section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1997 of 2643

HEATING AND VENTILATION SYSTEM 7A – 23

DAEWOO V–121 BL4

Tighten

Tighten the heater/air distributor case assembly

screws to 4 NSm (35 lb–in).

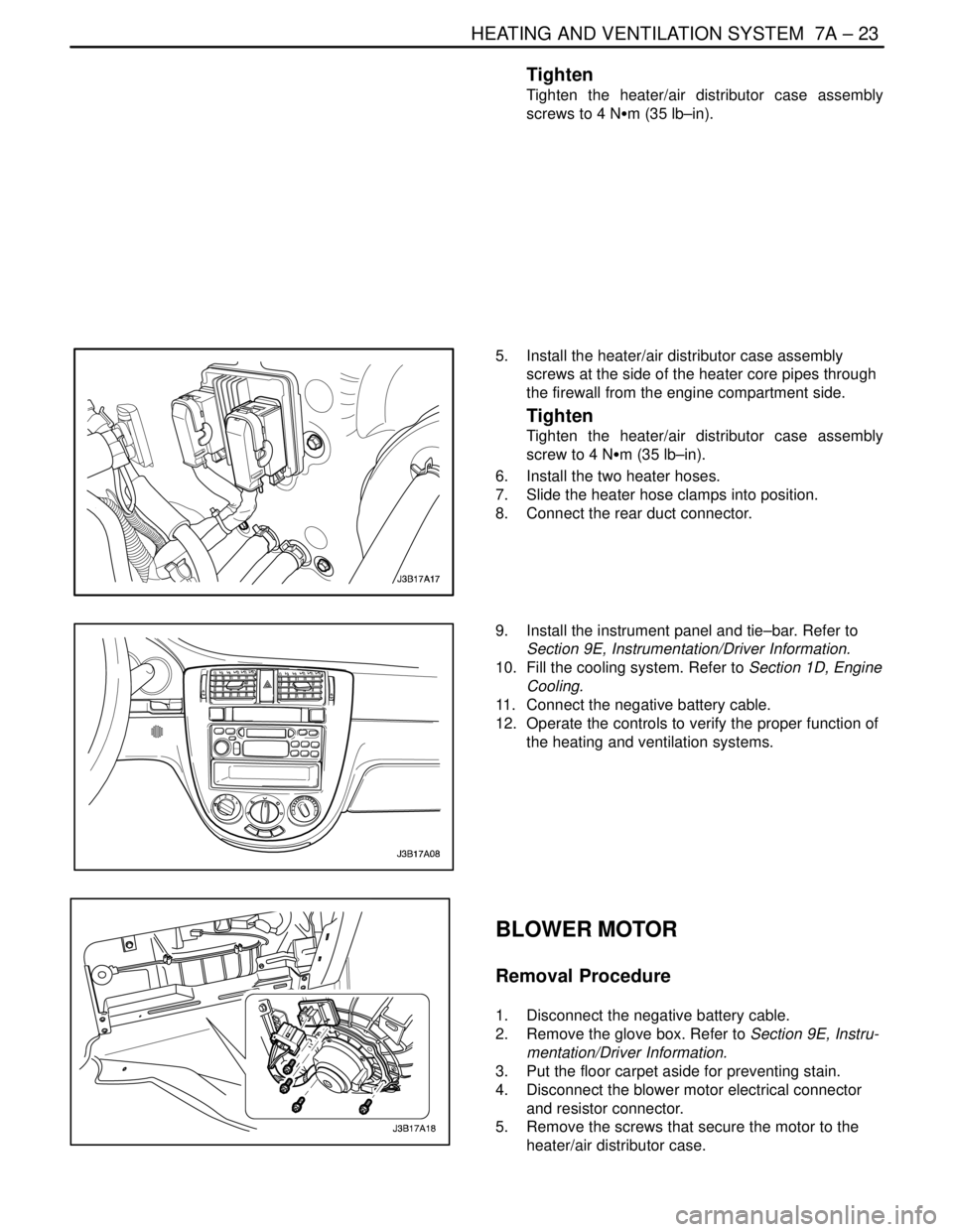

5. Install the heater/air distributor case assembly

screws at the side of the heater core pipes through

the firewall from the engine compartment side.

Tighten

Tighten the heater/air distributor case assembly

screw to 4 NSm (35 lb–in).

6. Install the two heater hoses.

7. Slide the heater hose clamps into position.

8. Connect the rear duct connector.

9. Install the instrument panel and tie–bar. Refer to

Section 9E, Instrumentation/Driver Information.

10. Fill the cooling system. Refer to Section 1D, Engine

Cooling.

11. Connect the negative battery cable.

12. Operate the controls to verify the proper function of

the heating and ventilation systems.

