brake DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 24 of 2643

GENERAL INFORMATION 0B – 17

DAEWOO V–121 BL4

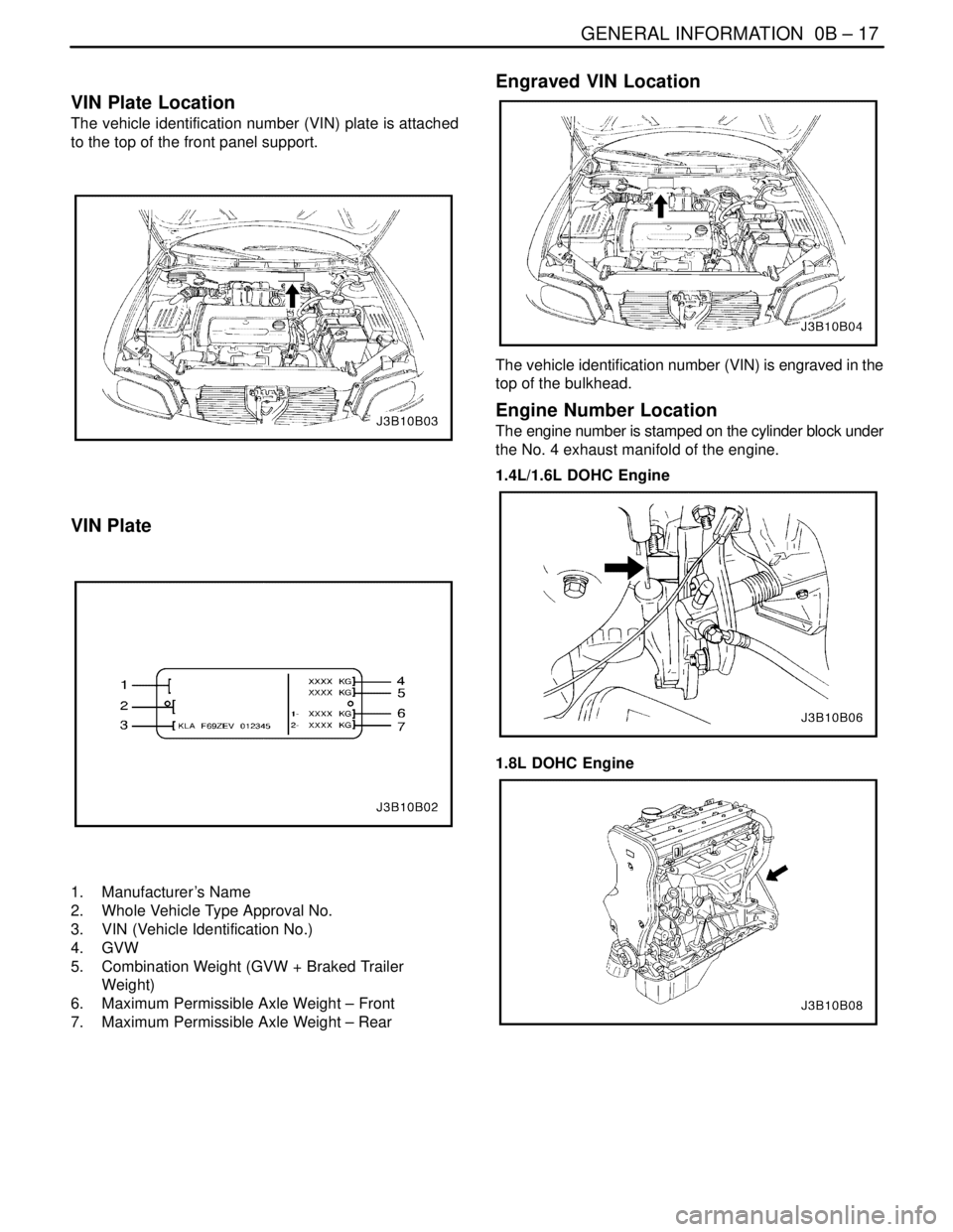

VIN Plate Location

The vehicle identification number (VIN) plate is attached

to the top of the front panel support.

VIN Plate

1. Manufacturer ’s Name

2. Whole Vehicle Type Approval No.

3. VIN (Vehicle Identification No.)

4. GVW

5. Combination Weight (GVW + Braked Trailer

Weight)

6. Maximum Permissible Axle Weight – Front

7. Maximum Permissible Axle Weight – Rear

Engraved VIN Location

The vehicle identification number (VIN) is engraved in the

top of the bulkhead.

Engine Number Location

The engine number is stamped on the cylinder block under

the No. 4 exhaust manifold of the engine.

