Vacuum actuator DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 325 of 2643

ENGINE CONTROLS 1F – 79

DAEWOO V–121 BL4

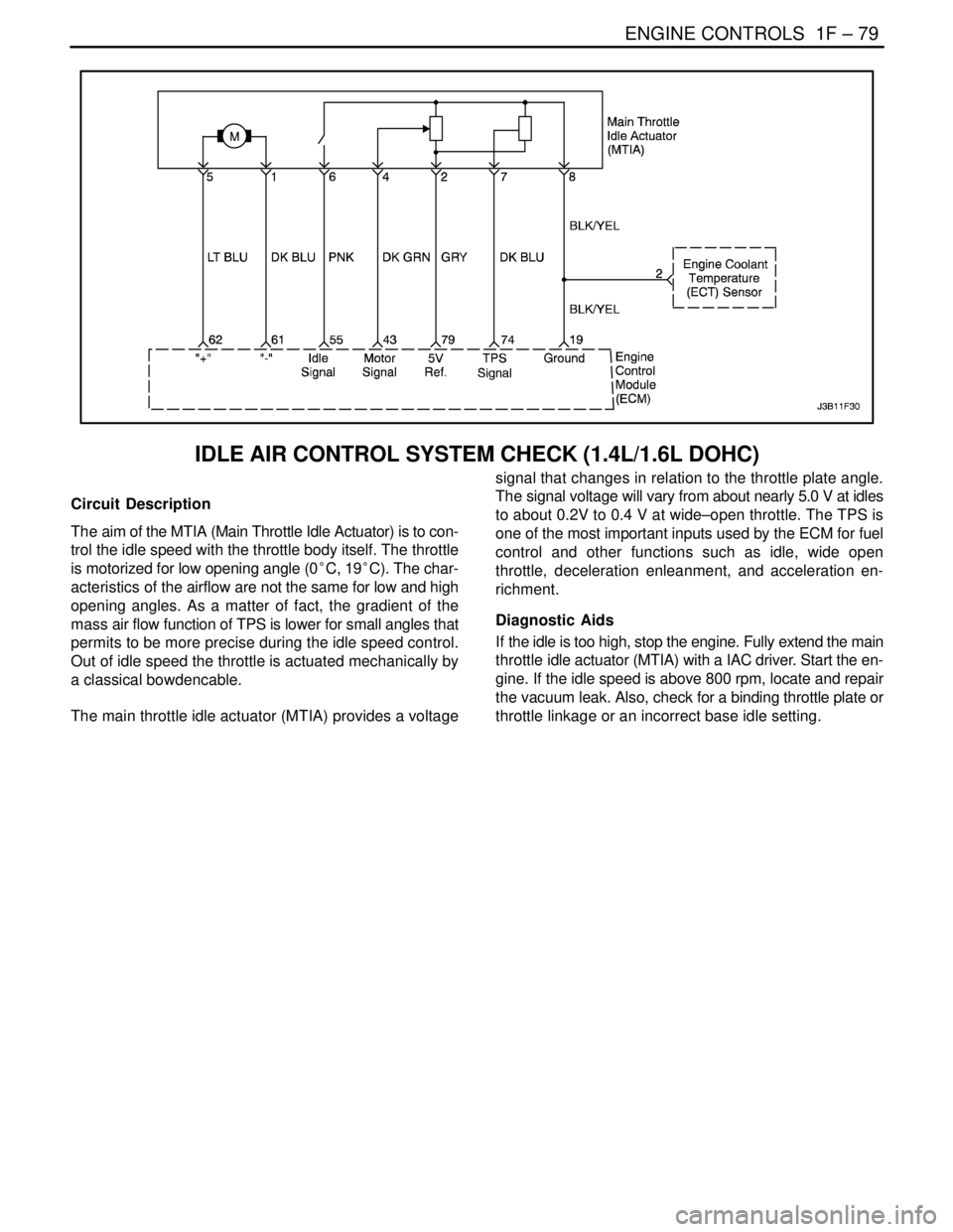

IDLE AIR CONTROL SYSTEM CHECK (1.4L/1.6L DOHC)

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (0°C, 19°C). The char-

acteristics of the airflow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical bowdencable.