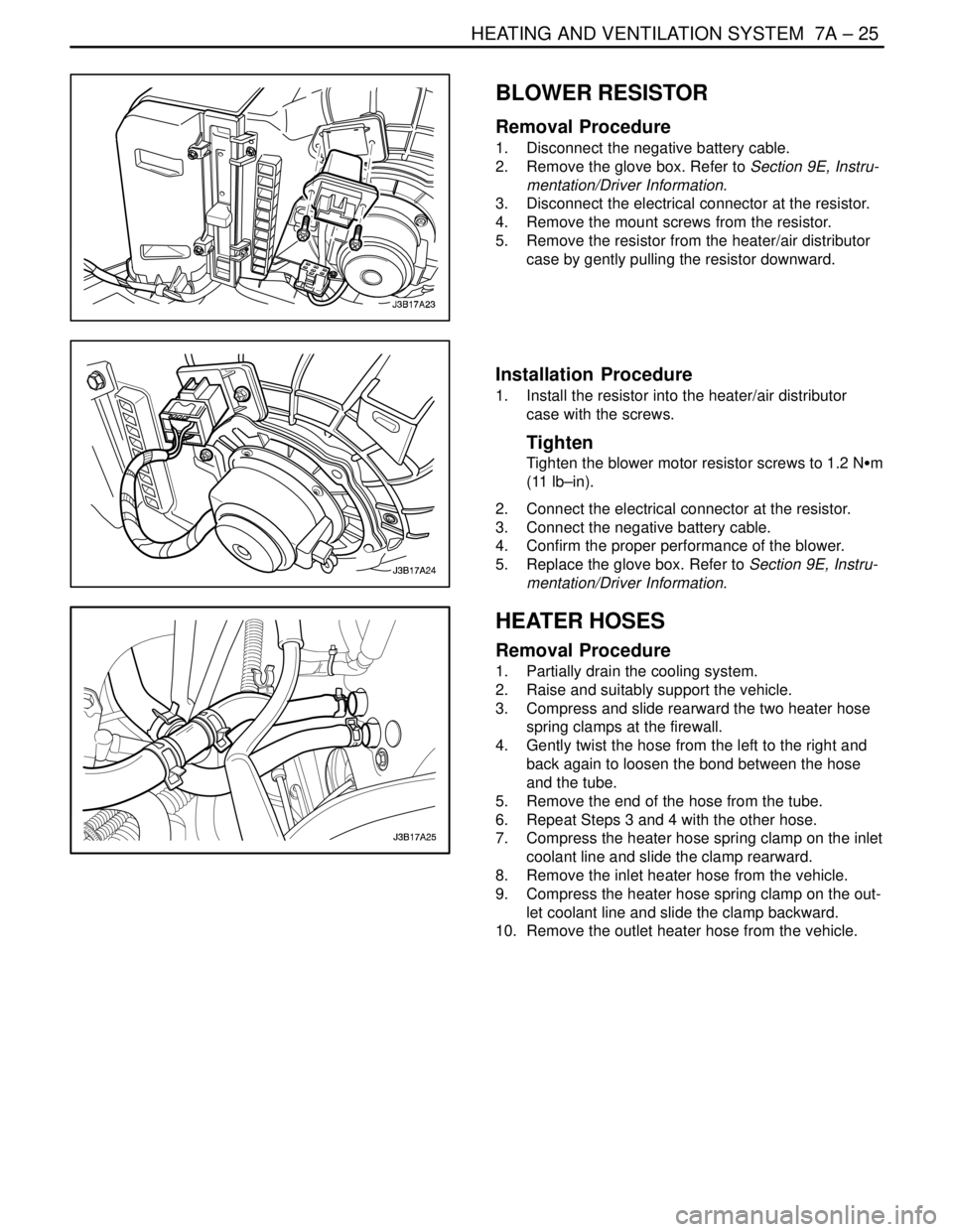

BLOWER MOTOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Put the floor carpet aside for preventing stain.

4. Disconnect the blower motor electrical connector

and resistor connector.

5. Remove the screws that secure the motor to the

heater/air distributor case.

