driver DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2329 of 2643

9E – 30IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the floor

console. To use the lighter, push it in completely. When the

lighter is hot, it will release itself from contact with the heat-

ing element. The lighter and the heating element can be

damaged if the lighter is not allowed to release itself fully

from the heating element.

ASHTRAY

The ashtray is located below the audio system. To access

the ashtray, pull it out from the center console. The ashtray

lamp will go on when the parking lamps or the headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel can

be adjusted up and down and from side to side. The side

vents can also be aimed toward the side windows in order

to defog them.

GLOVE BOX

The glove box can be opened by pulling up on the latch

handle. The glove box must be removed in order to gain

access to the passenger’s side airbag module.

DIGTAL CLOCK

The digital clock is located in the instrument panel, above

the audio system. The clock is capable of a 12–hour or a

24–hour display.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering col-

umn and in the instrument cluster trim panel. The instru-

ment cluster contains the instruments that provide the

driver with vehicle performance information. The instru-

ment cluster contains a speedometer, an odometer, a trip

odometer, a temperature gauge, a fuel gauge, and several

indicator lamps. For replacement of the indicator lamp

bulbs contained in the instrument cluster, refer to ”Instru-

ment Cluster Indicator Lamps Specifications” and”Instru-

ment Cluster Indicator Lamps” in this section.

SPEEDOMETER/ODOMETER/TRIP

ODOMETER

The speedometer measures the speed of the vehicle in

km/h (mph in some countries). It consists of an instrument

cluster gauge connected to the vehicle speed sensor

(VSS) on the transaxle output shaft.The odometer measures in kilometers (miles in some

countries) the total distance the vehicle has traveled since

it was manufactured. It consists of an instrument cluster

gauge connected to the VSS on the transaxle output shaft.

The trip odometer measures the distance the vehicle has

traveled since the odometer was last reset. It consists of

an instrument cluster gauge connected to the VSS on the

transaxle output shaft. The trip odometer can be reset to

zero at any time so that the driver can record the distance

traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank.

The fuel gauge indicates the quantity of fuel in the tank

only when the ignition switch is turned to ON or ACC.

When the ignition is turned to LOCK or START, the pointer

may come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument cluster

gauge connected to a temperature sensor that is in con-

tact with the circulating engine coolant.

The temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of the

gauge. The engine is overheating if the pointer moves into

the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER INDICATOR

LAMPS

The instrument cluster contains indicator lamps that indi-

cate the functioning of certain systems or the existence of

potential problems with the operation of the vehicle. The

indicator lamps are replaceable. For replacement of the in-

dicator lamps contained in the instrument cluster, refer to

”Instrument Cluster Indicator Lamps Specifications”

and”Instrument Cluster Indicator Lamps” in this section.

CHIME MODULE

The chime module is located above the instrument panel

fuse block and will sound in order to bring attention to one

or more of the following conditions:

S The lamps are on, the door is ajar, and the ignition

switch is not in ACC, ON, or START.

S The seat belt is unbuckled when the ignition switch

is in ON or START.

S The door is open when the ignition switch is in ON

or START.

S The key is left in the ignition switch when the igni-

tion is in LOCK and the door is open.

Page 2341 of 2643

SECTION : 9G

INTERIOR TRIM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9G–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9G–1. . . . . . . . . . .

SPECIAL TOOLS9G–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 9G–2. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9G–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9G–3. . . . . . . . . . . . . . . . . . . . .

Front Door Trim Panel 9G–3. . . . . . . . . . . . . . . . . . . . . .

Rear Door Trim Panel 9G–4. . . . . . . . . . . . . . . . . . . . . .

A–pillar Trim Panel 9G–4. . . . . . . . . . . . . . . . . . . . . . . . .

Upper B–pillar Trim Panel 9G–5. . . . . . . . . . . . . . . . . . .

Lower B–pillar Trim Panel 9G–5. . . . . . . . . . . . . . . . . . .

C–pillar Trim Panel 9G–6. . . . . . . . . . . . . . . . . . . . . . . . .

Deck Lid Sill Plate Cover 9G–6. . . . . . . . . . . . . . . . . . .

Front Rocker Trim Panel 9G–7. . . . . . . . . . . . . . . . . . . .

Rear Rocker Trim Panel 9G–7. . . . . . . . . . . . . . . . . . . .

