fuel type DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 590 of 2643

1F – 344IENGINE CONTROLS

DAEWOO V–121 BL4

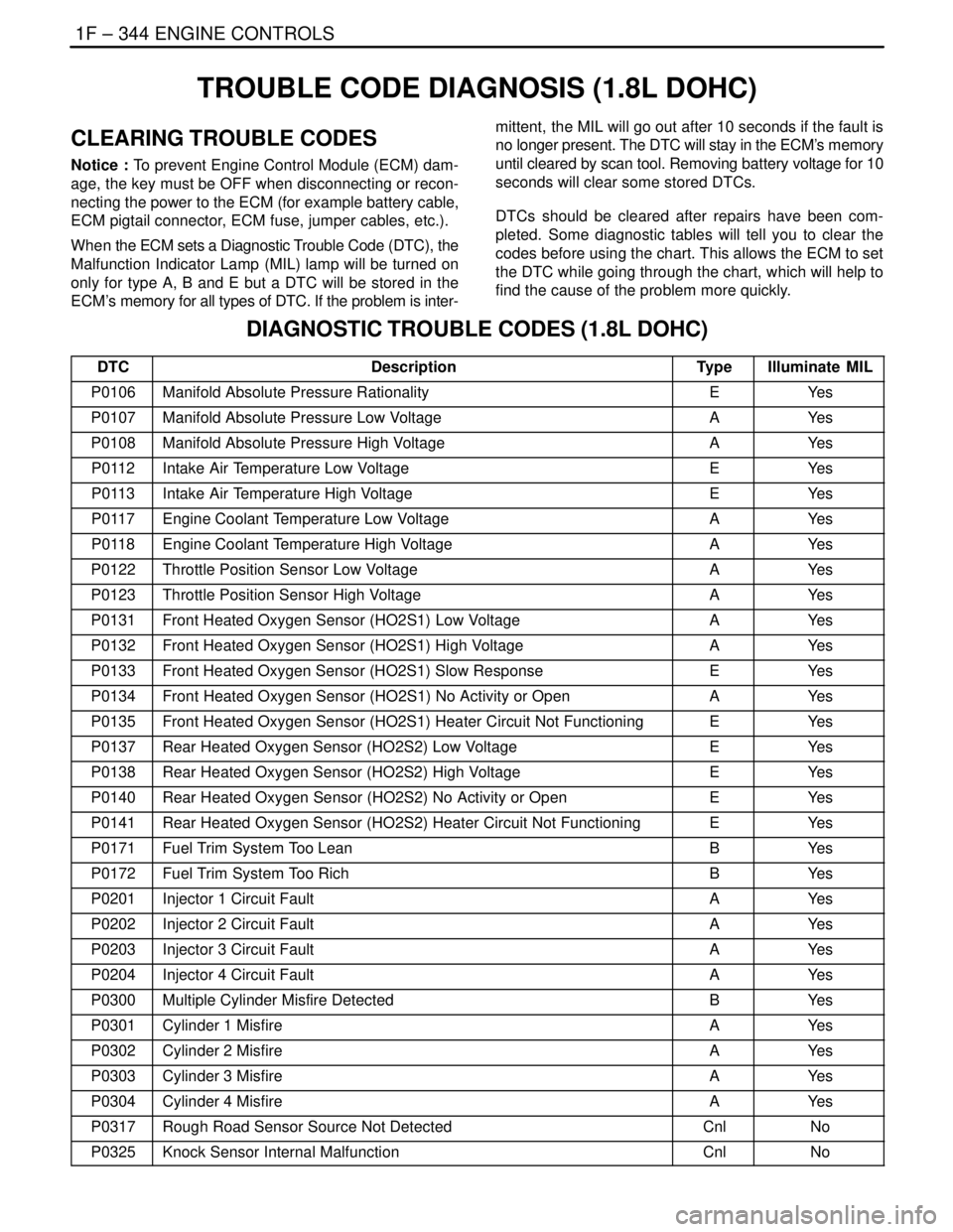

TROUBLE CODE DIAGNOSIS (1.8L DOHC)

CLEARING TROUBLE CODES

Notice : To prevent Engine Control Module (ECM) dam-

age, the key must be OFF when disconnecting or recon-

necting the power to the ECM (for example battery cable,

ECM pigtail connector, ECM fuse, jumper cables, etc.).

When the ECM sets a Diagnostic Trouble Code (DTC), the

Malfunction Indicator Lamp (MIL) lamp will be turned on

only for type A, B and E but a DTC will be stored in the

ECM’s memory for all types of DTC. If the problem is inter-mittent, the MIL will go out after 10 seconds if the fault is

no longer present. The DTC will stay in the ECM’s memory

until cleared by scan tool. Removing battery voltage for 10

seconds will clear some stored DTCs.

DTCs should be cleared after repairs have been com-

pleted. Some diagnostic tables will tell you to clear the

codes before using the chart. This allows the ECM to set

the DTC while going through the chart, which will help to

find the cause of the problem more quickly.