1.4L/1.6L DOHC Engine

1.8L DOHC Engine

Page 60 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 17

DAEWOO V–121 BL4

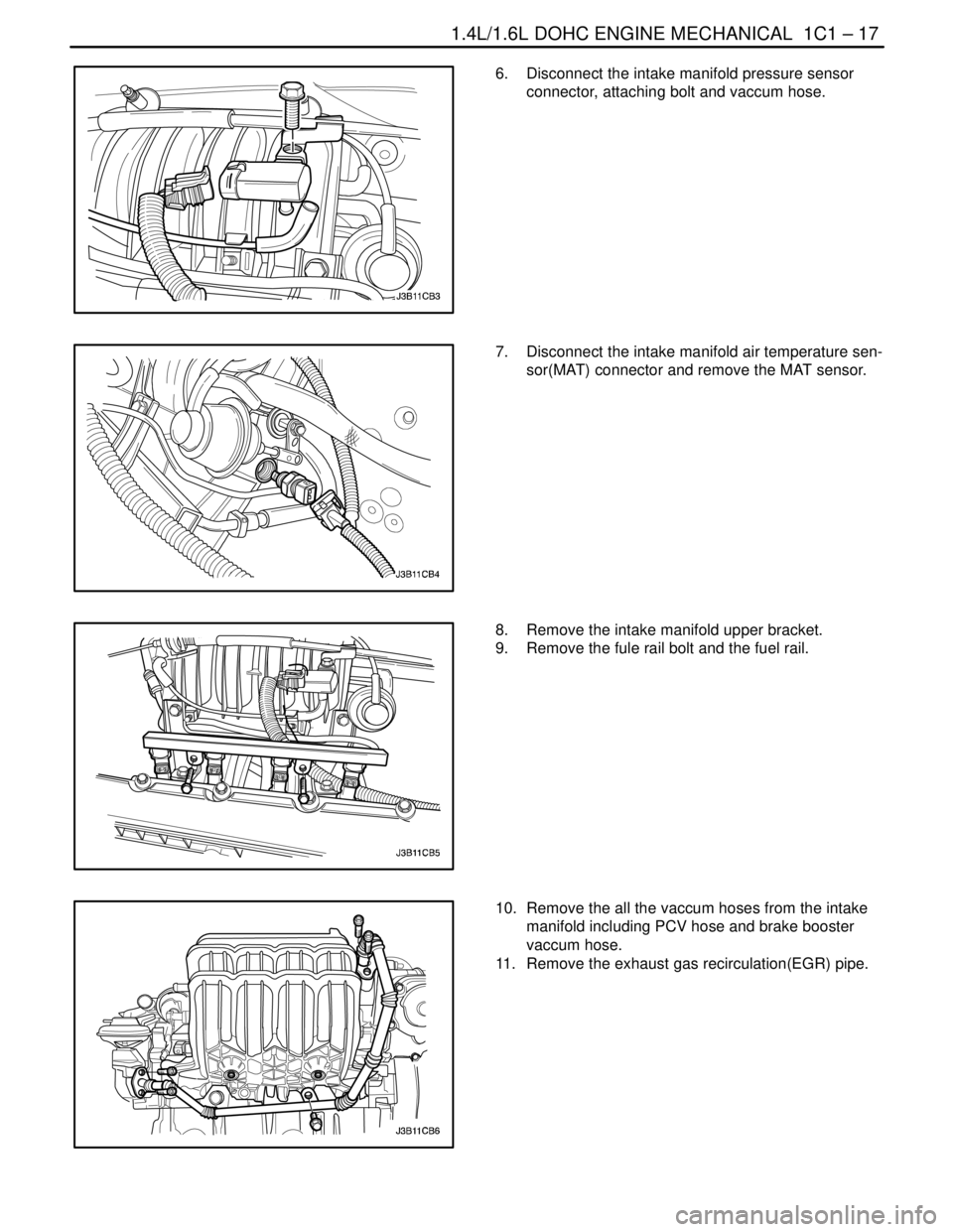

6. Disconnect the intake manifold pressure sensor

connector, attaching bolt and vaccum hose.

7. Disconnect the intake manifold air temperature sen-

sor(MAT) connector and remove the MAT sensor.

8. Remove the intake manifold upper bracket.

9. Remove the fule rail bolt and the fuel rail.

10. Remove the all the vaccum hoses from the intake

manifold including PCV hose and brake booster

vaccum hose.

11. Remove the exhaust gas recirculation(EGR) pipe.

Page 66 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 23

DAEWOO V–121 BL4

12. Remove the all the vaccum hoses from the intake

manifold including brake booster vaccum hose.

13. Remove the ignition cables from the spark plugs.

14. Remove the direct ignition coil(DIS) and the bracket

from the cylinder head.

15. Remove the serpentine accessory drive belt by ro-

tating the tensioner pulley bolt to clockwise using

DW110–080. Refer to Section 6B, Power Steering

Pump.

16. Remove the front passenger side tire. Refer to Sec-

tion 2E, Tires and Wheels.

17. Remove front wheel housing shield.

18. Remove the upper front timing belt cover bolts.

19. Remove the upper front timing belt cover.

20. Align the camshaft gear timing marks.

21. Remove the crank shaft pulley.

22. Remove the lower front timing belt cover bolts and

cover.

