engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 228 of 2643

1E – 14IENGINE ELECTRICAL

DAEWOO V–121 BL4

10. Install the air cleaner outlet hose and connect the

MAT electrical connector.

11. Connect the negative battery cable.

STARTER

Removal Procedure

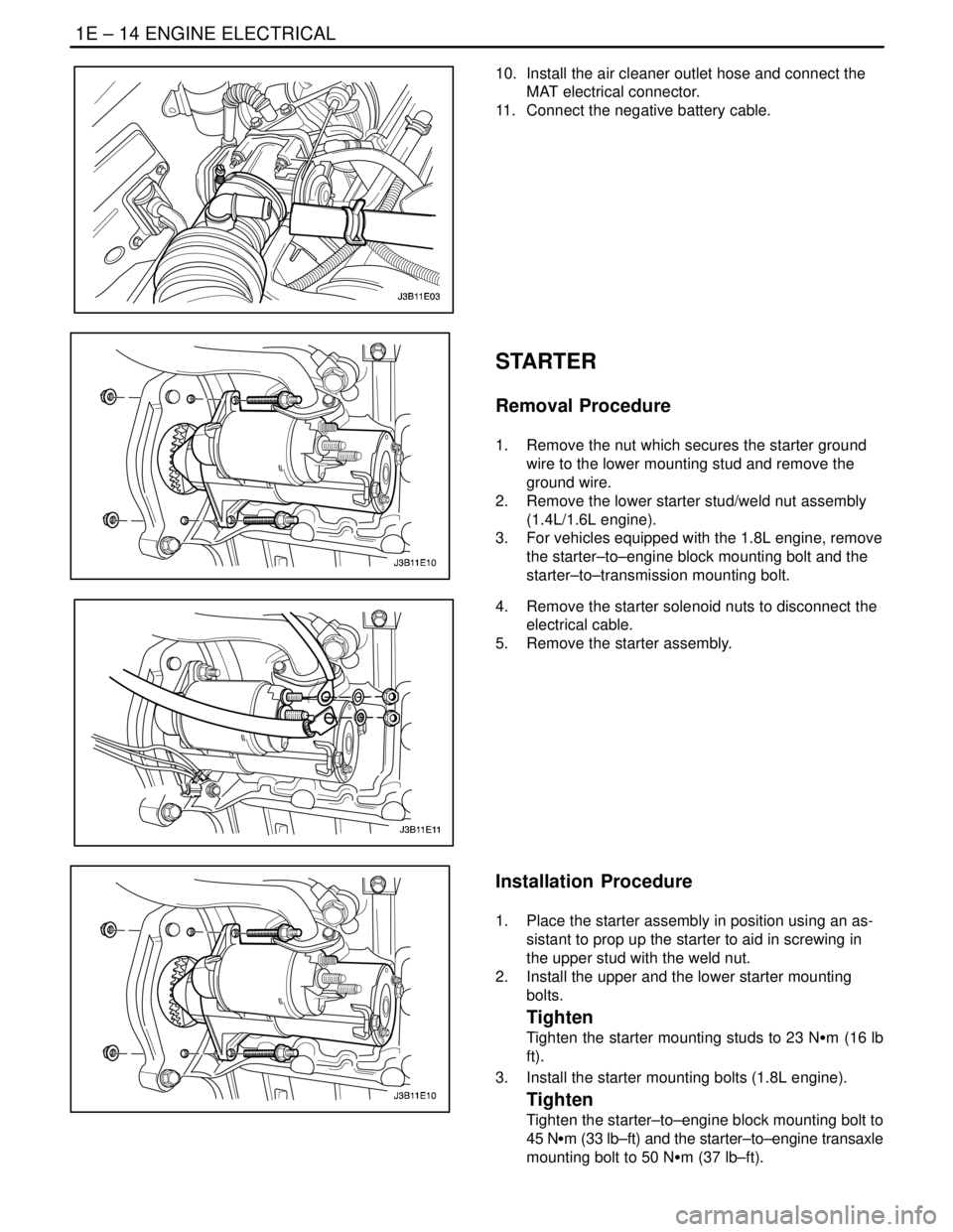

1. Remove the nut which secures the starter ground

wire to the lower mounting stud and remove the

ground wire.

2. Remove the lower starter stud/weld nut assembly

(1.4L/1.6L engine).

3. For vehicles equipped with the 1.8L engine, remove

the starter–to–engine block mounting bolt and the

starter–to–transmission mounting bolt.

4. Remove the starter solenoid nuts to disconnect the

electrical cable.

