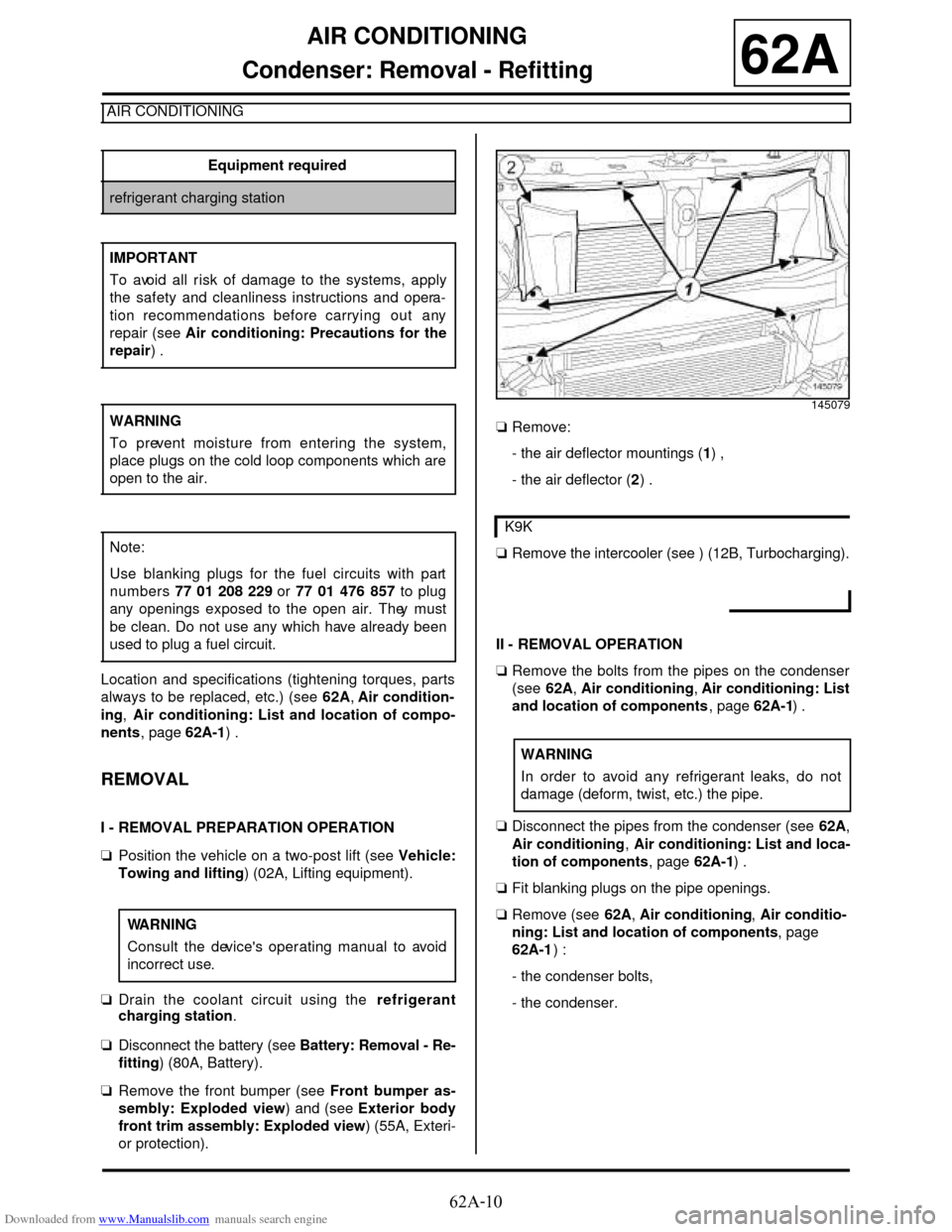

or protection).aRemove:

-the air deflector mountings (1) ,

-the air deflector (2) .

aRemove the intercooler (see ) (12B, Turbocharging).

