MAP DAEWOO NUBIRA 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 283 of 2643

ENGINE CONTROLS 1F – 37

DAEWOO V–121 BL4

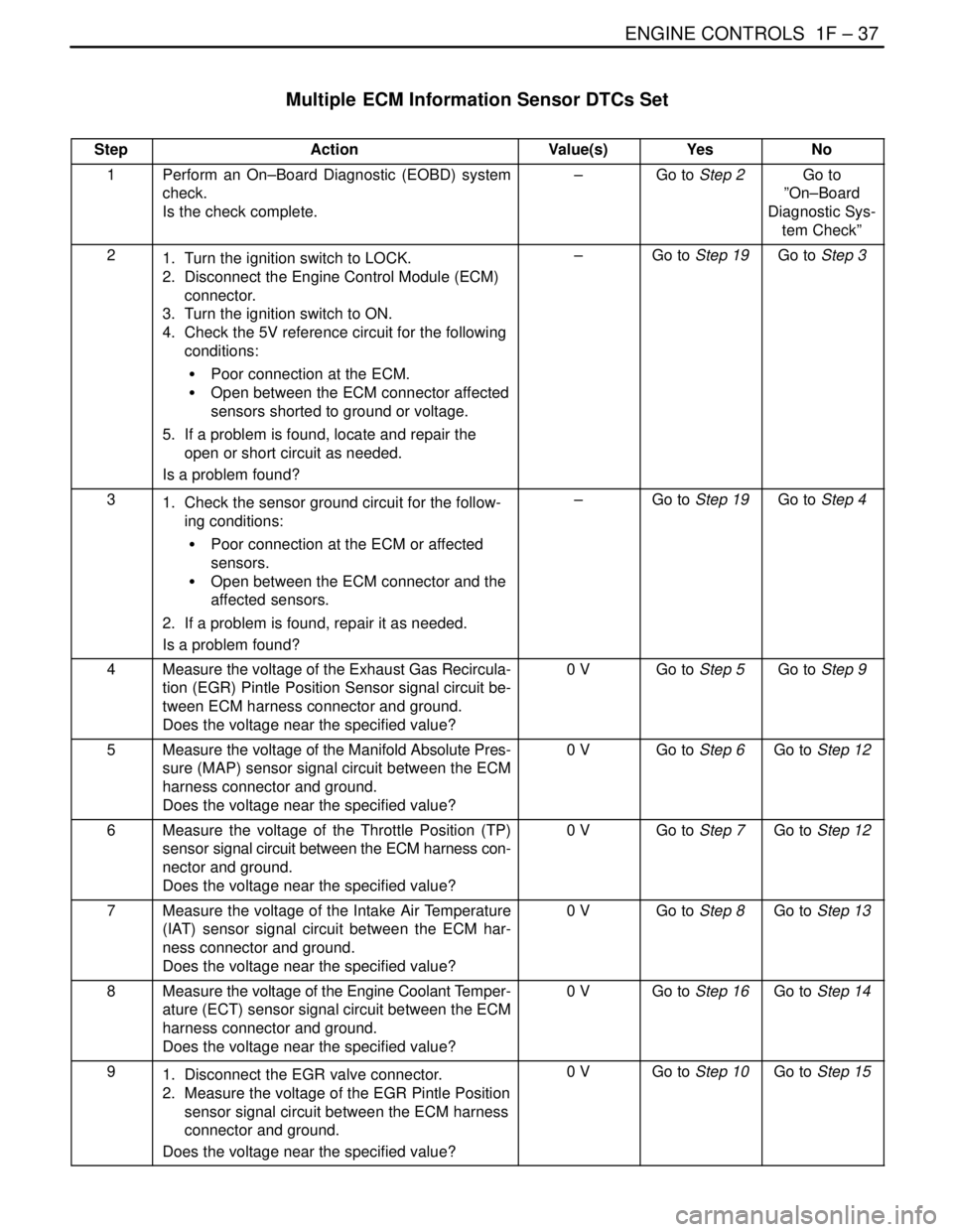

Multiple ECM Information Sensor DTCs Set

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Is the check complete.–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK.

2. Disconnect the Engine Control Module (ECM)

connector.

3. Turn the ignition switch to ON.

4. Check the 5V reference circuit for the following

conditions:

S Poor connection at the ECM.

S Open between the ECM connector affected

sensors shorted to ground or voltage.

5. If a problem is found, locate and repair the

open or short circuit as needed.

Is a problem found?–Go to Step 19Go to Step 3

31. Check the sensor ground circuit for the follow-

ing conditions:

S Poor connection at the ECM or affected

sensors.

S Open between the ECM connector and the

affected sensors.

2. If a problem is found, repair it as needed.

Is a problem found?–Go to Step 19Go to Step 4

4Measure the voltage of the Exhaust Gas Recircula-

tion (EGR) Pintle Position Sensor signal circuit be-

tween ECM harness connector and ground.

Does the voltage near the specified value?0 VGo to Step 5Go to Step 9

5Measure the voltage of the Manifold Absolute Pres-

sure (MAP) sensor signal circuit between the ECM

harness connector and ground.

Does the voltage near the specified value?0 VGo to Step 6Go to Step 12

6Measure the voltage of the Throttle Position (TP)

sensor signal circuit between the ECM harness con-

nector and ground.

Does the voltage near the specified value?0 VGo to Step 7Go to Step 12

7Measure the voltage of the Intake Air Temperature

(IAT) sensor signal circuit between the ECM har-

ness connector and ground.

Does the voltage near the specified value?0 VGo to Step 8Go to Step 13

8Measure the voltage of the Engine Coolant Temper-

ature (ECT) sensor signal circuit between the ECM

harness connector and ground.

Does the voltage near the specified value?0 VGo to Step 16Go to Step 14

91. Disconnect the EGR valve connector.

2. Measure the voltage of the EGR Pintle Position

sensor signal circuit between the ECM harness

connector and ground.

