torque converter bolt DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 37 of 2643

GENERAL ENGINE INFORMATION 1A – 5

DAEWOO V–121 BL4

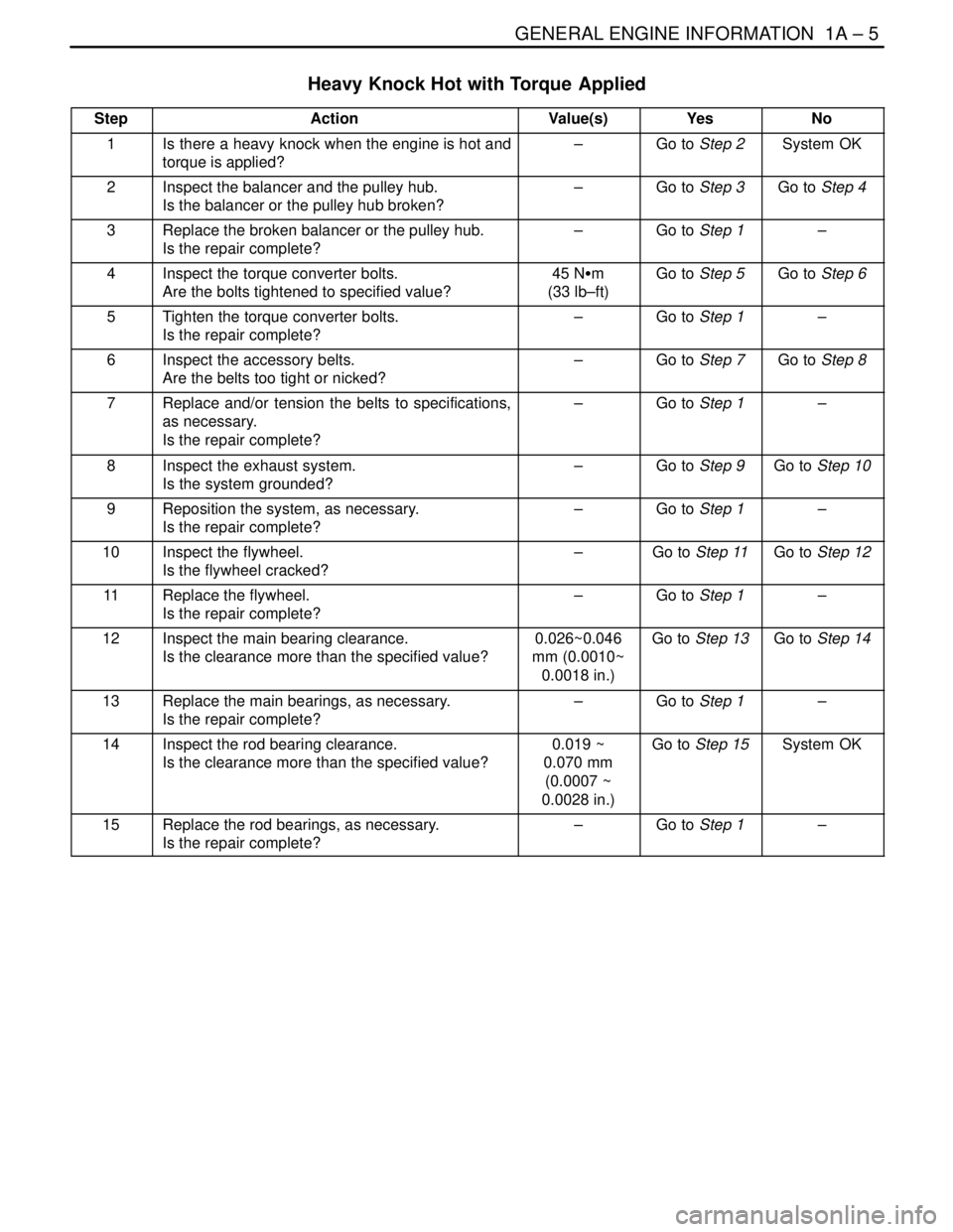

Heavy Knock Hot with Torque Applied

StepActionValue(s)YesNo

1Is there a heavy knock when the engine is hot and

torque is applied?–Go to Step 2System OK

2Inspect the balancer and the pulley hub.

Is the balancer or the pulley hub broken?–Go to Step 3Go to Step 4

3Replace the broken balancer or the pulley hub.

Is the repair complete?–Go to Step 1–

4Inspect the torque converter bolts.

Are the bolts tightened to specified value?45 NSm

(33 lb–ft)Go to Step 5Go to Step 6

5Tighten the torque converter bolts.

Is the repair complete?–Go to Step 1–

6Inspect the accessory belts.

Are the belts too tight or nicked?–Go to Step 7Go to Step 8

7Replace and/or tension the belts to specifications,

as necessary.

Is the repair complete?–Go to Step 1–

8Inspect the exhaust system.

Is the system grounded?–Go to Step 9Go to Step 10

9Reposition the system, as necessary.

Is the repair complete?–Go to Step 1–

10Inspect the flywheel.

Is the flywheel cracked?–Go to Step 11Go to Step 12

11Replace the flywheel.

Is the repair complete?–Go to Step 1–

12Inspect the main bearing clearance.

Is the clearance more than the specified value?0.026~0.046

mm (0.0010~

0.0018 in.)Go to Step 13Go to Step 14

13Replace the main bearings, as necessary.

Is the repair complete?–Go to Step 1–

14Inspect the rod bearing clearance.

Is the clearance more than the specified value?0.019 ~

0.070 mm

(0.0007 ~

0.0028 in.)Go to Step 15System OK

15Replace the rod bearings, as necessary.