DIAGNOSTIC TROUBLE CODES (1.8L DOHC)

DTCDescriptionTypeIlluminate MIL

P0106Manifold Absolute Pressure RationalityEYe s

P0107Manifold Absolute Pressure Low VoltageAYe s

P0108Manifold Absolute Pressure High VoltageAYe s

P0112Intake Air Temperature Low VoltageEYe s

P0113Intake Air Temperature High VoltageEYe s

P0117Engine Coolant Temperature Low VoltageAYe s

P0118Engine Coolant Temperature High VoltageAYe s

P0122Throttle Position Sensor Low VoltageAYe s

P0123Throttle Position Sensor High VoltageAYe s

P0131Front Heated Oxygen Sensor (HO2S1) Low VoltageAYe s

P0132Front Heated Oxygen Sensor (HO2S1) High VoltageAYe s

P0133Front Heated Oxygen Sensor (HO2S1) Slow ResponseEYe s

P0134Front Heated Oxygen Sensor (HO2S1) No Activity or OpenAYe s

P0135Front Heated Oxygen Sensor (HO2S1) Heater Circuit Not FunctioningEYe s

P0137Rear Heated Oxygen Sensor (HO2S2) Low VoltageEYe s

P0138Rear Heated Oxygen Sensor (HO2S2) High VoltageEYe s

P0140Rear Heated Oxygen Sensor (HO2S2) No Activity or OpenEYe s

P0141Rear Heated Oxygen Sensor (HO2S2) Heater Circuit Not FunctioningEYe s

P0171Fuel Trim System Too LeanBYe s

P0172Fuel Trim System Too RichBYe s

P0201Injector 1 Circuit FaultAYe s

P0202Injector 2 Circuit FaultAYe s

P0203Injector 3 Circuit FaultAYe s

P0204Injector 4 Circuit FaultAYe s

P0300Multiple Cylinder Misfire DetectedBYe s

P0301Cylinder 1 MisfireAYe s

P0302Cylinder 2 MisfireAYe s

P0303Cylinder 3 MisfireAYe s

P0304Cylinder 4 MisfireAYe s

P0317Rough Road Sensor Source Not DetectedCnlNo

P0325Knock Sensor Internal MalfunctionCnlNo

Page 591 of 2643

ENGINE CONTROLS 1F – 345

DAEWOO V–121 BL4

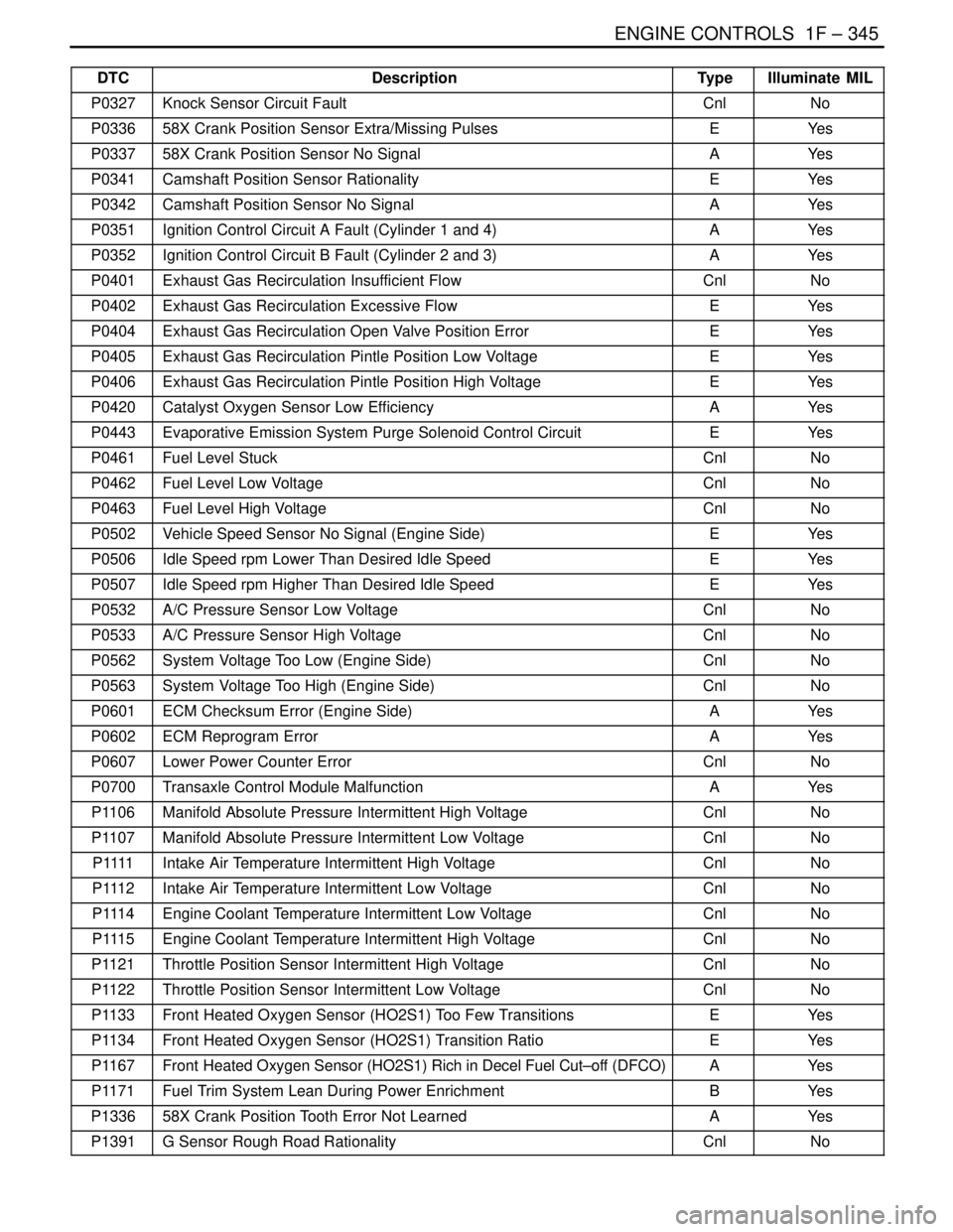

DTCIlluminate MIL Type Description

P0327Knock Sensor Circuit FaultCnlNo

P033658X Crank Position Sensor Extra/Missing PulsesEYe s

P033758X Crank Position Sensor No SignalAYe s

P0341Camshaft Position Sensor RationalityEYe s

P0342Camshaft Position Sensor No SignalAYe s

P0351Ignition Control Circuit A Fault (Cylinder 1 and 4)AYe s

P0352Ignition Control Circuit B Fault (Cylinder 2 and 3)AYe s

P0401Exhaust Gas Recirculation Insufficient FlowCnlNo

