Automatic DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 969 of 2643

TIRES AND WHEELS 2E – 7

DAEWOO V–121 BL4

Recoating Procedure

CAUTION : To avoid serious personal injury when ap-

plying any two–part component paint system, follow

the specific precautions provided by the paint

manufacturer. Failure to follow these precautions

may cause lung irritation and an allergic respiratory

reaction.

1. Clean the surface.

2. Soak the wheel with Amchem Alumi Prep No. 33 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

3. Soak the wheel with Amchem Alodine No. 1001 or

equivalent for 1 to 3 minutes. Rinse the wheel with

water and blow it dry.

4. Finish with Ditzler Delclear Urethane and Ditzler

Ultra–Urethane Additive or equivalent, using three

coats.

1st coat – spray on a light mist coat; let dry.

2nd coat – spray or paint on a light coat; let dry.

3rd coat – spray or paint on a heavy double wet

coat; let dry.

5. Let the urethane dry for 24 hours or flash for 30

minutes and force dry at 60°C (140°F) for 30 min-

utes. Allow the urethane to cool for 5 minutes be-

fore mounting the wheel on the vehicle.

OFF–VEHICLE BALANCING

Perform wheel balancing with an electronic off–vehicle ba-

lancer. The balancer is easy to use and gives both a static

and a dynamic balance. Unlike on–vehicle balancing, the

off–vehicle balancer does not correct for drum or rotor im-

balance. This drawback is overcome by its accuracy (usu-

ally to within 1/8 ounce). Secure the wheel on the balancer

with a cone through the back side of the centerhole, not

through the wheel bolt holes.

CORRECTING NON–UNIFORM TIRES

There are two ways to correct properly balanced tires

which still vibrate. One method uses an automatic ma-

chine which loads the tire and buffs small amounts of rub-

ber from high spots on the outer two tread rows. Correction

by this method is usually permanent and, if it is done prop-

erly, does not significantly affect the appearance or the

tread life of the tire. Tire truing with a blade–type machine

is not recommended because it substantially reduces the

tread life and often does not correct the problem perma-

nently.

Another method is to dismount the tire and rotate it 180 de-

grees on the rim. Do this only on the tire and wheel assem-

blies which are known to be causing a vibration because

this method is just as likely to cause good assemblies to

vibrate.

Page 990 of 2643

SECTION : 3A

AUTOMATIC TRANSAXLE DRIVE AXLE

TABLE OF CONTENTS

SPECIFICATIONS3A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 3A–1. . . . . . . . . .

SPECIAL TOOLS3A–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 3A–2. . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR3A–2 . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 3A–2. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR3A–4 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 3A–4. . . . . . . . . . . . . . . . . . . . .

Drive Axle Assembly 3A–4. . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 3A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Joint Seal 3A–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Inner Tripot Seal 3A–8. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION3A–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 3A–10. . . . . . . . . . . . . . . . . . . . . . . . . .

