ground DAEWOO LACETTI 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 98 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 55

DAEWOO V–121 BL4

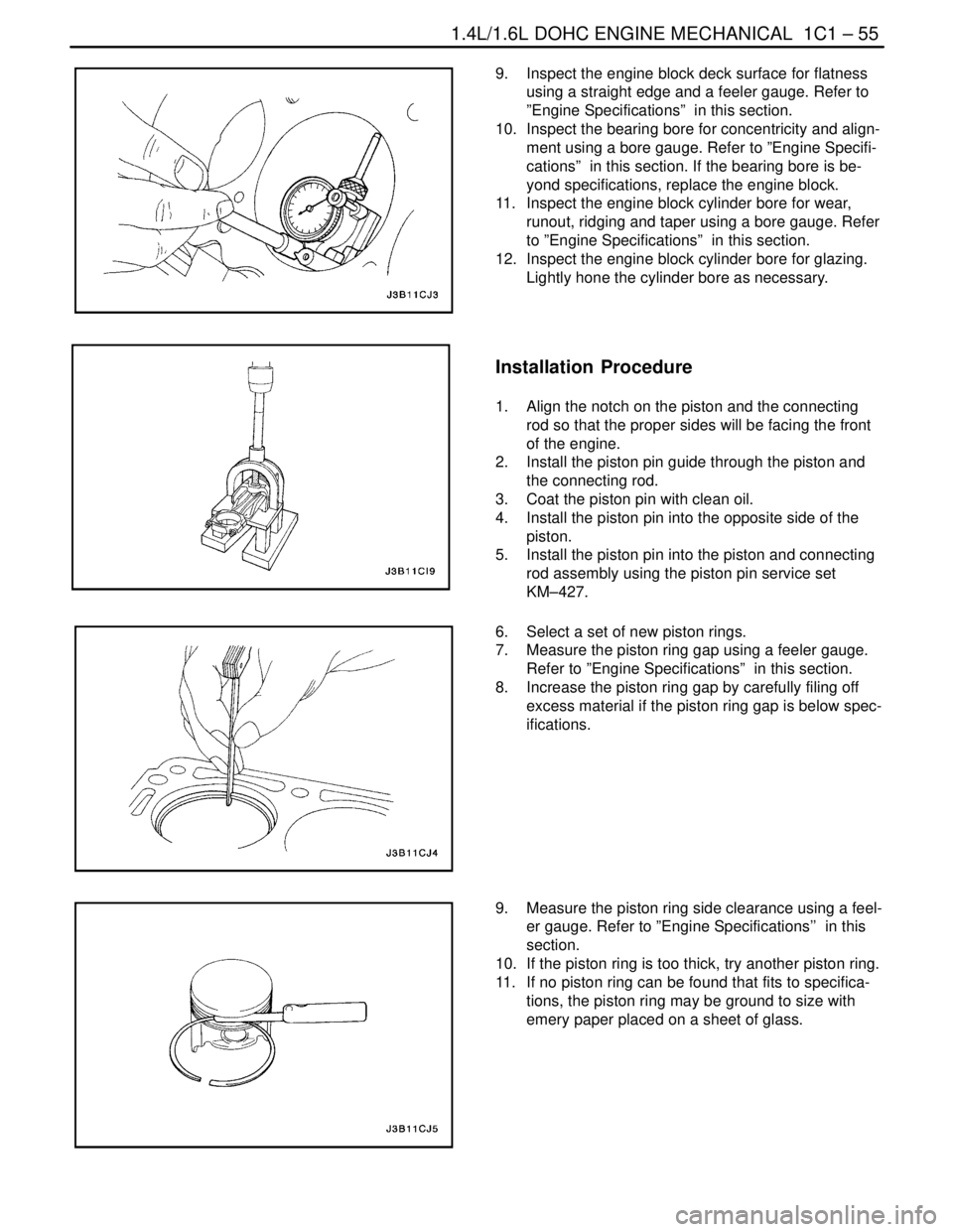

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using a bore gauge. Refer to ”Engine Specifi-

cations” in this section. If the bearing bore is be-

yond specifications, replace the engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

