engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1542 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 193

DAEWOO V–121 BL4

Repairing the Fluid Leak

The following are potential causes for fluid leaks. Check

and repair, as necessary.

S Fasteners are not tightened to specifications.

S Fastener threads and tapped holes are dirty or cor-

roded.

S Gaskets, seals or sleeves are misaligned, dam-

aged, or warped, or scratched.

S The manual shaft is nicked or damaged.

S There is a loose or worn bearing causing excess

seal or sleeve wear.

S Case or component porosity.

S The fluid level is too high.

S There is a plugged vent or a damaged vent tube.

S There is water or coolant in the fluid.

S Fluid drain back holes are plugged.

CASE POROSITY REPAIR

CAUTION : Epoxy adhesive may cause skin irritations

and eye damage. Read and follow all information on

the container label as provided by the manufacturer.

1. Thoroughly clean the area to be repaired with a

cleaning solvent. Air dry the area.

2. Using instructions from the manufacturer, mix a

sufficient amount of epoxy to make the repair.

3. While the transaxle case is still hot, apply the

epoxy. You can use a clean, dry soldering acid

brush to clean the area and also apply the epoxy

cement. Make certain that the area to be repaired is

fully covered.

4. Allow the epoxy cement to dry for 3 hours before

starting the engine.

5. Repeat the fluid leak diagnosis procedures. Refer

to ”Fluid Leak Diagnosis and Repair” in this sec-

tion.

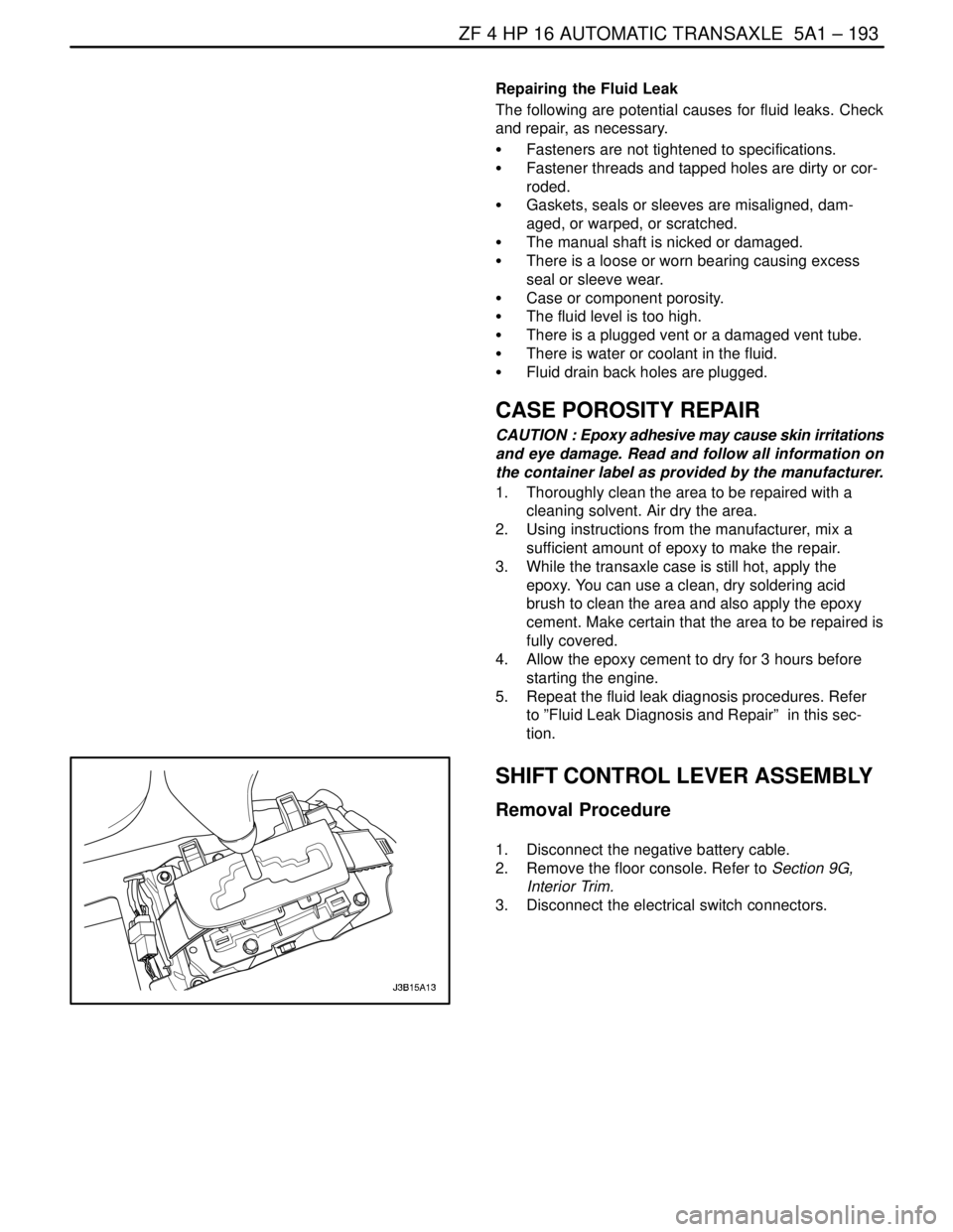

SHIFT CONTROL LEVER ASSEMBLY

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Disconnect the electrical switch connectors.

