drain bolt DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 152 of 2643

1C2 – 32I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

OIL PAN

Removal Procedure

1. Disconnect the negative battery cable.

2. Drain the engine oil from the engine crankcase.

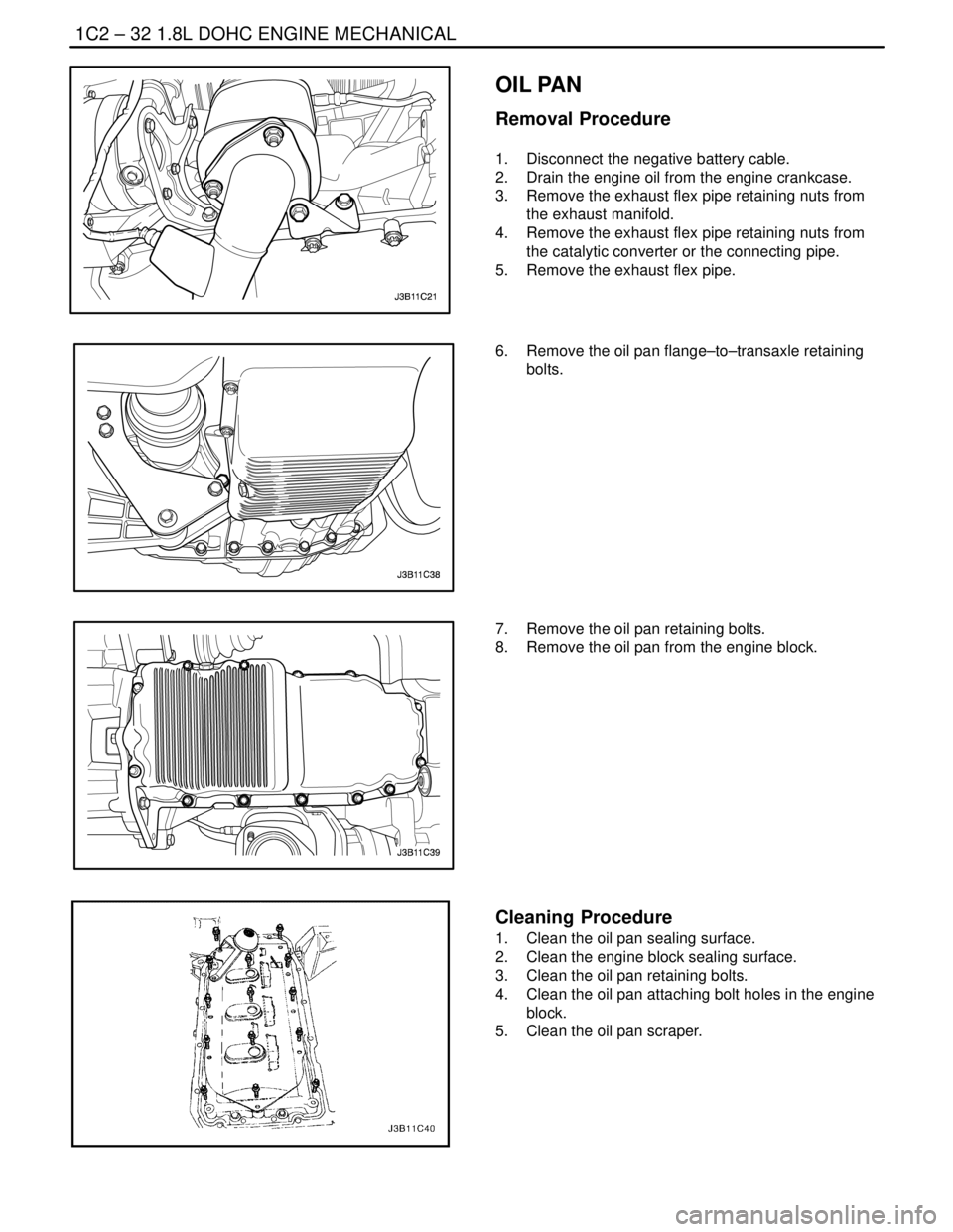

3. Remove the exhaust flex pipe retaining nuts from

the exhaust manifold.

4. Remove the exhaust flex pipe retaining nuts from

the catalytic converter or the connecting pipe.

