heating DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2429 of 2643

DOORS 9P – 9

DAEWOO V–121 BL4

System With Front and Rear Power Windows, One or Both Front

Windows are Inoperative

CAUTION : When powering the window motors directly from a battery with jumper wires, make sure one of the

jumper wires contains a fuse. If the jumpers are accidentally touched together, the fuse will prevent sparking

and burns from sudden terminal heating.

Step

ActionValue(s)YesNo

11. Turn the ignition ON.

2. Attempt to operate each front power window.

Is either window working?–Go to

Step 18Go to

Step 2

2Visually inspect the connection at the power

window main switch.

Is the electrical connector correctly attached

to the main switch?–Go to

Step 4Go to

Step 3

3Correctly attach the electrical connector to

the power window main switch.

Is the repair complete?–System

OK–

41. Disconnect the electrical connector from the

power window main switch.

2. Turn the ignition ON.

3. Check the voltage at terminal 3 and 10 of the

power window main switch connector.

Is the voltage equal to the specified value?11–14 vGo to

Step 16Go to

Step 5

5Check fuses EF14 and EF9.

Is either fuse blown?–Go to

Step 6Go to

Step 7

61. Check for a short circuit and repair, if neces-

sary.

2. Replace the blown fuse(s).

Is the repair complete?–System

OK–

71. Turn the ignition ON.

2. Check the voltages at fuses Ef9 and EF14.

Are both voltages equal to the specified val-

ue?11–14 vGo to

Step 9Go to

Step 8

8Repair the power supply to the fuse which did

not indicate battery voltage with the ignition

on.

Is the repair complete?–System

OK–

91. Remove the power window relay.

2. Turn the ignition ON.

3. Check the voltage at terminal 30 and terminal

86 of the power window relay socket. (Termi-

nals of the relay socket can be identified by

the markings on the bottom of the relay.)

Does the voltmeter indicate the specified val-

ue?11–14 vGo to

Step 11Go to

Step 10

10Repair the open circuit between the fuses and

the power window relay.

Is the repair complete?–System

OK–

Page 2432 of 2643

9P – 12IDOORS

DAEWOO V–121 BL4

System With Front and Rear Power Windows, One or Both Rear

Windows are Inoperative

CAUTION : When powering the window motors directly from a battery with jumper wires, make sure one of the

jumper wires contains a fuse. If the jumpers are accidentally touched together, the fuse will prevent sparking

and burns from sudden terminal heating.

Step

ActionValue(s)YesNo

11. Turn the ignition ON.

2. Make sure that the window lock position has

not been selected on the power window main

switch.

Is either rear power window working?–Go to

Step 18Go to

Step 2

2Visually inspect the connection at the power

window main switch.

Is the electrical connector correctly attached

to the main switch?–Go to

Step 4Go to

Step 3

3Correctly attach the electrical connector to

the power window main switch.

Is the repair complete?–System

OK–

41. Disconnect the electrical connector from the

power window main switch.

2. Turn the ignition ON.

3. Check the voltage at terminal 3 and 10 of the

power window main switch connector.

Is the voltage equal to the specified value?11–14 vGo to

Step 16Go to

Step 5

5Check fuses EF9 and EF14.

Is either fuse blown?–Go to

Step 6Go to

Step 7

61. Check for a short circuit and repair, if neces-

sary.

2. Replace the blown fuse(s).

Is the repair complete?–System

OK–

71. Turn the ignition ON.

2. Check the voltages at fuses Ef9 and EF14.

Are both voltages equal to the specified val-

ue?11–14 vGo to

Step 9Go to

Step 8

8Repair the power supply to the fuse which did

not indicate battery voltage with the ignition

on.

Is the repair complete?–System

OK–

91. Turn the ignition ON.

2. Remove the power window relay.

3. Check the voltage at terminal 30 and terminal

86 of the power window relay socket. (Termi-

nals of the relay socket can be identified by

the markings on the bottom of the relay.)

Does the voltmeter indicate the specified val-

ue?11–14 vGo to

Step 11Go to

Step 10

10Repair the open circuit between the fuses and

the power window relay.