1. Align the notch on the piston and the connecting

rod so that the proper sides will be facing the front

of the engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

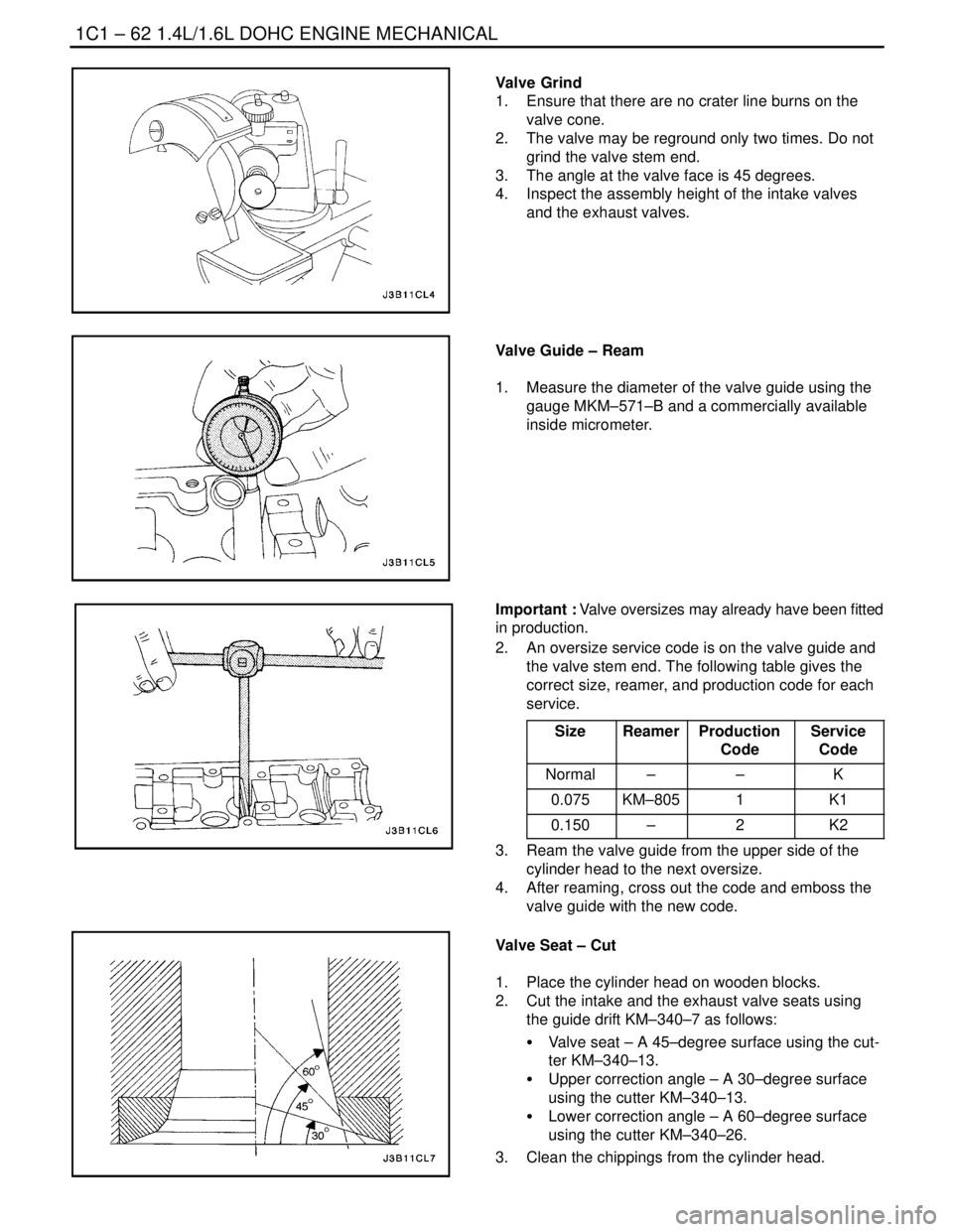

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

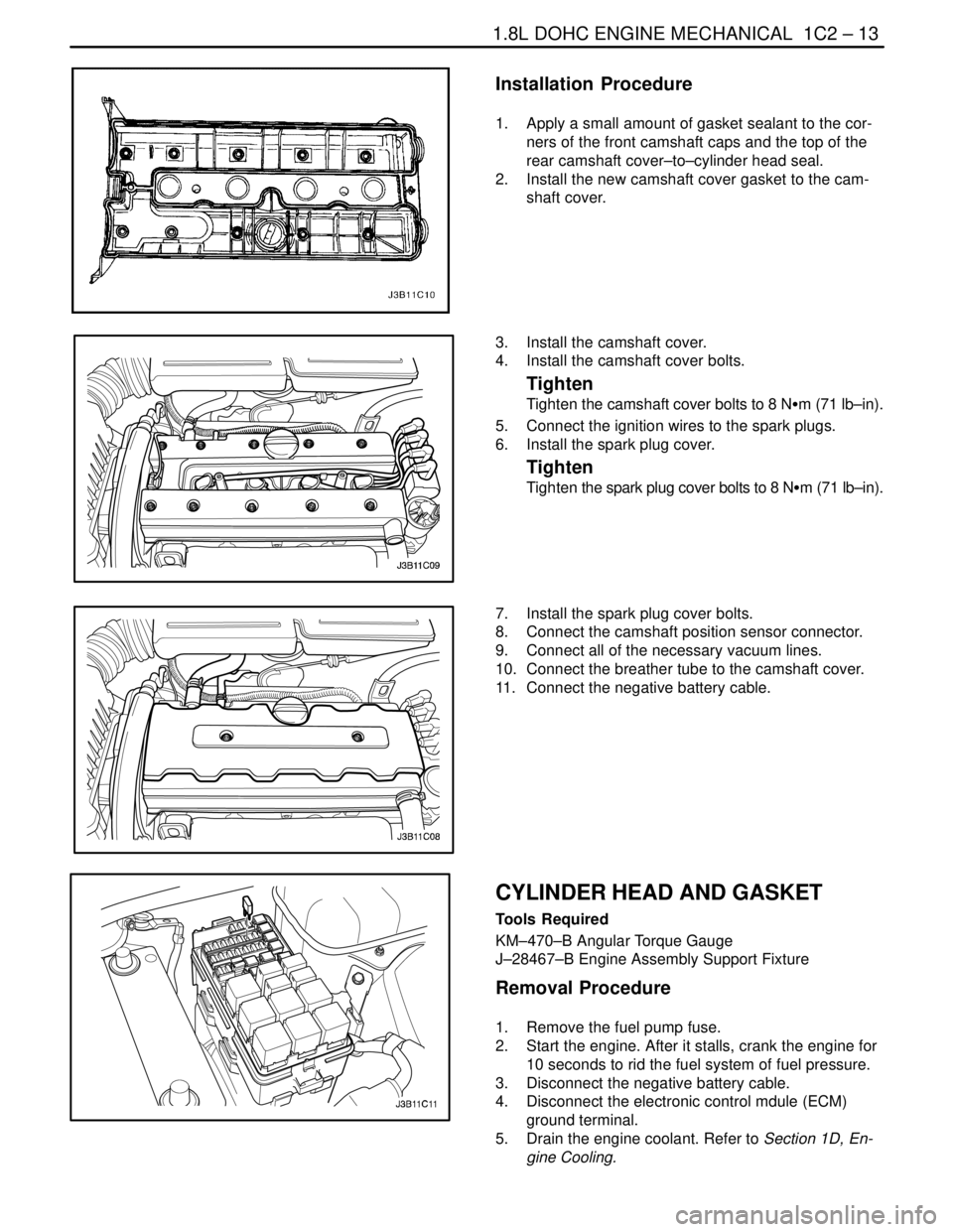

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.