Front Wheelhouse Trim 9G–8. . . . . . . . . . . . . . . . . . . . .

Rear Wheelhouse Trim 9G–8. . . . . . . . . . . . . . . . . . . . .

Floor Console 9G–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Floor Carpet 9G–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Luggage Compartment Rear Low Cover 9G–11. . . . .

Luggage Compartment Wheelhouse Trim

Panel 9G–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver’s Side Knee Bolster 9G–12. . . . . . . . . . . . . . . . .

Hatchback Door Lower Garnish Molding 9G–13. . . . .

Hatchback Door Upper Garnish Molding 9G–14. . . . .

Luggage Compartment Wheelhouse Trim Panel

(HATCHBACK) 9G–14. . . . . . . . . . . . . . . . . . . . . . . . .

Luggage Compartment Rear Trim Panel 9G–14. . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9G–16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interior Trim Panels 9G–16. . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Vent 9G–16. . . . . . . . . . . . . . . . . . . . . .

Floor Console 9G–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floor Carpet 9G–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Compartment Security Cover

(HATCHBACK) 9G–16. . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Door Trim Panel Screws2.5–22

Driver’s Side Knee Bolster Mounting Bolts10–89

Floor Console Screws2.5–22

Gearshift Housing Bolts8–70

Hood Latch Release Handle Mounting Screw3–27

Seat Belt Anchor Bolt3828–

Page 2352 of 2643

9G – 12IINTERIOR TRIM

DAEWOO V–121 BL4

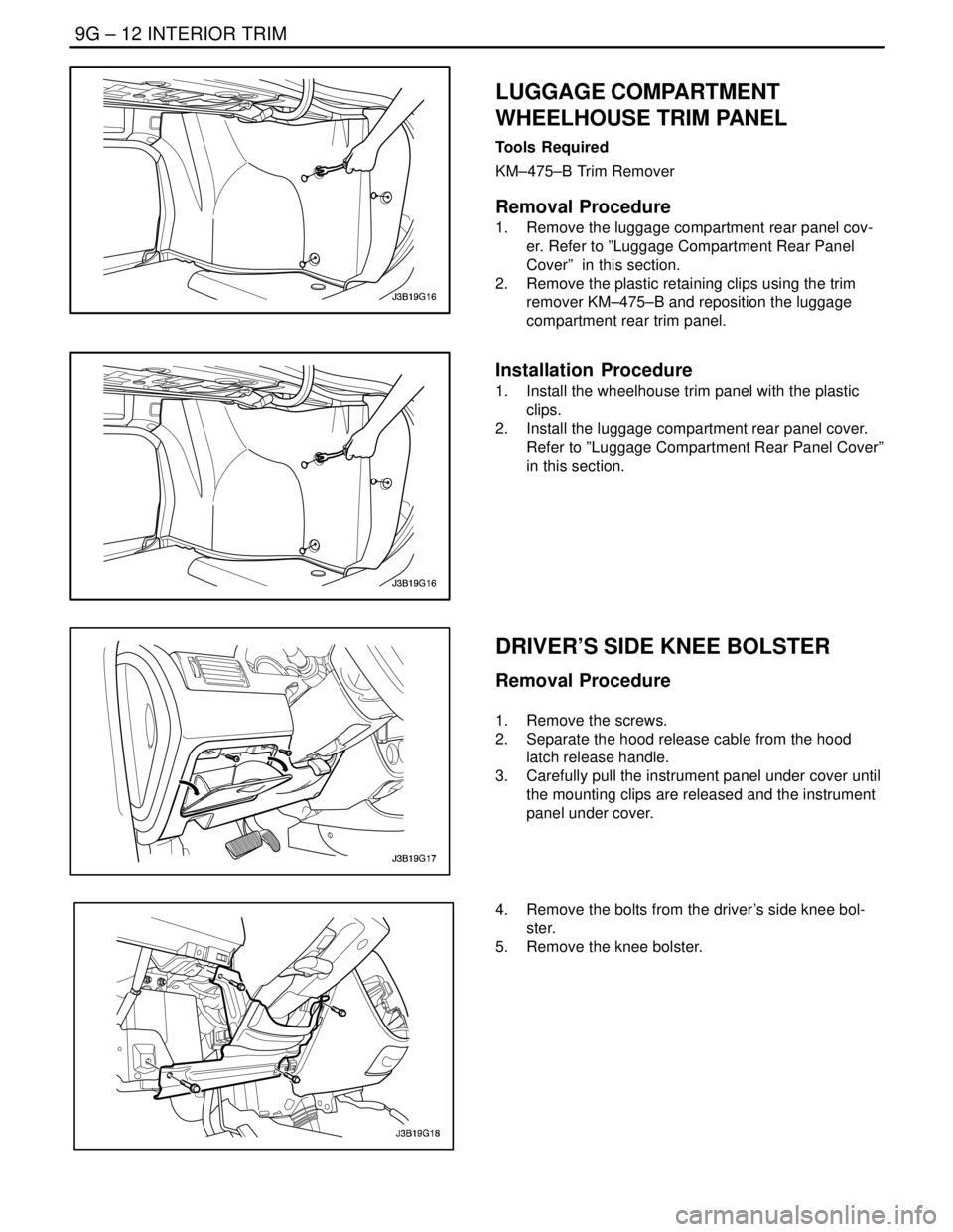

LUGGAGE COMPARTMENT

WHEELHOUSE TRIM PANEL

Tools Required

KM–475–B Trim Remover

Removal Procedure

1. Remove the luggage compartment rear panel cov-

er. Refer to ”Luggage Compartment Rear Panel

Cover” in this section.

2. Remove the plastic retaining clips using the trim

remover KM–475–B and reposition the luggage

compartment rear trim panel.

Installation Procedure

1. Install the wheelhouse trim panel with the plastic

clips.

2. Install the luggage compartment rear panel cover.

Refer to ”Luggage Compartment Rear Panel Cover”

in this section.

DRIVER’S SIDE KNEE BOLSTER

Removal Procedure

1. Remove the screws.

2. Separate the hood release cable from the hood

latch release handle.

3. Carefully pull the instrument panel under cover until

the mounting clips are released and the instrument

panel under cover.

4. Remove the bolts from the driver’s side knee bol-

ster.