Is the repair complete?–System

OK–

Page 2545 of 2643

NUBIRA/LACETTIFRONT 4–11

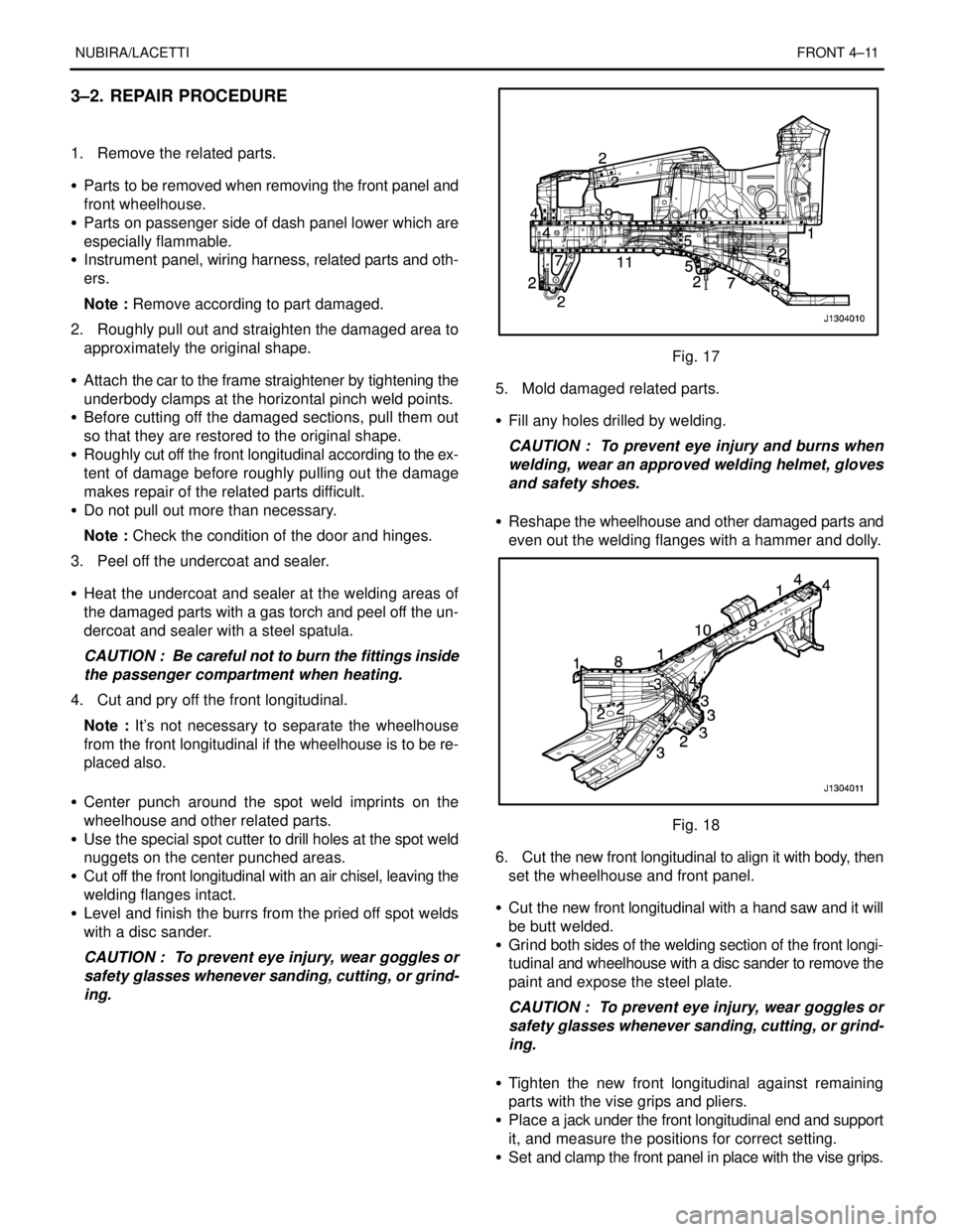

3–2. REPAIR PROCEDURE

1. Remove the related parts.

S Parts to be removed when removing the front panel and

front wheelhouse.

S Parts on passenger side of dash panel lower which are

especially flammable.

S Instrument panel, wiring harness, related parts and oth-

ers.

Note : Remove according to part damaged.

2. Roughly pull out and straighten the damaged area to

approximately the original shape.

S Attach the car to the frame straightener by tightening the

underbody clamps at the horizontal pinch weld points.

S Before cutting off the damaged sections, pull them out

so that they are restored to the original shape.

S Roughly cut off the front longitudinal according to the ex-

tent of damage before roughly pulling out the damage

makes repair of the related parts difficult.

S Do not pull out more than necessary.

Note : Check the condition of the door and hinges.

3. Peel off the undercoat and sealer.

S Heat the undercoat and sealer at the welding areas of

the damaged parts with a gas torch and peel off the un-

dercoat and sealer with a steel spatula.

CAUTION : Be careful not to burn the fittings inside

the passenger compartment when heating.

4. Cut and pry off the front longitudinal.

Note : It’s not necessary to separate the wheelhouse

from the front longitudinal if the wheelhouse is to be re-

placed also.

S Center punch around the spot weld imprints on the

wheelhouse and other related parts.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the center punched areas.

S Cut off the front longitudinal with an air chisel, leaving the

welding flanges intact.

S Level and finish the burrs from the pried off spot welds

with a disc sander.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

Fig. 17

5. Mold damaged related parts.

S Fill any holes drilled by welding.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Reshape the wheelhouse and other damaged parts and

even out the welding flanges with a hammer and dolly.

Fig. 18

6. Cut the new front longitudinal to align it with body, then

set the wheelhouse and front panel.

S Cut the new front longitudinal with a hand saw and it will

be butt welded.

S Grind both sides of the welding section of the front longi-

tudinal and wheelhouse with a disc sander to remove the

paint and expose the steel plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Tighten the new front longitudinal against remaining

parts with the vise grips and pliers.

S Place a jack under the front longitudinal end and support

it, and measure the positions for correct setting.

S Set and clamp the front panel in place with the vise grips.