5. Remove the starter assembly.

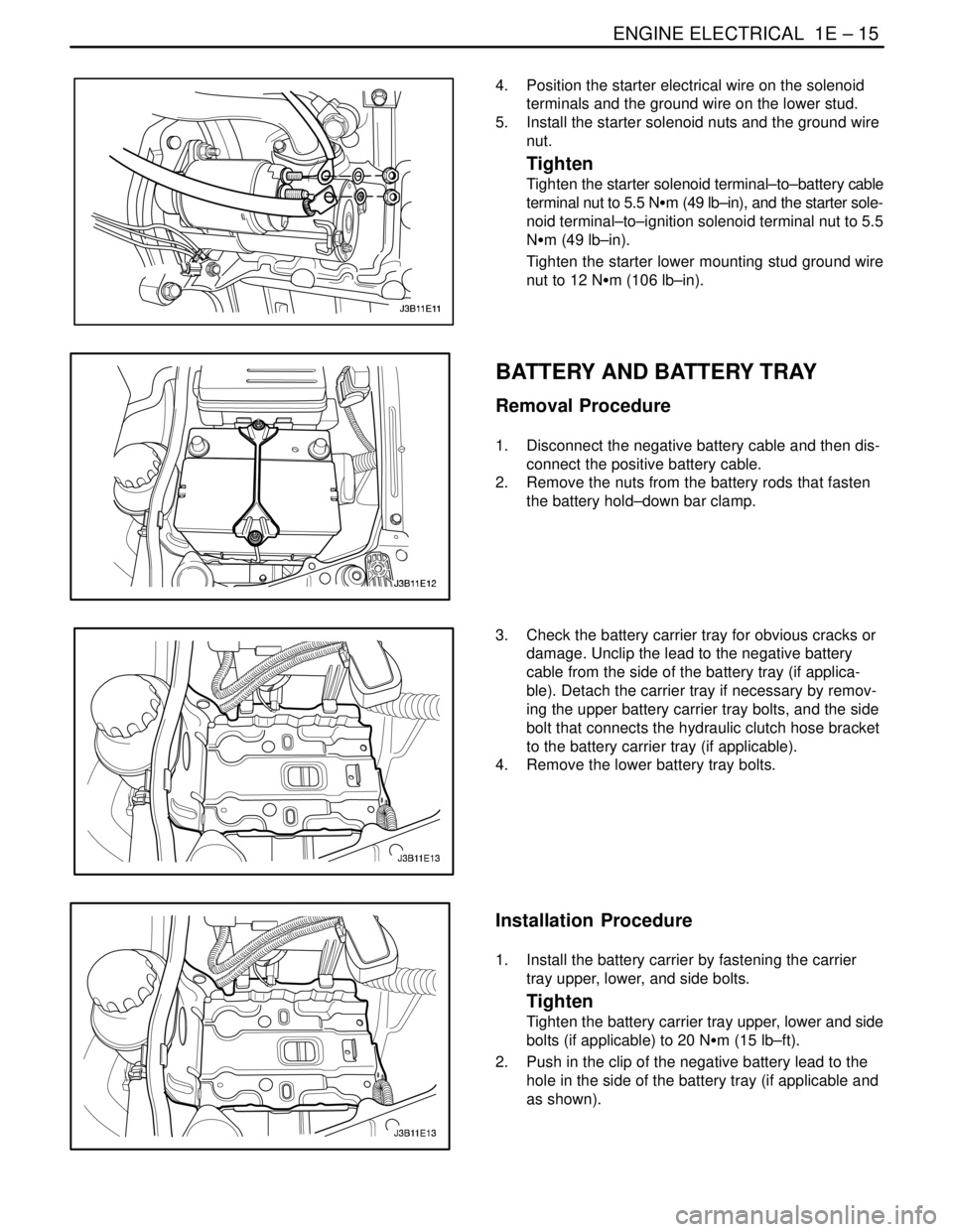

Installation Procedure

1. Place the starter assembly in position using an as-

sistant to prop up the starter to aid in screwing in

the upper stud with the weld nut.

2. Install the upper and the lower starter mounting

bolts.

Tighten

Tighten the starter mounting studs to 23 NSm (16 lb

ft).

3. Install the starter mounting bolts (1.8L engine).

Tighten

Tighten the starter–to–engine block mounting bolt to

45 NSm (33 lb–ft) and the starter–to–engine transaxle

mounting bolt to 50 NSm (37 lb–ft).

Page 229 of 2643

ENGINE ELECTRICAL 1E – 15

DAEWOO V–121 BL4

4. Position the starter electrical wire on the solenoid

terminals and the ground wire on the lower stud.

5. Install the starter solenoid nuts and the ground wire

nut.

Tighten

Tighten the starter solenoid terminal–to–battery cable

terminal nut to 5.5 NSm (49 lb–in), and the starter sole-

noid terminal–to–ignition solenoid terminal nut to 5.5

NSm (49 lb–in).

Tighten the starter lower mounting stud ground wire

nut to 12 NSm (106 lb–in).