Page 69 of 2643

1C1 – 26I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

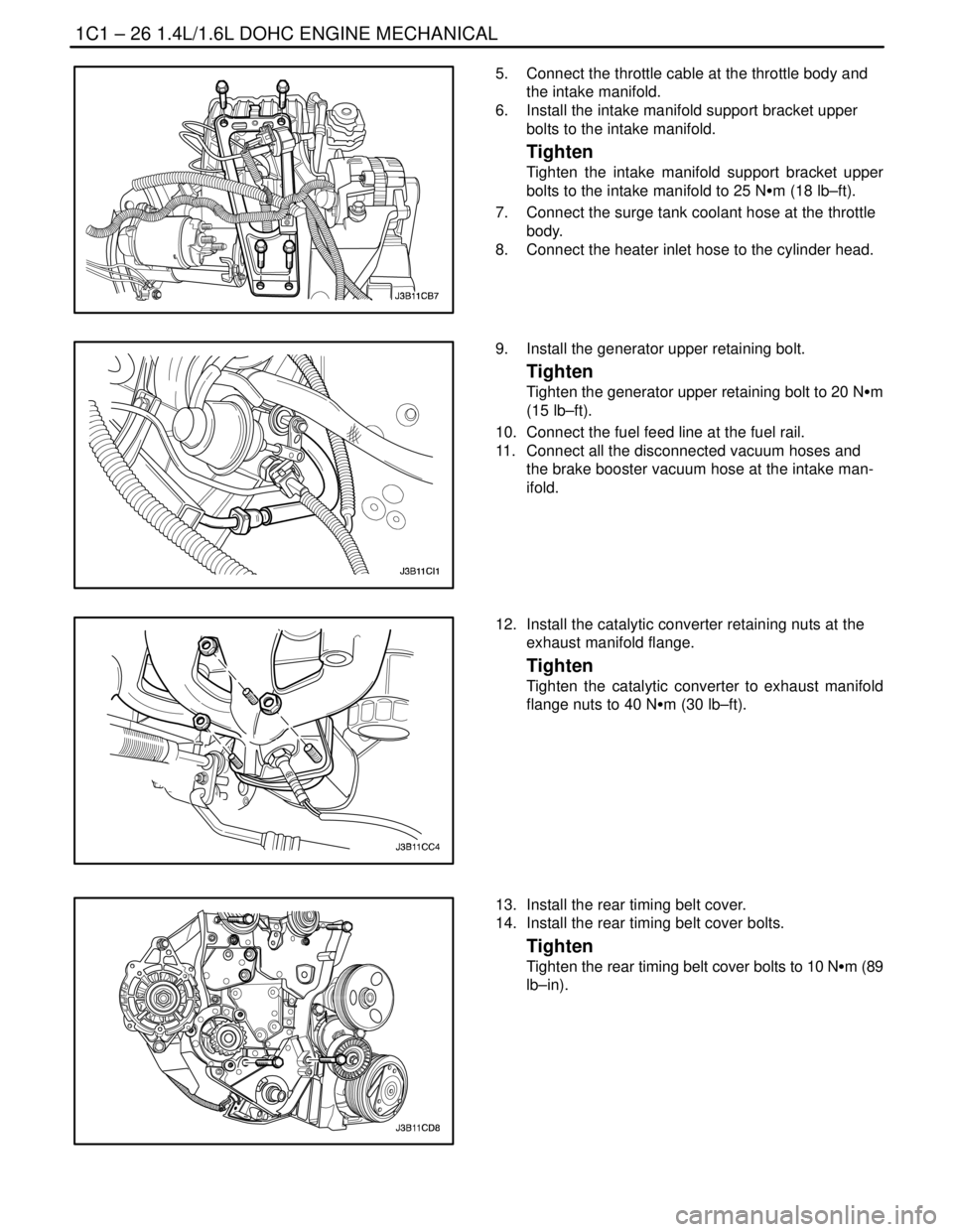

5. Connect the throttle cable at the throttle body and

the intake manifold.

6. Install the intake manifold support bracket upper

bolts to the intake manifold.

Tighten

Tighten the intake manifold support bracket upper

bolts to the intake manifold to 25 NSm (18 lb–ft).

7. Connect the surge tank coolant hose at the throttle

body.

8. Connect the heater inlet hose to the cylinder head.

9. Install the generator upper retaining bolt.

Tighten

Tighten the generator upper retaining bolt to 20 NSm

(15 lb–ft).

10. Connect the fuel feed line at the fuel rail.

11. Connect all the disconnected vacuum hoses and

the brake booster vacuum hose at the intake man-

ifold.

12. Install the catalytic converter retaining nuts at the

exhaust manifold flange.

Tighten

Tighten the catalytic converter to exhaust manifold

flange nuts to 40 NSm (30 lb–ft).

13. Install the rear timing belt cover.

14. Install the rear timing belt cover bolts.

Tighten

Tighten the rear timing belt cover bolts to 10 NSm (89

lb–in).

Page 92 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 49

DAEWOO V–121 BL4

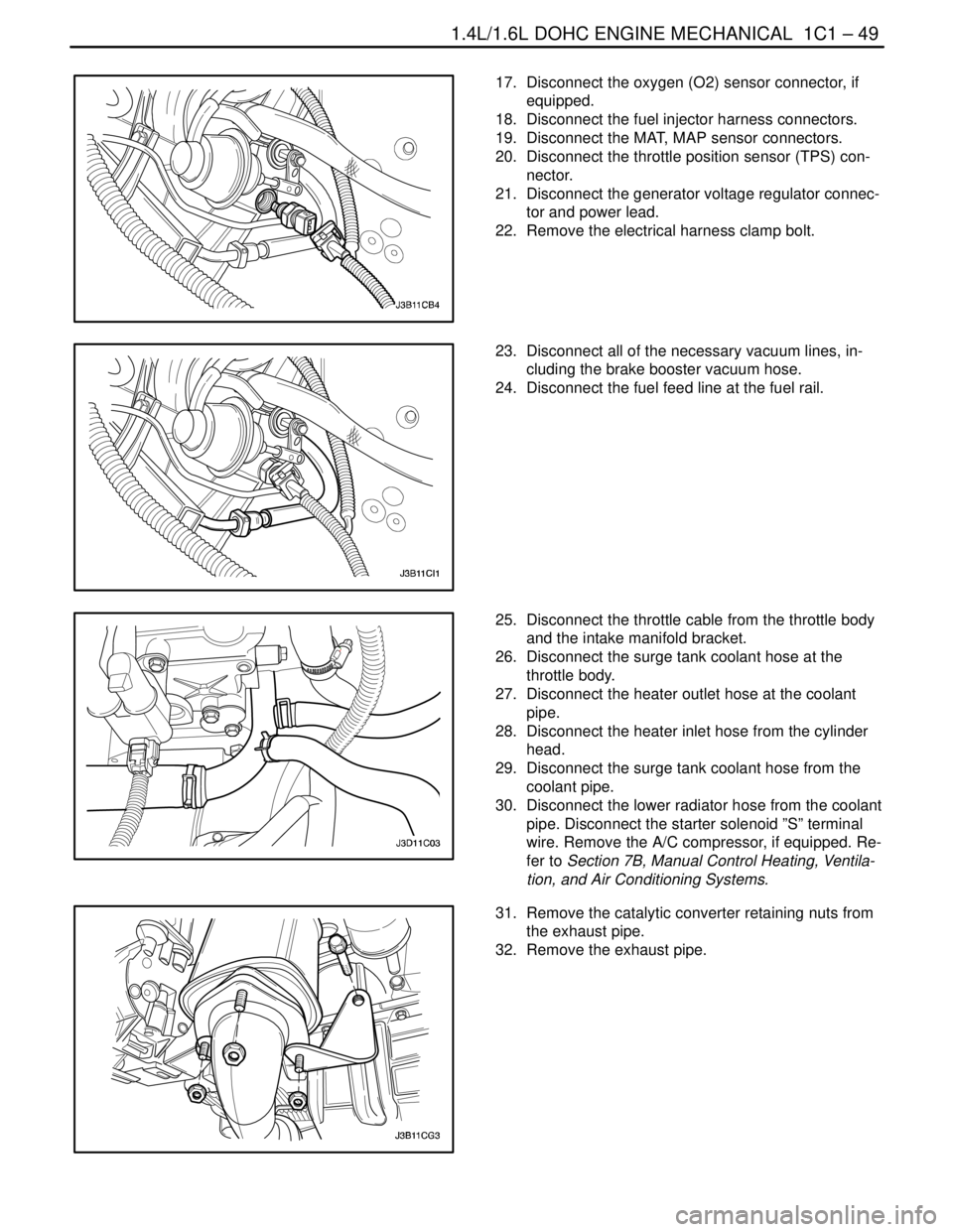

17. Disconnect the oxygen (O2) sensor connector, if

equipped.

