check engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 461 of 2643

ENGINE CONTROLS 1F – 215

DAEWOO V–121 BL4

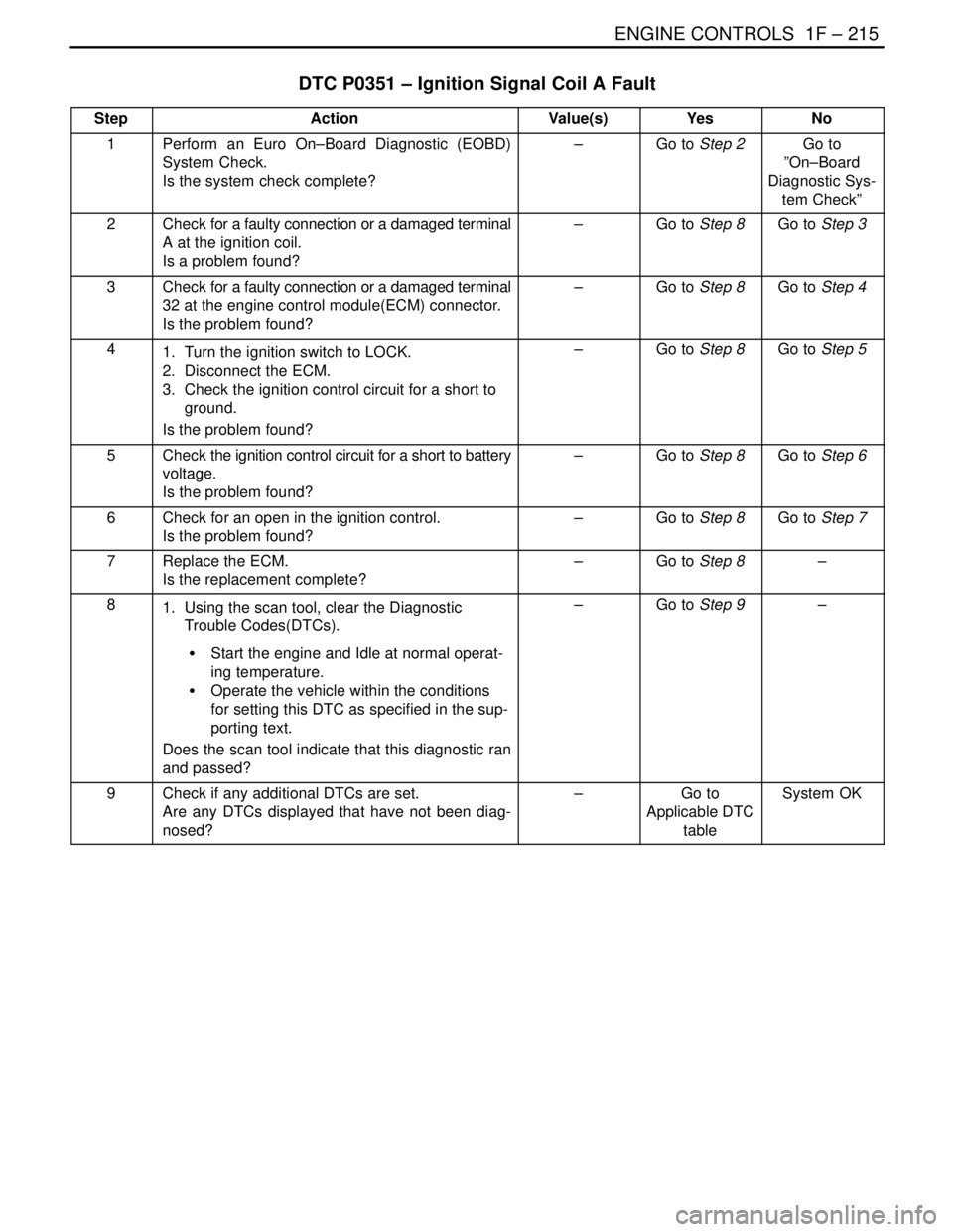

DTC P0351 – Ignition Signal Coil A Fault

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Check for a faulty connection or a damaged terminal

A at the ignition coil.

Is a problem found?–Go to Step 8Go to Step 3

3Check for a faulty connection or a damaged terminal

32 at the engine control module(ECM) connector.

Is the problem found?–Go to Step 8Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the ECM.

3. Check the ignition control circuit for a short to

ground.

Is the problem found?–Go to Step 8Go to Step 5

5Check the ignition control circuit for a short to battery

voltage.

Is the problem found?–Go to Step 8Go to Step 6

6Check for an open in the ignition control.

Is the problem found?–Go to Step 8Go to Step 7

7Replace the ECM.

Is the replacement complete?–Go to Step 8–

81. Using the scan tool, clear the Diagnostic

Trouble Codes(DTCs).

S Start the engine and Idle at normal operat-

ing temperature.

