light DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1936 of 2643

POWER STEERING GEAR 6C – 19

DAEWOO V–121 BL4

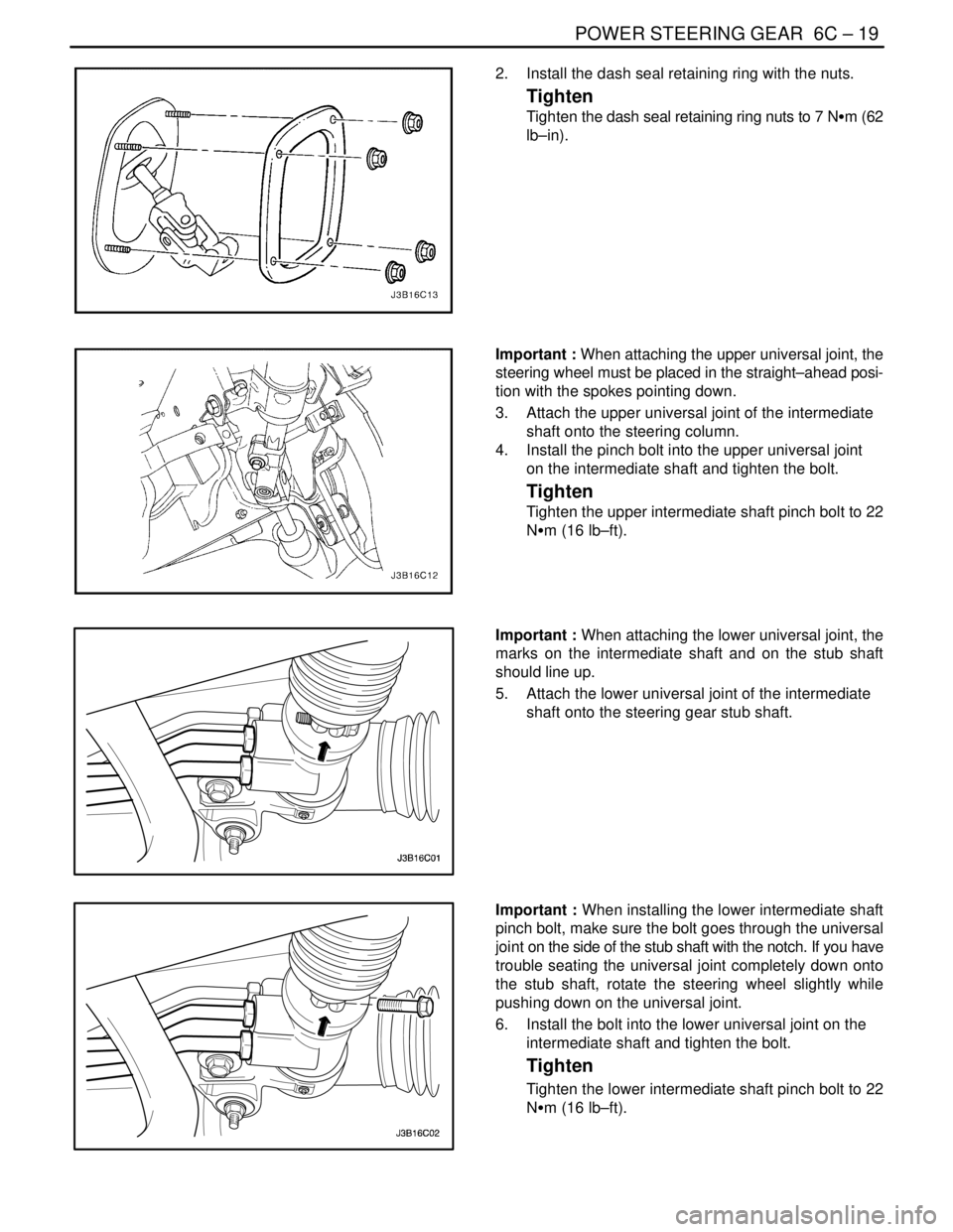

2. Install the dash seal retaining ring with the nuts.

Tighten

Tighten the dash seal retaining ring nuts to 7 NSm (62

lb–in).

