aisin automatic transaxle DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1687 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 97

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

TRANSAXLE FLUID LEVEL

CHECKING PROCEDURE

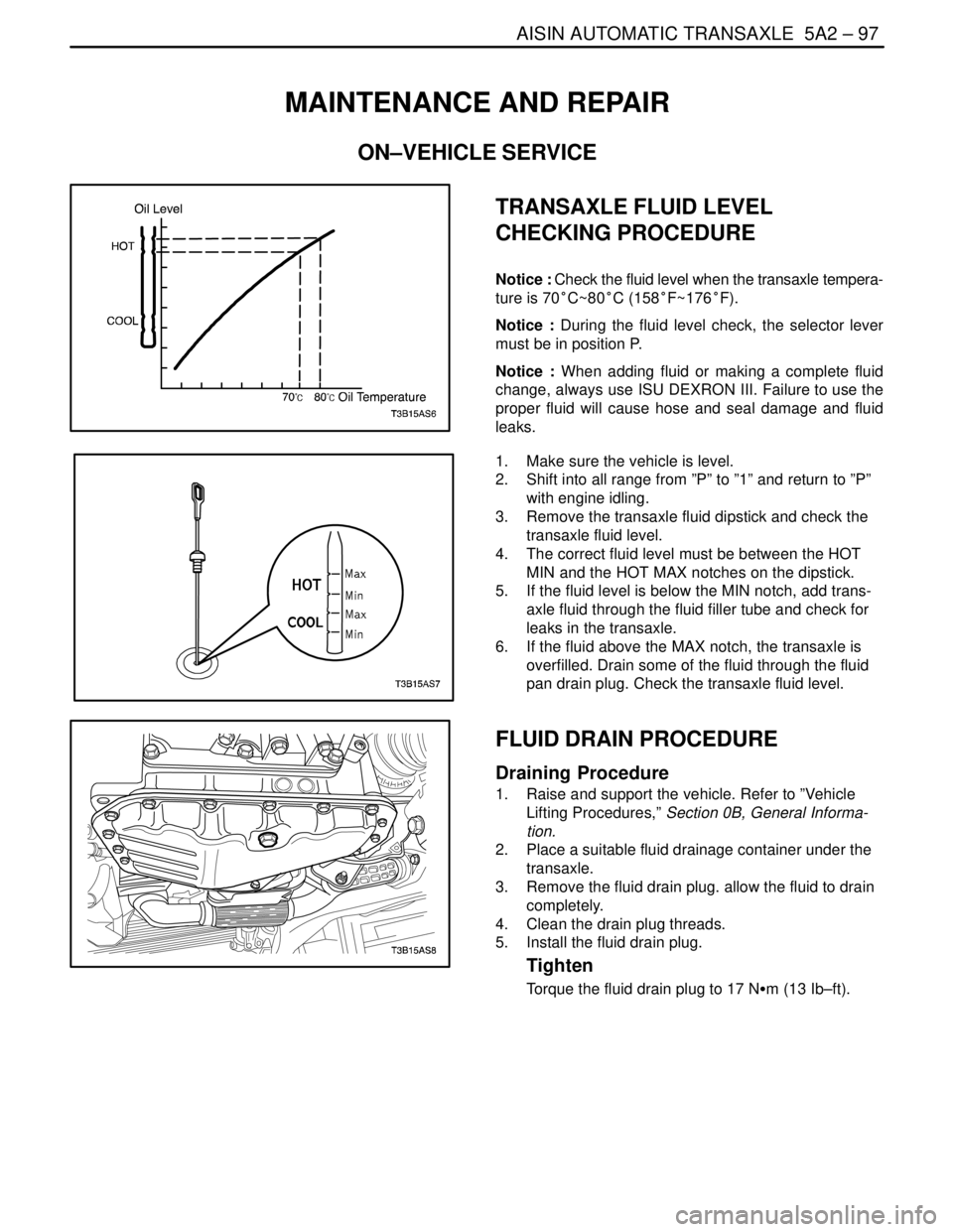

Notice : Check the fluid level when the transaxle tempera-

ture is 70°C~80°C (158°F~176°F).

Notice : During the fluid level check, the selector lever

must be in position P.

Notice : When adding fluid or making a complete fluid

change, always use ISU DEXRON III. Failure to use the

proper fluid will cause hose and seal damage and fluid

leaks.

1. Make sure the vehicle is level.

2. Shift into all range from ”P” to ”1” and return to ”P”

with engine idling.

3. Remove the transaxle fluid dipstick and check the

transaxle fluid level.

