hood DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 18 of 2643

GENERAL INFORMATION 0B – 11

DAEWOO V–121 BL4

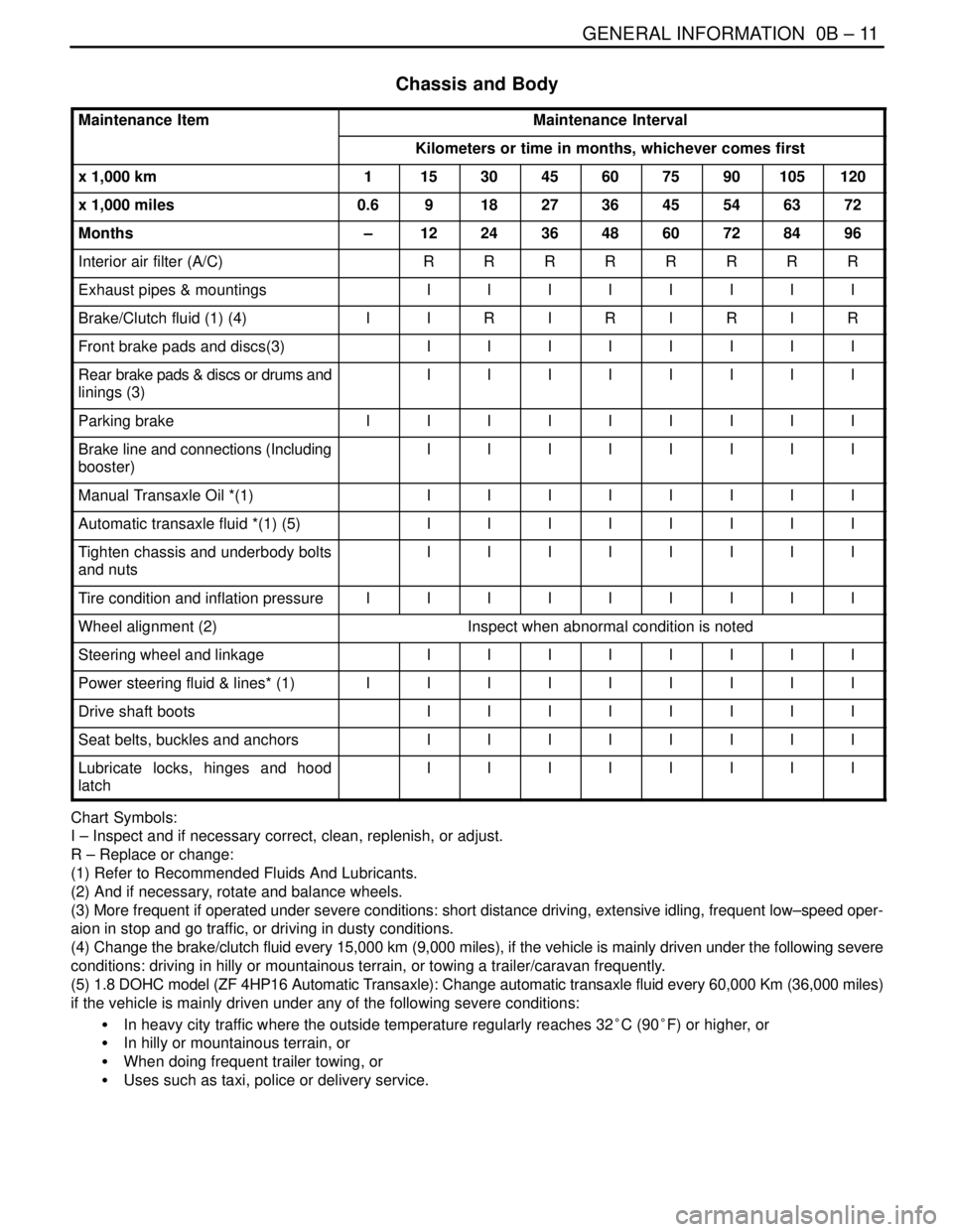

Chassis and Body

Maintenance ItemMaintenance Interval

Kilometers or time in months, whichever comes first

x 1,000 km1153045607590105120

x 1,000 miles0.6918273645546372

Months–1224364860728496

Interior air filter (A/C)RRRRRRRR

Exhaust pipes & mountingsIIIIIIII

Brake/Clutch fluid (1) (4)IIRIRIRIR

Front brake pads and discs(3)IIIIIIII

Rear brake pads & discs or drums and

linings (3)IIIIIIII

Parking brakeIIIIIIIII

Brake line and connections (Including

booster)IIIIIIII

Manual Transaxle Oil *(1)IIIIIIII

Automatic transaxle fluid *(1) (5)IIIIIIII

Tighten chassis and underbody bolts

and nutsIIIIIIII

Tire condition and inflation pressureIIIIIIIII

Wheel alignment (2)Inspect when abnormal condition is noted

Steering wheel and linkageIIIIIIII

Power steering fluid & lines* (1)IIIIIIIII

Drive shaft bootsIIIIIIII

Seat belts, buckles and anchorsIIIIIIII

Lubricate locks, hinges and hood

latchIIIIIIII

Chart Symbols:

I – Inspect and if necessary correct, clean, replenish, or adjust.

R – Replace or change:

(1) Refer to Recommended Fluids And Lubricants.

(2) And if necessary, rotate and balance wheels.

(3) More frequent if operated under severe conditions: short distance driving, extensive idling, frequent low–speed oper-

aion in stop and go traffic, or driving in dusty conditions.

(4) Change the brake/clutch fluid every 15,000 km (9,000 miles), if the vehicle is mainly driven under the following severe

conditions: driving in hilly or mountainous terrain, or towing a trailer/caravan frequently.

(5) 1.8 DOHC model (ZF 4HP16 Automatic Transaxle): Change automatic transaxle fluid every 60,000 Km (36,000 miles)

if the vehicle is mainly driven under any of the following severe conditions:

S In heavy city traffic where the outside temperature regularly reaches 32°C (90°F) or higher, or

S In hilly or mountainous terrain, or

S When doing frequent trailer towing, or

S Uses such as taxi, police or delivery service.

Page 20 of 2643

GENERAL INFORMATION 0B – 13

DAEWOO V–121 BL4

EACH TIME THE OIL IS CHANGED

Automatic Transaxle Fluid

Refer to fluid level service procedure of Section 5A, ZF

4HP16 Automatic Transaxle.

Manual Transaxle

Check the fluid level and add fluid as required. Refer to

Section 5B, Five–Speed Manual Transaxle.