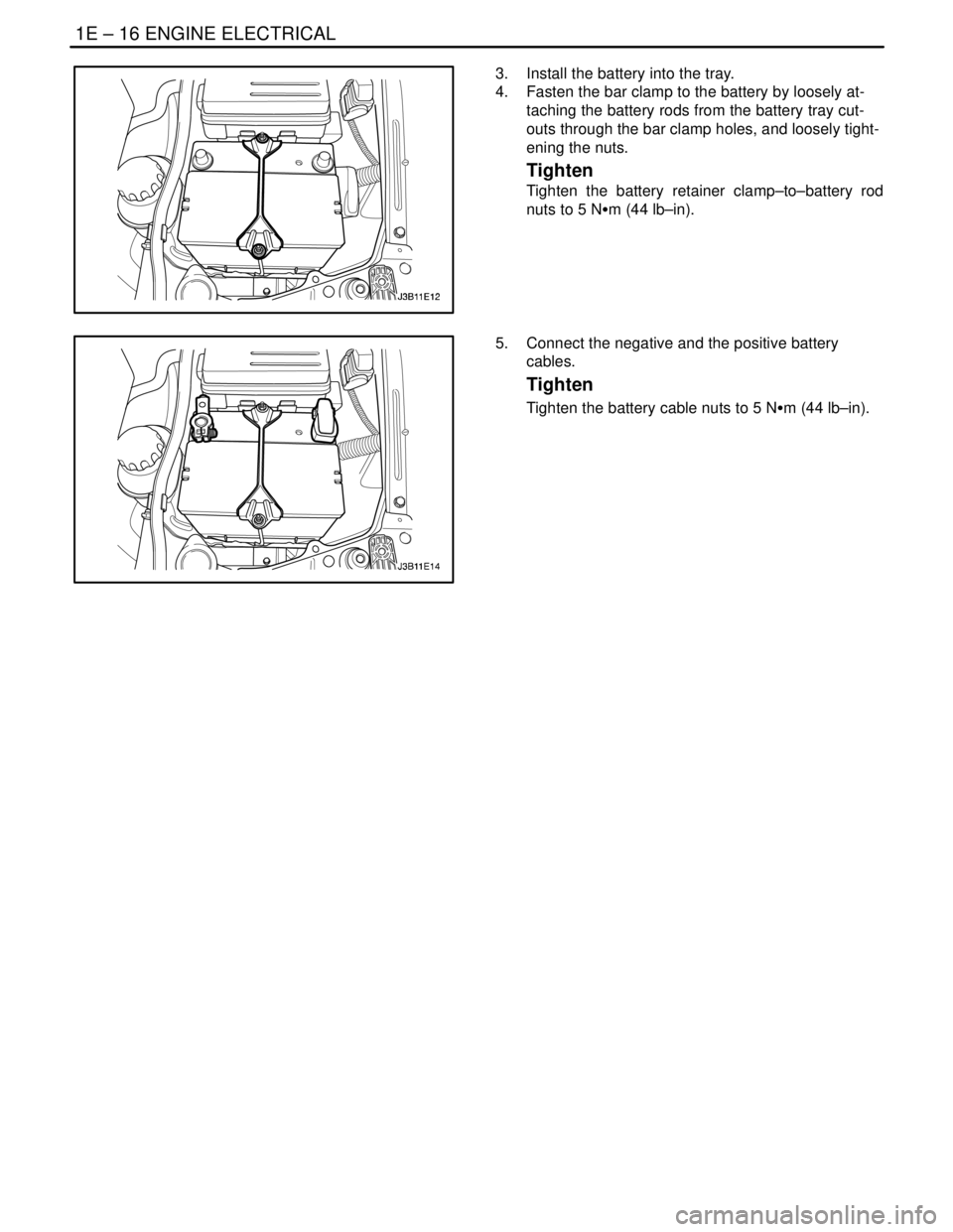

BATTERY AND BATTERY TRAY

Removal Procedure

1. Disconnect the negative battery cable and then dis-

connect the positive battery cable.

2. Remove the nuts from the battery rods that fasten

the battery hold–down bar clamp.

3. Check the battery carrier tray for obvious cracks or

damage. Unclip the lead to the negative battery

cable from the side of the battery tray (if applica-

ble). Detach the carrier tray if necessary by remov-

ing the upper battery carrier tray bolts, and the side

bolt that connects the hydraulic clutch hose bracket

to the battery carrier tray (if applicable).

4. Remove the lower battery tray bolts.

Installation Procedure

1. Install the battery carrier by fastening the carrier

tray upper, lower, and side bolts.

Tighten

Tighten the battery carrier tray upper, lower and side

bolts (if applicable) to 20 NSm (15 lb–ft).

2. Push in the clip of the negative battery lead to the

hole in the side of the battery tray (if applicable and

as shown).

Page 230 of 2643

1E – 16IENGINE ELECTRICAL

DAEWOO V–121 BL4

3. Install the battery into the tray.

4. Fasten the bar clamp to the battery by loosely at-

taching the battery rods from the battery tray cut-

outs through the bar clamp holes, and loosely tight-

ening the nuts.

Tighten

Tighten the battery retainer clamp–to–battery rod

nuts to 5 NSm (44 lb–in).

5. Connect the negative and the positive battery

cables.

Tighten

Tighten the battery cable nuts to 5 NSm (44 lb–in).

Page 231 of 2643

ENGINE ELECTRICAL 1E – 17

DAEWOO V–121 BL4

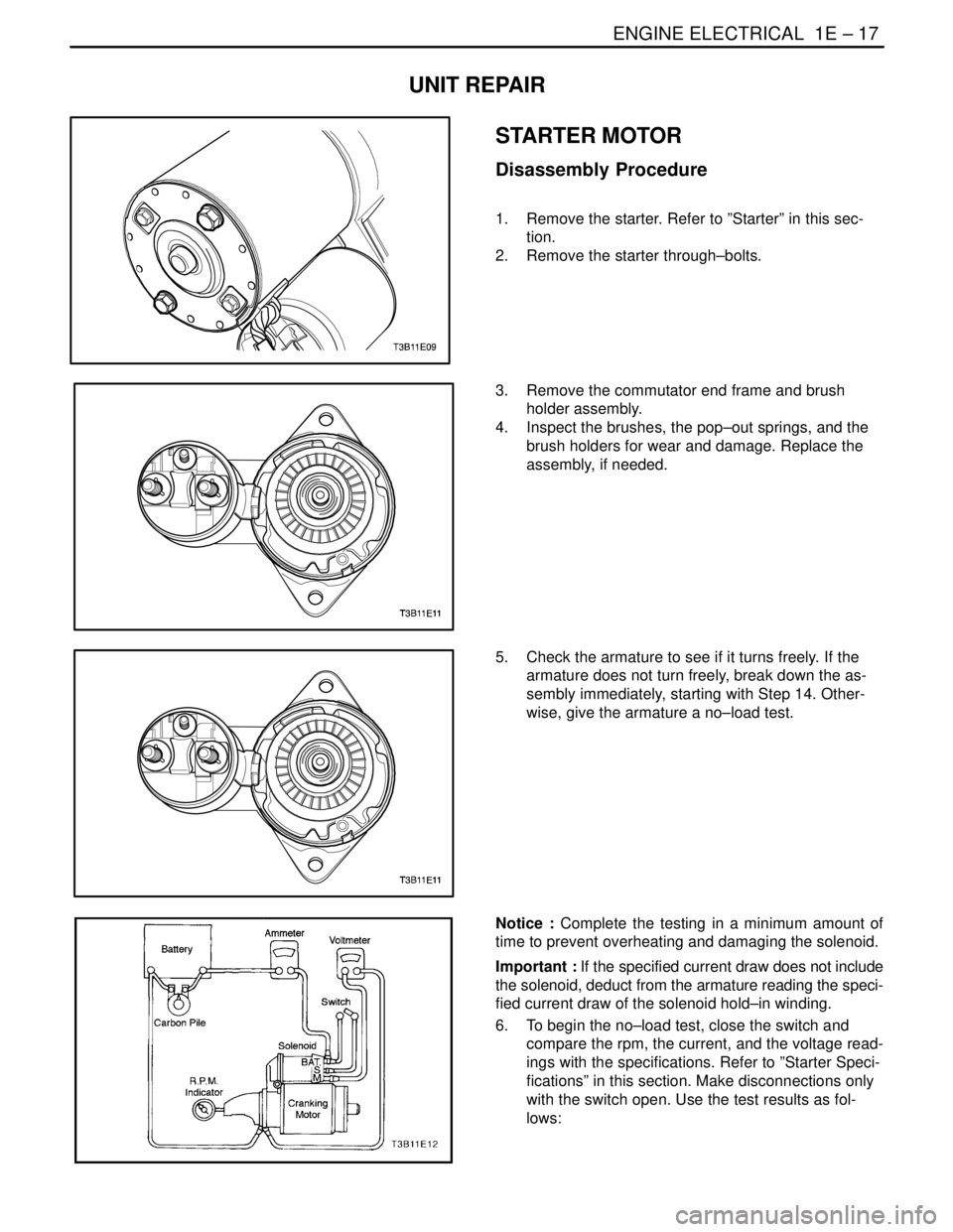

UNIT REPAIR

STARTER MOTOR

Disassembly Procedure

1. Remove the starter. Refer to ”Starter” in this sec-

tion.