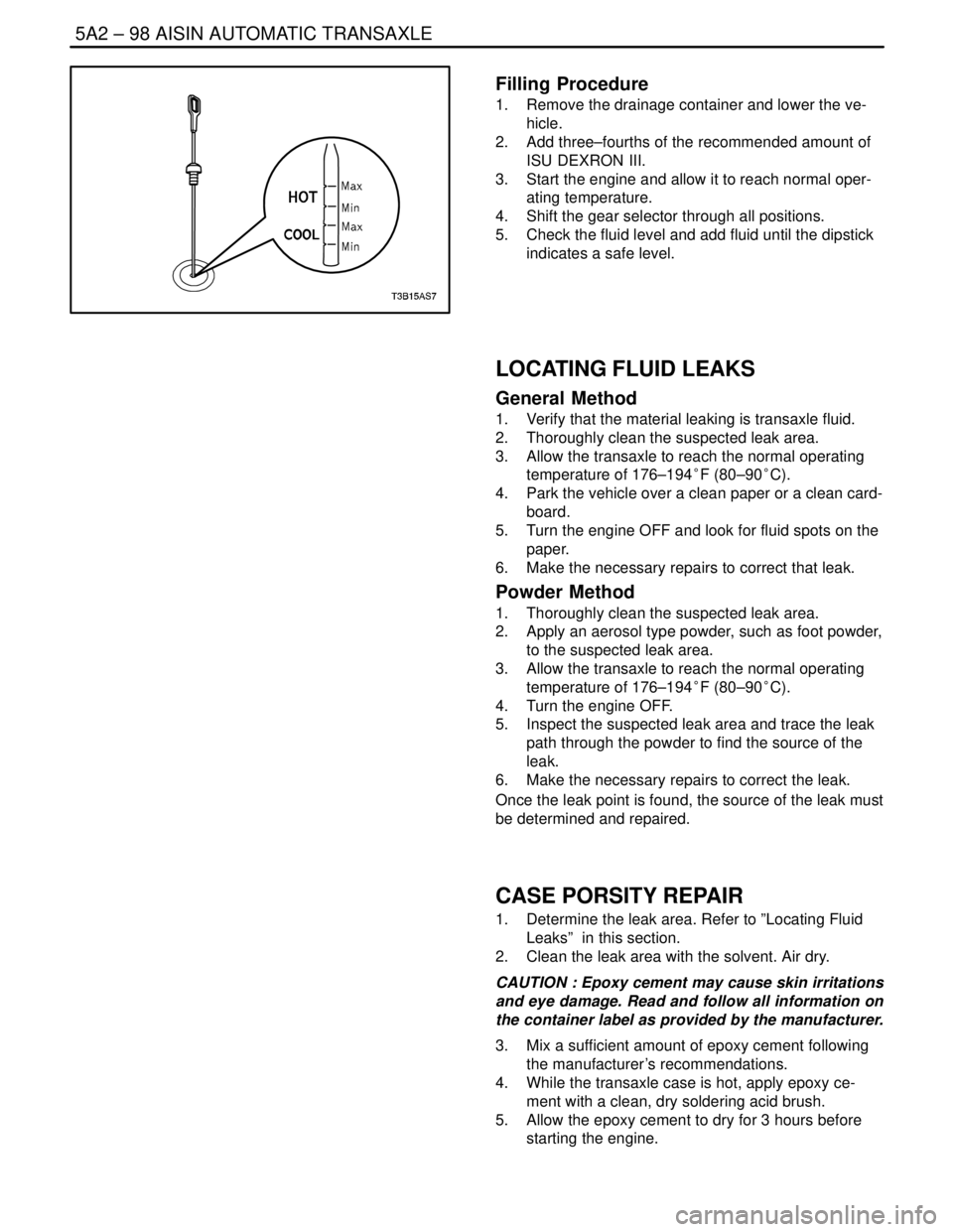

4. The correct fluid level must be between the HOT

MIN and the HOT MAX notches on the dipstick.

5. If the fluid level is below the MIN notch, add trans-

axle fluid through the fluid filler tube and check for

leaks in the transaxle.

6. If the fluid above the MAX notch, the transaxle is

overfilled. Drain some of the fluid through the fluid

pan drain plug. Check the transaxle fluid level.