Does the voltage near the specified value?0 VGo to Step 10Go to Step 15

Page 284 of 2643

1F – 38IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

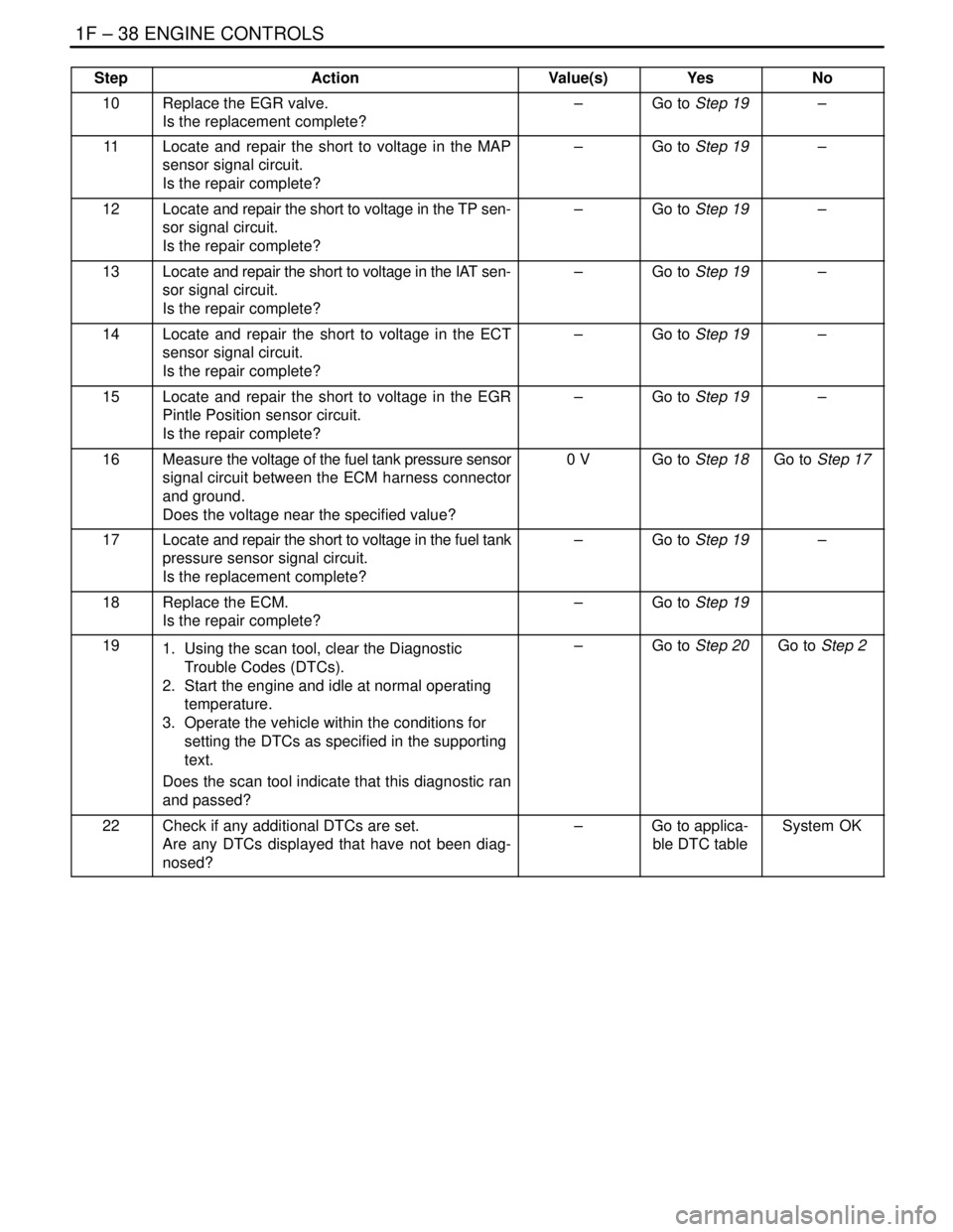

10Replace the EGR valve.

Is the replacement complete?–Go to Step 19–

11Locate and repair the short to voltage in the MAP

sensor signal circuit.

Is the repair complete?–Go to Step 19–

12Locate and repair the short to voltage in the TP sen-

sor signal circuit.

Is the repair complete?–Go to Step 19–

13Locate and repair the short to voltage in the IAT sen-

sor signal circuit.

Is the repair complete?–Go to Step 19–

14Locate and repair the short to voltage in the ECT

sensor signal circuit.

Is the repair complete?–Go to Step 19–

15Locate and repair the short to voltage in the EGR

Pintle Position sensor circuit.

Is the repair complete?–Go to Step 19–

16Measure the voltage of the fuel tank pressure sensor

signal circuit between the ECM harness connector

and ground.

Does the voltage near the specified value?0 VGo to Step 18Go to Step 17

17Locate and repair the short to voltage in the fuel tank

pressure sensor signal circuit.

Is the replacement complete?–Go to Step 19–

18Replace the ECM.

Is the repair complete?–Go to Step 19

191. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTCs as specified in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 20Go to Step 2

22Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to applica-

ble DTC tableSystem OK

Page 294 of 2643

1F – 48IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

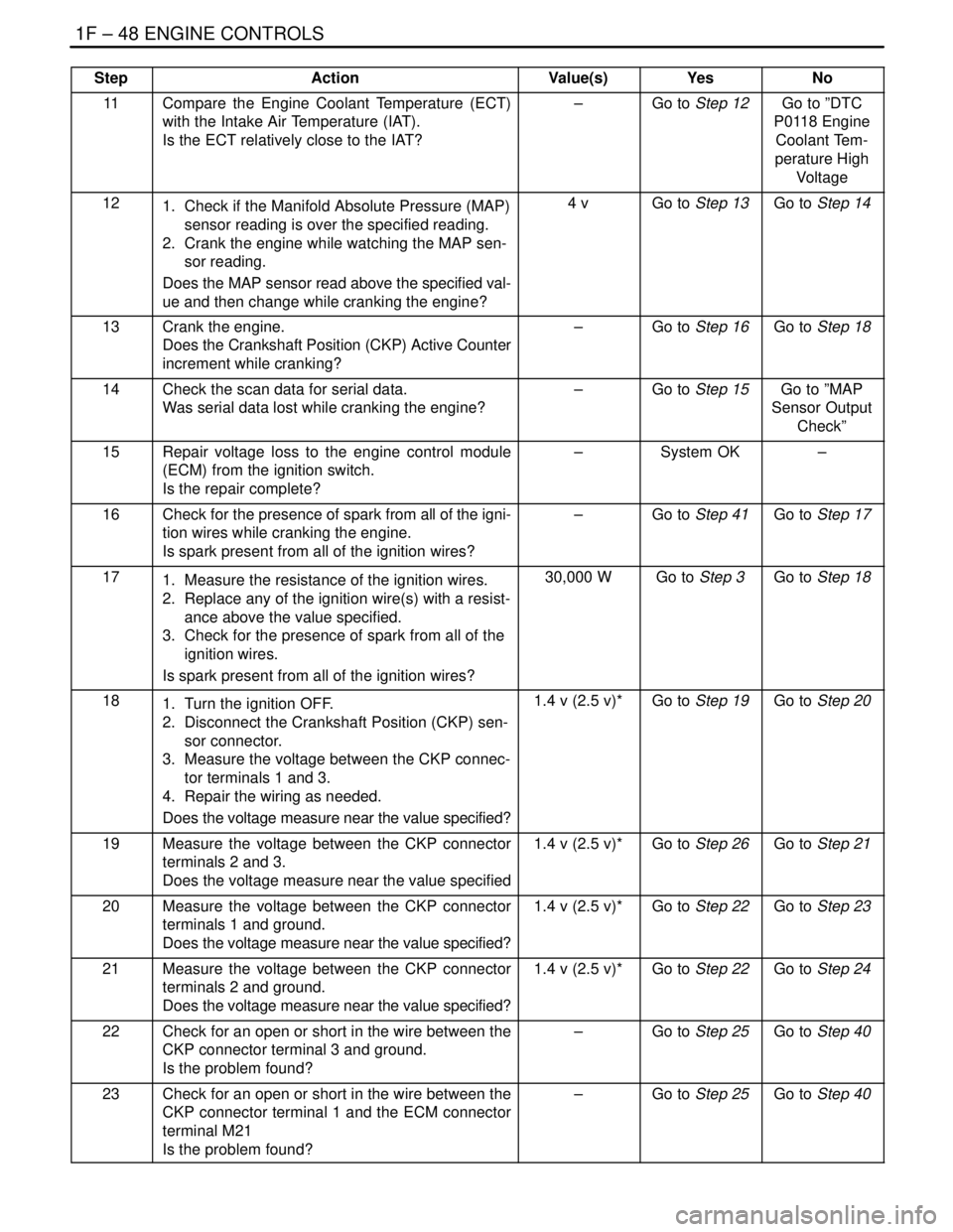

11Compare the Engine Coolant Temperature (ECT)

with the Intake Air Temperature (IAT).

Is the ECT relatively close to the IAT?–Go to Step 12Go to ”DTC

P0118 Engine

Coolant Tem-

perature High

Voltage

121. Check if the Manifold Absolute Pressure (MAP)

sensor reading is over the specified reading.

2. Crank the engine while watching the MAP sen-

sor reading.

Does the MAP sensor read above the specified val-

ue and then change while cranking the engine?4 vGo to Step 13Go to Step 14

13Crank the engine.

Does the Crankshaft Position (CKP) Active Counter

increment while cranking?–Go to Step 16Go to Step 18

14Check the scan data for serial data.

Was serial data lost while cranking the engine?–Go to Step 15Go to ”MAP

Sensor Output

Check”

15Repair voltage loss to the engine control module

(ECM) from the ignition switch.

Is the repair complete?–System OK–

16Check for the presence of spark from all of the igni-

tion wires while cranking the engine.

Is spark present from all of the ignition wires?–Go to Step 41Go to Step 17

171. Measure the resistance of the ignition wires.

2. Replace any of the ignition wire(s) with a resist-

ance above the value specified.

3. Check for the presence of spark from all of the

ignition wires.

Is spark present from all of the ignition wires?30,000 WGo to Step 3Go to Step 18

181. Turn the ignition OFF.

2. Disconnect the Crankshaft Position (CKP) sen-

sor connector.

3. Measure the voltage between the CKP connec-

tor terminals 1 and 3.

4. Repair the wiring as needed.

Does the voltage measure near the value specified?1.4 v (2.5 v)*Go to Step 19Go to Step 20

19Measure the voltage between the CKP connector

terminals 2 and 3.

Does the voltage measure near the value specified1.4 v (2.5 v)*Go to Step 26Go to Step 21

20Measure the voltage between the CKP connector

terminals 1 and ground.

Does the voltage measure near the value specified?1.4 v (2.5 v)*Go to Step 22Go to Step 23

21Measure the voltage between the CKP connector

terminals 2 and ground.

Does the voltage measure near the value specified?1.4 v (2.5 v)*Go to Step 22Go to Step 24

22Check for an open or short in the wire between the

CKP connector terminal 3 and ground.

