change key battery DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 360 of 2643

1F – 114IENGINE CONTROLS

DAEWOO V–121 BL4

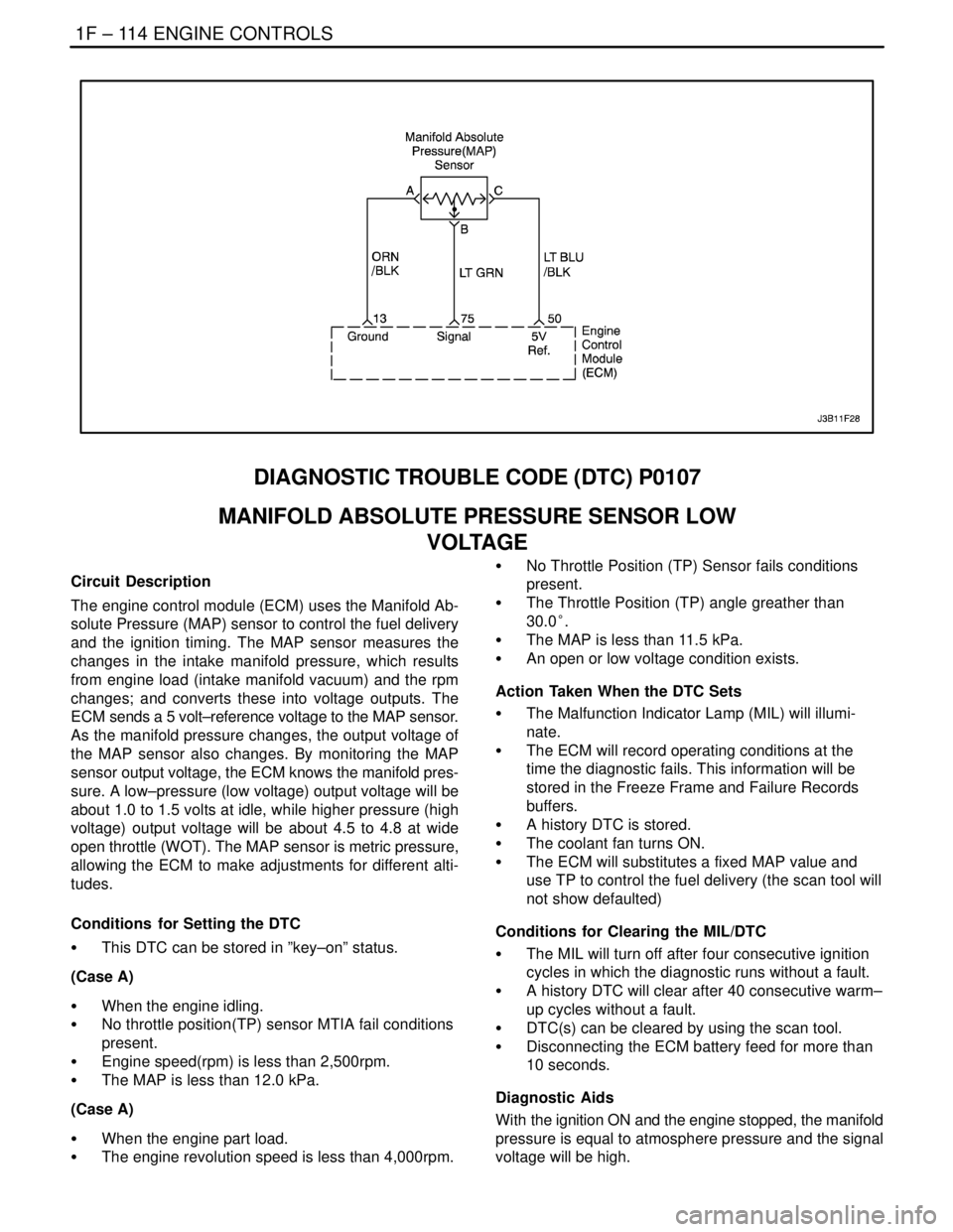

DIAGNOSTIC TROUBLE CODE (DTC) P0107

MANIFOLD ABSOLUTE PRESSURE SENSOR LOW

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

(Case A)

S When the engine idling.

S No throttle position(TP) sensor MTIA fail conditions

present.

S Engine speed(rpm) is less than 2,500rpm.

S The MAP is less than 12.0 kPa.