Important : When attaching the upper universal joint, the

steering wheel must be placed in the straight–ahead posi-

tion with the spokes pointing down.

3. Attach the upper universal joint of the intermediate

shaft onto the steering column.

4. Install the pinch bolt into the upper universal joint

on the intermediate shaft and tighten the bolt.

Tighten

Tighten the upper intermediate shaft pinch bolt to 22

NSm (16 lb–ft).

Important : When attaching the lower universal joint, the

marks on the intermediate shaft and on the stub shaft

should line up.

5. Attach the lower universal joint of the intermediate

shaft onto the steering gear stub shaft.

Important : When installing the lower intermediate shaft

pinch bolt, make sure the bolt goes through the universal

joint on the side of the stub shaft with the notch. If you have

trouble seating the universal joint completely down onto

the stub shaft, rotate the steering wheel slightly while

pushing down on the universal joint.

6. Install the bolt into the lower universal joint on the

intermediate shaft and tighten the bolt.

Tighten

Tighten the lower intermediate shaft pinch bolt to 22

NSm (16 lb–ft).

Page 1951 of 2643

6C – 34IPOWER STEERING GEAR

DAEWOO V–121 BL4

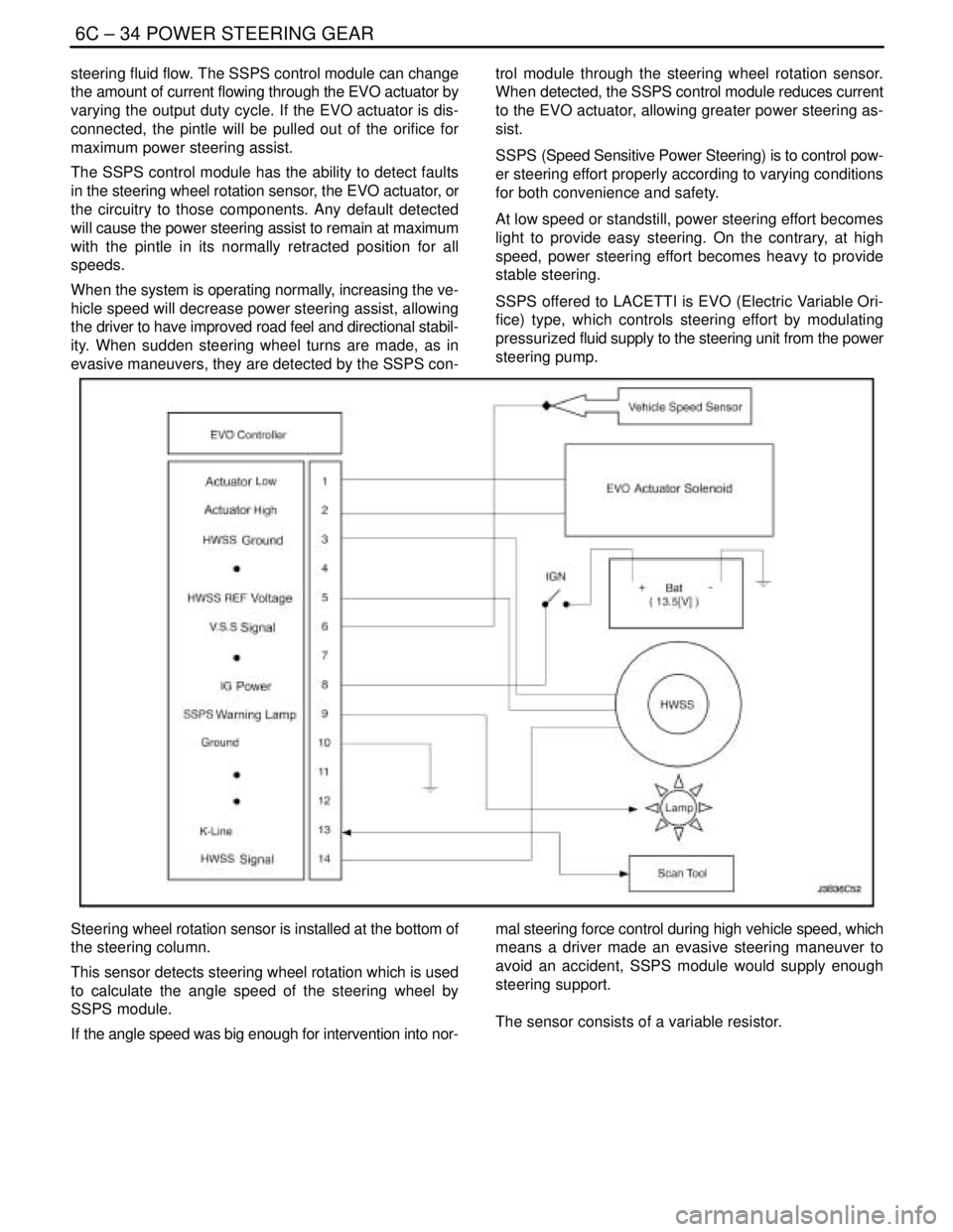

steering fluid flow. The SSPS control module can change

the amount of current flowing through the EVO actuator by

varying the output duty cycle. If the EVO actuator is dis-

connected, the pintle will be pulled out of the orifice for

maximum power steering assist.

The SSPS control module has the ability to detect faults

in the steering wheel rotation sensor, the EVO actuator, or