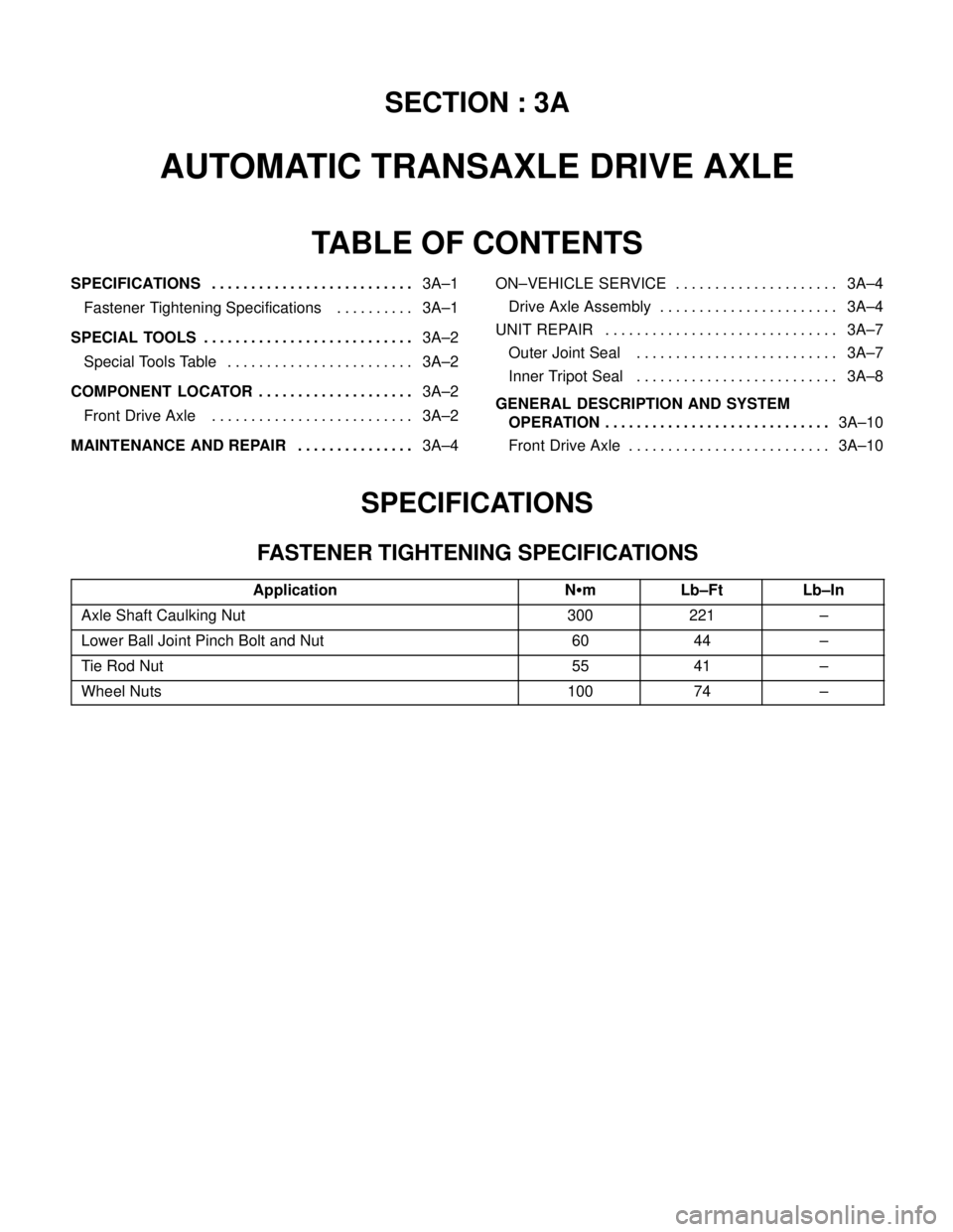

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Axle Shaft Caulking Nut300221–