5. Remove the exhaust flex pipe.

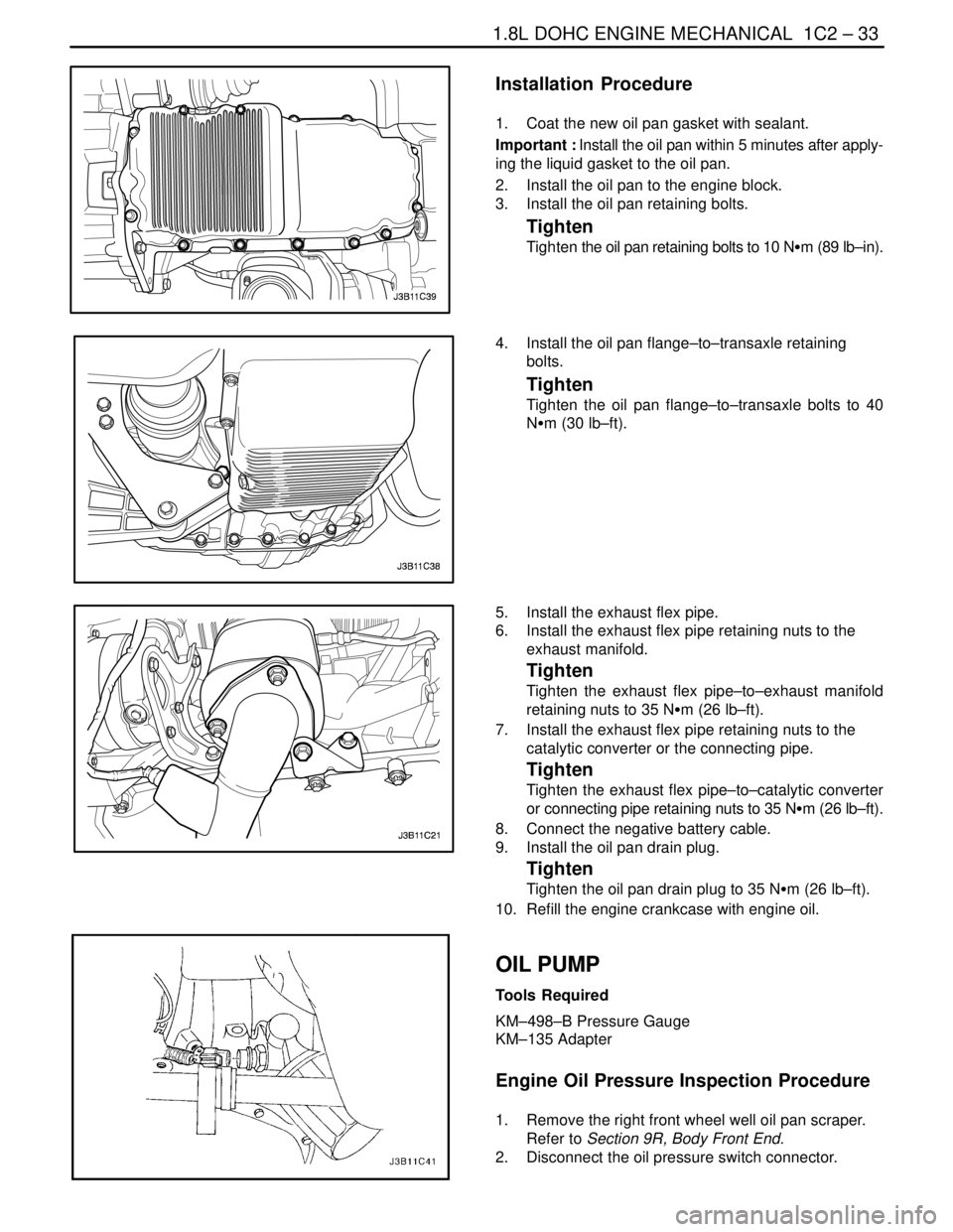

6. Remove the oil pan flange–to–transaxle retaining

bolts.