18. Disconnect the fuel injector harness connectors.

19. Disconnect the MAT, MAP sensor connectors.

20. Disconnect the throttle position sensor (TPS) con-

nector.

21. Disconnect the generator voltage regulator connec-

tor and power lead.

22. Remove the electrical harness clamp bolt.

23. Disconnect all of the necessary vacuum lines, in-

cluding the brake booster vacuum hose.

24. Disconnect the fuel feed line at the fuel rail.

25. Disconnect the throttle cable from the throttle body

and the intake manifold bracket.

26. Disconnect the surge tank coolant hose at the

throttle body.

27. Disconnect the heater outlet hose at the coolant

pipe.

28. Disconnect the heater inlet hose from the cylinder

head.

29. Disconnect the surge tank coolant hose from the

coolant pipe.

30. Disconnect the lower radiator hose from the coolant

pipe. Disconnect the starter solenoid ”S” terminal

wire. Remove the A/C compressor, if equipped. Re-

fer to Section 7B, Manual Control Heating, Ventila-

tion, and Air Conditioning Systems.

31. Remove the catalytic converter retaining nuts from

the exhaust pipe.

32. Remove the exhaust pipe.

Page 95 of 2643

1C1 – 52I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

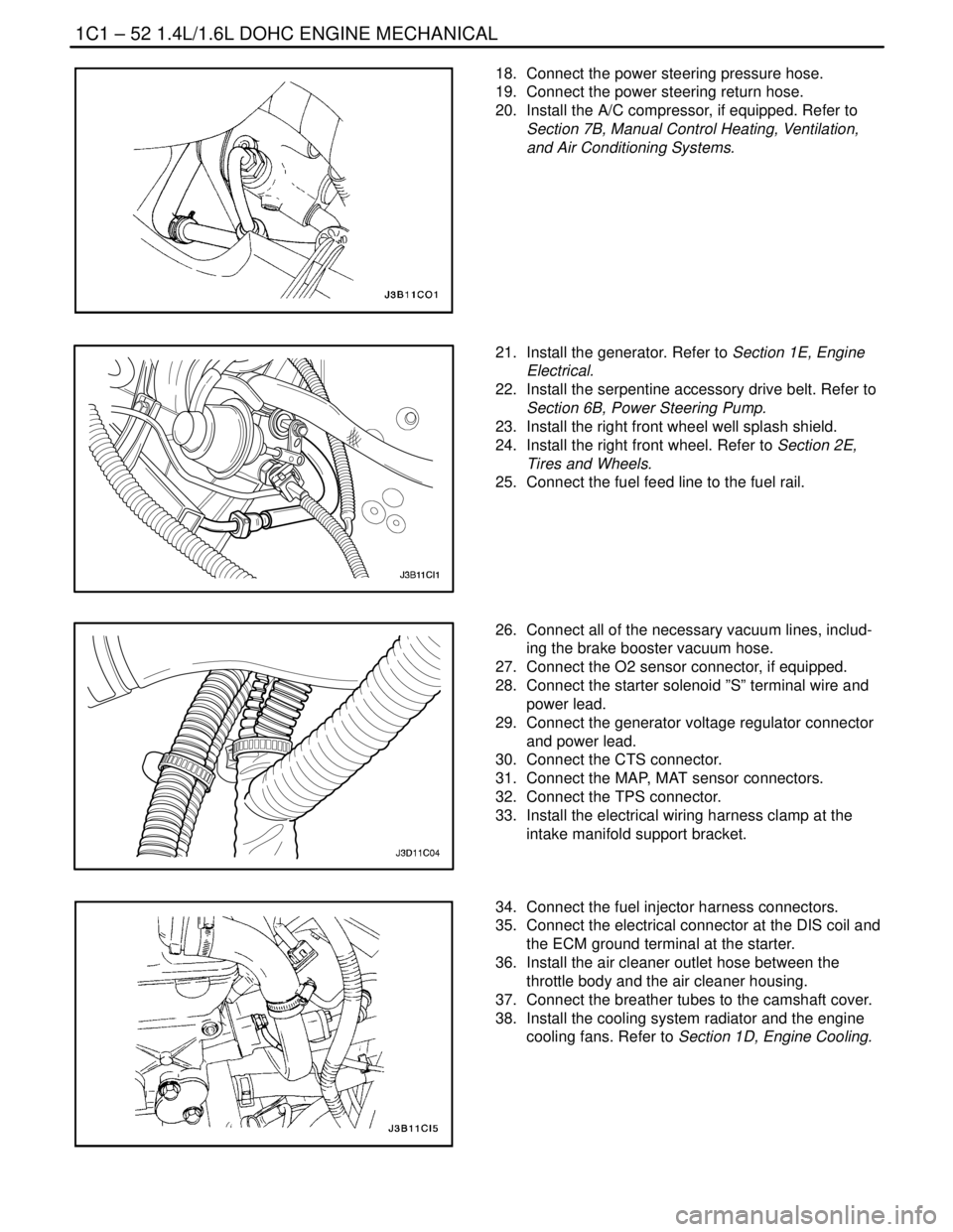

18. Connect the power steering pressure hose.

19. Connect the power steering return hose.

20. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning Systems.