Lower Ball Joint Pinch Bolt and Nut6044–

Tie Rod Nut5541–

Wheel Nuts10074–

Page 991 of 2643

3A – 2IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

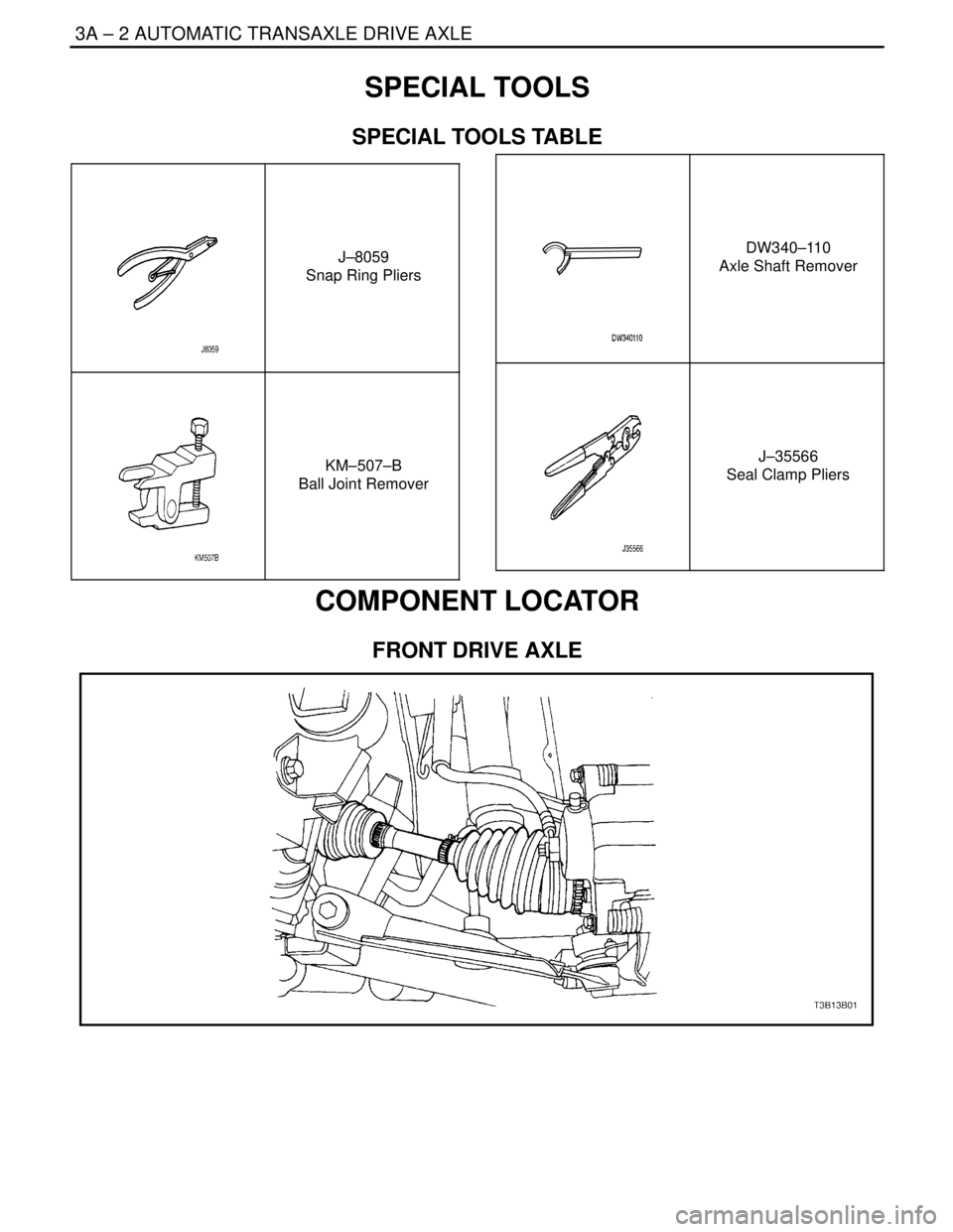

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J–8059

Snap Ring Pliers

KM–507–B

Ball Joint Remover

DW340–110

Axle Shaft Remover

J–35566

Seal Clamp Pliers

COMPONENT LOCATOR

FRONT DRIVE AXLE

Page 992 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 3

DAEWOO V–121 BL4

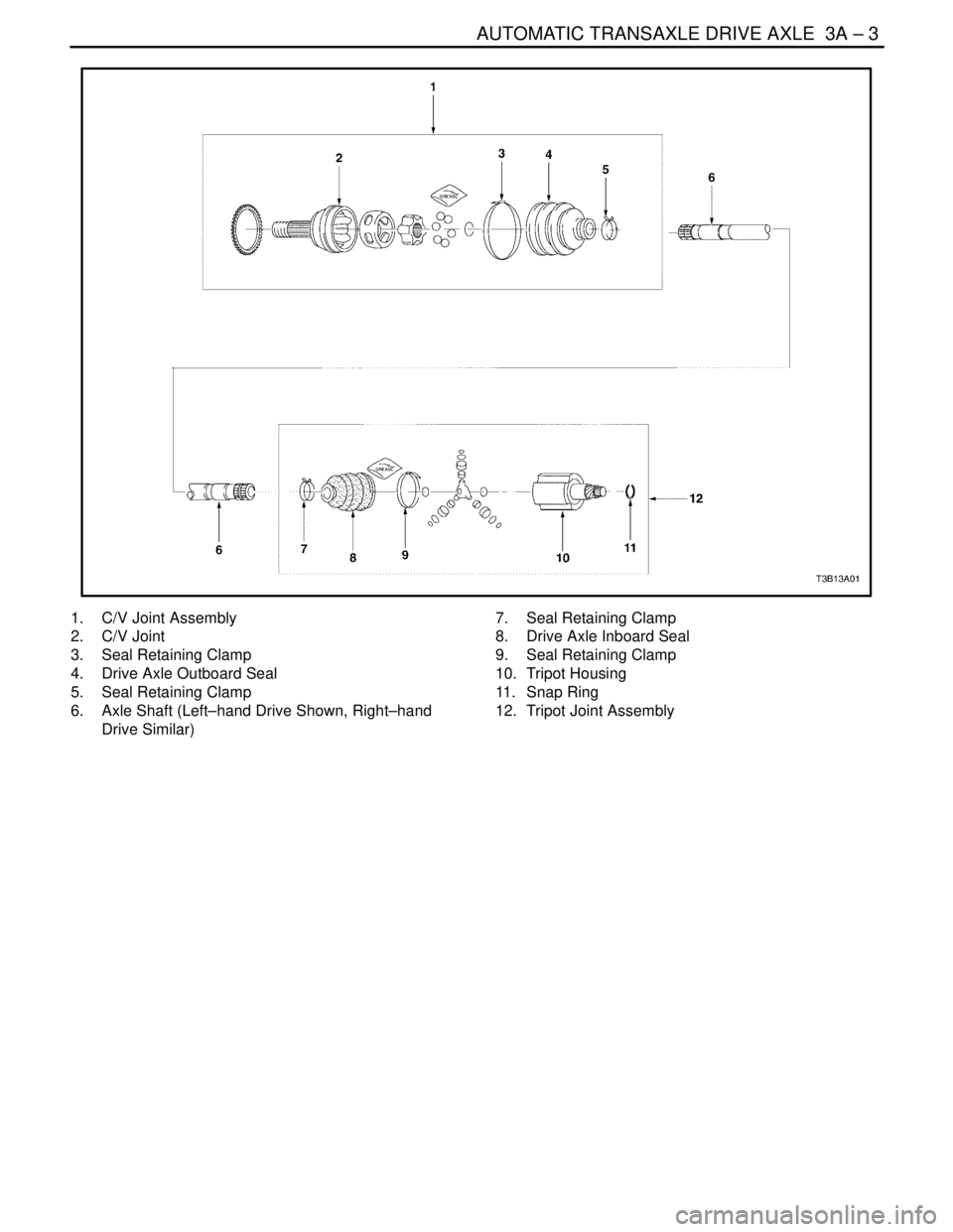

1. C/V Joint Assembly

2. C/V Joint

3. Seal Retaining Clamp

4. Drive Axle Outboard Seal

5. Seal Retaining Clamp

6. Axle Shaft (Left–hand Drive Shown, Right–hand

Drive Similar)7. Seal Retaining Clamp

8. Drive Axle Inboard Seal

9. Seal Retaining Clamp

10. Tripot Housing

11. Snap Ring

12. Tripot Joint Assembly

Page 993 of 2643

3A – 4IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