P0402Exhaust Gas Recirculation Excessive FlowEYe s

P0404Exhaust Gas Recirculation Open Valve Position ErrorEYe s

P0405Exhaust Gas Recirculation Pintle Position Low VoltageEYe s

P0406Exhaust Gas Recirculation Pintle Position High VoltageEYe s

P0420Catalyst Oxygen Sensor Low EfficiencyAYe s

P0443Evaporative Emission System Purge Solenoid Control CircuitEYe s

P0461Fuel Level StuckCnlNo

P0462Fuel Level Low VoltageCnlNo

P0463Fuel Level High VoltageCnlNo

P0502Vehicle Speed Sensor No Signal (Engine Side)EYe s

P0506Idle Speed rpm Lower Than Desired Idle SpeedEYe s

P0507Idle Speed rpm Higher Than Desired Idle SpeedEYe s

P0532A/C Pressure Sensor Low VoltageCnlNo

P0533A/C Pressure Sensor High VoltageCnlNo

P0562System Voltage Too Low (Engine Side)CnlNo

P0563System Voltage Too High (Engine Side)CnlNo

P0601ECM Checksum Error (Engine Side)AYe s

P0602ECM Reprogram ErrorAYe s

P0607Lower Power Counter ErrorCnlNo

P0700Transaxle Control Module MalfunctionAYe s

P1106Manifold Absolute Pressure Intermittent High VoltageCnlNo

P1107Manifold Absolute Pressure Intermittent Low VoltageCnlNo

P 1111Intake Air Temperature Intermittent High VoltageCnlNo

P1112Intake Air Temperature Intermittent Low VoltageCnlNo

P1114Engine Coolant Temperature Intermittent Low VoltageCnlNo

P1115Engine Coolant Temperature Intermittent High VoltageCnlNo

P1121Throttle Position Sensor Intermittent High VoltageCnlNo

P1122Throttle Position Sensor Intermittent Low VoltageCnlNo

P1133Front Heated Oxygen Sensor (HO2S1) Too Few TransitionsEYe s

P1134Front Heated Oxygen Sensor (HO2S1) Transition RatioEYe s

P1167Front Heated Oxygen Sensor (HO2S1) Rich in Decel Fuel Cut–off (DFCO)AYe s

P1171Fuel Trim System Lean During Power EnrichmentBYe s

P133658X Crank Position Tooth Error Not LearnedAYe s

P1391G Sensor Rough Road RationalityCnlNo

Page 667 of 2643

ENGINE CONTROLS 1F – 421

DAEWOO V–121 BL4

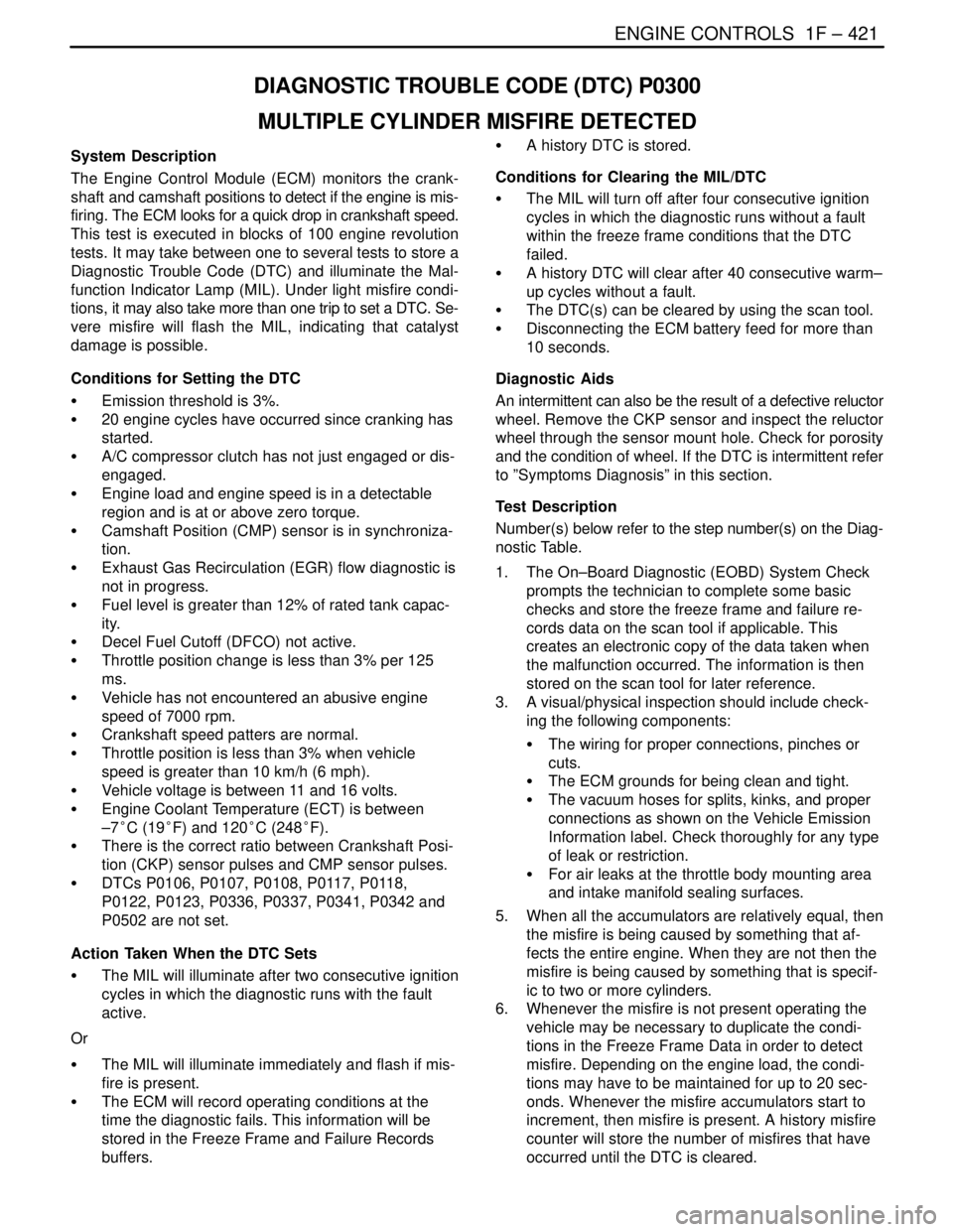

DIAGNOSTIC TROUBLE CODE (DTC) P0300

MULTIPLE CYLINDER MISFIRE DETECTED

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 672 of 2643

1F – 426IENGINE CONTROLS

DAEWOO V–121 BL4