Page 1545 of 2643

5A1 – 196IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

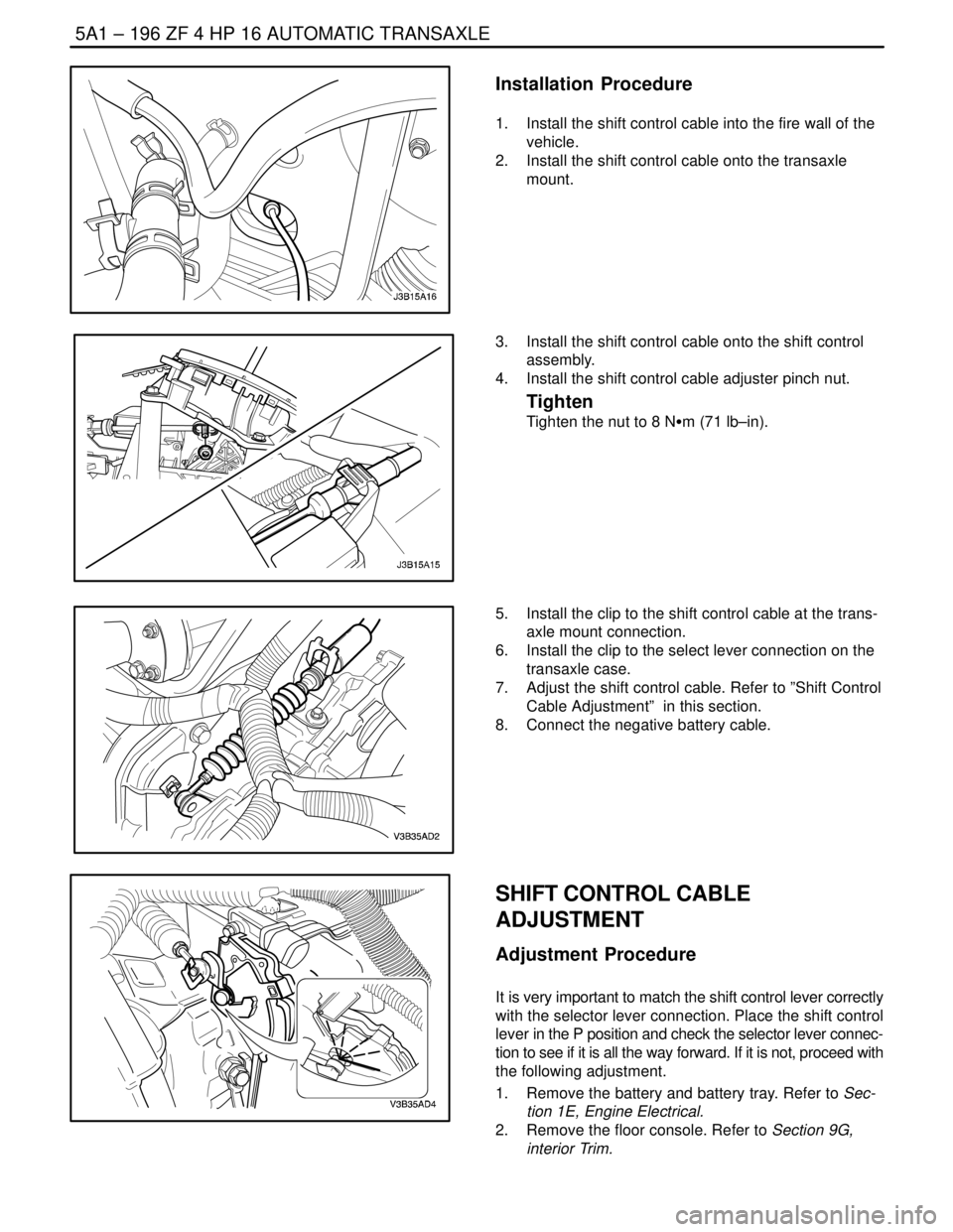

Installation Procedure

1. Install the shift control cable into the fire wall of the

vehicle.

2. Install the shift control cable onto the transaxle

mount.

3. Install the shift control cable onto the shift control

assembly.

4. Install the shift control cable adjuster pinch nut.

Tighten

Tighten the nut to 8 NSm (71 lb–in).

5. Install the clip to the shift control cable at the trans-

axle mount connection.

6. Install the clip to the select lever connection on the

transaxle case.

7. Adjust the shift control cable. Refer to ”Shift Control

Cable Adjustment” in this section.

8. Connect the negative battery cable.

SHIFT CONTROL CABLE

ADJUSTMENT

Adjustment Procedure

It is very important to match the shift control lever correctly

with the selector lever connection. Place the shift control

lever in the P position and check the selector lever connec-

tion to see if it is all the way forward. If it is not, proceed with

the following adjustment.

1. Remove the battery and battery tray. Refer to Sec-

tion 1E, Engine Electrical.

2. Remove the floor console. Refer to Section 9G,

interior Trim.

Page 1546 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 197

DAEWOO V–121 BL4

3. Place the shift control lever in the P position.

4. Loosen the pinch bolt nut on the shift control lever.

5. Place the selector lever connection all the way for-

ward on the transaxle case.

6. Insert the shift control cable into the shift control

lever tightly.

7. Secure the shift control cable with the shift control

cable adjuster pinch bolt and nut.

Tighten

Tighten the nut to 8 NSm (71 lb–in).

8. Install the floor console.

9. Install the battery and the battery tray. Refer to

Section 1E, Engine Electrical.

