tran DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2490 of 2643

REMOTE KEYLESS ENTRY AND ANTI–THEFT SYSTEM 9T1 – 9

DAEWOO V–121 BL4

length of time between flashes is used to indicate certain

vehicle conditions. Refer to ”Fault or Alarm Indication” in

this section.

AUTOLOCKING (SAFETY LOCK)

The remote keyless entry system features an autolocking

feature. If the doors are unlocked with the remote transmit-

ter when the control module/receiver is in the armed

mode, the doors are automatically re–locked after 30 sec-

onds unless any of the following events occur:

S A door is opened.

S The ignition is ON.

S The trunk is opened.

S The hood is opened.

CONTROL MODULE/RECEIVER

The remote keyless entry control module/receiver is con-

tained in the floor console. The module/receiver pro-

cesses signals from the remote transmitter and various

switches. It activates the alarm if an intrusion is detected.

The control module/receiver also has a self–diagnostic

function which will display trouble codes. In order to dis-

play trouble codes, a scan tool must be connected to the

data link connector (DLC).

The control module/receiver will not communicate with

transmitters from other vehicles because there are over

four billion possible electronic password combinations. Itis highly unlikely that any transmitters will use the same

password. The control module/receiver has an attached

antenna to detect signals from the transmitter.

FAULT OR ALARM INDICATION

When the UNLOCK button on the remote transmitter is

pressed, the control module/receiver will flash the parking

lights to indicate information about the remote keyless

entry and anti–theft system.

Normal Condition: If there has not been an intrusion, and

no fault has been detected, the control module/receiver

will signal a normal condition when the UNLOCK button is

pressed. The parking lights will flash twice for 0.5 second,

with a 0.5 second pause between flashes.

Fault Indication: If there is a fault in the remote keyless

entry and anti–theft system, the control module/receiver

will signal the fault when the UNLOCK button is pressed.

The parking lights will flash twice for 1 second, with a 0.5

second pause between flashes.

Alarm Indication: If there has been an intrusion since the

last time the LOCK button was pressed, the control mod-

ule/receiver will signal that there has been an intrusion

when the UNLOCK button is pressed. The parking lights

will flash twice for 0.5 second, with a 1.5 second pause be-

tween flashes.

Alarm and fault information will be erased the next time the

transmitter arms the control module/receiver by transmit-

ting a LOCK message.

Page 2491 of 2643

SECTION : 9T2

IMMOBILIZER ANTI–THEFT SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SCHEMATIC AND ROUTING DIAGRAMS9T2–2 . . . .

Immobilizer Anti–Theft System 9T2–2. . . . . . . . . . . . .

DIAGNOSTIC INFORMATION AND

PROCEDURES9T2–3 . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer System

(MR–140, HV–240, SIRIUS D4) 9T2–3. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1626 (MR–140,

HV–240), P1628 (SIRIUS) 9T2–4. . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1631 (MR–140,

HV–240), P1629 (SIRIUS D4) 9T2–6. . . . . . . . . . . .

Key Status Errors

(MR–140, HV–240, SIRIUS D4) 9T2–8. . . . . . . . . . .

Communication Between Immobilizer Control Unit and

Test Equipment

(MR–140, HV–240, SIRIUS D4) 9T2–8. . . . . . . . . . . MAINTENANCE AND REPAIR9T2–9 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T2–9. . . . . . . . . . . . . . . . . . . .

Key Coding Procedure 9T2–9. . . . . . . . . . . . . . . . . . . .

ID Code Reprogramming 9T2–9. . . . . . . . . . . . . . . . . .

Transponder 9T2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer Control Unit 9T2–9. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T2–11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer System 9T2–11. . . . . . . . . . . . . . . . . . . . . .

Electronically Coded Keys 9T2–11. . . . . . . . . . . . . . . .

Detection Coil 9T2–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Immobilizer Control Unit 9T2–11. . . . . . . . . . . . . . . . . .

Serial Data Link 9T2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Control Moudle (ECM) 9T2–12. . . . . . . . . .

