interior trim DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2099 of 2643

8A – 4ISEAT BELTS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

PRETENSIONER FRONT SEAT BELT

Removal Procedure

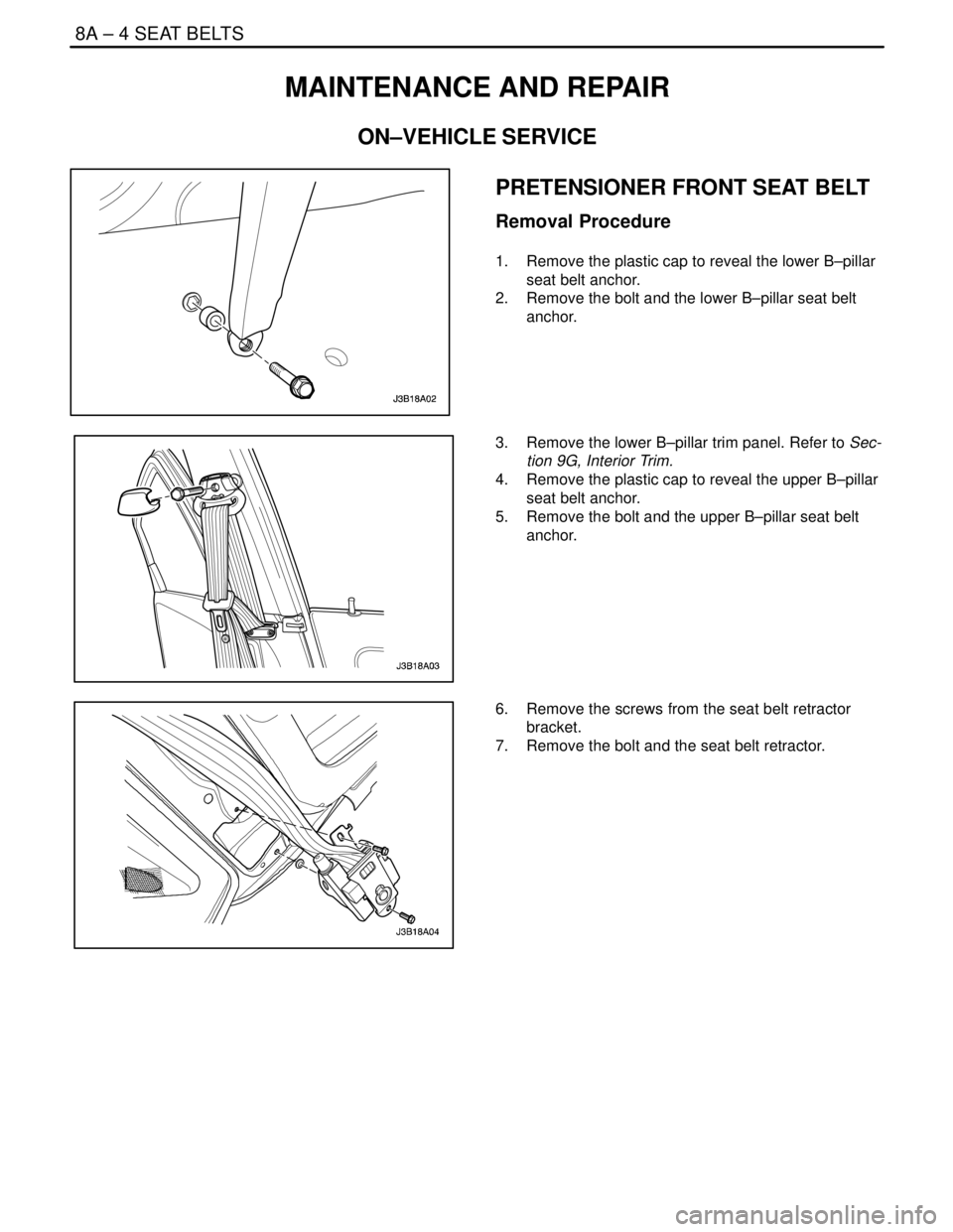

1. Remove the plastic cap to reveal the lower B–pillar

seat belt anchor.