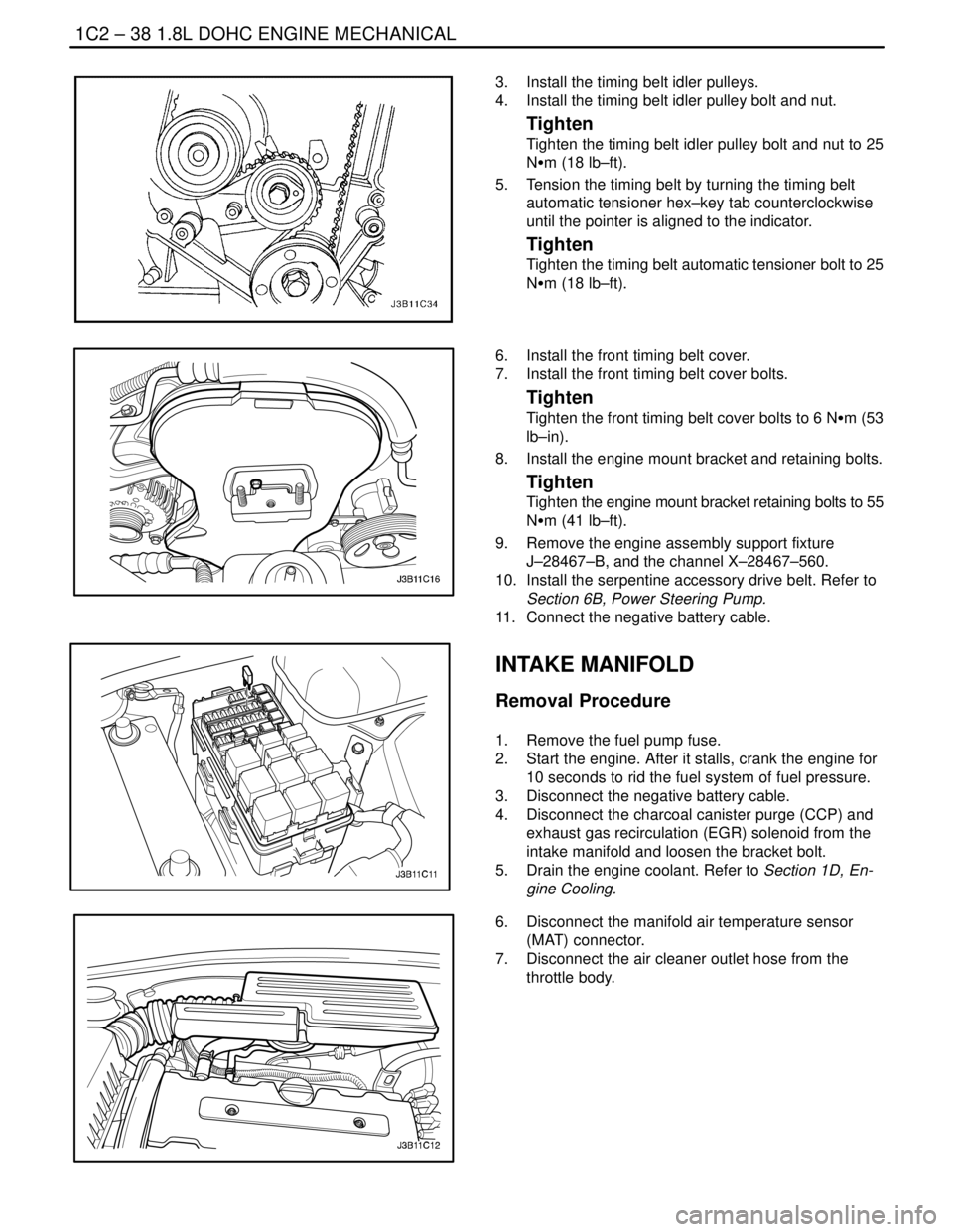

7. Remove the oil pan retaining bolts.

8. Remove the oil pan from the engine block.

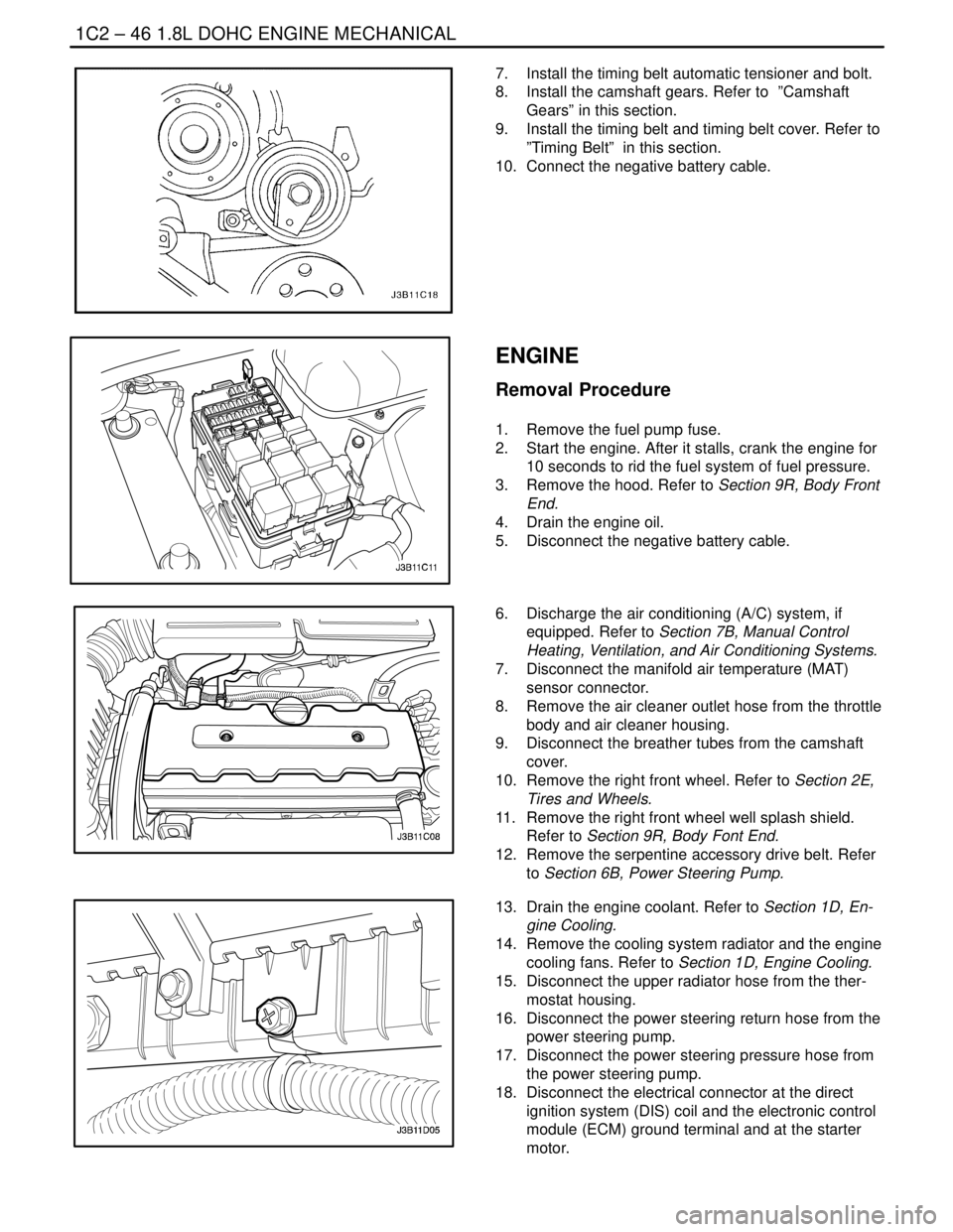

Cleaning Procedure

1. Clean the oil pan sealing surface.

2. Clean the engine block sealing surface.

3. Clean the oil pan retaining bolts.

4. Clean the oil pan attaching bolt holes in the engine

block.

5. Clean the oil pan scraper.

Page 153 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 33

DAEWOO V–121 BL4

Installation Procedure

1. Coat the new oil pan gasket with sealant.

Important : Install the oil pan within 5 minutes after apply-

ing the liquid gasket to the oil pan.

2. Install the oil pan to the engine block.

3. Install the oil pan retaining bolts.

Tighten

Tighten the oil pan retaining bolts to 10 NSm (89 lb–in).

4. Install the oil pan flange–to–transaxle retaining

bolts.

Tighten

Tighten the oil pan flange–to–transaxle bolts to 40

NSm (30 lb–ft).

5. Install the exhaust flex pipe.

6. Install the exhaust flex pipe retaining nuts to the

exhaust manifold.

Tighten

Tighten the exhaust flex pipe–to–exhaust manifold

retaining nuts to 35 NSm (26 lb–ft).

7. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

8. Connect the negative battery cable.

9. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 35 NSm (26 lb–ft).

10. Refill the engine crankcase with engine oil.

OIL PUMP

Tools Required

KM–498–B Pressure Gauge

KM–135 Adapter

Engine Oil Pressure Inspection Procedure

1. Remove the right front wheel well oil pan scraper.

Refer to Section 9R, Body Front End.

2. Disconnect the oil pressure switch connector.

Page 158 of 2643

1C2 – 38I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

3. Install the timing belt idler pulleys.

4. Install the timing belt idler pulley bolt and nut.

Tighten

Tighten the timing belt idler pulley bolt and nut to 25

NSm (18 lb–ft).

5. Tension the timing belt by turning the timing belt

automatic tensioner hex–key tab counterclockwise

until the pointer is aligned to the indicator.

Tighten

Tighten the timing belt automatic tensioner bolt to 25

NSm (18 lb–ft).

6. Install the front timing belt cover.

7. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

8. Install the engine mount bracket and retaining bolts.

Tighten

Tighten the engine mount bracket retaining bolts to 55

NSm (41 lb–ft).

9. Remove the engine assembly support fixture

J–28467–B, and the channel X–28467–560.

10. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

11. Connect the negative battery cable.

INTAKE MANIFOLD

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the charcoal canister purge (CCP) and

exhaust gas recirculation (EGR) solenoid from the

intake manifold and loosen the bracket bolt.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

6. Disconnect the manifold air temperature sensor

(MAT) connector.

7. Disconnect the air cleaner outlet hose from the

throttle body.

Page 166 of 2643

1C2 – 46I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

7. Install the timing belt automatic tensioner and bolt.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

10. Connect the negative battery cable.

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Discharge the air conditioning (A/C) system, if

equipped. Refer to Section 7B, Manual Control

Heating, Ventilation, and Air Conditioning Systems.

7. Disconnect the manifold air temperature (MAT)

sensor connector.

8. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

9. Disconnect the breather tubes from the camshaft

cover.

10. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

11. Remove the right front wheel well splash shield.

Refer to Section 9R, Body Font End.

12. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

13. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

14. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

15. Disconnect the upper radiator hose from the ther-

mostat housing.

16. Disconnect the power steering return hose from the

power steering pump.