the circuitry to those components. Any default detected

will cause the power steering assist to remain at maximum

with the pintle in its normally retracted position for all

speeds.

When the system is operating normally, increasing the ve-

hicle speed will decrease power steering assist, allowing

the driver to have improved road feel and directional stabil-

ity. When sudden steering wheel turns are made, as in

evasive maneuvers, they are detected by the SSPS con-trol module through the steering wheel rotation sensor.

When detected, the SSPS control module reduces current

to the EVO actuator, allowing greater power steering as-

sist.

SSPS (Speed Sensitive Power Steering) is to control pow-

er steering effort properly according to varying conditions

for both convenience and safety.

At low speed or standstill, power steering effort becomes

light to provide easy steering. On the contrary, at high

speed, power steering effort becomes heavy to provide

stable steering.

SSPS offered to LACETTI is EVO (Electric Variable Ori-

fice) type, which controls steering effort by modulating

pressurized fluid supply to the steering unit from the power

steering pump.

Steering wheel rotation sensor is installed at the bottom of

the steering column.

This sensor detects steering wheel rotation which is used

to calculate the angle speed of the steering wheel by

SSPS module.

If the angle speed was big enough for intervention into nor-mal steering force control during high vehicle speed, which

means a driver made an evasive steering maneuver to

avoid an accident, SSPS module would supply enough

steering support.

The sensor consists of a variable resistor.