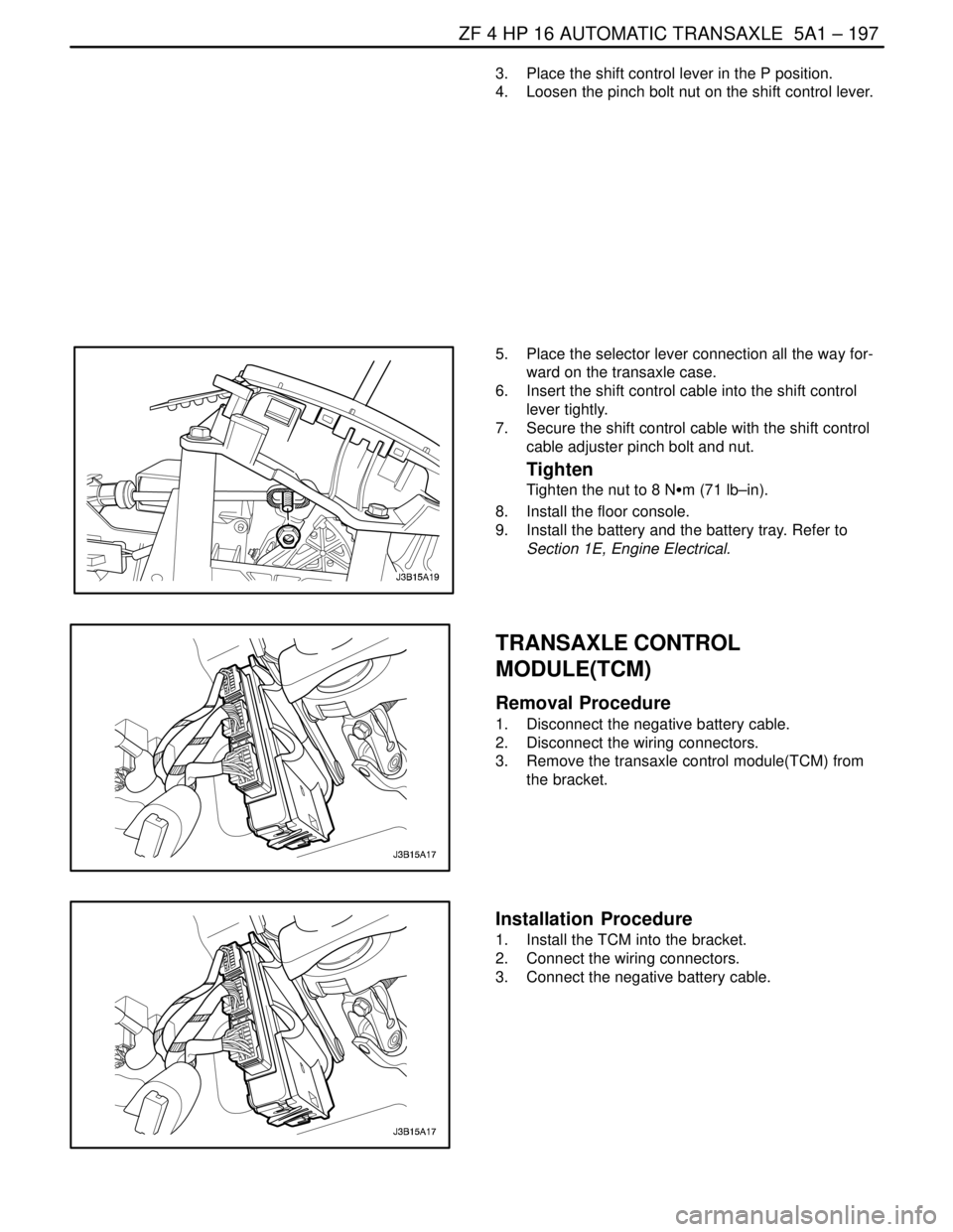

TRANSAXLE CONTROL

MODULE(TCM)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the wiring connectors.

3. Remove the transaxle control module(TCM) from

the bracket.

Installation Procedure

1. Install the TCM into the bracket.

2. Connect the wiring connectors.

3. Connect the negative battery cable.

Page 1548 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 199

DAEWOO V–121 BL4

3. Install the shift lever and the shift lever nut.

Tighten

Tighten the shift lever nut to 10 NSm (89 lb–in).

4. Connect the shift control cable and the retaining

clip.

5. Connect the park/neutral position switch electrical

connector.