21. Install the generator. Refer to Section 1E, Engine

Electrical.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

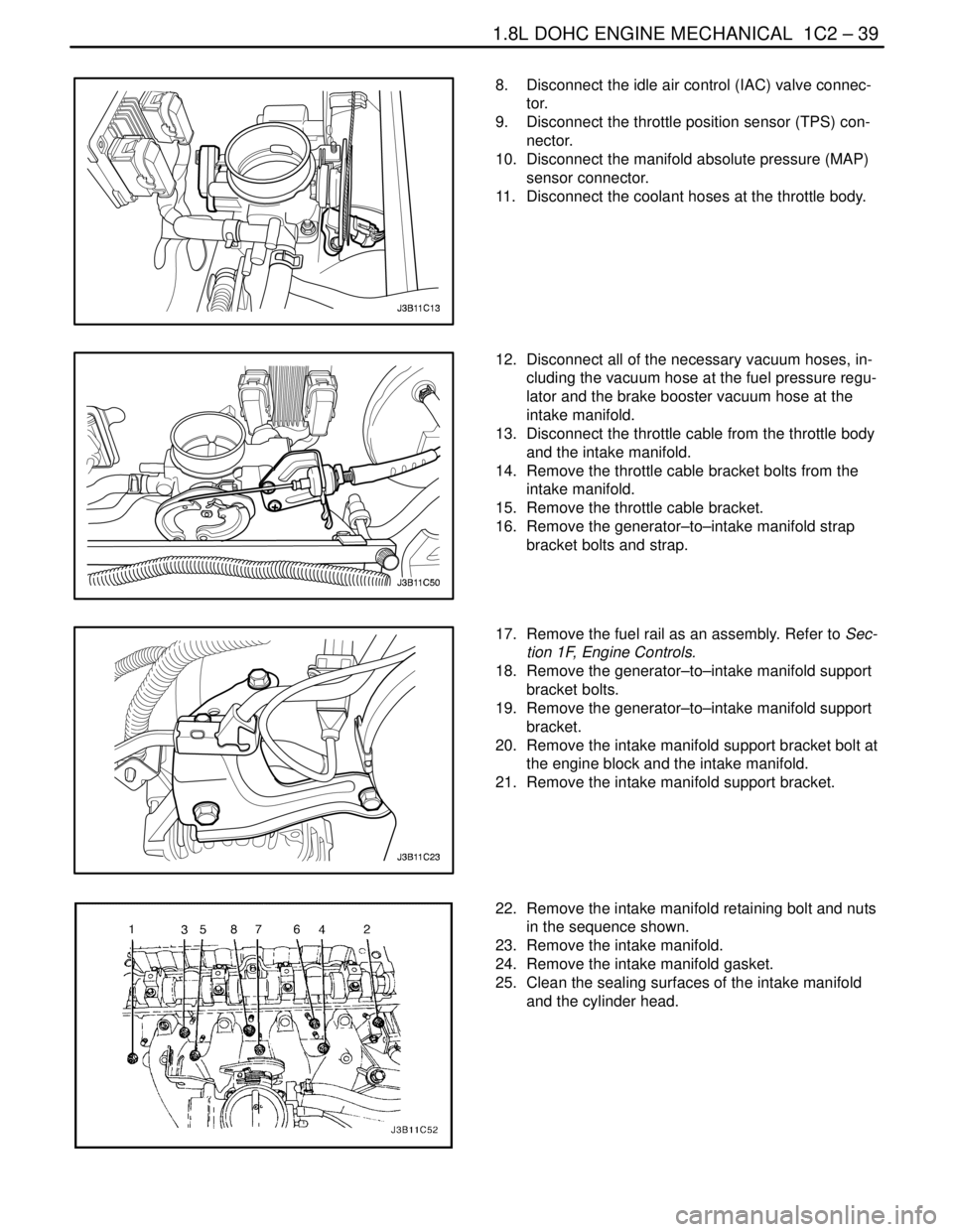

26. Connect all of the necessary vacuum lines, includ-

ing the brake booster vacuum hose.

27. Connect the O2 sensor connector, if equipped.

28. Connect the starter solenoid ”S” terminal wire and

power lead.

29. Connect the generator voltage regulator connector

and power lead.

30. Connect the CTS connector.

31. Connect the MAP, MAT sensor connectors.

32. Connect the TPS connector.

33. Install the electrical wiring harness clamp at the

intake manifold support bracket.

34. Connect the fuel injector harness connectors.

35. Connect the electrical connector at the DIS coil and

the ECM ground terminal at the starter.

36. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

37. Connect the breather tubes to the camshaft cover.

38. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 159 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 39