S Operate the vehicle within the conditions

for setting this DTC as specified in the sup-

porting text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 9–

9Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 462 of 2643

1F – 216IENGINE CONTROLS

DAEWOO V–121 BL4

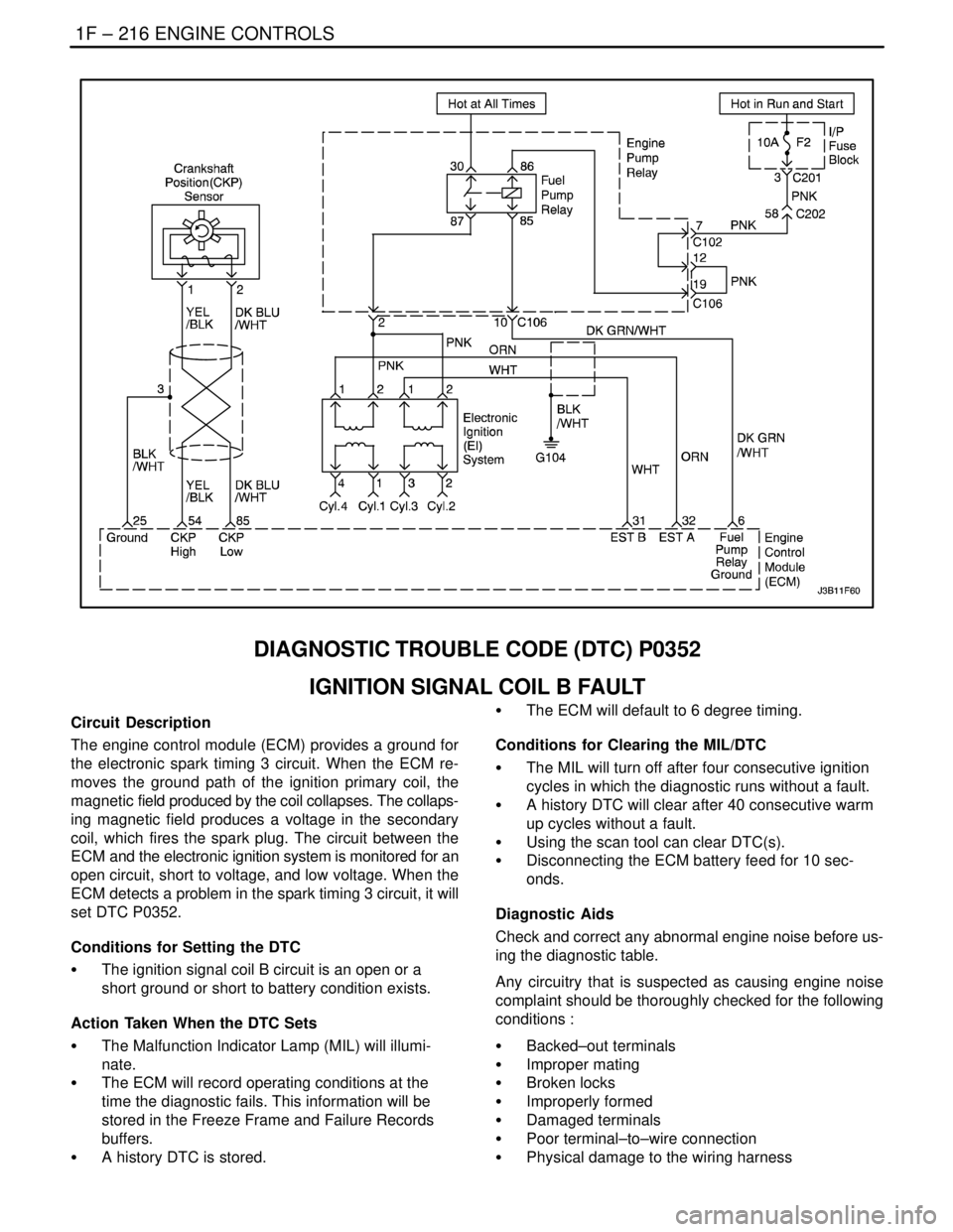

DIAGNOSTIC TROUBLE CODE (DTC) P0352

IGNITION SIGNAL COIL B FAULT

Circuit Description

The engine control module (ECM) provides a ground for

the electronic spark timing 3 circuit. When the ECM re-

moves the ground path of the ignition primary coil, the

magnetic field produced by the coil collapses. The collaps-

ing magnetic field produces a voltage in the secondary

coil, which fires the spark plug. The circuit between the

ECM and the electronic ignition system is monitored for an

open circuit, short to voltage, and low voltage. When the

ECM detects a problem in the spark timing 3 circuit, it will

set DTC P0352.

Conditions for Setting the DTC

S The ignition signal coil B circuit is an open or a

short ground or short to battery condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.S The ECM will default to 6 degree timing.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using the scan tool can clear DTC(s).

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

Check and correct any abnormal engine noise before us-

ing the diagnostic table.

Any circuitry that is suspected as causing engine noise

complaint should be thoroughly checked for the following

conditions :

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Page 463 of 2643

ENGINE CONTROLS 1F – 217

DAEWOO V–121 BL4

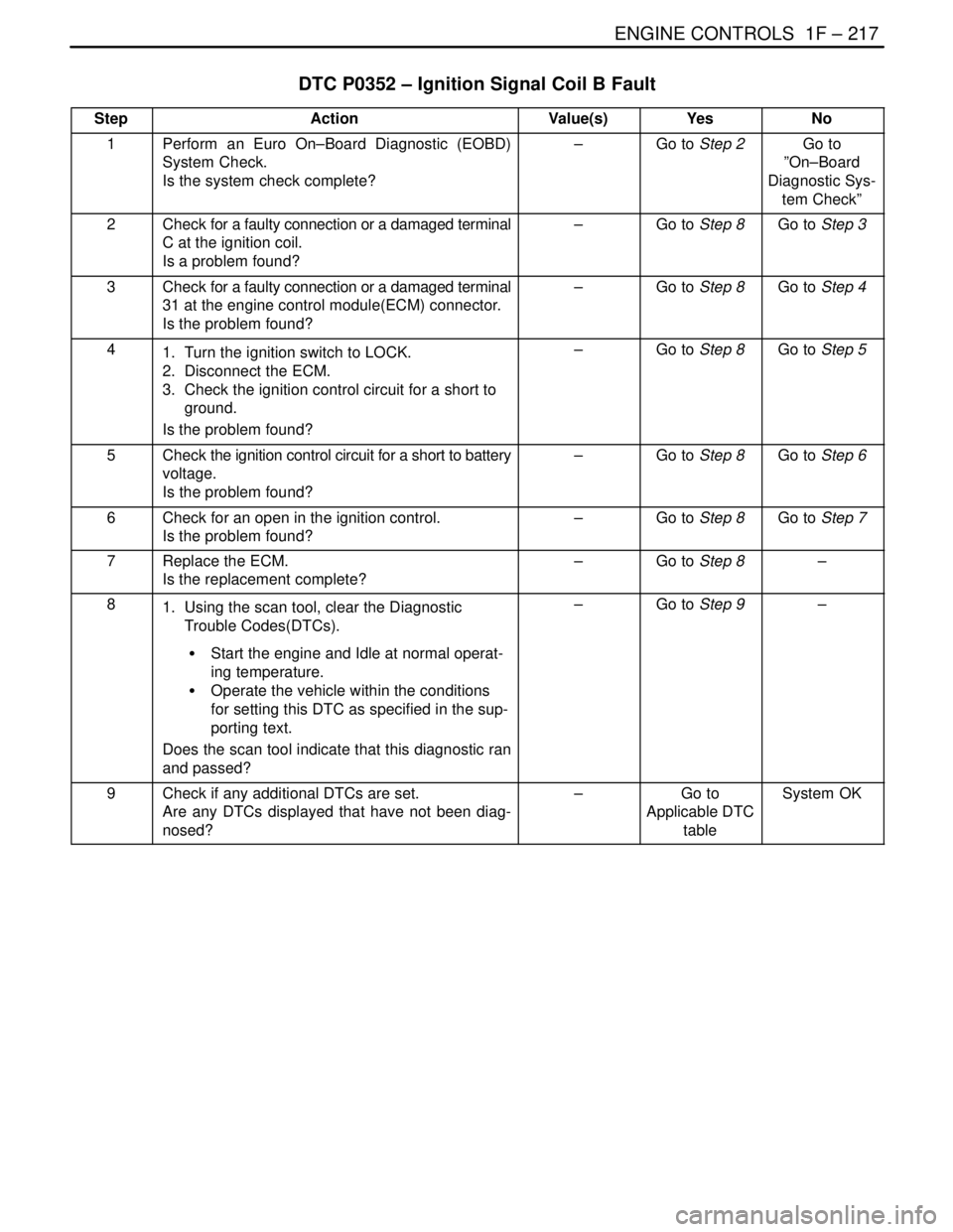

DTC P0352 – Ignition Signal Coil B Fault

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Check for a faulty connection or a damaged terminal

C at the ignition coil.