6. Connect the negative battery cable.

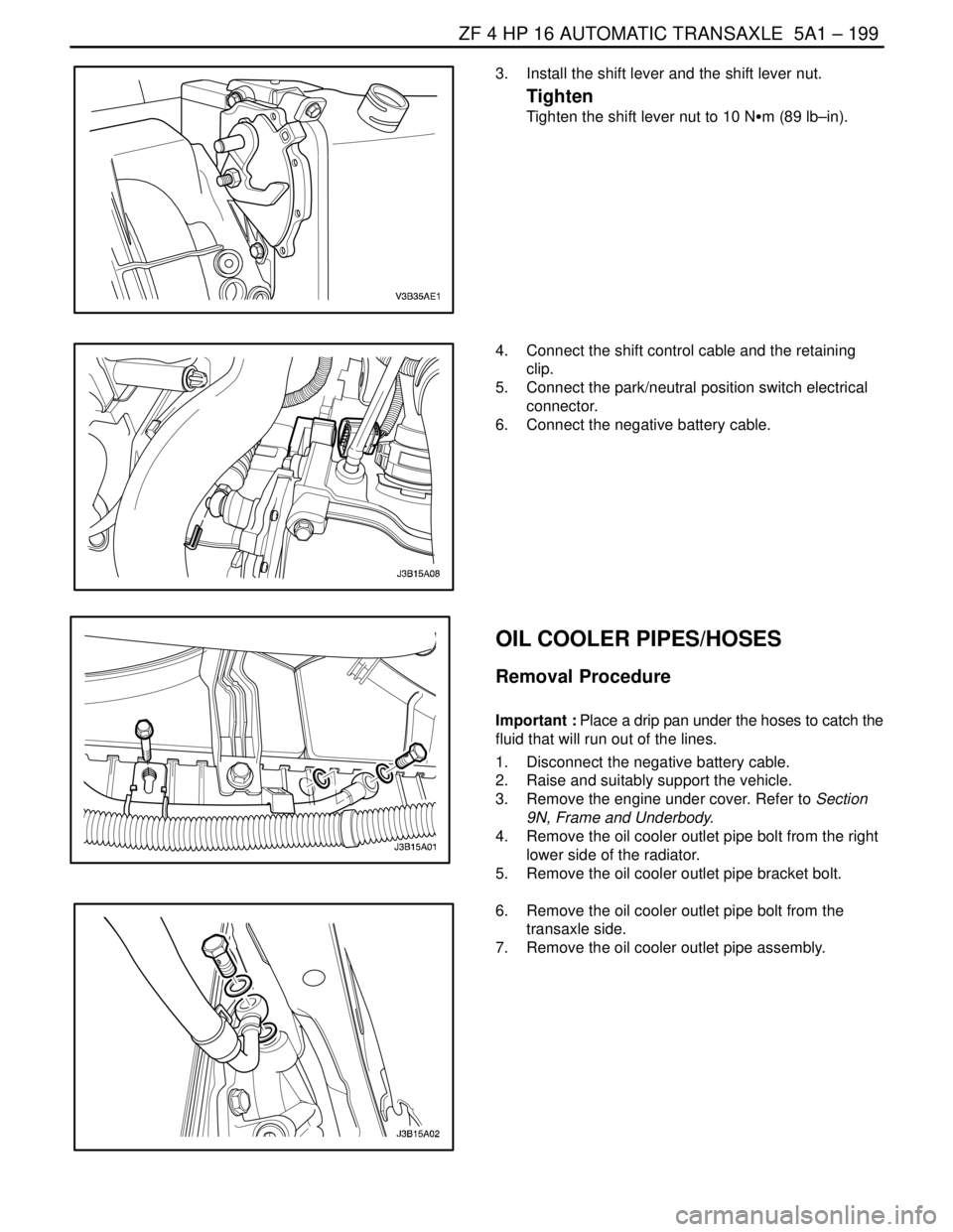

OIL COOLER PIPES/HOSES

Removal Procedure

Important : Place a drip pan under the hoses to catch the

fluid that will run out of the lines.

1. Disconnect the negative battery cable.

2. Raise and suitably support the vehicle.

3. Remove the engine under cover. Refer to Section

9N, Frame and Underbody.

4. Remove the oil cooler outlet pipe bolt from the right

lower side of the radiator.

5. Remove the oil cooler outlet pipe bracket bolt.

6. Remove the oil cooler outlet pipe bolt from the

transaxle side.

7. Remove the oil cooler outlet pipe assembly.

Page 1549 of 2643

5A1 – 200IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

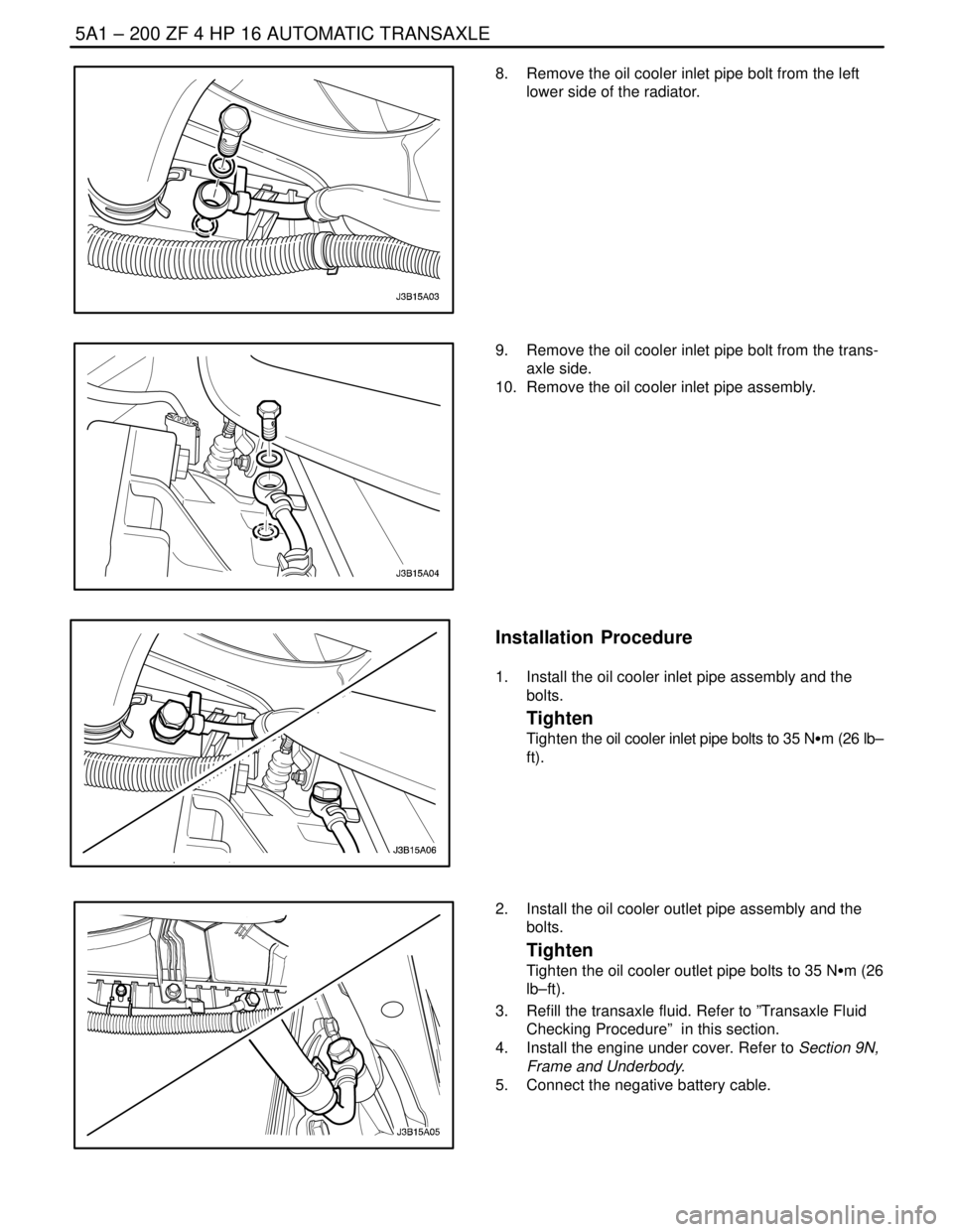

8. Remove the oil cooler inlet pipe bolt from the left

lower side of the radiator.

9. Remove the oil cooler inlet pipe bolt from the trans-

axle side.

10. Remove the oil cooler inlet pipe assembly.

Installation Procedure

1. Install the oil cooler inlet pipe assembly and the

bolts.