II - REMOVAL OPERATION

aRemove the bolts from the pipes on the condenser

(see 62A, Air conditioning, Air conditioning: List

and location of components, page 62A-1) .

aDisconnect the pipes from the condenser (see 62A,

Air conditioning, Air conditioning: List and loca-

tion of components, page 62A-1) .

aFit blanking plugs on the pipe openings.

aRemove (see 62A, Air conditioning, Air conditio-

ning: List and location of components, page

62A-1) :

-the condenser bolts,

-the condenser. Equipment required

refrigerant charging station

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see Air conditioning: Precautions for the

repair) .

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

145079

K9K

WARNING

In order to avoid any refrigerant leaks, do not

damage (deform, twist, etc.) the pipe.

Page 43 of 54

Downloaded from www.Manualslib.com manuals search engine 62A-12

AIR CONDITIONING

Compressor: Removal - Refitting

AIR CONDITIONING

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the coolant circuit using the refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) .

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the front bumper (see Front bumper: Removal -

Refitting) and (see Exterior body front trim as-

sembly: Exploded view) (55A, Exterior protec-

tion),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the accessories belt (see Accessories belt: Re-

moval - Refitting) (11A, Top and front of engine).

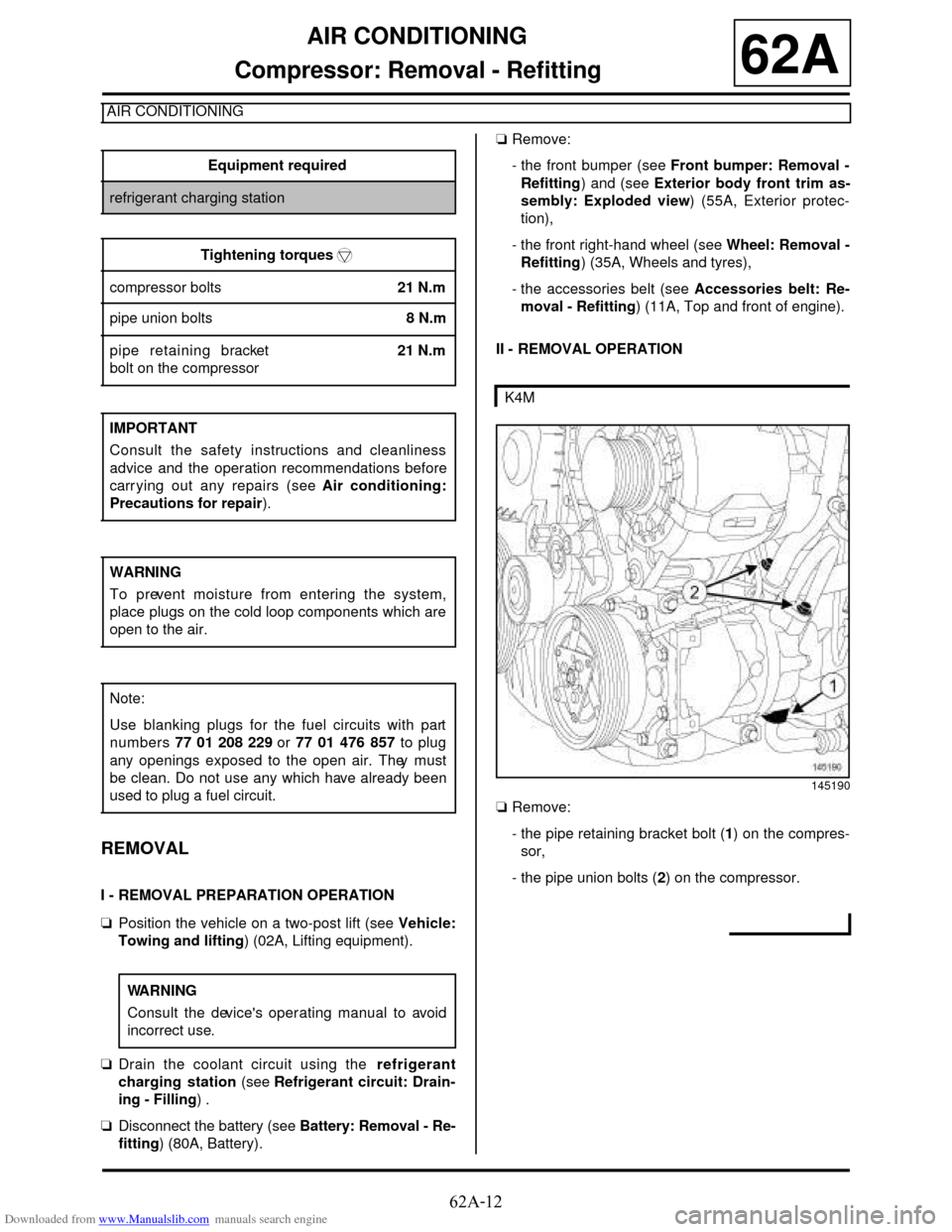

II - REMOVAL OPERATION

aRemove:

-the pipe retaining bracket bolt (1) on the compres-

sor,

-the pipe union bolts (2) on the compressor. Equipment required

refrigerant charging station

Tightening torquesm

compressor bolts21 N.m

pipe union bolts8 N.m

pipe retaining bracket

bolt on the compressor21 N.m

IMPORTANT

Consult the safety instructions and cleanliness

advice and the operation recommendations before

carrying out any repairs (see Air conditioning:

Precautions for repair).

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

K4M

145190

Page 47 of 54

Downloaded from www.Manualslib.com manuals search engine 62A-16

