boot DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1055 of 2643

FRONT DISC BRAKES 4D – 7

DAEWOO V–121 BL4

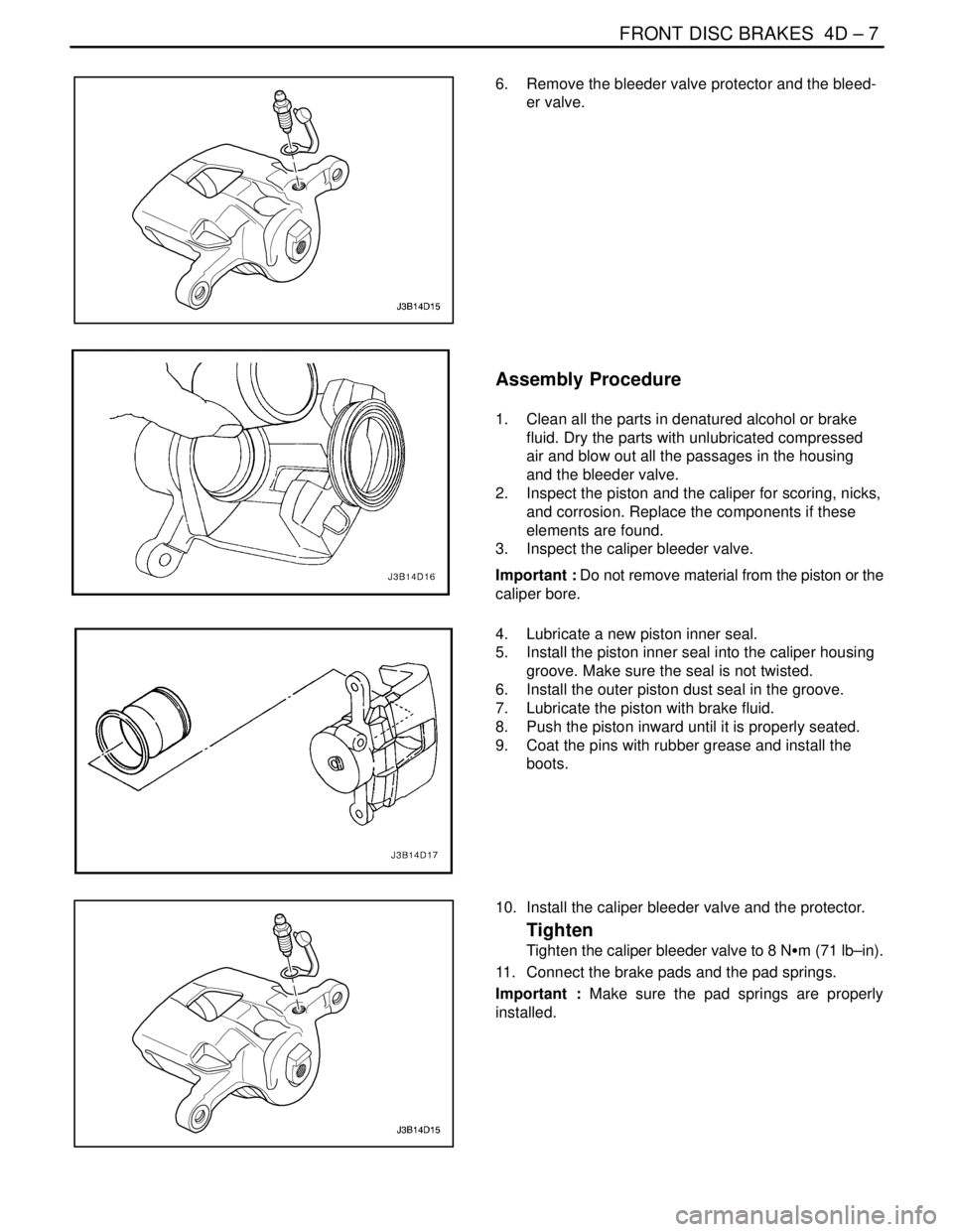

6. Remove the bleeder valve protector and the bleed-

er valve.