Is the problem found?–Go to Step 25Go to Step 40

23Check for an open or short in the wire between the

CKP connector terminal 1 and the ECM connector

terminal M21

Is the problem found?–Go to Step 25Go to Step 40

Page 321 of 2643

ENGINE CONTROLS 1F – 75

DAEWOO V–121 BL4

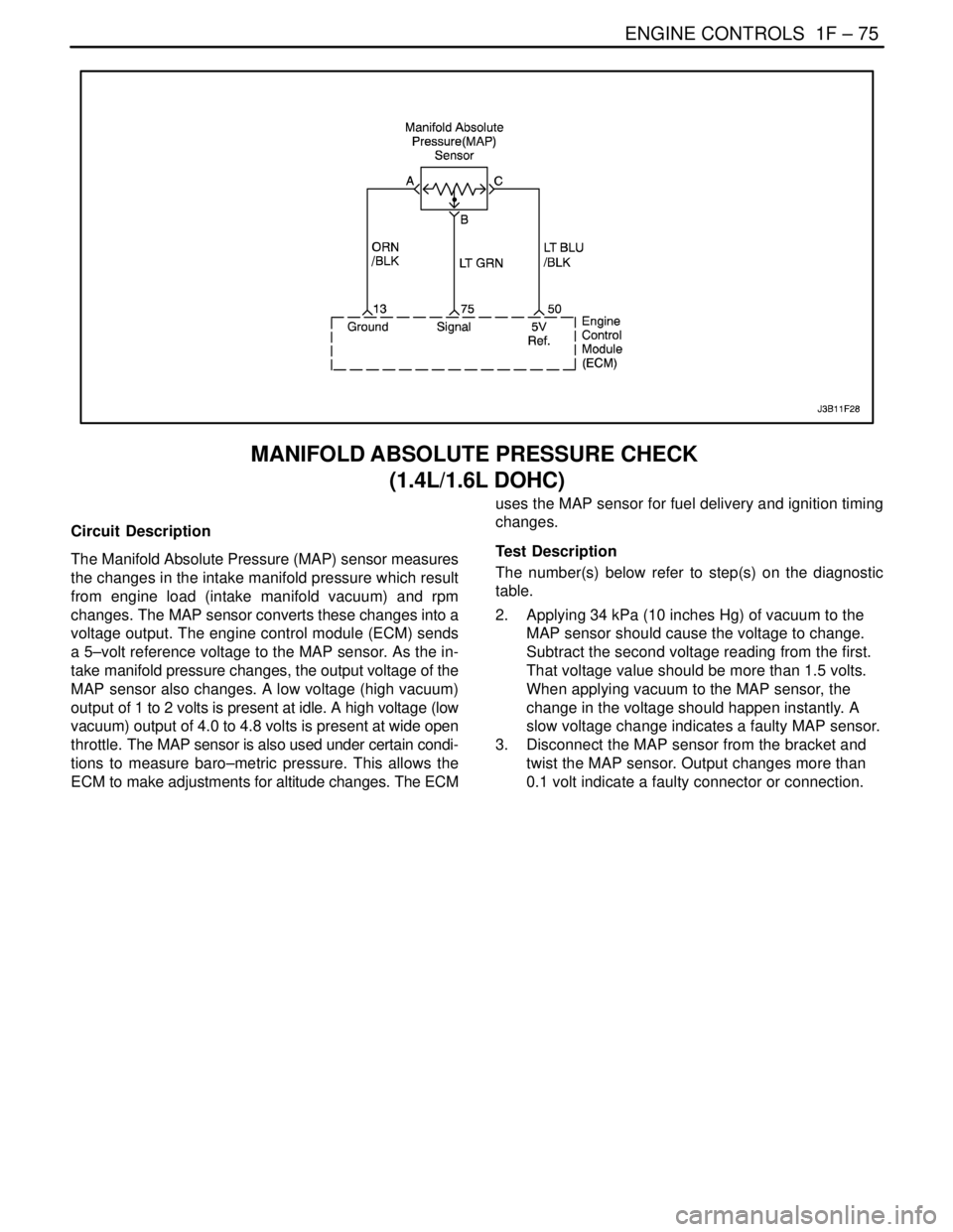

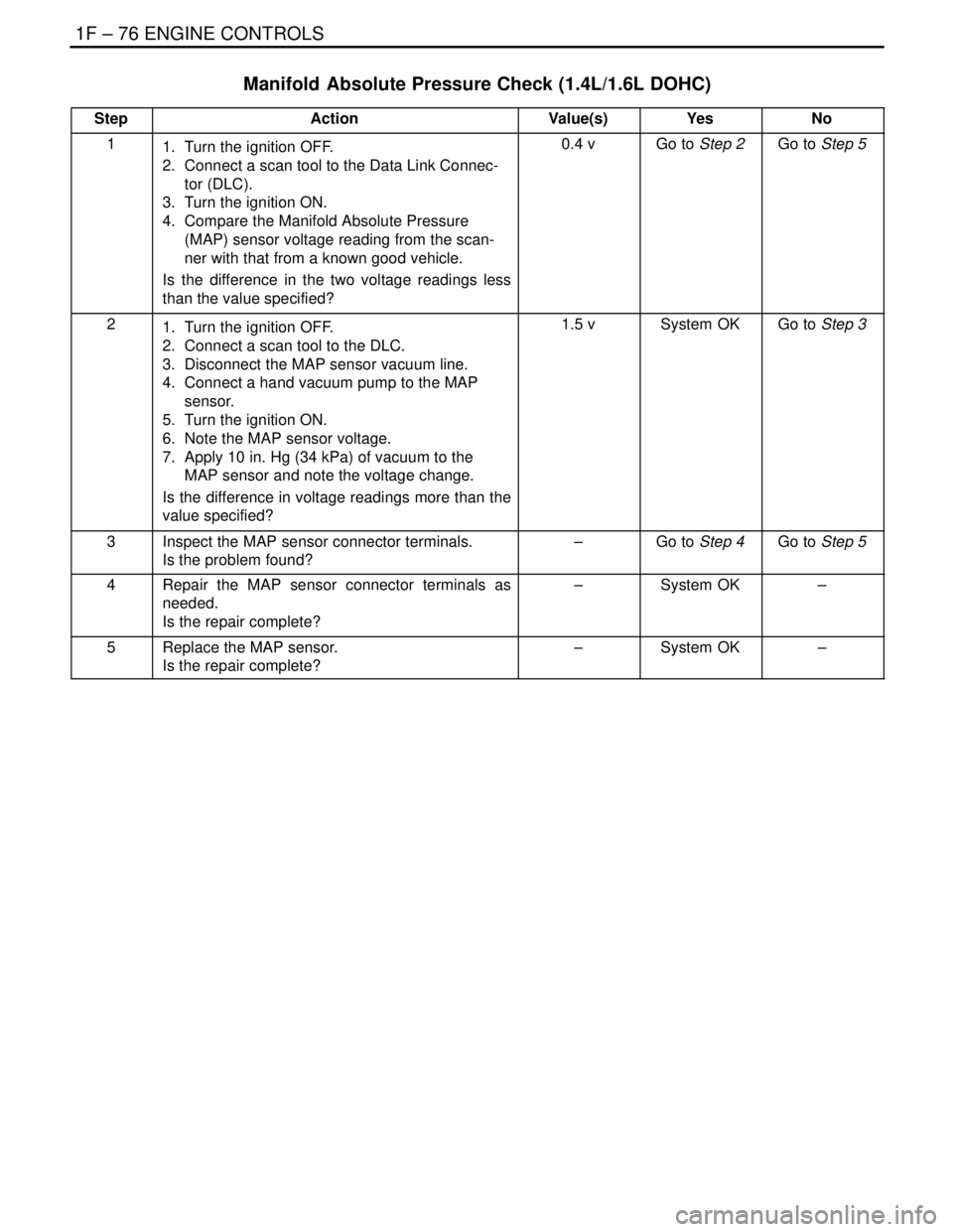

MANIFOLD ABSOLUTE PRESSURE CHECK

(1.4L/1.6L DOHC)

Circuit Description

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load (intake manifold vacuum) and rpm

changes. The MAP sensor converts these changes into a

voltage output. The engine control module (ECM) sends

a 5–volt reference voltage to the MAP sensor. As the in-

take manifold pressure changes, the output voltage of the

MAP sensor also changes. A low voltage (high vacuum)

output of 1 to 2 volts is present at idle. A high voltage (low

vacuum) output of 4.0 to 4.8 volts is present at wide open

throttle. The MAP sensor is also used under certain condi-

tions to measure baro–metric pressure. This allows the

ECM to make adjustments for altitude changes. The ECMuses the MAP sensor for fuel delivery and ignition timing

changes.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. Applying 34 kPa (10 inches Hg) of vacuum to the

MAP sensor should cause the voltage to change.

Subtract the second voltage reading from the first.

That voltage value should be more than 1.5 volts.

When applying vacuum to the MAP sensor, the

change in the voltage should happen instantly. A

slow voltage change indicates a faulty MAP sensor.

3. Disconnect the MAP sensor from the bracket and

twist the MAP sensor. Output changes more than

0.1 volt indicate a faulty connector or connection.

Page 322 of 2643

1F – 76IENGINE CONTROLS

DAEWOO V–121 BL4

Manifold Absolute Pressure Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Connect a scan tool to the Data Link Connec-

tor (DLC).

3. Turn the ignition ON.

4. Compare the Manifold Absolute Pressure

(MAP) sensor voltage reading from the scan-

ner with that from a known good vehicle.

Is the difference in the two voltage readings less

than the value specified?0.4 vGo to Step 2Go to Step 5

21. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. Disconnect the MAP sensor vacuum line.