Page 2493 of 2643

IMMOBILIZER ANTI–THEFT SYSTEM 9T2 – 3

DAEWOO V–121 BL4

DIAGNOSTIC INFORMATION AND

PROCEDURES

IMMOBILIZER SYSTEM (MR–140,

HV–240, SIRIUS D4)

The immobilizer anti–theft system requires diagnosis

when it is not possible to start the engine. If the no–start

condition occurs because of the immobilizer system, a

diagnostic trouble code (P) 1626, 1628, 1629, 1631 should

be set.

The immobilizer control unit monitors the detection and

the reading of the ignition key. The self–test capacity is lim-

ited to those functions. Faults are communicated to a scan

tool during diagnosis, but they are not stored in the immo-

bilizer control unit’s memory.Unauthorized use of a scan tool could be a method of de-

feating the immobilizer anti–theft system, so certain scan

tool procedures require the use of a password. The follow-

ing functions are password protected:

S Coding of an additional key.

S Deleting all key codes.

The following functions do not require a password:

S Reading an ignition key to determine if the trans-

ponder is working or if a key is authorized.

S Reading the immobilizer ID code to verify that it

matches the ECM ID code.

Page 2498 of 2643

9T2 – 8IIMMOBILIZER ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

KEY STATUS ERRORS (MR–140,

HV–240, SIRIUS D4)

The following KEY STATUS messages may be shown on

the scan tool after commanding FIRST KEY CODING and

KEY ADD:

S IGNITION OFF STATUS. This message informs

the technician that the ignition is off during the key

coding process. Turn the ignition ON during key

coding, but do not start the engine.

S KEY IS OCCUPIED. Only five keys may be coded.

If a new key is desired, the previous key codes

must be deleted. Up to five keys may then be au-

thorized.

S ALREADY AUTHORIZED. Key coding is being at-

tempted with a key that is already authorized.

S ERROR NO. A3, A4, A5. There is no communica-

tion between the transponder in the ignition key and

the detection coil. Follow the steps below to diag-

nose the problem:

1) Try a different key. If a different key works, the

problem was in the original key.

2) If trying a different key resulted in the same

error message, replace the detection coil.

S INVALID KEY. The communication between the

immobilizer control unit and the key transponder

has not validated the key. Follow the steps below to

diagnose the problem:

1) Code the key. Refer to ”Key Coding Procedure”

in this section.

2) If the same message is received after key cod-

ing, check the connection of the detection coil.

3) If the detection coil is okay, replace the immo-

bilizer. Refer to ”Immobilizer Control Unit” in

this section.S NO TRANSPONDER DETECTED. The fault may

be in ignition key transponder, the detection coil, or

the Immobilizer. Follow the steps below to diagnose

the problem:

1) Try a different key. If a different key works, the

problem was in the original key.

2) If trying a different key resulted in the same

error message, check the connection of the

detection coil.

3) If the connection of the detection coil is okay,

disconnect the detection coil and use an ohm-

meter to check for an open detection coil.

4) If the detection coil was not open, replace the

immobilizer control unit. Refer to ”Immobilizer

Control Unit” in this section.

COMMUNICATION BETWEEN

IMMOBILIZER CONTROL UNIT AND

TEST EQUIPMENT (MR–140, HV–240,

SIRIUS D4)

1. Connect the test equipment as described in the

Scan Tool Equipment Manual.

2. If communication between the scan tool and the

test equipment was unsuccessful, wait 30 seconds

and try again.

3. If communication was not successful on the second

try, turn the ignition OFF and check the wire and

connectors between the immobilizer control unit

terminal 7 and the data link connector (DLC) termi-

nal 7.

4. If the wire and connectors between the DLC and

the immobilizer control unit are okay, replace the

immobilizer control unit. Refer to ”Immobilizer Con-

trol Unit” in this section.

Page 2499 of 2643

IMMOBILIZER ANTI–THEFT SYSTEM 9T2 – 9

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

KEY CODING PROCEDURE

1. Install the immobilizer control unit cartridge in the

scan tool.

2. Turn the ignition off

3. Connect the scan tool

4. Turn the ignition on with the key to be coded

5. Enter the four–digit password that enables service

personnel to use the scan tool for key coding.

6. Use the scan tool command.

7. Verify that the key coding was successful by start-

ing the engine with each of the authorized keys.