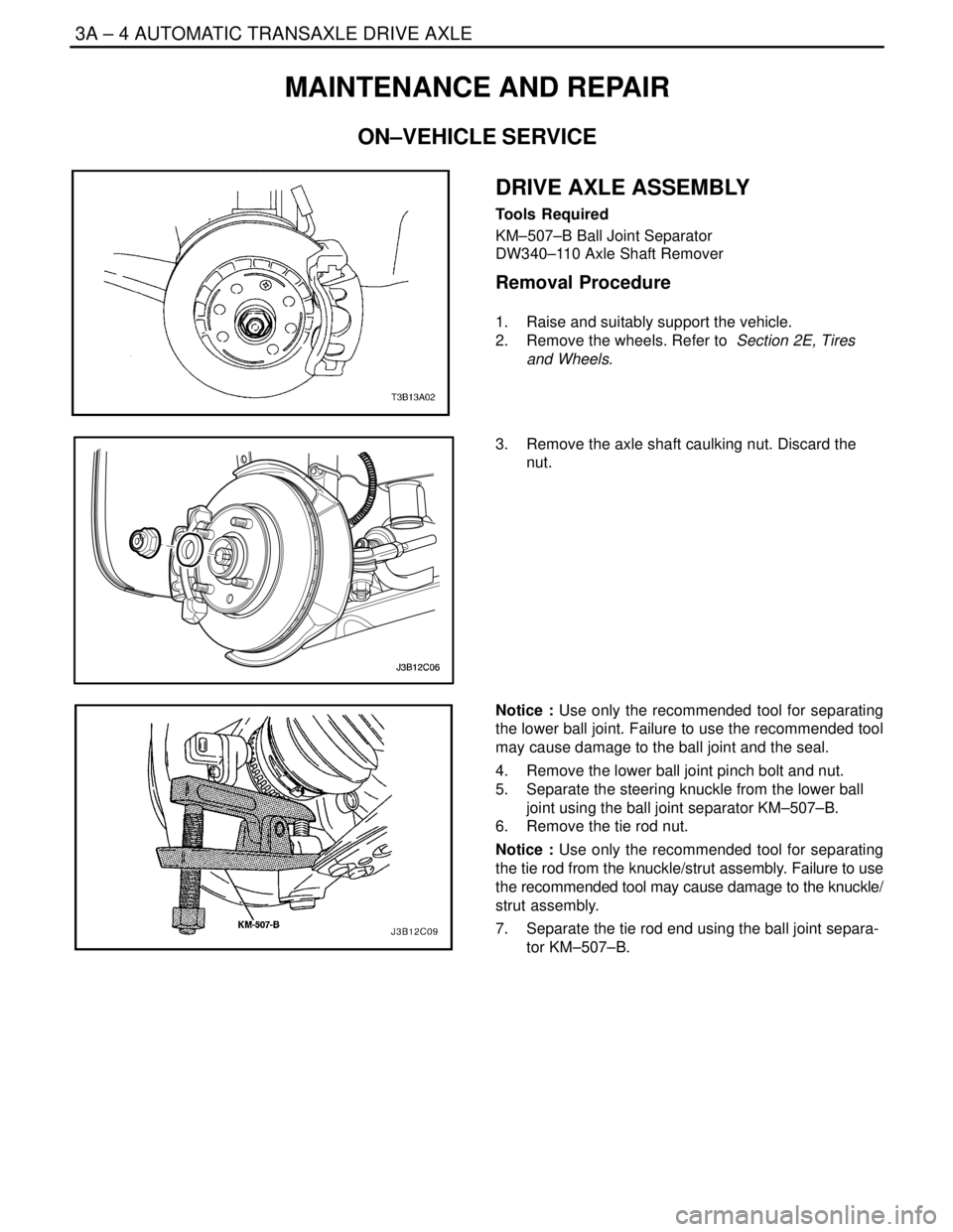

DRIVE AXLE ASSEMBLY

Tools Required

KM–507–B Ball Joint Separator

DW340–110 Axle Shaft Remover

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires

and Wheels.

3. Remove the axle shaft caulking nut. Discard the

nut.

Notice : Use only the recommended tool for separating

the lower ball joint. Failure to use the recommended tool

may cause damage to the ball joint and the seal.

4. Remove the lower ball joint pinch bolt and nut.

5. Separate the steering knuckle from the lower ball

joint using the ball joint separator KM–507–B.

6. Remove the tie rod nut.

Notice : Use only the recommended tool for separating

the tie rod from the knuckle/strut assembly. Failure to use

the recommended tool may cause damage to the knuckle/

strut assembly.

7. Separate the tie rod end using the ball joint separa-

tor KM–507–B.