Brake System Inspection

This inspection should be done when the wheels are re-

moved for rotation. Inspect the lines and the hoses for

proper hookup, binding, leaks, cracks, chafing, etc. In-

spect the disc brake pads for wear. Inspect the rotors for

surface condition. Also inspect the drum brake linings for

wear and cracks. Inspect other brake parts, including the

drums, the wheels cylinders, the parking brake, etc., at the

same time. Check the parking brake adjustment. Inspect

the brakes more often if habit or conditions result in fre-

quent braking.

Steering, Suspension and Front Drive Axle

Boot And Seal Inspection

Inspect the front and rear suspension and the steering

system for damaged, loose or missing parts, signs of wear

or lack of lubrication. Inspect the power steering lines and

the hoses for proper hookup, binding, leaks, cracks, chaf-

ing, etc. Clean and inspect the drive axle boot and seals

for damage, tears or leakage. Replace the seals if neces-

sary.

Exhaust System Inspection

Inspect the complete system (including the catalytic con-

verter if equipped). Inspect the body near the exhaust sys-

tem. Look for broken, damaged, missing, or out–of–posi-

tion parts as well as open seams, holes, loose

connections, or other conditions which could cause heat

buildup in the floor pan or could let exhaust fumes seep

into the trunk or passenger compartment.

Throttle Linkage Inspection

Inspect the throttle linkage for interference or binding,

damaged, or missing parts. Lubricate all linkage joints and

throttle cable joints, the intermediate throttle shaft bearing,

the return spring at throttle valve assembly, and the accel-

erator pedal sliding face with suitable grease. Check the

throttle cable for free movements.

Engine Drive Belts

Inspect all belts for cracks, fraying, wear and proper ten-

sion. Adjust or replace the belts as needed.

Hood Latch Operation

When opening the hood, note the operation of the secon-

dary latch. It should keep the hood from opening all the

way when the primary latch is released. The hood must

close firmly.

AT LEAST ANNUALLY

Lap and Shoulder Belts Condition and

Operation

Inspect the belt system including: the webbing, the

buckles, the latch plates, the retractor, the guide loops and

the anchors.

Movable Head Restraint Operation

On vehicles with movable head restraints, the restraints

must stay in the desired position.

Spare Tire and Jack Storage

Be alert to rattles in the rear of the vehicle. The spare tire,

all the jacking equipment, and the tools must be securely

stowed at all times. Oil the jack ratchet or the screw mech-

anism after each use.

Key Lock Service

Lubricate the key lock cylinder.

Body Lubrication Service

Lubricate all the body door hinges including the hood, the

fuel door, the rear compartment hinges and the latches,

the glove box and the console doors, and any folding seat

hardware.

Transaxle Neutral Switch Operation on

Automatic Transaxle

CAUTION : Take the following precautions because

the vehicle could move without warning and possibly

cause personal injury or property damage:

S Firmly apply the parking brake and the regular

brakes.

S Do not use the accelerator pedal.

S Be ready to promptly turn off the ignition if the ve-

hicle starts.

On automatic transaxle vehicles, try to start the engine in

each gear. The starter should crank only in P (Park) or N

(Neutral).

Parking Brake and Transaxle P (Park)

Mechanism Operation

CAUTION : In order to reduce the risk of personal in-

jury or property damage, be prepared to apply the reg-

ular brakes promptly if the vehicle begins to move.

Park on a fairly steep hill with enough room for movement

in the downhill direction. To check the parking brake, with

the engine running and the transaxle in N (Neutral), slowly

remove foot pressure from the regular brake pedal (until

only the parking brake is holding the vehicle).

To check the automatic transaxle P (Park) mechanism’s

holding ability, release all brakes after shifting the trans-

axle to P (Park).

Underbody Flushing

Flushing the underbody will remove any corrosive materi-

als used for ice and snow removal and dust control. At

least every spring clean the underbody. First, loosen the

sediment packed in closed areas of the vehicle. Then flush

the underbody with plain water.

Page 21 of 2643

0B – 14IGENERAL INFORMATION

DAEWOO V–121 BL4

Engine Cooling System

Inspect the coolant and freeze protection fluid. If the fluid

is dirty or rusty, drain, flush and refill the engine cooling

system with new coolant. Keep the coolant at the proper

mixture in order to ensure proper freeze protection, corro-sion protection and engine operating temperature. Inspect

the hoses. Replace the cracked, swollen, or deteriorated

hoses. Tighten the clamps. Clean the outside of the radia-

tor and the air conditioning condenser. Wash the filler cap

and the neck. Pressure test the cooling system and the

cap in order to help ensure proper operation.