Page 1998 of 2643

7A – 24IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

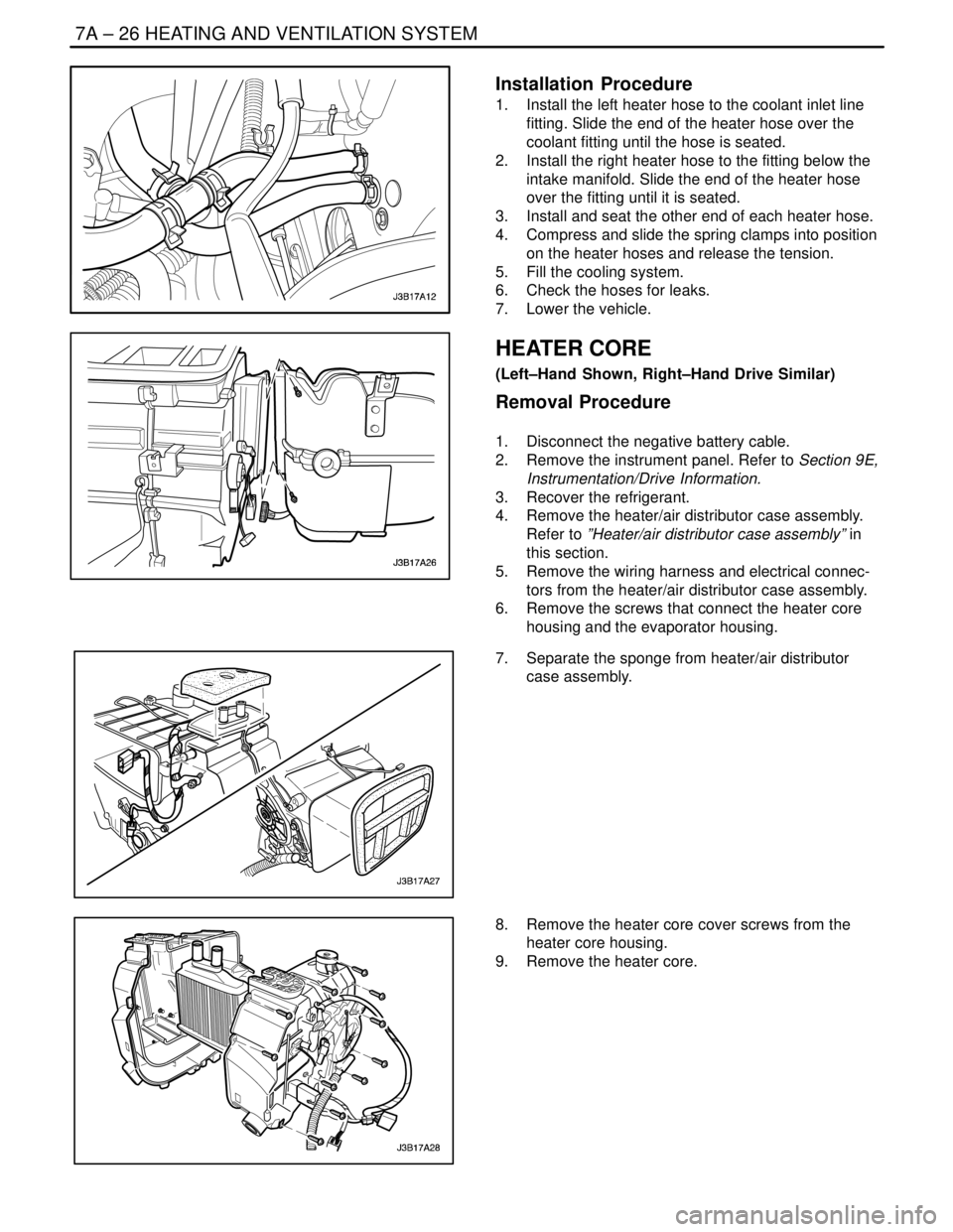

6. Remove the motor, the seal, and the shock mount

pads from the heater/air distributor case by gently

pulling the motor straight down and out.

Installation Procedure

1. Install the blower motor and the seal with the shock

mount pads in the heater/air distributor case. Hold

the blower motor in position.

2. Install the screws to secure the blower motor to the

heater/air distributor case.

Tighten

Tighten the blower motor retaining screws to 1.2 NSm

(11 lb–in).

3. Connect the blower motor electrical connector and

resistor connector.

4. Connect the negative battery cable.

5. Confirm that the blower motor operates properly.

6. Replace the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

HIGH–BLOWER RELAY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box housing. Refer to Section

9E, Instrumentation/Driver Information.

3. Separate the connector from the bracket.

4. Disconnect the relay from the connector.

Installation Procedure

1. Connect the relay to the connector.

2. Insert the connector to the bracket.

3. Install the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

Page 1999 of 2643

HEATING AND VENTILATION SYSTEM 7A – 25

DAEWOO V–121 BL4

BLOWER RESISTOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

3. Disconnect the electrical connector at the resistor.

4. Remove the mount screws from the resistor.

5. Remove the resistor from the heater/air distributor

case by gently pulling the resistor downward.

Installation Procedure

1. Install the resistor into the heater/air distributor

case with the screws.

Tighten

Tighten the blower motor resistor screws to 1.2 NSm

(11 lb–in).

2. Connect the electrical connector at the resistor.

3. Connect the negative battery cable.

4. Confirm the proper performance of the blower.

5. Replace the glove box. Refer to Section 9E, Instru-

mentation/Driver Information.

HEATER HOSES

Removal Procedure

1. Partially drain the cooling system.

2. Raise and suitably support the vehicle.

3. Compress and slide rearward the two heater hose

spring clamps at the firewall.

4. Gently twist the hose from the left to the right and

back again to loosen the bond between the hose

and the tube.