Page 994 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 5

DAEWOO V–121 BL4

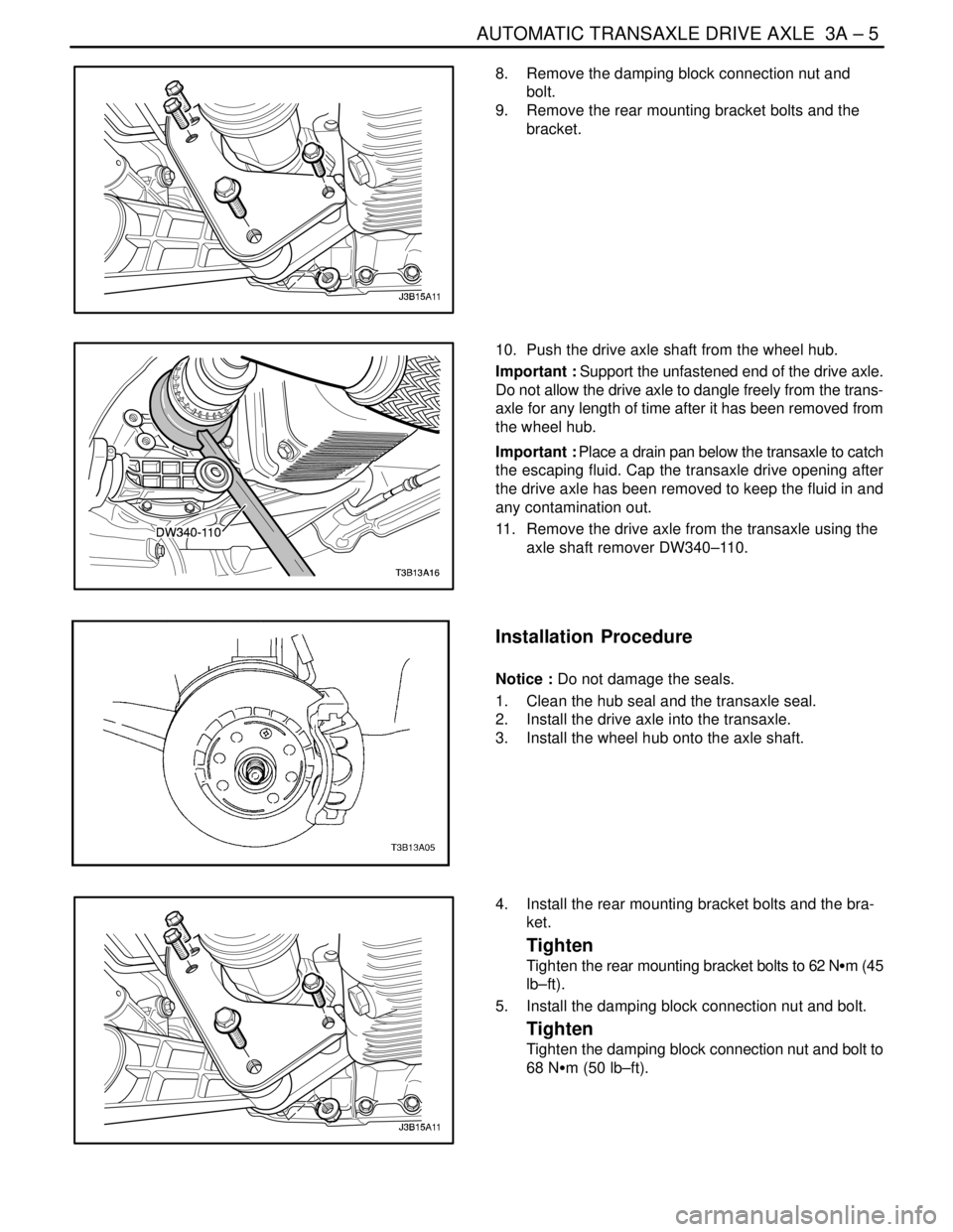

8. Remove the damping block connection nut and

bolt.

9. Remove the rear mounting bracket bolts and the

bracket.

10. Push the drive axle shaft from the wheel hub.

Important : Support the unfastened end of the drive axle.

Do not allow the drive axle to dangle freely from the trans-

axle for any length of time after it has been removed from

the wheel hub.

Important : Place a drain pan below the transaxle to catch

the escaping fluid. Cap the transaxle drive opening after

the drive axle has been removed to keep the fluid in and

any contamination out.

11. Remove the drive axle from the transaxle using the

axle shaft remover DW340–110.