Page 1953 of 2643

6C – 36IPOWER STEERING GEAR

DAEWOO V–121 BL4

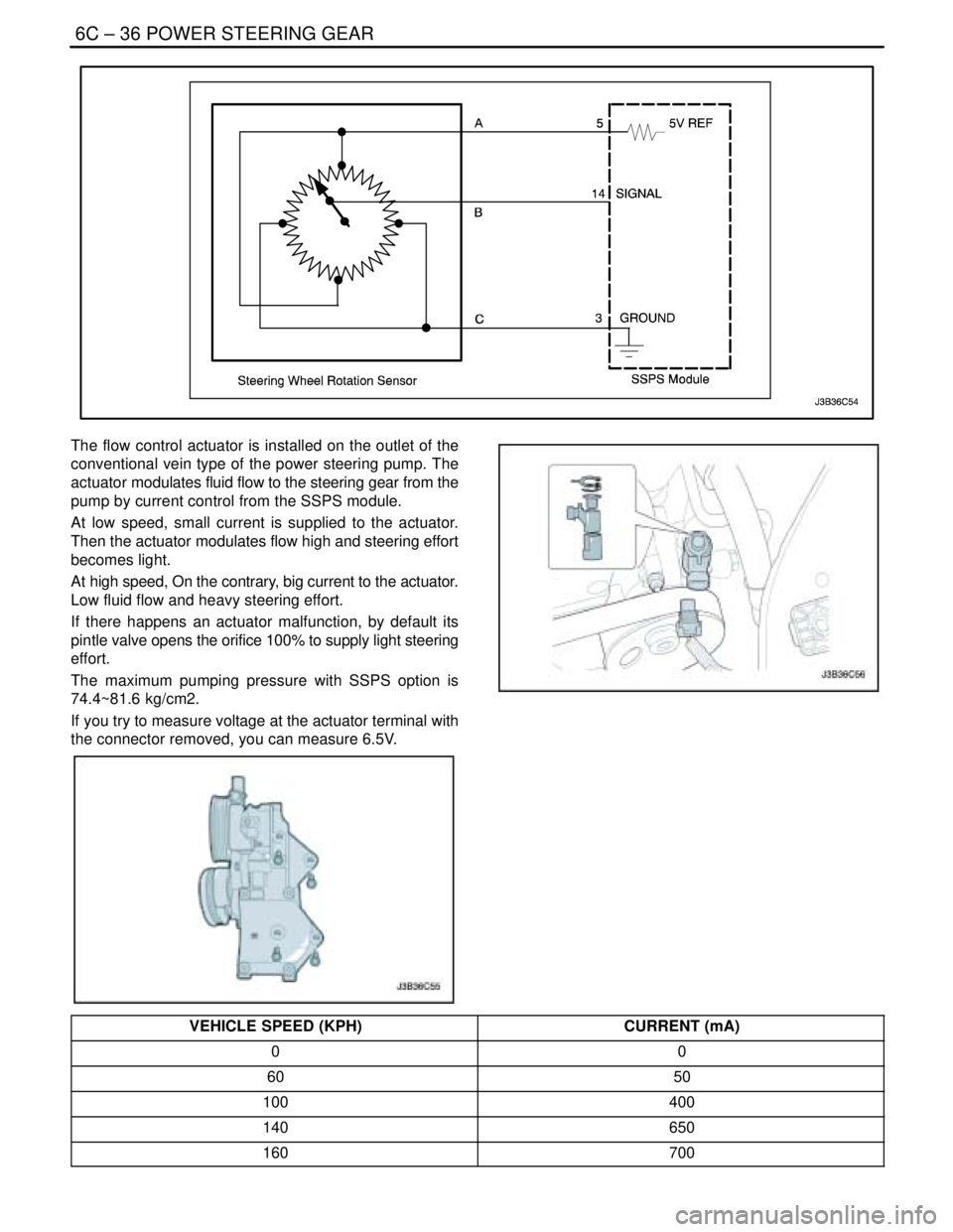

The flow control actuator is installed on the outlet of the

conventional vein type of the power steering pump. The

actuator modulates fluid flow to the steering gear from the

pump by current control from the SSPS module.

At low speed, small current is supplied to the actuator.

Then the actuator modulates flow high and steering effort

becomes light.

At high speed, On the contrary, big current to the actuator.

Low fluid flow and heavy steering effort.

If there happens an actuator malfunction, by default its

pintle valve opens the orifice 100% to supply light steering

effort.

The maximum pumping pressure with SSPS option is

74.4~81.6 kg/cm2.

If you try to measure voltage at the actuator terminal with

the connector removed, you can measure 6.5V.

VEHICLE SPEED (KPH)CURRENT (mA)

00

6050

100400

140650

160700

Page 1954 of 2643

![DAEWOO NUBIRA 2004 Service Repair Manual POWER STEERING GEAR 6C – 37

DAEWOO V–121 BL4

[Vehicle Speed – Actuator Current Relation]

SOLENOID RESISTANCE

13 W

The control module is installed on the right side of the au-

dio and can be acc DAEWOO NUBIRA 2004 Service Repair Manual POWER STEERING GEAR 6C – 37

DAEWOO V–121 BL4

[Vehicle Speed – Actuator Current Relation]

SOLENOID RESISTANCE

13 W

The control module is installed on the right side of the au-

dio and can be acc](/img/54/56879/w960_56879-1953.png)

POWER STEERING GEAR 6C – 37

DAEWOO V–121 BL4

[Vehicle Speed – Actuator Current Relation]

SOLENOID RESISTANCE

13 W

The control module is installed on the right side of the au-

dio and can be accessible after the glove box is removed.