FLUID DRAIN PROCEDURE

Draining Procedure

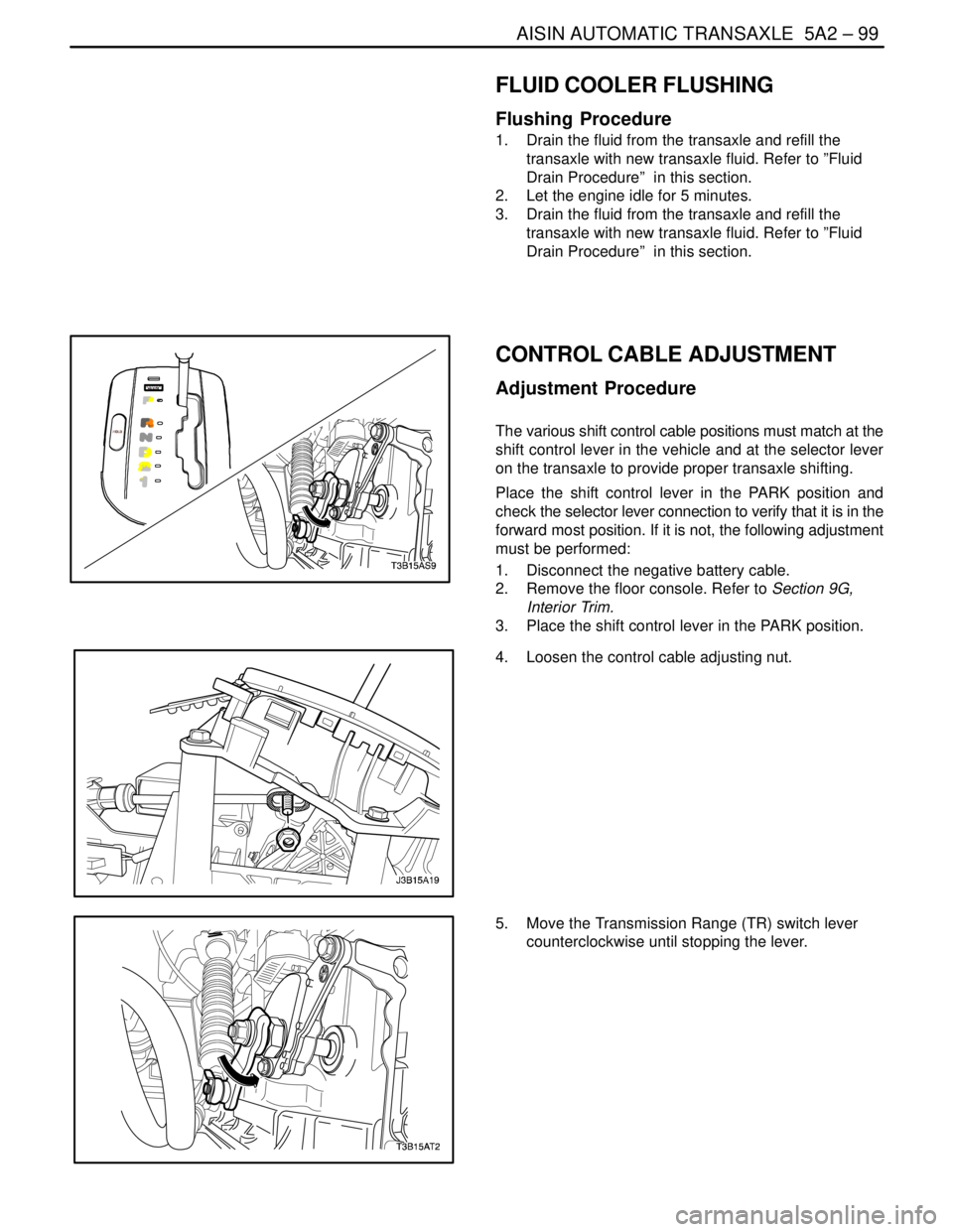

1. Raise and support the vehicle. Refer to ”Vehicle

Lifting Procedures,” Section 0B, General Informa-

tion.

2. Place a suitable fluid drainage container under the

transaxle.

3. Remove the fluid drain plug. allow the fluid to drain

completely.

4. Clean the drain plug threads.

5. Install the fluid drain plug.

Tighten

Torque the fluid drain plug to 17 NSm (13 Ib–ft).

Page 1688 of 2643

5A2 – 98IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

Filling Procedure

1. Remove the drainage container and lower the ve-

hicle.

2. Add three–fourths of the recommended amount of

ISU DEXRON III.

3. Start the engine and allow it to reach normal oper-

ating temperature.

4. Shift the gear selector through all positions.

5. Check the fluid level and add fluid until the dipstick

indicates a safe level.

LOCATING FLUID LEAKS

General Method

1. Verify that the material leaking is transaxle fluid.

2. Thoroughly clean the suspected leak area.

3. Allow the transaxle to reach the normal operating

temperature of 176–194°F (80–90°C).

4. Park the vehicle over a clean paper or a clean card-

board.

5. Turn the engine OFF and look for fluid spots on the

paper.

6. Make the necessary repairs to correct that leak.

Powder Method

1. Thoroughly clean the suspected leak area.

2. Apply an aerosol type powder, such as foot powder,

to the suspected leak area.

3. Allow the transaxle to reach the normal operating

temperature of 176–194°F (80–90°C).

4. Turn the engine OFF.

5. Inspect the suspected leak area and trace the leak

path through the powder to find the source of the

leak.

6. Make the necessary repairs to correct the leak.

Once the leak point is found, the source of the leak must

be determined and repaired.

CASE PORSITY REPAIR

1. Determine the leak area. Refer to ”Locating Fluid

Leaks” in this section.

2. Clean the leak area with the solvent. Air dry.

CAUTION : Epoxy cement may cause skin irritations

and eye damage. Read and follow all information on

the container label as provided by the manufacturer.

3. Mix a sufficient amount of epoxy cement following

the manufacturer’s recommendations.

4. While the transaxle case is hot, apply epoxy ce-

ment with a clean, dry soldering acid brush.

5. Allow the epoxy cement to dry for 3 hours before

starting the engine.

Page 1689 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 99

DAEWOO V–121 BL4

FLUID COOLER FLUSHING

Flushing Procedure

1. Drain the fluid from the transaxle and refill the

transaxle with new transaxle fluid. Refer to ”Fluid

Drain Procedure” in this section.

2. Let the engine idle for 5 minutes.

3. Drain the fluid from the transaxle and refill the

transaxle with new transaxle fluid. Refer to ”Fluid

Drain Procedure” in this section.