5. Remove the knee bolster.

Page 2353 of 2643

INTERIOR TRIM 9G – 13

DAEWOO V–121 BL4

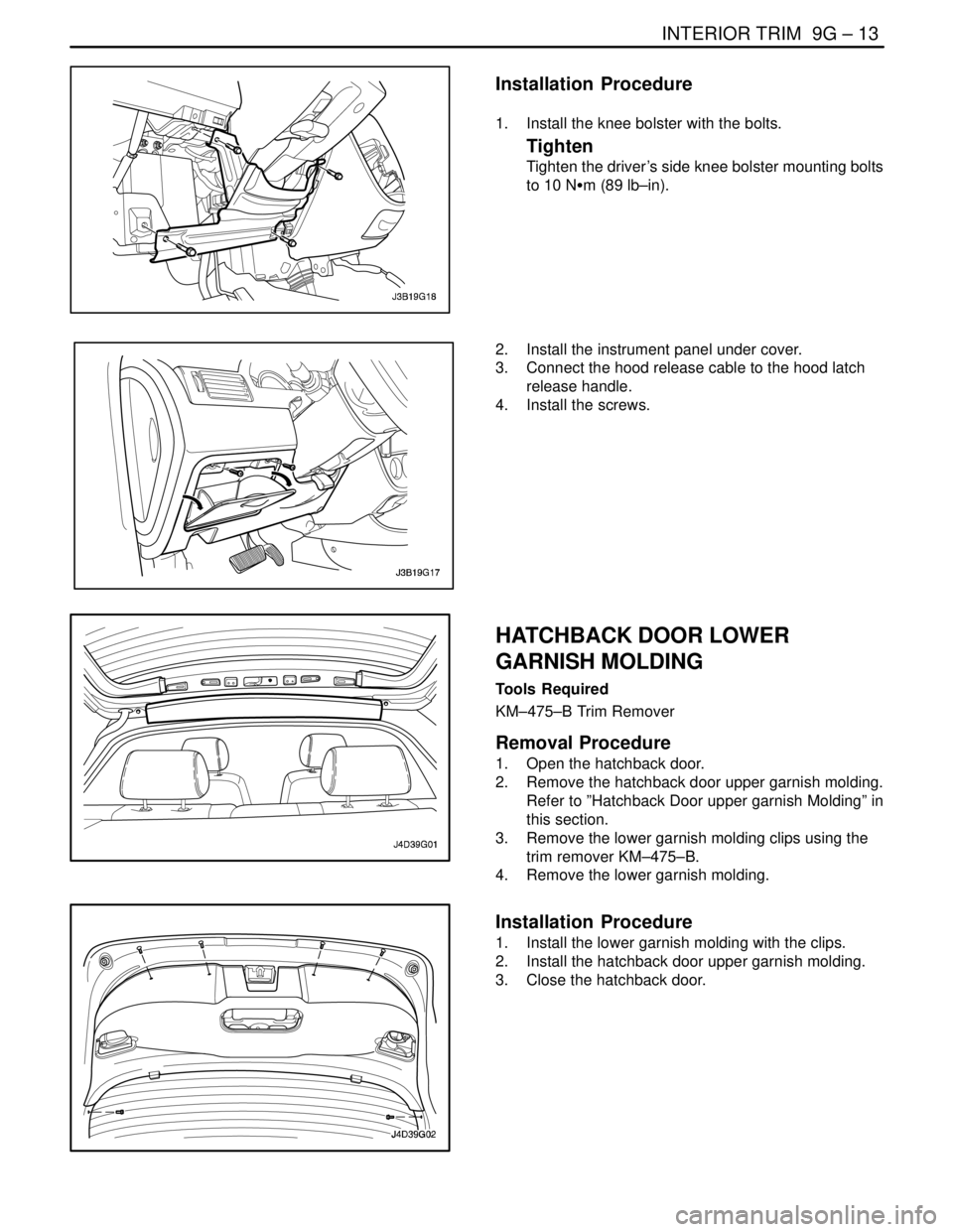

Installation Procedure

1. Install the knee bolster with the bolts.

Tighten

Tighten the driver’s side knee bolster mounting bolts

to 10 NSm (89 lb–in).

2. Install the instrument panel under cover.

3. Connect the hood release cable to the hood latch

release handle.

4. Install the screws.

HATCHBACK DOOR LOWER

GARNISH MOLDING

Tools Required

KM–475–B Trim Remover

Removal Procedure

1. Open the hatchback door.

2. Remove the hatchback door upper garnish molding.

Refer to ”Hatchback Door upper garnish Molding” in

this section.

3. Remove the lower garnish molding clips using the

trim remover KM–475–B.