(Case A)

S When the engine part load.

S The engine revolution speed is less than 4,000rpm.S No Throttle Position (TP) Sensor fails conditions

present.

S The Throttle Position (TP) angle greather than

30.0°.

S The MAP is less than 11.5 kPa.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The coolant fan turns ON.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

Page 363 of 2643

ENGINE CONTROLS 1F – 117

DAEWOO V–121 BL4

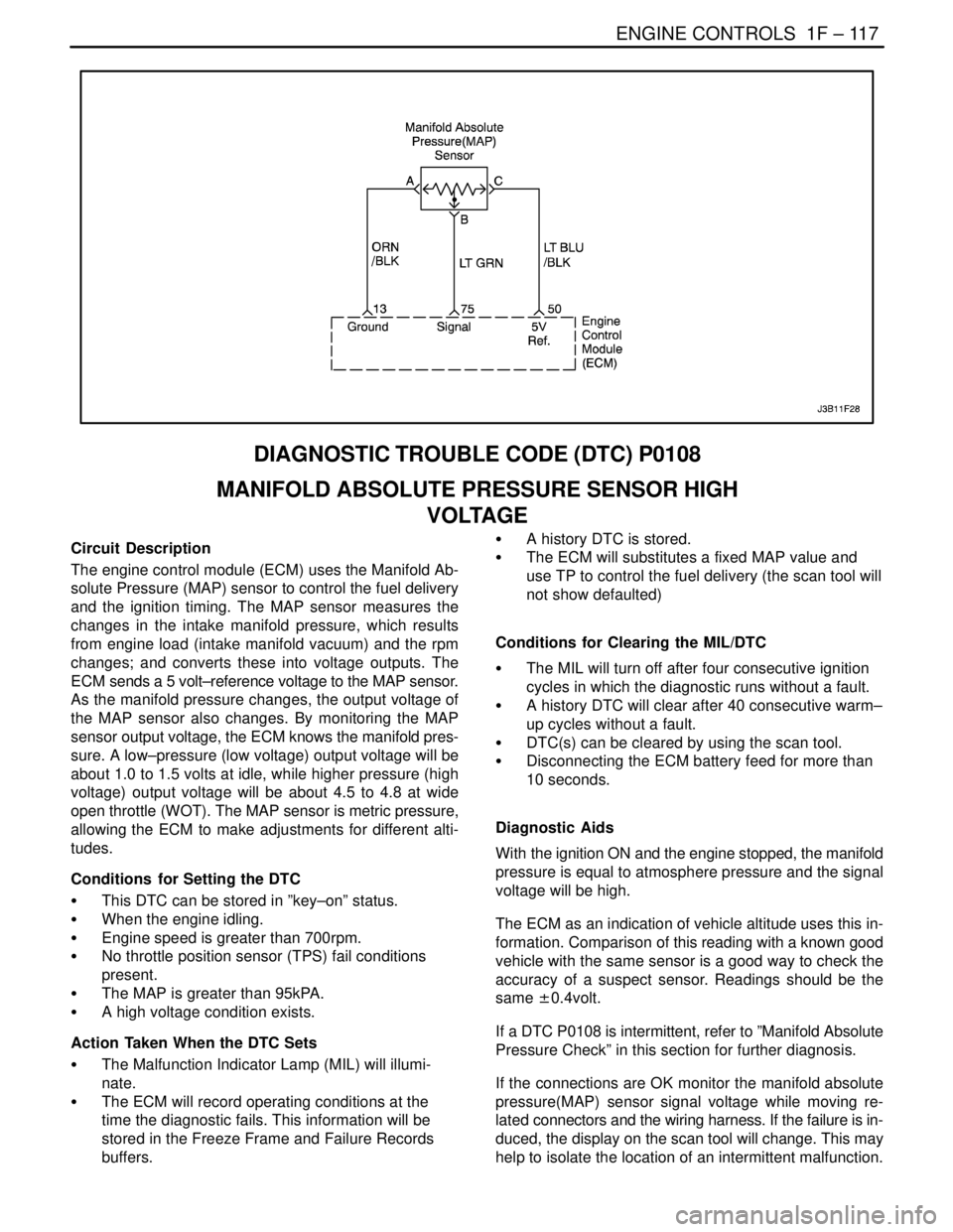

DIAGNOSTIC TROUBLE CODE (DTC) P0108

MANIFOLD ABSOLUTE PRESSURE SENSOR HIGH

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S When the engine idling.