ID CODE REPROGRAMMING

Reprogram the identification (ID) code in the following si-

tuations:

S An immobilizer control unit has been replaced.

S An electronic control module (ECM) has been re-

placed.

If a valid key has been lost, refer to ”Key Coding Proce-

dure” in this section.

TRANSPONDER

Each valid ignition key has an internal transponder which

is a read /write transponder.

The transponder contains an implementation of a crypto–

algorithm with 96 bits of user configurable secret–key con-

tained in EEPROM and transmits data to the ICU by mod-

ulating the amplitude of the electromagnetic field, and

receives data and commands in a similar way.

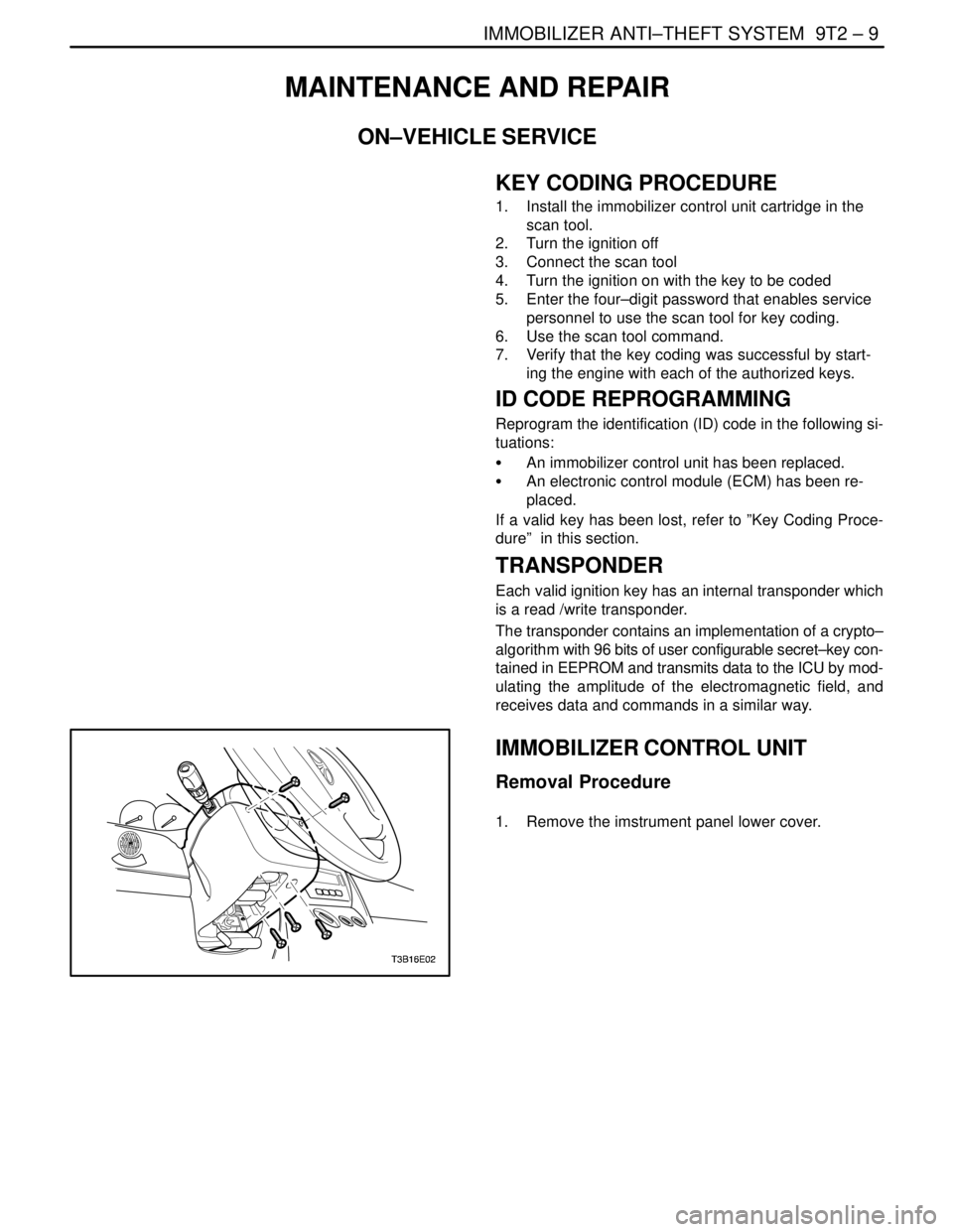

IMMOBILIZER CONTROL UNIT

Removal Procedure

1. Remove the imstrument panel lower cover.

Page 2501 of 2643

IMMOBILIZER ANTI–THEFT SYSTEM 9T2 – 11

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IMMOBILIZER SYSTEM

The purpose of the Immobilizer system is to provide addi-

tional theft deterrence to the vehicle in which it is installed

and to prevent it from being stolen or driven by unautho-

rized users.

The verification of the user authorization is done by an igni-

tion key with integrated transponder.

The external LED displays the Immobilizer status and has

an additional theft deterrence function.

To secure the communication, the status is exchanged be-

tween the Immobilizer and the ECM in a 5 byte of encoded

data.

These 5 bytes are composed by a mixture of random data

and two types of fixed code

S a vehicle model identification number : MIN

S a vehicle specific identification : VIN

The MIN is known from the first supply of the system.

The VIN is realized by ICU on the special order from the

key coding (reading of transponder code and storing it as

valid key code in Immobilizer EEPROM).

A different random data is computed at each key transi-

tion.

All the immobilization communication between the ECM

and ICU is made on K–line (K line : Serial data line ’7’).

Due to the learning of the Vehicle specific identification

Number, both ICU and ECM can stay in 3 stable modes

S Virgin mode (VIN not learnt)

S Learnt mode (VIN learnt)

S Neutral mode (for a new VIN learning)

In case of using valid key, the release message commu-

nication with the ECM take place and the LED displays the

Immobilizer status valid key In case of using invalid key,

the ECM disables the fuel injector circuit with coded inter-

vention and sets DTC(Diagnostic Trouble Code)