CONTROL CABLE ADJUSTMENT

Adjustment Procedure

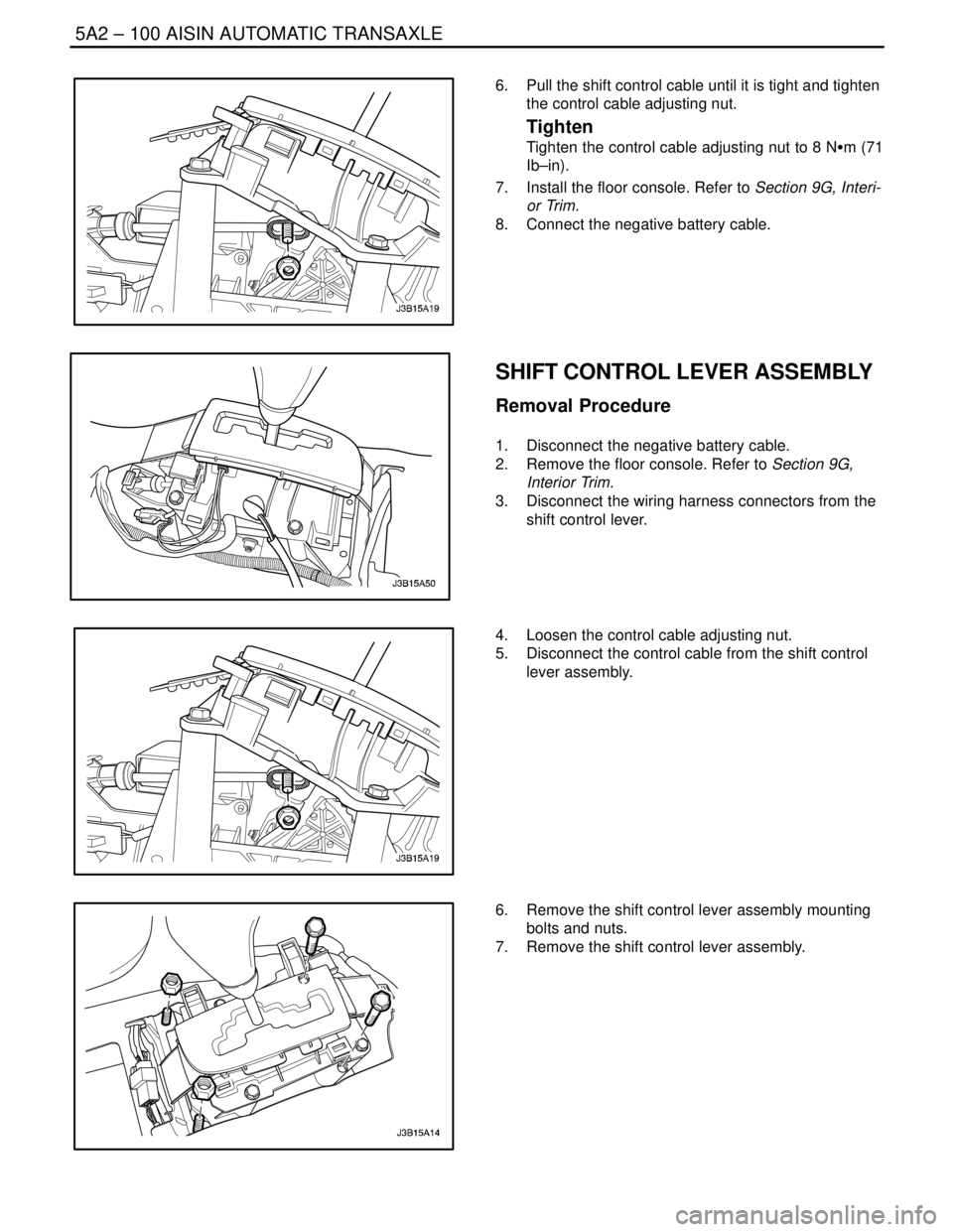

The various shift control cable positions must match at the

shift control lever in the vehicle and at the selector lever

on the transaxle to provide proper transaxle shifting.

Place the shift control lever in the PARK position and

check the selector lever connection to verify that it is in the

forward most position. If it is not, the following adjustment

must be performed:

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Place the shift control lever in the PARK position.

4. Loosen the control cable adjusting nut.

5. Move the Transmission Range (TR) switch lever

counterclockwise until stopping the lever.

Page 1690 of 2643

5A2 – 100IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

6. Pull the shift control cable until it is tight and tighten

the control cable adjusting nut.

Tighten

Tighten the control cable adjusting nut to 8 NSm (71

Ib–in).

7. Install the floor console. Refer to Section 9G, Interi-

or Trim.

8. Connect the negative battery cable.

SHIFT CONTROL LEVER ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Disconnect the wiring harness connectors from the

shift control lever.

4. Loosen the control cable adjusting nut.

5. Disconnect the control cable from the shift control

lever assembly.

6. Remove the shift control lever assembly mounting

bolts and nuts.