Assembly Procedure

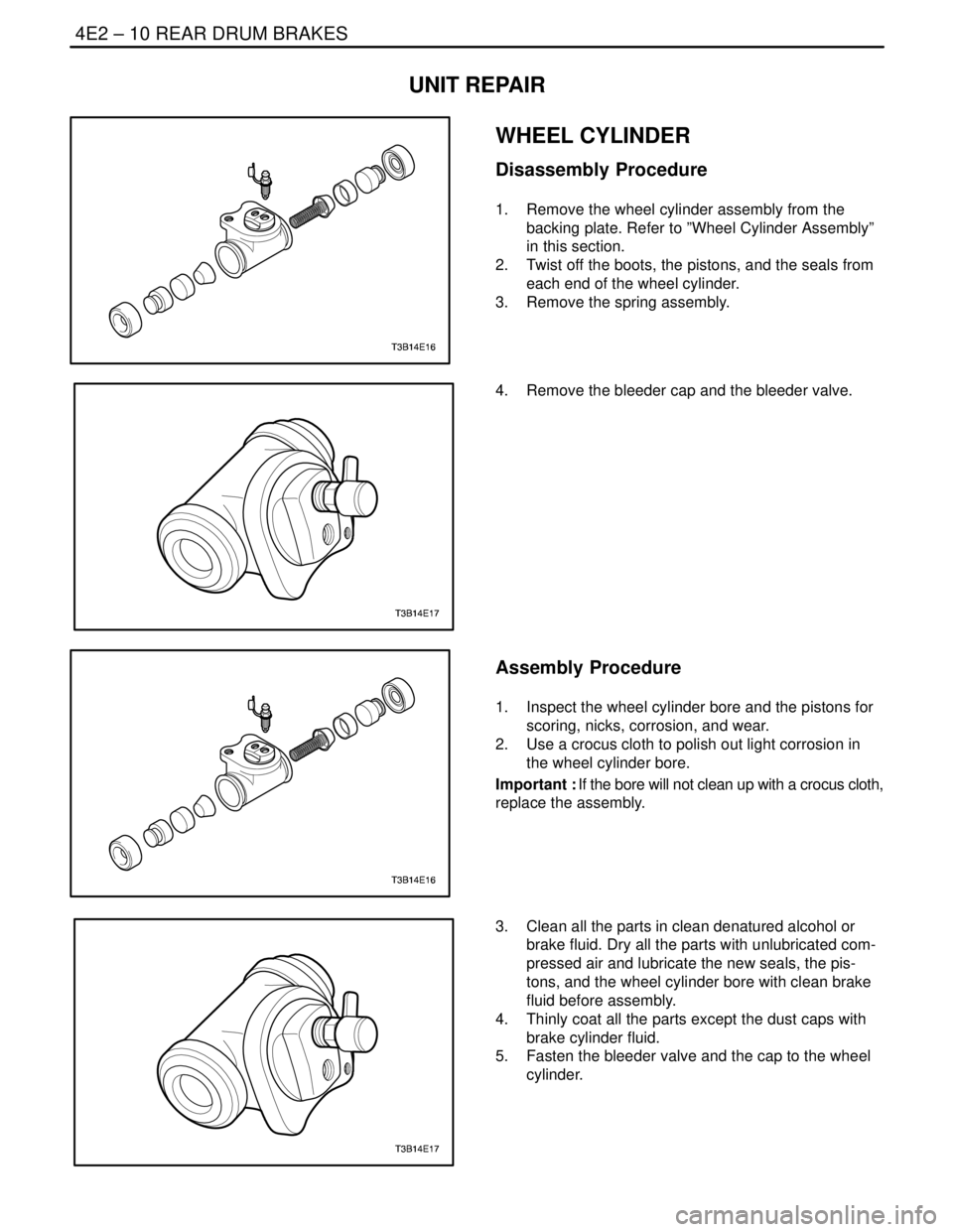

1. Clean all the parts in denatured alcohol or brake

fluid. Dry the parts with unlubricated compressed

air and blow out all the passages in the housing

and the bleeder valve.

2. Inspect the piston and the caliper for scoring, nicks,

and corrosion. Replace the components if these

elements are found.

3. Inspect the caliper bleeder valve.

Important : Do not remove material from the piston or the

caliper bore.

4. Lubricate a new piston inner seal.

5. Install the piston inner seal into the caliper housing

groove. Make sure the seal is not twisted.

6. Install the outer piston dust seal in the groove.

7. Lubricate the piston with brake fluid.

8. Push the piston inward until it is properly seated.

9. Coat the pins with rubber grease and install the

boots.

10. Install the caliper bleeder valve and the protector.

Tighten

Tighten the caliper bleeder valve to 8 NSm (71 lb–in).

11. Connect the brake pads and the pad springs.

Important : Make sure the pad springs are properly

installed.