2. Remove the starter through–bolts.

3. Remove the commutator end frame and brush

holder assembly.

4. Inspect the brushes, the pop–out springs, and the

brush holders for wear and damage. Replace the

assembly, if needed.

5. Check the armature to see if it turns freely. If the

armature does not turn freely, break down the as-

sembly immediately, starting with Step 14. Other-

wise, give the armature a no–load test.

Notice : Complete the testing in a minimum amount of

time to prevent overheating and damaging the solenoid.

Important : If the specified current draw does not include

the solenoid, deduct from the armature reading the speci-

fied current draw of the solenoid hold–in winding.

6. To begin the no–load test, close the switch and

compare the rpm, the current, and the voltage read-

ings with the specifications. Refer to ”Starter Speci-

fications” in this section. Make disconnections only

with the switch open. Use the test results as fol-

lows:

Page 232 of 2643

1E – 18IENGINE ELECTRICAL

DAEWOO V–121 BL4

1) Rated current draw and no–load speed indicate

a normal condition for the starter motor.

2) Low rpm combined with high current draw is an

indication of excessive friction caused by tight,

dirty, or worn bearings; a bent armature shaft;

a shorted armature; or a shorted field coils.

3) Failure to operate with high current draw indi-

cates a direct ground in the terminal or fields,

or ”frozen” bearings.

4) Failure to operate with no current draw indi-

cates an open field circuit, open armature coils,

broken brush springs, worn brushes, high in-

sulation between the commutator bars, or oth-

er causes which would prevent good contact

between the brushes and the commutator.

5) Low, no–load speed and low current indicate

high internal resistance and high current draw,

which usually mean shorted fields.

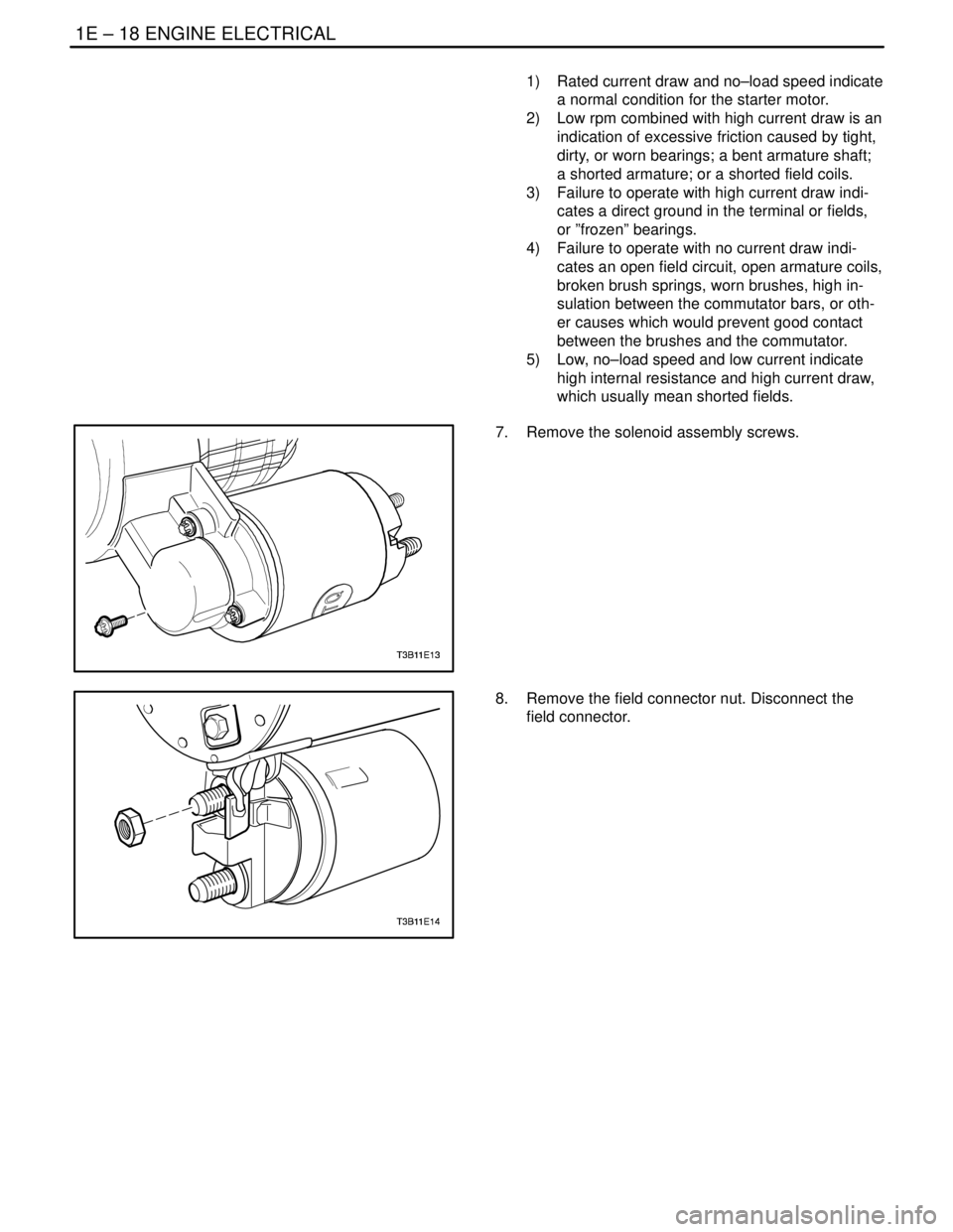

7. Remove the solenoid assembly screws.

8. Remove the field connector nut. Disconnect the

field connector.