It receives signals from the vehicle speed sensor and the

steering wheel rotation sensor and processes them to de-

cide proper fluid flow through the actuator.

It also has a self–diagnosis. If it detects any malfunction,

it starts default mode, which is basically actuator full open

for light steering effort.

TERMINALCOLORFUNCTION

1SBActuator Low

2VActuator High

3BWSteering Wheel Sensor Ground

4–Not used

5GrSteering Wheel Sensor 5V ref.

6GWVSS

7–Not Used

8PIGN ON

9BrWarning Lamp

10BWGround

11–Not Used

12–Not Used

13LDiagnosis

14SBSteering Wheel Sensor Signal

Page 1960 of 2643

6E – 6ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

Turn Signal/Dimmer Switch

Turn Signal Will Not Stay in the Turn Position

ChecksAction

Check the turn signal switch for an improper installation.Remove and inspect the turn signal switch. Reinstall the

switch.

Check the cancelling mechanism for broken or missing

components.Replace the cancelling mechanism.

Check the turn signal switch housing for foreign material.Remove any foreign material.

Turn Signal Will Not Cancel

ChecksAction

Check the cancelling mechanism for broken or missing

components.Replace the cancelling mechanism.

Turn Signal/Dimmer Switch Difficult to Operate

ChecksAction

Check the turn signal/dimmer switch and turn signal/dim-

mer switch lever for improper installation.Remove and inspect the turn signal/dimmer switch and

signal/dimmer switch lever. Reinstall the signal/dimmer

switch and signal/dimmer switch lever.

Check the signal/dimmer switch housing for foreign mate-

rial.Remove any foreign material.

Turn Signal Will Not Indicate Lane Change

ChecksAction

Check for a broken lane change pressure pad or a broken

spring hanger.Replace the lane change pressure pad or the spring hang-

er.

Check for improper functioning of the lane change spring.Replace the lane change spring.

Check the turn signal switch for improper installation.Replace the turn signal switch.

No Turn Signal Lights

ChecksAction

Check for an inoperative turn signal flasher.Replace the turn signal flasher.

Check for a faulty turn signal switch.Replace the turn signal switch.

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Turn Indicator Lights On, but Not Flashing

ChecksAction

Check for an inoperative turn signal flasher.Replace the turn signal flasher.

Check for a faulty turn signal switch.Replace the turn signal switch.