5. Remove the end of the hose from the tube.

6. Repeat Steps 3 and 4 with the other hose.

7. Compress the heater hose spring clamp on the inlet

coolant line and slide the clamp rearward.

8. Remove the inlet heater hose from the vehicle.

9. Compress the heater hose spring clamp on the out-

let coolant line and slide the clamp backward.

10. Remove the outlet heater hose from the vehicle.

Page 2000 of 2643

7A – 26IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

Installation Procedure

1. Install the left heater hose to the coolant inlet line

fitting. Slide the end of the heater hose over the

coolant fitting until the hose is seated.

2. Install the right heater hose to the fitting below the

intake manifold. Slide the end of the heater hose

over the fitting until it is seated.

3. Install and seat the other end of each heater hose.

4. Compress and slide the spring clamps into position

on the heater hoses and release the tension.

5. Fill the cooling system.

6. Check the hoses for leaks.

7. Lower the vehicle.

HEATER CORE

(Left–Hand Shown, Right–Hand Drive Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel. Refer to Section 9E,

Instrumentation/Drive Information.

3. Recover the refrigerant.

4. Remove the heater/air distributor case assembly.

Refer to ”Heater/air distributor case assembly” in

this section.

5. Remove the wiring harness and electrical connec-

tors from the heater/air distributor case assembly.

6. Remove the screws that connect the heater core

housing and the evaporator housing.

7. Separate the sponge from heater/air distributor

case assembly.

8. Remove the heater core cover screws from the

heater core housing.

9. Remove the heater core.

Page 2003 of 2643

SECTION : 7B

MANUAL CONTROL HEATING, VENTILATION

AND AIR CONDITIONING SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS7B–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 7B–2. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 7B–2. . . . . . . . . . .

SPECIAL TOOLS7B–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 7B–3. . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS7B–6 . . . . .

A/C System – Typical 7B–6. . . . . . . . . . . . . . . . . . . . . .

Manual Control A/C Diagram 7B–7. . . . . . . . . . . . . . . .

DIAGNOSIS7B–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DIAGNOSIS 7B–8. . . . . . . . . . . . . . . . . . . . . .

Testing the Refrigerant System 7B–8. . . . . . . . . . . . . .

Insufficient Cooling ”Quick Check” Procedure 7B–8. .

A/C Performance Test 7B–9. . . . . . . . . . . . . . . . . . . . . .

Pressure–Temperature Relationship of

R–134A 7B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing Refrigerant System 7B–11. . . . . . . . . . . .

V5 SYSTEM AIR CONDITIONING DIAGNOSIS 7B–12

Insufficient Cooling Diagnosis 7B–12. . . . . . . . . . . . . .

SYMPTOM DIAGNOSIS 7B–16. . . . . . . . . . . . . . . . . . . .

Pressure Test Chart (R–134A System) 7B–16. . . . . .

Low and High Side Pressure Relationship

Chart 7B–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR7B–19 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 7B–19. . . . . . . . . . . . . . . . . . . .

GENERAL A/C SYSTEM SERVICE

PROCEDURES 7B–19. . . . . . . . . . . . . . . . . . . . . . . . . .

O–Ring Replacement 7B–19. . . . . . . . . . . . . . . . . . . . .

Handling Refrigerant 7B–19. . . . . . . . . . . . . . . . . . . . . .

Handling of Refrigerant Lines and Fittings 7B–19. . . .

Maintaining Chemical Stability in the Refrigeration

System 7B–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System 7B–20. . . . . . . . . . . . . .

SERVICEABLE COMPONENTS 7B–23. . . . . . . . . . . . . Components Used In Non–A/C Systems 7B–23. . . . .

A/C Pressure Transducer 7B–24. . . . . . . . . . . . . . . . . .

A/C Compressor Relay 7B–24. . . . . . . . . . . . . . . . . . . .

Air Filter 7B–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C Expansion Valve 7B–25. . . . . . . . . . . . . . . . . . . . . .

A/C High–Pressure Pipe Line 7B–26. . . . . . . . . . . . . . .

Evaporator Core 7B–29. . . . . . . . . . . . . . . . . . . . . . . . . .

A/C Suction Hose Assembly 7B–30. . . . . . . . . . . . . . .

A/C Discharge Hose Compressor to

Condenser 7B–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver–Dryer 7B–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor 7B–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser 7B–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 7B–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR 7B–37. . . . . . . . . . . . . . . . . . .

V5 Compressor 7B–37. . . . . . . . . . . . . . . . . . . . . . . . . . .

V5 AIR CONDITIONING COMPRESSOR

OVERHAUL 7B–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Plate and Hub Assembly 7B–38. . . . . . . . . . . .

Clutch Rotor and Bearing 7B–40. . . . . . . . . . . . . . . . . .

Clutch Coil 7B–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft Seal Replacement 7B–44. . . . . . . . . . . . . . . . . . .

Control Valve Assembly 7B–46. . . . . . . . . . . . . . . . . . .