Page 233 of 2643

ENGINE ELECTRICAL 1E – 19

DAEWOO V–121 BL4

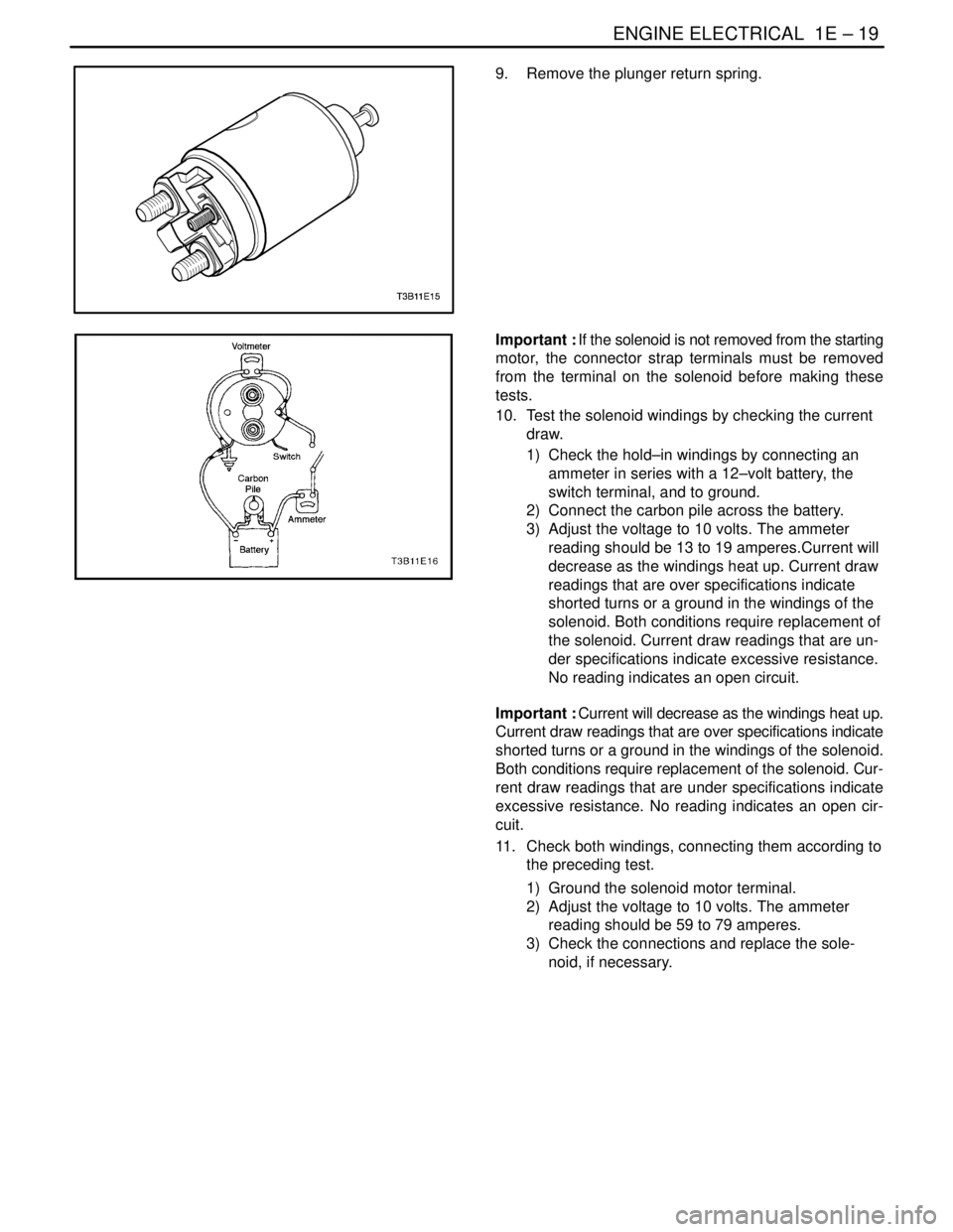

9. Remove the plunger return spring.

Important : If the solenoid is not removed from the starting

motor, the connector strap terminals must be removed

from the terminal on the solenoid before making these

tests.

10. Test the solenoid windings by checking the current

draw.

1) Check the hold–in windings by connecting an

ammeter in series with a 12–volt battery, the

switch terminal, and to ground.

2) Connect the carbon pile across the battery.

3) Adjust the voltage to 10 volts. The ammeter

reading should be 13 to 19 amperes.Current will

decrease as the windings heat up. Current draw

readings that are over specifications indicate

shorted turns or a ground in the windings of the

solenoid. Both conditions require replacement of

the solenoid. Current draw readings that are un-

der specifications indicate excessive resistance.

No reading indicates an open circuit.

Important : Current will decrease as the windings heat up.

Current draw readings that are over specifications indicate

shorted turns or a ground in the windings of the solenoid.

Both conditions require replacement of the solenoid. Cur-

rent draw readings that are under specifications indicate

excessive resistance. No reading indicates an open cir-

cuit.

11. Check both windings, connecting them according to

the preceding test.

1) Ground the solenoid motor terminal.

2) Adjust the voltage to 10 volts. The ammeter

reading should be 59 to 79 amperes.

3) Check the connections and replace the sole-

noid, if necessary.