DAEWOO V–121 BL4

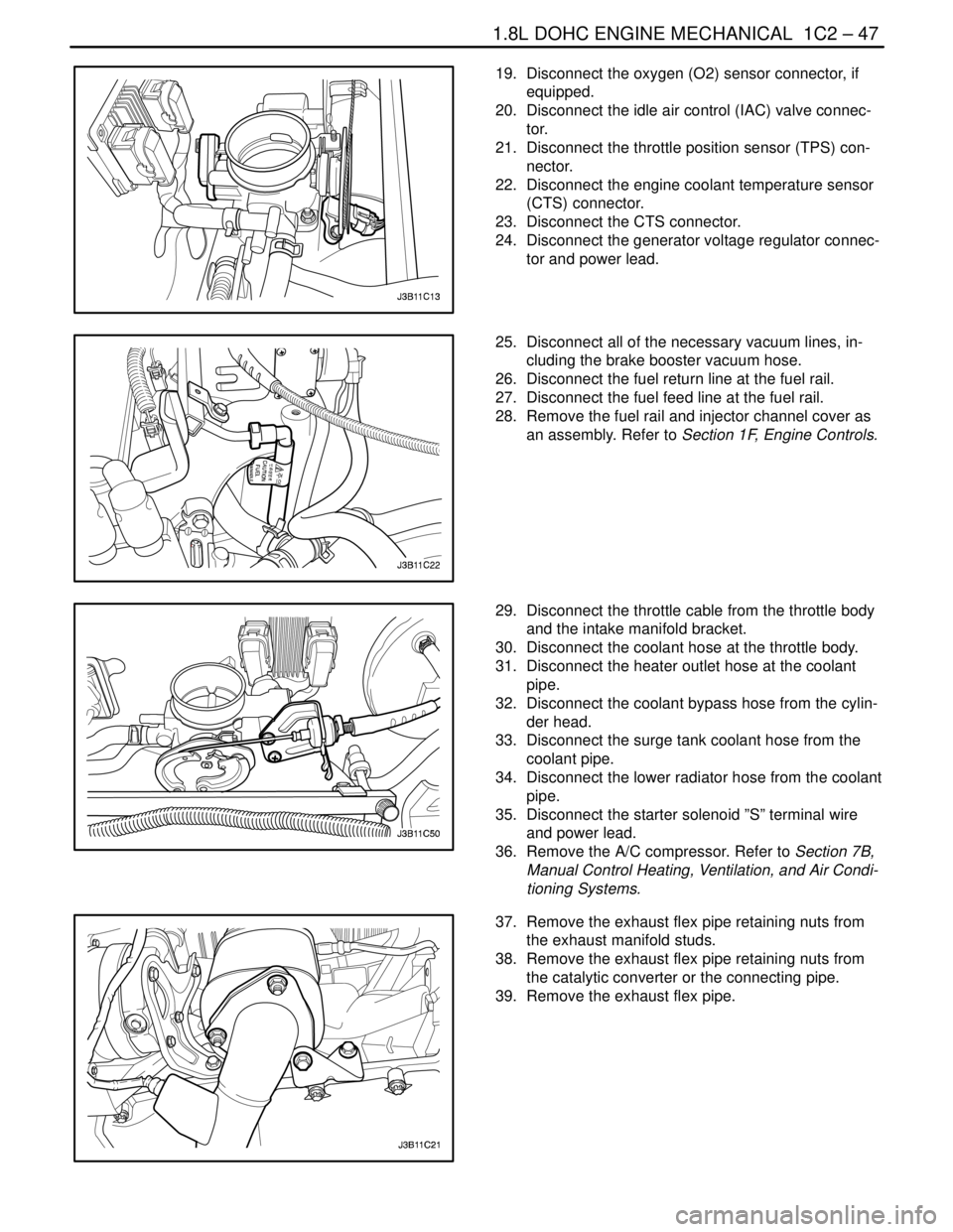

8. Disconnect the idle air control (IAC) valve connec-

tor.

9. Disconnect the throttle position sensor (TPS) con-

nector.

10. Disconnect the manifold absolute pressure (MAP)

sensor connector.

11. Disconnect the coolant hoses at the throttle body.

12. Disconnect all of the necessary vacuum hoses, in-

cluding the vacuum hose at the fuel pressure regu-

lator and the brake booster vacuum hose at the

intake manifold.

13. Disconnect the throttle cable from the throttle body

and the intake manifold.

14. Remove the throttle cable bracket bolts from the

intake manifold.

15. Remove the throttle cable bracket.

16. Remove the generator–to–intake manifold strap

bracket bolts and strap.

17. Remove the fuel rail as an assembly. Refer to Sec-

tion 1F, Engine Controls.

18. Remove the generator–to–intake manifold support

bracket bolts.

19. Remove the generator–to–intake manifold support

bracket.

20. Remove the intake manifold support bracket bolt at

the engine block and the intake manifold.

21. Remove the intake manifold support bracket.

22. Remove the intake manifold retaining bolt and nuts

in the sequence shown.

23. Remove the intake manifold.

24. Remove the intake manifold gasket.

25. Clean the sealing surfaces of the intake manifold

and the cylinder head.