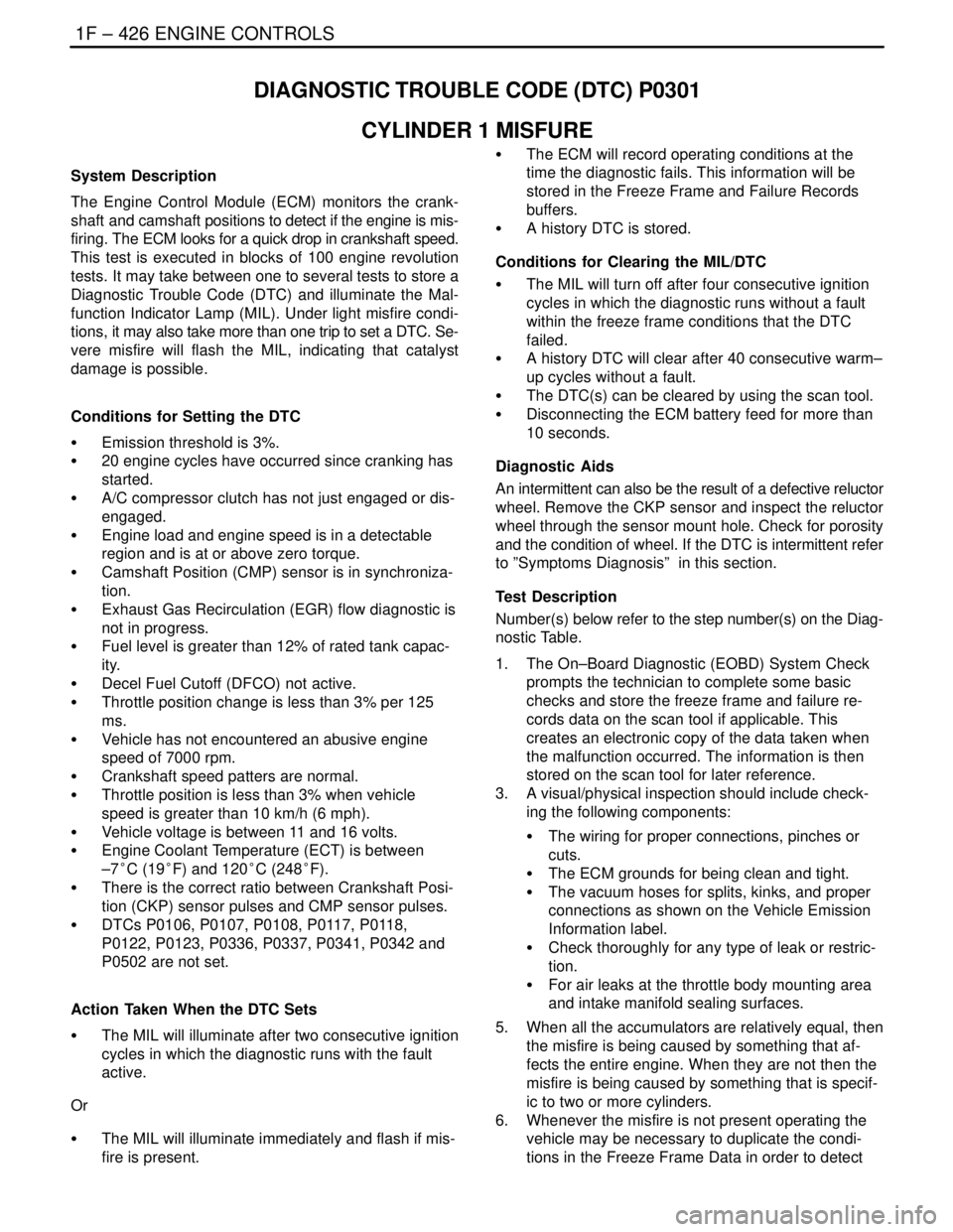

DIAGNOSTIC TROUBLE CODE (DTC) P0301

CYLINDER 1 MISFURE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to ”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label.

S Check thoroughly for any type of leak or restric-

tion.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

Page 677 of 2643

ENGINE CONTROLS 1F – 431

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0302

CYLINDER 2 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 682 of 2643

1F – 436IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0303

CYLINDER 3 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 687 of 2643

ENGINE CONTROLS 1F – 441

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0304

CYLINDER 4 MISFIRE

System Description

The Engine Control Module (ECM) monitors the crank-

shaft and camshaft positions to detect if the engine is mis-

firing. The ECM looks for a quick drop in crankshaft speed.

This test is executed in blocks of 100 engine revolution

tests. It may take between one to several tests to store a

Diagnostic Trouble Code (DTC) and illuminate the Mal-

function Indicator Lamp (MIL). Under light misfire condi-

tions, it may also take more than one trip to set a DTC. Se-

vere misfire will flash the MIL, indicating that catalyst

damage is possible.

Conditions for Setting the DTC

S Emission threshold is 3%.

S 20 engine cycles have occurred since cranking has

started.

S A/C compressor clutch has not just engaged or dis-

engaged.

S Engine load and engine speed is in a detectable

region and is at or above zero torque.

S Camshaft Position (CMP) sensor is in synchroniza-

tion.

S Exhaust Gas Recirculation (EGR) flow diagnostic is

not in progress.

S Fuel level is greater than 12% of rated tank capac-

ity.

S Decel Fuel Cutoff (DFCO) not active.

S Throttle position change is less than 3% per 125

ms.

S Vehicle has not encountered an abusive engine

speed of 7000 rpm.

S Crankshaft speed patters are normal.

S Throttle position is less than 3% when vehicle

speed is greater than 10 km/h (6 mph).

S Vehicle voltage is between 11 and 16 volts.