2. Remove the bolt and the lower B–pillar seat belt

anchor.

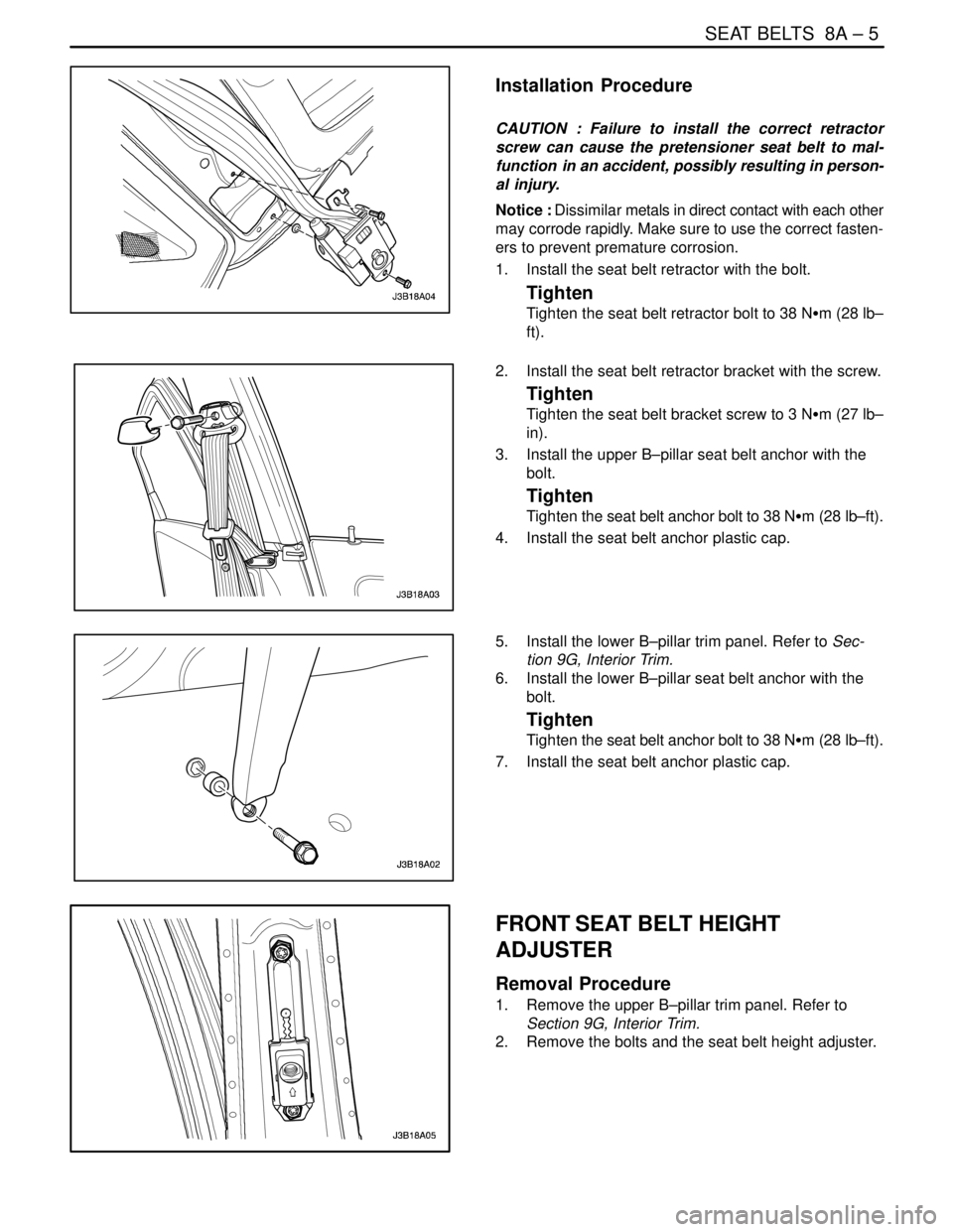

3. Remove the lower B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

4. Remove the plastic cap to reveal the upper B–pillar

seat belt anchor.