Tighten

Tighten the oil cooler inlet pipe bolts to 35 NSm (26 lb–

ft).

2. Install the oil cooler outlet pipe assembly and the

bolts.

Tighten

Tighten the oil cooler outlet pipe bolts to 35 NSm (26

lb–ft).

3. Refill the transaxle fluid. Refer to ”Transaxle Fluid

Checking Procedure” in this section.

4. Install the engine under cover. Refer to Section 9N,

Frame and Underbody.

5. Connect the negative battery cable.

Page 1550 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 201

DAEWOO V–121 BL4

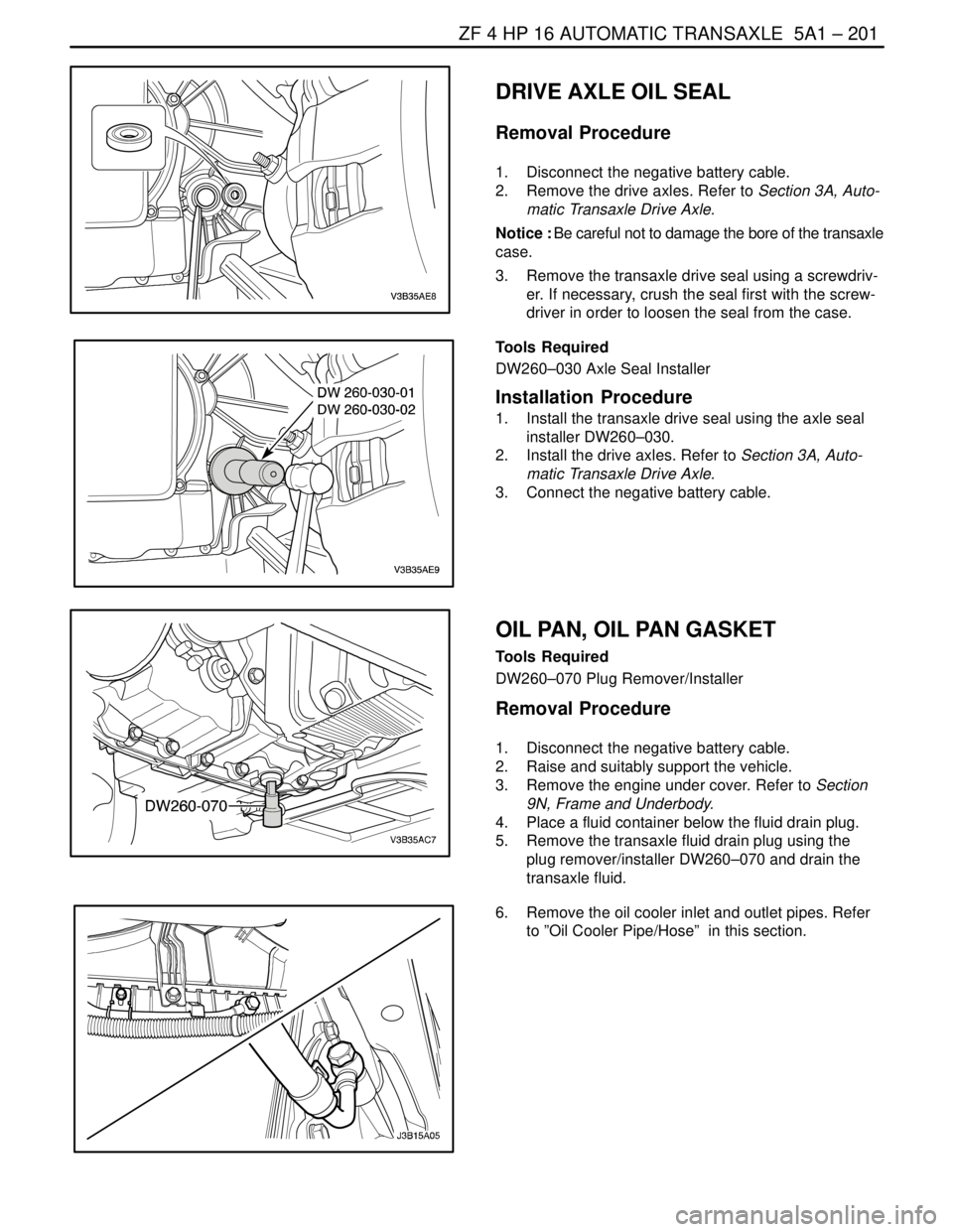

DRIVE AXLE OIL SEAL

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the drive axles. Refer to Section 3A, Auto-

matic Transaxle Drive Axle.

Notice : Be careful not to damage the bore of the transaxle

case.

3. Remove the transaxle drive seal using a screwdriv-

er. If necessary, crush the seal first with the screw-

driver in order to loosen the seal from the case.

Tools Required

DW260–030 Axle Seal Installer

Installation Procedure

1. Install the transaxle drive seal using the axle seal

installer DW260–030.

2. Install the drive axles. Refer to Section 3A, Auto-

matic Transaxle Drive Axle.