9. Measure the piston ring side clearance using a feel-

er gauge. Refer to ”Engine Specifications’’ in this

section.

10. If the piston ring is too thick, try another piston ring.

11. If no piston ring can be found that fits to specifica-

tions, the piston ring may be ground to size with

emery paper placed on a sheet of glass.

Page 105 of 2643

1C1 – 62I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

Valve Grind

1. Ensure that there are no crater line burns on the

valve cone.

2. The valve may be reground only two times. Do not

grind the valve stem end.

3. The angle at the valve face is 45 degrees.

4. Inspect the assembly height of the intake valves

and the exhaust valves.

Valve Guide – Ream

1. Measure the diameter of the valve guide using the

gauge MKM–571–B and a commercially available

inside micrometer.

Important : Valve oversizes may already have been fitted

in production.

2. An oversize service code is on the valve guide and

the valve stem end. The following table gives the

correct size, reamer, and production code for each

service.

Size

ReamerProduction

CodeService

Code

Normal––K

0.075KM–8051K1

0.150–2K2

3. Ream the valve guide from the upper side of the

cylinder head to the next oversize.

4. After reaming, cross out the code and emboss the

valve guide with the new code.

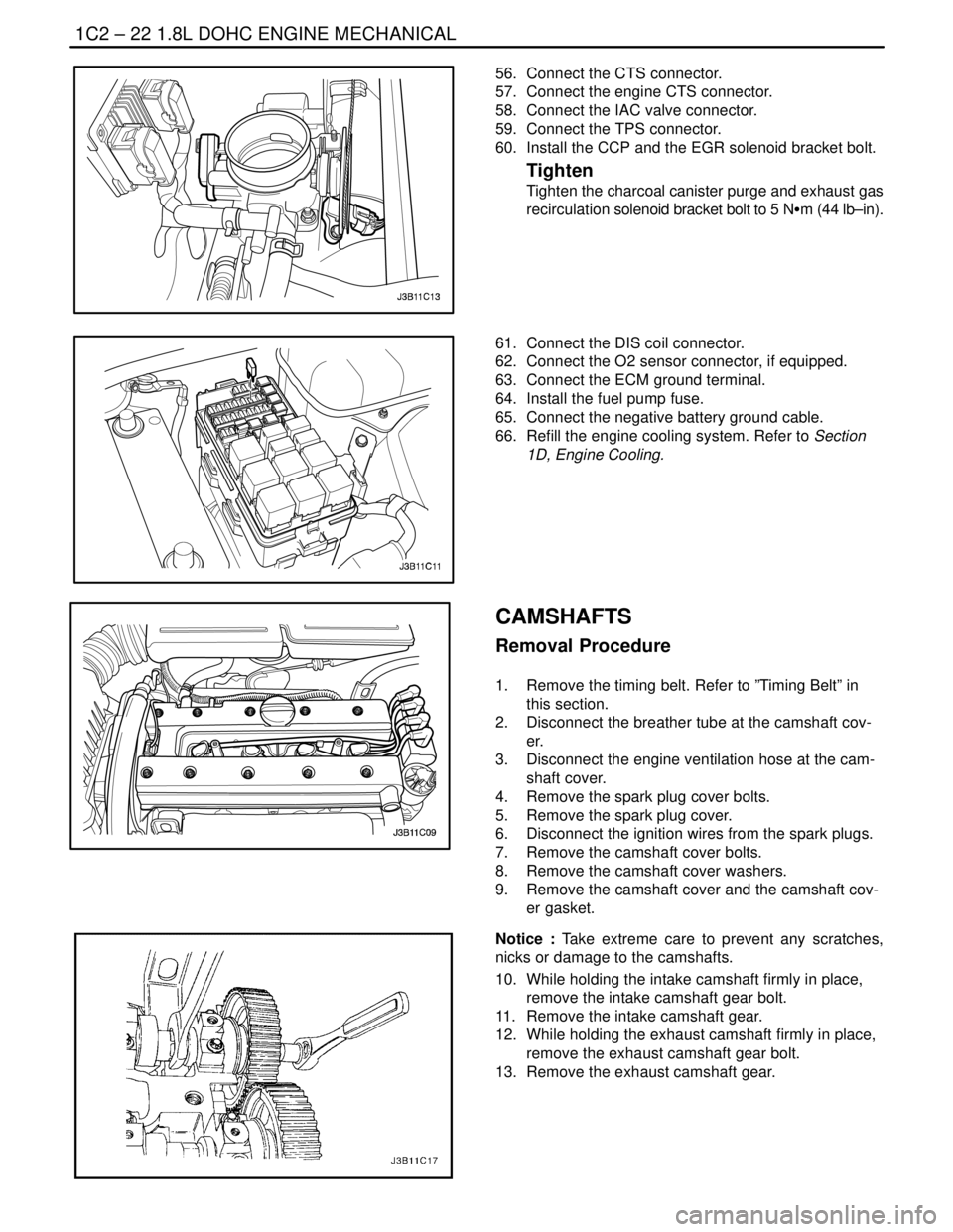

Valve Seat – Cut

1. Place the cylinder head on wooden blocks.

2. Cut the intake and the exhaust valve seats using

the guide drift KM–340–7 as follows:

S Valve seat – A 45–degree surface using the cut-

ter KM–340–13.

S Upper correction angle – A 30–degree surface

using the cutter KM–340–13.

S Lower correction angle – A 60–degree surface

using the cutter KM–340–26.

3. Clean the chippings from the cylinder head.

Page 133 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 13

DAEWOO V–121 BL4

Installation Procedure

1. Apply a small amount of gasket sealant to the cor-

ners of the front camshaft caps and the top of the

rear camshaft cover–to–cylinder head seal.

2. Install the new camshaft cover gasket to the cam-

shaft cover.