S Engine speed is greater than 700rpm.

S No throttle position sensor (TPS) fail conditions

present.

S The MAP is greater than 95kPA.

S A high voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.S A history DTC is stored.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

The ECM as an indication of vehicle altitude uses this in-

formation. Comparison of this reading with a known good

vehicle with the same sensor is a good way to check the

accuracy of a suspect sensor. Readings should be the

same ±0.4volt.

If a DTC P0108 is intermittent, refer to ”Manifold Absolute

Pressure Check” in this section for further diagnosis.

If the connections are OK monitor the manifold absolute

pressure(MAP) sensor signal voltage while moving re-

lated connectors and the wiring harness. If the failure is in-

duced, the display on the scan tool will change. This may

help to isolate the location of an intermittent malfunction.

Page 450 of 2643

1F – 204IENGINE CONTROLS

DAEWOO V–121 BL4

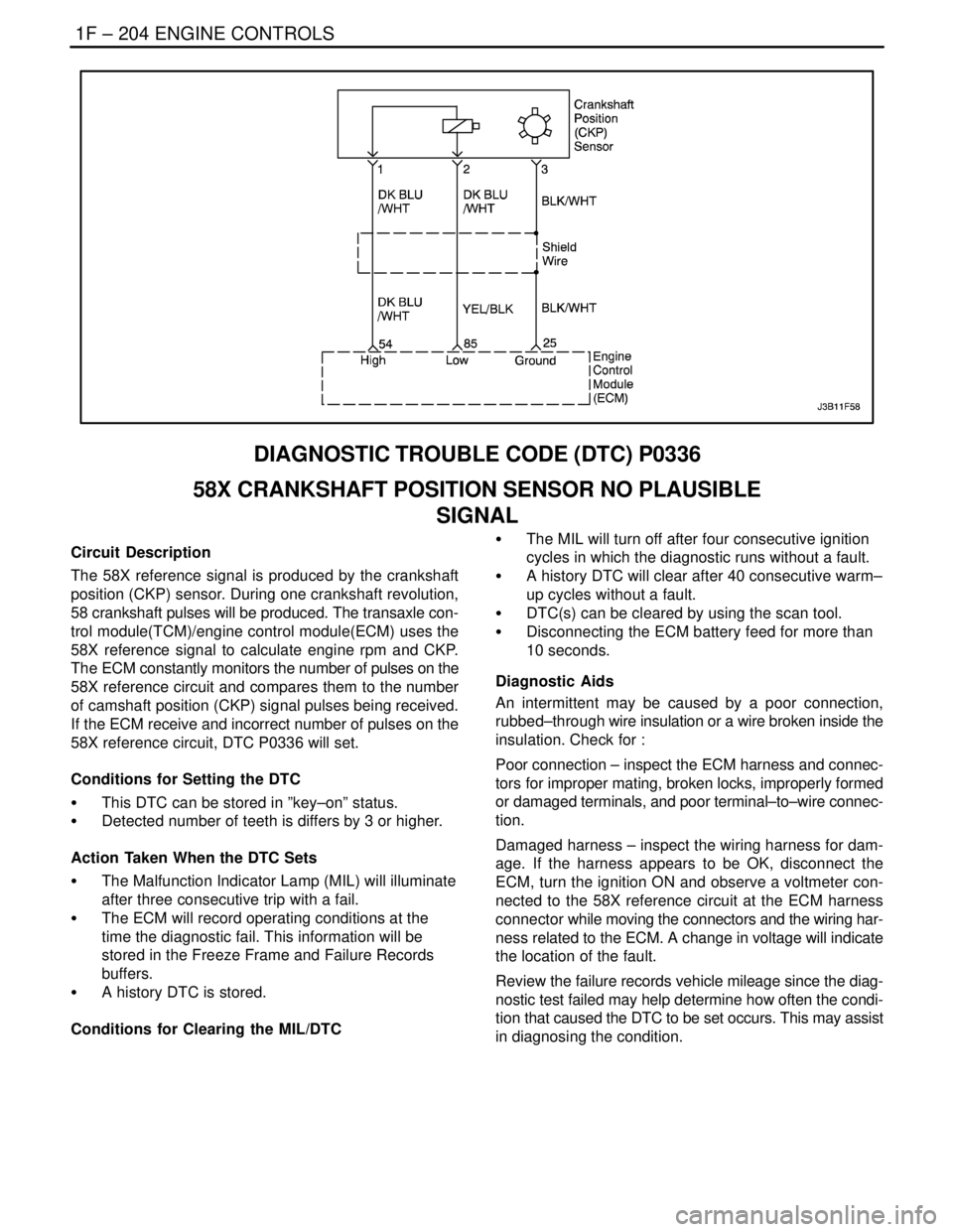

DIAGNOSTIC TROUBLE CODE (DTC) P0336

58X CRANKSHAFT POSITION SENSOR NO PLAUSIBLE

SIGNAL

Circuit Description

The 58X reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

58 crankshaft pulses will be produced. The transaxle con-

trol module(TCM)/engine control module(ECM) uses the

58X reference signal to calculate engine rpm and CKP.

The ECM constantly monitors the number of pulses on the

58X reference circuit and compares them to the number

of camshaft position (CKP) signal pulses being received.

If the ECM receive and incorrect number of pulses on the

58X reference circuit, DTC P0336 will set.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S Detected number of teeth is differs by 3 or higher.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTCS The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for :

Poor connection – inspect the ECM harness and connec-

tors for improper mating, broken locks, improperly formed

or damaged terminals, and poor terminal–to–wire connec-

tion.

Damaged harness – inspect the wiring harness for dam-

age. If the harness appears to be OK, disconnect the

ECM, turn the ignition ON and observe a voltmeter con-

nected to the 58X reference circuit at the ECM harness

connector while moving the connectors and the wiring har-

ness related to the ECM. A change in voltage will indicate

the location of the fault.

Review the failure records vehicle mileage since the diag-

nostic test failed may help determine how often the condi-

tion that caused the DTC to be set occurs. This may assist

in diagnosing the condition.