Page 1079 of 2643

4E2 – 10IREAR DRUM BRAKES

DAEWOO V–121 BL4

UNIT REPAIR

WHEEL CYLINDER

Disassembly Procedure

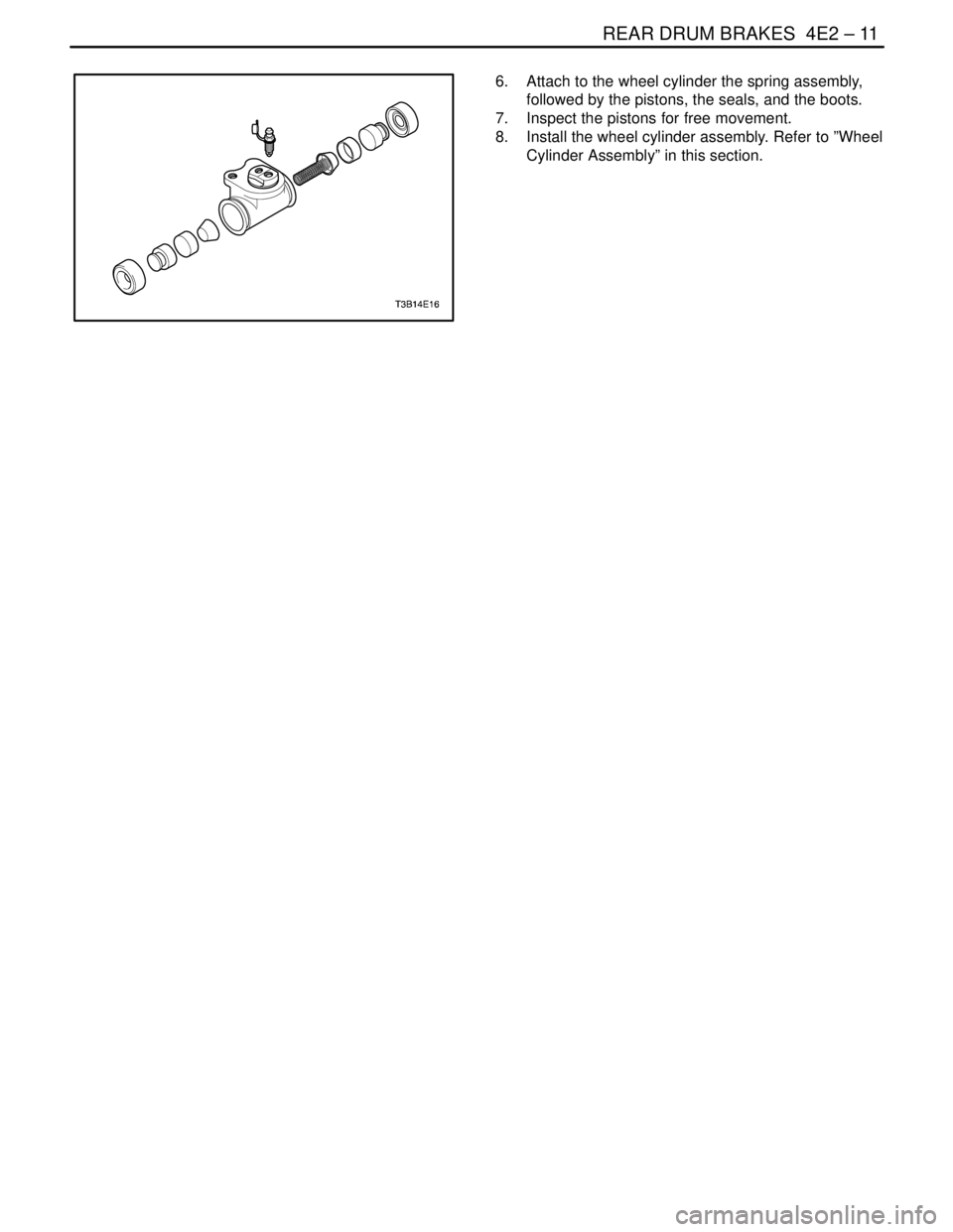

1. Remove the wheel cylinder assembly from the

backing plate. Refer to ”Wheel Cylinder Assembly”

in this section.

2. Twist off the boots, the pistons, and the seals from

each end of the wheel cylinder.

3. Remove the spring assembly.

4. Remove the bleeder cap and the bleeder valve.

Assembly Procedure

1. Inspect the wheel cylinder bore and the pistons for

scoring, nicks, corrosion, and wear.

2. Use a crocus cloth to polish out light corrosion in

the wheel cylinder bore.

Important : If the bore will not clean up with a crocus cloth,

replace the assembly.

3. Clean all the parts in clean denatured alcohol or

brake fluid. Dry all the parts with unlubricated com-

pressed air and lubricate the new seals, the pis-

tons, and the wheel cylinder bore with clean brake

fluid before assembly.

4. Thinly coat all the parts except the dust caps with

brake cylinder fluid.

5. Fasten the bleeder valve and the cap to the wheel

cylinder.

Page 1080 of 2643

REAR DRUM BRAKES 4E2 – 11

DAEWOO V–121 BL4

6. Attach to the wheel cylinder the spring assembly,

followed by the pistons, the seals, and the boots.

7. Inspect the pistons for free movement.

8. Install the wheel cylinder assembly. Refer to ”Wheel

Cylinder Assembly” in this section.