3. Install the camshaft cover.

4. Install the camshaft cover bolts.

Tighten

Tighten the camshaft cover bolts to 8 NSm (71 lb–in).

5. Connect the ignition wires to the spark plugs.

6. Install the spark plug cover.

Tighten

Tighten the spark plug cover bolts to 8 NSm (71 lb–in).

7. Install the spark plug cover bolts.

8. Connect the camshaft position sensor connector.

9. Connect all of the necessary vacuum lines.

10. Connect the breather tube to the camshaft cover.

11. Connect the negative battery cable.

CYLINDER HEAD AND GASKET

Tools Required

KM–470–B Angular Torque Gauge

J–28467–B Engine Assembly Support Fixture

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the electronic control mdule (ECM)

ground terminal.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

Page 142 of 2643

1C2 – 22I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

56. Connect the CTS connector.

57. Connect the engine CTS connector.

58. Connect the IAC valve connector.

59. Connect the TPS connector.

60. Install the CCP and the EGR solenoid bracket bolt.

Tighten

Tighten the charcoal canister purge and exhaust gas

recirculation solenoid bracket bolt to 5 NSm (44 lb–in).

61. Connect the DIS coil connector.

62. Connect the O2 sensor connector, if equipped.

63. Connect the ECM ground terminal.

64. Install the fuel pump fuse.

65. Connect the negative battery ground cable.

66. Refill the engine cooling system. Refer to Section

1D, Engine Cooling.

CAMSHAFTS

Removal Procedure

1. Remove the timing belt. Refer to ”Timing Belt” in

this section.

2. Disconnect the breather tube at the camshaft cov-

er.

3. Disconnect the engine ventilation hose at the cam-

shaft cover.

4. Remove the spark plug cover bolts.

5. Remove the spark plug cover.

6. Disconnect the ignition wires from the spark plugs.

7. Remove the camshaft cover bolts.

8. Remove the camshaft cover washers.

9. Remove the camshaft cover and the camshaft cov-

er gasket.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

10. While holding the intake camshaft firmly in place,

remove the intake camshaft gear bolt.

11. Remove the intake camshaft gear.

12. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft gear bolt.

13. Remove the exhaust camshaft gear.

Page 166 of 2643

1C2 – 46I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

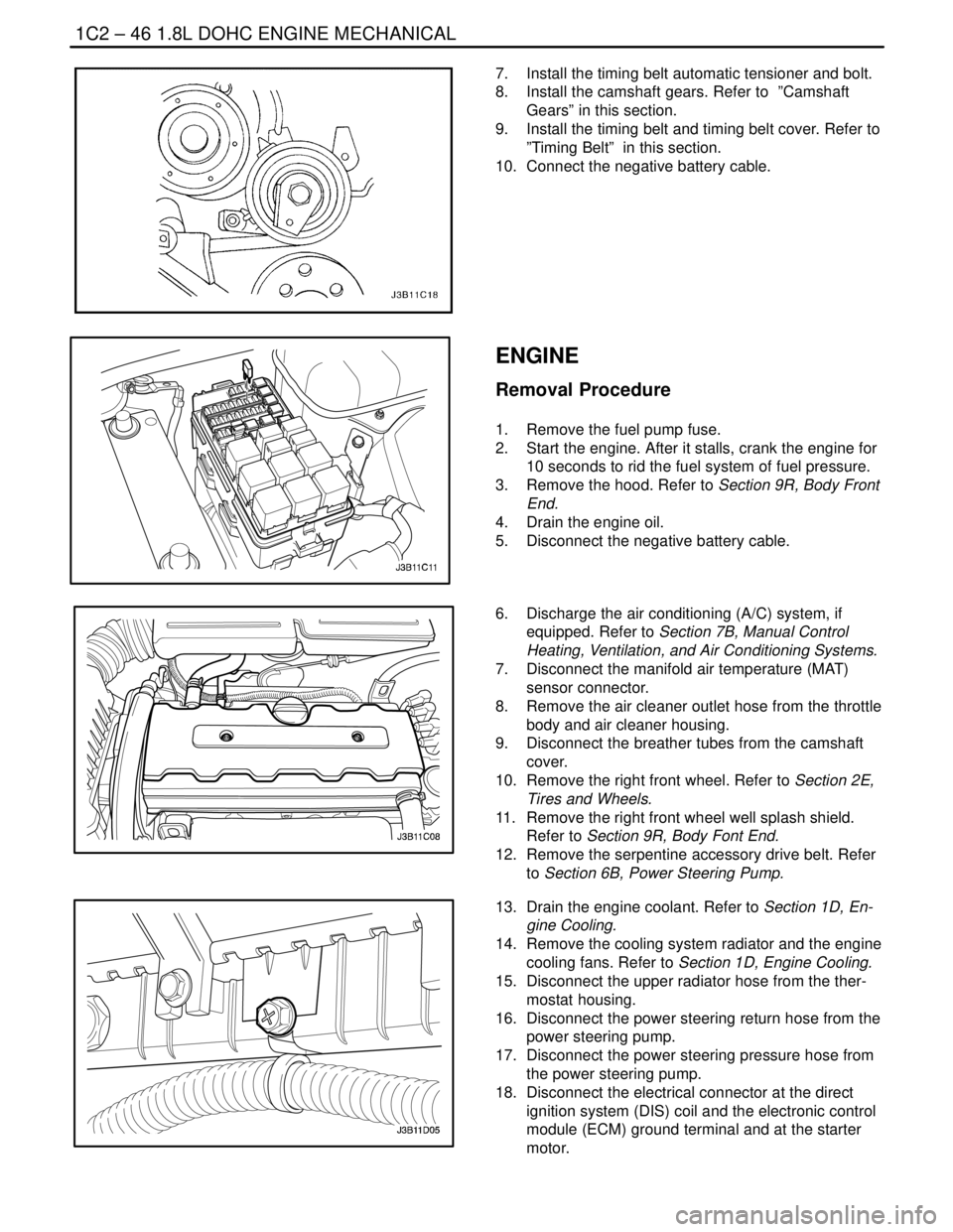

7. Install the timing belt automatic tensioner and bolt.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

10. Connect the negative battery cable.

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Discharge the air conditioning (A/C) system, if

equipped. Refer to Section 7B, Manual Control

Heating, Ventilation, and Air Conditioning Systems.