Is a problem found?–Go to Step 8Go to Step 3

3Check for a faulty connection or a damaged terminal

31 at the engine control module(ECM) connector.

Is the problem found?–Go to Step 8Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the ECM.

3. Check the ignition control circuit for a short to

ground.

Is the problem found?–Go to Step 8Go to Step 5

5Check the ignition control circuit for a short to battery

voltage.

Is the problem found?–Go to Step 8Go to Step 6

6Check for an open in the ignition control.

Is the problem found?–Go to Step 8Go to Step 7

7Replace the ECM.

Is the replacement complete?–Go to Step 8–

81. Using the scan tool, clear the Diagnostic

Trouble Codes(DTCs).

S Start the engine and Idle at normal operat-

ing temperature.

S Operate the vehicle within the conditions

for setting this DTC as specified in the sup-

porting text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 9–

9Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 465 of 2643

ENGINE CONTROLS 1F – 219

DAEWOO V–121 BL4

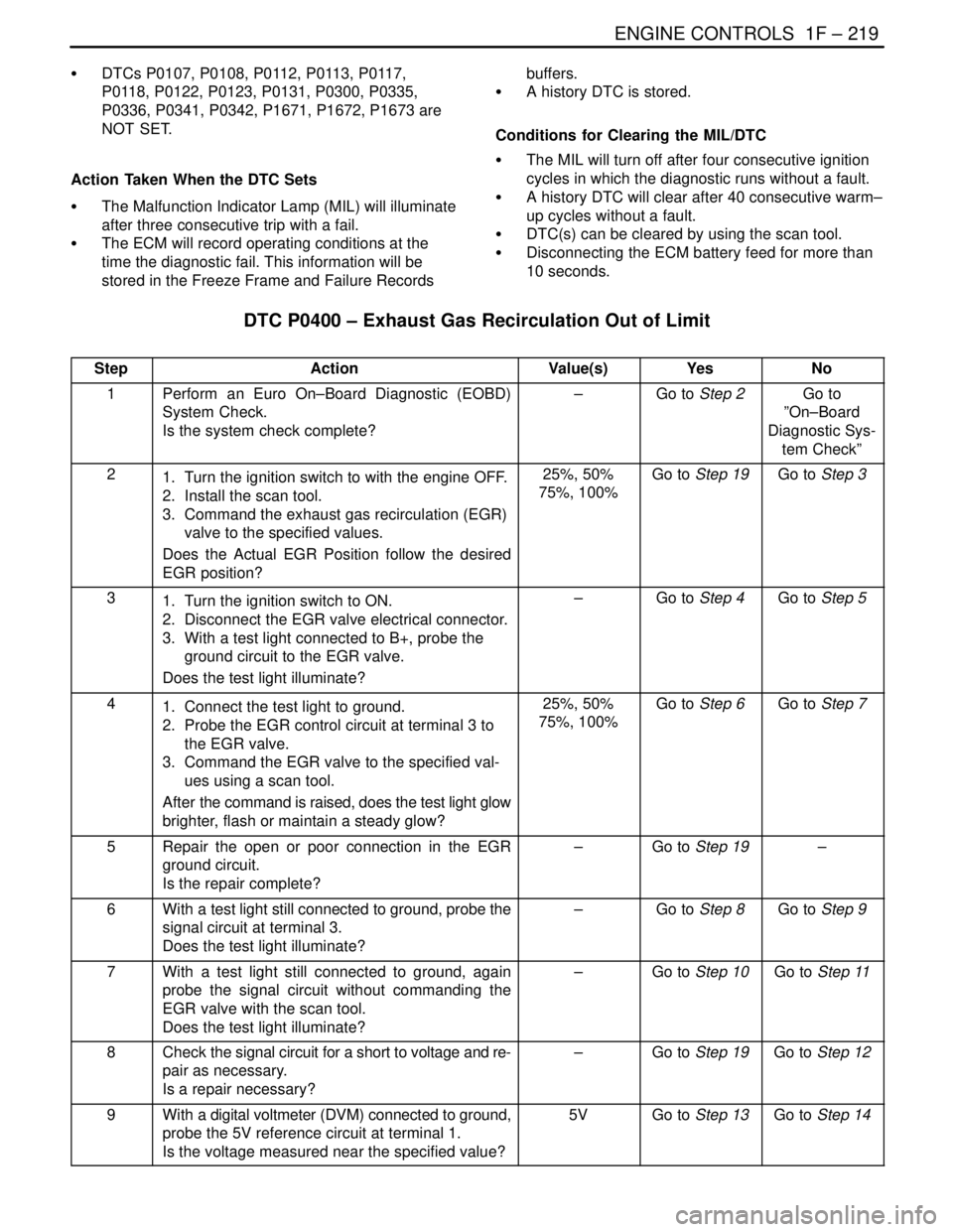

S DTCs P0107, P0108, P0112, P0113, P0117,

P0118, P0122, P0123, P0131, P0300, P0335,

P0336, P0341, P0342, P1671, P1672, P1673 are

NOT SET.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Recordsbuffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P0400 – Exhaust Gas Recirculation Out of Limit

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to with the engine OFF.

2. Install the scan tool.

3. Command the exhaust gas recirculation (EGR)

valve to the specified values.

Does the Actual EGR Position follow the desired

EGR position?25%, 50%

75%, 100%Go to Step 19Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the EGR valve electrical connector.

3. With a test light connected to B+, probe the

ground circuit to the EGR valve.

Does the test light illuminate?–Go to Step 4Go to Step 5

41. Connect the test light to ground.

2. Probe the EGR control circuit at terminal 3 to

the EGR valve.