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Page 1961 of 2643

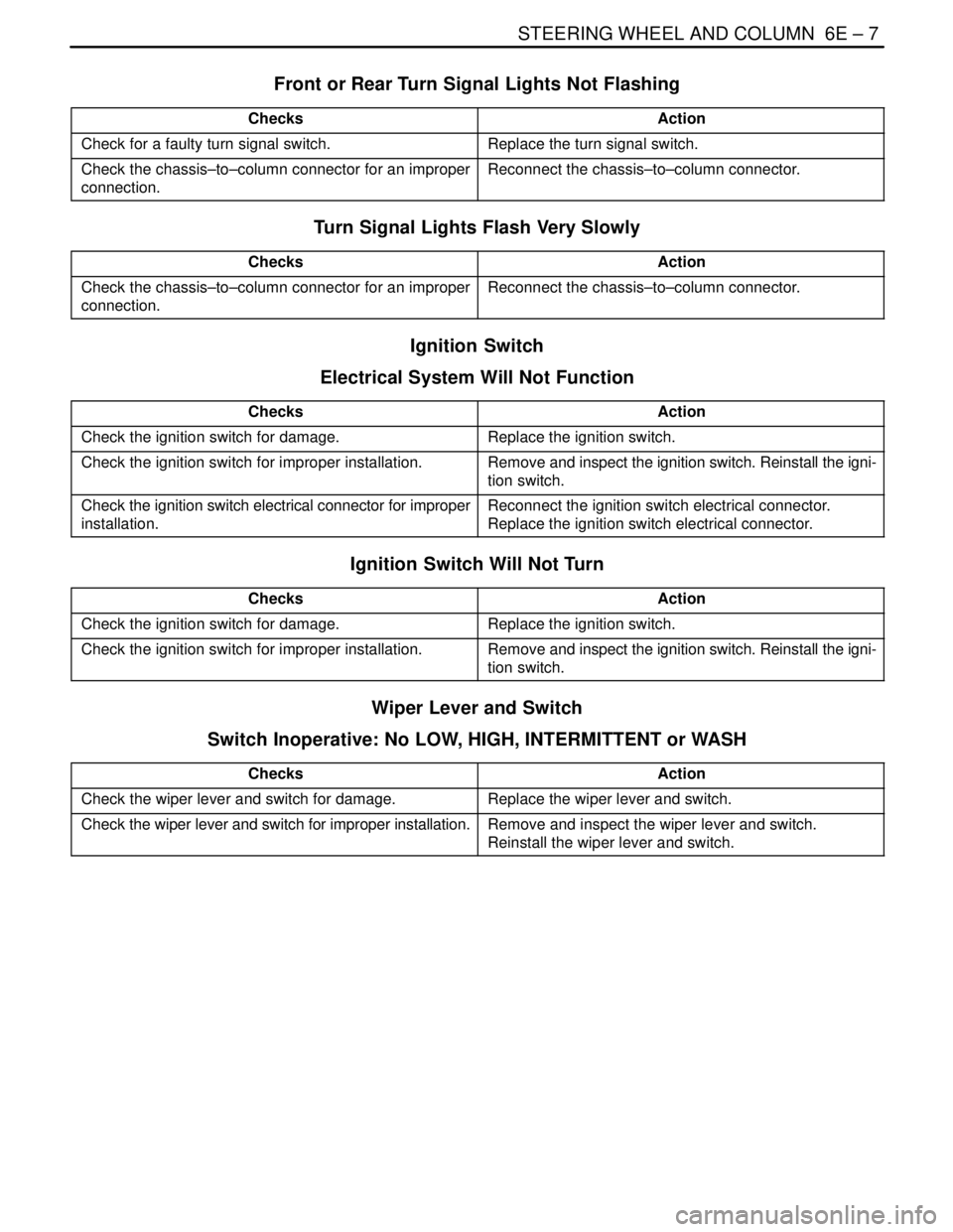

STEERING WHEEL AND COLUMN 6E – 7

DAEWOO V–121 BL4

Front or Rear Turn Signal Lights Not Flashing

ChecksAction

Check for a faulty turn signal switch.Replace the turn signal switch.

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Turn Signal Lights Flash Very Slowly

ChecksAction

Check the chassis–to–column connector for an improper

connection.Reconnect the chassis–to–column connector.

Ignition Switch

Electrical System Will Not Function

ChecksAction

Check the ignition switch for damage.Replace the ignition switch.

Check the ignition switch for improper installation.Remove and inspect the ignition switch. Reinstall the igni-

tion switch.

Check the ignition switch electrical connector for improper

installation.Reconnect the ignition switch electrical connector.

Replace the ignition switch electrical connector.

Ignition Switch Will Not Turn

ChecksAction

Check the ignition switch for damage.Replace the ignition switch.

Check the ignition switch for improper installation.Remove and inspect the ignition switch. Reinstall the igni-

tion switch.

Wiper Lever and Switch

Switch Inoperative: No LOW, HIGH, INTERMITTENT or WASH

ChecksAction

Check the wiper lever and switch for damage.Replace the wiper lever and switch.

Check the wiper lever and switch for improper installation.Remove and inspect the wiper lever and switch.

Reinstall the wiper lever and switch.