7. Disconnect the manifold air temperature (MAT)

sensor connector.

8. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

9. Disconnect the breather tubes from the camshaft

cover.

10. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

11. Remove the right front wheel well splash shield.

Refer to Section 9R, Body Font End.

12. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

13. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

14. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

15. Disconnect the upper radiator hose from the ther-

mostat housing.

16. Disconnect the power steering return hose from the

power steering pump.

17. Disconnect the power steering pressure hose from

the power steering pump.

18. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal and at the starter

motor.

Page 170 of 2643

1C2 – 50I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

18. Install the exhaust flex pipe retaining nuts to the

catalytic converter or the connecting pipe.

Tighten

Tighten the exhaust flex pipe–to–catalytic converter

or connecting pipe retaining nuts to 35 NSm (26 lb–ft).

19. Connect the power steering pressure hose.

20. Connect the power steering return hose.

21. Install the A/C compressor, if equipped. Refer to

Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

22. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

23. Install the right front wheel well splash shield.

24. Install the right front wheel. Refer to Section 2E,

Tires and Wheels.

25. Connect the fuel feed line to the fuel rail.

26. Connect the fuel return line to fuel rail.

27. Install the fuel rail and injector channel cover as an

assembly. Refer to Section 1F, Engine Controls.

28. Connect all of the necessary vacuum lines including

the brake booster vacuum hose.

29. Connect the O2 sensor connector, if equipped.

30. Connect the starter solenoid ”S” terminal wire and

power lead.

31. Connect the generator voltage regulator connector.

32. Connect the CTS connector.

33. Connect the engine CTS connector.

34. Connect the TPS connector.

35. Connect the IAC valve connector.

36. Connect the MAP sensor connector.

37. Connect the knock sensor, if necessary

38. Connect the electrical connector at the DIS ignition

coil and the ECM ground terminal and at the starter

motor.

39. Install the air cleaner outlet hose between the

throttle body and the air cleaner housing.

40. Connect the breather tubes to the camshaft cover.

41. Connect the MAT sensor connector.

42. Install the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

Page 174 of 2643

1C2 – 54I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

9. Measure the piston ring side clearance using a feel-

er gauge. Refer to ”Engine Specifications’’ in this

section.

10. If the piston ring is too thick, try another piston ring.

11. If no piston ring can be found that fits to specifica-

tions, the piston ring may be ground to size with

emery paper placed on a sheet of glass.

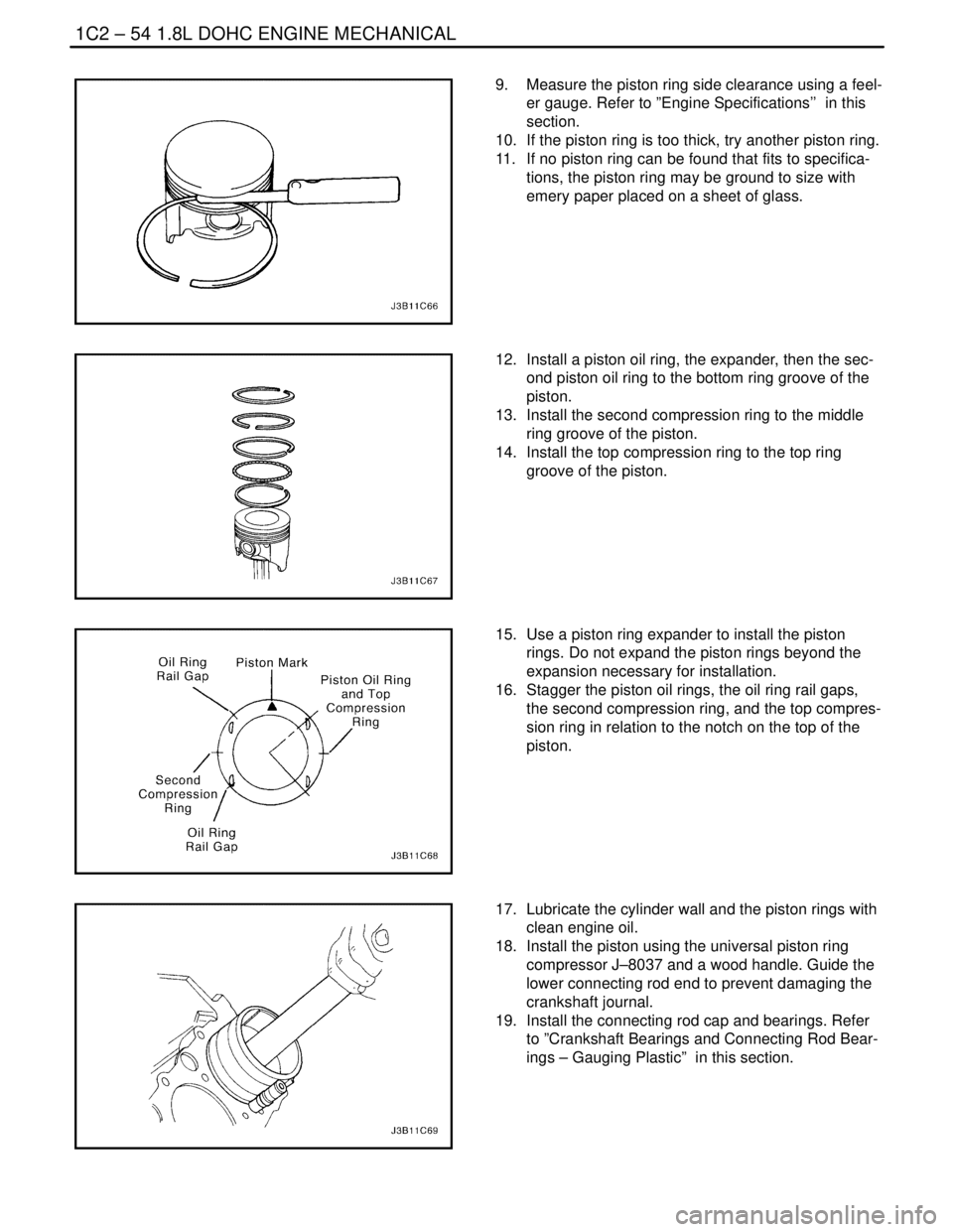

12. Install a piston oil ring, the expander, then the sec-

ond piston oil ring to the bottom ring groove of the

piston.