Page 234 of 2643

1E – 20IENGINE ELECTRICAL

DAEWOO V–121 BL4

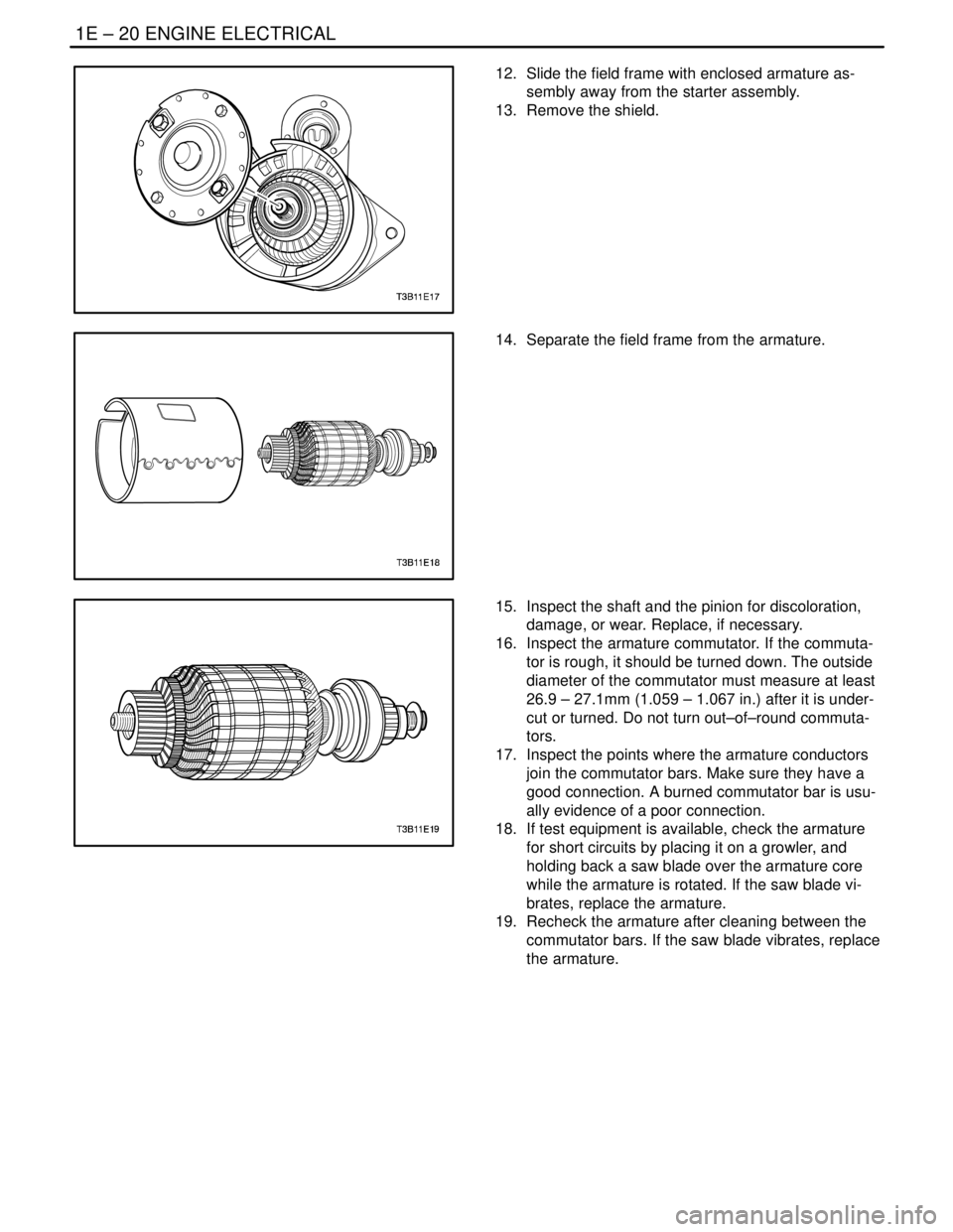

12. Slide the field frame with enclosed armature as-

sembly away from the starter assembly.

13. Remove the shield.

14. Separate the field frame from the armature.

15. Inspect the shaft and the pinion for discoloration,

damage, or wear. Replace, if necessary.

16. Inspect the armature commutator. If the commuta-

tor is rough, it should be turned down. The outside

diameter of the commutator must measure at least

26.9 – 27.1mm (1.059 – 1.067 in.) after it is under-

cut or turned. Do not turn out–of–round commuta-

tors.

17. Inspect the points where the armature conductors

join the commutator bars. Make sure they have a

good connection. A burned commutator bar is usu-

ally evidence of a poor connection.

18. If test equipment is available, check the armature

for short circuits by placing it on a growler, and

holding back a saw blade over the armature core

while the armature is rotated. If the saw blade vi-

brates, replace the armature.

19. Recheck the armature after cleaning between the

commutator bars. If the saw blade vibrates, replace

the armature.