S Engine Coolant Temperature (ECT) is between

–7°C (19°F) and 120°C (248°F).

S There is the correct ratio between Crankshaft Posi-

tion (CKP) sensor pulses and CMP sensor pulses.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0336, P0337, P0341, P0342 and

P0502 are not set.

Action Taken When the DTC Sets

S The MIL will illuminate after two consecutive ignition

cycles in which the diagnostic runs with the fault

active.

Or

S The MIL will illuminate immediately and flash if mis-

fire is present.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault

within the freeze frame conditions that the DTC

failed.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent can also be the result of a defective reluctor

wheel. Remove the CKP sensor and inspect the reluctor

wheel through the sensor mount hole. Check for porosity

and the condition of wheel. If the DTC is intermittent refer

to”Symptoms Diagnosis” in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. A visual/physical inspection should include check-

ing the following components:

S The wiring for proper connections, pinches or

cuts.

S The ECM grounds for being clean and tight.

S The vacuum hoses for splits, kinks, and proper

connections as shown on the Vehicle Emission

Information label. Check thoroughly for any type

of leak or restriction.

S For air leaks at the throttle body mounting area

and intake manifold sealing surfaces.

5. When all the accumulators are relatively equal, then

the misfire is being caused by something that af-

fects the entire engine. When they are not then the

misfire is being caused by something that is specif-

ic to two or more cylinders.

6. Whenever the misfire is not present operating the

vehicle may be necessary to duplicate the condi-

tions in the Freeze Frame Data in order to detect

misfire. Depending on the engine load, the condi-

tions may have to be maintained for up to 20 sec-

onds. Whenever the misfire accumulators start to

increment, then misfire is present. A history misfire

counter will store the number of misfires that have

occurred until the DTC is cleared.