Page 453 of 2643

ENGINE CONTROLS 1F – 207

DAEWOO V–121 BL4

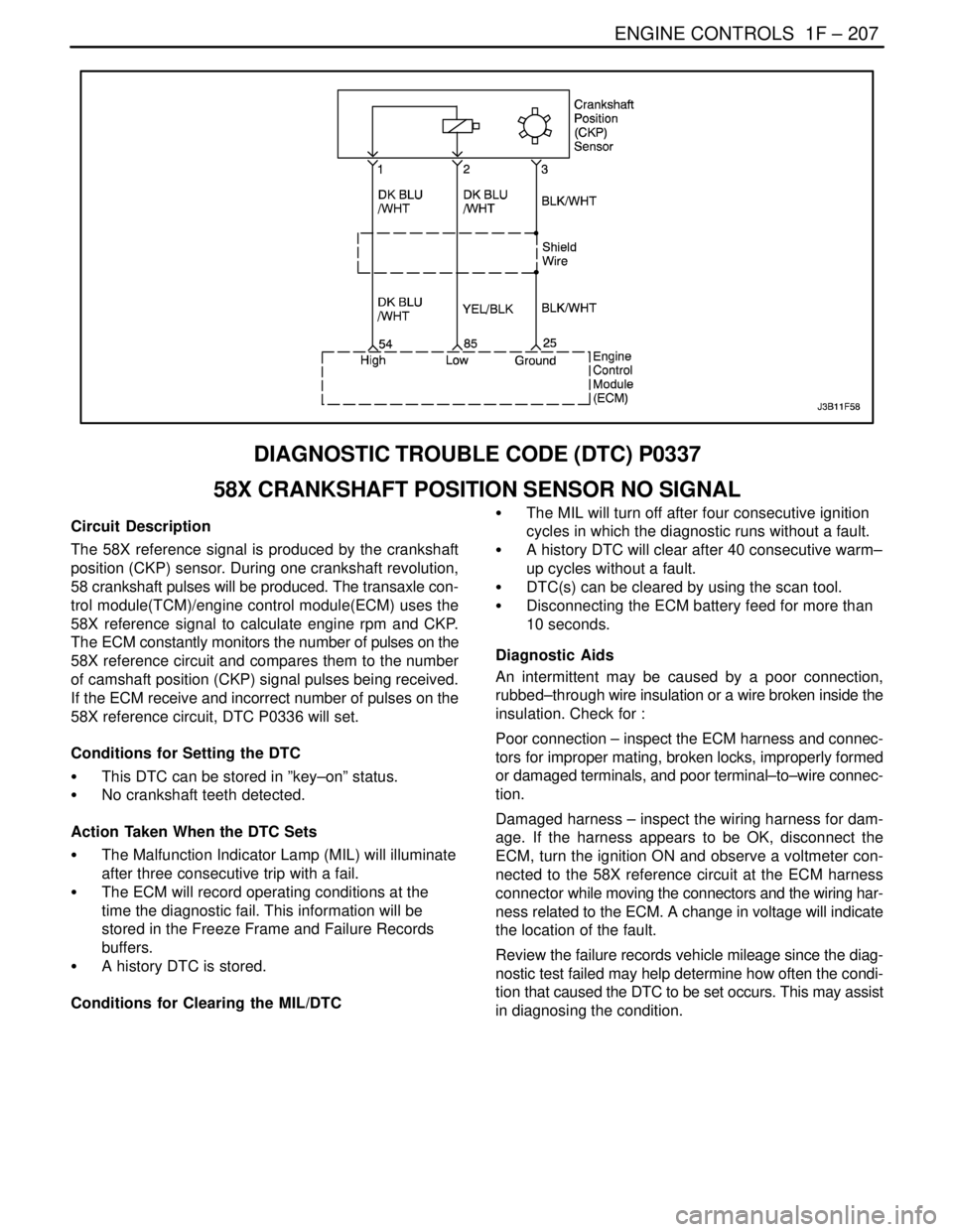

DIAGNOSTIC TROUBLE CODE (DTC) P0337

58X CRANKSHAFT POSITION SENSOR NO SIGNAL

Circuit Description

The 58X reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

58 crankshaft pulses will be produced. The transaxle con-

trol module(TCM)/engine control module(ECM) uses the

58X reference signal to calculate engine rpm and CKP.

The ECM constantly monitors the number of pulses on the

58X reference circuit and compares them to the number

of camshaft position (CKP) signal pulses being received.

If the ECM receive and incorrect number of pulses on the

58X reference circuit, DTC P0336 will set.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

S No crankshaft teeth detected.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTCS The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for :

Poor connection – inspect the ECM harness and connec-

tors for improper mating, broken locks, improperly formed

or damaged terminals, and poor terminal–to–wire connec-

tion.

Damaged harness – inspect the wiring harness for dam-

age. If the harness appears to be OK, disconnect the

ECM, turn the ignition ON and observe a voltmeter con-

nected to the 58X reference circuit at the ECM harness

connector while moving the connectors and the wiring har-

ness related to the ECM. A change in voltage will indicate

the location of the fault.

Review the failure records vehicle mileage since the diag-