The above conditions are maintained until the ignition is

switched off.

An ECM without an immobilizer control unit cannot be in-

terchanged for an ECM that is used with an immobilizer

control unit system. The Immobilizer control unit and ECM

must have a matching ID code. ID coding and key coding

are accomplished by using Scanner–100

The Immobilizer system consists of

S a maximum or 5 ignition keys with integrated trans-

ponder

S the toroidal coil (Detection coil) for energizing and

reading the transponder mounted at the ignition

lock.S the Immobilizer control unit(ICU) with :

– power supply

– ignition input circuit

– transponder modulation and demodulation unit

– EEPROM

– driver electronic for the external status LED

– serial data link hardware

S the external status LED for displaying the Immobi-

lizer status

S the serial data link between Immobilizer and ECM

ELECTRONICALLY CODED KEYS

Each valid ignition key has an internal transponder which

is a read /write transponder.

The transponder contains an implementation of a crypto–

algorithm with 96 bits of user configurable s cret–key con-

tained in EEPROM and transmits data to the ICU by mod-

ulating the amplitude of the ele tromagnetic field, and

receives data and commands in a similar way.

DETECTION COIL

The toroidal coil is mounted at the ignition lock in front of

the key barrel.

It is connected to the ICU with a four terminal connector

fixed at the body of the coil.

The length of the connection between coil and Immobilizer

is restricted to 50cm. The correct placement on the ignition

lock and the exact electrical data is very important for the

reading distance of transponder.

he toroidal coil and receiving coil inside the transponder

built a transformer. During the readingprocess the coil in-

duces energy into the transponder. The transponder

charges the field and generates an amplitude modulated

signal with the manchester coded data. This charge of the

field is demodulated inside the Immobilizer.

The Immobilizer contains the coil driver hardware for di-

rect connection of the toroidal coil.

IMMOBILIZER CONTROL UNIT

The function of the Immobilizer System is shared between

the ICU and the ECM.

The task of the Immobilizer Electronic Control unit (ICU)

are:

S Reading of the input information ”ignition ON/OFF”

S Controlling the states LED

S Controlling the transponder read/write process

(modulation, demodulation, decoding, comparison

of the read code with the code of the valid keys).