Page 844 of 2643

1F – 598IENGINE CONTROLS

DAEWOO V–121 BL4

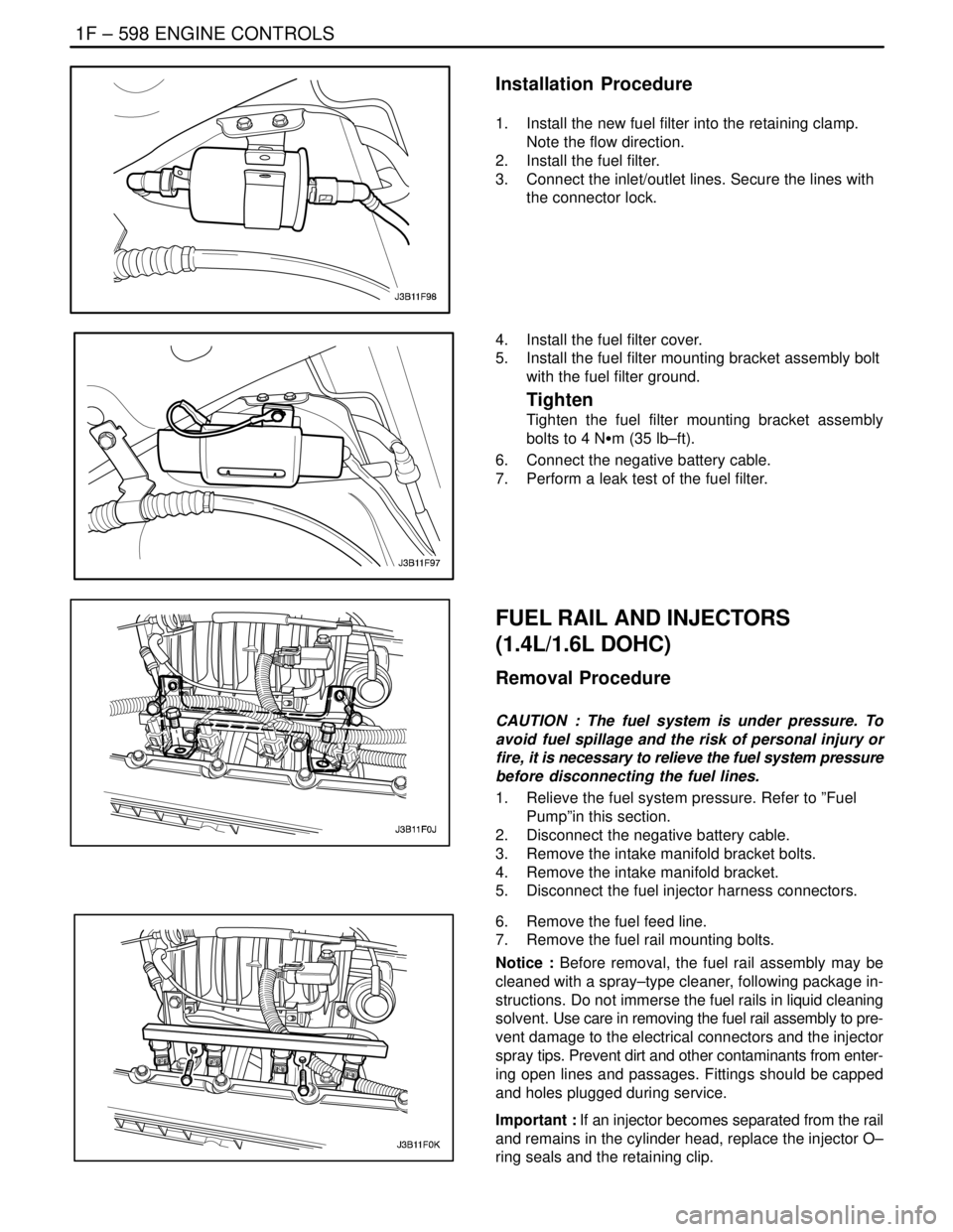

Installation Procedure

1. Install the new fuel filter into the retaining clamp.

Note the flow direction.

2. Install the fuel filter.

3. Connect the inlet/outlet lines. Secure the lines with

the connector lock.

4. Install the fuel filter cover.

5. Install the fuel filter mounting bracket assembly bolt

with the fuel filter ground.

Tighten

Tighten the fuel filter mounting bracket assembly

bolts to 4 NSm (35 lb–ft).

6. Connect the negative battery cable.

7. Perform a leak test of the fuel filter.

FUEL RAIL AND INJECTORS

(1.4L/1.6L DOHC)

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel system pressure. Refer to ”Fuel

Pump”in this section.

2. Disconnect the negative battery cable.

3. Remove the intake manifold bracket bolts.

4. Remove the intake manifold bracket.

5. Disconnect the fuel injector harness connectors.

6. Remove the fuel feed line.

7. Remove the fuel rail mounting bolts.

Notice : Before removal, the fuel rail assembly may be

cleaned with a spray–type cleaner, following package in-

structions. Do not immerse the fuel rails in liquid cleaning

solvent. Use care in removing the fuel rail assembly to pre-

vent damage to the electrical connectors and the injector

spray tips. Prevent dirt and other contaminants from enter-

ing open lines and passages. Fittings should be capped

and holes plugged during service.