4. Remove the lower garnish molding.

Installation Procedure

1. Install the lower garnish molding with the clips.

2. Install the hatchback door upper garnish molding.

3. Close the hatchback door.

Page 2363 of 2643

SEATS 9H – 7

DAEWOO V–121 BL4

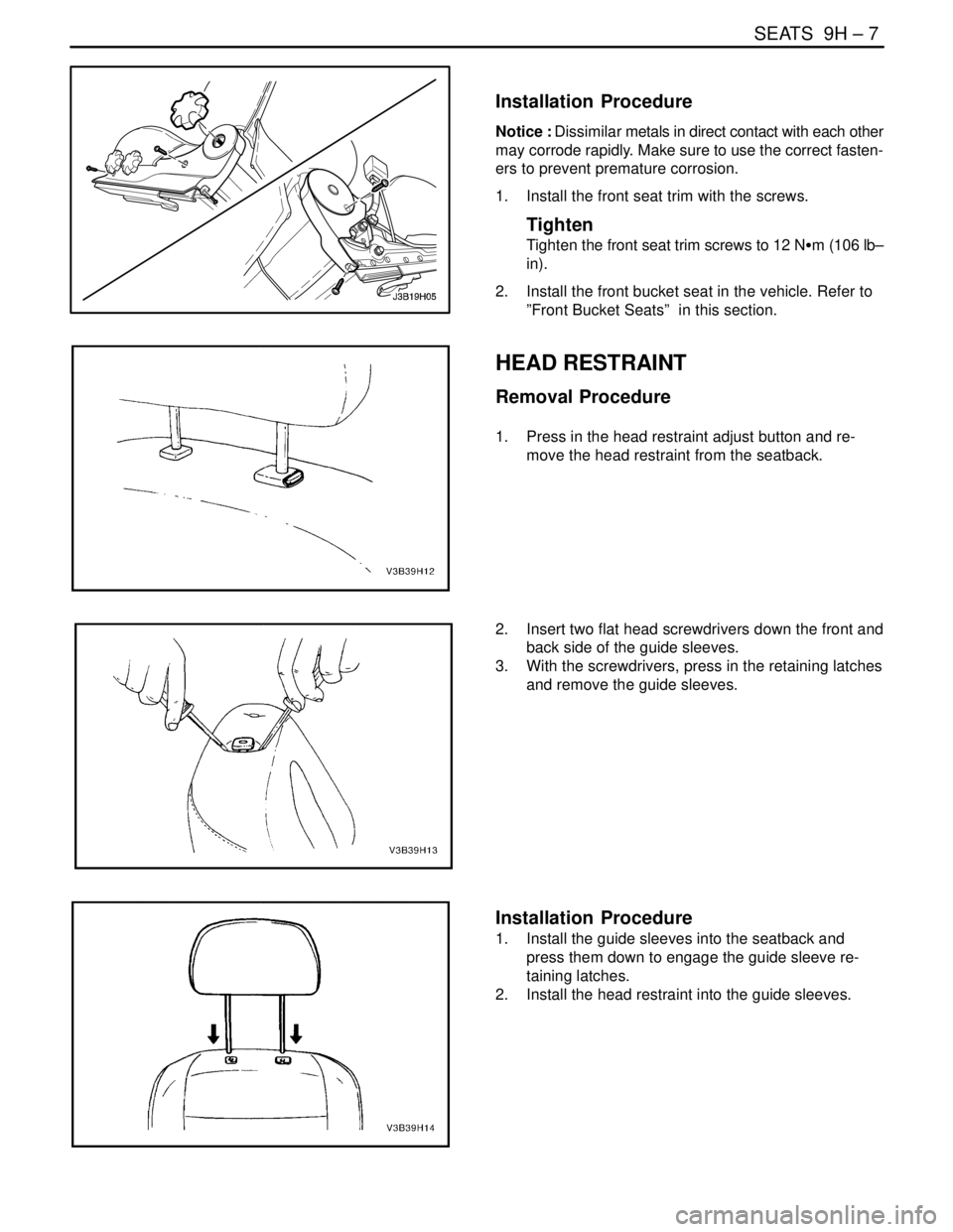

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the front seat trim with the screws.

Tighten

Tighten the front seat trim screws to 12 NSm (106 lb–

in).

2. Install the front bucket seat in the vehicle. Refer to

”Front Bucket Seats” in this section.

HEAD RESTRAINT

Removal Procedure

1. Press in the head restraint adjust button and re-

move the head restraint from the seatback.

2. Insert two flat head screwdrivers down the front and

back side of the guide sleeves.

3. With the screwdrivers, press in the retaining latches

and remove the guide sleeves.