S Communication with the ECM after ignition ON (re-

ceiving of the ECM–request and transmission of

release message).

S Special functions for calculation and handling of the

VIN–code.

The VIN code is calculated by the Immobilizer using a ran-

dom generator.

Page 2502 of 2643

9T2 – 12IIMMOBILIZER ANTI–THEFT SYSTEM

DAEWOO V–121 BL4

The VIN code is transmitted from the Immobilizer in the re-

lease message communication only incase of using an au-

thorized key. Without an authorized key it is not possible

to getthe system VIN code.In case of ECM internal state

is in Virgin mode or neutral mode the ECM learns the sys-

tem VIN code automatically after receiving the first release

response message.

To get a synchronized Immobilizer system (same VIN–

code in Immobilizer and ECM,authorized key) the DLC

test equipment has to be used for authorization of the

keys(first key coding). The usage of this test equipment is

restricted to authorized persons.

S Communication with the DLC–test equipment. Main

functions are the key coding procedure, the VIN–

code handling and the support for system test func-

tions.

S Handling of the software watchdog

Operation

In the active mode of immobilizer (engine OFF, IG key

OFF) the status LED isblinking as mode A. When ignition

is turned ON, the system wakes up and tries to read out

the transponder.

In case of the detection of a valid key , The release mes-

sage communication with the ECM takes place. The sta-

tus LED displays the Immobilizer state ”valid key”.

After turning off the ignition(ignition OFF detection similar

to the ECM ignition OFF detection), the Immobilizer

changes to the active mode. The status LED is blinking as

Mode A.

Data Link Connector (DLC) Mode

When the ignition is on, a scan tool can switch the immobi-

lizer control unit to the DLC mode for diagnostics, key cod-

ing and ID coding.

S The status LED is turned off during DLC–mode

S The Immobilizer will answer all correct messages,

which are defined as Immobilizer messages.

ID Code Handling

One of 65,535 VIN codes is stored in the immobilizer EE-

PROM.

The VIN code can be erased by using ”Reset VIN code”

command of the scan tool.

When the immobilizer control unit calculates a new VIN

code, ECM VIN code should be reset to get identical with

the immobilizer control unit’s.

During diagnostic procedures, the VIN code can be read

for comparison with the ECM VIN code by using the scan

tool’s ”Read immobilizer control unit VIN code” command.