Is the repair complete?–Go to Step 1–

Page 38 of 2643

1A – 6IGENERAL ENGINE INFORMATION

DAEWOO V–121 BL4

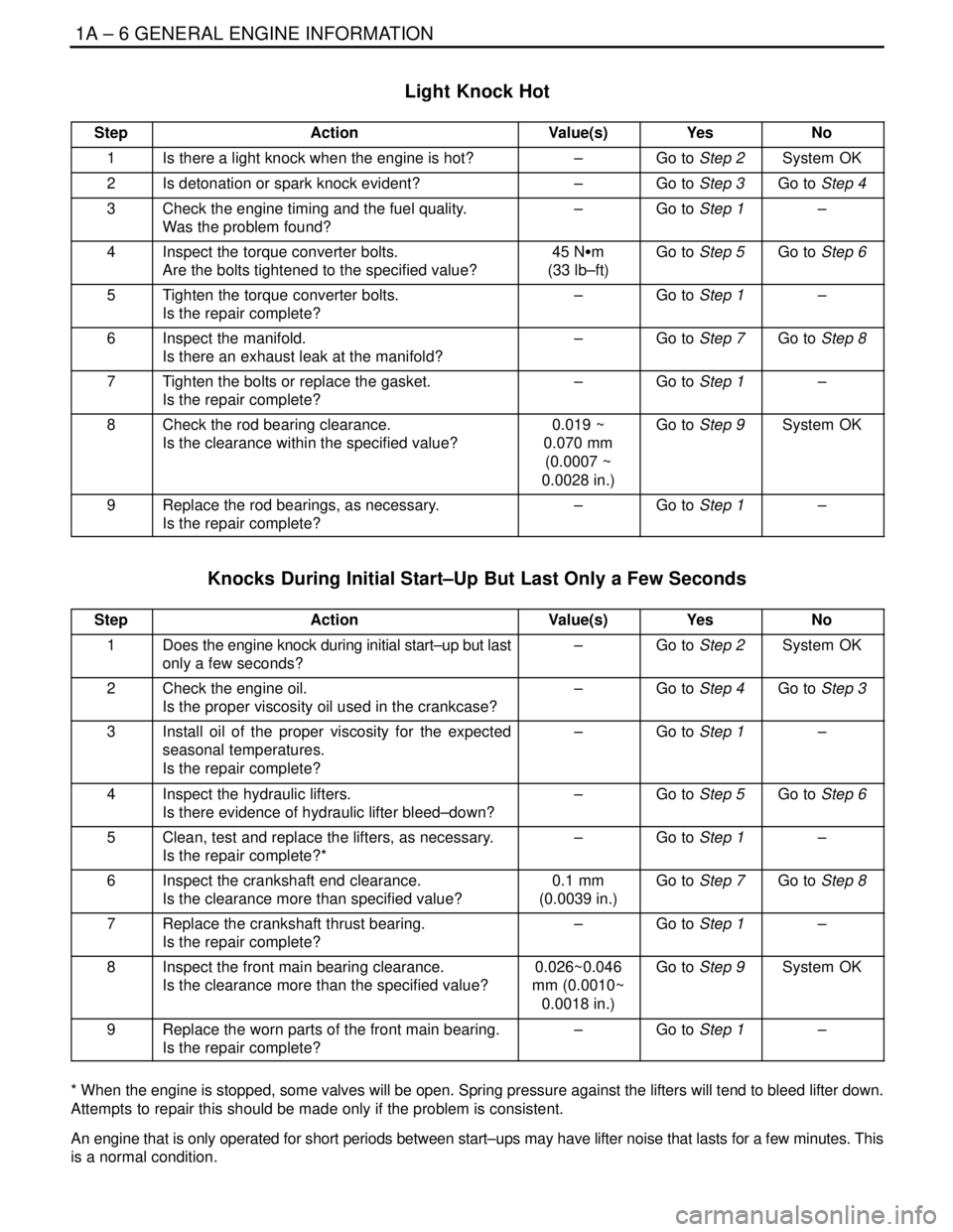

Light Knock Hot

StepActionValue(s)YesNo

1Is there a light knock when the engine is hot?–Go to Step 2System OK

2Is detonation or spark knock evident?–Go to Step 3Go to Step 4

3Check the engine timing and the fuel quality.

Was the problem found?–Go to Step 1–

4Inspect the torque converter bolts.

Are the bolts tightened to the specified value?45 NSm

(33 lb–ft)Go to Step 5Go to Step 6

5Tighten the torque converter bolts.

Is the repair complete?–Go to Step 1–

6Inspect the manifold.

Is there an exhaust leak at the manifold?–Go to Step 7Go to Step 8

7Tighten the bolts or replace the gasket.

Is the repair complete?–Go to Step 1–

8Check the rod bearing clearance.

Is the clearance within the specified value?0.019 ~

0.070 mm

(0.0007 ~

0.0028 in.)Go to Step 9System OK

9Replace the rod bearings, as necessary.

Is the repair complete?–Go to Step 1–

Knocks During Initial Start–Up But Last Only a Few Seconds

StepActionValue(s)YesNo

1Does the engine knock during initial start–up but last

only a few seconds?–Go to Step 2System OK

2Check the engine oil.

Is the proper viscosity oil used in the crankcase?–Go to Step 4Go to Step 3

3Install oil of the proper viscosity for the expected

seasonal temperatures.

Is the repair complete?–Go to Step 1–

4Inspect the hydraulic lifters.

Is there evidence of hydraulic lifter bleed–down?–Go to Step 5Go to Step 6

5Clean, test and replace the lifters, as necessary.

Is the repair complete?*–Go to Step 1–

6Inspect the crankshaft end clearance.

Is the clearance more than specified value?0.1 mm

(0.0039 in.)Go to Step 7Go to Step 8

7Replace the crankshaft thrust bearing.

Is the repair complete?–Go to Step 1–

8Inspect the front main bearing clearance.

Is the clearance more than the specified value?0.026~0.046

mm (0.0010~

0.0018 in.)Go to Step 9System OK

9Replace the worn parts of the front main bearing.

Is the repair complete?–Go to Step 1–

* When the engine is stopped, some valves will be open. Spring pressure against the lifters will tend to bleed lifter down.

Attempts to repair this should be made only if the problem is consistent.

An engine that is only operated for short periods between start–ups may have lifter noise that lasts for a few minutes. This

is a normal condition.