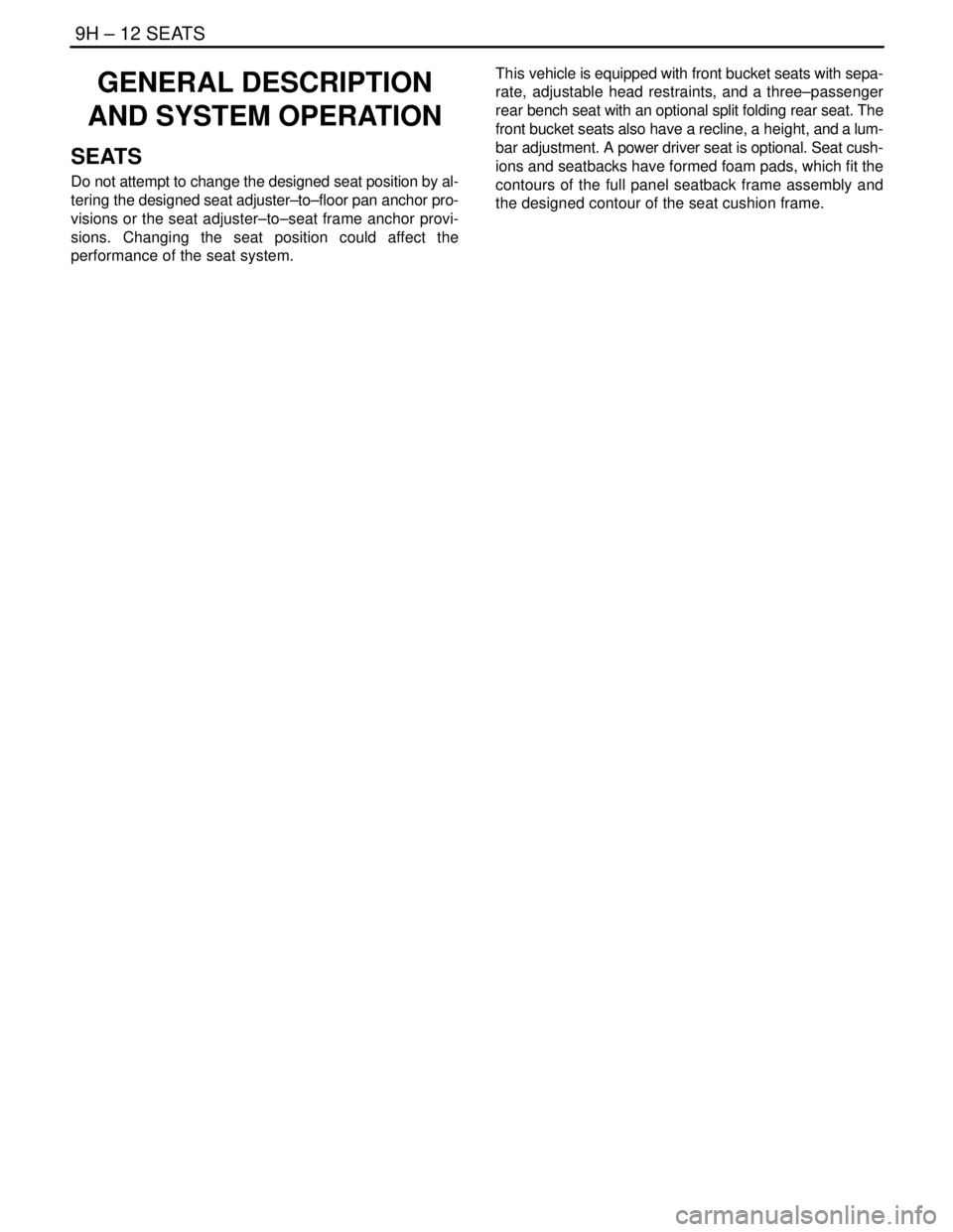

Installation Procedure

1. Install the guide sleeves into the seatback and

press them down to engage the guide sleeve re-

taining latches.

2. Install the head restraint into the guide sleeves.

Page 2368 of 2643

9H – 12ISEATS

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

SEATS

Do not attempt to change the designed seat position by al-

tering the designed seat adjuster–to–floor pan anchor pro-

visions or the seat adjuster–to–seat frame anchor provi-

sions. Changing the seat position could affect the

performance of the seat system.This vehicle is equipped with front bucket seats with sepa-

rate, adjustable head restraints, and a three–passenger

rear bench seat with an optional split folding rear seat. The

front bucket seats also have a recline, a height, and a lum-

bar adjustment. A power driver seat is optional. Seat cush-

ions and seatbacks have formed foam pads, which fit the

contours of the full panel seatback frame assembly and

the designed contour of the seat cushion frame.

Page 2375 of 2643

SECTION : 9J

WINDNOISE

TABLE OF CONTENTS

DIAGNOSIS9J–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windnoise Diagnosis 9J–1. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9J–2 . . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9J–2. . . . . . . . . . . . . . . . . . . . . .

Windnoise Repair 9J–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

WINDNOISE DIAGNOSIS

CAUTION : An assistant should drive the vehicle

while the technician checks for the location of the

windnoise, in order to prevent personal injury or ve-

hicle damage.

A test drive in the vehicle is necessary to accurately deter-

mine the location of the windnoise. Often there is a primary

leak and secondary leaks. Failure to repair all leaks will

only reduce the windnoise, not eliminate it.

During the test drive the technician should bring the follow-

ing items to aid in determining the location of the wind-

noise.

S A mechanics stethoscope or vacuum hose

S Masking tape

S Strip caulk

S A china marking pencil

S A screwdriver

Perform the following steps in order to conduct the road

test:

1. Choose a route that includes smooth straight

streets that run in all four directions (north, south,

east, and west).

2. Choose streets with little traffic or noise that would

interfere with the test.

3. Drive the vehicle at the speeds at which the noise

was noticed by the customer or until the noise is

produced. Do not exceed legal speed limits.