Page 1160 of 2643

4G – 8IPARKING BRAKE

DAEWOO V–121 BL4

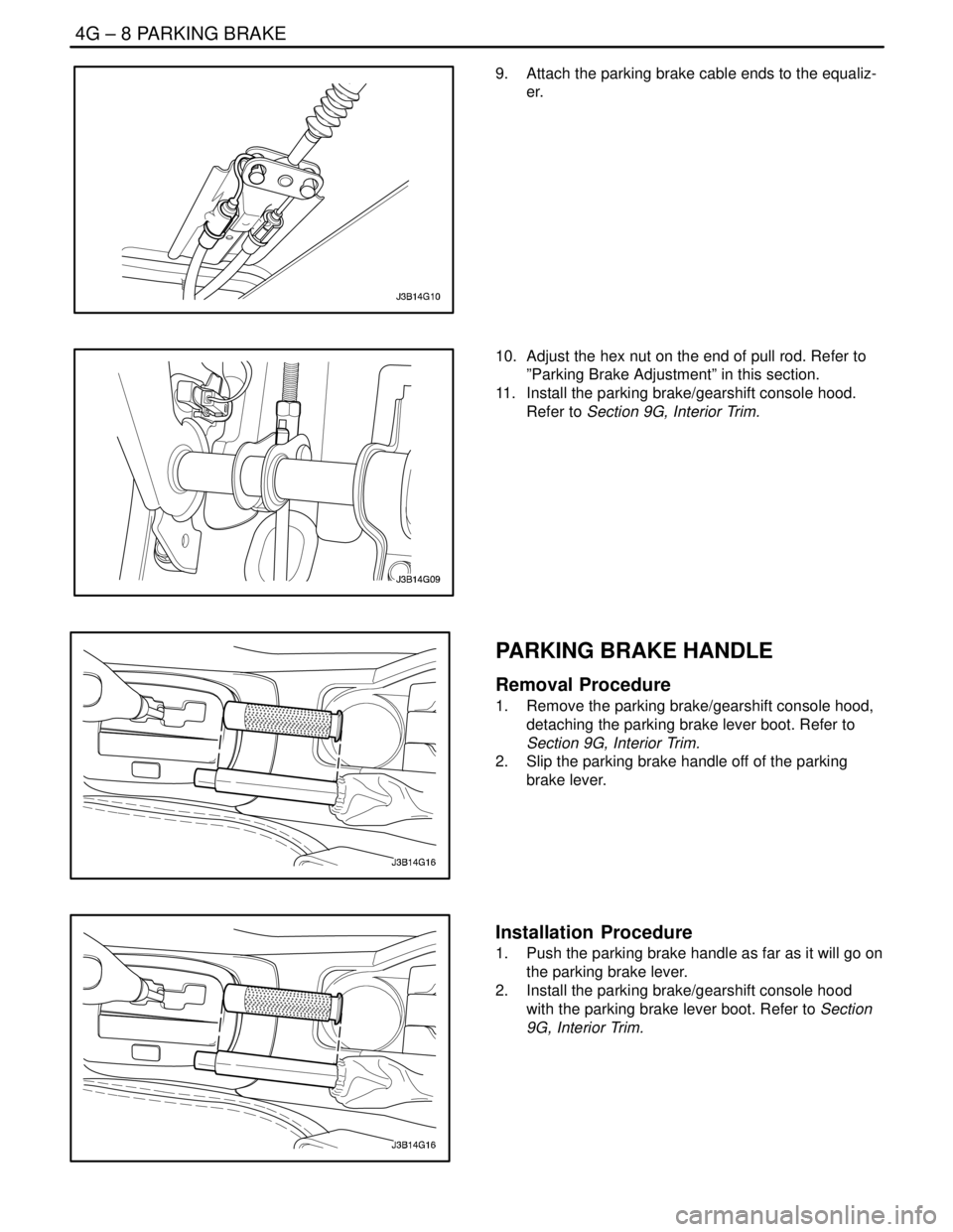

9. Attach the parking brake cable ends to the equaliz-

er.

10. Adjust the hex nut on the end of pull rod. Refer to

”Parking Brake Adjustment” in this section.

11. Install the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

PARKING BRAKE HANDLE

Removal Procedure

1. Remove the parking brake/gearshift console hood,

detaching the parking brake lever boot. Refer to

Section 9G, Interior Trim.

2. Slip the parking brake handle off of the parking

brake lever.

Installation Procedure

1. Push the parking brake handle as far as it will go on

the parking brake lever.

2. Install the parking brake/gearshift console hood

with the parking brake lever boot. Refer to Section

9G, Interior Trim.

Page 1840 of 2643

5B – 16IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

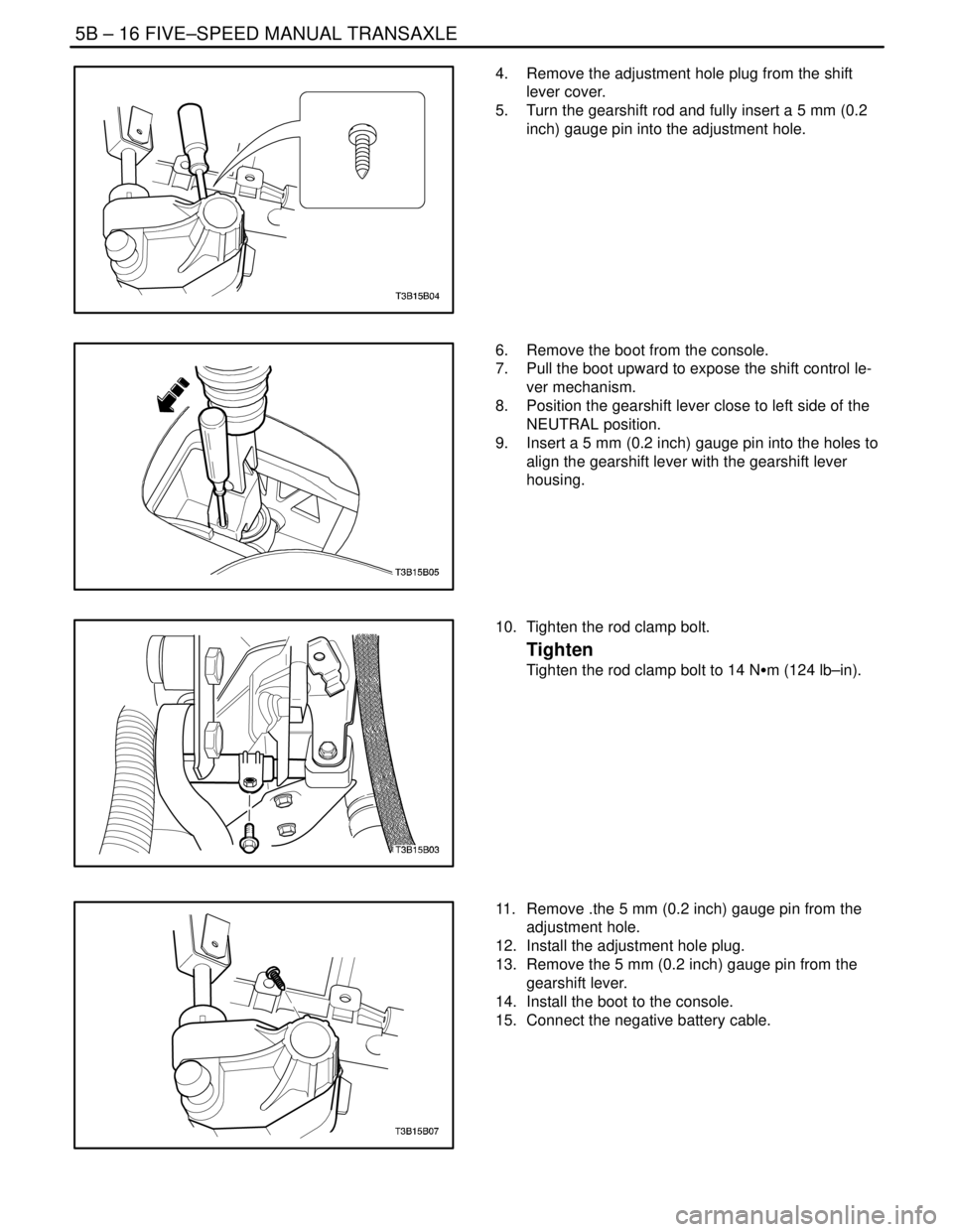

4. Remove the adjustment hole plug from the shift

lever cover.