Page 49 of 2643

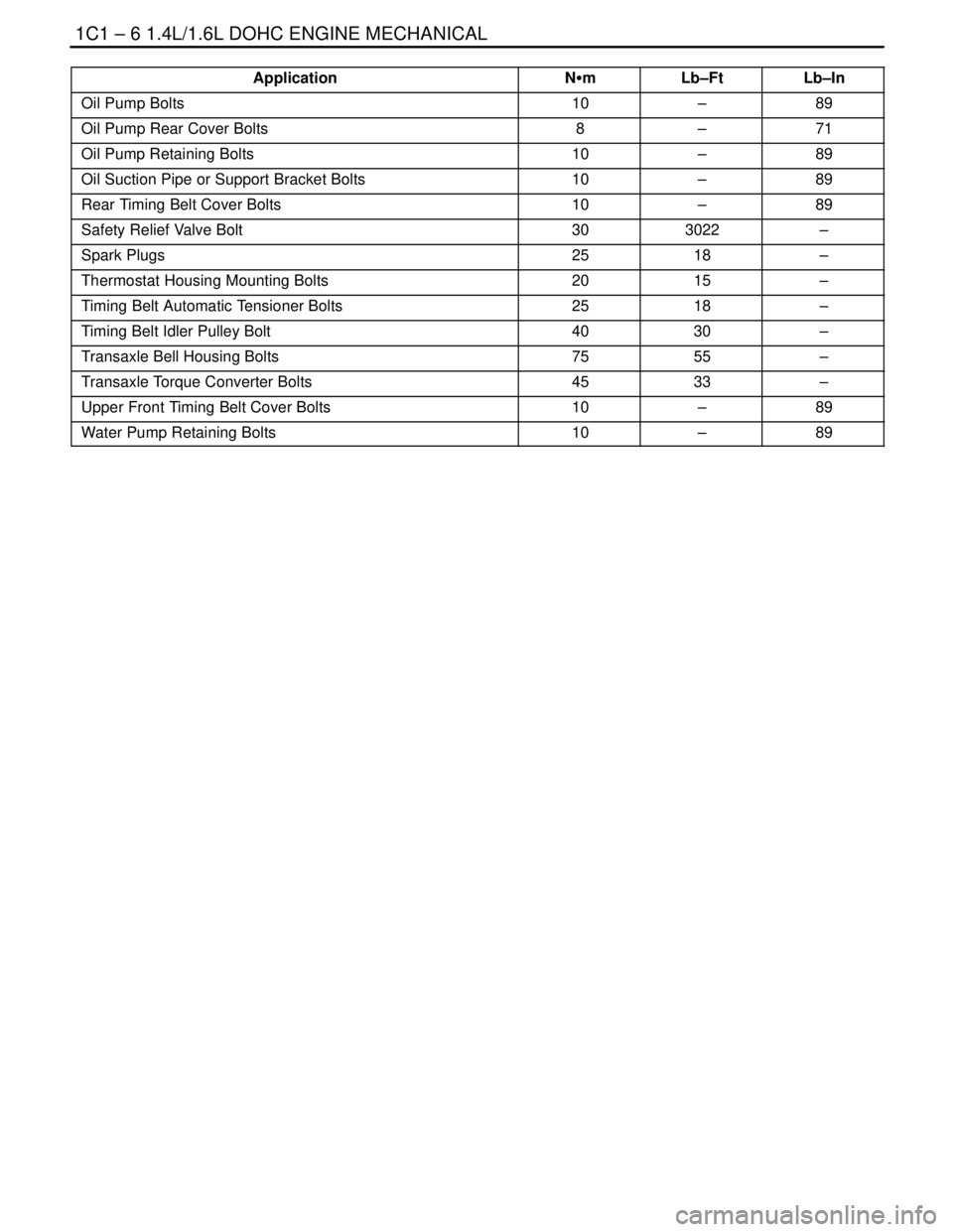

1C1 – 6I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

Application Lb–InLb–Ft NSm

Oil Pump Bolts10–89

Oil Pump Rear Cover Bolts8–71

Oil Pump Retaining Bolts10–89

Oil Suction Pipe or Support Bracket Bolts10–89

Rear Timing Belt Cover Bolts10–89

Safety Relief Valve Bolt303022–

Spark Plugs2518–

Thermostat Housing Mounting Bolts2015–

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt4030–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts4533–