Page 2617 of 2643

9–14 SEALING, CAULKING AND DEADNER NUBIRA/LACETTI

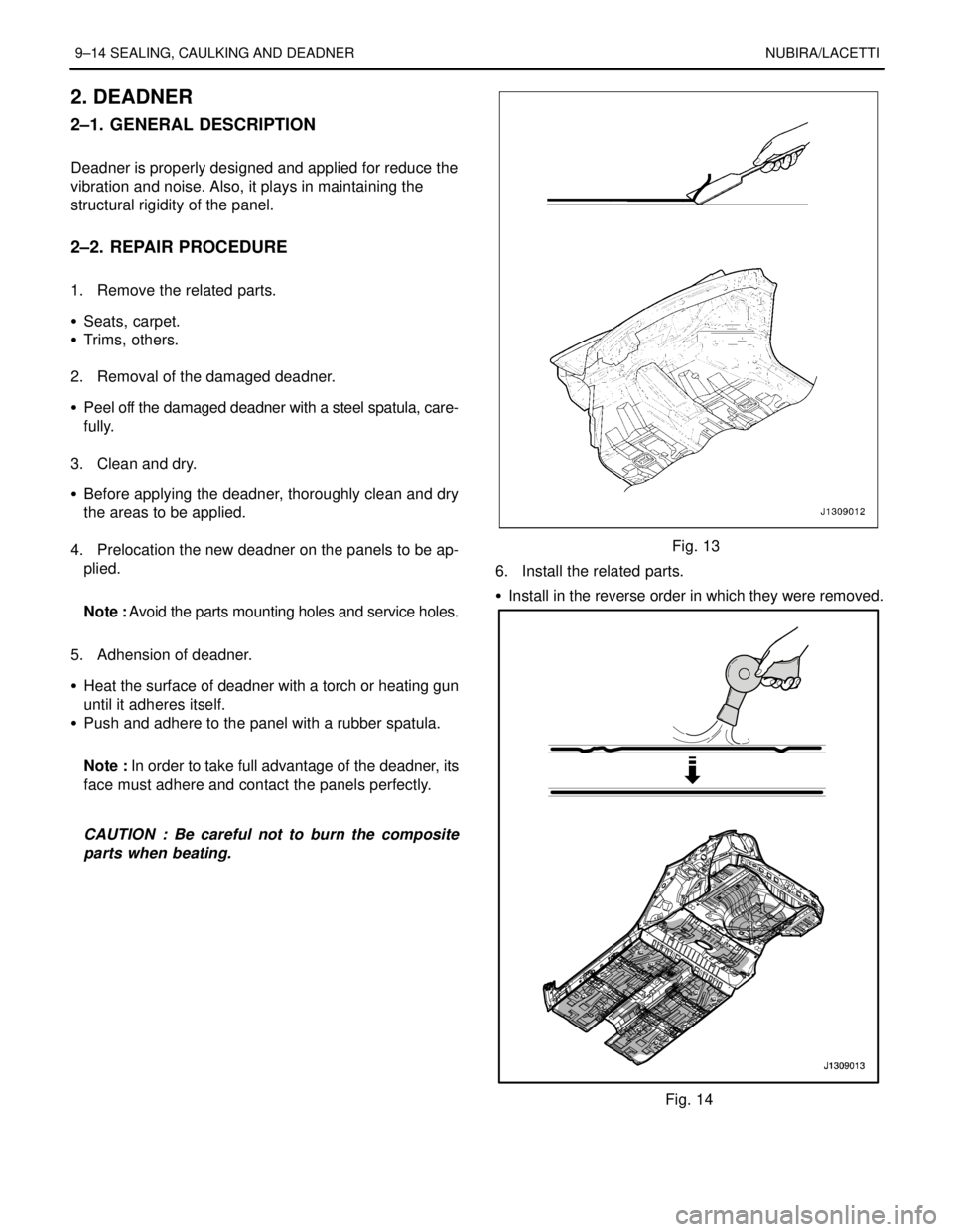

2. DEADNER

2–1. GENERAL DESCRIPTION

.

Deadner is properly designed and applied for reduce the

vibration and noise. Also, it plays in maintaining the

structural rigidity of the panel.

.

2–2. REPAIR PROCEDURE

.

1. Remove the related parts.

S Seats, carpet.

S Trims, others.

.

2. Removal of the damaged deadner.

S Peel off the damaged deadner with a steel spatula, care-

fully.

.

3. Clean and dry.

S Before applying the deadner, thoroughly clean and dry

the areas to be applied.

.

4. Prelocation the new deadner on the panels to be ap-

plied.

.

Note : Avoid the parts mounting holes and service holes.

.

5. Adhension of deadner.

S Heat the surface of deadner with a torch or heating gun

until it adheres itself.

S Push and adhere to the panel with a rubber spatula.

.

Note : In order to take full advantage of the deadner, its

face must adhere and contact the panels perfectly.

.

CAUTION : Be careful not to burn the composite

parts when beating.

Fig. 13

6. Install the related parts.

S Install in the reverse order in which they were removed.

Fig. 14