13. Install the second compression ring to the middle

ring groove of the piston.

14. Install the top compression ring to the top ring

groove of the piston.

15. Use a piston ring expander to install the piston

rings. Do not expand the piston rings beyond the

expansion necessary for installation.

16. Stagger the piston oil rings, the oil ring rail gaps,

the second compression ring, and the top compres-

sion ring in relation to the notch on the top of the

piston.

17. Lubricate the cylinder wall and the piston rings with

clean engine oil.

18. Install the piston using the universal piston ring

compressor J–8037 and a wood handle. Guide the

lower connecting rod end to prevent damaging the

crankshaft journal.

19. Install the connecting rod cap and bearings. Refer

to ”Crankshaft Bearings and Connecting Rod Bear-

ings – Gauging Plastic” in this section.

Page 180 of 2643

1C2 – 60I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

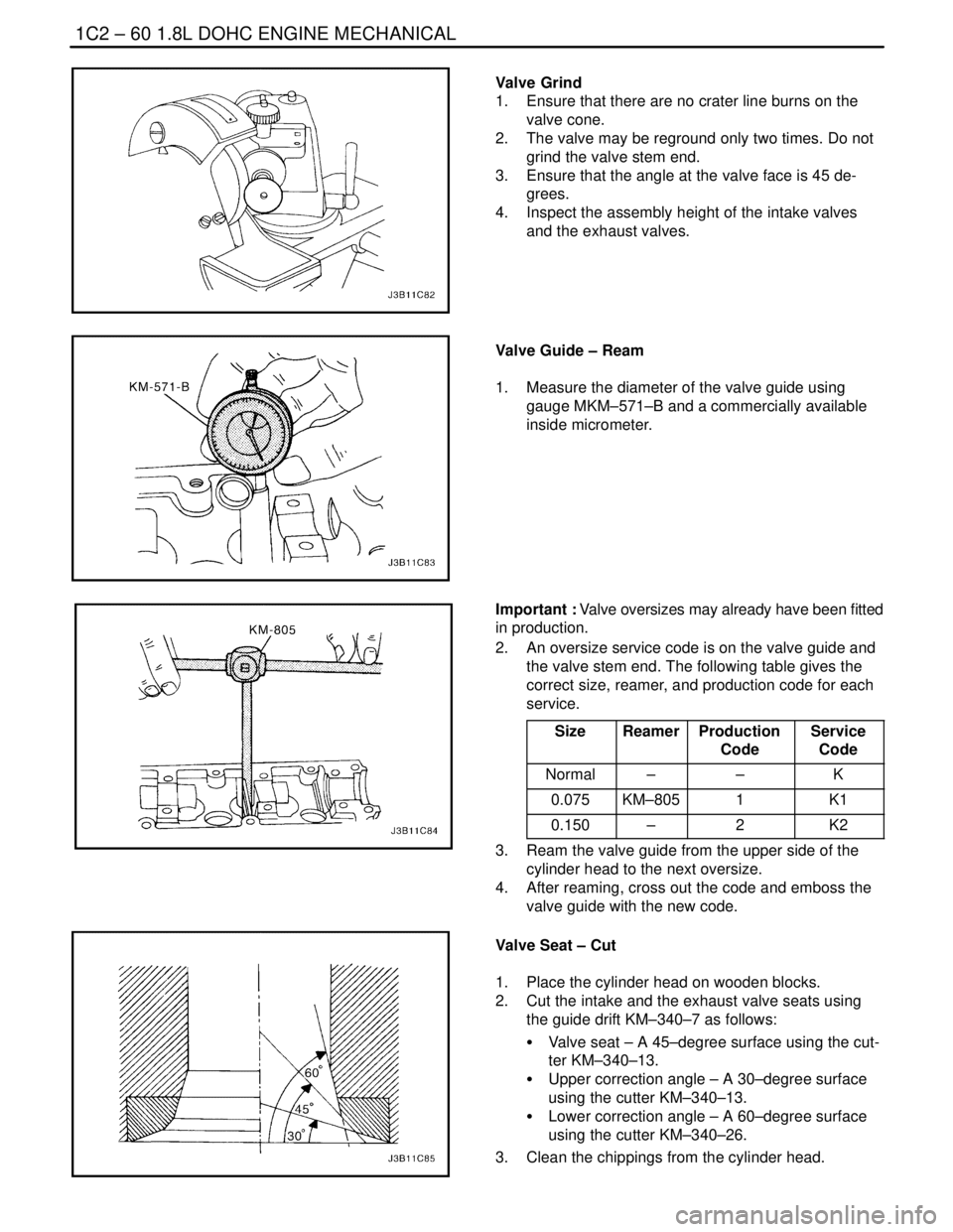

Valve Grind

1. Ensure that there are no crater line burns on the

valve cone.

2. The valve may be reground only two times. Do not

grind the valve stem end.

3. Ensure that the angle at the valve face is 45 de-

grees.

4. Inspect the assembly height of the intake valves

and the exhaust valves.

Valve Guide – Ream

1. Measure the diameter of the valve guide using

gauge MKM–571–B and a commercially available

inside micrometer.