Upper Front Timing Belt Cover Bolts10–89

Water Pump Retaining Bolts10–89

Page 64 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 21

DAEWOO V–121 BL4

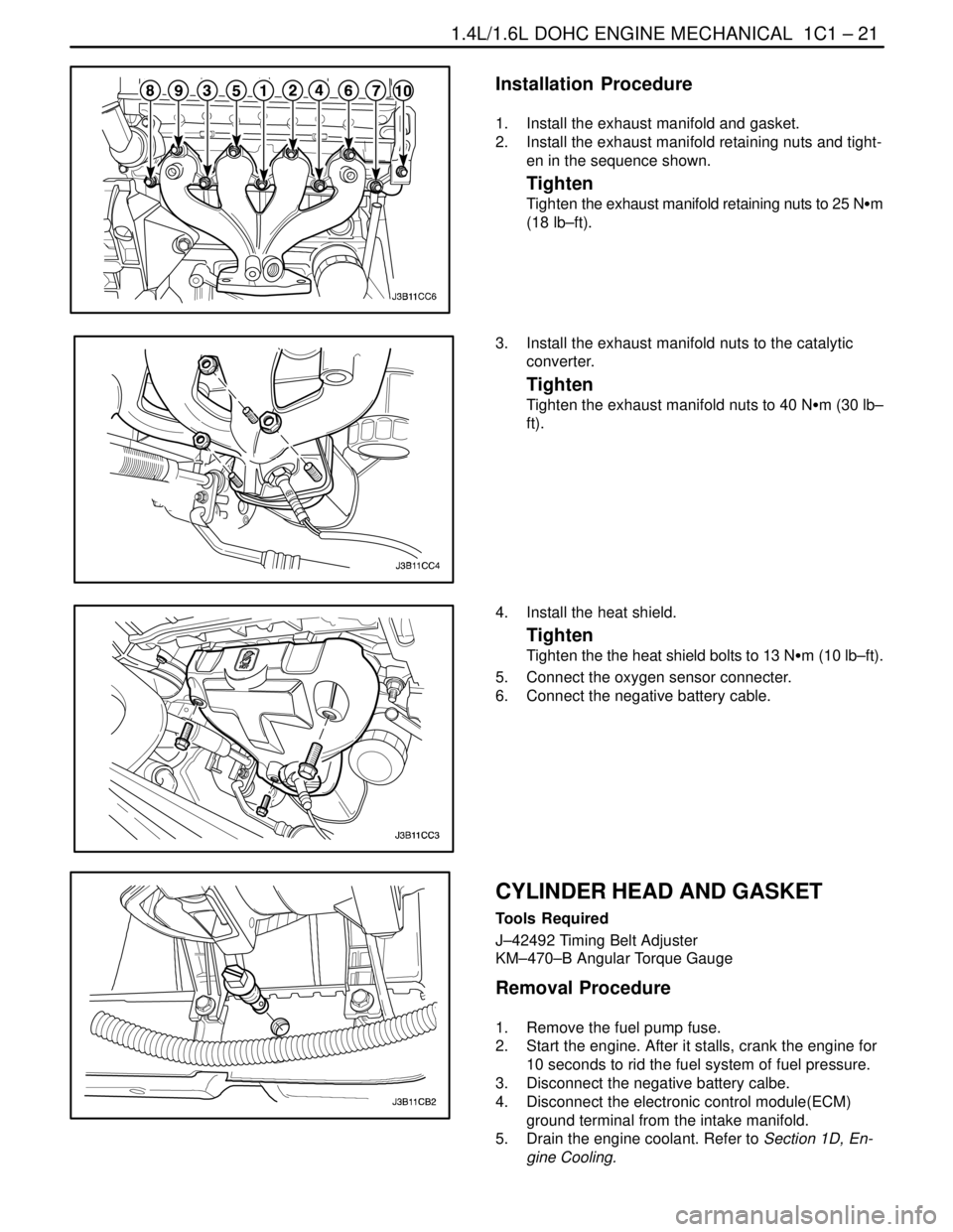

Installation Procedure

1. Install the exhaust manifold and gasket.

2. Install the exhaust manifold retaining nuts and tight-

en in the sequence shown.

Tighten

Tighten the exhaust manifold retaining nuts to 25 NSm

(18 lb–ft).

3. Install the exhaust manifold nuts to the catalytic

converter.

Tighten

Tighten the exhaust manifold nuts to 40 NSm (30 lb–

ft).

4. Install the heat shield.

Tighten

Tighten the the heat shield bolts to 13 NSm (10 lb–ft).

5. Connect the oxygen sensor connecter.

6. Connect the negative battery cable.

CYLINDER HEAD AND GASKET

Tools Required

J–42492 Timing Belt Adjuster

KM–470–B Angular Torque Gauge

Removal Procedure

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery calbe.

4. Disconnect the electronic control module(ECM)

ground terminal from the intake manifold.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

Page 93 of 2643

1C1 – 50I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

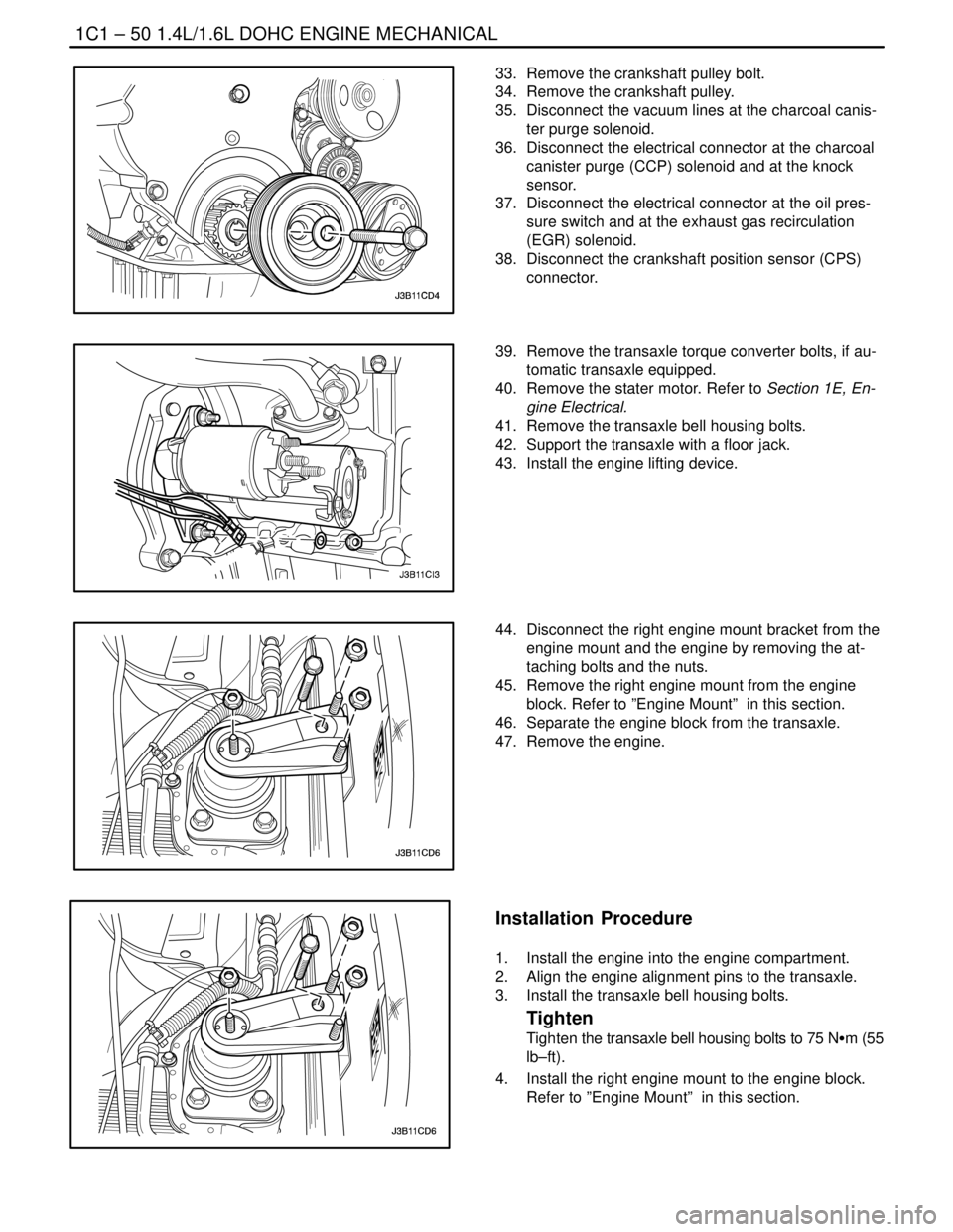

33. Remove the crankshaft pulley bolt.

34. Remove the crankshaft pulley.

35. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

36. Disconnect the electrical connector at the charcoal

canister purge (CCP) solenoid and at the knock

sensor.

37. Disconnect the electrical connector at the oil pres-

sure switch and at the exhaust gas recirculation

(EGR) solenoid.

38. Disconnect the crankshaft position sensor (CPS)

connector.