Rear Head, Gasket, Valve Plate, Reed Plate,

and O–ring 7B–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder to Front Head O–ring 7B–48. . . . . . . . . . . . . .

Leak Testing (External) 7B–50. . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION7B–51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 7B–51. . . . . . . . . . . . . . . . . .

The V5 A/C System 7B–51. . . . . . . . . . . . . . . . . . . . . . .

System Components – Functional 7B–51. . . . . . . . . .

System Components – Control 7B–52. . . . . . . . . . . . .

V5 Compressor – General Description 7B–52. . . . . . .

V5 Compressor – Description of Operation 7B–52. . .

Page 2010 of 2643

7B – 8IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

GENERAL DIAGNOSIS

TESTING THE REFRIGERANT

SYSTEM

If you suspect a problem in the refrigerant system, check

for the following conditions:

1. Check the outer surfaces of the radiator and the

condenser cores to be sure that the airflow is not

blocked by dirt, leaves, or other foreign material.

Check between the condenser and the radiator, as

well as all outer surfaces.

2. Check for restrictions or kinks in the condenser

core, the hoses, and the tubes.

3. Check the operation of the blower fan.

4. Check all the air ducts for leaks or restrictions. Low

airflow rate may indicate a restricted evaporator

core.

5. Check for slippage of the compressor clutch.

6. Check the drive belt tension.

INSUFFICIENT COOLING ”QUICK

CHECK” PROCEDURE

Perform the following ”hand–feel” procedure to get a quick

idea of whether the A/C system has the proper charge of

Refrigerant–134a. The air temperature must be above

21°C (70°F) for most models.

1. Warm up engine. Run the engine at idle.

2. Open the hood and all the doors.

3. Turn the A/C switch ON.

4. Set the temperature control to the full cold position.

5. Set the blower speed switch on the maximum

speed setting.

6. ”Hand–feel” the temperature of the evaporator out-

let pipe. The pipe should be cold.

7. Check for other problems. Refer to ”Testing the Re-

frigerant System” in this section.

8. Leak check the system. Refer to ”Leak Testing the

Refrigerant System” in this section. If you find a

leak, discharge the system and repair the leak as

required. After completing the repair, evacuate the

system and charge it.

9. If there is no leak, refer to ”Insufficient Cooling

Diagnosis” in this section.

Page 2013 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 11

DAEWOO V–121 BL4

LEAK TESTING REFRIGERANT

SYSTEM

Test for leaks whenever you suspect a refrigerant leak in

the system. You should also test for leaks whenever you

perform a service operation which results in disturbing the

lines or the connections. Leaks are commonly found at the

refrigerant fittings or at the connections. Leaks are com-

monly caused by the following problems:

S Improper torque.

S Damaged O–ring seals.

S Dirt or lint on the O–ring seals.

Liquid Leak Detectors

Use a liquid leak detector solution on locations such as fit-

tings. Apply the solution to the area in question with the

swab that is supplied with the solution. Look for bubbles

to appear. This will indicate the existence and the location

of any leak.

For areas where this is not practical, such as sections of

the evaporator and the condenser, an electronic leak de-

tector is more useful.

Electronic Leak Detectors

Follow the manufacturer’s instructions for calibration, op-

eration, and maintenance of an electronic leak detector.

Battery condition is especially important to the accuracy

of a portable model. Set the detector to R–134a before be-

ginning the test.

Notice : Electronic leak detectors are sensitive to wind-

shield washing solutions, solvents and cleaners, and cer-

tain vehicle adhesives. Surfaces must be clean to prevent

false readings. Make sure that all surfaces are dry to pre-

vent damage to the detector.

General Testing Instructions

1. Follow the entire path of the refrigerant system.

2. Completely circle each joint at 25 to 50 mm (1 to 2

inches) per second.

3. Hold the probe tip within 6 mm (1/4 inch) of the sur-

face.4. Do not block the air intake.

5. The audible tone changes from 1 to 2 clicks per

second into a solid alarm if there is a leak. Adjust

the balance control to maintain 1 to 2 clicks per

second.

6. Test all of the following areas, even after one leak

has been confirmed:

S Evaporator inlet and outlet.

S Receiver–drier inlet and outlet.

S Condenser inlet and outlet.

S Brazed and welded areas.

S Damaged areas.

S Hose couplings.

S Compressor rear head.

S All fittings and joints.

Testing Service Ports/Access Valves

The sealing caps provide protection for the service ports.

Make sure that these caps are not missing or loose. Al-

ways use the correct cap for each port.

Testing the Evaporator Core

Leaks in the evaporator core are difficult to find. Test the

evaporator core using the following procedure:

1. Run the blower fan at the maximum speed setting

for at least 15 minutes.

2. Turn the blower OFF.

3. Wait for 10 minutes.

4. Remove the blower motor resistor. Refer to Section

7A, Heating and Ventilation System.