3. Connect the negative battery cable.

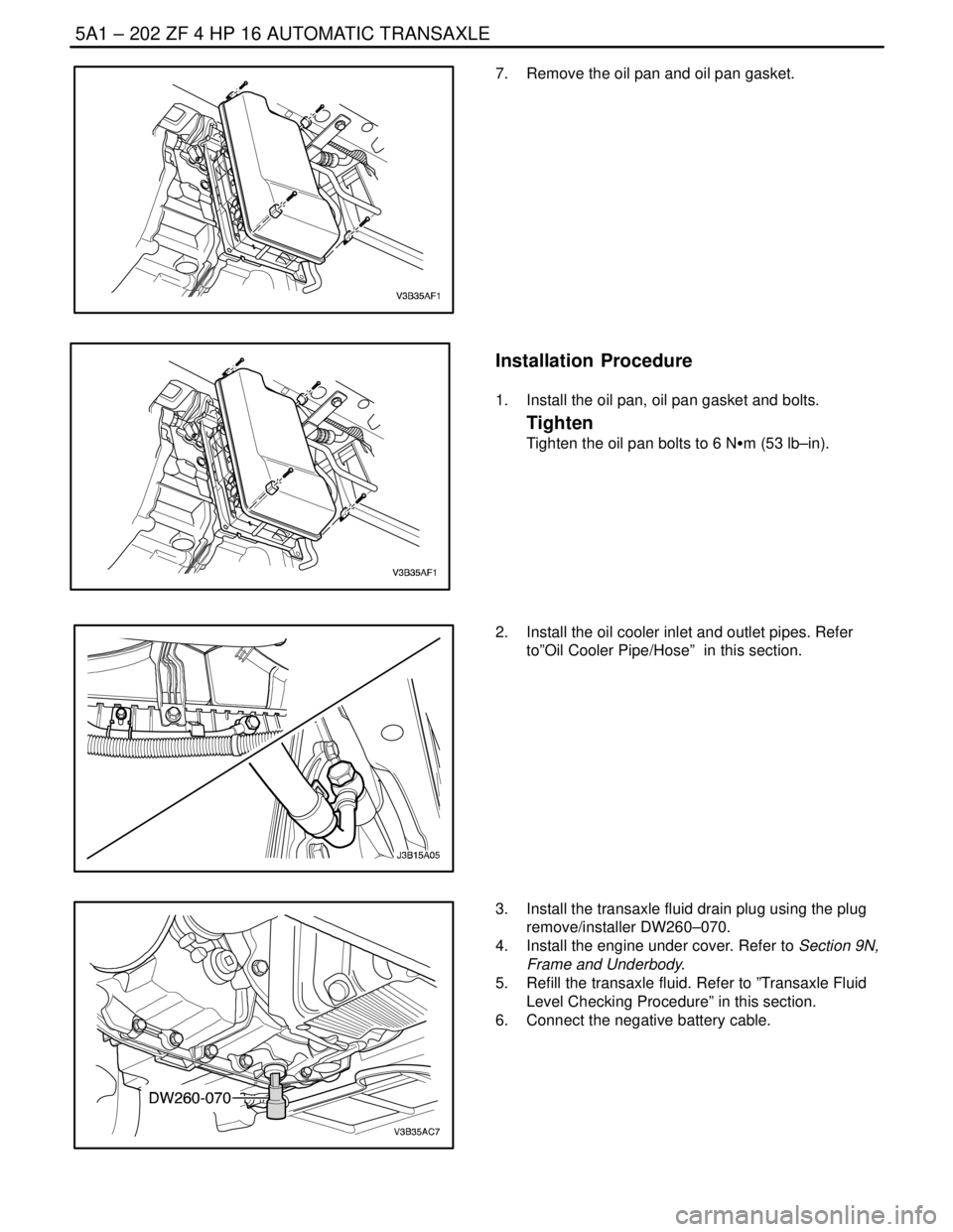

OIL PAN, OIL PAN GASKET

Tools Required

DW260–070 Plug Remover/Installer

Removal Procedure

1. Disconnect the negative battery cable.

2. Raise and suitably support the vehicle.

3. Remove the engine under cover. Refer to Section

9N, Frame and Underbody.

4. Place a fluid container below the fluid drain plug.

5. Remove the transaxle fluid drain plug using the

plug remover/installer DW260–070 and drain the

transaxle fluid.

6. Remove the oil cooler inlet and outlet pipes. Refer

to ”Oil Cooler Pipe/Hose” in this section.

Page 1551 of 2643

5A1 – 202IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

7. Remove the oil pan and oil pan gasket.

Installation Procedure

1. Install the oil pan, oil pan gasket and bolts.

Tighten

Tighten the oil pan bolts to 6 NSm (53 lb–in).

2. Install the oil cooler inlet and outlet pipes. Refer

to”Oil Cooler Pipe/Hose” in this section.

3. Install the transaxle fluid drain plug using the plug

remove/installer DW260–070.

4. Install the engine under cover. Refer to Section 9N,

Frame and Underbody.

5. Refill the transaxle fluid. Refer to ”Transaxle Fluid

Level Checking Procedure” in this section.