Important : If an injector becomes separated from the rail

and remains in the cylinder head, replace the injector O–

ring seals and the retaining clip.

Page 847 of 2643

ENGINE CONTROLS 1F – 601

DAEWOO V–121 BL4

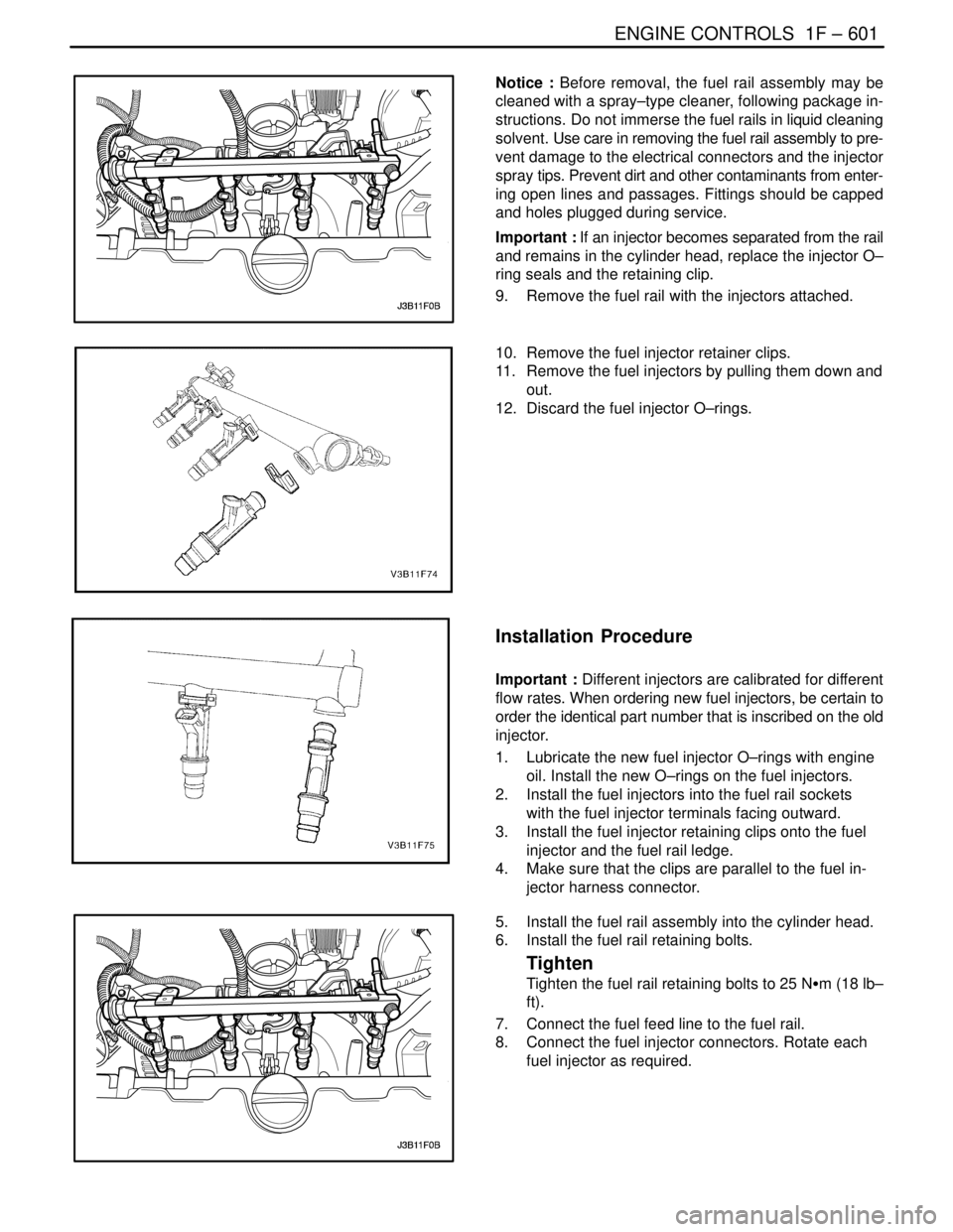

Notice : Before removal, the fuel rail assembly may be

cleaned with a spray–type cleaner, following package in-

structions. Do not immerse the fuel rails in liquid cleaning

solvent. Use care in removing the fuel rail assembly to pre-

vent damage to the electrical connectors and the injector

spray tips. Prevent dirt and other contaminants from enter-

ing open lines and passages. Fittings should be capped

and holes plugged during service.

Important : If an injector becomes separated from the rail

and remains in the cylinder head, replace the injector O–

ring seals and the retaining clip.

9. Remove the fuel rail with the injectors attached.

10. Remove the fuel injector retainer clips.

11. Remove the fuel injectors by pulling them down and

out.

12. Discard the fuel injector O–rings.

Installation Procedure

Important : Different injectors are calibrated for different

flow rates. When ordering new fuel injectors, be certain to

order the identical part number that is inscribed on the old

injector.

1. Lubricate the new fuel injector O–rings with engine

oil. Install the new O–rings on the fuel injectors.