17. Disconnect the power steering pressure hose from

the power steering pump.

18. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal and at the starter

motor.

Page 199 of 2643

1D – 4IENGINE COOLING

DAEWOO V–121 BL4

COOLING SYSTEM DIAGNOSIS

Engine Overheats

ChecksAction

Check for a loss of the coolant.Add the coolant.

Check for a weak coolant solution.Confirm that the coolant solution is a 50/50 mixture of eth-

ylene glycol and water.

Check the front of the radiator for any dirt, any leaves, or

any insects.Clean the front of the radiator.

Check for leakage from the hoses, the coolant pump, the

heater, the thermostat housing, the radiator, the core

plugs, or the head gasket.Replace any damaged components.

Check for a faulty thermostat.Replace a damaged thermostat.

Check for retarded ignition timing.Perform an ECM code diagnosis. Confirm the integrity of

the timing belt.

Check for an improperly operating electric cooling fan.Replace the electric cooling fan.

Check for radiator hoses that are plugged or rotted.Replace any damaged radiator hoses.

Check for a faulty water pump.Replace a faulty water pump.

Check for a faulty surge tank cap.Replace a faulty surge tank cap.

Check for a cylinder head or an engine block that is

cracked or plugged.Repair the damaged cylinder head or the damaged engine

block.

Loss of Coolant

ChecksAction

Check for a leak in the radiator.Replace a damaged radiator.

Check for a leak in the following locations:

S Surge tank.

S Hose.Replace the following parts, as needed:

S Surge tank.

S Hose.

Check for loose or damaged radiator hoses, heater hoses,

and connections.Reseat the hoses.

Replace the hoses or the clamps.

Check for leaks in the coolant pump seal.Replace the coolant pump seal.

Check for leaks in the coolant pump gasket.Replace the coolant pump gasket.

Check for an improper cylinder head torque.Tighten the cylinder head bolts to specifications.

Replace the cylinder head gasket, if needed.

Check for leaks in the following locations:

S Intake manifold.

S Cylinder head gasket.

S Cylinder block plug.

S Heater core.

S Radiator drain plug.Repair or replace any components, as needed, to correct

the leak.

Engine Fails to Reach Normal Operating Temperature or Cool Air

from the Heater

ChecksAction

Check to determine if the thermostat is stuck open or is the

wrong type of thermostat.Install a new thermostat of the correct type and heat range.

Check the coolant level to determine if it is below the MIN

mark on the surge tank.Add sufficient coolant to raise the fluid to the specified

mark on the surge tank.

Page 204 of 2643

ENGINE COOLING 1D – 9

DAEWOO V–121 BL4

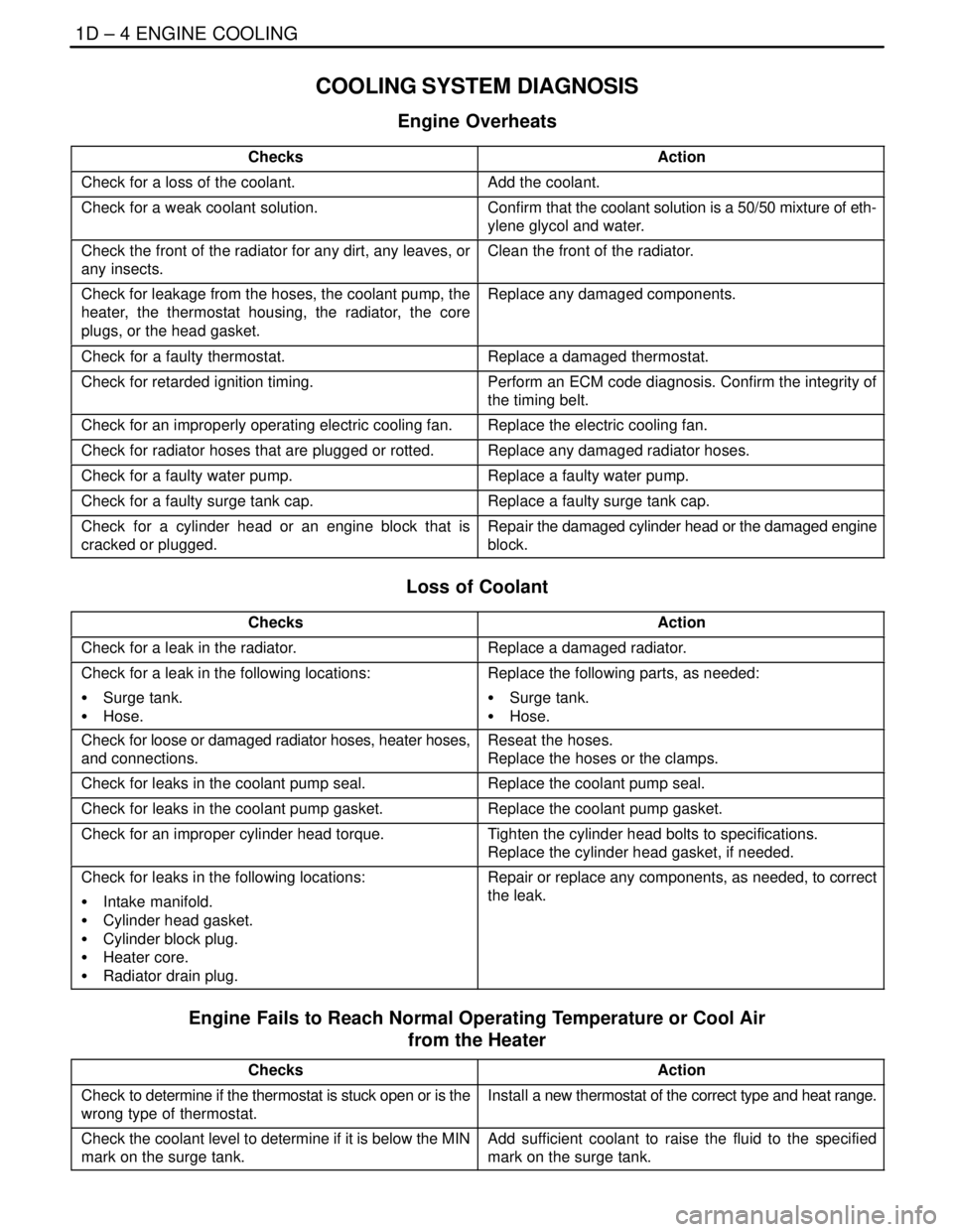

THERMOSTAT (1.4L/1.6L DOHC)

Removal Procedure

CAUTION : To prevent personal injury, do not remove

the surge tank cap while the engine and the radiator

are hot because the heat causes the system to remain

under pressure. Scalding fluid and steam may be

blown out under pressure.