5. Turn the gearshift rod and fully insert a 5 mm (0.2

inch) gauge pin into the adjustment hole.

6. Remove the boot from the console.

7. Pull the boot upward to expose the shift control le-

ver mechanism.

8. Position the gearshift lever close to left side of the

NEUTRAL position.

9. Insert a 5 mm (0.2 inch) gauge pin into the holes to

align the gearshift lever with the gearshift lever

housing.

10. Tighten the rod clamp bolt.

Tighten

Tighten the rod clamp bolt to 14 NSm (124 lb–in).

11. Remove .the 5 mm (0.2 inch) gauge pin from the

adjustment hole.

12. Install the adjustment hole plug.

13. Remove the 5 mm (0.2 inch) gauge pin from the

gearshift lever.

14. Install the boot to the console.

15. Connect the negative battery cable.

Page 1841 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 17

DAEWOO V–121 BL4

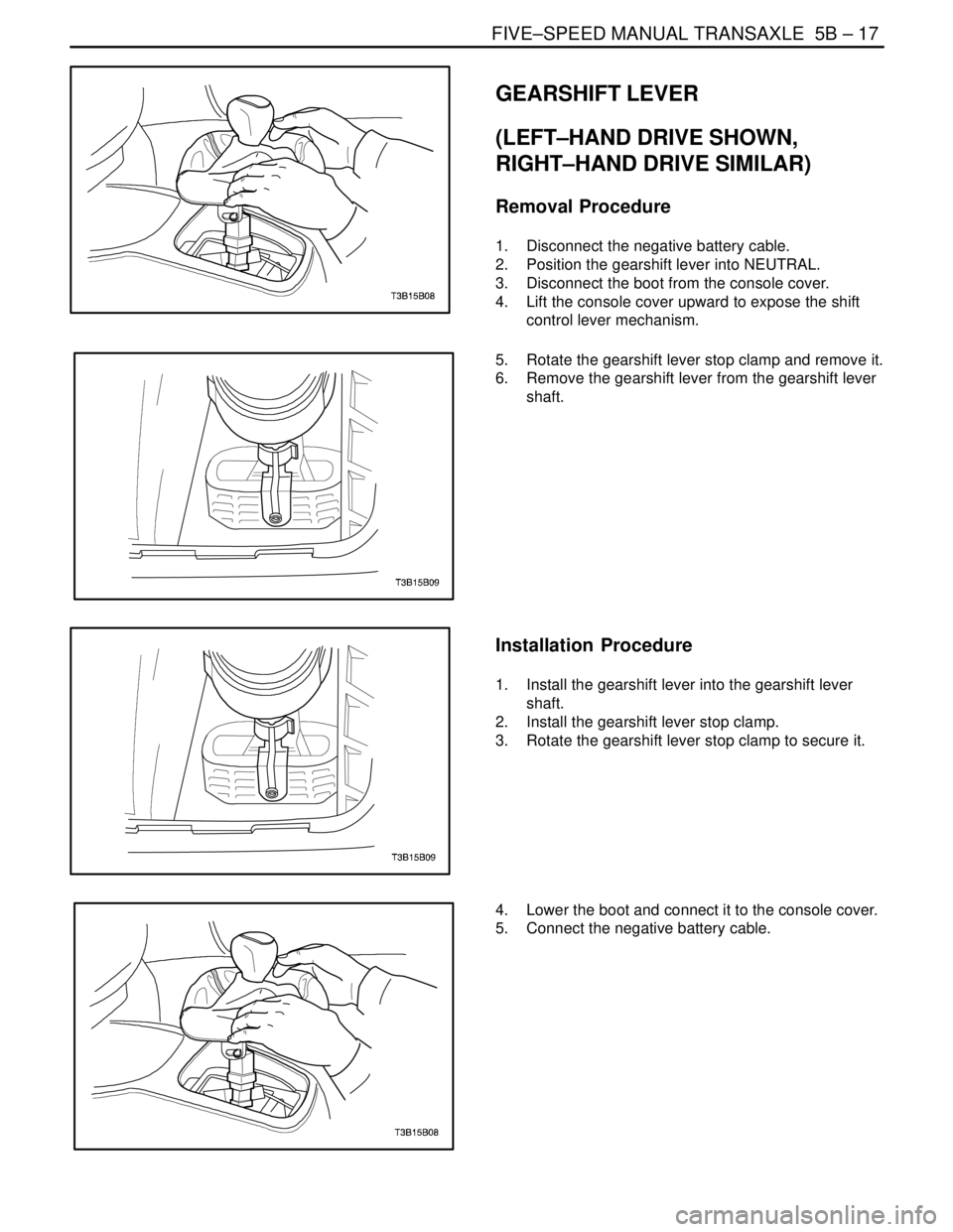

GEARSHIFT LEVER

(LEFT–HAND DRIVE SHOWN,

RIGHT–HAND DRIVE SIMILAR)

Removal Procedure

1. Disconnect the negative battery cable.

2. Position the gearshift lever into NEUTRAL.

3. Disconnect the boot from the console cover.

4. Lift the console cover upward to expose the shift

control lever mechanism.