5. Remove the bolt and the upper B–pillar seat belt

anchor.

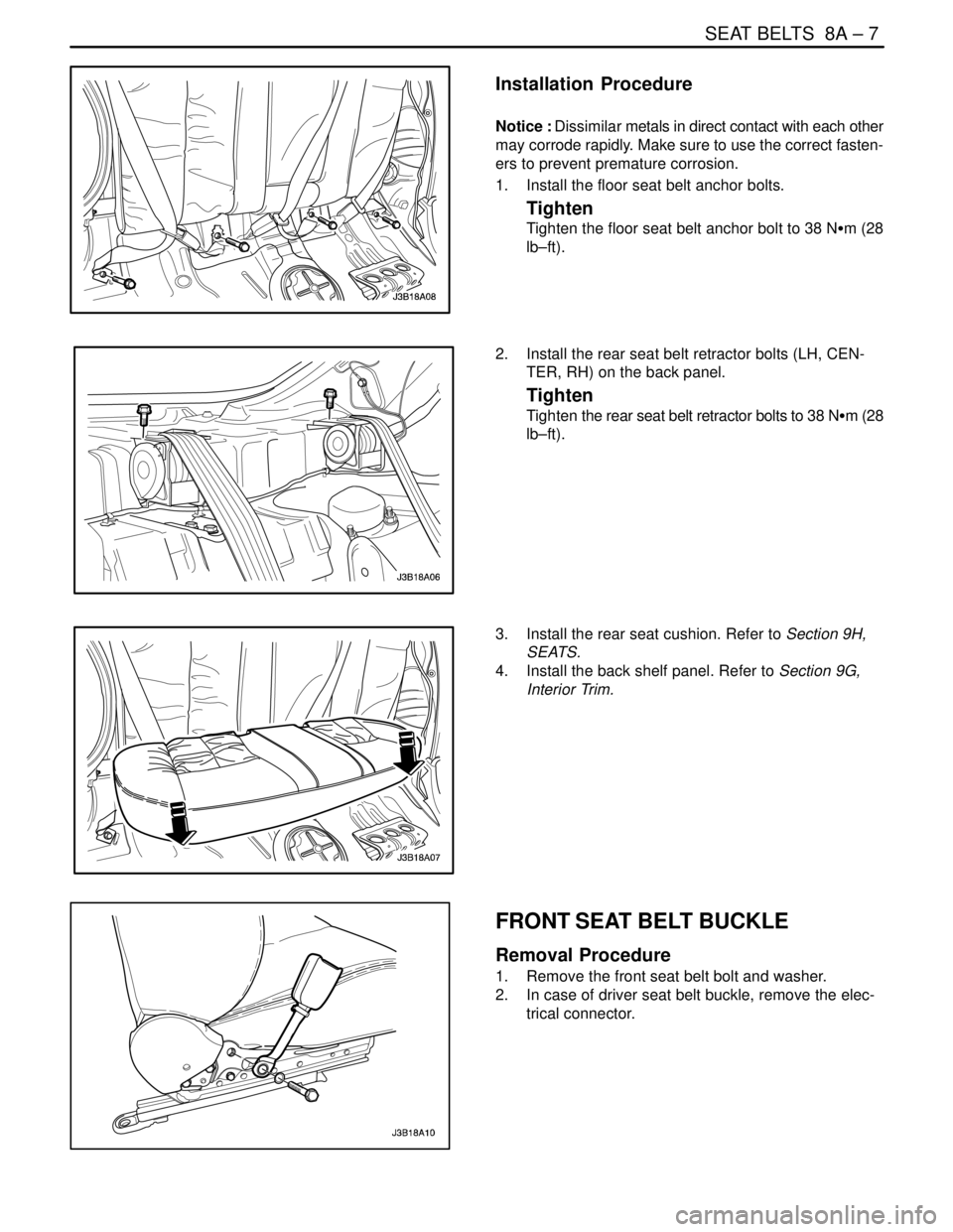

6. Remove the screws from the seat belt retractor

bracket.