3. Command the EGR valve to the specified val-

ues using a scan tool.

After the command is raised, does the test light glow

brighter, flash or maintain a steady glow?25%, 50%

75%, 100%Go to Step 6Go to Step 7

5Repair the open or poor connection in the EGR

ground circuit.

Is the repair complete?–Go to Step 19–

6With a test light still connected to ground, probe the

signal circuit at terminal 3.

Does the test light illuminate?–Go to Step 8Go to Step 9

7With a test light still connected to ground, again

probe the signal circuit without commanding the

EGR valve with the scan tool.

Does the test light illuminate?–Go to Step 10Go to Step 11

8Check the signal circuit for a short to voltage and re-

pair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

9With a digital voltmeter (DVM) connected to ground,

probe the 5V reference circuit at terminal 1.

Is the voltage measured near the specified value?5VGo to Step 13Go to Step 14

Page 466 of 2643

1F – 220IENGINE CONTROLS

DAEWOO V–121 BL4

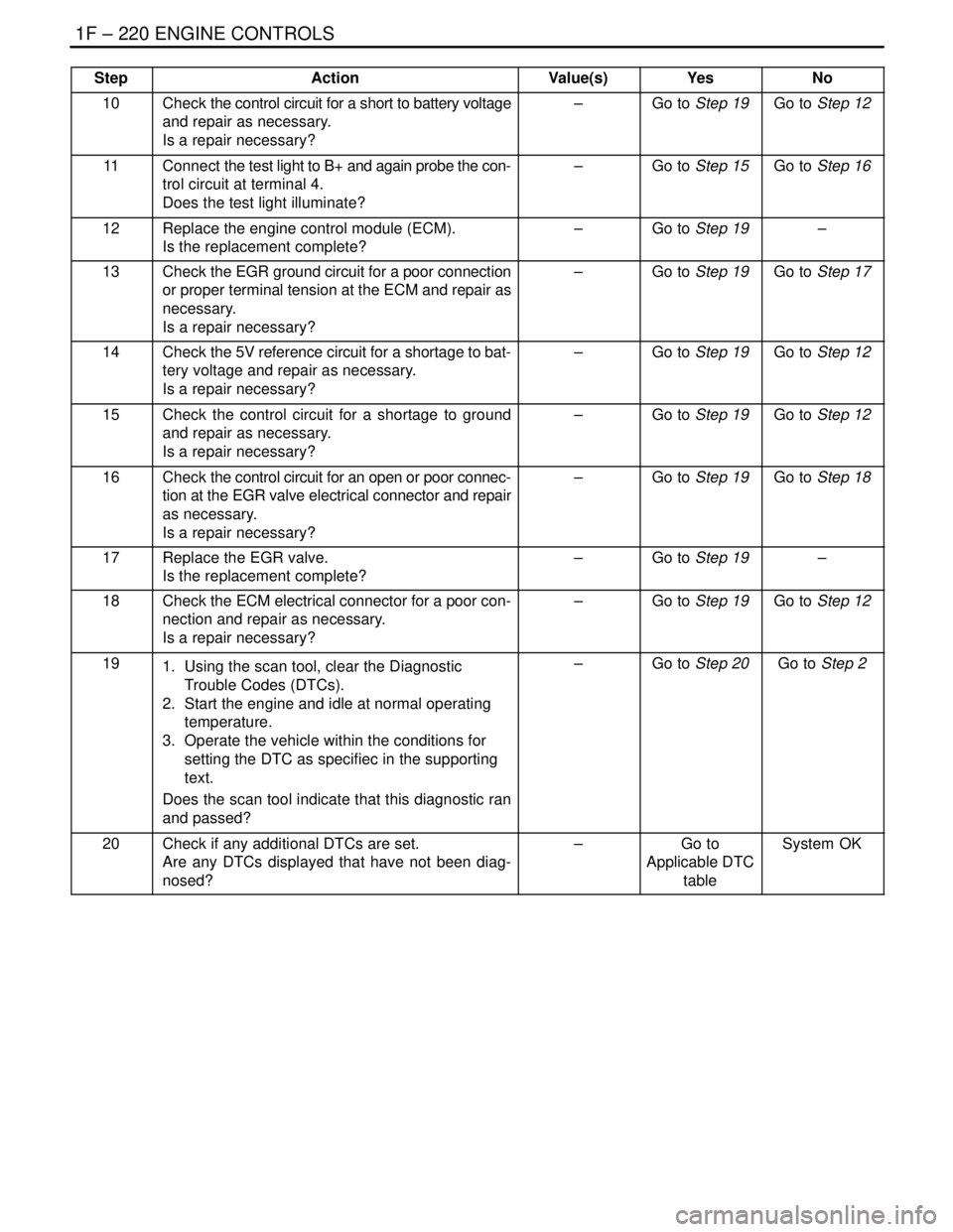

StepNo Yes Value(s) Action

10Check the control circuit for a short to battery voltage

and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

11Connect the test light to B+ and again probe the con-

trol circuit at terminal 4.

Does the test light illuminate?–Go to Step 15Go to Step 16

12Replace the engine control module (ECM).

Is the replacement complete?–Go to Step 19–

13Check the EGR ground circuit for a poor connection

or proper terminal tension at the ECM and repair as

necessary.

Is a repair necessary?–Go to Step 19Go to Step 17

14Check the 5V reference circuit for a shortage to bat-

tery voltage and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

15Check the control circuit for a shortage to ground

and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

16Check the control circuit for an open or poor connec-

tion at the EGR valve electrical connector and repair

as necessary.

Is a repair necessary?–Go to Step 19Go to Step 18

17Replace the EGR valve.

Is the replacement complete?–Go to Step 19–

18Check the ECM electrical connector for a poor con-

nection and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

191. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 20Go to Step 2

20Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 468 of 2643

1F – 222IENGINE CONTROLS

DAEWOO V–121 BL4

S Disconnecting the ECM battery feed for more than

10 seconds.