Page 235 of 2643

ENGINE ELECTRICAL 1E – 21

DAEWOO V–121 BL4

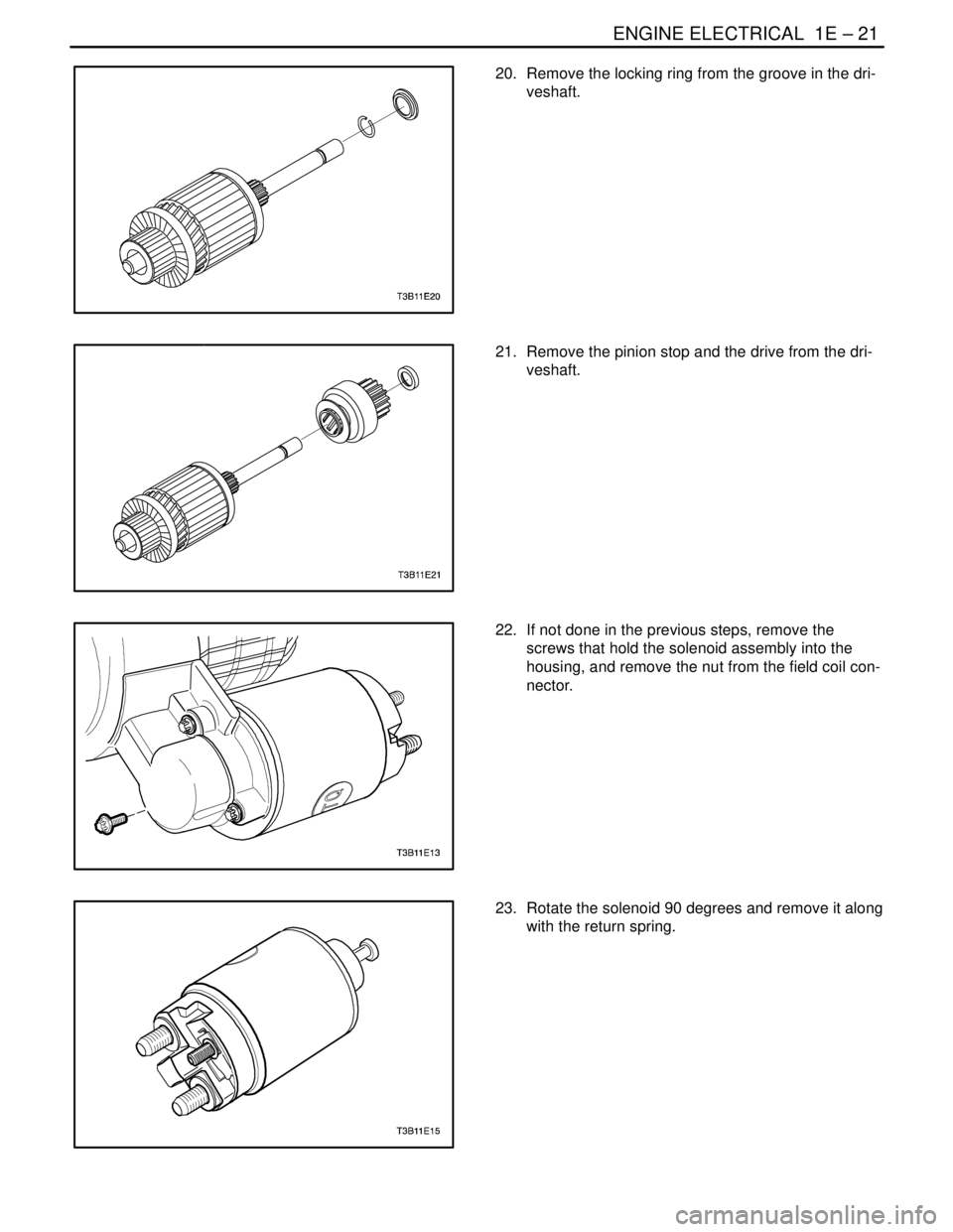

20. Remove the locking ring from the groove in the dri-

veshaft.

21. Remove the pinion stop and the drive from the dri-

veshaft.

22. If not done in the previous steps, remove the

screws that hold the solenoid assembly into the

housing, and remove the nut from the field coil con-

nector.

23. Rotate the solenoid 90 degrees and remove it along

with the return spring.

Page 236 of 2643

1E – 22IENGINE ELECTRICAL

DAEWOO V–121 BL4

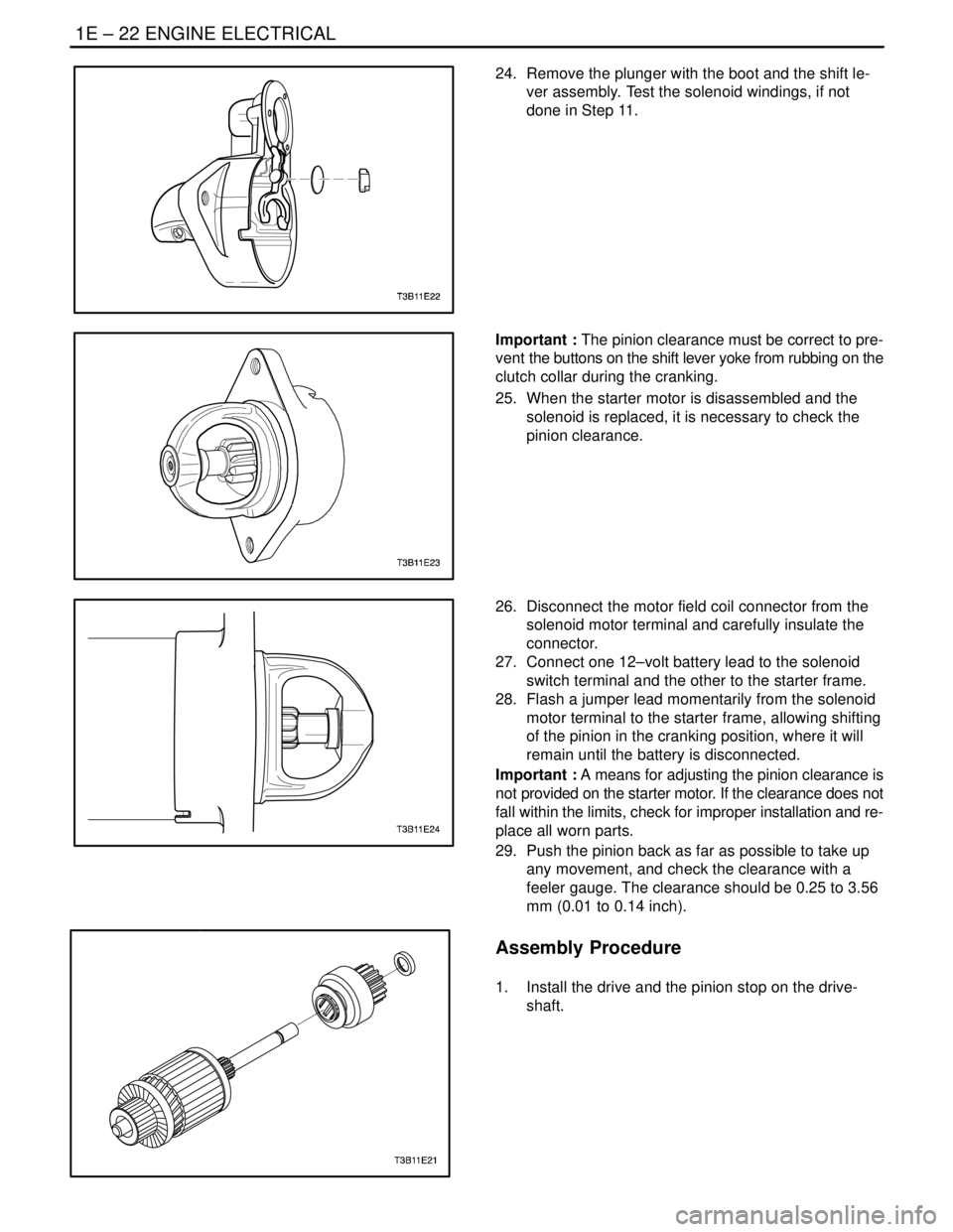

24. Remove the plunger with the boot and the shift le-

ver assembly. Test the solenoid windings, if not

done in Step 11.