5. Rotate the gearshift lever stop clamp and remove it.

6. Remove the gearshift lever from the gearshift lever

shaft.

Installation Procedure

1. Install the gearshift lever into the gearshift lever

shaft.

2. Install the gearshift lever stop clamp.

3. Rotate the gearshift lever stop clamp to secure it.

4. Lower the boot and connect it to the console cover.

5. Connect the negative battery cable.

Page 1918 of 2643

SECTION : 6C

POWER STEERING GEAR

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6C–1. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6C–2. . . . . . . . . . .

SPECIAL TOOLS6C–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6C–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6C–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion Steering Gear 6C–3. . . . . . . .

Power Rack and Pinion Steering Gear Bench

Testing 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–6. . . . . .

Speed Sensitive Power Steering System Operating

With Full Assist At All Times 6C–7. . . . . . . . . . . . . . .

Speed Sensitive Power Steering System Operating

with Decreased Assist At All Times 6C–9. . . . . . . . .

MAINTENANCE AND REPAIR6C–11 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6C–11. . . . . . . . . . . . . . . . . . . .

Rack and Pinion Assembly 6C–11. . . . . . . . . . . . . . . . . Outer Tie Rod 6C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dust Boot 6C–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Straight–Ahead Check 6C–16. . . . . . . . . . . . . . . . . . . .

Intermediate Shaft and Dash Seal 6C–17. . . . . . . . . .

Hydraulic Cylinder Lines 6C–20. . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering Control

Module 6C–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack and Pinion 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . .

Stub Shaft Seals and Upper and Lower

Bearing 6C–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing 6C–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing Preload Adjustment 6C–30. . . . . . . . . . .

Valve and Pinion 6C–30. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6C–33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion 6C–33. . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–33. . . . .

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Capacity1.1 Liter (1.16 qt)