7. Remove the shift control lever assembly.

Page 1691 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 101

DAEWOO V–121 BL4

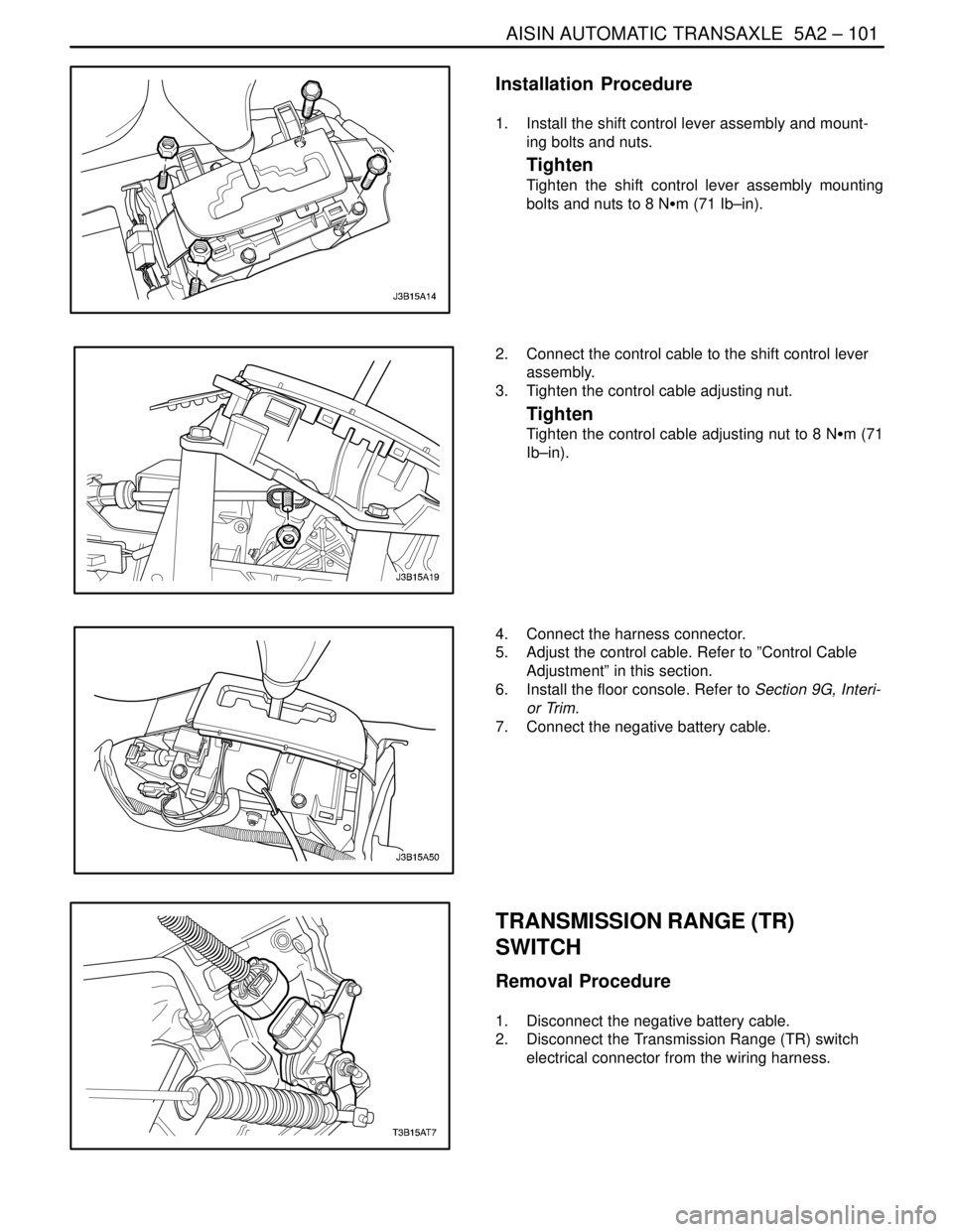

Installation Procedure

1. Install the shift control lever assembly and mount-

ing bolts and nuts.

Tighten

Tighten the shift control lever assembly mounting

bolts and nuts to 8 NSm (71 Ib–in).