The main throttle idle actuator (MTIA) provides a voltagesignal that changes in relation to the throttle plate angle.

The signal voltage will vary from about nearly 5.0 V at idles

to about 0.2V to 0.4 V at wide–open throttle. The TPS is

one of the most important inputs used by the ECM for fuel

control and other functions such as idle, wide open

throttle, deceleration enleanment, and acceleration en-

richment.

Diagnostic Aids

If the idle is too high, stop the engine. Fully extend the main

throttle idle actuator (MTIA) with a IAC driver. Start the en-

gine. If the idle speed is above 800 rpm, locate and repair

the vacuum leak. Also, check for a binding throttle plate or

throttle linkage or an incorrect base idle setting.

Page 1986 of 2643

7A – 12IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

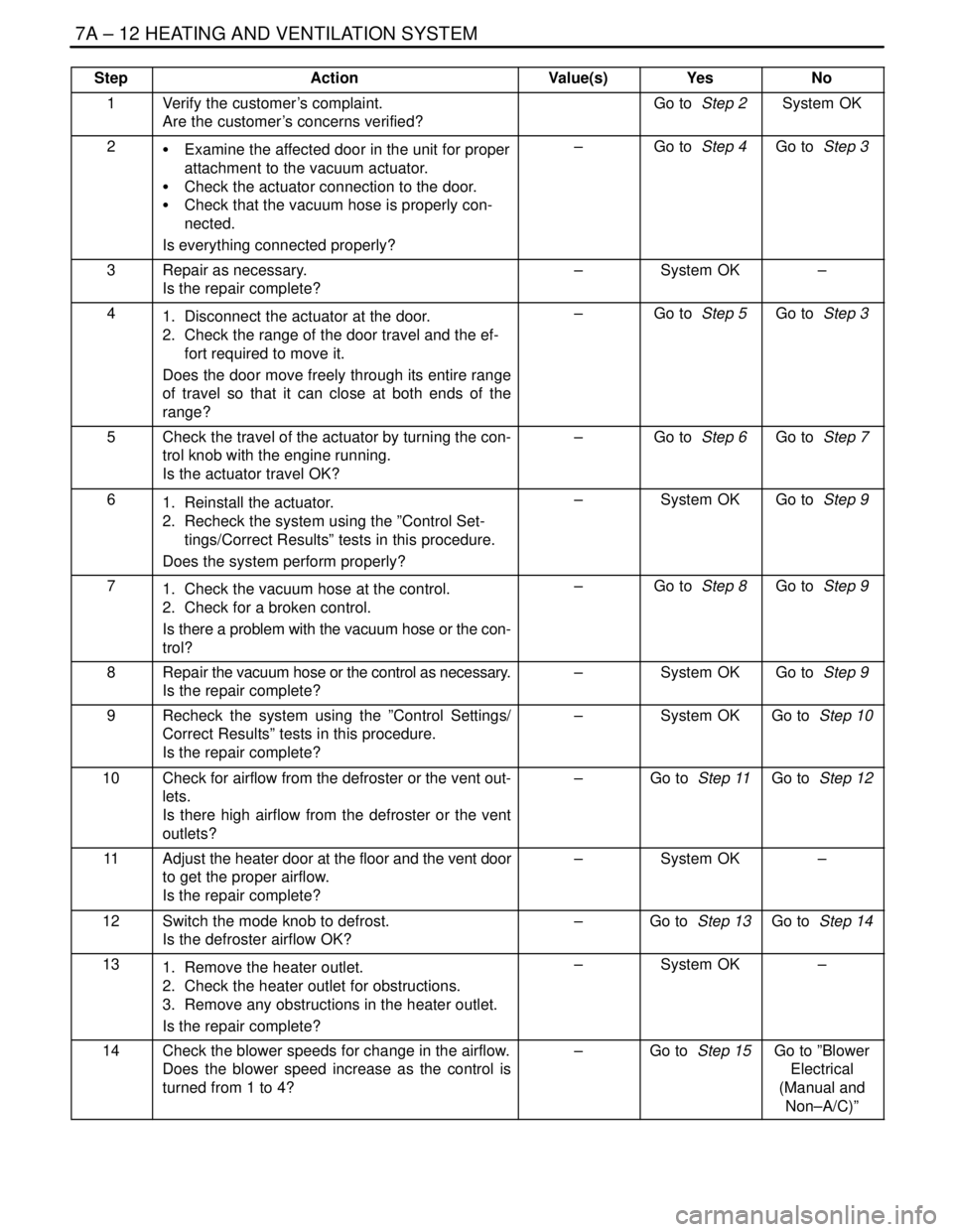

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?Go to Step 2System OK

2S Examine the affected door in the unit for proper

attachment to the vacuum actuator.

S Check the actuator connection to the door.

S Check that the vacuum hose is properly con-

nected.

Is everything connected properly?–Go to Step 4Go to Step 3

3Repair as necessary.

Is the repair complete?–System OK–

41. Disconnect the actuator at the door.

2. Check the range of the door travel and the ef-

fort required to move it.

Does the door move freely through its entire range

of travel so that it can close at both ends of the