1. Drain the coolant. Refer to ”Draining and Refilling

the Cooling System” in this section.

2. Loosen the hose clamp on the upper radiator hose

at the thermostat housing.

3. Disconnect the upper radiator hose from the ther-

mostat housing.

4. Loosen the clamp on the bypass hose.

5. Disconnect the bypass hose from the thermostat

housing.

6. Remove the mounting bolts that hold the thermo-

stat housing to the cylinder head.

7. Remove the thermostat housing from the head.

8. Remove the O–ring seal from the head.

9. Check the valve seat for foreign matter that could

prevent the valve from seating properly.

10. Check the thermostat for proper operation. Refer to

”Thermostat Test” in this section.

11. Clean the thermostat housing and the cylinder head

mating surfaces.

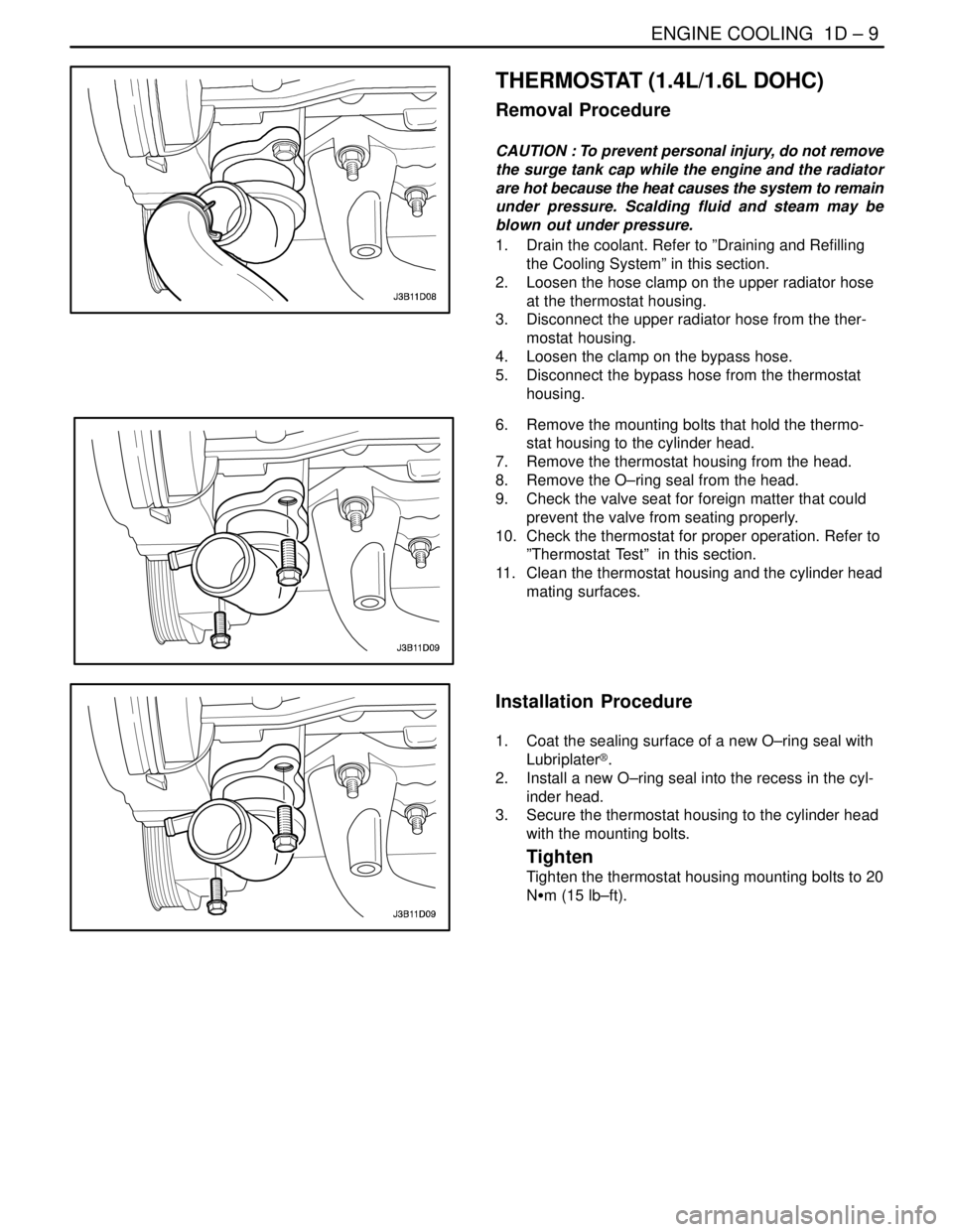

Installation Procedure

1. Coat the sealing surface of a new O–ring seal with

Lubriplater®.

2. Install a new O–ring seal into the recess in the cyl-

inder head.

3. Secure the thermostat housing to the cylinder head

with the mounting bolts.

Tighten

Tighten the thermostat housing mounting bolts to 20

NSm (15 lb–ft).

Page 205 of 2643

1D – 10IENGINE COOLING

DAEWOO V–121 BL4

4. Connect the upper radiator hose to the thermostat

housing.

5. Secure the upper radiator hose to the thermostat

housing with a hose clamp.

6. Connect the bypass hose to the thermostat hous-

ing.