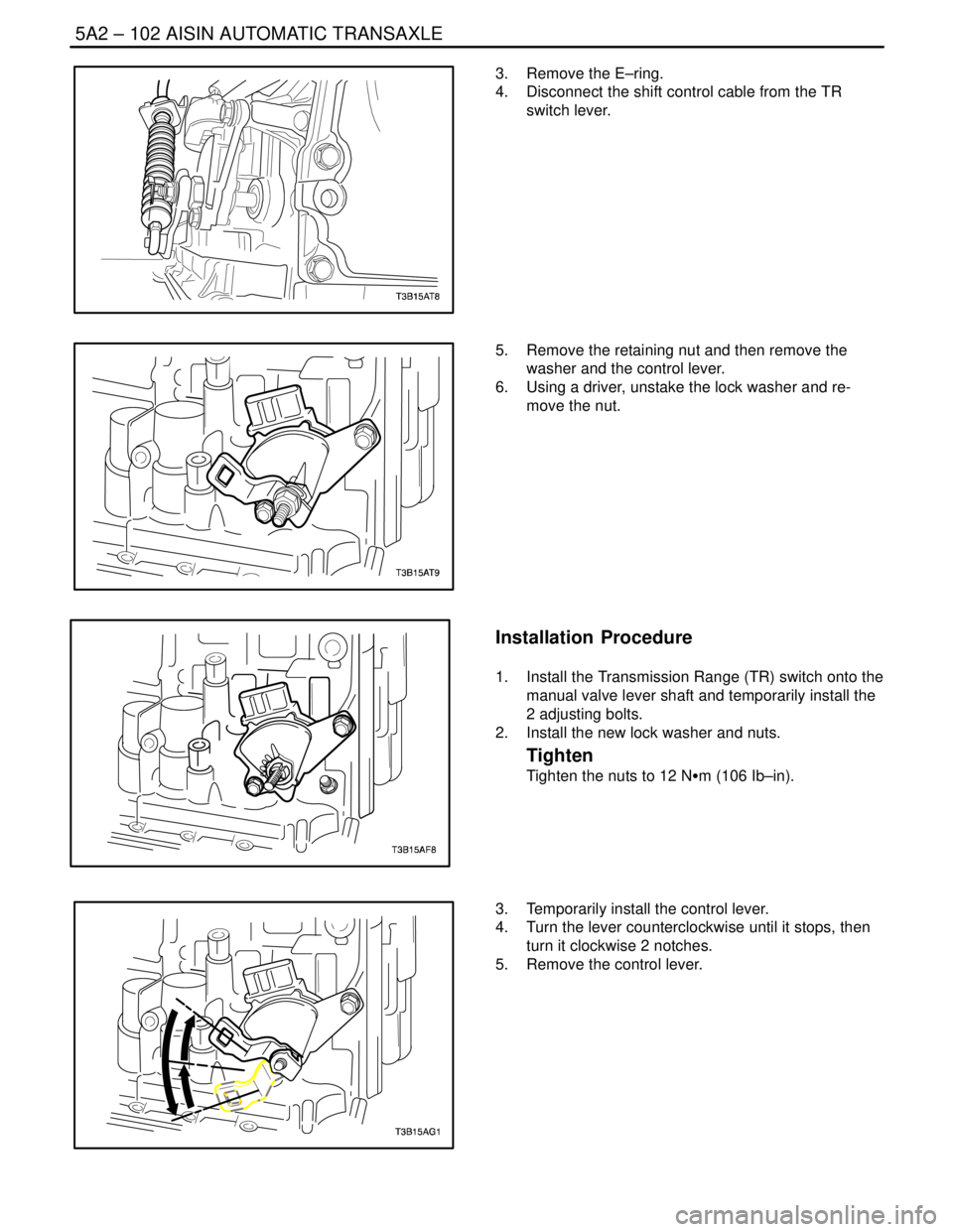

2. Connect the control cable to the shift control lever

assembly.

3. Tighten the control cable adjusting nut.

Tighten

Tighten the control cable adjusting nut to 8 NSm (71

Ib–in).

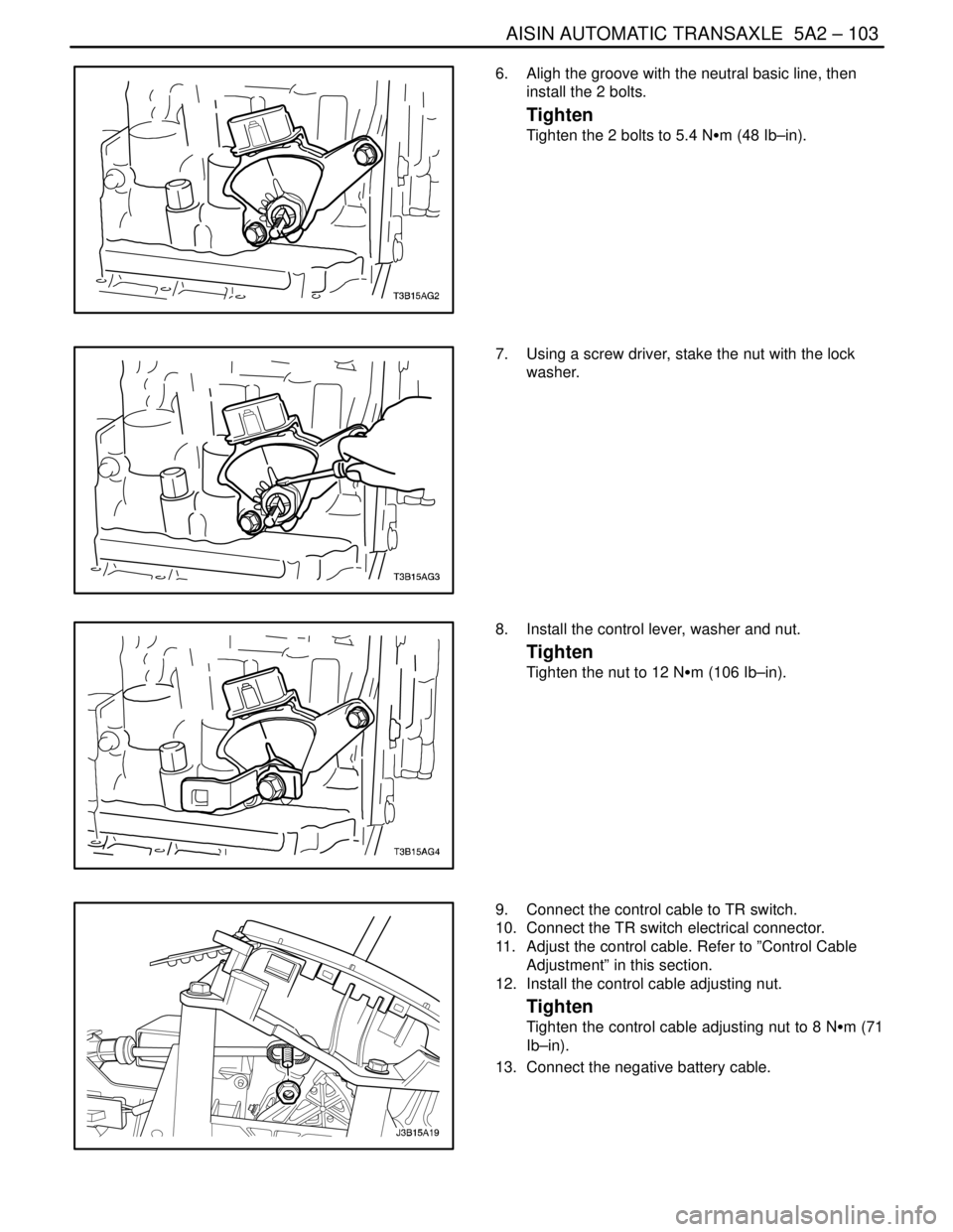

4. Connect the harness connector.

5. Adjust the control cable. Refer to ”Control Cable

Adjustment” in this section.

6. Install the floor console. Refer to Section 9G, Interi-

or Trim.