range?–Go to Step 5Go to Step 3

5Check the travel of the actuator by turning the con-

trol knob with the engine running.

Is the actuator travel OK?–Go to Step 6Go to Step 7

61. Reinstall the actuator.

2. Recheck the system using the ”Control Set-

tings/Correct Results” tests in this procedure.

Does the system perform properly?–System OKGo to Step 9

71. Check the vacuum hose at the control.

2. Check for a broken control.

Is there a problem with the vacuum hose or the con-

trol?–Go to Step 8Go to Step 9

8Repair the vacuum hose or the control as necessary.

Is the repair complete?–System OKGo to Step 9

9Recheck the system using the ”Control Settings/

Correct Results” tests in this procedure.

Is the repair complete?–System OKGo to Step 10

10Check for airflow from the defroster or the vent out-

lets.

Is there high airflow from the defroster or the vent

outlets?–Go to Step 11Go to Step 12

11Adjust the heater door at the floor and the vent door

to get the proper airflow.

Is the repair complete?–System OK–

12Switch the mode knob to defrost.

Is the defroster airflow OK?–Go to Step 13Go to Step 14

131. Remove the heater outlet.

2. Check the heater outlet for obstructions.

3. Remove any obstructions in the heater outlet.

Is the repair complete?–System OK–

14Check the blower speeds for change in the airflow.

Does the blower speed increase as the control is

turned from 1 to 4?–Go to Step 15Go to ”Blower

Electrical

(Manual and

Non–A/C)”