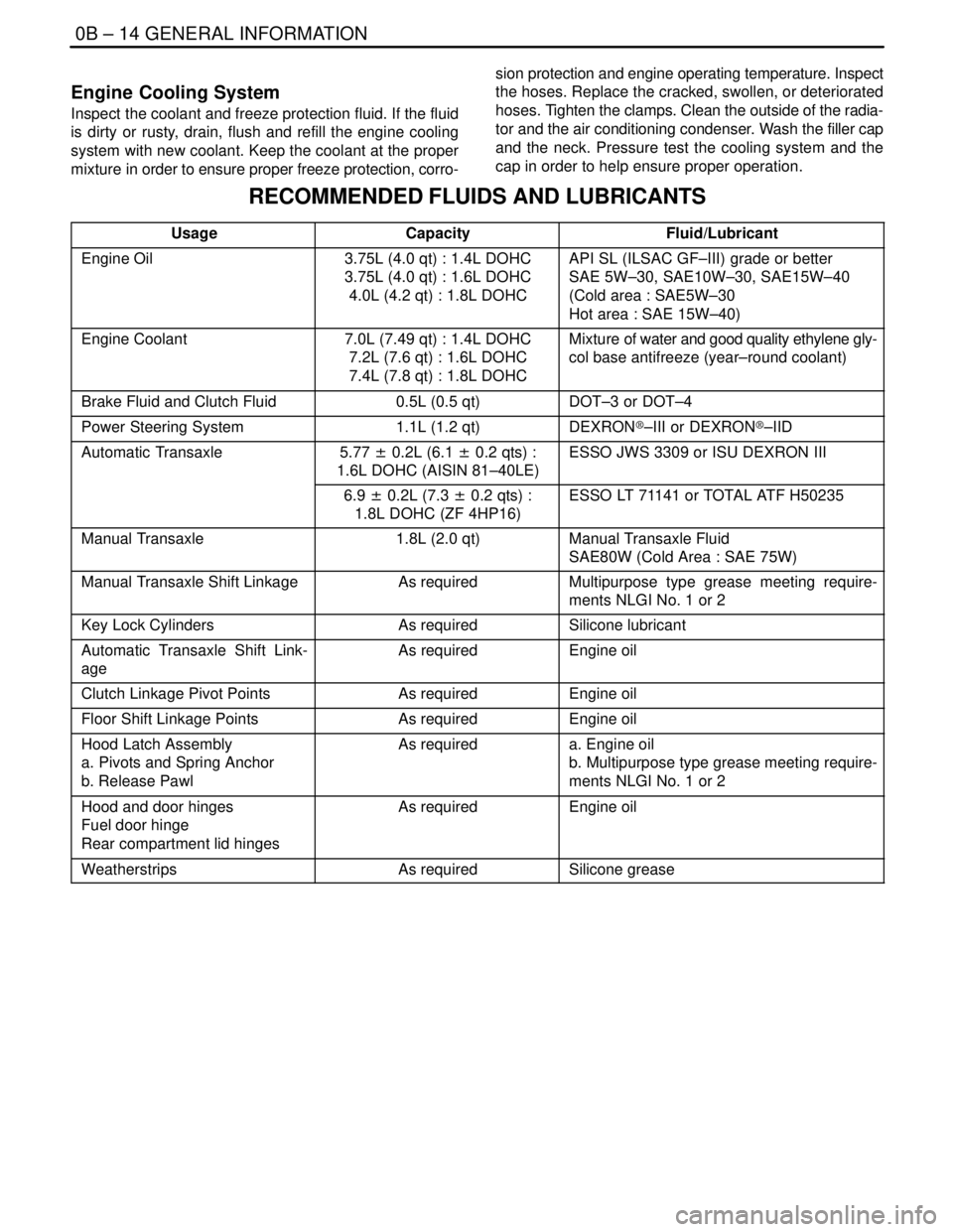

RECOMMENDED FLUIDS AND LUBRICANTS

UsageCapacityFluid/Lubricant

Engine Oil3.75L (4.0 qt) : 1.4L DOHC

3.75L (4.0 qt) : 1.6L DOHC

4.0L (4.2 qt) : 1.8L DOHCAPI SL (ILSAC GF–III) grade or better

SAE 5W–30, SAE10W–30, SAE15W–40

(Cold area : SAE5W–30

Hot area : SAE 15W–40)

Engine Coolant7.0L (7.49 qt) : 1.4L DOHC

7.2L (7.6 qt) : 1.6L DOHC

7.4L (7.8 qt) : 1.8L DOHCMixture of water and good quality ethylene gly-

col base antifreeze (year–round coolant)

Brake Fluid and Clutch Fluid0.5L (0.5 qt)DOT–3 or DOT–4

Power Steering System1.1L (1.2 qt)DEXRON®–III or DEXRON®–IID

Automatic Transaxle5.77 ± 0.2L (6.1 ± 0.2 qts) :

1.6L DOHC (AISIN 81–40LE)ESSO JWS 3309 or ISU DEXRON III

6.9 ± 0.2L (7.3 ± 0.2 qts) :

1.8L DOHC (ZF 4HP16)ESSO LT 71141 or TOTAL ATF H50235

Manual Transaxle1.8L (2.0 qt)Manual Transaxle Fluid

SAE80W (Cold Area : SAE 75W)

Manual Transaxle Shift LinkageAs requiredMultipurpose type grease meeting require-