5. Insert the leak detector probe as close as possible

to the evaporator core. The detector will indicate a

leak with a solid alarm.

6. Use a flashlight to search for refrigerant oil on the

core surface.

Testing the Compressor Shaft Seal

1. Blow shop air behind and in front of the compressor

clutch/pulley for at least 15 seconds.

2. Wait 1 to 2 minutes.

3. Probe the area in front of the pulley. If the detector

emits a solid alarm, there is a leak.

Page 2016 of 2643

7B – 14IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

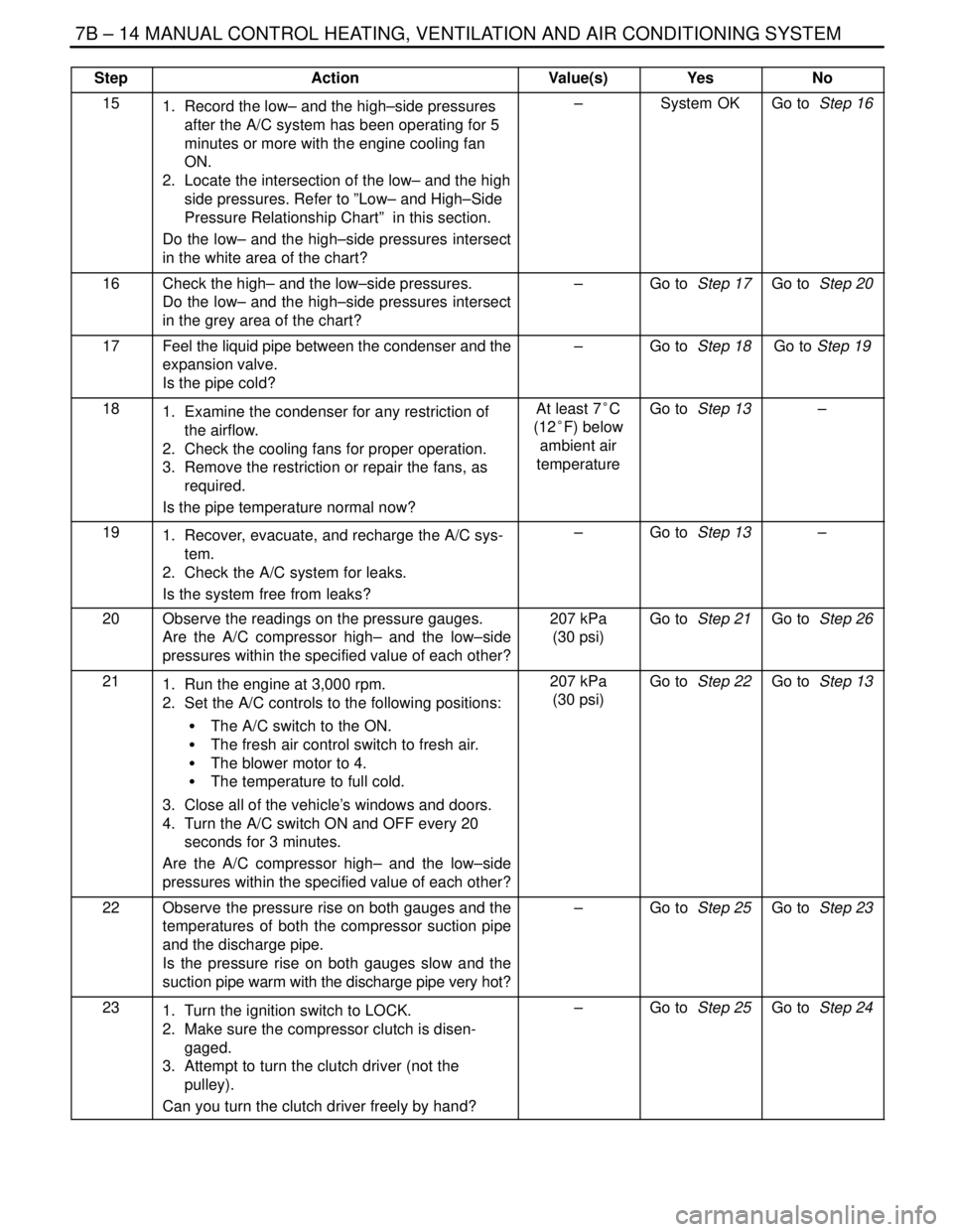

StepNo Yes Value(s) Action

151. Record the low– and the high–side pressures

after the A/C system has been operating for 5

minutes or more with the engine cooling fan

ON.

2. Locate the intersection of the low– and the high

side pressures. Refer to ”Low– and High–Side

Pressure Relationship Chart” in this section.

Do the low– and the high–side pressures intersect

in the white area of the chart?–System OKGo to Step 16

16Check the high– and the low–side pressures.