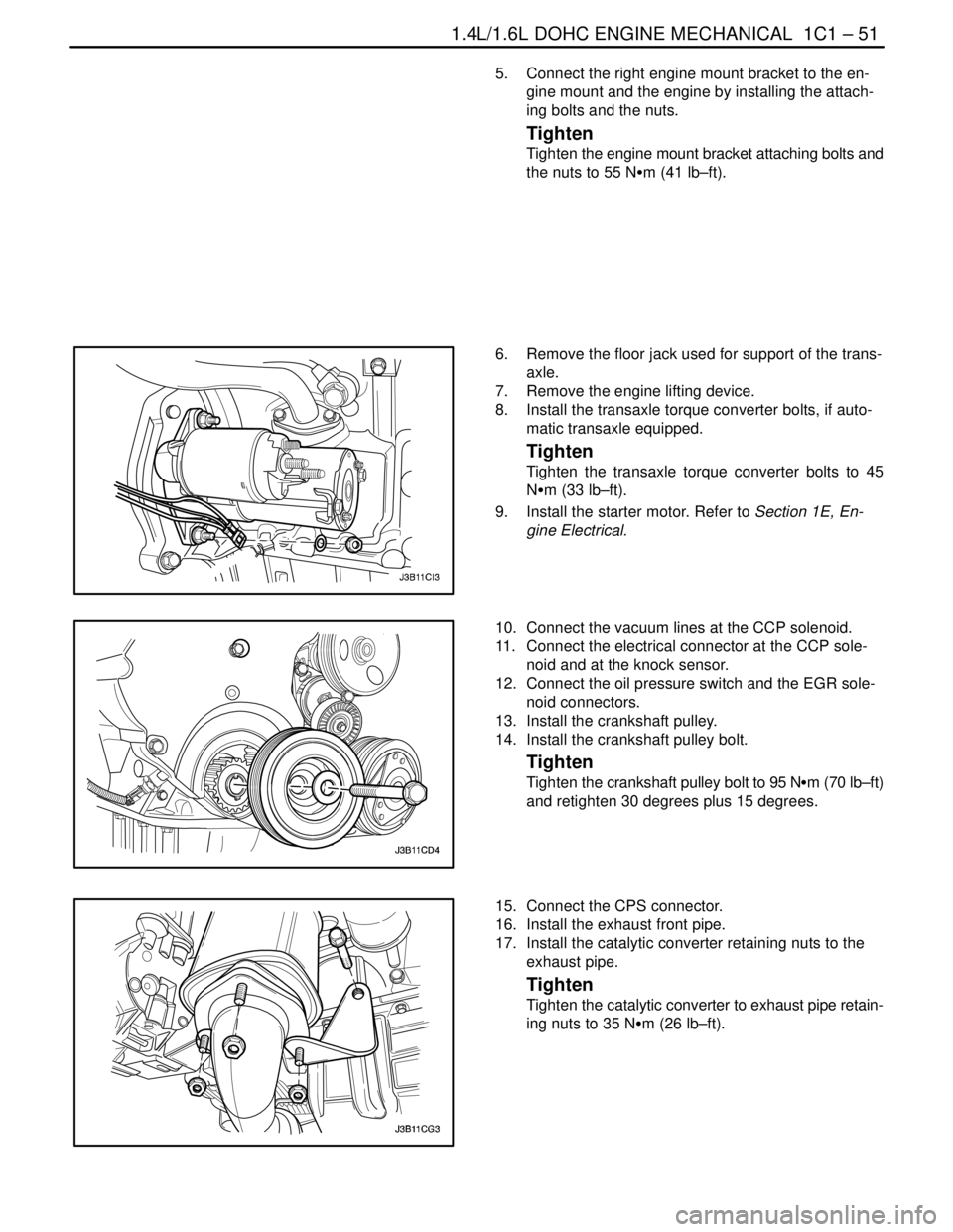

39. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

40. Remove the stater motor. Refer to Section 1E, En-

gine Electrical.