ments NLGI No. 1 or 2

Key Lock CylindersAs requiredSilicone lubricant

Automatic Transaxle Shift Link-

ageAs requiredEngine oil

Clutch Linkage Pivot PointsAs requiredEngine oil

Floor Shift Linkage PointsAs requiredEngine oil

Hood Latch Assembly

a. Pivots and Spring Anchor

b. Release PawlAs requireda. Engine oil

b. Multipurpose type grease meeting require-

ments NLGI No. 1 or 2

Hood and door hinges

Fuel door hinge

Rear compartment lid hingesAs requiredEngine oil

WeatherstripsAs requiredSilicone grease

Page 91 of 2643

1C1 – 48I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

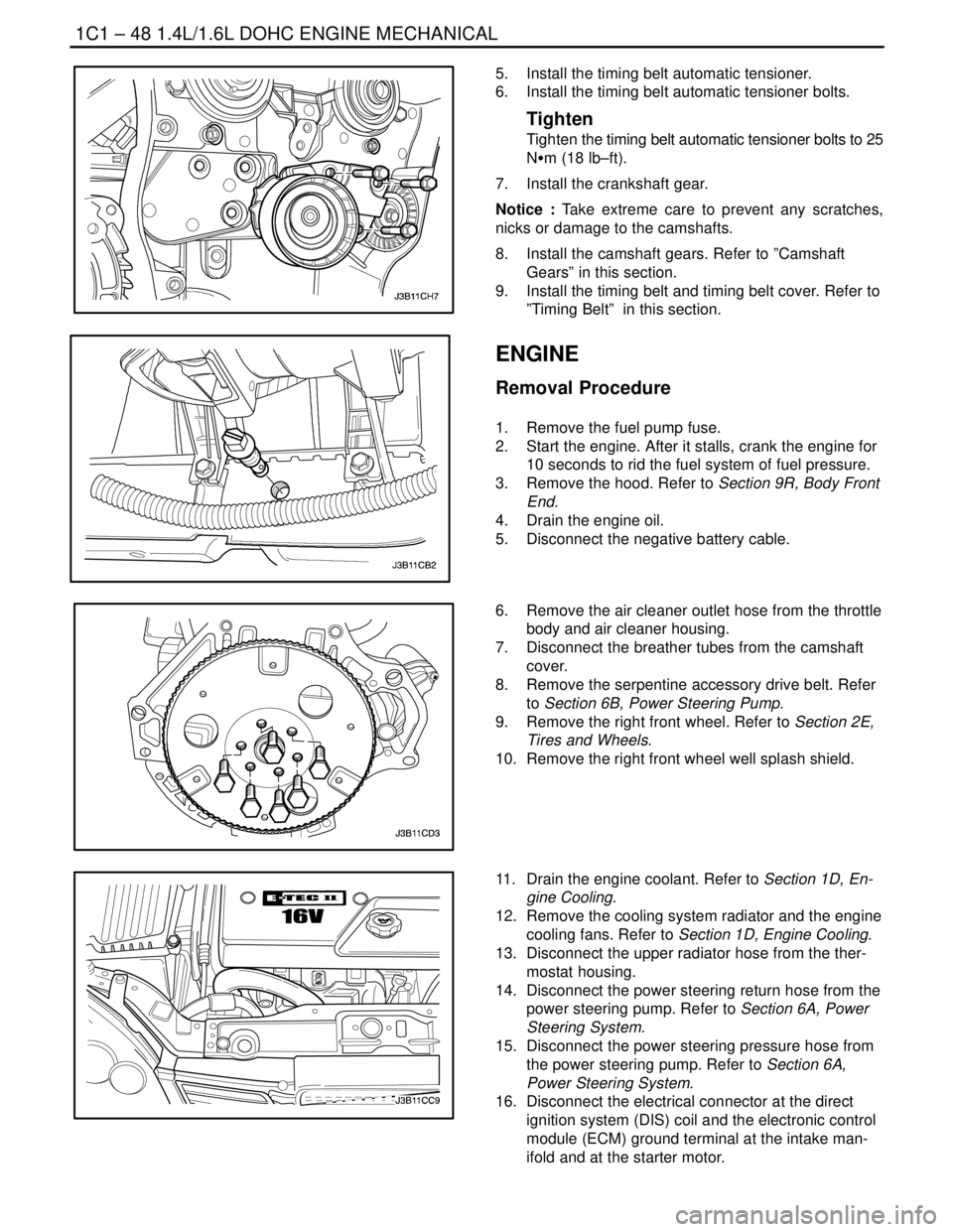

5. Install the timing belt automatic tensioner.

6. Install the timing belt automatic tensioner bolts.

Tighten

Tighten the timing belt automatic tensioner bolts to 25

NSm (18 lb–ft).

7. Install the crankshaft gear.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

7. Disconnect the breather tubes from the camshaft

cover.

8. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

9. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

10. Remove the right front wheel well splash shield.

11. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

12. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

13. Disconnect the upper radiator hose from the ther-

mostat housing.

14. Disconnect the power steering return hose from the

power steering pump. Refer to Section 6A, Power

Steering System.

15. Disconnect the power steering pressure hose from

the power steering pump. Refer to Section 6A,

Power Steering System.

16. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal at the intake man-

ifold and at the starter motor.

Page 96 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 53

DAEWOO V–121 BL4

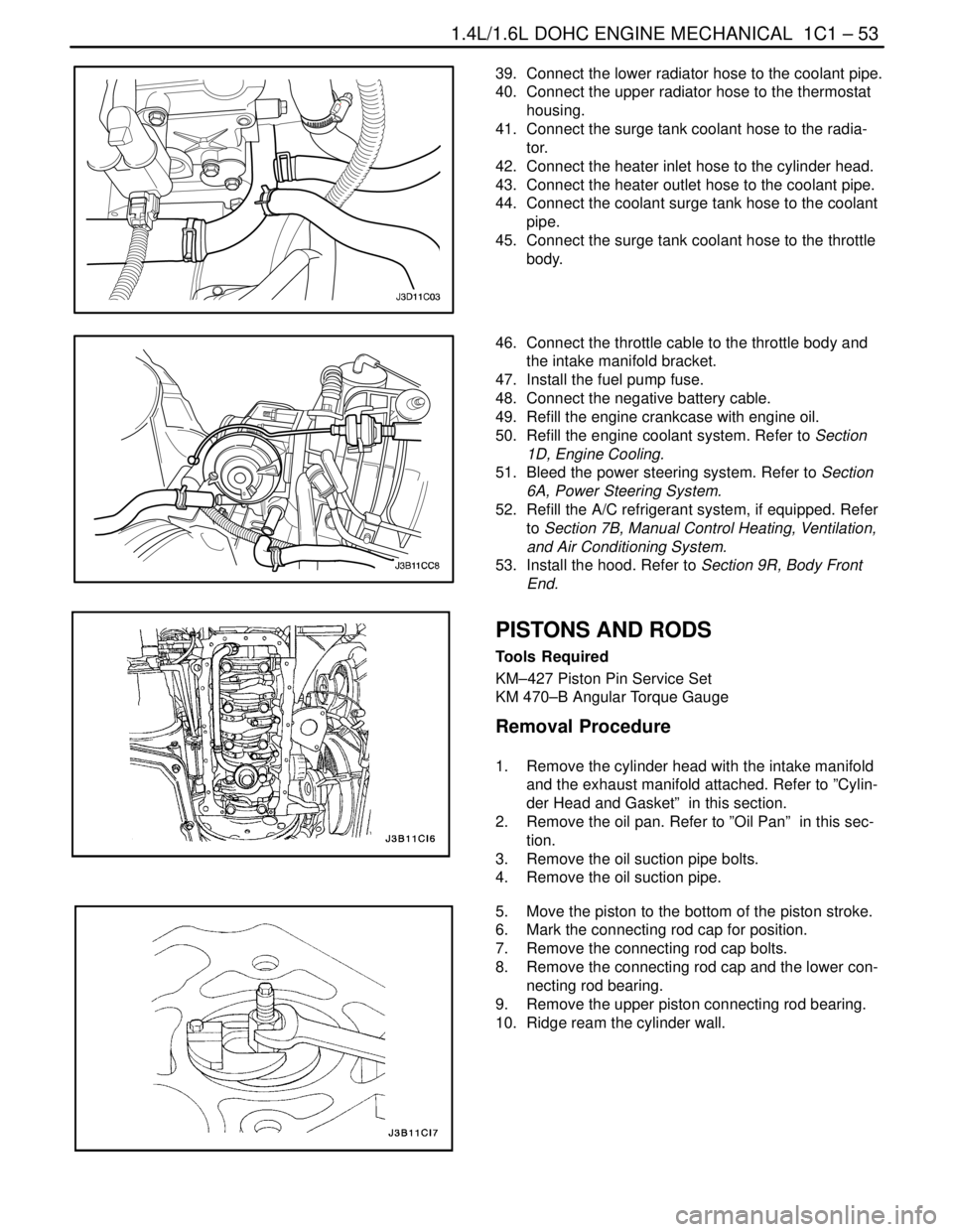

39. Connect the lower radiator hose to the coolant pipe.

40. Connect the upper radiator hose to the thermostat

housing.

41. Connect the surge tank coolant hose to the radia-

tor.

42. Connect the heater inlet hose to the cylinder head.

43. Connect the heater outlet hose to the coolant pipe.

44. Connect the coolant surge tank hose to the coolant

pipe.