6. Connect the negative battery cable.

Page 1552 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 203

DAEWOO V–121 BL4

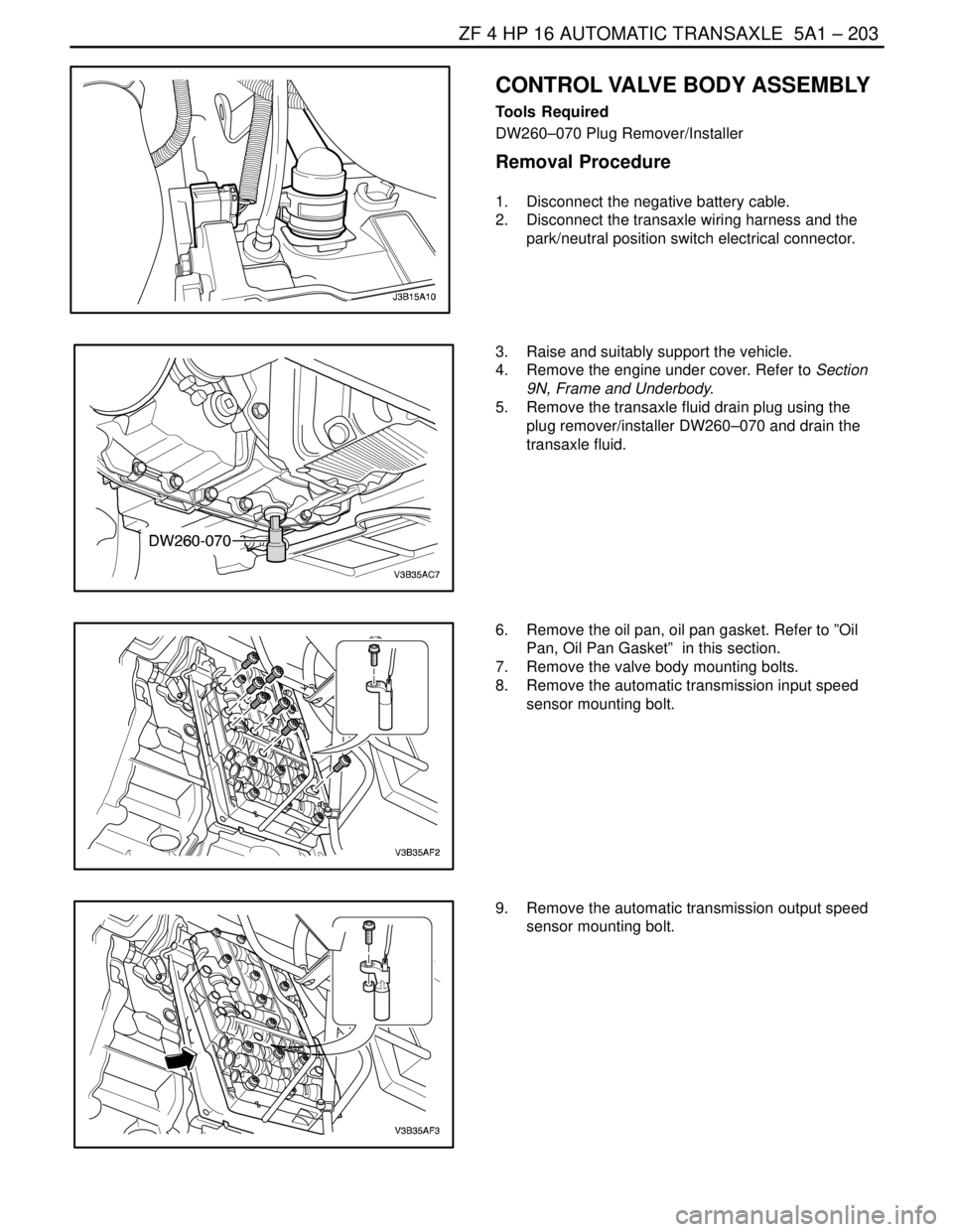

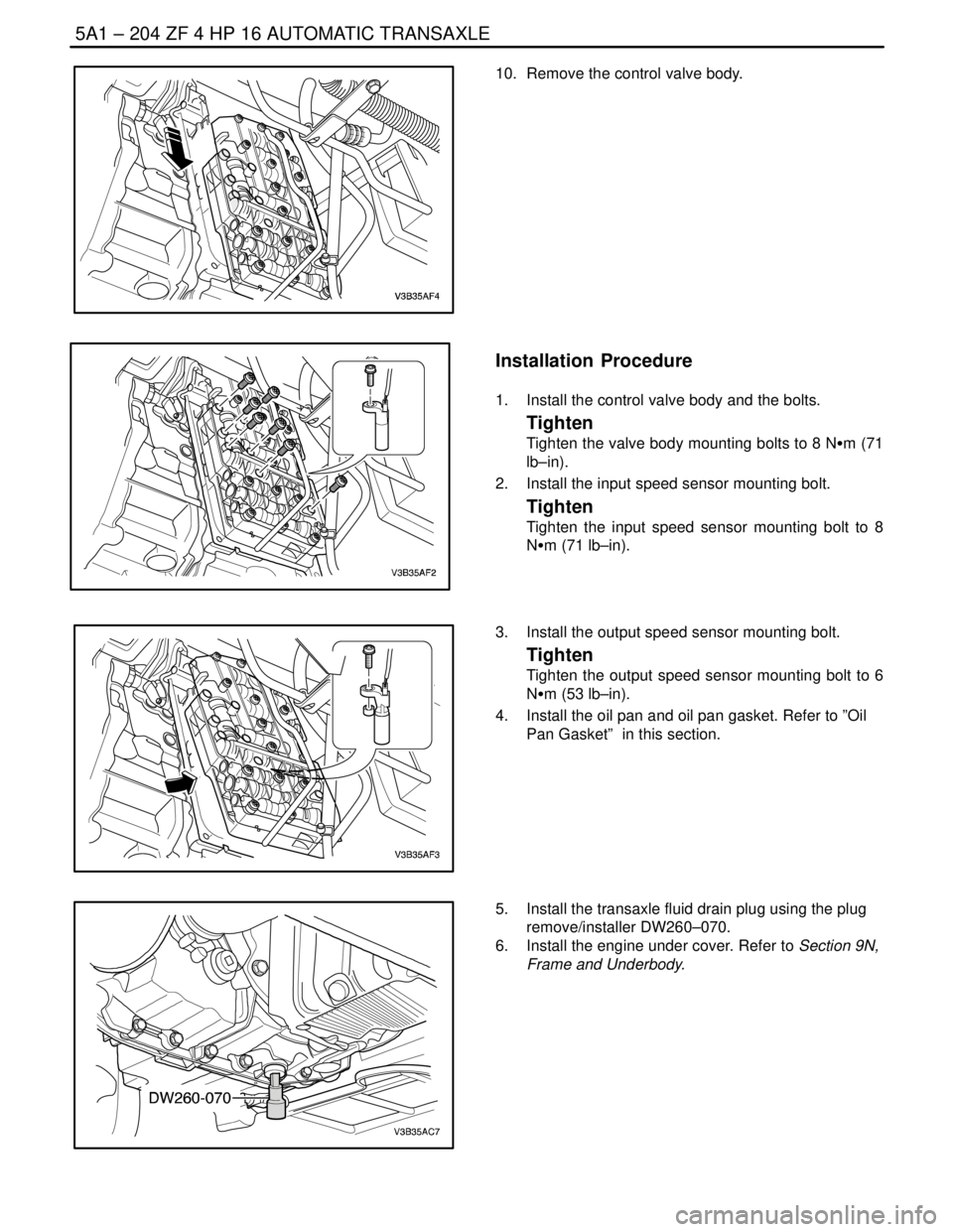

CONTROL VALVE BODY ASSEMBLY

Tools Required

DW260–070 Plug Remover/Installer

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the transaxle wiring harness and the

park/neutral position switch electrical connector.