2. Install the fuel injectors into the fuel rail sockets

with the fuel injector terminals facing outward.

3. Install the fuel injector retaining clips onto the fuel

injector and the fuel rail ledge.

4. Make sure that the clips are parallel to the fuel in-

jector harness connector.

5. Install the fuel rail assembly into the cylinder head.

6. Install the fuel rail retaining bolts.

Tighten

Tighten the fuel rail retaining bolts to 25 NSm (18 lb–

ft).

7. Connect the fuel feed line to the fuel rail.

8. Connect the fuel injector connectors. Rotate each

fuel injector as required.

Page 869 of 2643

ENGINE CONTROLS 1F – 623

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distribu-

tor and coil. It uses a crankshaft position sensor input to

the engine control module (ECM). The ECM then deter-

mines Electronic Spark Timing (EST) and triggers the di-

rect ignition system ignition coil.

This type of distributorless ignition system uses a ”waste

spark” method of spark distribution. Each cylinder is

paired with the cylinder that is opposite it (1–4 or 2–3). The

spark occurs simultaneously in the cylinder coming up on

the compression stroke and in the cylinder coming up on

the exhaust stroke. The cylinder on the exhaust stroke re-

quires very little of the available energy to fire the spark

plug. The remaining energy is available to the spark plug

in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to con-

trol the electronic spark timing. The ECM uses the follow-

ing information:

S Engine load (manifold pressure or vacuum).

S Atmospheric (barometric) pressure.

S Engine temperature.

S Intake air temperature.

S Crankshaft position.

S Engine speed (rpm).

ELECTRONIC IGNITION SYSTEM

IGNITION COIL

The Electronic Ignition (EI) system ignition coil provides

the spark for two spark plugs simultaneously. The EI sys-

tem ignition coil is not serviceable and must be replaced

as an assembly.

CRANKSHAFT POSITION SENSOR

This direct ignition system uses a magnetic crankshaft

position sensor. This sensor protrudes through its mount

to within approximately 0.05 inch (1.3 mm) of the crank-

shaft reluctor. The reluctor is a special wheel attached to

the crankshaft or crankshaft pulley with 58 slots machined

into it, 57 of which are equally spaced in 6 degree intervals.

The last slot is wider and serves to generate a ”sync

pulse.” As the crankshaft rotates, the slots in the reluctor

change the magnetic field of the sensor, creating an in-

duced voltage pulse. The longer pulse of the 58th slot

identifies a specific orientation of the crankshaft and al-

lows the engine control module (ECM) to determine the

crankshaft orientation at all times. The ECM uses this in-

formation to generate timed ignition and injection pulses

that it sends to the ignition coils and to the fuel injectors.

CAMAHAFT POSITION SENSOR

The Camshaft Position (CMP) sensor sends a CMP sen-

sor signal to the engine control module (ECM). The ECM

uses this signal as a ”sync pulse” to trigger the injectors in

the proper sequence. The ECM uses the CMP sensor sig-

nal to indicate the position of the #1 piston during its power

stroke. This allows the ECM to calculate true sequential

fuel injection mode of operation. If the ECM detects an in-

correct CMP sensor signal while the engine is running,

DTC P0341 will set. If the CMP sensor signal is lost while

the engine is running, the fuel injection system will shift to

a calculated sequential fuel injection mode based on the

last fuel injection pulse, and the engine will continue to run.

As long as the fault is present, the engine can be restarted.

It will run in the calculated sequential mode with a 1–in–6

chance of the injector sequence being correct.

IDLE AIR SYSTEM OPERATION

The idle air system operation is controlled by the base idle

setting of the throttle body and the Idle Air Control (IAC)

valve.

The engine control module (ECM) uses the IAC valve to

set the idle speed dependent on conditions. The ECM

uses information from various inputs, such as coolant tem-

perature, manifold vacuum, etc., for the effective control

of the idle speed.

FUEL CONTROL SYSTEM

OPERATION

The function of the fuel metering system is to deliver the

correct amount of fuel to the engine under all operating

conditions. The fuel is delivered to the engine by the indi-

vidual fuel injectors mounted into the intake manifold near

each cylinder.

The two main fuel control sensors are the Manifold Abso-

lute Pressure (MAP) sensor, the Front Heated Oxygen

Sensor (HO2S1) and the Rear Heated Oxygen Sensor

(HO2S2).

The MAP sensor measures or senses the intake manifold

vacuum. Under high fuel demands the MAP sensor reads

a low vacuum condition, such as wide open throttle. The

engine control module (ECM) uses this information to ri-

chen the mixture, thus increasing the fuel injector on–time,

to provide the correct amount of fuel. When decelerating,

the vacuum increases. This vacuum change is sensed by

the MAP sensor and read by the ECM, which then de-

creases the fuel injector on–time due to the low fuel de-

mand conditions.

HO2S Sensors

The HO2S sensor is located in the exhaust manifold. The

HO2S sensor indicates to the ECM the amount of oxygen

in the exhaust gas and the ECM changes the air/fuel ratio

to the engine by controlling the fuel injectors. The best air/

fuel ratio to minimize exhaust emissions is 14.7 to 1, which

allows the catalytic converter to operate most efficiently.