45. Connect the surge tank coolant hose to the throttle

body.

46. Connect the throttle cable to the throttle body and

the intake manifold bracket.

47. Install the fuel pump fuse.

48. Connect the negative battery cable.

49. Refill the engine crankcase with engine oil.

50. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

51. Bleed the power steering system. Refer to Section

6A, Power Steering System.

52. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

53. Install the hood. Refer to Section 9R, Body Front

End.

PISTONS AND RODS

Tools Required

KM–427 Piston Pin Service Set

KM 470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and the exhaust manifold attached. Refer to ”Cylin-

der Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts.

4. Remove the oil suction pipe.

5. Move the piston to the bottom of the piston stroke.

6. Mark the connecting rod cap for position.

7. Remove the connecting rod cap bolts.

8. Remove the connecting rod cap and the lower con-

necting rod bearing.

9. Remove the upper piston connecting rod bearing.

10. Ridge ream the cylinder wall.

Page 166 of 2643

1C2 – 46I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

7. Install the timing belt automatic tensioner and bolt.

8. Install the camshaft gears. Refer to ”Camshaft

Gears” in this section.

9. Install the timing belt and timing belt cover. Refer to

”Timing Belt” in this section.

10. Connect the negative battery cable.

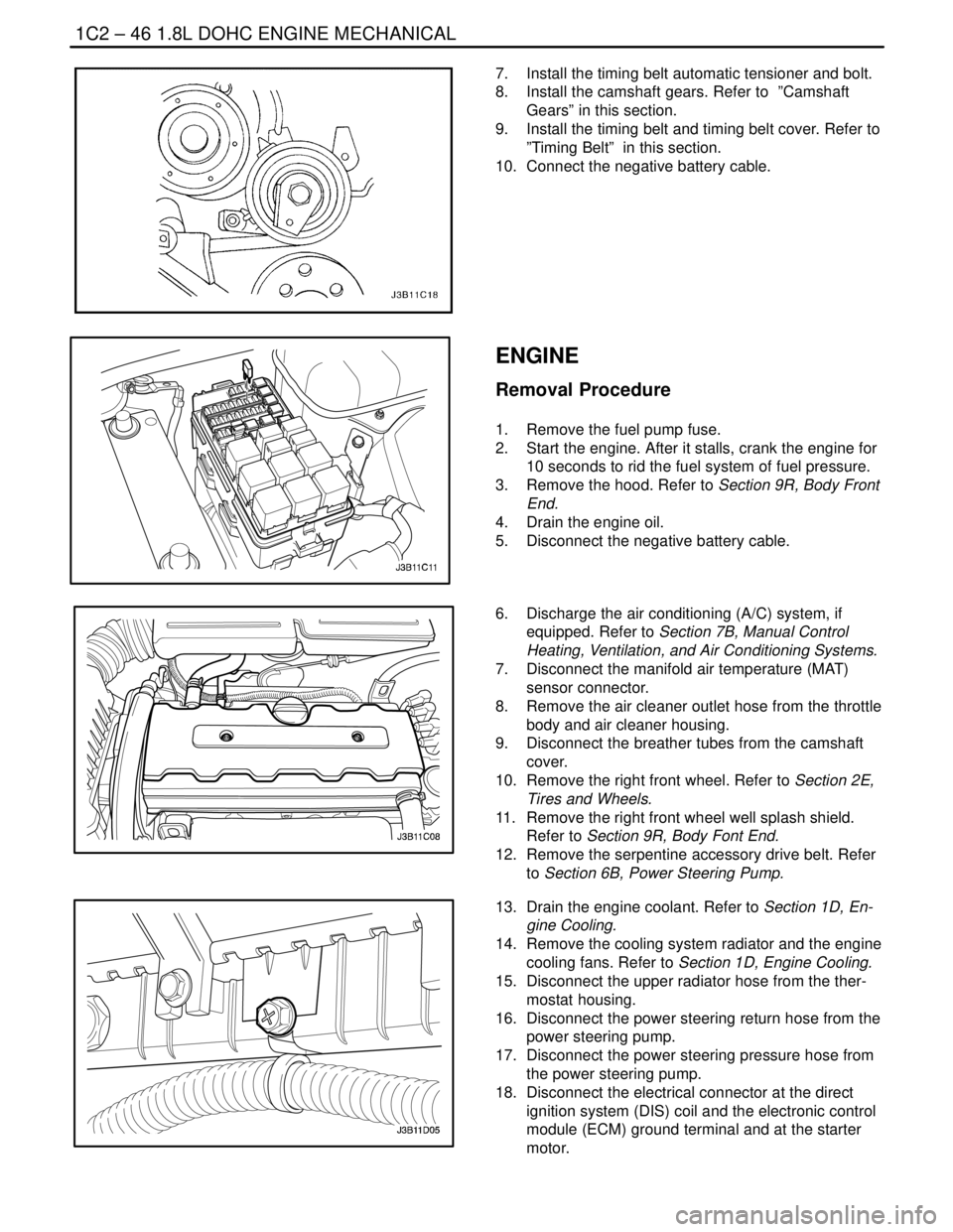

ENGINE

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Remove the hood. Refer to Section 9R, Body Front

End.

4. Drain the engine oil.

5. Disconnect the negative battery cable.

6. Discharge the air conditioning (A/C) system, if

equipped. Refer to Section 7B, Manual Control

Heating, Ventilation, and Air Conditioning Systems.

7. Disconnect the manifold air temperature (MAT)

sensor connector.

8. Remove the air cleaner outlet hose from the throttle

body and air cleaner housing.

9. Disconnect the breather tubes from the camshaft

cover.

10. Remove the right front wheel. Refer to Section 2E,

Tires and Wheels.

11. Remove the right front wheel well splash shield.

Refer to Section 9R, Body Font End.

12. Remove the serpentine accessory drive belt. Refer

to Section 6B, Power Steering Pump.

13. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

14. Remove the cooling system radiator and the engine

cooling fans. Refer to Section 1D, Engine Cooling.

15. Disconnect the upper radiator hose from the ther-

mostat housing.

16. Disconnect the power steering return hose from the

power steering pump.

17. Disconnect the power steering pressure hose from

the power steering pump.

18. Disconnect the electrical connector at the direct

ignition system (DIS) coil and the electronic control

module (ECM) ground terminal and at the starter

motor.

Page 171 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 51

DAEWOO V–121 BL4

43. Connect the lower radiator hose to the coolant pipe.

44. Connect the upper radiator hose to the thermostat

housing.