Page 167 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 47

DAEWOO V–121 BL4

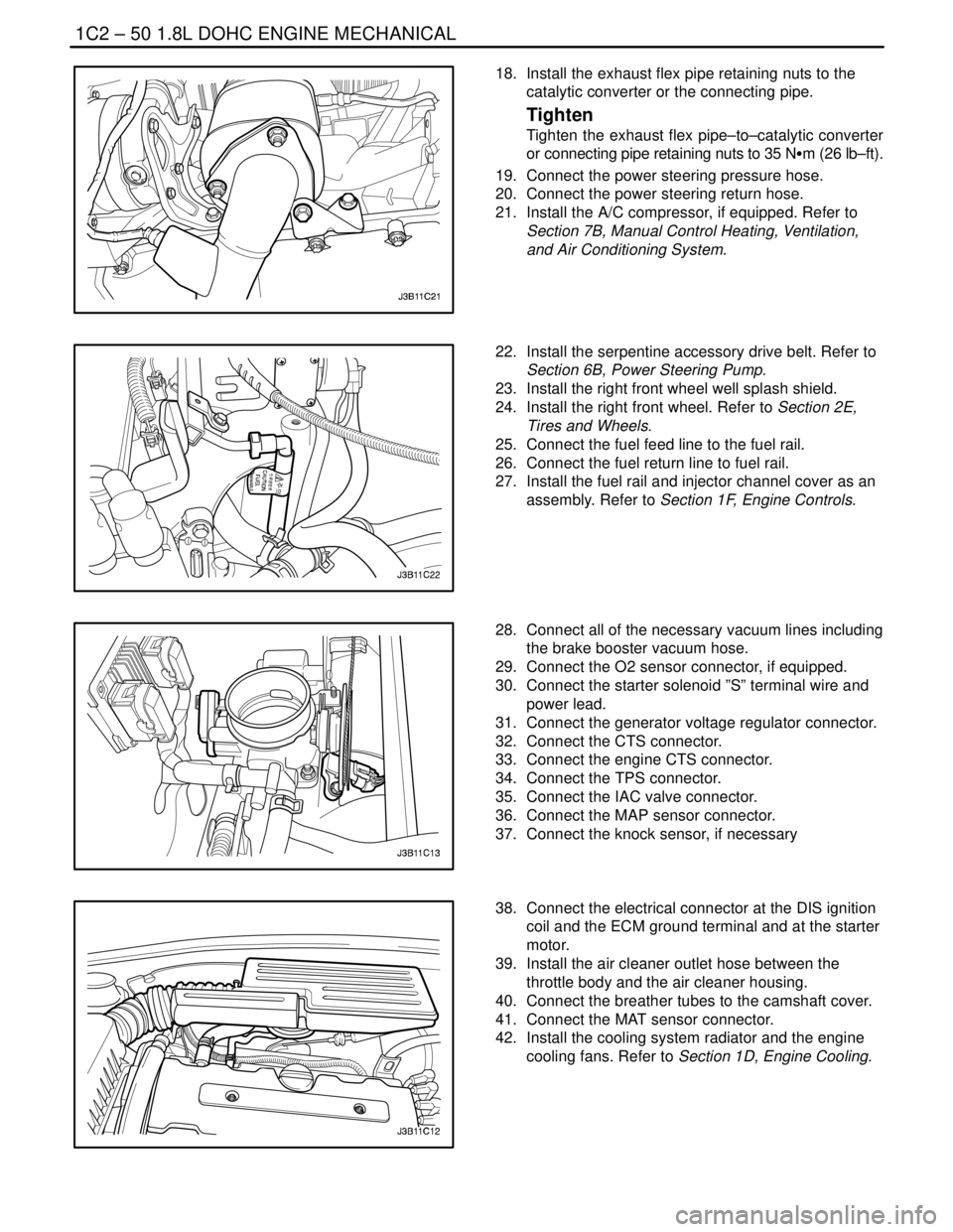

19. Disconnect the oxygen (O2) sensor connector, if

equipped.

20. Disconnect the idle air control (IAC) valve connec-

tor.

21. Disconnect the throttle position sensor (TPS) con-

nector.

22. Disconnect the engine coolant temperature sensor

(CTS) connector.

23. Disconnect the CTS connector.

24. Disconnect the generator voltage regulator connec-

tor and power lead.

25. Disconnect all of the necessary vacuum lines, in-

cluding the brake booster vacuum hose.

26. Disconnect the fuel return line at the fuel rail.

27. Disconnect the fuel feed line at the fuel rail.

28. Remove the fuel rail and injector channel cover as

an assembly. Refer to Section 1F, Engine Controls.

29. Disconnect the throttle cable from the throttle body

and the intake manifold bracket.

30. Disconnect the coolant hose at the throttle body.

31. Disconnect the heater outlet hose at the coolant

pipe.

32. Disconnect the coolant bypass hose from the cylin-

der head.

33. Disconnect the surge tank coolant hose from the

coolant pipe.

34. Disconnect the lower radiator hose from the coolant

pipe.

35. Disconnect the starter solenoid ”S” terminal wire

and power lead.

36. Remove the A/C compressor. Refer to Section 7B,

Manual Control Heating, Ventilation, and Air Condi-

tioning Systems.

37. Remove the exhaust flex pipe retaining nuts from

the exhaust manifold studs.

38. Remove the exhaust flex pipe retaining nuts from

the catalytic converter or the connecting pipe.

39. Remove the exhaust flex pipe.

Page 170 of 2643

1C2 – 50I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

19. Connect the power steering pressure hose.

20. Connect the power steering return hose.

21. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect the fuel return line to fuel rail.

27. Install the fuel rail and injector channel cover as an

assembly. Refer to Section 1F, Engine Controls.

28. Connect all of the necessary vacuum lines including

the brake booster vacuum hose.

29. Connect the O2 sensor connector, if equipped.

30. Connect the starter solenoid ”S” terminal wire and

power lead.

31. Connect the generator voltage regulator connector.

32. Connect the CTS connector.

33. Connect the engine CTS connector.

34. Connect the TPS connector.

35. Connect the IAC valve connector.

36. Connect the MAP sensor connector.

37. Connect the knock sensor, if necessary

38. Connect the electrical connector at the DIS ignition

coil and the ECM ground terminal and at the starter

motor.

39. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

40. Connect the breather tubes to the camshaft cover.

41. Connect the MAT sensor connector.

42. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 245 of 2643

ENGINE ELECTRICAL 1E – 31

DAEWOO V–121 BL4

trolyte and the plates are at room temperature. A

battery that is extremely cold may not accept cur-

rent for several hours after starting the charger.

3. Charge the battery until the green dot appears. The

battery should be checked every half–hour while

charging. Tipping or shaking the battery may be

necessary to make the green dot appear.

4. After charging, the battery should be load tested.

Refer to ”Starter Motor” in this section.

CHARGING TIME REQUIRED

The time required to charge a battery will vary depending

upon the following factors:

S Size of Battery – A completely discharged large

heavy–duty battery requires more than twice the re-

charging time as a completely discharged small pas-

senger car battery.

S Temperature – A longer time will be needed to

charge any battery at –18°C (0°F) than at 27°C

(80°F). When a fast charger is connected to a cold

battery, the current accepted by the battery will be

very low at first. The battery will accept a higher cur-

rent rate as the battery warms.

S Charger Capacity – A charger which can supply only

5 amperes will require a much longer charging period

than a charger that can supply 30 amperes or more.

S State–of–Charge – A completely discharged battery

requires more than twice as much charge as a one–

half charged battery. Because the electrolyte is nearly

pure water and a poor conductor in a completely dis-

charged battery, the current accepted by the battery

is very low at first. Later, as the charging current

causes the electrolyte acid content to increase, the

charging current will likewise increase.

CHARGING A COMPLETELY

DISCHARGED BATTERY (OFF THE

VEHICLE)

Unless this procedure is properly followed, a perfectly

good battery may need to be replaced.

The following procedure should be used to recharge a

completely discharged battery:

1. Measure the voltage at the battery terminals with

an accurate voltmeter. If the reading is below 10

volts, the charge current will be very low, and it

could take some time before the battery accepts

the current in excess of a few milliamperes. Refer

to ””Charging Time Required” in this section, which

focuses on the factors affecting both the charging

time required and the rough estimates in the table

below. Such low current may not be detectable on

ammeters available in the field.