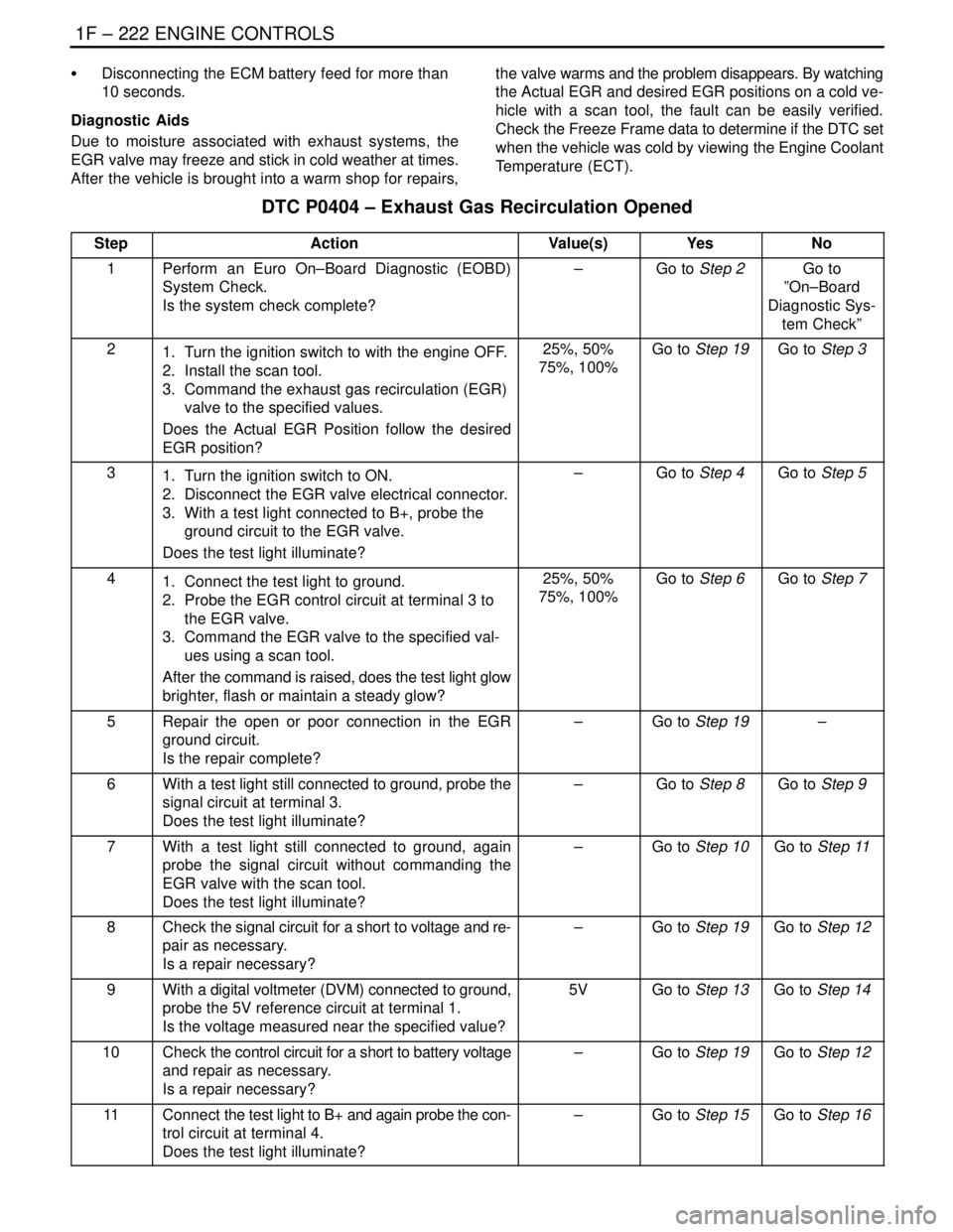

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,the valve warms and the problem disappears. By watching

the Actual EGR and desired EGR positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the Freeze Frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

DTC P0404 – Exhaust Gas Recirculation Opened

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to with the engine OFF.

2. Install the scan tool.

3. Command the exhaust gas recirculation (EGR)

valve to the specified values.

Does the Actual EGR Position follow the desired

EGR position?25%, 50%

75%, 100%Go to Step 19Go to Step 3

31. Turn the ignition switch to ON.

2. Disconnect the EGR valve electrical connector.

3. With a test light connected to B+, probe the

ground circuit to the EGR valve.

Does the test light illuminate?–Go to Step 4Go to Step 5

41. Connect the test light to ground.

2. Probe the EGR control circuit at terminal 3 to

the EGR valve.

3. Command the EGR valve to the specified val-

ues using a scan tool.

After the command is raised, does the test light glow

brighter, flash or maintain a steady glow?25%, 50%

75%, 100%Go to Step 6Go to Step 7

5Repair the open or poor connection in the EGR

ground circuit.

Is the repair complete?–Go to Step 19–

6With a test light still connected to ground, probe the

signal circuit at terminal 3.

Does the test light illuminate?–Go to Step 8Go to Step 9

7With a test light still connected to ground, again

probe the signal circuit without commanding the

EGR valve with the scan tool.

Does the test light illuminate?–Go to Step 10Go to Step 11

8Check the signal circuit for a short to voltage and re-

pair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

9With a digital voltmeter (DVM) connected to ground,

probe the 5V reference circuit at terminal 1.

Is the voltage measured near the specified value?5VGo to Step 13Go to Step 14

10Check the control circuit for a short to battery voltage

and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

11Connect the test light to B+ and again probe the con-

trol circuit at terminal 4.