Page 1987 of 2643

HEATING AND VENTILATION SYSTEM 7A – 13

DAEWOO V–121 BL4

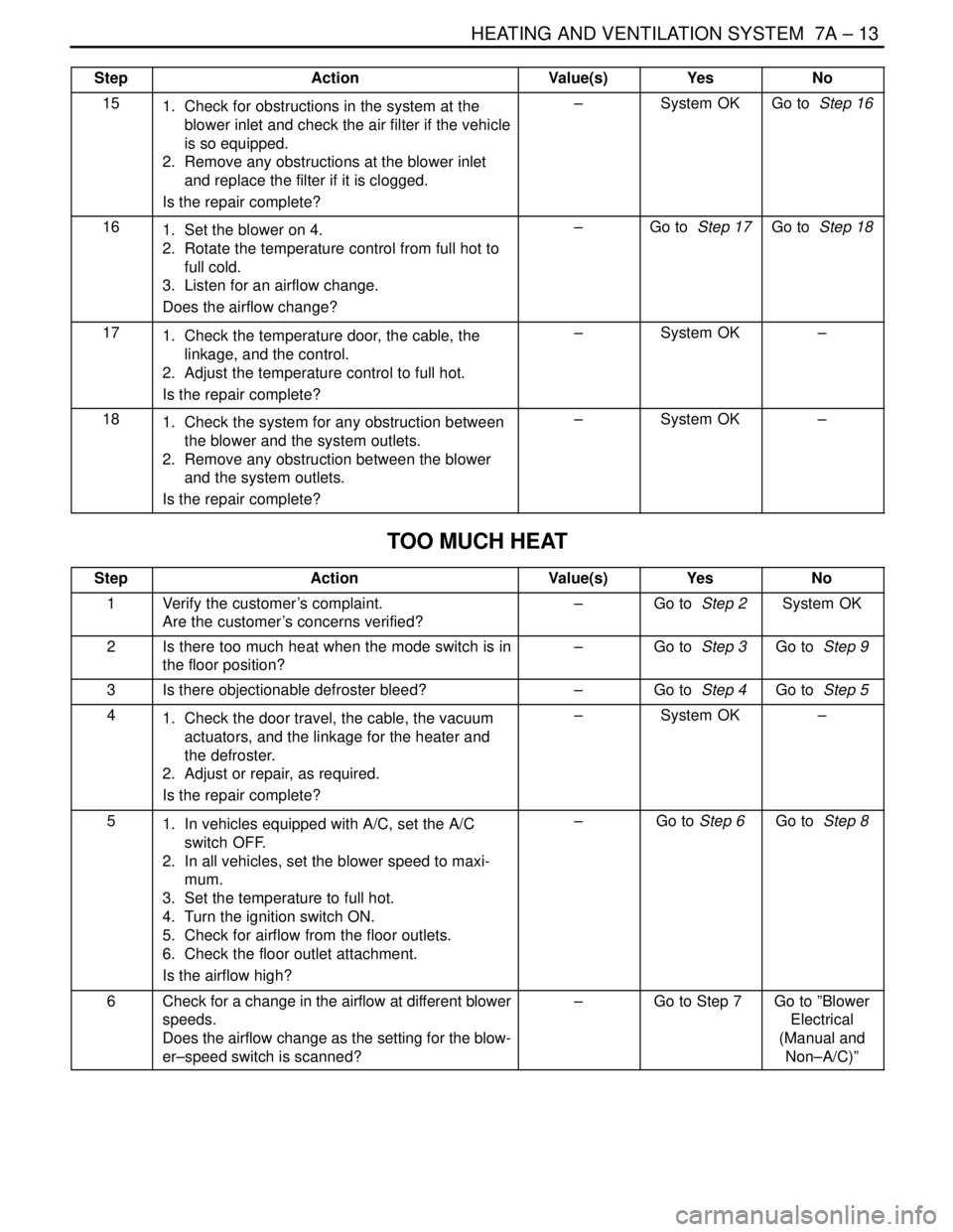

StepNo Yes Value(s) Action

151. Check for obstructions in the system at the

blower inlet and check the air filter if the vehicle

is so equipped.

2. Remove any obstructions at the blower inlet

and replace the filter if it is clogged.

Is the repair complete?–System OKGo to Step 16

161. Set the blower on 4.

2. Rotate the temperature control from full hot to

full cold.

3. Listen for an airflow change.

Does the airflow change?–Go to Step 17Go to Step 18

171. Check the temperature door, the cable, the

linkage, and the control.

2. Adjust the temperature control to full hot.

Is the repair complete?–System OK–

181. Check the system for any obstruction between

the blower and the system outlets.

2. Remove any obstruction between the blower

and the system outlets.

Is the repair complete?–System OK–

TOO MUCH HEAT

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

2Is there too much heat when the mode switch is in

the floor position?–Go to Step 3Go to Step 9

3Is there objectionable defroster bleed?–Go to Step 4Go to Step 5

41. Check the door travel, the cable, the vacuum

actuators, and the linkage for the heater and

the defroster.

2. Adjust or repair, as required.

Is the repair complete?–System OK–

51. In vehicles equipped with A/C, set the A/C

switch OFF.

2. In all vehicles, set the blower speed to maxi-

mum.

3. Set the temperature to full hot.

4. Turn the ignition switch ON.

5. Check for airflow from the floor outlets.

6. Check the floor outlet attachment.

Is the airflow high?–Go to Step 6Go to Step 8

6Check for a change in the airflow at different blower

speeds.

Does the airflow change as the setting for the blow-

er–speed switch is scanned?–Go to Step 7 Go to ”Blower

Electrical

(Manual and

Non–A/C)”