Do the low– and the high–side pressures intersect

in the grey area of the chart?–Go to Step 17Go to Step 20

17Feel the liquid pipe between the condenser and the

expansion valve.

Is the pipe cold?–Go to Step 18Go to Step 19

181. Examine the condenser for any restriction of

the airflow.

2. Check the cooling fans for proper operation.

3. Remove the restriction or repair the fans, as

required.

Is the pipe temperature normal now?At least 7°C

(12°F) below

ambient air

temperatureGo to Step 13–

191. Recover, evacuate, and recharge the A/C sys-

tem.

2. Check the A/C system for leaks.

Is the system free from leaks?–Go to Step 13–

20Observe the readings on the pressure gauges.

Are the A/C compressor high– and the low–side

pressures within the specified value of each other?207 kPa

(30 psi)Go to Step 21Go to Step 26

211. Run the engine at 3,000 rpm.

2. Set the A/C controls to the following positions:

S The A/C switch to the ON.

S The fresh air control switch to fresh air.

S The blower motor to 4.

S The temperature to full cold.

3. Close all of the vehicle’s windows and doors.

4. Turn the A/C switch ON and OFF every 20

seconds for 3 minutes.

Are the A/C compressor high– and the low–side

pressures within the specified value of each other?207 kPa

(30 psi)Go to Step 22Go to Step 13

22Observe the pressure rise on both gauges and the

temperatures of both the compressor suction pipe

and the discharge pipe.

Is the pressure rise on both gauges slow and the

suction pipe warm with the discharge pipe very hot?–Go to Step 25Go to Step 23

231. Turn the ignition switch to LOCK.

2. Make sure the compressor clutch is disen-

gaged.

3. Attempt to turn the clutch driver (not the

pulley).

Can you turn the clutch driver freely by hand?–Go to Step 25Go to Step 24

Page 2021 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 19

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

GENERAL A/C SYSTEM SERVICE PROCEDURES

O–RING REPLACEMENT

Important : Even though O–rings may look identical, it is

extremely important that only recommended service re-

placement air conditioning O–rings be used or excessive

leakage of refrigerant may occur.

Important : Always slip the O–ring onto the flange tube to

ensure proper locating and sealing.

Install new Daewoo–approved service replacement air

conditioning (A/C) O–rings whenever a joint or a fitting is

disassembled, except when the O–rings are provided on

new components.

When replacing O–rings on an A/C component or a joint

connection, the fitting design should be identified to en-

sure installation of the correct air conditioning service re-

placement O–ring. Some joint connections and compo-

nents will implement a ”captured” O–ring design fitting that

uses a groove to retain the O–ring. Others do not have a

groove and use a ”non–captured” or ”standard” O–ring.

Assembly and tightening procedures are the same for

both designs, but the O–rings are different.

Notice : Before installation, verify that both O–rings and

fittings have not been nicked or deformed. Deformed or

nicked parts must be replaced. Failure to use the proper

service replacement parts and procedures may result in

excessive refrigerant leakage.

HANDLING REFRIGERANT

CAUTION : Always work in a well–ventilated area and

avoid breathing any refrigerant fumes. If you have dif-

ficulty with breathing, seek medical attention immedi-

ately. If refrigerant comes in contact with any part of

your body, flush the exposed area with water. If a rash

or pain develops, seek medical attention.

Air conditioning systems contain refrigerant. This is a

chemical mixture which requires special handling proce-

dures to avoid personal injury.

Always wear goggles and wrap a clean cloth around the

fittings, the valves and the connections when performing

work that involves opening the refrigerant system. Do not

weld or steam clean on or near any vehicle–installed air

conditioning lines or components.

All refrigerant drums are shipped with a heavy metal screw

cap. The purpose of the cap is to protect the valve and the

safety plug from damage. It is good practice to replace the

cap after each use of the drum.If it is necessary to transport or carry any container of re-

frigerant in a vehicle, do not carry it in the passenger

compartment.

HANDLING OF REFRIGERANT LINES

AND FITTINGS

Notice : Using too low or too high torque when tightening

a fitting can result in loose joints or deformed joint parts.

Both conditions can result in refrigerant leakage.

S Keep all metal tubing lines free of dents or kinks.

Any line restrictions will cause the loss of system

capacity.

S Never bend a flexible hose line to a radius of less

than four times the diameter of the hose.

S Never allow a flexible hose line to come within 65

mm (2–1/2 inches) of the exhaust manifold.

S Inspect flexible hose lines regularly for leaks or

brittleness.

S Replace flexible hose lines with new lines if you find

signs of deterioration or leaking.

S Discharge all refrigerant of the refrigeration system

before disconnecting any fitting in the refrigeration

system.

S Proceed very cautiously regardless of the gauge

readings.

CAUTION : Keep your face and your hands away from

the fitting so that you will not be injured if there hap-

pens to be liquid refrigerant in the line.

S Open the fittings very slowly.