45. Connect the heater inlet hose to the cylinder head.

46. Connect the heater outlet hose to the coolant pipe.

47. Connect the coolant surge tank hose to the coolant

pipe.

48. Connect the coolant hose to the throttle body.

49. Connect the throttle cable to the throttle body and

the intake manifold bracket.

50. Install the fuel pump fuse.

51. Connect the negative battery cable.

52. Refill the engine crankcase with engine oil.

53. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

54. Bleed the power steering system. Refer to Section

6A, Power Steering.

55. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

56. Install the hood. Refer to Section 9R, Body Front

End.

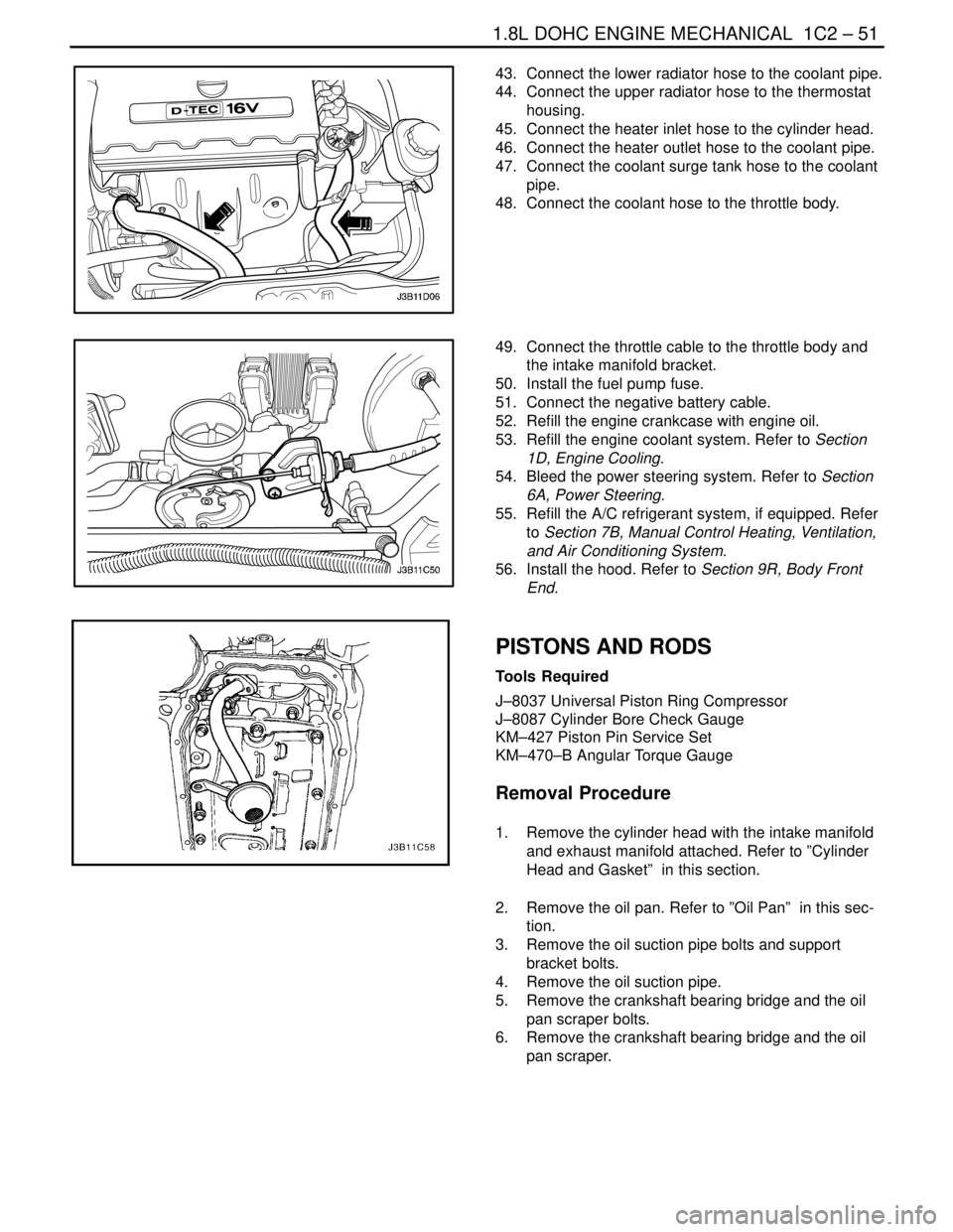

PISTONS AND RODS

Tools Required

J–8037 Universal Piston Ring Compressor

J–8087 Cylinder Bore Check Gauge

KM–427 Piston Pin Service Set

KM–470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and exhaust manifold attached. Refer to ”Cylinder

Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts and support

bracket bolts.

4. Remove the oil suction pipe.

5. Remove the crankshaft bearing bridge and the oil

pan scraper bolts.

6. Remove the crankshaft bearing bridge and the oil

pan scraper.

Page 1014 of 2643

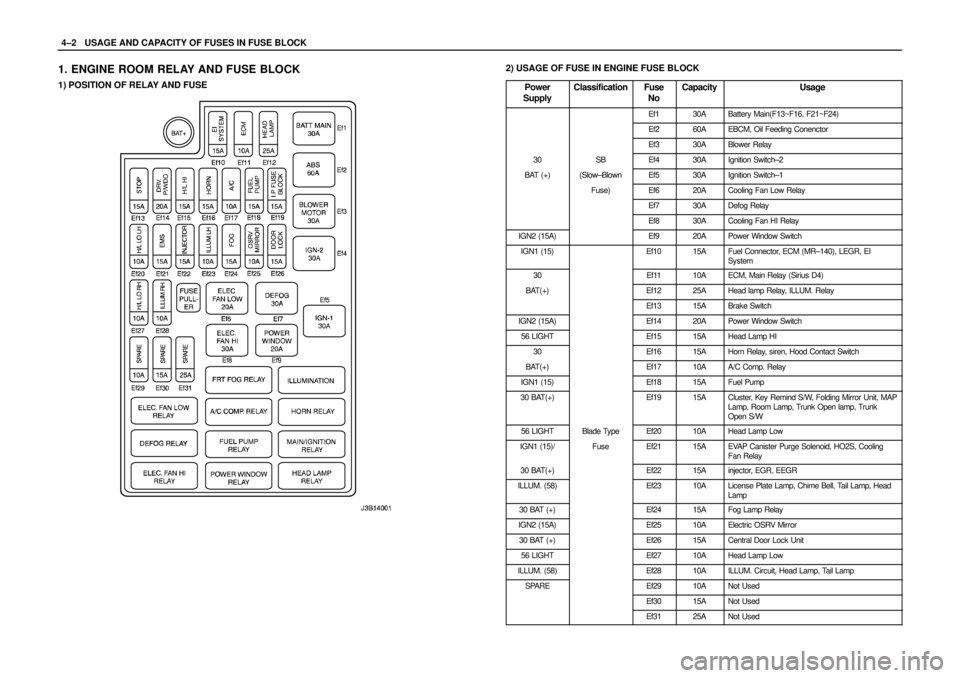

4–2WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

1. ENGINE ROOM RELAY AND FUSE BLOCK

1) POSITION OF RELAY AND FUSE

2) USAGE OF FUSE IN ENGINE FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