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING

62A

Location and specifications (tightening torques, parts

always to be replaced, etc.) (see 62A, Air condition-

ing, Air conditioning: List and location of compo-

nents, page 62A-1) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aDrain the coolant circuit using the refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) .

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine cover.aMove aside the bulkhead soundproofing.

II - REMOVAL OPERATION

aRemove the bolts from the pipes on the expansion

valve (see 62A, Air conditioning, Air condition-

ing: List and location of components, page 62A-

1) .

aDisconnect the pipes from the expansion valve (see

62A, Air conditioning, Air conditioning: List and

location of components, page 62A-1) .

aFit blanking plugs on the pipe openings.

aRemove (see 62A, Air conditioning, Air conditio-

ning: List and location of components, page

62A-1) :

-the expansion valve bolts,

-the expansion valve.

REFITTING

I - REFITTING PREPARATION OPERATION

a

aCheck, and if necessary replace, the refrigerant cir-

cuit pipe seal. Equipment required

refrigerant charging station

IMPORTANT

Consult the safety instructions and cleanliness

advice and the operation recommendations before

carrying out any repairs (see Air conditioning:

Precautions for repair).

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

K9K

WARNING

In order to avoid any refrigerant leaks, do not

damage (deform, twist, etc.) the pipe.

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Page 52 of 54

Downloaded from www.Manualslib.com manuals search engine 62A-21

AIR CONDITIONING

Refrigerant circuit pipe: Removal - Refitting

AIR CONDITIONING

62A

Location and specifications (tightening torques, parts

always to be replaced, etc.) (see 62A, Air condition-

ing, Air conditioning: List and location of compo-

nents, page 62A-1) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

Drain the coolant circuit using the refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) .