41. Remove the transaxle bell housing bolts.

42. Support the transaxle with a floor jack.

43. Install the engine lifting device.

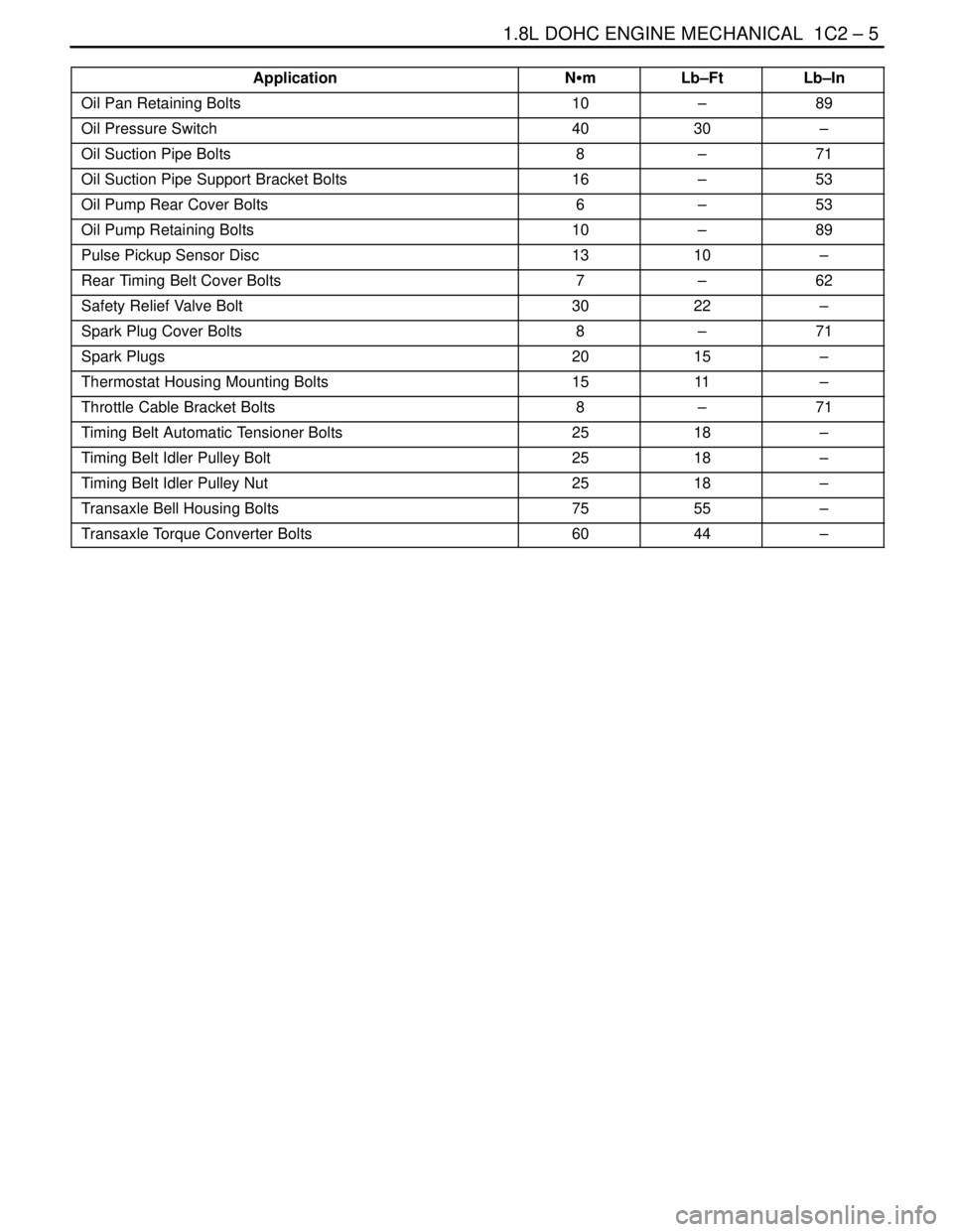

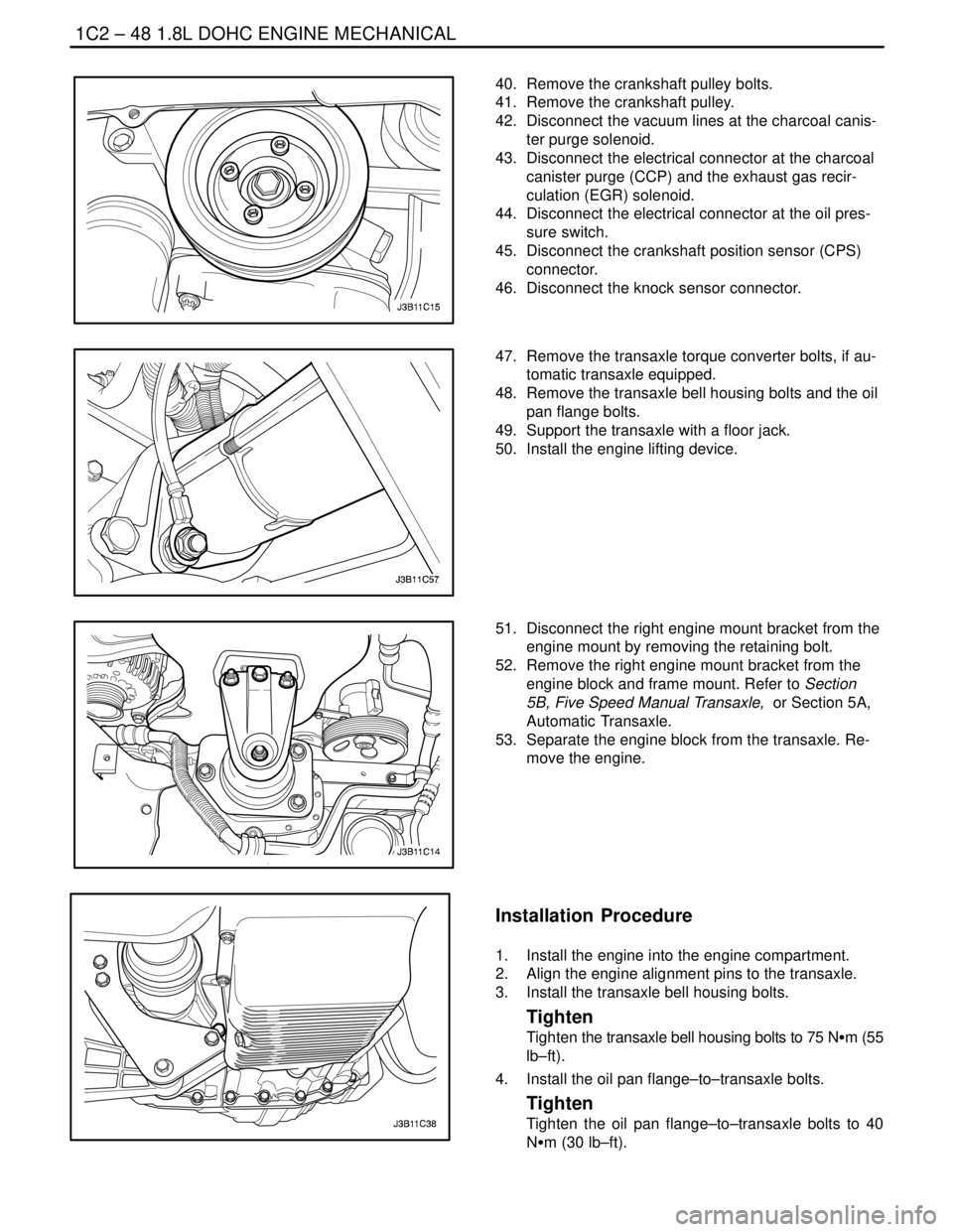

44. Disconnect the right engine mount bracket from the

engine mount and the engine by removing the at-

taching bolts and the nuts.

45. Remove the right engine mount from the engine

block. Refer to ”Engine Mount” in this section.

46. Separate the engine block from the transaxle.

47. Remove the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the right engine mount to the engine block.

Refer to ”Engine Mount” in this section.

Page 94 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 51

DAEWOO V–121 BL4

5. Connect the right engine mount bracket to the en-

gine mount and the engine by installing the attach-

ing bolts and the nuts.

Tighten

Tighten the engine mount bracket attaching bolts and

the nuts to 55 NSm (41 lb–ft).

6. Remove the floor jack used for support of the trans-

axle.

7. Remove the engine lifting device.

8. Install the transaxle torque converter bolts, if auto-

matic transaxle equipped.

Tighten

Tighten the transaxle torque converter bolts to 45

NSm (33 lb–ft).

9. Install the starter motor. Refer to Section 1E, En-

gine Electrical.

10. Connect the vacuum lines at the CCP solenoid.

11. Connect the electrical connector at the CCP sole-

noid and at the knock sensor.

12. Connect the oil pressure switch and the EGR sole-

noid connectors.

13. Install the crankshaft pulley.

14. Install the crankshaft pulley bolt.

Tighten

Tighten the crankshaft pulley bolt to 95 NSm (70 lb–ft)

and retighten 30 degrees plus 15 degrees.