7. Remove the bolt and the seat belt retractor.

Page 2100 of 2643

SEAT BELTS 8A – 5

DAEWOO V–121 BL4

Installation Procedure

CAUTION : Failure to install the correct retractor

screw can cause the pretensioner seat belt to mal-

function in an accident, possibly resulting in person-

al injury.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seat belt retractor with the bolt.

Tighten

Tighten the seat belt retractor bolt to 38 NSm (28 lb–

ft).

2. Install the seat belt retractor bracket with the screw.

Tighten

Tighten the seat belt bracket screw to 3 NSm (27 lb–

in).

3. Install the upper B–pillar seat belt anchor with the

bolt.

Tighten

Tighten the seat belt anchor bolt to 38 NSm (28 lb–ft).

4. Install the seat belt anchor plastic cap.

5. Install the lower B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

6. Install the lower B–pillar seat belt anchor with the

bolt.

Tighten

Tighten the seat belt anchor bolt to 38 NSm (28 lb–ft).

7. Install the seat belt anchor plastic cap.

FRONT SEAT BELT HEIGHT

ADJUSTER

Removal Procedure

1. Remove the upper B–pillar trim panel. Refer to

Section 9G, Interior Trim.

2. Remove the bolts and the seat belt height adjuster.

Page 2101 of 2643

8A – 6ISEAT BELTS

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seat belt height adjuster with the bolts.

Tighten

Tighten the front seat belt height adjuster bolts to 23

NSm (17 lb–ft).

2. Install the upper B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

THREE–POINT REAR SEAT BELT

(LH,CENTER, RH)

Removal Procedure

1. Remove the back shelf panel. Refer to Section 9G,

Interior Trim.

2. Remove the rear seat belt retractor securing bolts

(LH, CENTER, RH) from the back panel.

3. Remove the rear seat cushion. Refer to Section 9H,

SEATS.

4. Remove the floor seat belt anchor bolts.

5. Remove the seat belt.

Page 2102 of 2643

SEAT BELTS 8A – 7

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the floor seat belt anchor bolts.

Tighten

Tighten the floor seat belt anchor bolt to 38 NSm (28

lb–ft).

2. Install the rear seat belt retractor bolts (LH, CEN-

TER, RH) on the back panel.

Tighten

Tighten the rear seat belt retractor bolts to 38 NSm (28

lb–ft).

3. Install the rear seat cushion. Refer to Section 9H,

SEATS.

4. Install the back shelf panel. Refer to Section 9G,

Interior Trim.

FRONT SEAT BELT BUCKLE

Removal Procedure

1. Remove the front seat belt bolt and washer.

2. In case of driver seat belt buckle, remove the elec-

trical connector.

Page 2195 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 91

DAEWOO V–121 BL4

Important : If the vehicle interior has been exposed to ex-

tensive water intrusion such as water leaks, driving

through high water, flooding or other causes, then the

SDM and SDM connector may need to be replaced. With

the ignition OFF, inspect the area of SDM, including the

carpet. If any significant soaking or evidence of previous

soaking is detected, the water must be removed, the water

damage repaired and the SDM and SDM connector must

be replaced. Before attempting any of these repairs, the

SRS must be disabled. Refer to ”Disabling the SIR” in this

section.