S If you notice pressure when you loosen a fitting,

allow the pressure to bleed off as described under

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

S Cap or tape any refrigerant line immediately after it

is opened. This will prevent the entrance of mois-

ture and dirt, which can cause internal compressor

wear or plugged lines in the condenser, the evapo-

rator core, the expansion valve, or the compressor

inlet screens.

Important : Use two proper wrenches to connect the O–

ring fittings.

S Back up the opposing fitting to prevent distortion of

the connecting lines or the components.

S Back up both the swagged fitting on the flexible

hose connections and the coupling to which it is

attached with two wrenches to prevent turning the

fitting and damaging the ground seat.

S Keep the O–rings and the seats in perfect condi-

tion. A burr or a piece of dirt may cause a refriger-

ant leak.

Page 2022 of 2643

7B – 20IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

S Dip new O–rings in clean polyalkaline glycol refrig-

erant oil before installation.

MAINTAINING CHEMICAL STABILITY

IN THE REFRIGERATION SYSTEM

The efficient operation and the life of the air conditioning

(A/C) system is dependent upon the chemical stability of

the refrigeration system. When foreign materials, such as

dirt, air, or moisture, contaminate the refrigeration system,

they will change the stability of the refrigerant and the poly-

alkaline glycol (PAG) compressor oil. They will also affect

the pressure–temperature relationship, reduce efficient

operation, and can possibly cause interior corrosion and

abnormal wear of moving parts.

Observe the following practices to ensure chemical stabil-

ity in the system:

S Wipe away dirt or oil at and near any connection

before opening that connection. This will reduce the

chance of dirt entering the system.

S Cap, plug, or tape both sides of a connection as

soon as possible after opening the connection. This

will prevent the entry of dirt, foreign material, and

moisture.

S Keep all tools clean and dry, including the manifold

gauge set and all replacement parts.

S Use a clean and dry transfer device and container

to add polyalkaline glycol refrigerant oil. This will

ensure that the oil remains as moisture–free as

possible. Refer to ”Discharging, Adding Oil, Eva-

cuating, and Charging Procedures for A/C System”

in this section.

S Have everything you need ready to allow you to

perform all operations quickly when opening an A/C

system. Do not leave the A/C system open any lon-

ger than necessary.

S Evacuate and recharge any A/C system that has

been opened. Refer to ”Discharging, Adding Oil,

Evacuating, and Charging Procedures for A/C Sys-

tem” in this section for the instructions to perform

this procedure properly.

All service parts are dehydrated and sealed before ship-

ping. They should remain sealed until just before making

connections. All the parts should be at room temperature

before uncapping. This prevents condensation of mois-

ture from the air from entering the system. Reseal all parts

as soon as possible.

DISCHARGING, ADDING OIL,

EVACUATING, AND CHARGING

PROCEDURES FOR A/C SYSTEM

CAUTION : Use only refillable refrigerant tanks that

are authorized for the charging station being used.

The use of other tanks may cause personal injury or

void the warranty. Refer to the manufacturer’s in-

structions for the charging station.CAUTION : To avoid personal injury, always wear

goggles and gloves when performing work that in-

volves opening the refrigeration system.

A charging station discharges, evacuates, and recharges

an air–conditioning (A/C) system with one hookup. Filter-

ing the refrigerant during the recovery cycle together with

filtering during the evacuation cycle ensures a supply of

clean, dry refrigerant for A/C system charging.

S Never use the R–134a charging station on a sys-

tem charged with R–12. The refrigerants and the

oils from each system are not compatible with

those from the other system and must never be

mixed, even in the smallest amount. Mixing refriger-

ant residue will damage the equipment.

S Never use adapters which convert from one size

fitting to another. Such use allows contamination,

which may cause system failure.

Charging Station Setup and Maintenance

There are many charging stations available. All perform

the various tasks required to discharge the system and re-

cover refrigerant, evacuate the system, add a measured

amount of oil, and recharge an A/C system with a mea-

sured amount of refrigerant. Refer to the manufacturer’s

instructions for all initial setup procedures and all mainte-

nance procedures.

Control Panel Functions

A charging station will have controls and indicators to allow

the operator to control and monitor the operation in prog-

ress. Refer to the manufacturer’s instructions for details.

These can be expected to include the following:

1. Main Power Switch

S Supplies electrical power to the control panel.

2. Display

S Shows the time programmed for vacuum.

S Shows the weight of the refrigerant programmed

for recharging.

S Refer to the manufacturer’s instructions for de-

tailed programming information.

3. Low–Side Manifold Gauge

S Shows the system’s low–side pressure.

4. High–Side Manifold Gauge

S Shows the system’s high–side pressure.

5. Controls Panel

S Controls the various operating functions.

6. Low–Side Valve

S Connects the low side of the A/C system to the

unit.

7. Moisture Indicator

S Shows whether the refrigerant is wet or dry.

8. High–Side Valve

S Connects the high side of the A/C system to the

unit.