4. The windnoise is external if any of the following

conditions occur:

S The windnoise is caused by the wind.S The windnoise can be heard with the door glass

lowered and while the vehicle is being driven.

S The windnoise is eliminated when tape is placed

over various moldings and gaps.

5. Internal windnoise is air leaving the vehicle and

should be repaired in the following manner.

S In order to locate the leak, tape off the body lock

pillar pressure relief valves. This will cause air

pressure to build up inside the vehicle and en-

hance the windnoise.

S Use a stethoscope or a vacuum hose to locate

the leak.

S Temporarily repair the leak with masking tape.

S Continue testing in order to determine if the

noise has been eliminated or if other leaks exist.

S When all leaks have been found, return to the

shop and make permanent repairs with the

proper alignment techniques and sealing materi-

als.

Page 2386 of 2643

GLASS AND MIRRORS 9L – 7

DAEWOO V–121 BL4

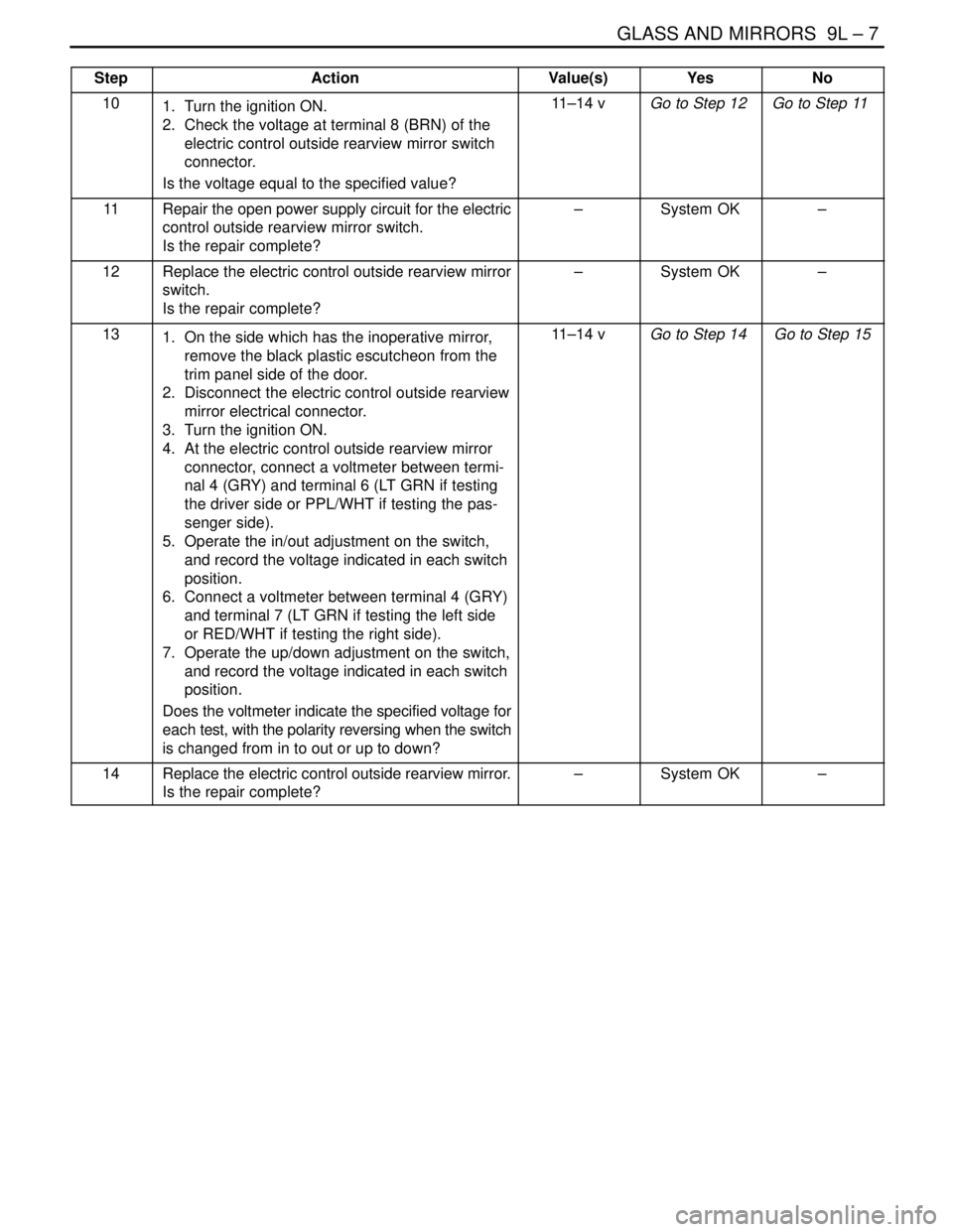

StepNo Yes Value(s) Action

101. Turn the ignition ON.

2. Check the voltage at terminal 8 (BRN) of the

electric control outside rearview mirror switch

connector.