2. Set the battery charger on the high setting.Important : Some chargers feature polarity protection cir-

cuitry, which prevents charging unless the charger leads

are correctly connected to the battery terminals. A com-

pletely discharged battery may not have enough voltage

to activate this circuitry, even though the leads are con-

nected properly, making it appear that the battery will not

accept charging current. Therefore, follow the specific

charger manufacturer’s instruction for bypassing or over-

riding the circuitry so that the charger will turn on and

charge a low–voltage battery.

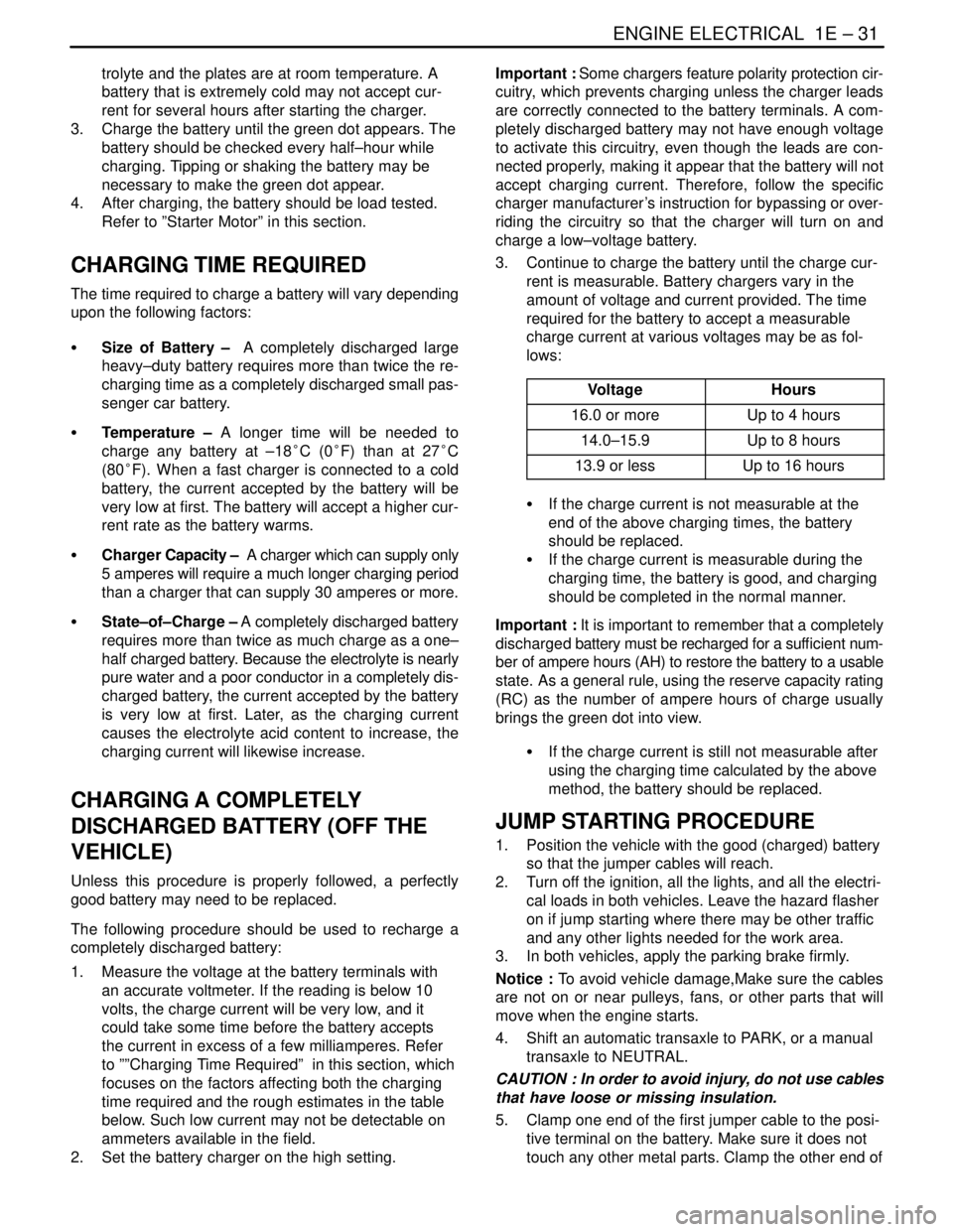

3. Continue to charge the battery until the charge cur-

rent is measurable. Battery chargers vary in the

amount of voltage and current provided. The time

required for the battery to accept a measurable

charge current at various voltages may be as fol-

lows:

Voltage

Hours

16.0 or moreUp to 4 hours

14.0–15.9Up to 8 hours

13.9 or lessUp to 16 hours

S If the charge current is not measurable at the

end of the above charging times, the battery

should be replaced.

S If the charge current is measurable during the

charging time, the battery is good, and charging

should be completed in the normal manner.

Important : It is important to remember that a completely

discharged battery must be recharged for a sufficient num-

ber of ampere hours (AH) to restore the battery to a usable

state. As a general rule, using the reserve capacity rating

(RC) as the number of ampere hours of charge usually

brings the green dot into view.

S If the charge current is still not measurable after

using the charging time calculated by the above

method, the battery should be replaced.

JUMP STARTING PROCEDURE

1. Position the vehicle with the good (charged) battery

so that the jumper cables will reach.

2. Turn off the ignition, all the lights, and all the electri-

cal loads in both vehicles. Leave the hazard flasher

on if jump starting where there may be other traffic

and any other lights needed for the work area.

3. In both vehicles, apply the parking brake firmly.

Notice : To avoid vehicle damage,Make sure the cables

are not on or near pulleys, fans, or other parts that will

move when the engine starts.

4. Shift an automatic transaxle to PARK, or a manual

transaxle to NEUTRAL.

CAUTION : In order to avoid injury, do not use cables

that have loose or missing insulation.

5. Clamp one end of the first jumper cable to the posi-

tive terminal on the battery. Make sure it does not

touch any other metal parts. Clamp the other end of