7. Secure the bypass hose with a hose clamp.

8. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

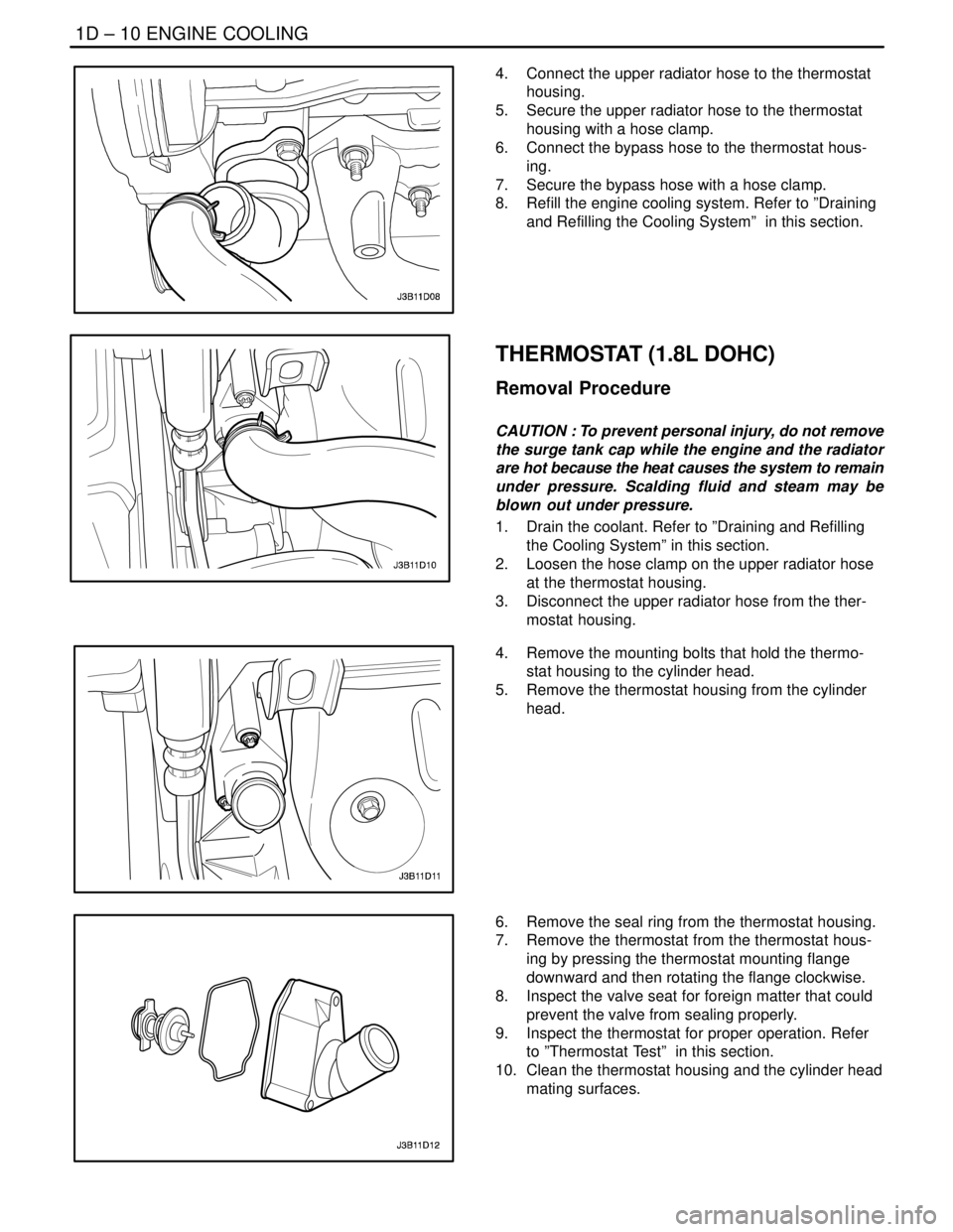

THERMOSTAT (1.8L DOHC)

Removal Procedure

CAUTION : To prevent personal injury, do not remove

the surge tank cap while the engine and the radiator

are hot because the heat causes the system to remain

under pressure. Scalding fluid and steam may be

blown out under pressure.

1. Drain the coolant. Refer to ”Draining and Refilling

the Cooling System” in this section.

2. Loosen the hose clamp on the upper radiator hose

at the thermostat housing.

3. Disconnect the upper radiator hose from the ther-

mostat housing.

4. Remove the mounting bolts that hold the thermo-

stat housing to the cylinder head.

5. Remove the thermostat housing from the cylinder

head.

6. Remove the seal ring from the thermostat housing.

7. Remove the thermostat from the thermostat hous-

ing by pressing the thermostat mounting flange

downward and then rotating the flange clockwise.

8. Inspect the valve seat for foreign matter that could

prevent the valve from sealing properly.

9. Inspect the thermostat for proper operation. Refer

to ”Thermostat Test” in this section.

10. Clean the thermostat housing and the cylinder head

mating surfaces.