Is the voltage equal to the specified value?11–14 vGo to Step 12 Go to Step 11

11Repair the open power supply circuit for the electric

control outside rearview mirror switch.

Is the repair complete?–System OK–

12Replace the electric control outside rearview mirror

switch.

Is the repair complete?–System OK–

131. On the side which has the inoperative mirror,

remove the black plastic escutcheon from the

trim panel side of the door.

2. Disconnect the electric control outside rearview

mirror electrical connector.

3. Turn the ignition ON.

4. At the electric control outside rearview mirror

connector, connect a voltmeter between termi-

nal 4 (GRY) and terminal 6 (LT GRN if testing

the driver side or PPL/WHT if testing the pas-

senger side).

5. Operate the in/out adjustment on the switch,

and record the voltage indicated in each switch

position.

6. Connect a voltmeter between terminal 4 (GRY)

and terminal 7 (LT GRN if testing the left side

or RED/WHT if testing the right side).

7. Operate the up/down adjustment on the switch,

and record the voltage indicated in each switch

position.

Does the voltmeter indicate the specified voltage for

each test, with the polarity reversing when the switch

is changed from in to out or up to down?11–14 vGo to Step 14 Go to Step 15

14Replace the electric control outside rearview mirror.

Is the repair complete?–System OK–

Page 2398 of 2643

GLASS AND MIRRORS 9L – 19

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

STATIONARY GLASS

Stationary glass consists of all the glass on the vehicle

which is immovable within its frame, such as the wind-

shield glass, the back glass, and the inside rearview mir-

ror.

ELECTRIC CONTROL HEATED

OUTSIDE REARVIEW MIRROR

The electric control for the heated outside rearview mirroris on the driver’s side door. The mirror defogger is acti-

vated by the rear window defogger switch.

INSIDE REARVIEW MIRROR

The rearview mirror pivots at the ball–and–socket mirror

pivot and can be manually adjusted up/down and left/right.

FOLDING MIRROR UNIT

The folding mirror system is automatically folding the mir-

ror in parking state.

Page 2449 of 2643

DOORS 9P – 29

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DOOR LOCK STRIKER

The front and the rear door lock strikers each consist of a

striker with two screws threaded into a floating cage plate

in the B–pillars and the C–pillars. The door is secured in

the closed position when the door lock fork snaps over and

engages the striker.

CHILDPROOF REAR DOOR LOCK

The childproof rear door locks help prevent passengers,

especially children, from opening the rear doors of the ve-

hicle from the inside.

To activate the locks, move the levers of both rear doors

to the lock position. Then, close both doors. The rear pas-

sengers will be unable to open the doors from inside of the

vehicle.

To deactivate the locks, unlock the door from the inside of

the vehicle and open the door from the outside. Move the

lever to the unlock position. The rear door will now work

normally.

POWER DOOR LOCKS

The power door locks use a solenoid that is contained in

each door lock assembly. The door locks are activated by

the actuator on the inside door handle or by the lock cylin-

der on the driver’s side door only. When the driver’s side

door is locked or unlocked by the actuator or the lock cylin-

der, all doors are locked or unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical switches

on the door panels and are operated by a motor at each

window regulator. Each door has a switch to control its

window, and the driver’s side door has four switches to

control all door windows on the vehicle. The windows are

lowered by pressing the switch and raised by pulling up on

the switch. The window will stop movement when the

switch is released or when the window is completely open

or closed.

The driver’s side window opens automatically. By pressing

and releasing the switch, the driver ’s side window will low-

er and will stop only when the switch is activated again, or

when the window is completely open.

The driver’s side door control also contains a window lock

button that will prevent the operation of the front passen-

ger door or the rear door windows when pressed.