4. Connect a hand vacuum pump to the MAP

sensor.

5. Turn the ignition ON.

6. Note the MAP sensor voltage.

7. Apply 10 in. Hg (34 kPa) of vacuum to the

MAP sensor and note the voltage change.

Is the difference in voltage readings more than the

value specified?1.5 vSystem OKGo to Step 3

3Inspect the MAP sensor connector terminals.

Is the problem found?–Go to Step 4Go to Step 5

4Repair the MAP sensor connector terminals as

needed.

Is the repair complete?–System OK–

5Replace the MAP sensor.

Is the repair complete?–System OK–

Page 323 of 2643

ENGINE CONTROLS 1F – 77

DAEWOO V–121 BL4

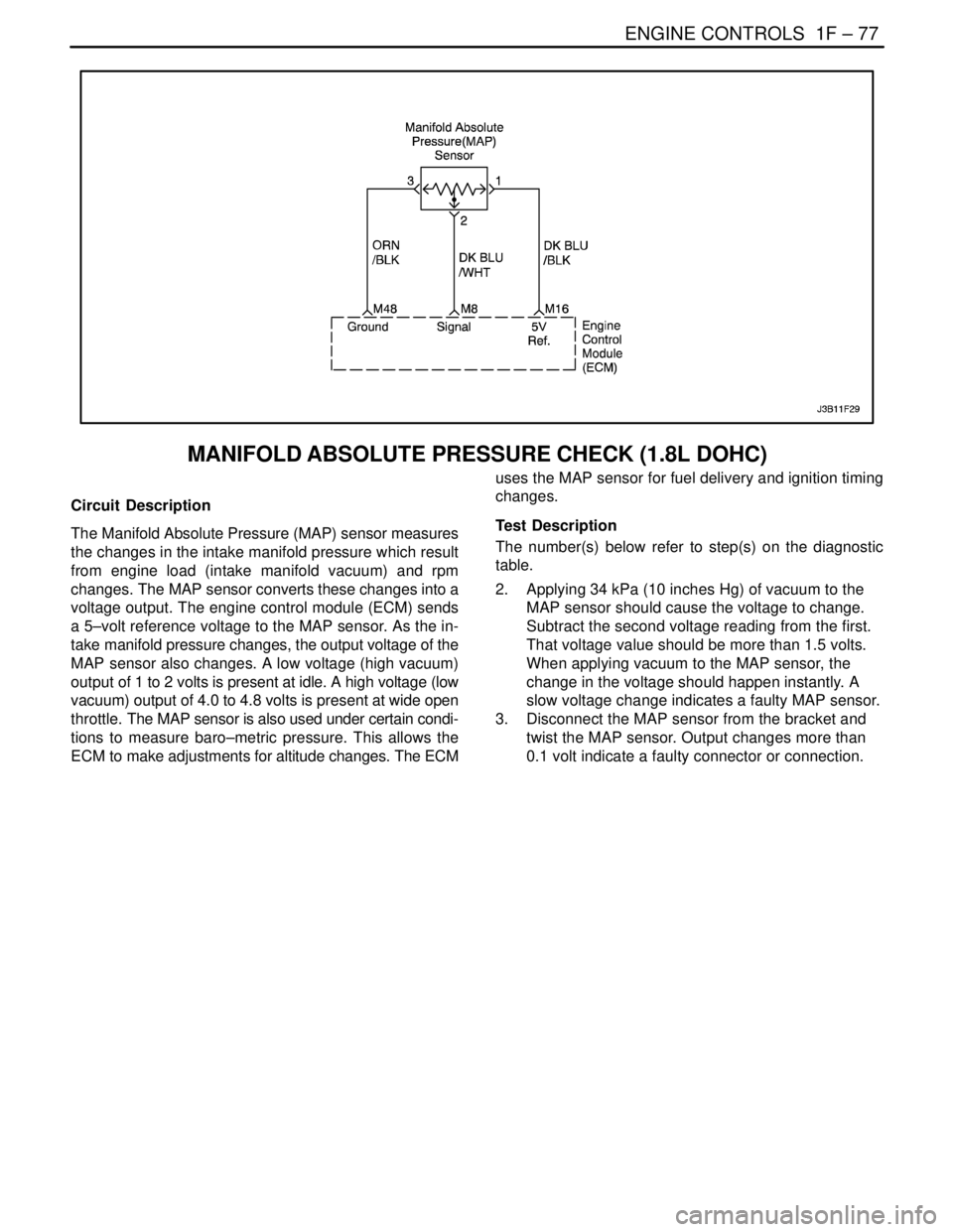

MANIFOLD ABSOLUTE PRESSURE CHECK (1.8L DOHC)

Circuit Description

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load (intake manifold vacuum) and rpm

changes. The MAP sensor converts these changes into a

voltage output. The engine control module (ECM) sends

a 5–volt reference voltage to the MAP sensor. As the in-

take manifold pressure changes, the output voltage of the

MAP sensor also changes. A low voltage (high vacuum)

output of 1 to 2 volts is present at idle. A high voltage (low

vacuum) output of 4.0 to 4.8 volts is present at wide open

throttle. The MAP sensor is also used under certain condi-

tions to measure baro–metric pressure. This allows the

ECM to make adjustments for altitude changes. The ECMuses the MAP sensor for fuel delivery and ignition timing

changes.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. Applying 34 kPa (10 inches Hg) of vacuum to the

MAP sensor should cause the voltage to change.

Subtract the second voltage reading from the first.

That voltage value should be more than 1.5 volts.

When applying vacuum to the MAP sensor, the

change in the voltage should happen instantly. A

slow voltage change indicates a faulty MAP sensor.

3. Disconnect the MAP sensor from the bracket and

twist the MAP sensor. Output changes more than

0.1 volt indicate a faulty connector or connection.