LubricantPower Steering Fluid DEXRON®–II or III

Page 1932 of 2643

POWER STEERING GEAR 6C – 15

DAEWOO V–121 BL4

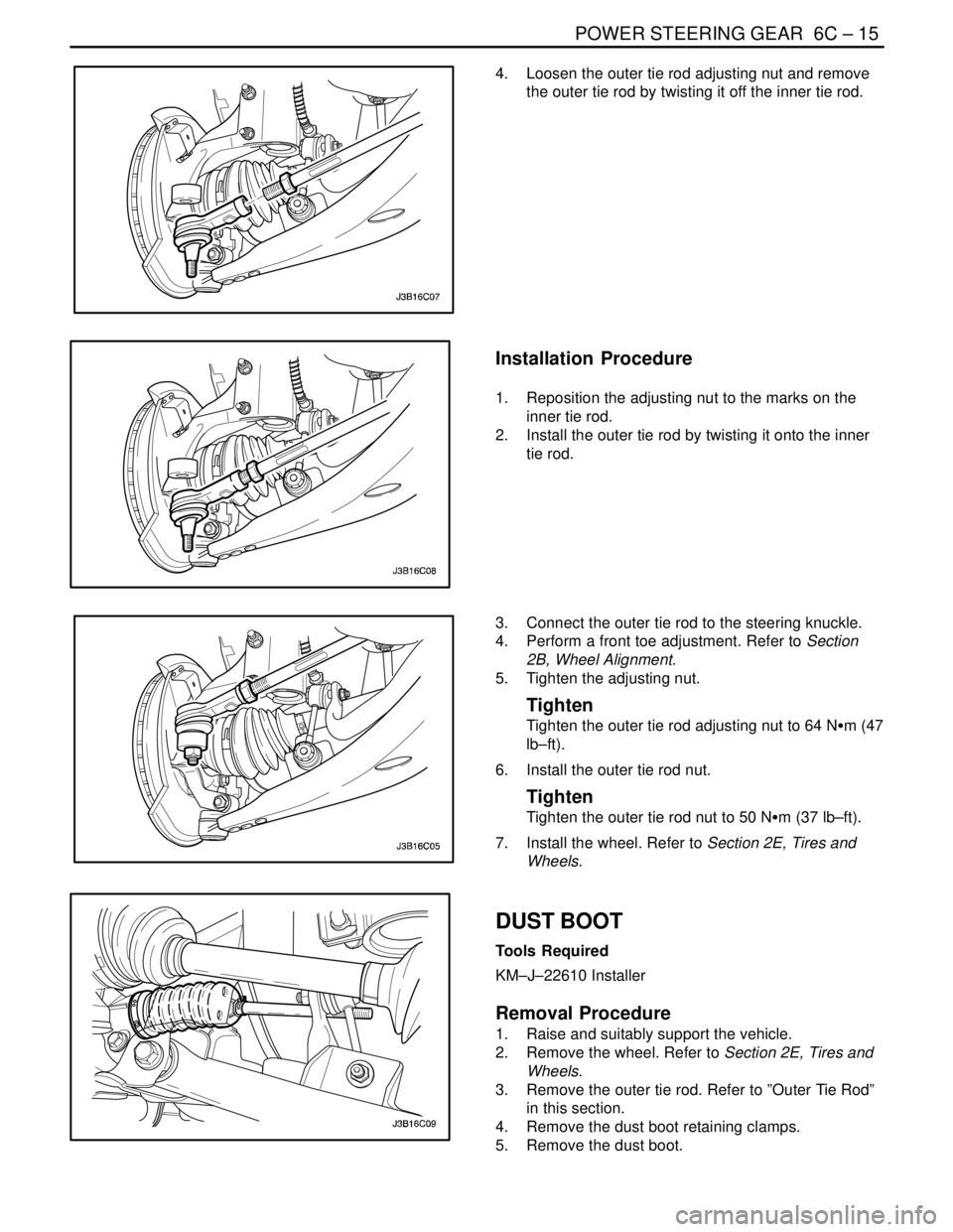

4. Loosen the outer tie rod adjusting nut and remove

the outer tie rod by twisting it off the inner tie rod.

Installation Procedure

1. Reposition the adjusting nut to the marks on the

inner tie rod.

2. Install the outer tie rod by twisting it onto the inner

tie rod.

3. Connect the outer tie rod to the steering knuckle.

4. Perform a front toe adjustment. Refer to Section

2B, Wheel Alignment.

5. Tighten the adjusting nut.

Tighten

Tighten the outer tie rod adjusting nut to 64 NSm (47

lb–ft).

6. Install the outer tie rod nut.

Tighten

Tighten the outer tie rod nut to 50 NSm (37 lb–ft).

7. Install the wheel. Refer to Section 2E, Tires and

Wheels.

DUST BOOT

Tools Required

KM–J–22610 Installer

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Remove the outer tie rod. Refer to ”Outer Tie Rod”

in this section.

4. Remove the dust boot retaining clamps.

5. Remove the dust boot.

Page 1933 of 2643

6C – 16IPOWER STEERING GEAR

DAEWOO V–121 BL4

Installation Procedure

1. Install the dust boot.

2. Install the tie rod end dust boot retaining clamp.

Install the cylinder end dust boot retaining clamp

with the installer KM–J–22610.

3. Install the outer tie rod. Refer to ”Outer Tie Rod” in

this section.

4. Install the wheel. Refer to Section 2E, Tires and

Wheels.

5. Lower the vehicle.

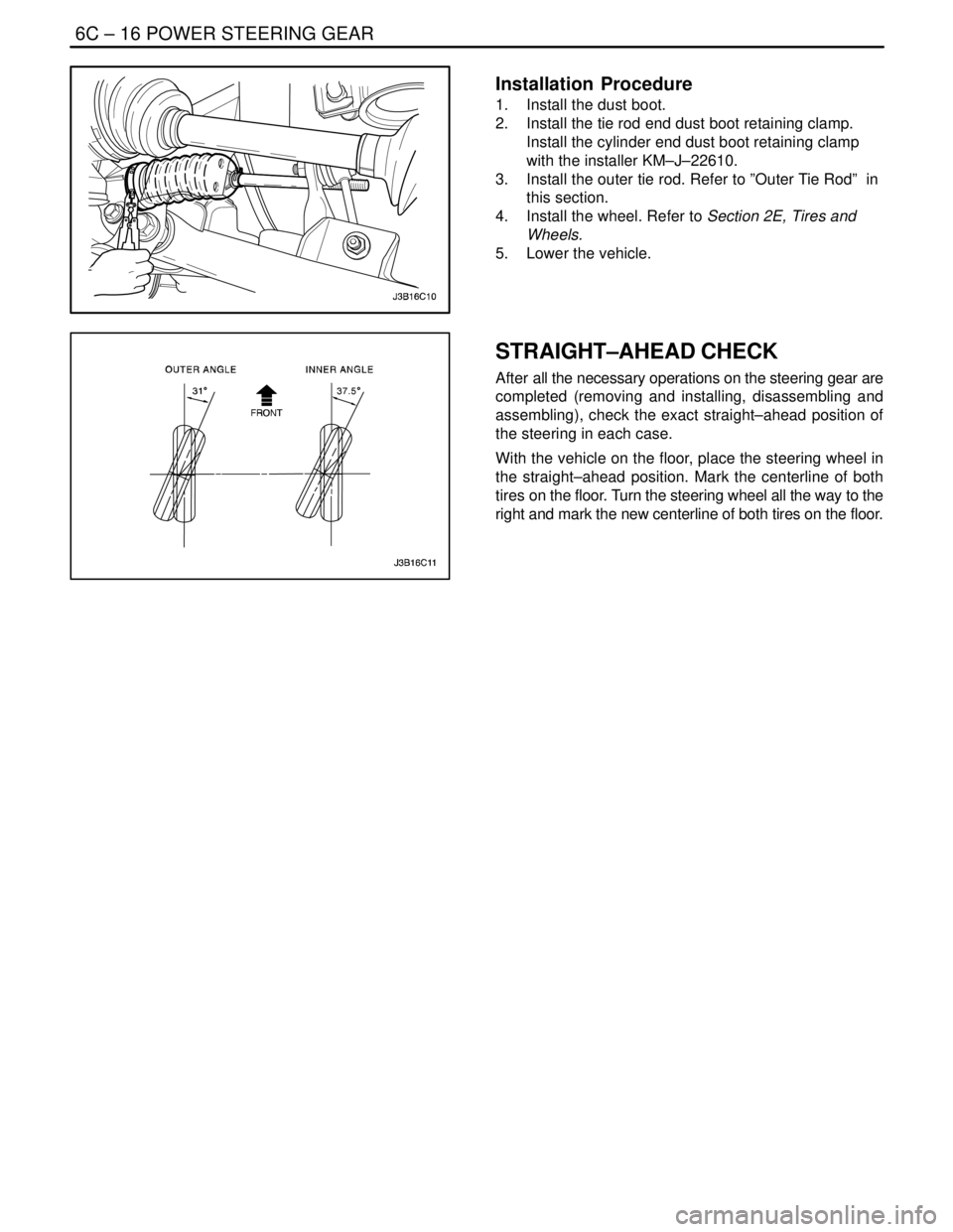

STRAIGHT–AHEAD CHECK

After all the necessary operations on the steering gear are

completed (removing and installing, disassembling and

assembling), check the exact straight–ahead position of

the steering in each case.