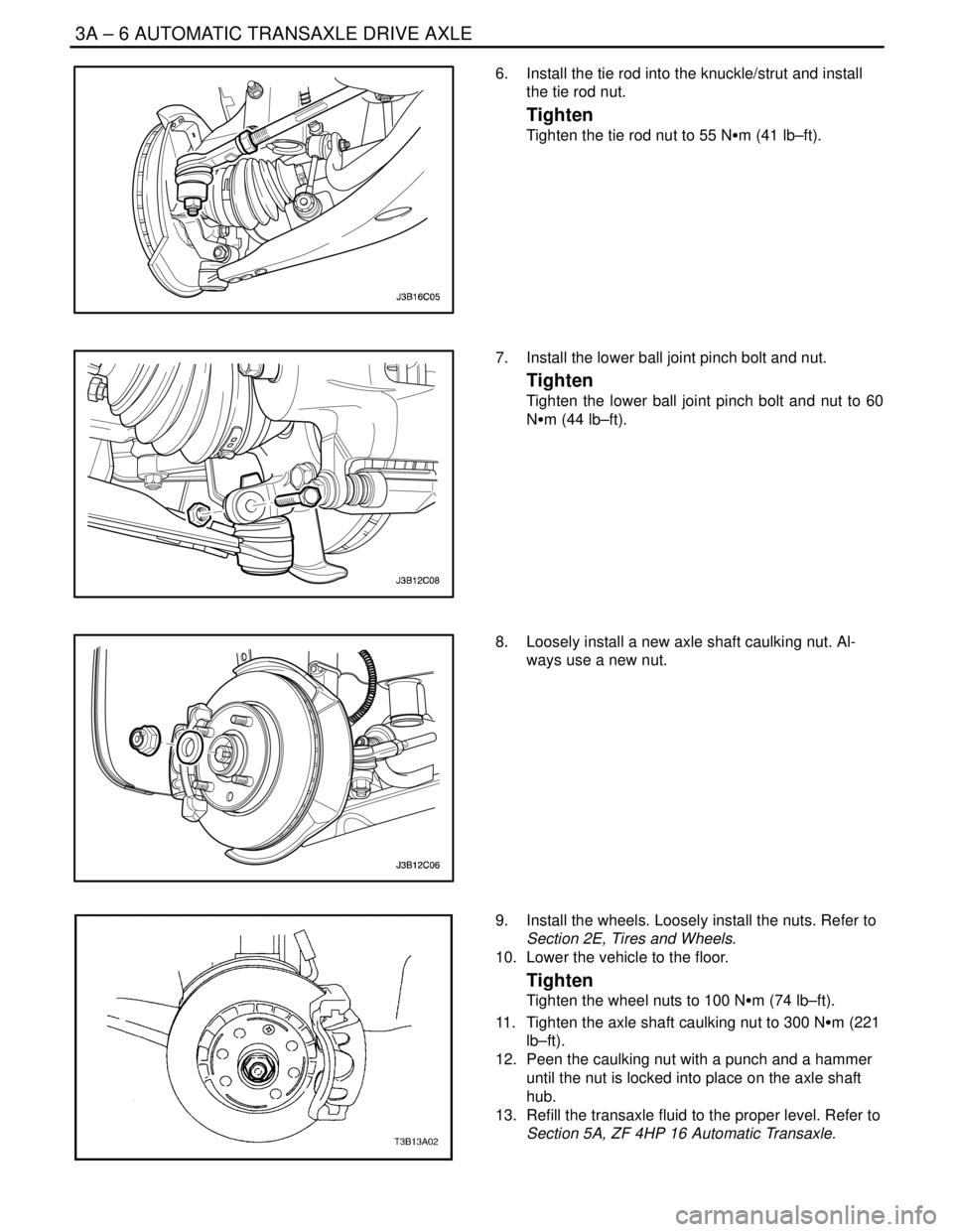

Installation Procedure

Notice : Do not damage the seals.

1. Clean the hub seal and the transaxle seal.

2. Install the drive axle into the transaxle.

3. Install the wheel hub onto the axle shaft.

4. Install the rear mounting bracket bolts and the bra-

ket.

Tighten

Tighten the rear mounting bracket bolts to 62 NSm (45

lb–ft).

5. Install the damping block connection nut and bolt.

Tighten

Tighten the damping block connection nut and bolt to

68 NSm (50 lb–ft).

Page 995 of 2643

3A – 6IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

6. Install the tie rod into the knuckle/strut and install

the tie rod nut.

Tighten

Tighten the tie rod nut to 55 NSm (41 lb–ft).

7. Install the lower ball joint pinch bolt and nut.

Tighten

Tighten the lower ball joint pinch bolt and nut to 60

NSm (44 lb–ft).

8. Loosely install a new axle shaft caulking nut. Al-

ways use a new nut.

9. Install the wheels. Loosely install the nuts. Refer to

Section 2E, Tires and Wheels.

10. Lower the vehicle to the floor.

Tighten

Tighten the wheel nuts to 100 NSm (74 lb–ft).

11. Tighten the axle shaft caulking nut to 300 NSm (221

lb–ft).

12. Peen the caulking nut with a punch and a hammer

until the nut is locked into place on the axle shaft

hub.

13. Refill the transaxle fluid to the proper level. Refer to

Section 5A, ZF 4HP 16 Automatic Transaxle.