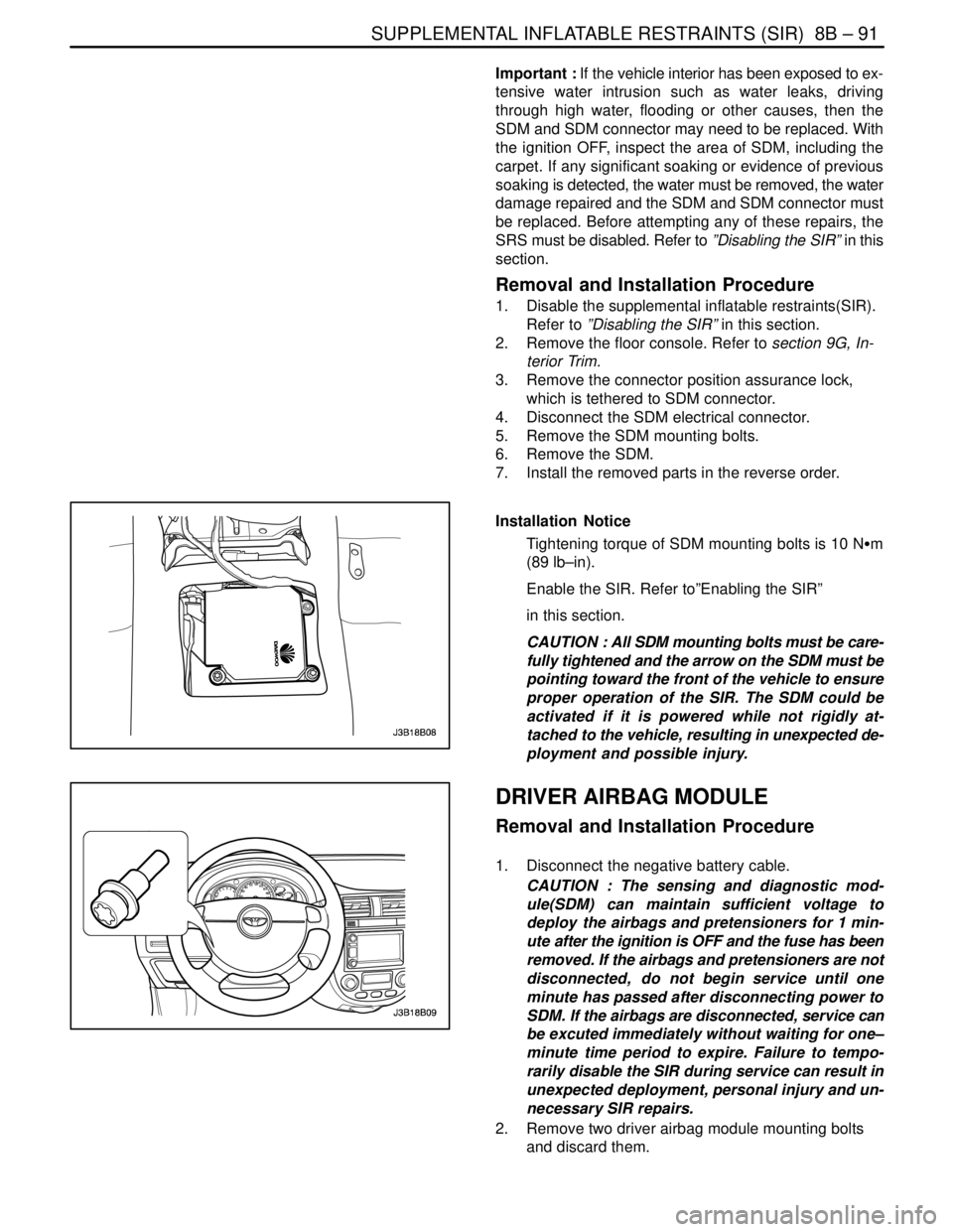

Removal and Installation Procedure

1. Disable the supplemental inflatable restraints(SIR).

Refer to ”Disabling the SIR” in this section.

2. Remove the floor console. Refer to section 9G, In-

terior Trim.

3. Remove the connector position assurance lock,

which is tethered to SDM connector.

4. Disconnect the SDM electrical connector.

5. Remove the SDM mounting bolts.

6. Remove the SDM.

7. Install the removed parts in the reverse order.

Installation Notice

Tightening torque of SDM mounting bolts is 10 NSm

(89 lb–in).

Enable the SIR. Refer to”Enabling the SIR”

in this section.

CAUTION : All SDM mounting bolts must be care-

fully tightened and the arrow on the SDM must be

pointing toward the front of the vehicle to ensure

proper operation of the SIR. The SDM could be

activated if it is powered while not rigidly at-

tached to the vehicle, resulting in unexpected de-

ployment and possible injury.