Page 206 of 2643

ENGINE COOLING 1D – 11

DAEWOO V–121 BL4

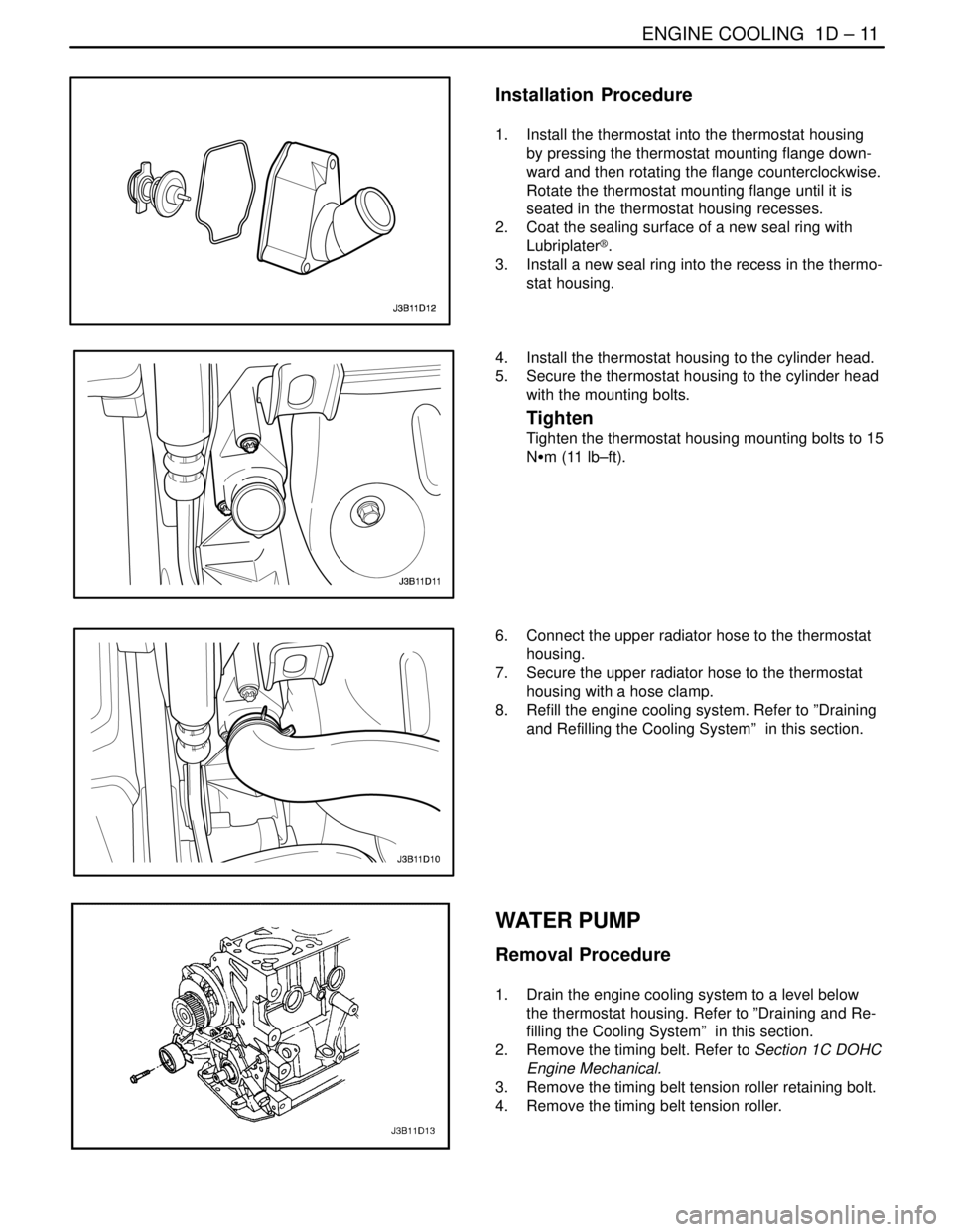

Installation Procedure

1. Install the thermostat into the thermostat housing

by pressing the thermostat mounting flange down-

ward and then rotating the flange counterclockwise.

Rotate the thermostat mounting flange until it is

seated in the thermostat housing recesses.

2. Coat the sealing surface of a new seal ring with

Lubriplater®.

3. Install a new seal ring into the recess in the thermo-

stat housing.

4. Install the thermostat housing to the cylinder head.

5. Secure the thermostat housing to the cylinder head

with the mounting bolts.

Tighten

Tighten the thermostat housing mounting bolts to 15

NSm (11 lb–ft).

6. Connect the upper radiator hose to the thermostat

housing.

7. Secure the upper radiator hose to the thermostat

housing with a hose clamp.

8. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

WATER PUMP

Removal Procedure

1. Drain the engine cooling system to a level below

the thermostat housing. Refer to ”Draining and Re-

filling the Cooling System” in this section.

2. Remove the timing belt. Refer to Section 1C DOHC

Engine Mechanical.

3. Remove the timing belt tension roller retaining bolt.

4. Remove the timing belt tension roller.

Page 207 of 2643

1D – 12IENGINE COOLING

DAEWOO V–121 BL4

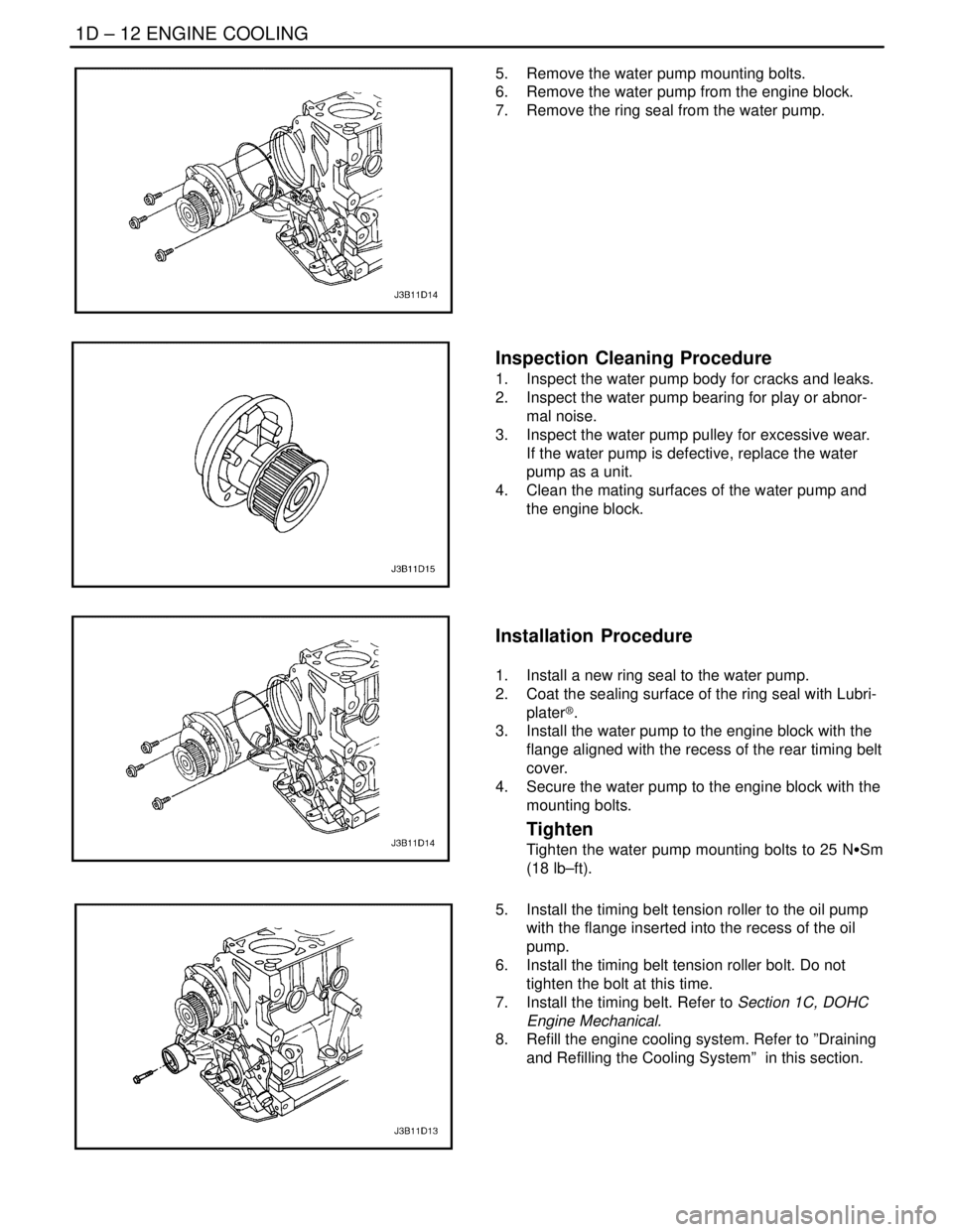

5. Remove the water pump mounting bolts.

6. Remove the water pump from the engine block.

7. Remove the ring seal from the water pump.

Inspection Cleaning Procedure

1. Inspect the water pump body for cracks and leaks.

2. Inspect the water pump bearing for play or abnor-

mal noise.