Page 996 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 7

DAEWOO V–121 BL4

UNIT REPAIR

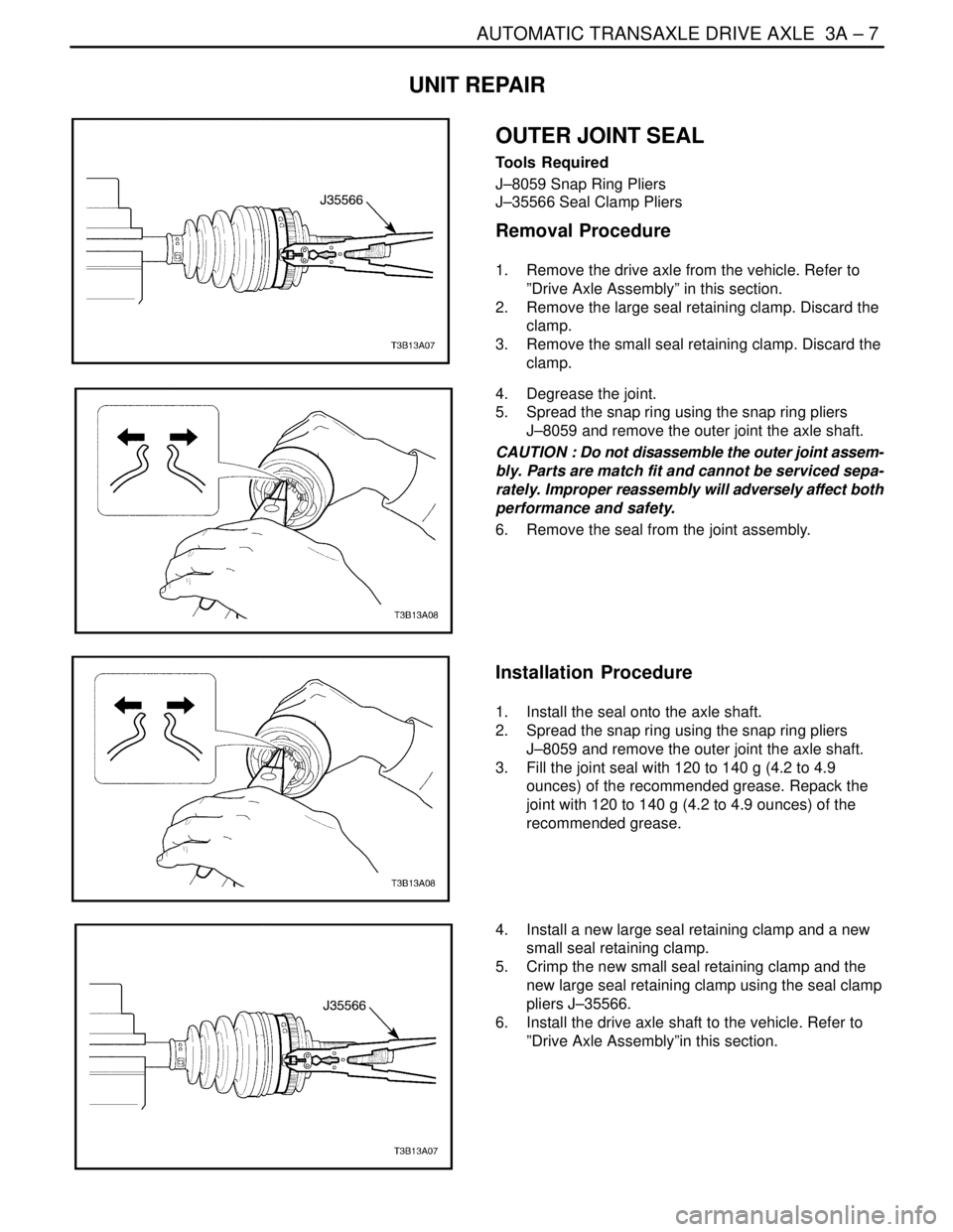

OUTER JOINT SEAL

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle Assembly” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

CAUTION : Do not disassemble the outer joint assem-

bly. Parts are match fit and cannot be serviced sepa-

rately. Improper reassembly will adversely affect both

performance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

3. Fill the joint seal with 120 to 140 g (4.2 to 4.9

ounces) of the recommended grease. Repack the

joint with 120 to 140 g (4.2 to 4.9 ounces) of the

recommended grease.

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J–35566.

6. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly”in this section.