0

DRIVER AIRBAG MODULE

Removal and Installation Procedure

1. Disconnect the negative battery cable.

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be excuted immediately without waiting for one–

minute time period to expire. Failure to tempo-

rarily disable the SIR during service can result in

unexpected deployment, personal injury and un-

necessary SIR repairs.

2. Remove two driver airbag module mounting bolts

and discard them.

Page 2200 of 2643

8B – 96ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

Deployment Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect both battery cables and place the bat-

tery at least 10 meters (33 feet) from the vehicle.

2. Remove the driver side knee bolster or instrument

panel lower cover from the steering column. Refer

to Section 9G, Interior Trim.

3. At the lower steering column, cut the two wires

leading from the supplemental inflatable re-

straints(SIR) harness to the clock spring.

4. Strip 13mm(0.5 inch) of the insulation from the end

of the wires leading to the clock spring.

5. Use two additional wires, each at least 10 me-

ters(33 feet) long, to reach from the deployment

battery to the inflator module.

6. Strip 13mm(0.5 inch) of the insulation from the end

of these two additional wires.

7. Twist the two wires together at one end.

8. Place the twisted ends of the two wires near the

deployment battery. Do not connect the wires to the

battery at this time.

9. Using the free ends of the 10 meters(33 feet) wires

leading to the clock spring, make two splices, one

at each wires from the airbag modules.

10. Wrap the wires with insulation tape.

11. Now that the free ends of the 10 meters(33 feet)

wires are spliced to the airbag module wires, and

the ends that are twisted together are near the de-

ployment battery. Clear the area.

12. Untwist the wires that near the deployment battery.

13. Touch one wire to the positive battery terminal and

touch the other wire to the negative battery termi-

nal. The airbag will deploy.

14. Repeat this procedure for the passenger airbag,

side airbags and pretensioners.

15. Using proper precautions, dispose of the deployed

airbags/pretensioners. Refer to ”Deployed Airbag

Module Disposal Procedure” in this section.

Page 2272 of 2643

9B – 46ILITHING SYSTEMS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

HEADLAMPS–ON REMINDER CHIME

When the headlamp switch is in the headlamps–on or

parking lamps–on position, voltage is applied to the chime

module. When the ignition is in ON, ACC or START, volt-

age is applied through the fuse block to the module. These

two voltages are sensed, and the chime module is not

sounded.

When the ignition is not in ON, ACC or START, the module

loses voltage. The chime module senses change. If the

voltage is still available, it is applied to sound the chime.

The chime can be turned off by turning the headlamp

switch off. The module no longer senses voltage from the

headlamp switch, so the chime module does not sound.

HEADLAMPS

The headlamps are controlled by the multifunction lever

located on the left side of the steering column. They will

come on with the ignition switch in any position. Turning

the headlamp switch to the first position turns on the park-

ing lamps, the license plate lamps and the instrument pan-

el illumination. Turning the switch to the second position

turns on all of the previous lamps and the headlamps.

Turning the switch to the OFF position turns off all the

lamps.

Headlamp high beams and low beams are also controlled

by this lever. When the headlamps are on, pushing the le-

ver away from the driver until the switch clicks changes the

lamp from low beam to high beam. An indicator lamp on

the instrument cluster assembly will come on when the

high beam headlamps are on. To return the headlamps to

low beam, pull the lever toward the driver.

The headlamps must be aimed for proper illumination of

the road. Headlamp aim should be checked whenever a

new headlamp assembly is installed, or whenever service

repairs to the front end area may have disturbed the head-

lamp assembly or its mountings.

DAYTIME RUNNING LAMPS

The Daytime Running Lamps (DRL) will come on when:

S The ignition is ON.

S The light is OFF.

S The parking brake is released.

When the exterior lights are on, the DRL will turn off. To

turn the DRL off when idling, apply the parking brake.

PARKING AND TURN SIGNAL LAMPS

The parking lamps can be turned on by turning the lighting

switch to the first position. The parking lamps can be

turned off by turning the switch to the OFF position.When the turn signals are activated, the front and rear turn

signal lamps flash to signal a turn. The turn signals work

only when the ignition is ON.