nostic test failed may help determine how often the condi-

tion that caused the DTC to be set occurs. This may assist

in diagnosing the condition.

Page 638 of 2643

1F – 392IENGINE CONTROLS

DAEWOO V–121 BL4

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S The DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Rich exhaust – An overly rich exhaust may load the

catalyst, causing high HO2S2 signal voltages.

S Silicone contamination – A false rich condition may

be caused by silicone contamination of the HO2S2.

This will be indicated by a powdery white deposit on

the sensor.

S Faulty HO2S2 – If HO2S2 is internally shorted, the

HO2S2 voltage displayed on a scan tool will be

over 1 volt. Disconnect the HO2S2 and jumper the

sensor low circuit to engine ground; if the displayed

voltage goes from over 1000 millivolt to around 450

millivolt, replace the HO2S2.S Intermittent test – Observe HO2S2 on the scan tool

while moving related connectors and the wiring har-

ness with the key in the ON position. If the failure is

induced, the HO2S2 display will change. This may

help isolate the location of the malfunction.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0138 is the result of

a hard failure or an intermittent condition.

5. Disconnecting the HO2S2 and jumpering the sen-

sor signal circuit and the sensor low circuit to

ground should cause the scan tool to display

HO2S2 voltage below 100 mv (0.1 v). If the signal

voltage is still high, the ECM is malfunctioning.

6. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

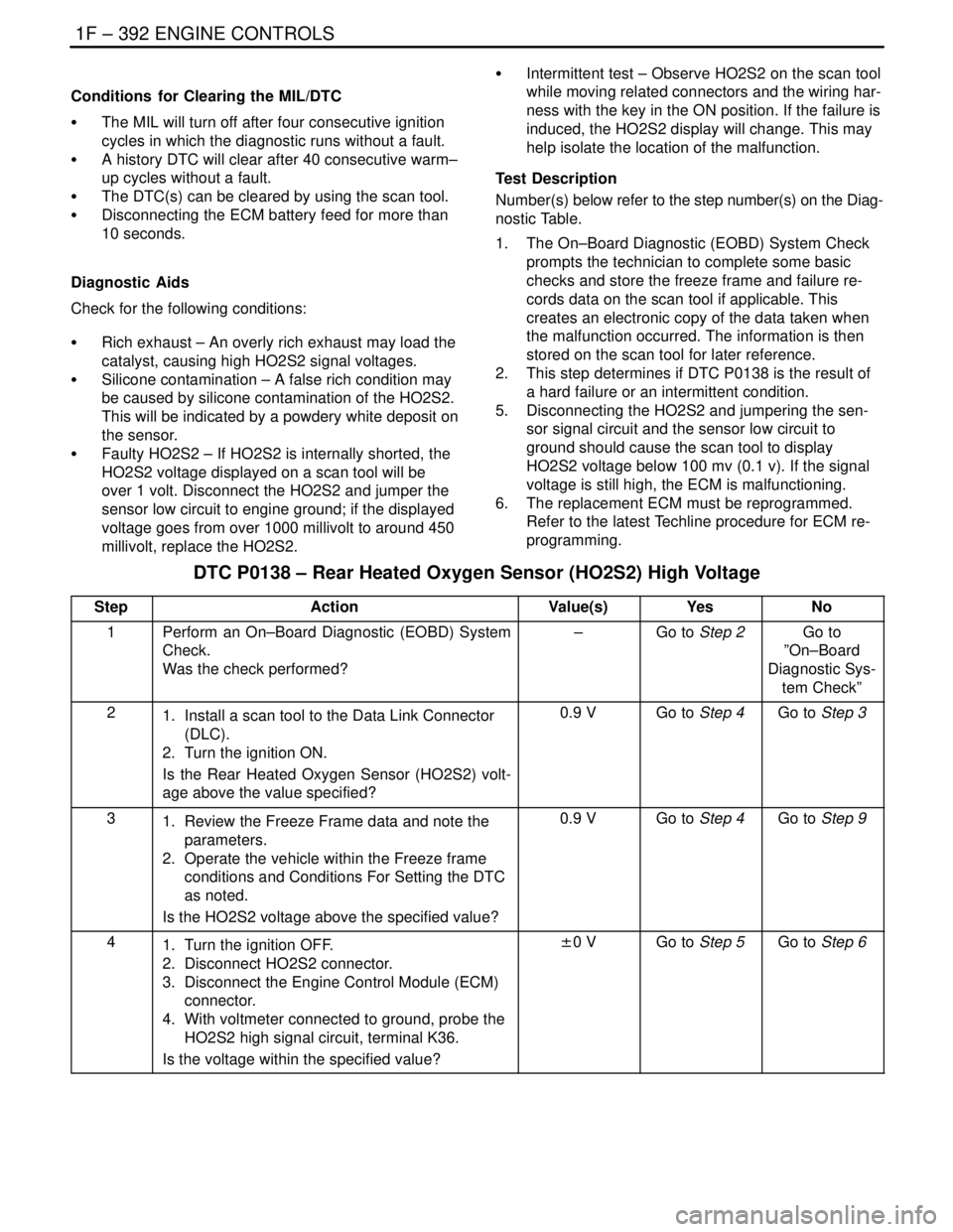

DTC P0138 – Rear Heated Oxygen Sensor (HO2S2) High Voltage

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Is the Rear Heated Oxygen Sensor (HO2S2) volt-

age above the value specified?0.9 VGo to Step 4Go to Step 3

31. Review the Freeze Frame data and note the

parameters.

2. Operate the vehicle within the Freeze frame

conditions and Conditions For Setting the DTC

as noted.

Is the HO2S2 voltage above the specified value?0.9 VGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Disconnect HO2S2 connector.

3. Disconnect the Engine Control Module (ECM)

connector.

4. With voltmeter connected to ground, probe the

HO2S2 high signal circuit, terminal K36.