3. Inspect the water pump pulley for excessive wear.

If the water pump is defective, replace the water

pump as a unit.

4. Clean the mating surfaces of the water pump and

the engine block.

Installation Procedure

1. Install a new ring seal to the water pump.

2. Coat the sealing surface of the ring seal with Lubri-

plater®.

3. Install the water pump to the engine block with the

flange aligned with the recess of the rear timing belt

cover.

4. Secure the water pump to the engine block with the

mounting bolts.

Tighten

Tighten the water pump mounting bolts to 25 NSSm

(18 lb–ft).

5. Install the timing belt tension roller to the oil pump

with the flange inserted into the recess of the oil

pump.

6. Install the timing belt tension roller bolt. Do not

tighten the bolt at this time.

7. Install the timing belt. Refer to Section 1C, DOHC

Engine Mechanical.

8. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

Page 209 of 2643

1D – 14IENGINE COOLING

DAEWOO V–121 BL4

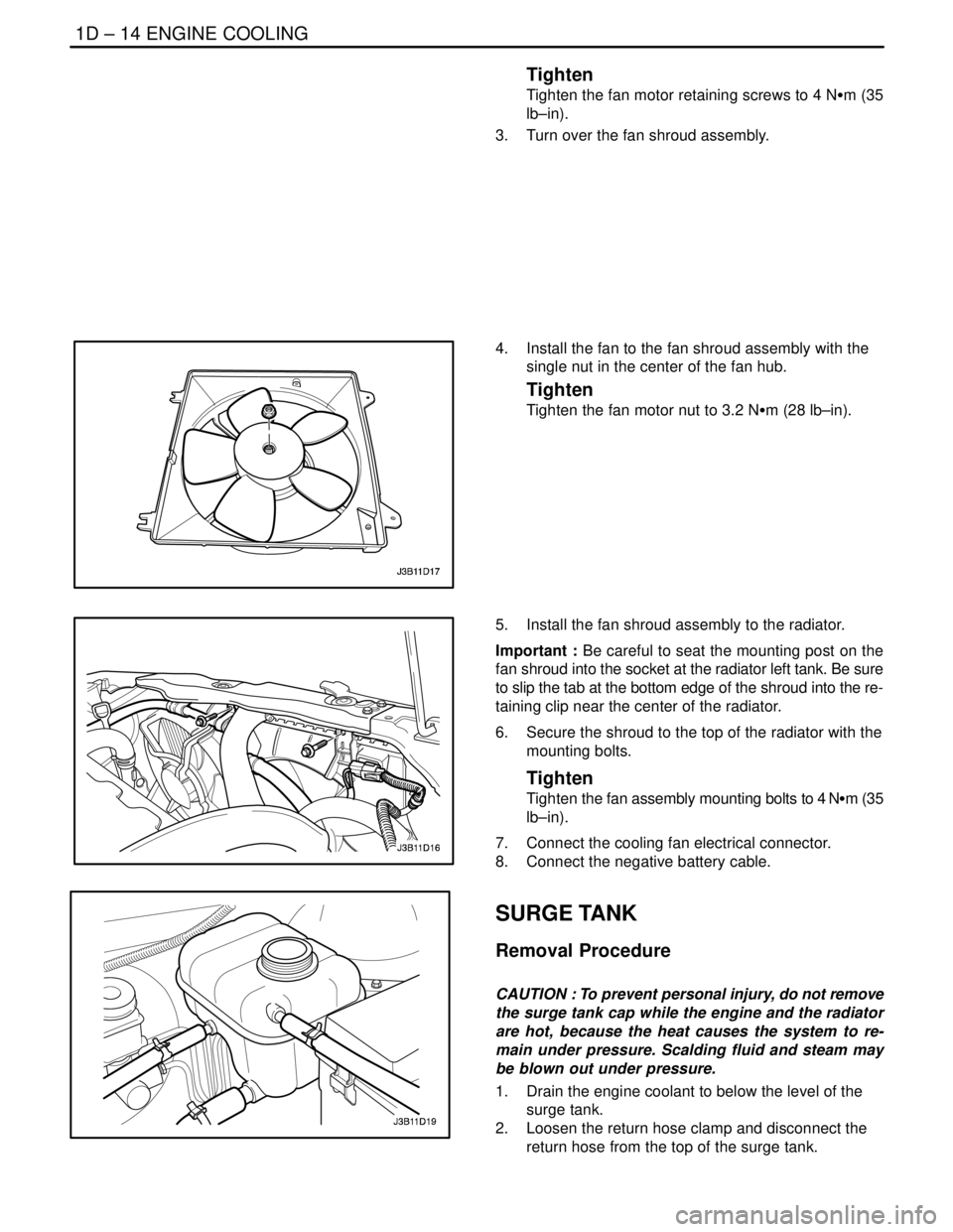

Tighten

Tighten the fan motor retaining screws to 4 NSm (35

lb–in).

3. Turn over the fan shroud assembly.

4. Install the fan to the fan shroud assembly with the

single nut in the center of the fan hub.

Tighten

Tighten the fan motor nut to 3.2 NSm (28 lb–in).

5. Install the fan shroud assembly to the radiator.

Important : Be careful to seat the mounting post on the

fan shroud into the socket at the radiator left tank. Be sure

to slip the tab at the bottom edge of the shroud into the re-

taining clip near the center of the radiator.

6. Secure the shroud to the top of the radiator with the

mounting bolts.

Tighten

Tighten the fan assembly mounting bolts to 4 NSm (35

lb–in).

7. Connect the cooling fan electrical connector.

8. Connect the negative battery cable.

SURGE TANK

Removal Procedure

CAUTION : To prevent personal injury, do not remove

the surge tank cap while the engine and the radiator

are hot, because the heat causes the system to re-

main under pressure. Scalding fluid and steam may

be blown out under pressure.

1. Drain the engine coolant to below the level of the

surge tank.

2. Loosen the return hose clamp and disconnect the

return hose from the top of the surge tank.