The turn signals are controlled by the light switch on the

left side of the steering column. Moving the lever all the

way up or down (past the detent) will turn on the front and

rear turn signals. When the turn is completed, the lever will

return to horizontal and the turn signals will stop flashing.

For changing lanes, or for shallow turns in which the steer-

ing wheel does not turn far enough to cancel the signal,

move the signal lever only to the first detent and hold it

there. When the lever is released, it will return to horizontal

and the turn signals will cancel.

FOG LAMPS

The fog lamp switch is on the instrument panel to the right

of the steering column. To use the fog lamps, first turn on

the headlamps or the parking lamps. Then push the fog

lamp switch. The indicator light in the switch will illuminate

to indicate that the fog lamps are on. Push the switch again

to turn off the fog lamps. The indicator light will then go off.

The fog lamps should not be used as a substitute for the

headlamps.

The fog lamps must be aimed for proper illumination of the

road. Fog lamp aim should be checked when a new bulb

is installed or if service or repairs in the front end area may

have disturbed the fog lamp mountings.

REAR COMBINATION LAMPS

The taillamps, stoplamps, turn signal lamps and backup

lamp are one assembly.

Turning on either the headlamps or the parking lamps will

also turn on the taillamps. When the brake pedal is

pushed, the taillamps will glow brighter to serve as sto-

plamps.

The center high–mounted stoplamp is located in the rear

window and will come on when the brake pedal is pressed.

LICENSE PLATE LAMP

The license plate lamps will come on when the headlamps

or the parking lamps are on. The license plate lamps are

mounted above the license plate.

INTERIOR COURTESY LAMP

The courtesy lamp is located on the headliner just behind

the front seats. The lamp switch has three positions. If the

switch is left in the center position, the lamp will go on

whenever a door is opened and go off when it is closed.

In the ON position, the lamp will stay on until it is turned off.

In the OFF position, the lamp will not come on, even when

a door is opened.

LUGGAGE COMPARTMENT LAMP

The luggage compartment lamp is located under the deck

lid sill plate on the notchback. The lamp is located on the

left–side wheelhouse trim panel on the hatchback. It will

come on whenever the luggage compartment is opened.

Page 2297 of 2643

9D – 20IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the rear wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 11 NSm (97 Ib–in).