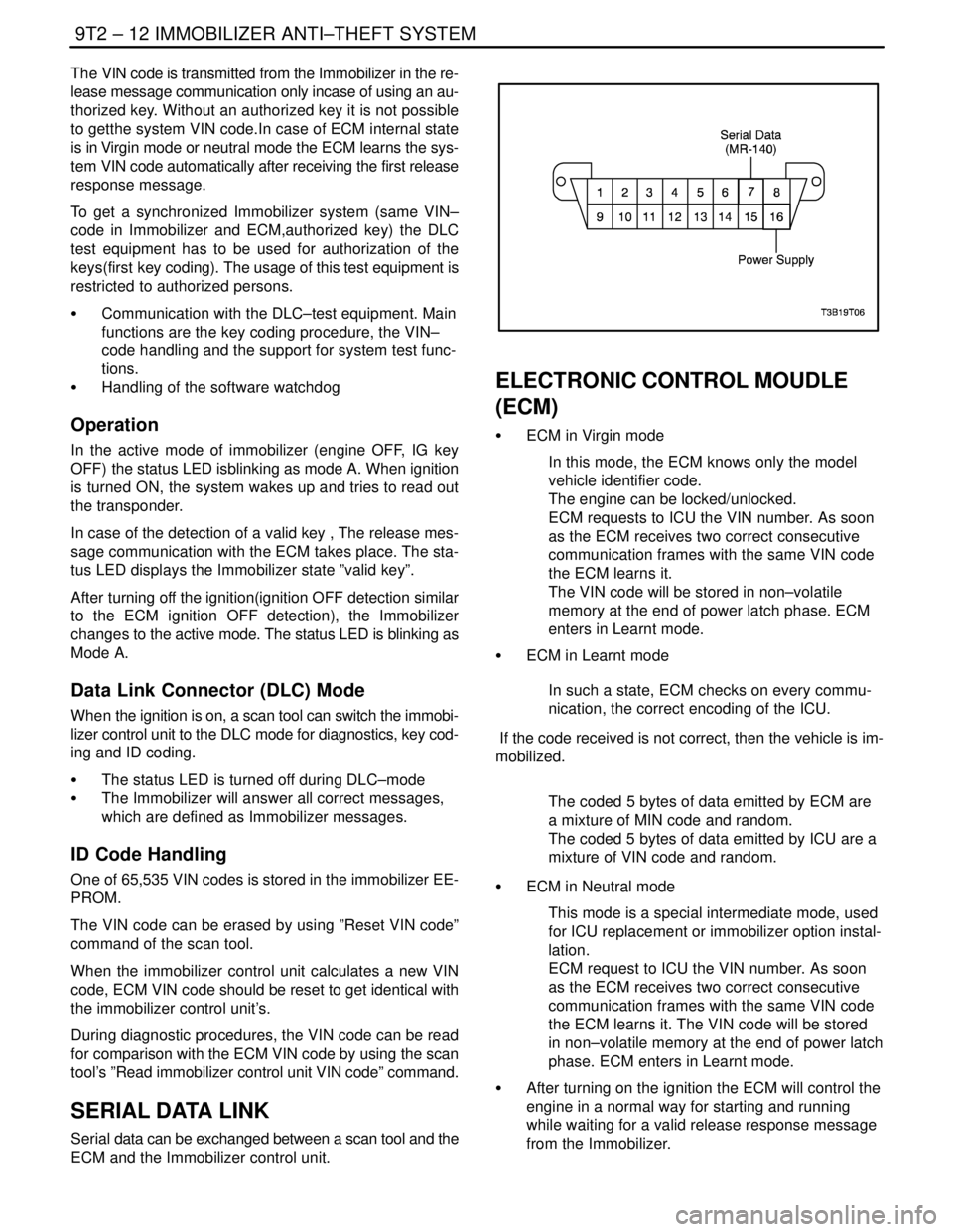

SERIAL DATA LINK

Serial data can be exchanged between a scan tool and the

ECM and the Immobilizer control unit.

ELECTRONIC CONTROL MOUDLE

(ECM)

S ECM in Virgin mode

In this mode, the ECM knows only the model

vehicle identifier code.

The engine can be locked/unlocked.

ECM requests to ICU the VIN number. As soon

as the ECM receives two correct consecutive

communication frames with the same VIN code

the ECM learns it.

The VIN code will be stored in non–volatile

memory at the end of power latch phase. ECM

enters in Learnt mode.

S ECM in Learnt mode

In such a state, ECM checks on every commu-

nication, the correct encoding of the ICU.

If the code received is not correct, then the vehicle is im-

mobilized.

The coded 5 bytes of data emitted by ECM are

a mixture of MIN code and random.

The coded 5 bytes of data emitted by ICU are a

mixture of VIN code and random.

S ECM in Neutral mode

This mode is a special intermediate mode, used

for ICU replacement or immobilizer option instal-

lation.

ECM request to ICU the VIN number. As soon

as the ECM receives two correct consecutive

communication frames with the same VIN code

the ECM learns it. The VIN code will be stored

in non–volatile memory at the end of power latch

phase. ECM enters in Learnt mode.

S After turning on the ignition the ECM will control the

engine in a normal way for starting and running

while waiting for a valid release response message

from the Immobilizer.

Page 2506 of 2643

NUBIRA/LACETTISERVICE NOTICE 0–3

1. HOW TO USE THIS MANUAL

.

This manual covers the repairs of NUBIRA/LACETTI

automobile which has been involved in accidents, and it

describes the work related to the replacement of dam-

aged body parts.

Please read through these instructions and familiarize

yourself with them before actually using this manual.

.

Note : Refer to NUBIRA/LACETTI Service Manual for

specifications, wire harness locations, safety stand sup-

port points, etc.

2. SPECIAL INFORMATION

.

Indicates a strong possibility of personal injury or equip-

ment damage if instructions are not followed.