Important : The pinion clearance must be correct to pre-

vent the buttons on the shift lever yoke from rubbing on the

clutch collar during the cranking.

25. When the starter motor is disassembled and the

solenoid is replaced, it is necessary to check the

pinion clearance.

26. Disconnect the motor field coil connector from the

solenoid motor terminal and carefully insulate the

connector.

27. Connect one 12–volt battery lead to the solenoid

switch terminal and the other to the starter frame.

28. Flash a jumper lead momentarily from the solenoid

motor terminal to the starter frame, allowing shifting

of the pinion in the cranking position, where it will

remain until the battery is disconnected.

Important : A means for adjusting the pinion clearance is

not provided on the starter motor. If the clearance does not

fall within the limits, check for improper installation and re-

place all worn parts.

29. Push the pinion back as far as possible to take up

any movement, and check the clearance with a

feeler gauge. The clearance should be 0.25 to 3.56

mm (0.01 to 0.14 inch).

Assembly Procedure

1. Install the drive and the pinion stop on the drive-

shaft.

Page 237 of 2643

ENGINE ELECTRICAL 1E – 23

DAEWOO V–121 BL4

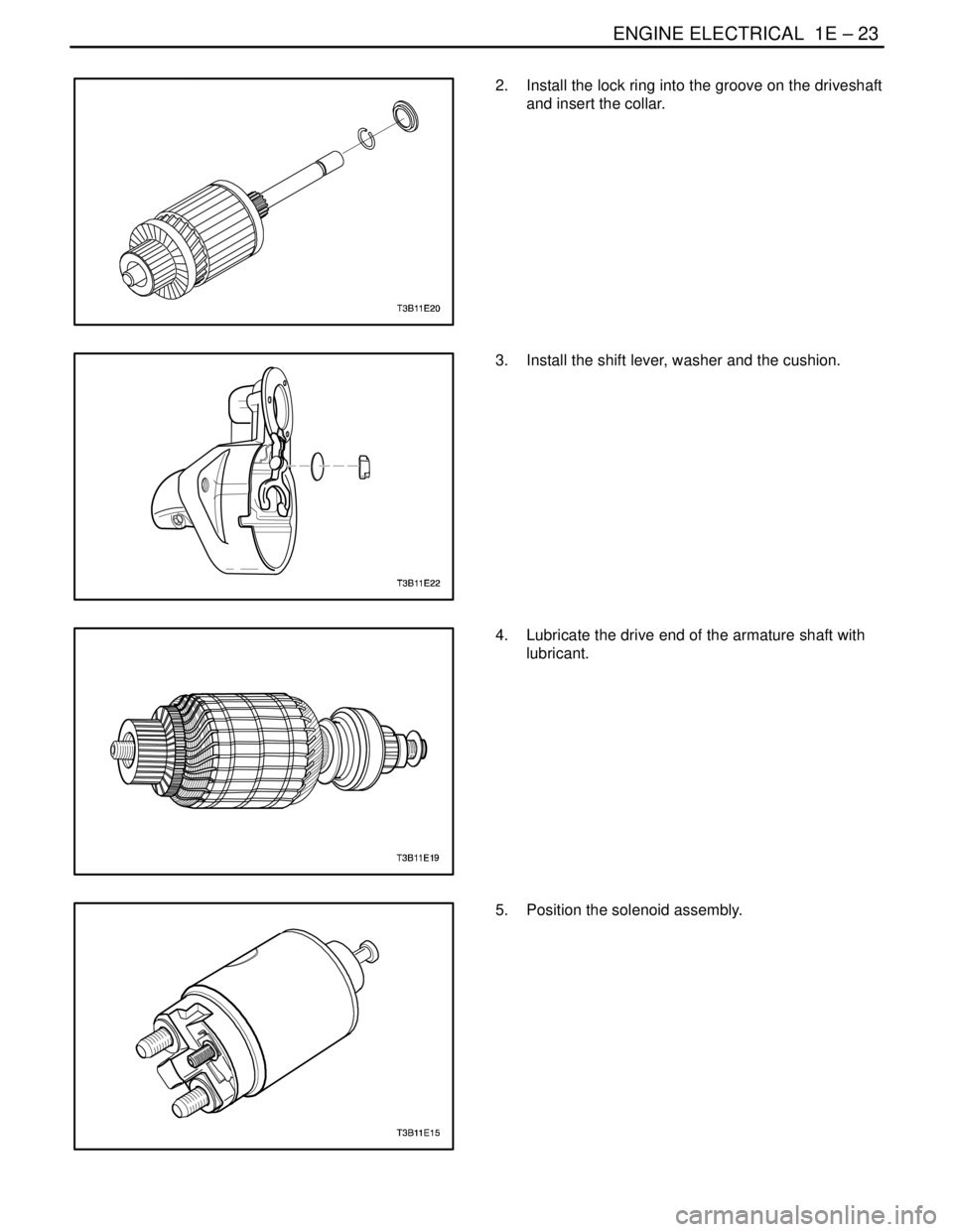

2. Install the lock ring into the groove on the driveshaft

and insert the collar.

3. Install the shift lever, washer and the cushion.

4. Lubricate the drive end of the armature shaft with

lubricant.

5. Position the solenoid assembly.