Does the test light illuminate?–Go to Step 15Go to Step 16

Page 469 of 2643

ENGINE CONTROLS 1F – 223

DAEWOO V–121 BL4

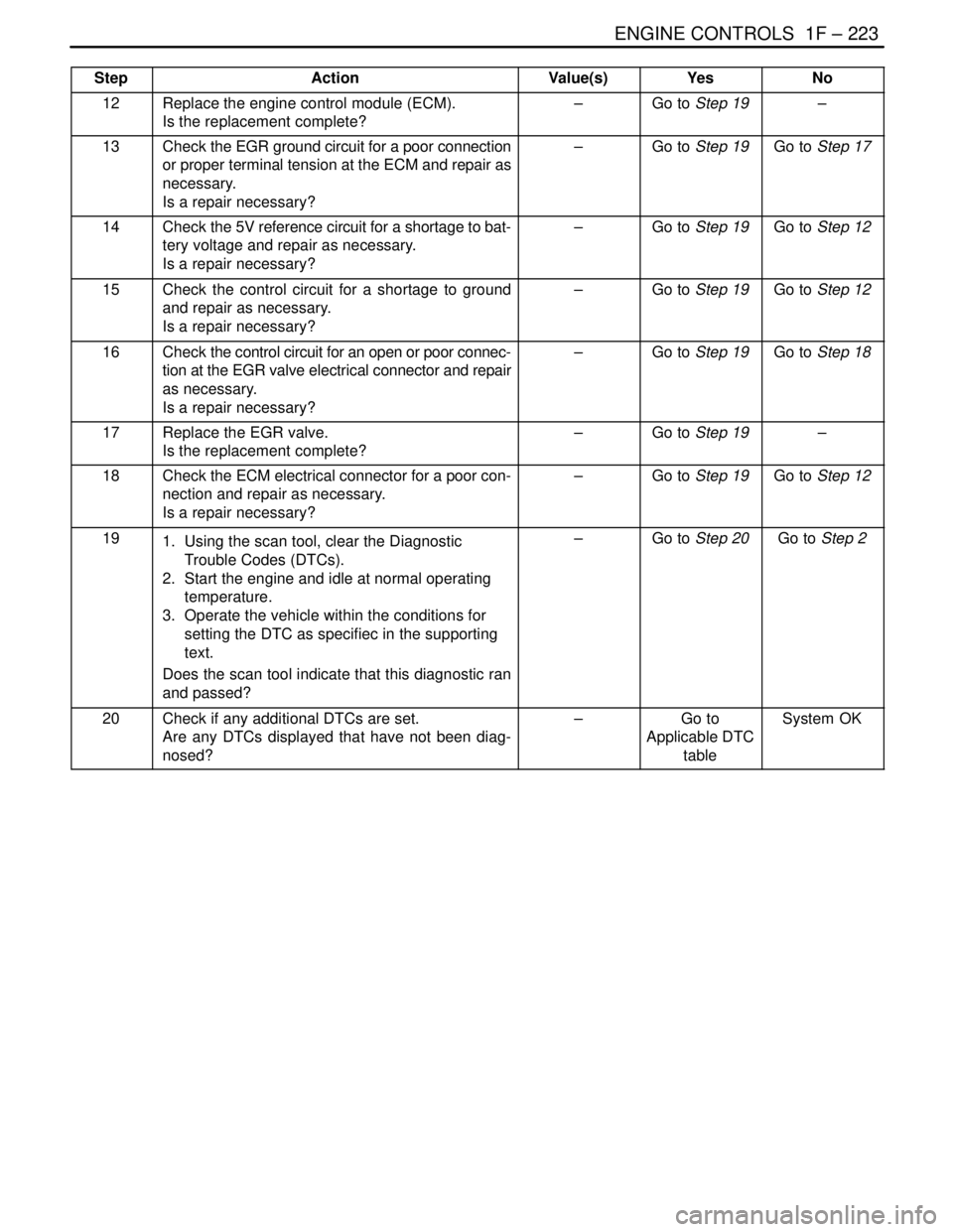

StepNo Yes Value(s) Action

12Replace the engine control module (ECM).

Is the replacement complete?–Go to Step 19–

13Check the EGR ground circuit for a poor connection

or proper terminal tension at the ECM and repair as

necessary.

Is a repair necessary?–Go to Step 19Go to Step 17

14Check the 5V reference circuit for a shortage to bat-

tery voltage and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

15Check the control circuit for a shortage to ground

and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

16Check the control circuit for an open or poor connec-

tion at the EGR valve electrical connector and repair

as necessary.

Is a repair necessary?–Go to Step 19Go to Step 18

17Replace the EGR valve.

Is the replacement complete?–Go to Step 19–

18Check the ECM electrical connector for a poor con-

nection and repair as necessary.

Is a repair necessary?–Go to Step 19Go to Step 12

191. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specifiec in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 20Go to Step 2

20Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 471 of 2643

ENGINE CONTROLS 1F – 225

DAEWOO V–121 BL4

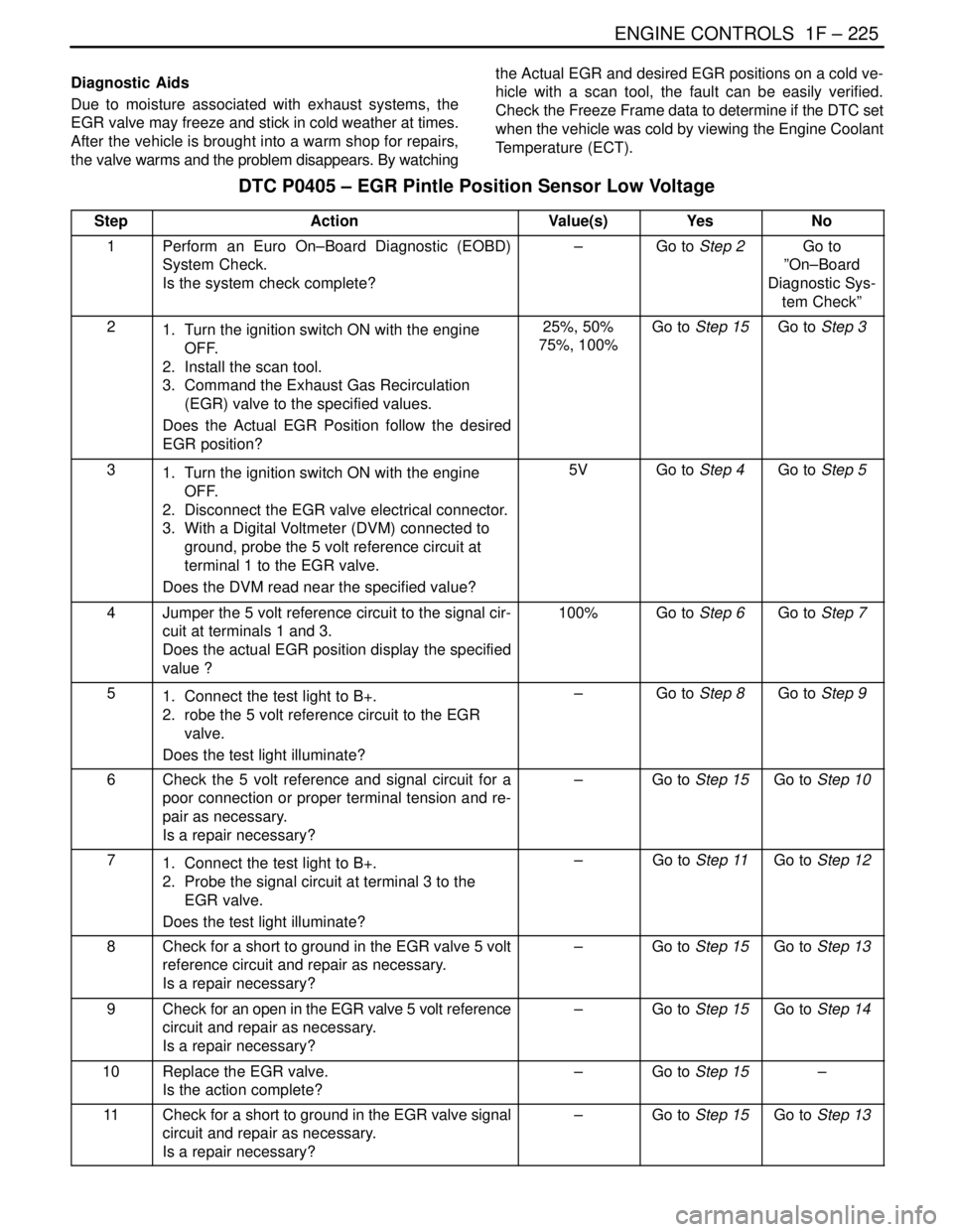

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watchingthe Actual EGR and desired EGR positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the Freeze Frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

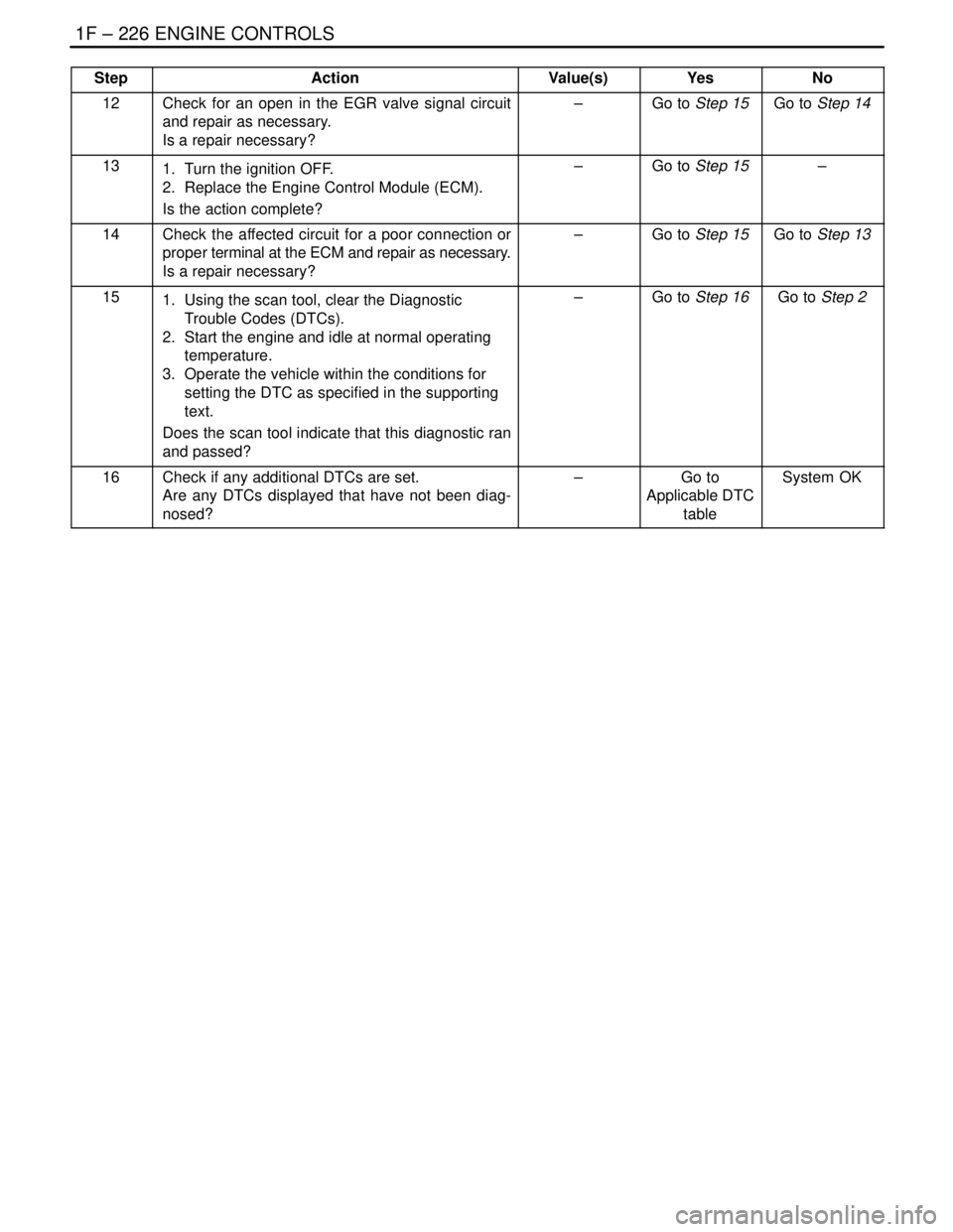

DTC P0405 – EGR Pintle Position Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch ON with the engine

OFF.

2. Install the scan tool.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specified values.

Does the Actual EGR Position follow the desired

EGR position?25%, 50%

75%, 100%Go to Step 15Go to Step 3

31. Turn the ignition switch ON with the engine

OFF.

2. Disconnect the EGR valve electrical connector.

3. With a Digital Voltmeter (DVM) connected to

ground, probe the 5 volt reference circuit at

terminal 1 to the EGR valve.

Does the DVM read near the specified value?5VGo to Step 4Go to Step 5

4Jumper the 5 volt reference circuit to the signal cir-

cuit at terminals 1 and 3.

Does the actual EGR position display the specified

value ?100%Go to Step 6Go to Step 7

51. Connect the test light to B+.

2. robe the 5 volt reference circuit to the EGR

valve.

Does the test light illuminate?–Go to Step 8Go to Step 9

6Check the 5 volt reference and signal circuit for a

poor connection or proper terminal tension and re-

pair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 10

71. Connect the test light to B+.

2. Probe the signal circuit at terminal 3 to the

EGR valve.

Does the test light illuminate?–Go to Step 11Go to Step 12

8Check for a short to ground in the EGR valve 5 volt

reference circuit and repair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 13

9Check for an open in the EGR valve 5 volt reference

circuit and repair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 14

10Replace the EGR valve.

Is the action complete?–Go to Step 15–

11Check for a short to ground in the EGR valve signal

circuit and repair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 13

Page 472 of 2643

1F – 226IENGINE CONTROLS

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

12Check for an open in the EGR valve signal circuit

and repair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 14

131. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the action complete?–Go to Step 15–

14Check the affected circuit for a poor connection or

proper terminal at the ECM and repair as necessary.