7. Connect the negative battery cable.

TRANSMISSION RANGE (TR)

SWITCH

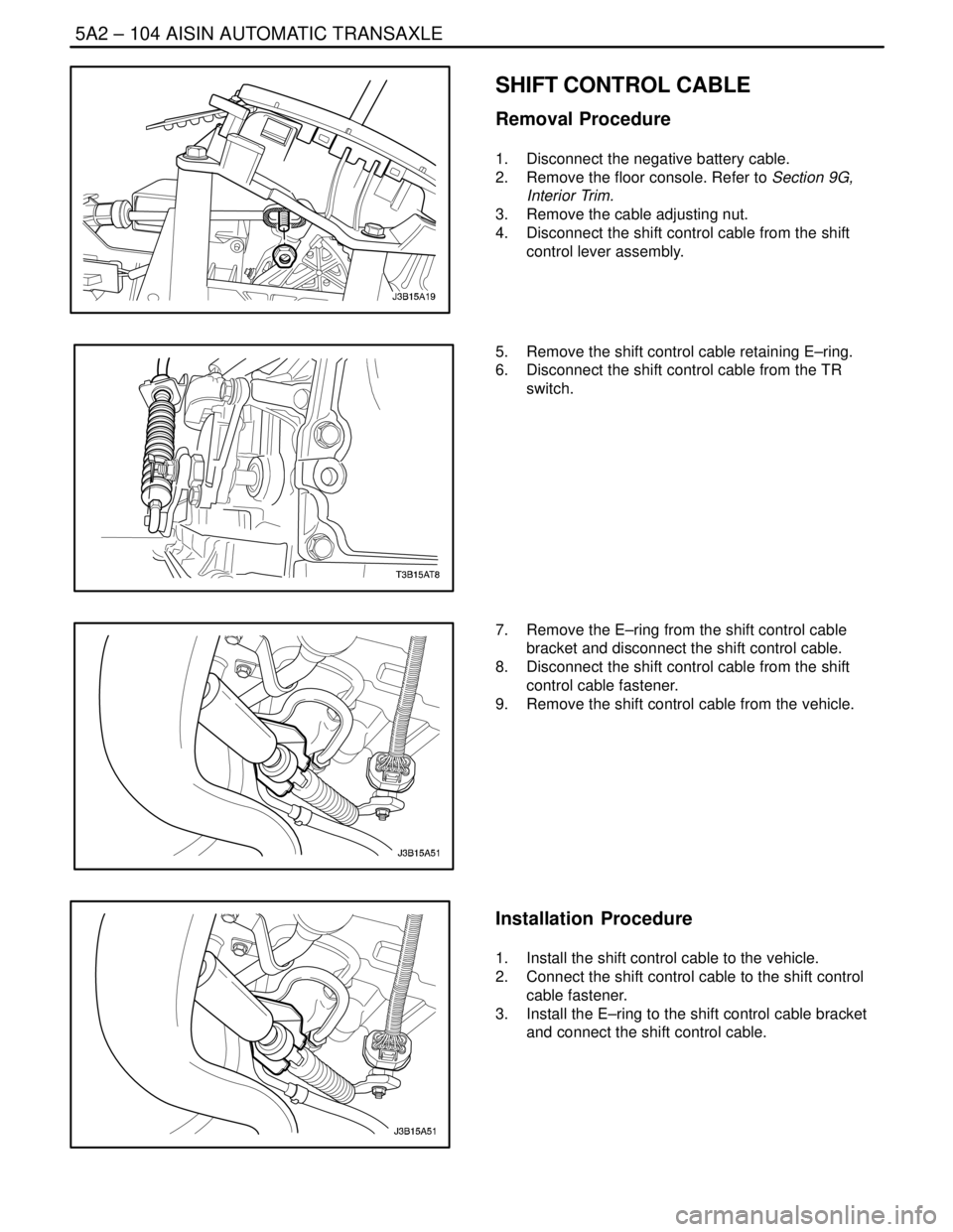

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the Transmission Range (TR) switch

electrical connector from the wiring harness.

Page 1692 of 2643

5A2 – 102IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

3. Remove the E–ring.

4. Disconnect the shift control cable from the TR

switch lever.

5. Remove the retaining nut and then remove the

washer and the control lever.

6. Using a driver, unstake the lock washer and re-

move the nut.

Installation Procedure

1. Install the Transmission Range (TR) switch onto the

manual valve lever shaft and temporarily install the

2 adjusting bolts.

2. Install the new lock washer and nuts.

Tighten

Tighten the nuts to 12 NSm (106 Ib–in).

3. Temporarily install the control lever.

4. Turn the lever counterclockwise until it stops, then

turn it clockwise 2 notches.

5. Remove the control lever.

Page 1693 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 103

DAEWOO V–121 BL4

6. Aligh the groove with the neutral basic line, then

install the 2 bolts.

Tighten

Tighten the 2 bolts to 5.4 NSm (48 Ib–in).

7. Using a screw driver, stake the nut with the lock

washer.

8. Install the control lever, washer and nut.

Tighten

Tighten the nut to 12 NSm (106 Ib–in).

9. Connect the control cable to TR switch.

10. Connect the TR switch electrical connector.

11. Adjust the control cable. Refer to ”Control Cable

Adjustment” in this section.

12. Install the control cable adjusting nut.

Tighten

Tighten the control cable adjusting nut to 8 NSm (71

Ib–in).

13. Connect the negative battery cable.

Page 1694 of 2643

5A2 – 104IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

SHIFT CONTROL CABLE

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Remove the cable adjusting nut.

4. Disconnect the shift control cable from the shift

control lever assembly.