Ef130ABattery Main(F13~F16, F21~F24)

Ef260AEBCM, Oil Feeding Conenctor

Ef330ABlower Relay

30SBEf430AIgnition Switch–2

BAT (+)(Slow–BlownEf530AIgnition Switch–1

Fuse)Ef620ACooling Fan Low Relay

Ef730ADefog Relay

Ef830ACooling Fan HI Relay

IGN2 (15A)Ef920APower Window Switch

IGN1 (15)Ef1015AFuel Connector, ECM (MR–140), LEGR, EI

System

30Ef1110AECM, Main Relay (Sirius D4)

BAT(+)Ef1225AHead lamp Relay, ILLUM. Relay

Ef1315ABrake Switch

IGN2 (15A)Ef1420APower Window Switch

56 LIGHTEf1515AHead Lamp HI

30Ef1615AHorn Relay, siren, Hood Contact Switch

BAT(+)Ef1710AA/C Comp. Relay

IGN1 (15)Ef1815AFuel Pump

30 BAT(+)Ef1915ACluster, Key Remind S/W, Folding Mirror Unit, MAP

Lamp, Room Lamp, Trunk Open lamp, Trunk

Open S/W

56 LIGHTBlade TypeEf2010AHead Lamp Low

IGN1 (15)/FuseEf2115AEVAP Canister Purge Solenoid, HO2S, Cooling

Fan Relay

30 BAT(+)Ef2215Ainjector, EGR, EEGR

ILLUM. (58)Ef2310ALicense Plate Lamp, Chime Bell, Tail Lamp, Head

Lamp

30 BAT (+)Ef2415AFog Lamp Relay

IGN2 (15A)Ef2510AElectric OSRV Mirror

30 BAT (+)Ef2615ACentral Door Lock Unit

56 LIGHTEf2710AHead Lamp Low

ILLUM. (58)Ef2810AILLUM. Circuit, Head Lamp, Tail Lamp

SPAREEf2910ANot Used

Ef3015ANot Used

Ef3125ANot Used

Page 1154 of 2643

4G – 2IPARKING BRAKE

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

PARKING BRAKE ADJUSTMENT

REAR DRUM BRAKES

Adjustment Procedure

1. Adjust the rear brakes. Refer to Section 4E1, Rear

Disc Brakes.

2. Release the parking brake.

3. Raise and suitably support the vehicle.

4. Check the parking brake cables for free movement.

5. Lower the vehicle

6. Remove the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

7. Partially raise the vehicle.

8. Turn the self–locking nut on the parking brake lever

assembly until the wheels are difficult to turn.

9. Back off the nut until the rear wheels are just free to

turn.

10. Lower the vehicle

11. Install the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

PARKING BRAKE ADJUSTMENT

REAR DISC BRAKES

Adjustment Procedure

1. Release the parking brake.

2. Raise and suitably support the vehicle.

3. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

4. Remove the caliper and rotor assemblies. Refer to

Section 4E1, Rear Disc Brakes.

5. Remove the brake rotors on each side of the ve-

hicle. Refer to Section 4E1, Rear Disc Brakes.

6. Disconnect the parking brake cable from the back-

plate operating lever on each side of the vehicle.