Is the voltage within the specified value?±0 VGo to Step 5Go to Step 6

Page 768 of 2643

1F – 522IENGINE CONTROLS

DAEWOO V–121 BL4

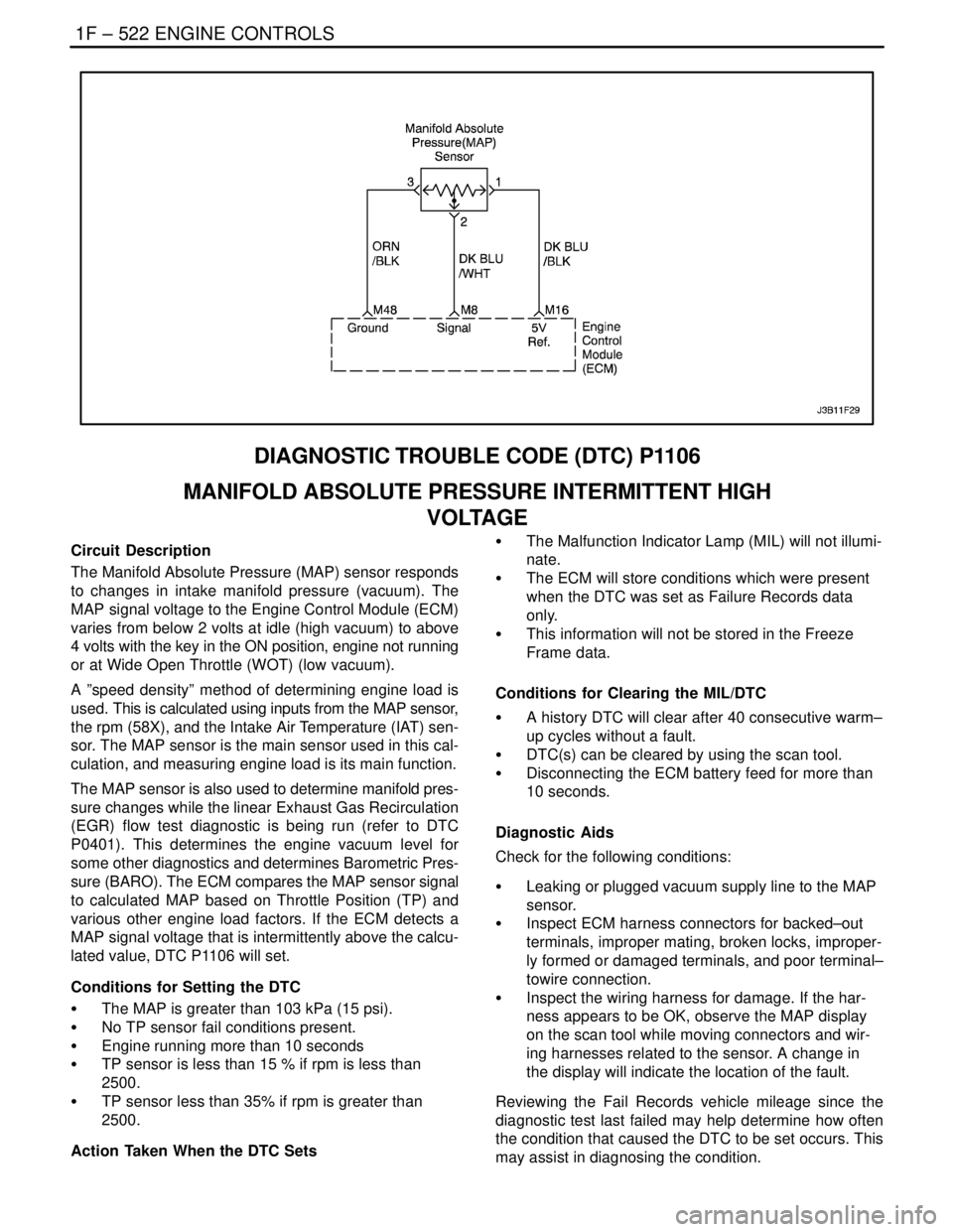

DIAGNOSTIC TROUBLE CODE (DTC) P1106

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT HIGH

VOLTAGE

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently above the calcu-

lated value, DTC P1106 will set.

Conditions for Setting the DTC

S The MAP is greater than 103 kPa (15 psi).

S No TP sensor fail conditions present.

S Engine running more than 10 seconds

S TP sensor is less than 15 % if rpm is less than

2500.