5. Remove the shift control cable retaining E–ring.

6. Disconnect the shift control cable from the TR

switch.

7. Remove the E–ring from the shift control cable

bracket and disconnect the shift control cable.

8. Disconnect the shift control cable from the shift

control cable fastener.

9. Remove the shift control cable from the vehicle.

Installation Procedure

1. Install the shift control cable to the vehicle.

2. Connect the shift control cable to the shift control

cable fastener.

3. Install the E–ring to the shift control cable bracket

and connect the shift control cable.

Page 1695 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 105

DAEWOO V–121 BL4

4. Connect the shift control cable to the TR switch.

5. Install the shift control cable retaining E–ring.

6. Connect the shift control cable to the shift control

lever assembly.

7. Install the cable adjusting nut.

Tighten

Tighten the cable adjusting nut to 8 NSm (71 Ib–in).

8. Install the trim panel to the floor console. Refer to

Section 9G, Interior Trim.

9. Connect the negative battery cable.

SHIFT SELECT COVER

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Remove the shift select lever knob.

4. Disconnect the connectors.

5. Remove the shift select cover from the shift select

housing.

Page 1696 of 2643

5A2 – 106IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

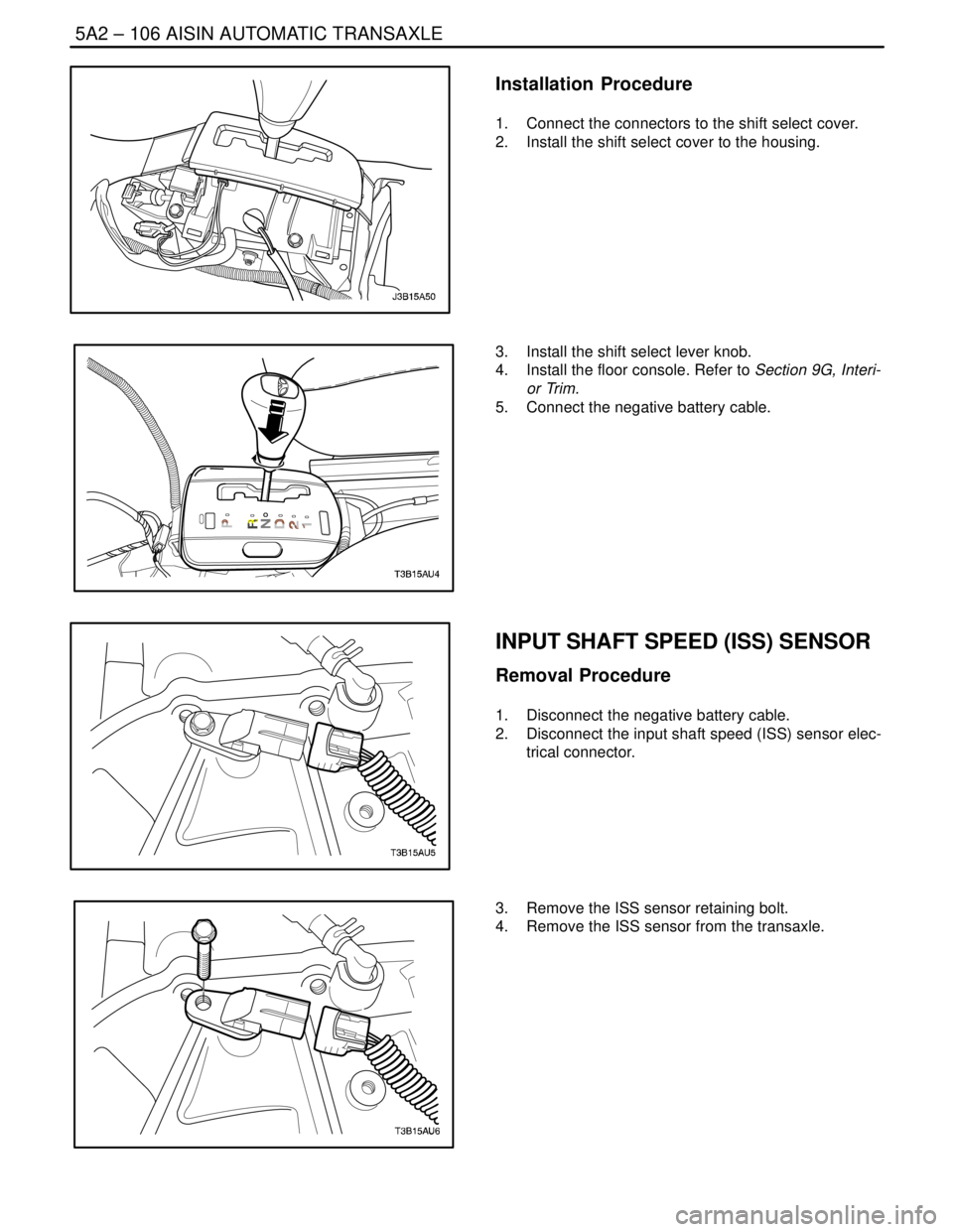

Installation Procedure

1. Connect the connectors to the shift select cover.

2. Install the shift select cover to the housing.

3. Install the shift select lever knob.

4. Install the floor console. Refer to Section 9G, Interi-

or Trim.

5. Connect the negative battery cable.

INPUT SHAFT SPEED (ISS) SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the input shaft speed (ISS) sensor elec-

trical connector.

3. Remove the ISS sensor retaining bolt.

4. Remove the ISS sensor from the transaxle.