Page 324 of 2643

1F – 78IENGINE CONTROLS

DAEWOO V–121 BL4

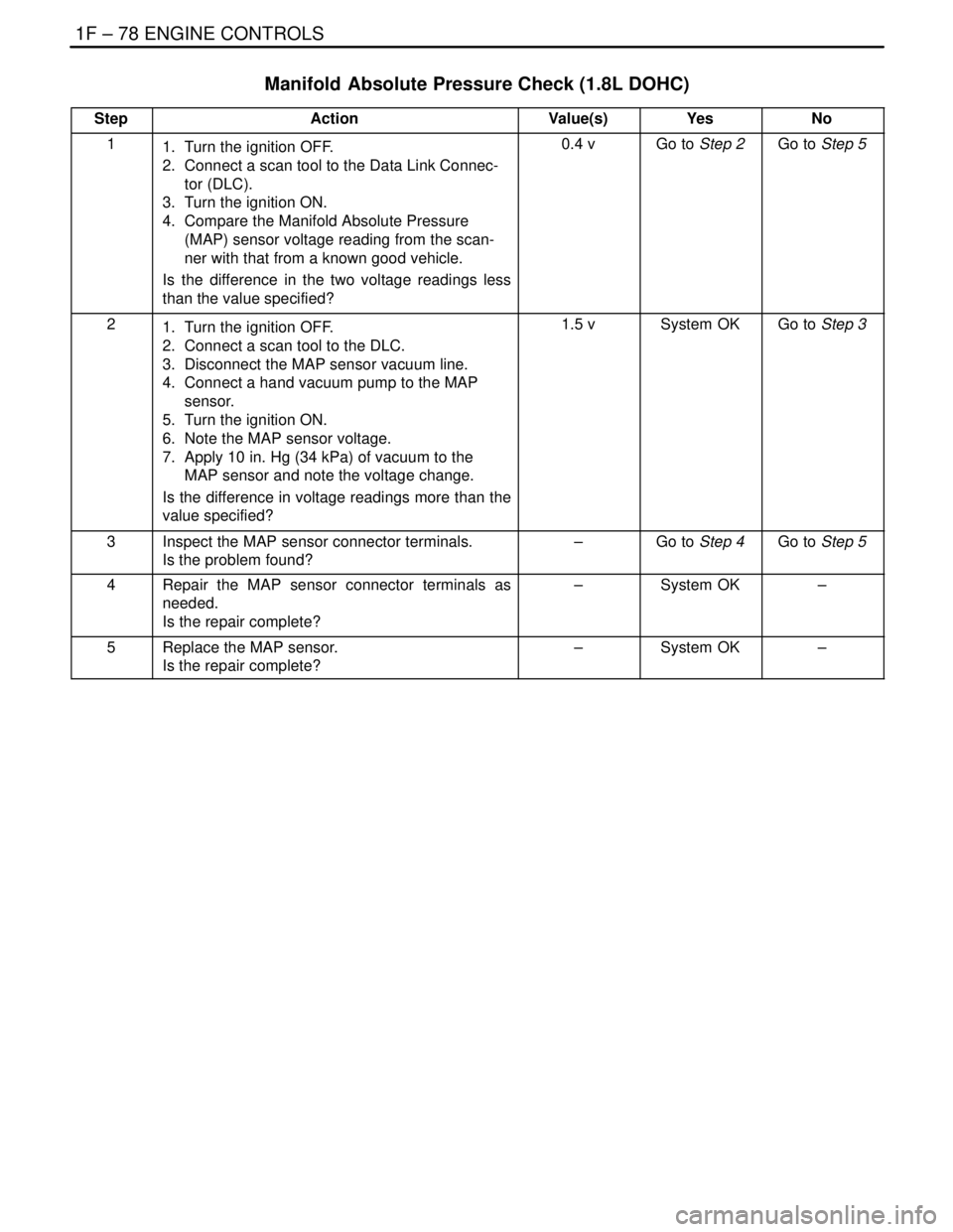

Manifold Absolute Pressure Check (1.8L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Connect a scan tool to the Data Link Connec-

tor (DLC).

3. Turn the ignition ON.

4. Compare the Manifold Absolute Pressure

(MAP) sensor voltage reading from the scan-

ner with that from a known good vehicle.

Is the difference in the two voltage readings less

than the value specified?0.4 vGo to Step 2Go to Step 5

21. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. Disconnect the MAP sensor vacuum line.

4. Connect a hand vacuum pump to the MAP

sensor.

5. Turn the ignition ON.

6. Note the MAP sensor voltage.

7. Apply 10 in. Hg (34 kPa) of vacuum to the

MAP sensor and note the voltage change.

Is the difference in voltage readings more than the

value specified?1.5 vSystem OKGo to Step 3

3Inspect the MAP sensor connector terminals.

Is the problem found?–Go to Step 4Go to Step 5

4Repair the MAP sensor connector terminals as

needed.

Is the repair complete?–System OK–

5Replace the MAP sensor.