Page 997 of 2643

3A – 8IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

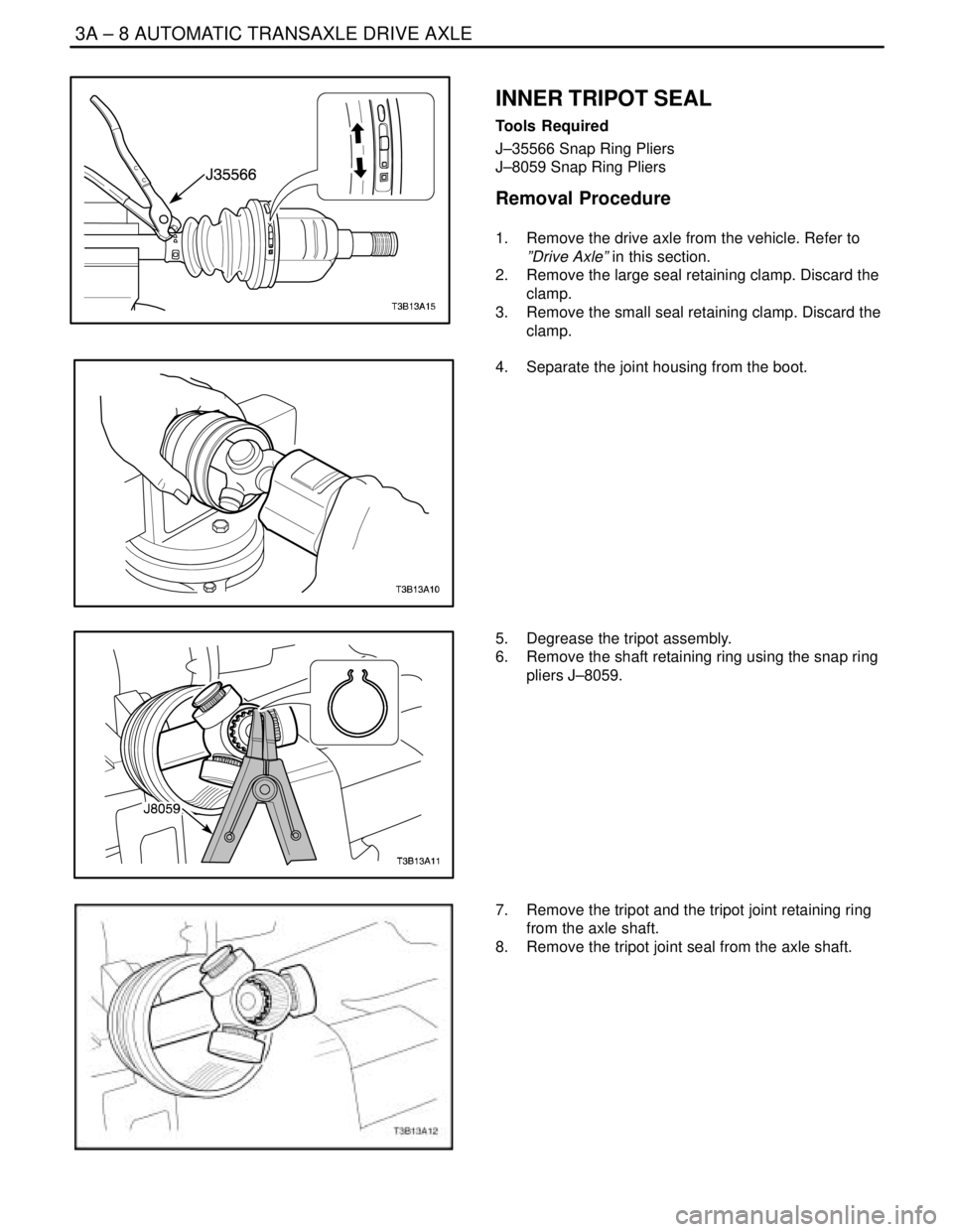

INNER TRIPOT SEAL

Tools Required

J–35566 Snap Ring Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Separate the joint housing from the boot.

5. Degrease the tripot assembly.

6. Remove the shaft retaining ring using the snap ring

pliers J–8059.

7. Remove the tripot and the tripot joint retaining ring

from the axle shaft.

8. Remove the tripot joint seal from the axle shaft.

Page 998 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 9

DAEWOO V–121 BL4

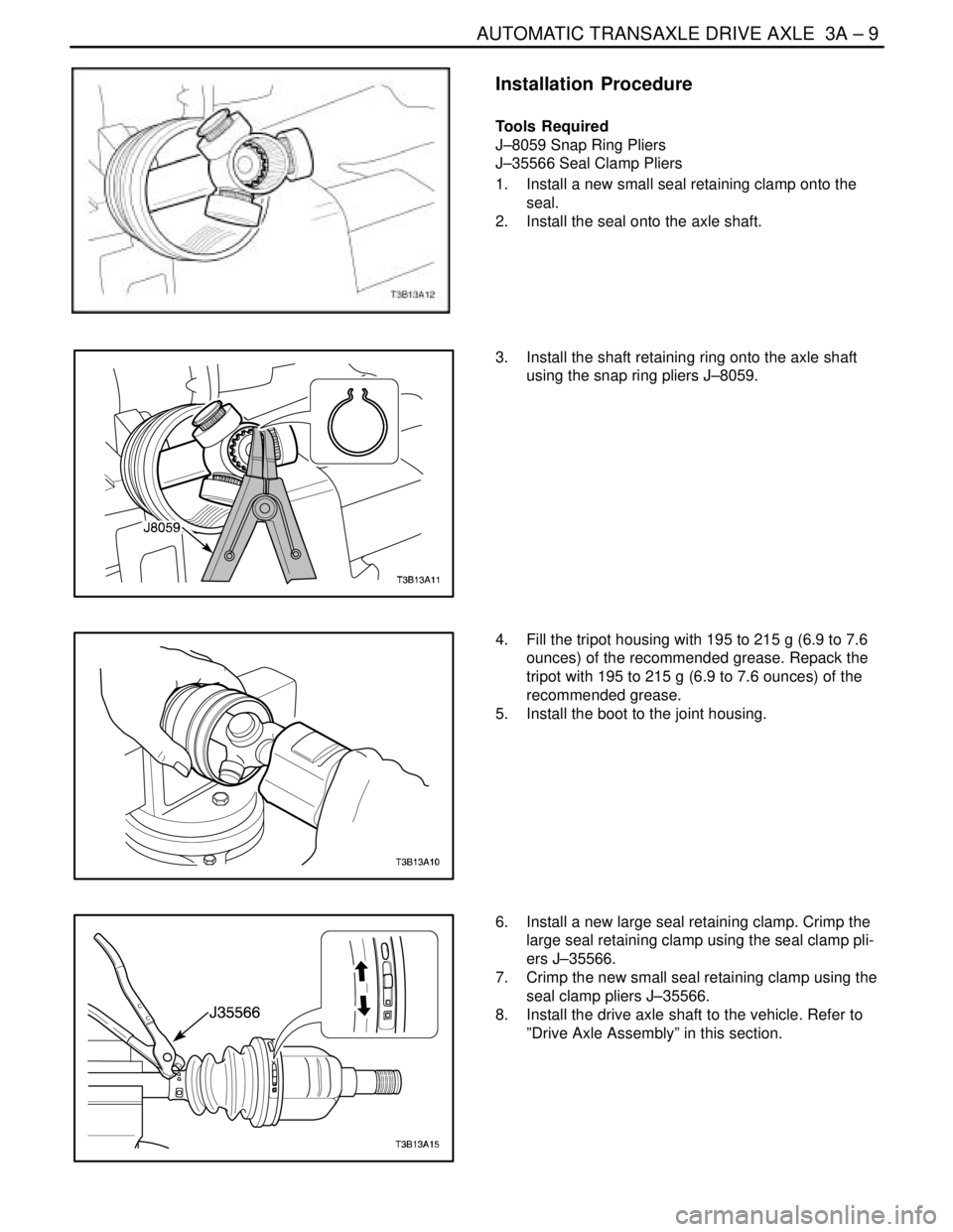

Installation Procedure

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the

seal.

2. Install the seal onto the axle shaft.

3. Install the shaft retaining ring onto the axle shaft

using the snap ring pliers J–8059.

4. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

5. Install the boot to the joint housing.

6. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp pli-

ers J–35566.

7. Crimp the new small seal retaining clamp using the

seal clamp pliers J–35566.

8. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.