.

Note : Gives helpful information.

.

CAUTION : Detailed descriptions of standard work-

shop procedures, safety principles and service op-

erations are not included. Please note that this manu-

al does contain warnings and cautions against some

specific service methods which could cause PER-

SONAL INJURY, or could damage a vehicle or make

it unsafe. Please understand that these warnings can-

not cover all conceivable ways in which service,

whether or not recommended by GM DAEWOO might

be done or of the possible hazardous consequences

of each conceivable way, not could GM DAEWOO in-

vestigate all such ways. Anyone using service proce-

dures or tools, whether or not recommended by GM

DAEWOO, must satisfy himself thoroughly that nei-

ther personal safety or tools, whether or not recom-

mended by GM DAEWOO, must satisfy himself thor-

oughly that neither personal safety or vehicle safety

will be jeopardized.

.

All information contained in this manual is based on the

latest product information available at the time of print-

ing. We reserve the right to make changes at any time

without notice. No part of this publication may be repro-

duced, stored in retrieval system, or transmitted, in any

form by any means, electronic, mechanical, photocopy-

ing, recording, or otherwise, without the prior written

permission of the publisher. This includes text, figures

and tables.

Page 2524 of 2643

2–4 PREPARATIONS OF BODYWORK NUBIRA/LACETTI

2. CHECKPOINTS

S Accurate Inspection of Damaged Parts(Visual)

.

Seat Belts

Always replace the seat belt if :

1. The belt material is cut, punctured, burned or in any

way damaged.

2. The buckle or retractor does not work properly.

3. They were being worn at the time of a collision(also

check for damage at the seat belt anchor points).

4. Their condition is questionable.

.

Front Section :

1. Is there any bending, splitting, denting or other dam-

age to the suspension and its related parts?

2. Is there any deformation of the front panel or radiator

crossmember? Have any of the connected sections

come apart?

3. Are there any creases or distortion in the front wheel-

house or side frame? Have any of the connected sec-

tions come apart?

4. Is there any bending or twisting of the whole front

area?

5. Is there any deformation like creases, bulges, or dents

in the front pillar, dash panel, floor, etc.?

6. Is there any vertical twisting or misaligned clearance

in the door?

7. Is the windshield seal broken?

8. Is there any deformation in the vicinity of the top part

of the roof panel’s center pillar?

9. Is there any damage inside the automobile(is there

any twisting of the dash panel, or anything irregular with

the clearances or sheet–mounting parts)?

10. Is there any damage to the steering wheel? Is there

any deformation in the column and the column–mounted

parts?

11. Is there any oil or water leakage and damage to the en-

gine, transmission or brakes?

12. Is there any irregular noise in the gear changing opera-

tion, engine and transmission rotation?

13. Are there any traces of contact between the engine

block and the center crossmember ?

14. Is there any damage to brake or fuel lines, or wire har-

nesses?Rear Section :

1. Is there any twisting, bulging or denting of the rear floor

any rear bolsters? Have any of the connected sections

come apart?

2. Is there any irregular bulging or denting in the rear

fender?

3. Is there any distortion in the rear inner panel? Is there

any bending and denting in the vicinity of the rear pillar?

4. Is there any distortion or creasing is the rear wheel-

house and arch sections? Have any of the connected

sections come apart?

5. Is there anything irregular in the rear glass seal clear-

ance?

6. Is there any twisting or misalignment of the clearance

of the trunk lid opening section?

7. Is there any bending, splitting, denting or other dam-

age to the suspension and its related parts?

8. Is there any deformation of the rear floor crossmem-

ber, trunk floor panel and back panel? Have any of the

connected sections come apart?

.

Impact Beam :

Always replace the door assembly if :

1. The external force makes the impact beam of door in-

ner deform.

Always replace impact beam if :

2. The external force makes the impact beam of front

bumper and rear bumper deform.