15. Connect the CPS connector.

16. Install the exhaust front pipe.

17. Install the catalytic converter retaining nuts to the

exhaust pipe.

Tighten

Tighten the catalytic converter to exhaust pipe retain-

ing nuts to 35 NSm (26 lb–ft).

Page 125 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 5

DAEWOO V–121 BL4

Application Lb–InLb–Ft NSm

Oil Pan Retaining Bolts10–89

Oil Pressure Switch4030–

Oil Suction Pipe Bolts8–71

Oil Suction Pipe Support Bracket Bolts16–53

Oil Pump Rear Cover Bolts6–53

Oil Pump Retaining Bolts10–89

Pulse Pickup Sensor Disc1310–

Rear Timing Belt Cover Bolts7–62

Safety Relief Valve Bolt3022–

Spark Plug Cover Bolts8–71

Spark Plugs2015–

Thermostat Housing Mounting Bolts1511–

Throttle Cable Bracket Bolts8–71

Timing Belt Automatic Tensioner Bolts2518–

Timing Belt Idler Pulley Bolt2518–

Timing Belt Idler Pulley Nut2518–

Transaxle Bell Housing Bolts7555–

Transaxle Torque Converter Bolts6044–

Page 168 of 2643

1C2 – 48I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

40. Remove the crankshaft pulley bolts.

41. Remove the crankshaft pulley.

42. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

43. Disconnect the electrical connector at the charcoal

canister purge (CCP) and the exhaust gas recir-

culation (EGR) solenoid.

44. Disconnect the electrical connector at the oil pres-

sure switch.

45. Disconnect the crankshaft position sensor (CPS)

connector.

46. Disconnect the knock sensor connector.

47. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

48. Remove the transaxle bell housing bolts and the oil

pan flange bolts.

49. Support the transaxle with a floor jack.

50. Install the engine lifting device.

51. Disconnect the right engine mount bracket from the

engine mount by removing the retaining bolt.

52. Remove the right engine mount bracket from the

engine block and frame mount. Refer to Section

5B, Five Speed Manual Transaxle, or Section 5A,

Automatic Transaxle.

53. Separate the engine block from the transaxle. Re-

move the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the oil pan flange–to–transaxle bolts.

Tighten

Tighten the oil pan flange–to–transaxle bolts to 40

NSm (30 lb–ft).

Page 169 of 2643

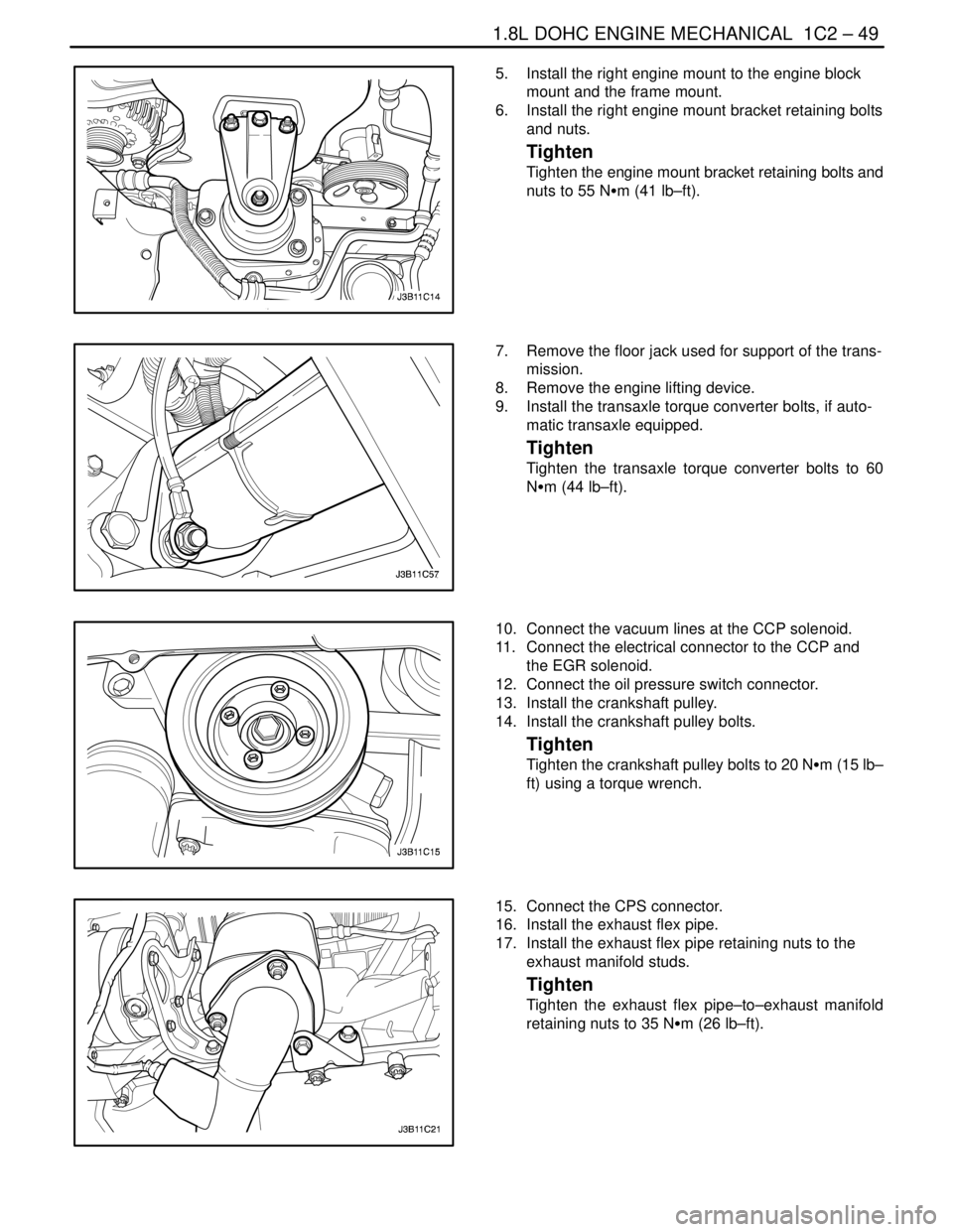

1.8L DOHC ENGINE MECHANICAL 1C2 – 49

DAEWOO V–121 BL4

5. Install the right engine mount to the engine block

mount and the frame mount.