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

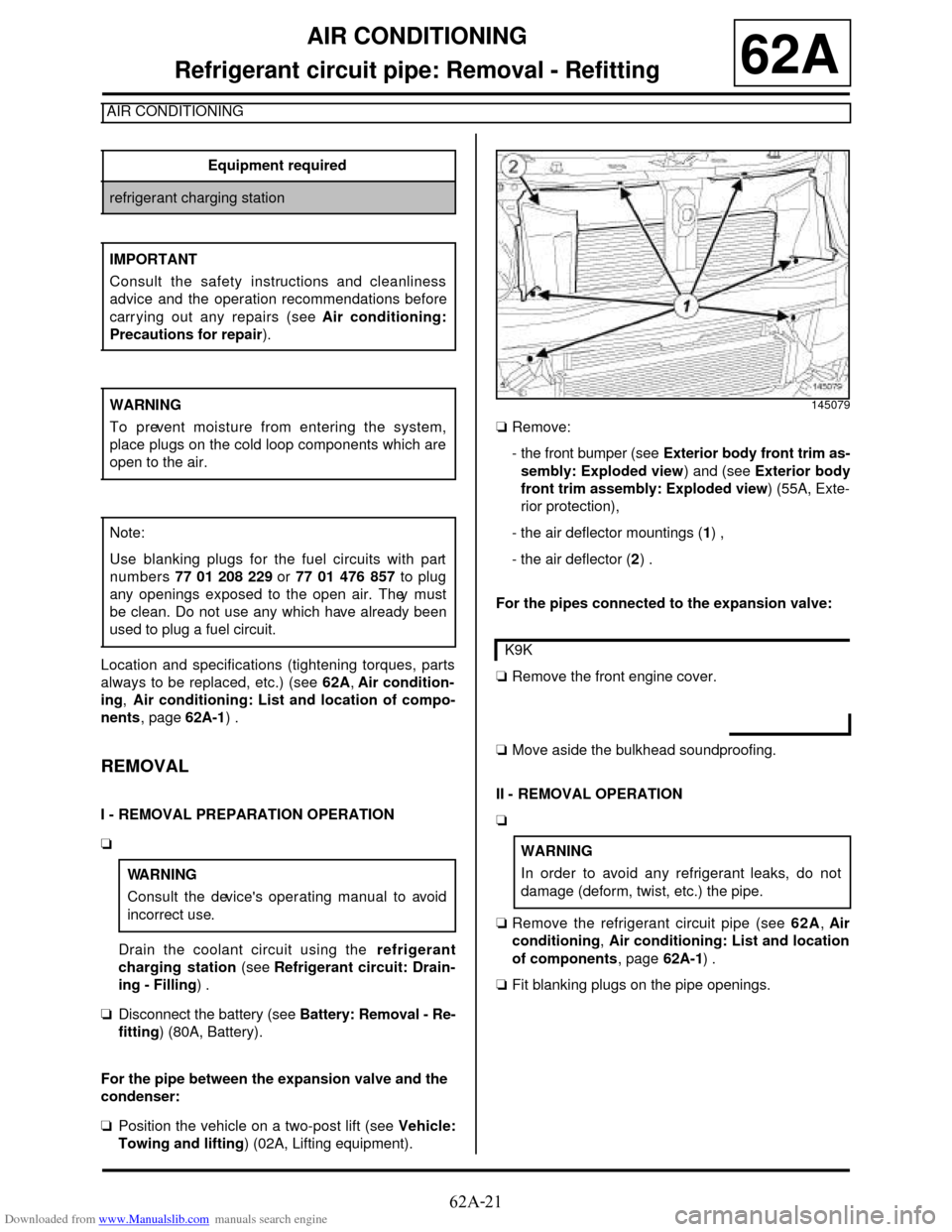

For the pipe between the expansion valve and the

condenser:

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).aRemove:

-the front bumper (see Exterior body front trim as-

sembly: Exploded view) and (see Exterior body

front trim assembly: Exploded view) (55A, Exte-

rior protection),

-the air deflector mountings (1) ,

-the air deflector (2) .

For the pipes connected to the expansion valve:

aRemove the front engine cover.

aMove aside the bulkhead soundproofing.

II - REMOVAL OPERATION

a

aRemove the refrigerant circuit pipe (see 62A, Air

conditioning, Air conditioning: List and location

of components, page 62A-1) .

aFit blanking plugs on the pipe openings. Equipment required

refrigerant charging station

IMPORTANT

Consult the safety instructions and cleanliness

advice and the operation recommendations before

carrying out any repairs (see Air conditioning:

Precautions for repair).

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

145079

K9K

WARNING

In order to avoid any refrigerant leaks, do not

damage (deform, twist, etc.) the pipe.