Is the repair complete?–System OK–

Page 360 of 2643

1F – 114IENGINE CONTROLS

DAEWOO V–121 BL4

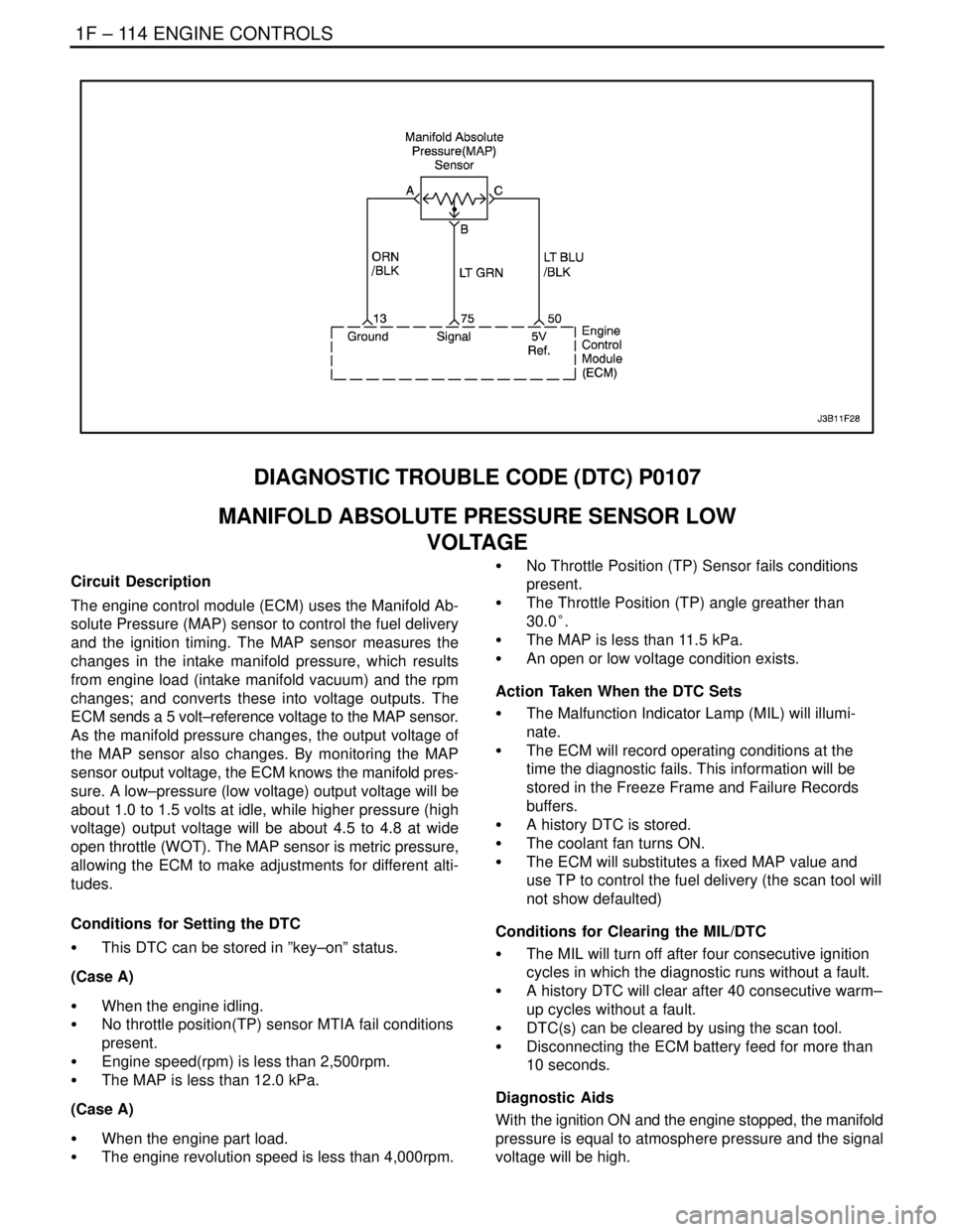

DIAGNOSTIC TROUBLE CODE (DTC) P0107

MANIFOLD ABSOLUTE PRESSURE SENSOR LOW

VOLTAGE

Circuit Description

The engine control module (ECM) uses the Manifold Ab-

solute Pressure (MAP) sensor to control the fuel delivery

and the ignition timing. The MAP sensor measures the

changes in the intake manifold pressure, which results

from engine load (intake manifold vacuum) and the rpm

changes; and converts these into voltage outputs. The

ECM sends a 5 volt–reference voltage to the MAP sensor.

As the manifold pressure changes, the output voltage of

the MAP sensor also changes. By monitoring the MAP

sensor output voltage, the ECM knows the manifold pres-

sure. A low–pressure (low voltage) output voltage will be

about 1.0 to 1.5 volts at idle, while higher pressure (high

voltage) output voltage will be about 4.5 to 4.8 at wide

open throttle (WOT). The MAP sensor is metric pressure,

allowing the ECM to make adjustments for different alti-

tudes.

Conditions for Setting the DTC

S This DTC can be stored in ”key–on” status.

(Case A)

S When the engine idling.

S No throttle position(TP) sensor MTIA fail conditions

present.

S Engine speed(rpm) is less than 2,500rpm.

S The MAP is less than 12.0 kPa.

(Case A)

S When the engine part load.

S The engine revolution speed is less than 4,000rpm.S No Throttle Position (TP) Sensor fails conditions

present.

S The Throttle Position (TP) angle greather than

30.0°.

S The MAP is less than 11.5 kPa.

S An open or low voltage condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The coolant fan turns ON.

S The ECM will substitutes a fixed MAP value and

use TP to control the fuel delivery (the scan tool will

not show defaulted)

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

With the ignition ON and the engine stopped, the manifold

pressure is equal to atmosphere pressure and the signal

voltage will be high.

Page 361 of 2643

ENGINE CONTROLS 1F – 115

DAEWOO V–121 BL4

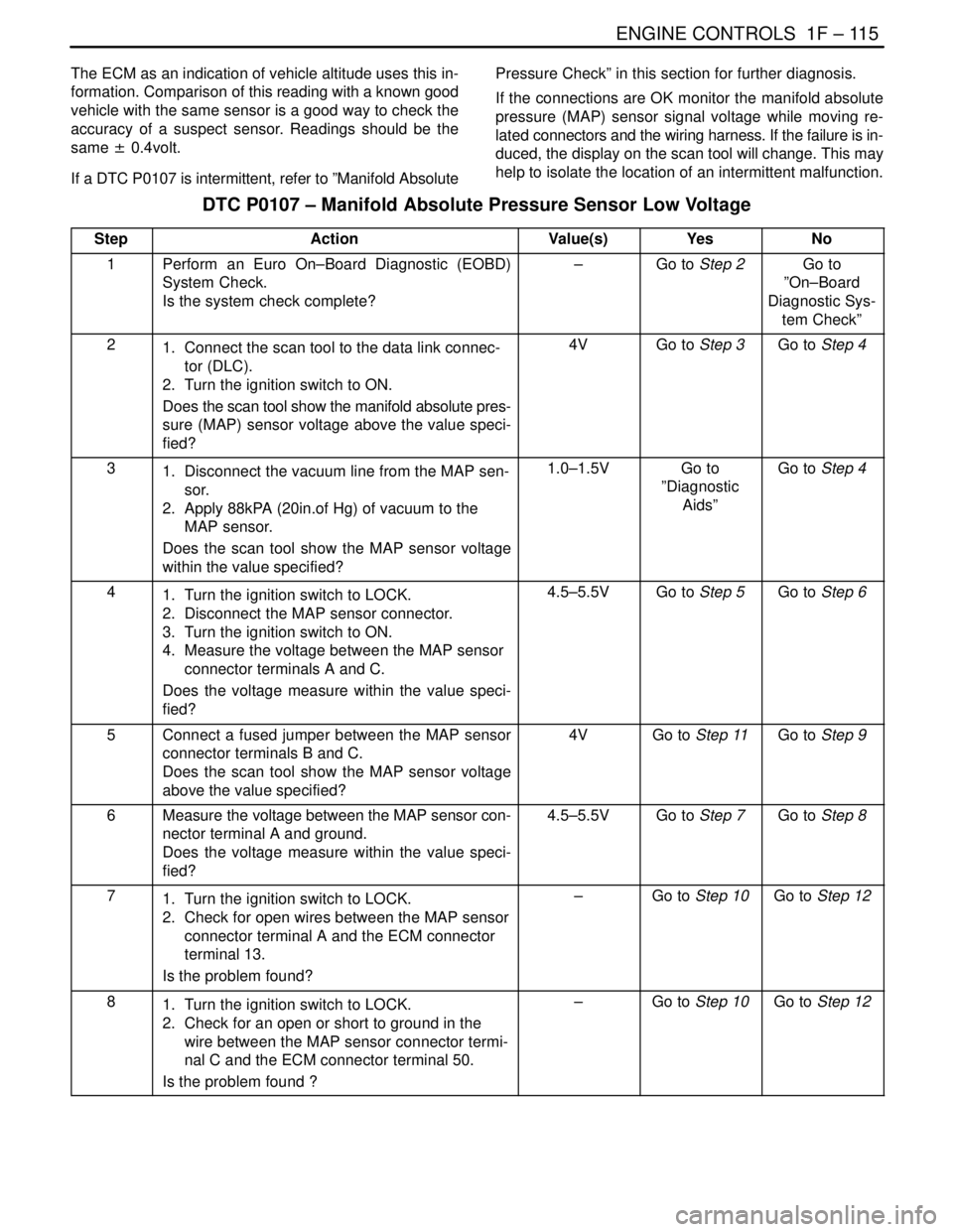

The ECM as an indication of vehicle altitude uses this in-

formation. Comparison of this reading with a known good

vehicle with the same sensor is a good way to check the

accuracy of a suspect sensor. Readings should be the

same ± 0.4volt.