With the vehicle on the floor, place the steering wheel in

the straight–ahead position. Mark the centerline of both

tires on the floor. Turn the steering wheel all the way to the

right and mark the new centerline of both tires on the floor.

Page 1939 of 2643

6C – 22IPOWER STEERING GEAR

DAEWOO V–121 BL4

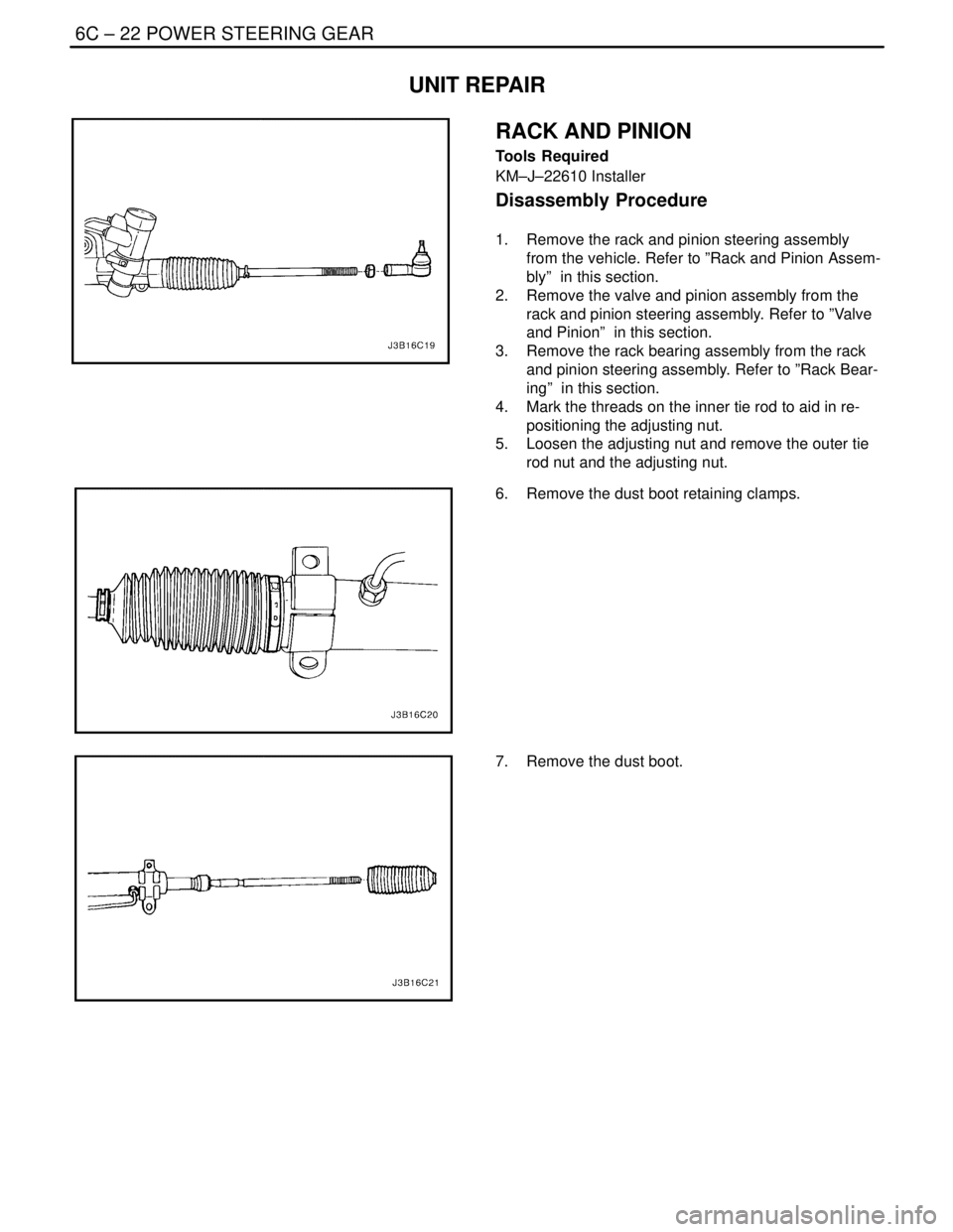

UNIT REPAIR

RACK AND PINION

Tools Required

KM–J–22610 Installer

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the valve and pinion assembly from the

rack and pinion steering assembly. Refer to ”Valve

and Pinion” in this section.

3. Remove the rack bearing assembly from the rack

and pinion steering assembly. Refer to ”Rack Bear-

ing” in this section.

4. Mark the threads on the inner tie rod to aid in re-

positioning the adjusting nut.

5. Loosen the adjusting nut and remove the outer tie

rod nut and the adjusting nut.

6. Remove the dust boot retaining clamps.

7. Remove the dust boot.