3. Raise and suitably support the vehicle.

4. Remove the engine under cover. Refer to Section

9N, Frame and Underbody.

5. Remove the transaxle fluid drain plug using the

plug remover/installer DW260–070 and drain the

transaxle fluid.

6. Remove the oil pan, oil pan gasket. Refer to ”Oil

Pan, Oil Pan Gasket” in this section.

7. Remove the valve body mounting bolts.

8. Remove the automatic transmission input speed

sensor mounting bolt.

9. Remove the automatic transmission output speed

sensor mounting bolt.

Page 1553 of 2643

5A1 – 204IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

10. Remove the control valve body.

Installation Procedure

1. Install the control valve body and the bolts.

Tighten

Tighten the valve body mounting bolts to 8 NSm (71

lb–in).

2. Install the input speed sensor mounting bolt.

Tighten

Tighten the input speed sensor mounting bolt to 8

NSm (71 lb–in).

3. Install the output speed sensor mounting bolt.

Tighten

Tighten the output speed sensor mounting bolt to 6

NSm (53 lb–in).

4. Install the oil pan and oil pan gasket. Refer to ”Oil

Pan Gasket” in this section.

5. Install the transaxle fluid drain plug using the plug

remove/installer DW260–070.

6. Install the engine under cover. Refer to Section 9N,

Frame and Underbody.

Page 1554 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 205

DAEWOO V–121 BL4

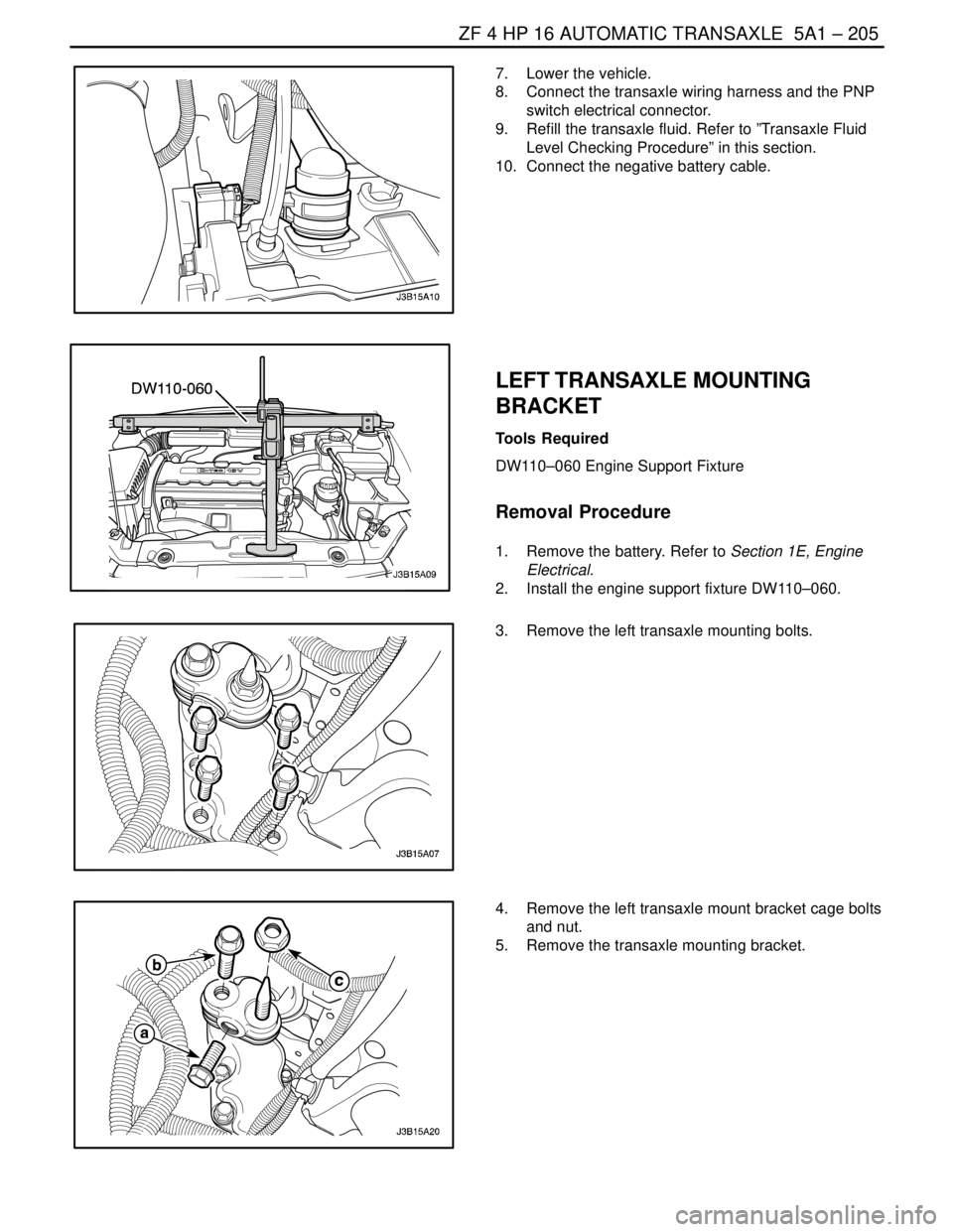

7. Lower the vehicle.

8. Connect the transaxle wiring harness and the PNP

switch electrical connector.

9. Refill the transaxle fluid. Refer to ”Transaxle Fluid

Level Checking Procedure” in this section.

10. Connect the negative battery cable.

LEFT TRANSAXLE MOUNTING

BRACKET

Tools Required

DW110–060 Engine Support Fixture

Removal Procedure

1. Remove the battery. Refer to Section 1E, Engine

Electrical.

2. Install the engine support fixture DW110–060.

3. Remove the left transaxle mounting bolts.

4. Remove the left transaxle mount bracket cage bolts

and nut.

5. Remove the transaxle mounting bracket.