Page 1155 of 2643

PARKING BRAKE 4G – 3

DAEWOO V–121 BL4

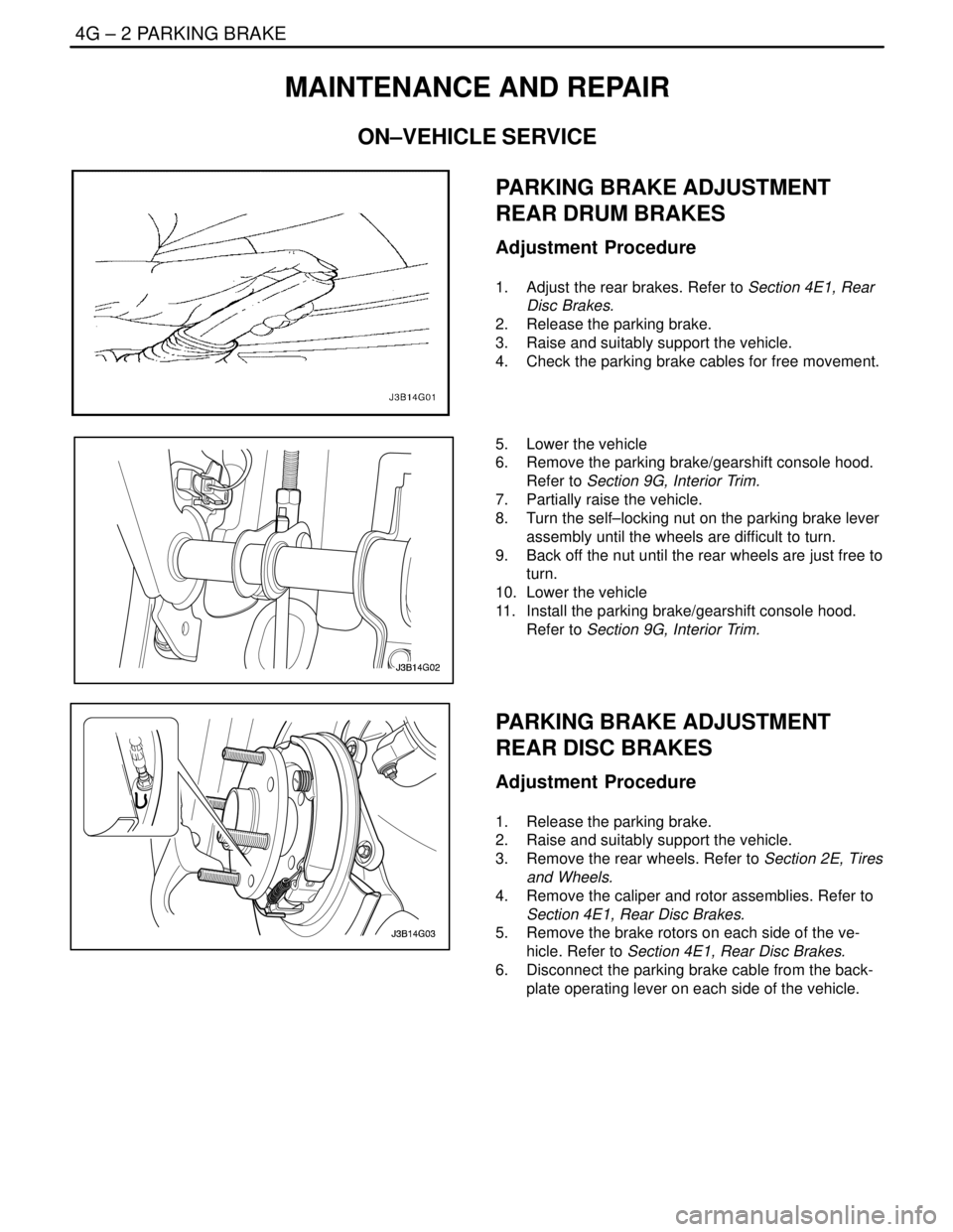

7. Inspect and replace any parts of doubtful strength

or quality. This can be shown by discoloration from

heat or stress.

8. Using a vernier caliper, adjust the shoe assembly to

167.6 to 167.8 mm (6.60 to 6.61 inches) by turning

the adjuster nut clockwise to increase the diameter.

Measure the shoe assembly diameter as closely as

possible to the center of the lining material.

9. Inspect and install the rotors and calipers. Refer to

Section 4E1, Rear Disc Brakes.

10. Install the parking brake cable to the backplate le-

ver on each side of the vehicle.

11. In the vehicle cabin, pull on the parking brake han-

dle. Stop after hearing two clicks.

12. Turn the rear wheel by hand until the wheel begins

to drag.

13. Release the parking brake.

14. Turn the rear wheel by hand to check the drag. Re-

adjust the cable, if necessary.

15. Repeat the process for the other rear wheel.

16. Lower the vehicle.

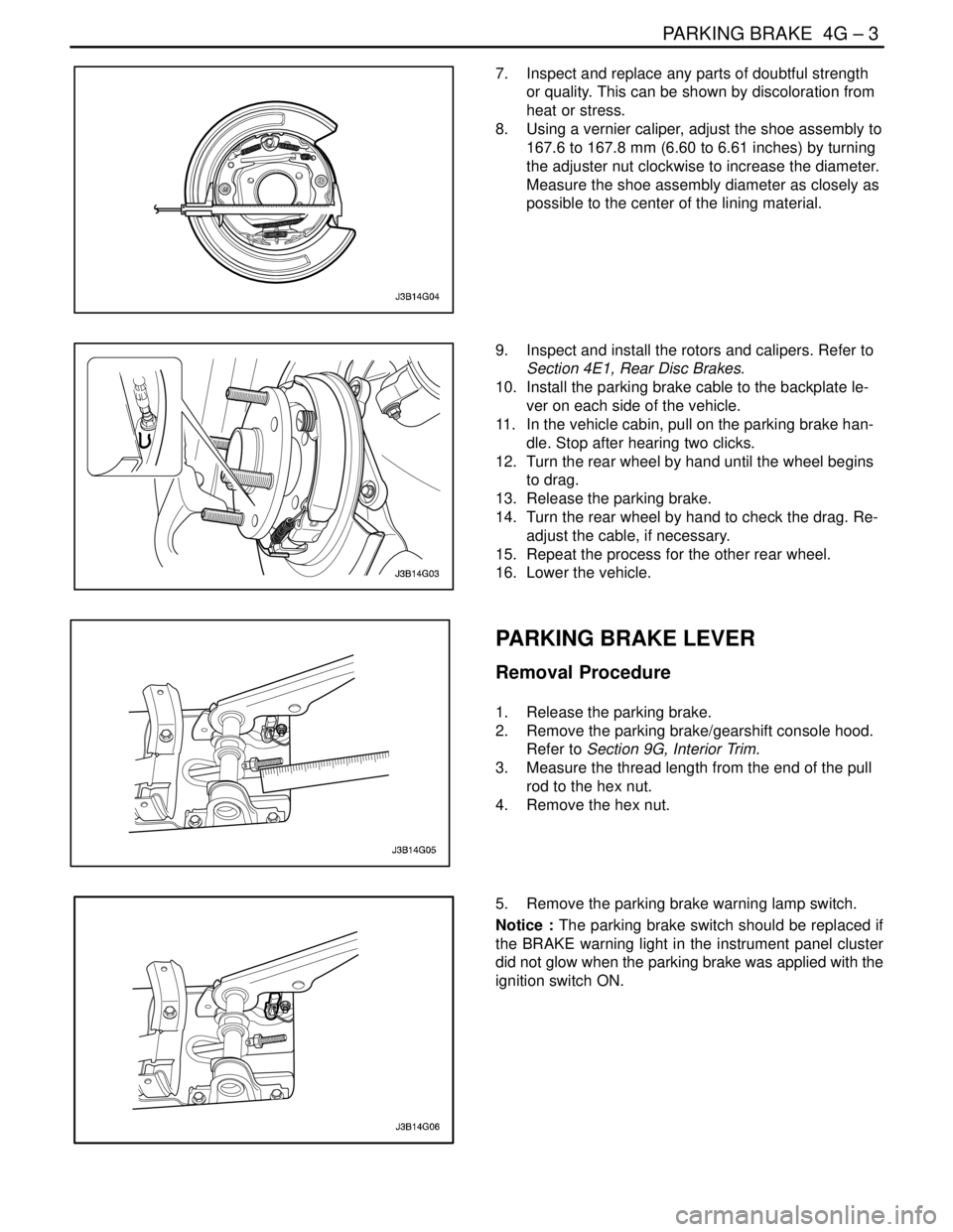

PARKING BRAKE LEVER

Removal Procedure

1. Release the parking brake.

2. Remove the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

3. Measure the thread length from the end of the pull

rod to the hex nut.

4. Remove the hex nut.

5. Remove the parking brake warning lamp switch.

Notice : The parking brake switch should be replaced if

the BRAKE warning light in the instrument panel cluster

did not glow when the parking brake was applied with the

ignition switch ON.