Page 2544 of 2643

4–10 FRONTNUBIRA/LACETTI

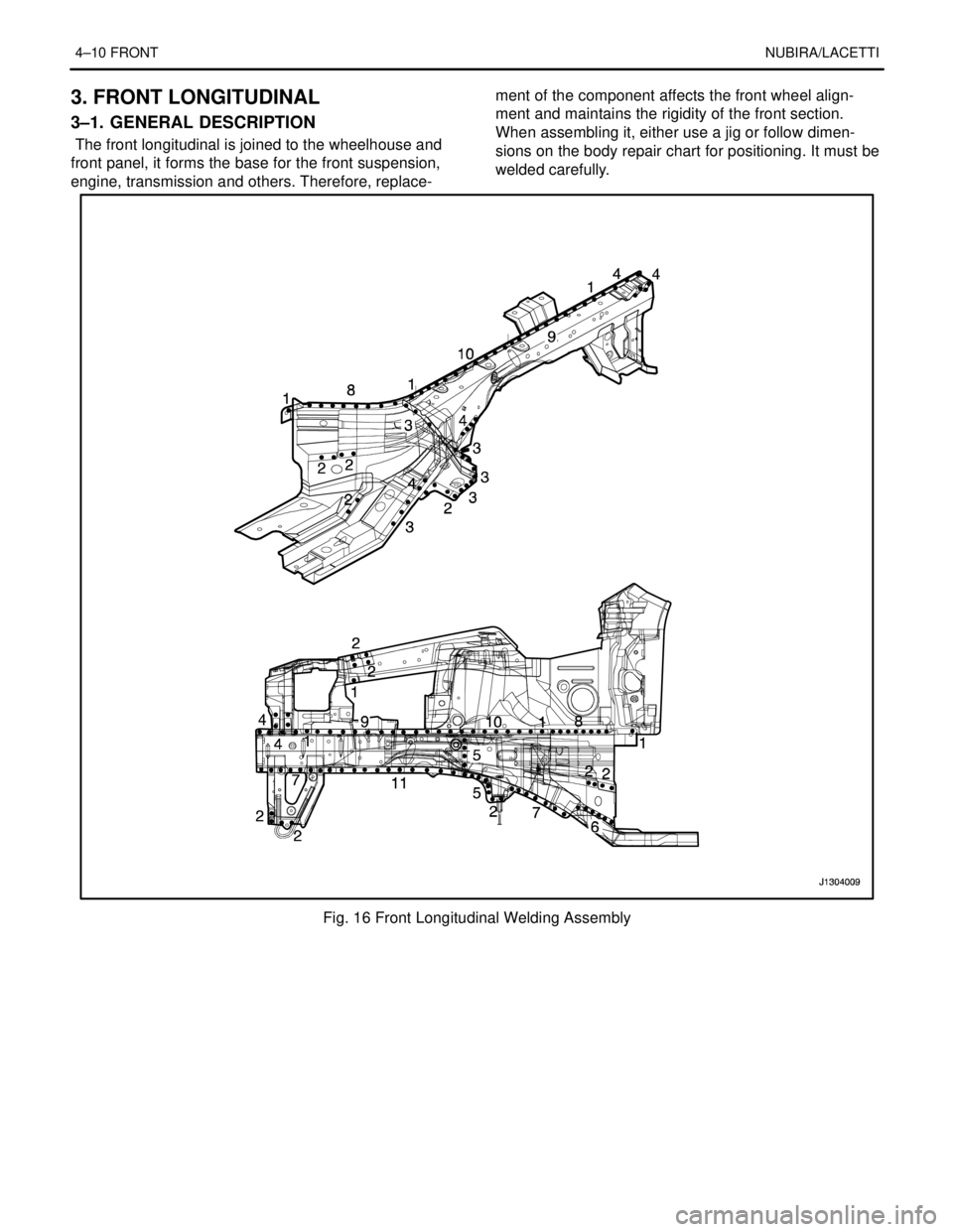

3. FRONT LONGITUDINAL

3–1. GENERAL DESCRIPTION

The front longitudinal is joined to the wheelhouse and

front panel, it forms the base for the front suspension,

engine, transmission and others. Therefore, replace-ment of the component affects the front wheel align-

ment and maintains the rigidity of the front section.

When assembling it, either use a jig or follow dimen-

sions on the body repair chart for positioning. It must be

welded carefully.

Fig. 16 Front Longitudinal Welding Assembly