Important : Valve oversizes may already have been fitted

in production.

2. An oversize service code is on the valve guide and

the valve stem end. The following table gives the

correct size, reamer, and production code for each

service.

Size

ReamerProduction

CodeService

Code

Normal––K

0.075KM–8051K1

0.150–2K2

3. Ream the valve guide from the upper side of the

cylinder head to the next oversize.

4. After reaming, cross out the code and emboss the

valve guide with the new code.

Valve Seat – Cut

1. Place the cylinder head on wooden blocks.

2. Cut the intake and the exhaust valve seats using

the guide drift KM–340–7 as follows:

S Valve seat – A 45–degree surface using the cut-

ter KM–340–13.

S Upper correction angle – A 30–degree surface

using the cutter KM–340–13.

S Lower correction angle – A 60–degree surface

using the cutter KM–340–26.

3. Clean the chippings from the cylinder head.

Page 203 of 2643

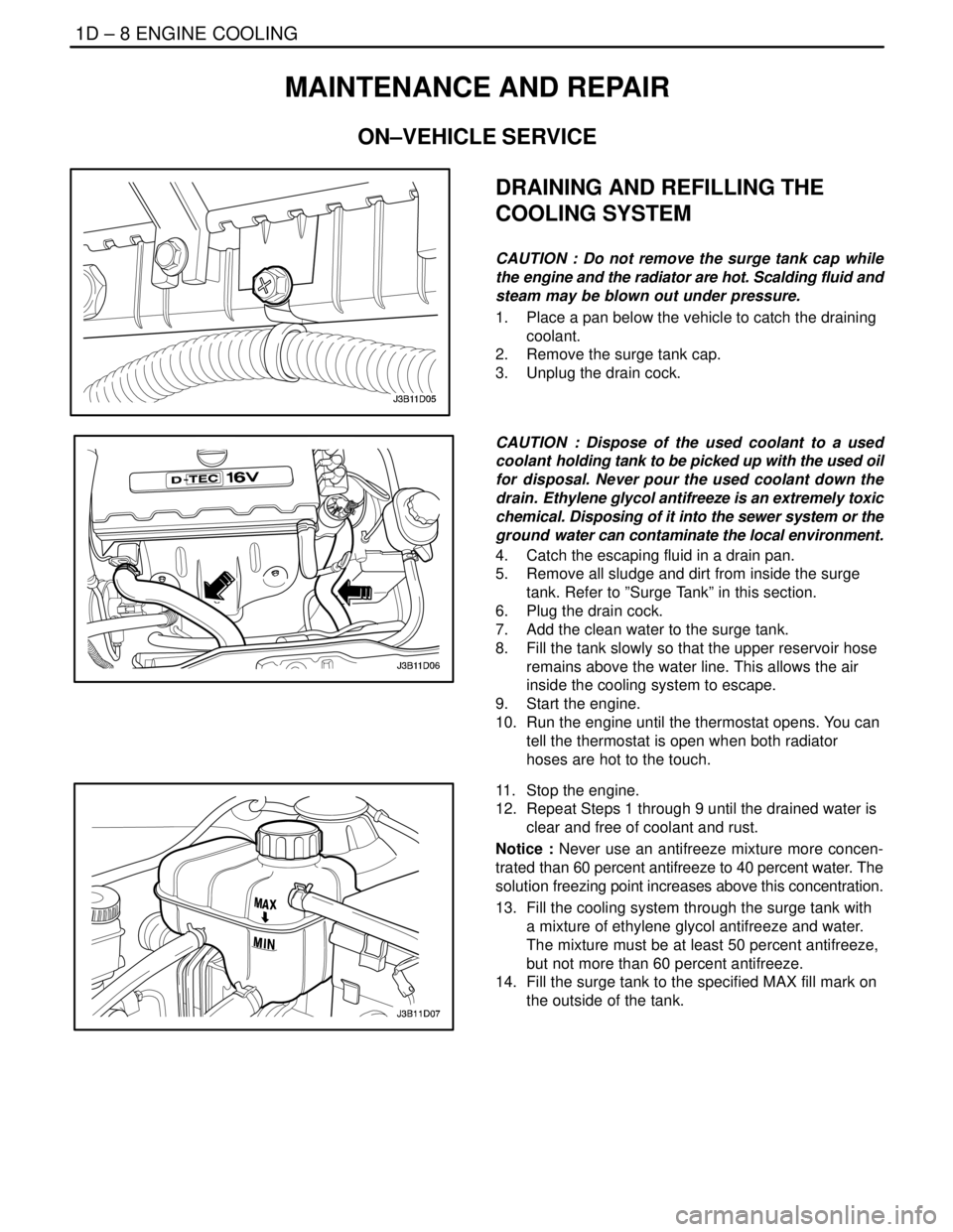

1D – 8IENGINE COOLING

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

DRAINING AND REFILLING THE

COOLING SYSTEM

CAUTION : Do not remove the surge tank cap while

the engine and the radiator are hot. Scalding fluid and

steam may be blown out under pressure.

1. Place a pan below the vehicle to catch the draining

coolant.

2. Remove the surge tank cap.

3. Unplug the drain cock.

CAUTION : Dispose of the used coolant to a used

coolant holding tank to be picked up with the used oil

for disposal. Never pour the used coolant down the

drain. Ethylene glycol antifreeze is an extremely toxic

chemical. Disposing of it into the sewer system or the

ground water can contaminate the local environment.

4. Catch the escaping fluid in a drain pan.

5. Remove all sludge and dirt from inside the surge

tank. Refer to ”Surge Tank” in this section.

6. Plug the drain cock.

7. Add the clean water to the surge tank.

8. Fill the tank slowly so that the upper reservoir hose

remains above the water line. This allows the air

inside the cooling system to escape.

9. Start the engine.

10. Run the engine until the thermostat opens. You can

tell the thermostat is open when both radiator

hoses are hot to the touch.