2. Close the wiper arm access cap.

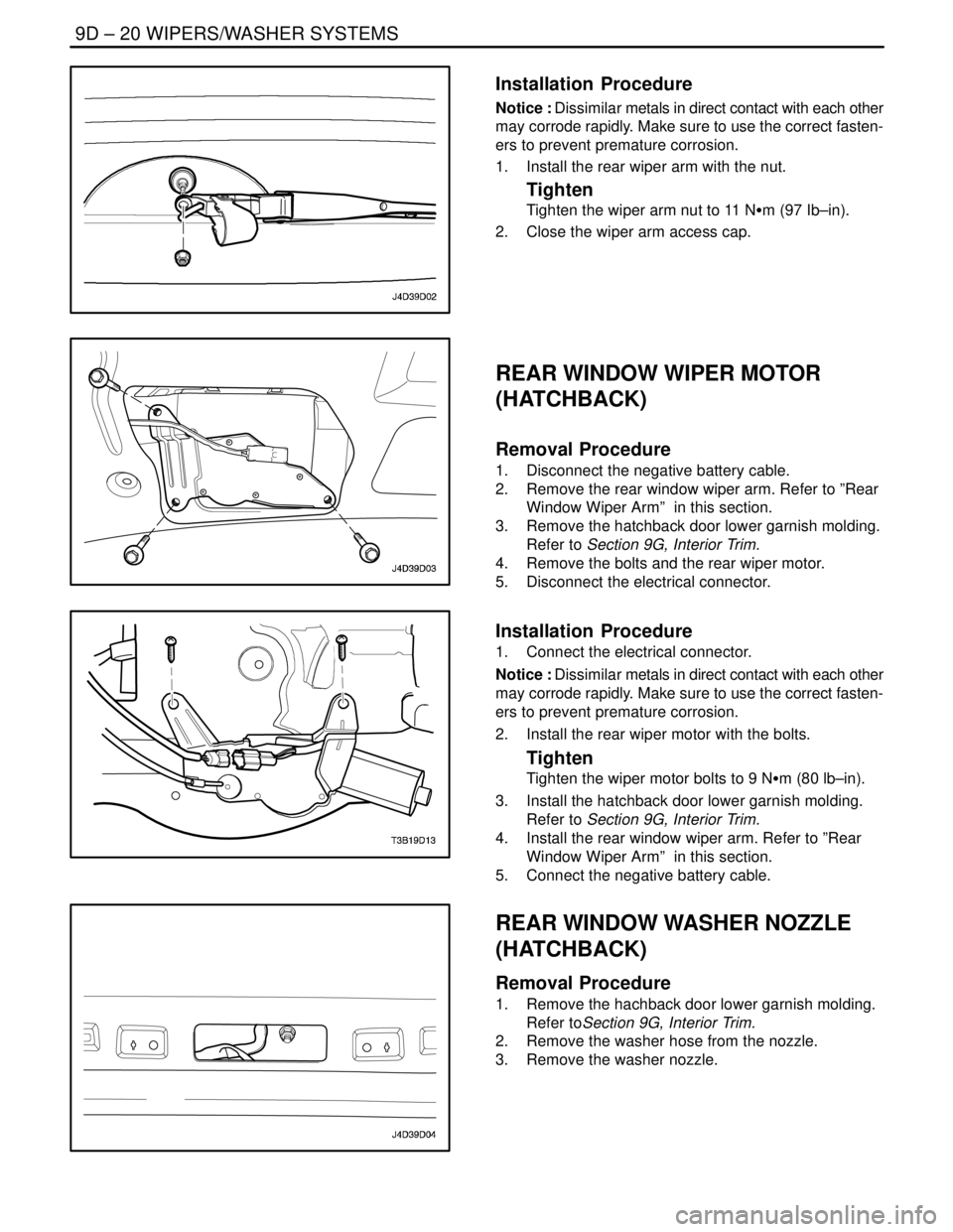

REAR WINDOW WIPER MOTOR

(HATCHBACK)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

3. Remove the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Remove the bolts and the rear wiper motor.

5. Disconnect the electrical connector.

Installation Procedure

1. Connect the electrical connector.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the rear wiper motor with the bolts.

Tighten

Tighten the wiper motor bolts to 9 NSm (80 lb–in).

3. Install the hatchback door lower garnish molding.

Refer to Section 9G, Interior Trim.

4. Install the rear window wiper arm. Refer to ”Rear

Window Wiper Arm” in this section.

5. Connect the negative battery cable.

REAR WINDOW WASHER NOZZLE

(HATCHBACK)

Removal Procedure

1. Remove the hachback door lower garnish molding.

Refer toSection 9G, Interior Trim.

2. Remove the washer hose from the nozzle.

3. Remove the washer nozzle.

Page 2298 of 2643

WIPERS/WASHER SYSTEMS 9D – 21

DAEWOO V–121 BL4

Installation Procedure

1. Install the washer nozzle.

2. Install the washer hose to the nozzle.

3. Install the hachback door lower garnish molding.

Refer toSection 9G, Interior Trim.

Page 2323 of 2643

9E – 24IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

Installation Procedure

1. Connect the electrical connectors.

2. Install the instrument cluster dimmer switch assem-

bly.

INSTRUMENT CLUSTER INDICATOR

LAMPS

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument cluster. Refer to ”Instru-

ment Cluster” in this section.

3. Remove the defective bulb from the rear of the

cluster.

Installation Procedure

1. Install the new bulb.

2. Install the instrument cluster. Refer to ”Instrument

Cluster” in this section.

3. Connect the negative battery cable.

INSTRUMENT PANEL

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Remove the sun sensor. Refer to Section 7D, Auto-

matic Temperature Control Heating, Ventilation, and

Air Condition System.

4. Remove the stereo cassette AM/FM radio. Refer to

Section 9F, Audio Systems.

5. Remove the center molding.

6. Remove the instrument cluster dimmer switch as-

sembly.