S TP sensor less than 35% if rpm is greater than

2500.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

towire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 770 of 2643

1F – 524IENGINE CONTROLS

DAEWOO V–121 BL4

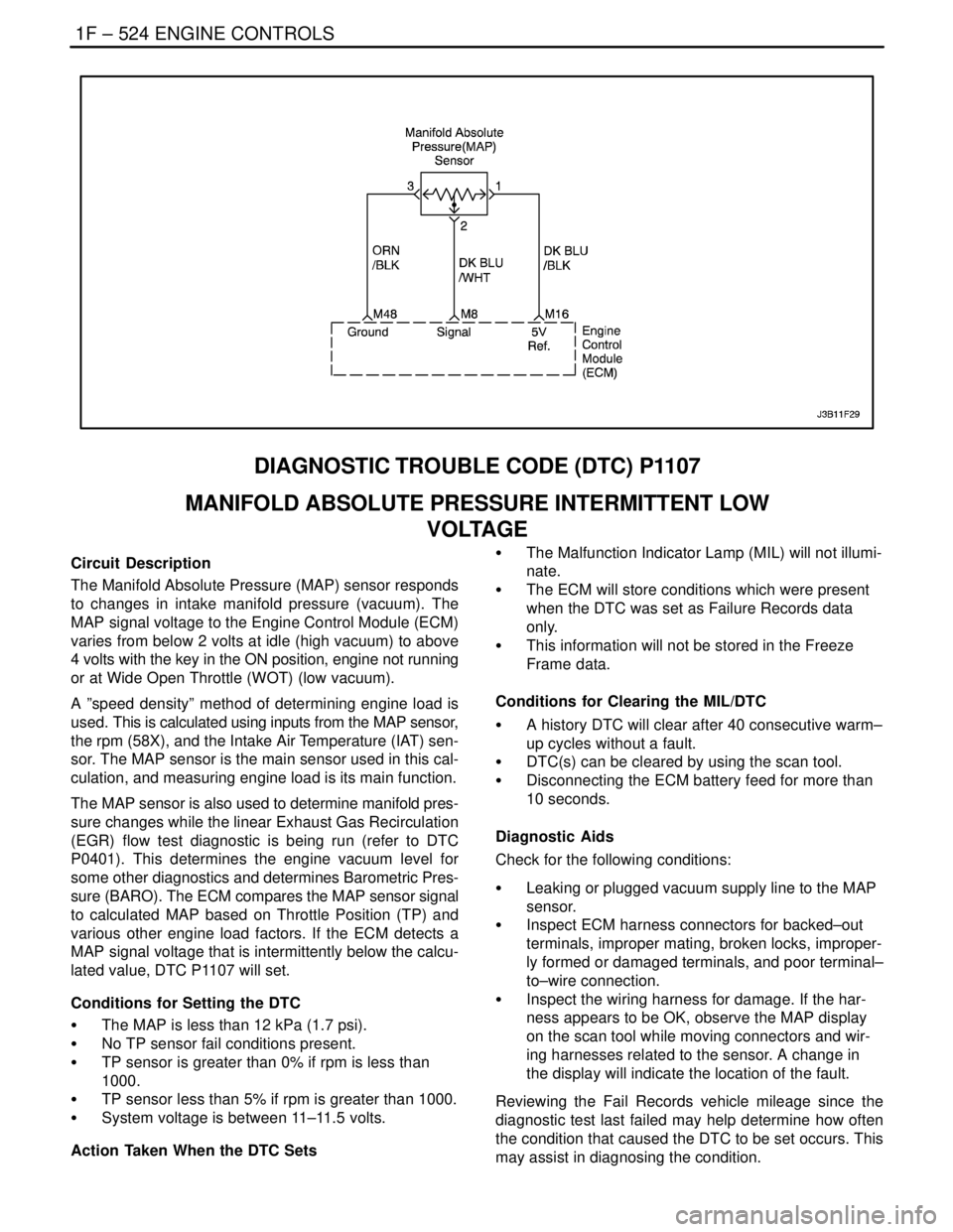

DIAGNOSTIC TROUBLE CODE (DTC) P1107

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT LOW

VOLTAGE

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently below the calcu-

lated value, DTC P1107 will set.

Conditions for Setting the DTC

S The MAP is less than 12 kPa (1.7 psi).

S No TP sensor fail conditions present.

S TP sensor is greater than 0% if rpm is less than

1000.

S TP sensor less than 5% if rpm is greater than 1000.

S System voltage is between 11–11.5 volts.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

to–wire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.