Is a repair necessary?–Go to Step 15Go to Step 13

151. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting the DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic ran

and passed?–Go to Step 16Go to Step 2

16Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 474 of 2643

1F – 228IENGINE CONTROLS

DAEWOO V–121 BL4

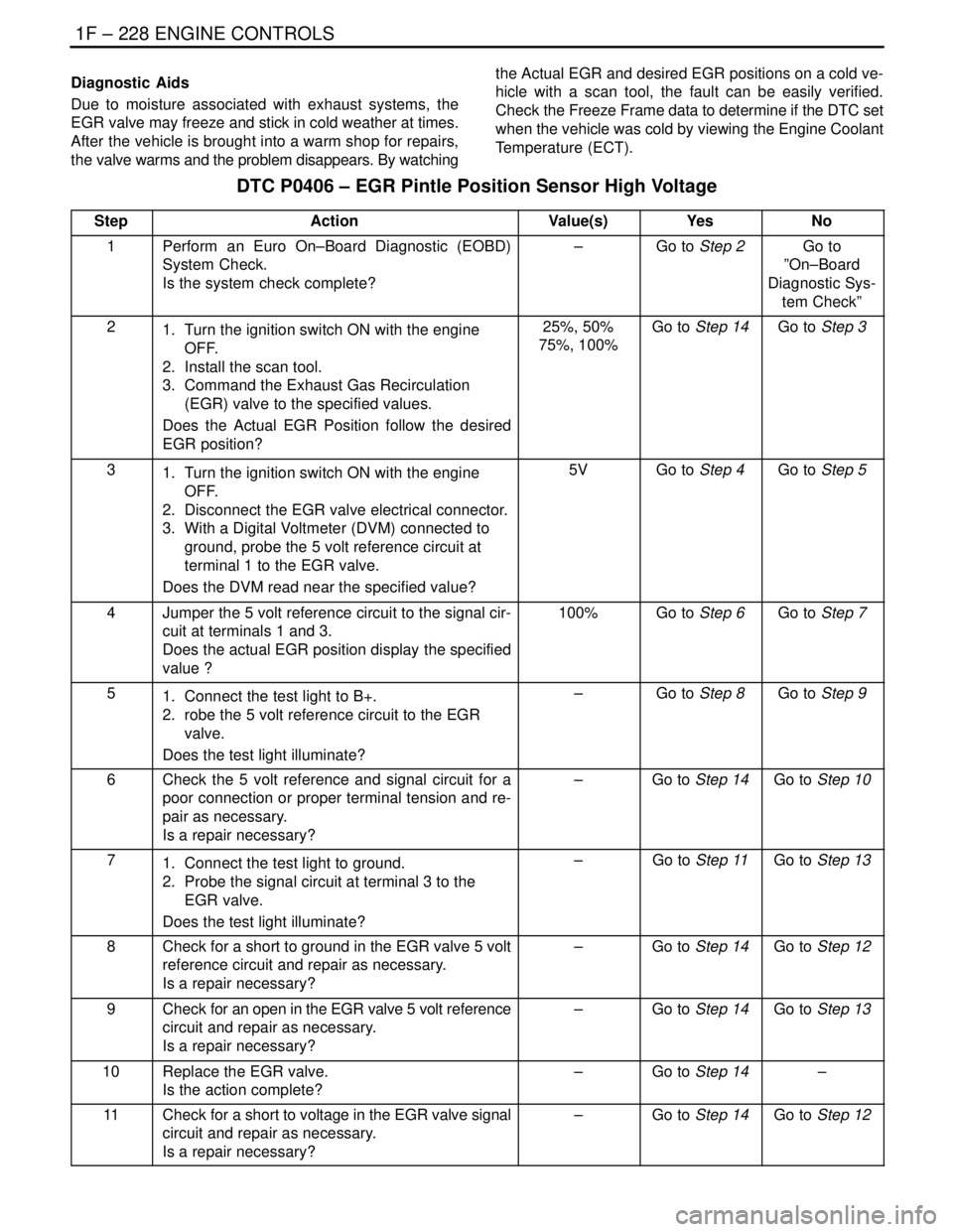

Diagnostic Aids

Due to moisture associated with exhaust systems, the

EGR valve may freeze and stick in cold weather at times.

After the vehicle is brought into a warm shop for repairs,

the valve warms and the problem disappears. By watchingthe Actual EGR and desired EGR positions on a cold ve-

hicle with a scan tool, the fault can be easily verified.

Check the Freeze Frame data to determine if the DTC set

when the vehicle was cold by viewing the Engine Coolant

Temperature (ECT).

DTC P0406 – EGR Pintle Position Sensor High Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch ON with the engine

OFF.

2. Install the scan tool.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specified values.

Does the Actual EGR Position follow the desired

EGR position?25%, 50%

75%, 100%Go to Step 14Go to Step 3

31. Turn the ignition switch ON with the engine

OFF.

2. Disconnect the EGR valve electrical connector.

3. With a Digital Voltmeter (DVM) connected to

ground, probe the 5 volt reference circuit at

terminal 1 to the EGR valve.

Does the DVM read near the specified value?5VGo to Step 4Go to Step 5

4Jumper the 5 volt reference circuit to the signal cir-

cuit at terminals 1 and 3.

Does the actual EGR position display the specified

value ?100%Go to Step 6Go to Step 7

51. Connect the test light to B+.

2. robe the 5 volt reference circuit to the EGR

valve.

Does the test light illuminate?–Go to Step 8Go to Step 9

6Check the 5 volt reference and signal circuit for a

poor connection or proper terminal tension and re-

pair as necessary.

Is a repair necessary?–Go to Step 14Go to Step 10

71. Connect the test light to ground.

2. Probe the signal circuit at terminal 3 to the

EGR valve.

Does the test light illuminate?–Go to Step 11Go to Step 13

8Check for a short to ground in the EGR valve 5 volt

reference circuit and repair as necessary.

Is a repair necessary?–Go to Step 14Go to Step 12

9Check for an open in the EGR valve 5 volt reference

circuit and repair as necessary.

Is a repair necessary?–Go to Step 14Go to Step 13

10Replace the EGR valve.

Is the action complete?–Go to Step 14–

11Check for a short to voltage in the EGR valve signal

circuit and repair as necessary.

Is a repair necessary?–Go to Step 14Go to Step 12