11. Stop the engine.

12. Repeat Steps 1 through 9 until the drained water is

clear and free of coolant and rust.

Notice : Never use an antifreeze mixture more concen-

trated than 60 percent antifreeze to 40 percent water. The

solution freezing point increases above this concentration.

13. Fill the cooling system through the surge tank with

a mixture of ethylene glycol antifreeze and water.

The mixture must be at least 50 percent antifreeze,

but not more than 60 percent antifreeze.

14. Fill the surge tank to the specified MAX fill mark on

the outside of the tank.

Page 217 of 2643

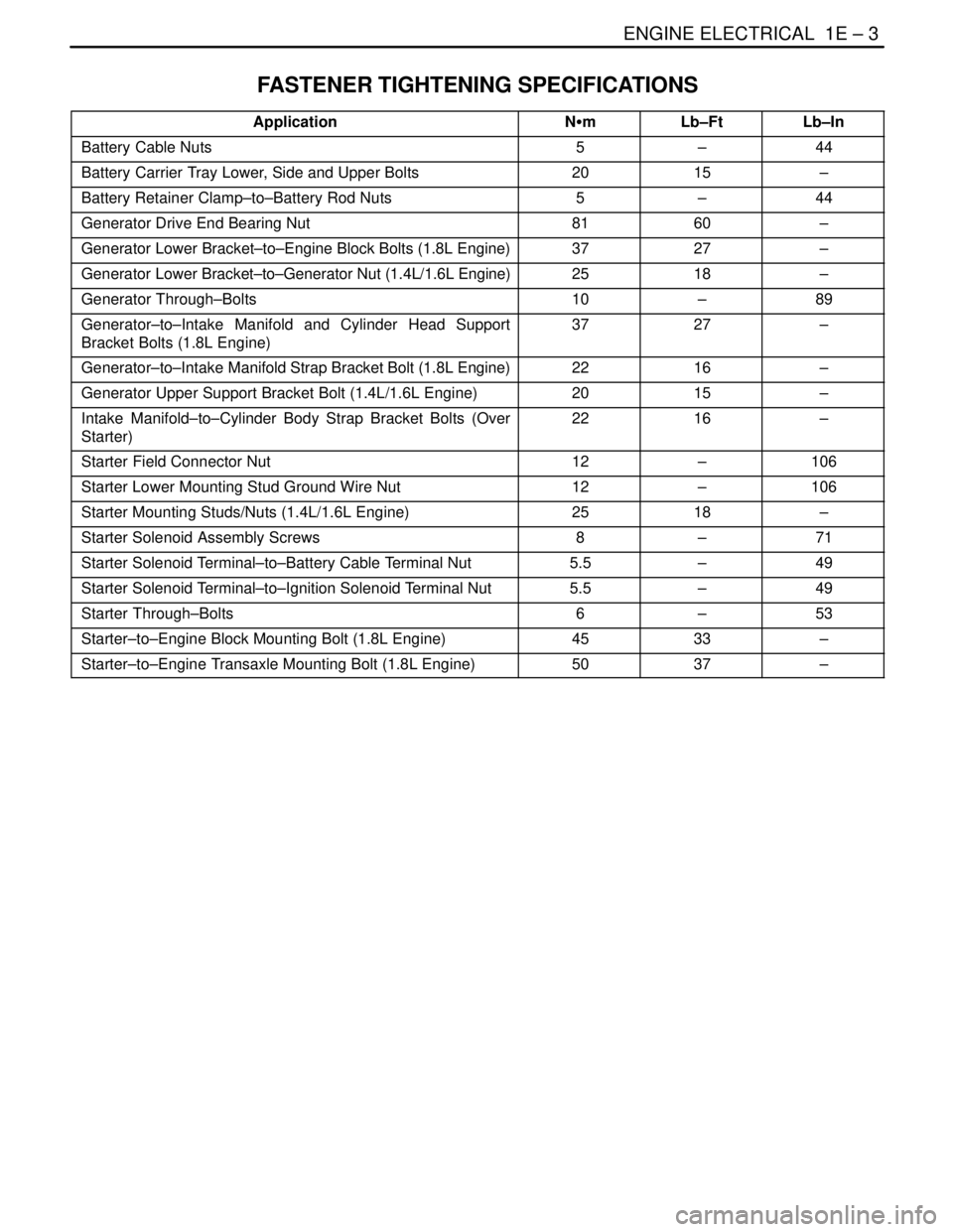

ENGINE ELECTRICAL 1E – 3

DAEWOO V–121 BL4

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Battery Cable Nuts5–44

Battery Carrier Tray Lower, Side and Upper Bolts2015–

Battery Retainer Clamp–to–Battery Rod Nuts5–44

Generator Drive End Bearing Nut8160–

Generator Lower Bracket–to–Engine Block Bolts (1.8L Engine)3727–

Generator Lower Bracket–to–Generator Nut (1.4L/1.6L Engine)2518–

Generator Through–Bolts10–89

Generator–to–Intake Manifold and Cylinder Head Support

Bracket Bolts (1.8L Engine)3727–

Generator–to–Intake Manifold Strap Bracket Bolt (1.8L Engine)2216–

Generator Upper Support Bracket Bolt (1.4L/1.6L Engine)2015–

Intake Manifold–to–Cylinder Body Strap Bracket Bolts (Over

Starter)2216–

Starter Field Connector Nut12–106

Starter Lower Mounting Stud Ground Wire Nut12–106

Starter Mounting Studs/Nuts (1.4L/1.6L Engine)2518–

Starter Solenoid Assembly Screws8–71

Starter Solenoid Terminal–to–Battery Cable Terminal Nut5.5–49

Starter Solenoid Terminal–to–Ignition Solenoid Terminal Nut5.5–49

Starter Through–Bolts6–53

Starter–to–Engine Block Mounting Bolt (1.8L Engine)4533–

Starter–to–Engine Transaxle Mounting Bolt (1.8L Engine)5037–