If a DTC P0107 is intermittent, refer to ”Manifold AbsolutePressure Check” in this section for further diagnosis.

If the connections are OK monitor the manifold absolute

pressure (MAP) sensor signal voltage while moving re-

lated connectors and the wiring harness. If the failure is in-

duced, the display on the scan tool will change. This may

help to isolate the location of an intermittent malfunction.

DTC P0107 – Manifold Absolute Pressure Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the data link connec-

tor (DLC).

2. Turn the ignition switch to ON.

Does the scan tool show the manifold absolute pres-

sure (MAP) sensor voltage above the value speci-

fied?4VGo to Step 3Go to Step 4

31. Disconnect the vacuum line from the MAP sen-

sor.

2. Apply 88kPA (20in.of Hg) of vacuum to the

MAP sensor.

Does the scan tool show the MAP sensor voltage

within the value specified?1.0–1.5VGo to

”Diagnostic

Aids”Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the MAP sensor connector.

3. Turn the ignition switch to ON.

4. Measure the voltage between the MAP sensor

connector terminals A and C.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 5Go to Step 6

5Connect a fused jumper between the MAP sensor

connector terminals B and C.

Does the scan tool show the MAP sensor voltage

above the value specified?4VGo to Step 11Go to Step 9

6Measure the voltage between the MAP sensor con-

nector terminal A and ground.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 7Go to Step 8

71. Turn the ignition switch to LOCK.

2. Check for open wires between the MAP sensor

connector terminal A and the ECM connector

terminal 13.

Is the problem found?–Go to Step 10Go to Step 12

81. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal C and the ECM connector terminal 50.

Is the problem found ?–Go to Step 10Go to Step 12

Page 362 of 2643

1F – 116IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

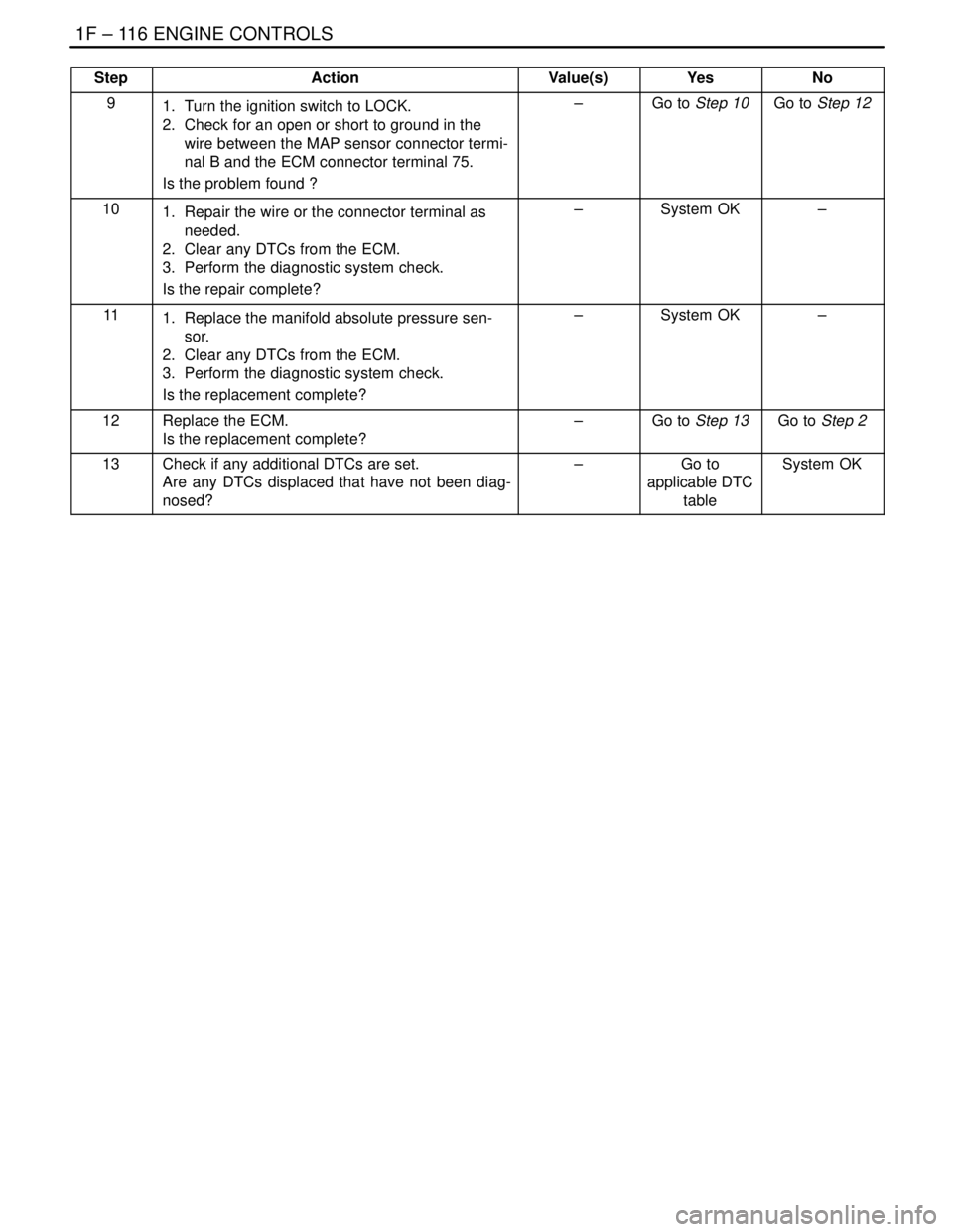

91. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal B and the ECM connector terminal 75.

Is the problem found ?–Go to Step 10Go to Step 12

101. Repair the wire or the connector terminal as

needed.

2. Clear any DTCs from the ECM.

3. Perform the diagnostic system check.

Is the repair complete?–System OK–

111. Replace the manifold absolute pressure sen-

sor.

2. Clear any DTCs from the ECM.

3. Perform the diagnostic system check.

Is the replacement complete?–System OK–

12Replace the ECM.

Is the replacement complete?–Go to Step 13Go to Step 2

13Check if any additional DTCs are set.

Are any DTCs displaced that have not been diag-

nosed?–Go to

applicable DTC

tableSystem OK