6. Install the right engine mount bracket retaining bolts

and nuts.

Tighten

Tighten the engine mount bracket retaining bolts and

nuts to 55 NSm (41 lb–ft).

7. Remove the floor jack used for support of the trans-

mission.

8. Remove the engine lifting device.

9. Install the transaxle torque converter bolts, if auto-

matic transaxle equipped.

Tighten

Tighten the transaxle torque converter bolts to 60

NSm (44 lb–ft).

10. Connect the vacuum lines at the CCP solenoid.

11. Connect the electrical connector to the CCP and

the EGR solenoid.

12. Connect the oil pressure switch connector.

13. Install the crankshaft pulley.

14. Install the crankshaft pulley bolts.

Tighten

Tighten the crankshaft pulley bolts to 20 NSm (15 lb–

ft) using a torque wrench.

15. Connect the CPS connector.

16. Install the exhaust flex pipe.

17. Install the exhaust flex pipe retaining nuts to the

exhaust manifold studs.

Tighten

Tighten the exhaust flex pipe–to–exhaust manifold

retaining nuts to 35 NSm (26 lb–ft).

Page 1354 of 2643

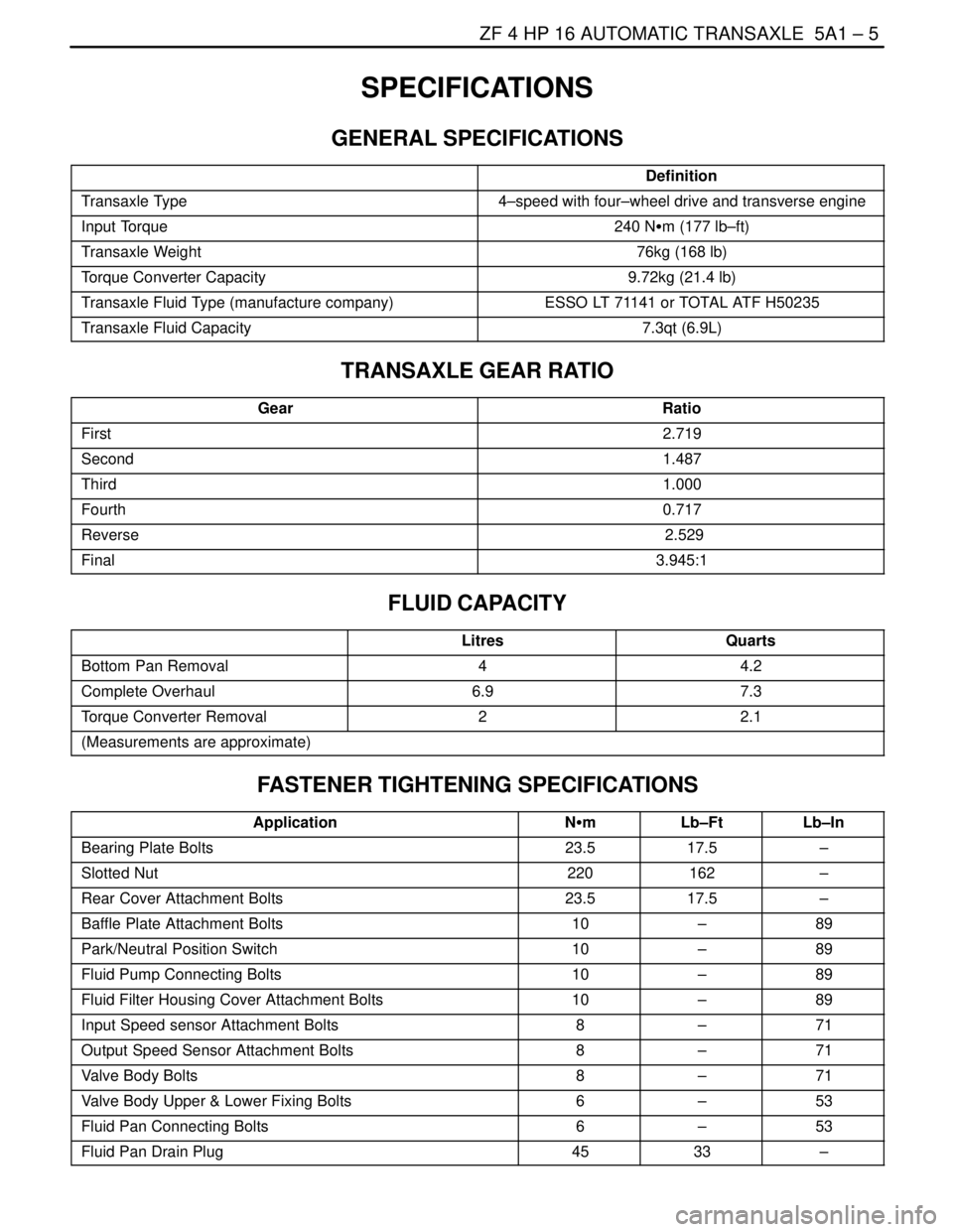

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 5

DAEWOO V–121 BL4

SPECIFICATIONS

GENERAL SPECIFICATIONS

Definition

Transaxle Type4–speed with four–wheel drive and transverse engine

Input Torque240 NSm (177 lb–ft)

Transaxle Weight76kg (168 lb)

Torque Converter Capacity9.72kg (21.4 lb)

Transaxle Fluid Type (manufacture company)ESSO LT 71141 or TOTAL ATF H50235

Transaxle Fluid Capacity7.3qt (6.9L)

TRANSAXLE GEAR RATIO

GearRatio

First2.719

Second1.487

Third1.000

Fourth0.717

Reverse 2.529

Final3.945:1

FLUID CAPACITY

LitresQuarts

Bottom Pan Removal44.2

Complete Overhaul6.97.3

Torque Converter Removal22.1

(Measurements are approximate)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Bearing Plate Bolts23.517.5–

Slotted Nut220162–

Rear Cover Attachment Bolts23.517.5–

Baffle Plate Attachment Bolts10–89

Park/Neutral Position Switch10–89

Fluid Pump Connecting Bolts10–89

Fluid Filter Housing Cover Attachment Bolts10–89

Input Speed sensor Attachment Bolts8–71

Output Speed Sensor Attachment Bolts8–71

Valve Body Bolts8–71

Valve Body Upper & Lower Fixing Bolts6–53

Fluid Pan Connecting Bolts6–53

Fluid Pan Drain Plug4533–