Page 1974 of 2643

6E – 20ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

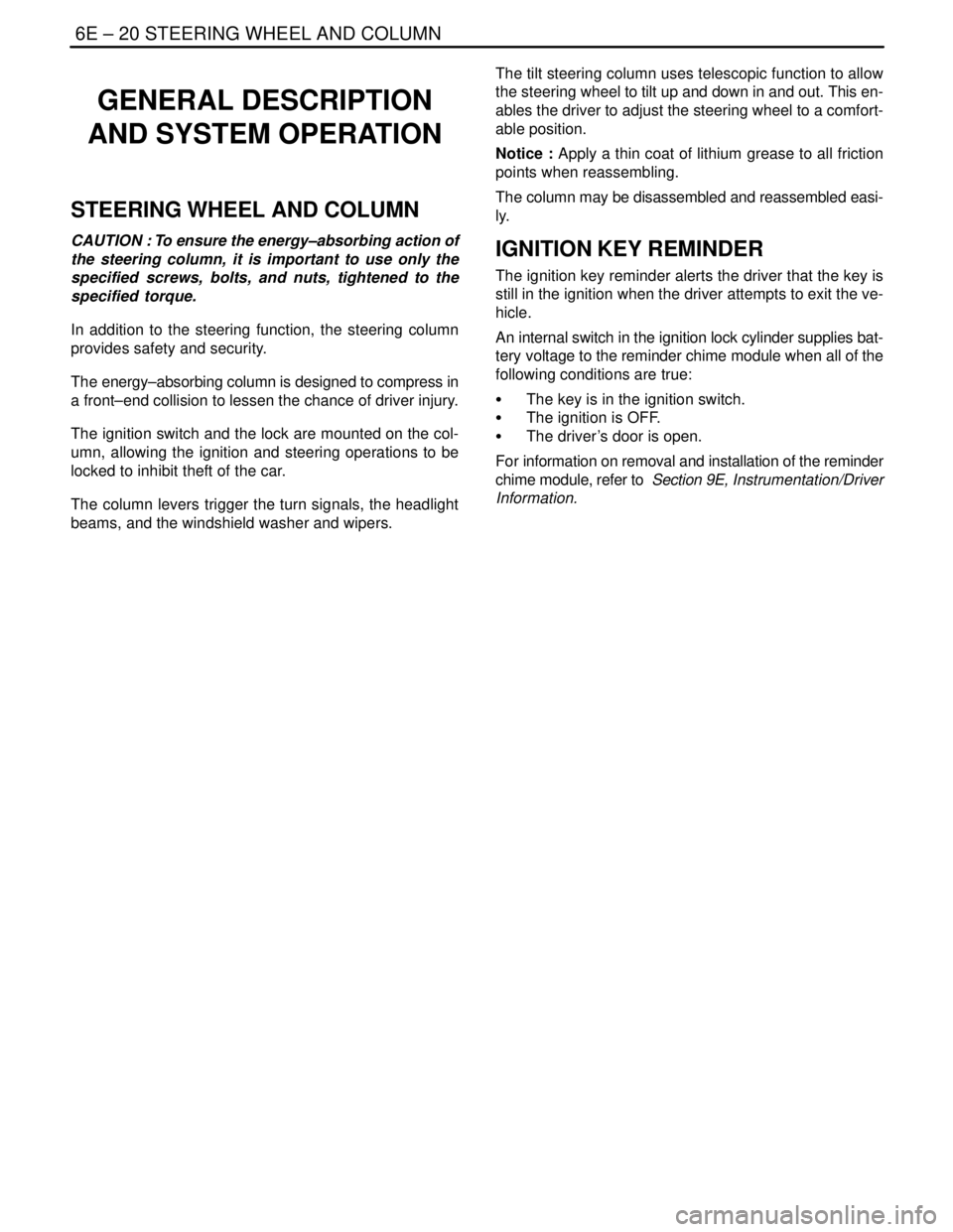

GENERAL DESCRIPTION

AND SYSTEM OPERATION

STEERING WHEEL AND COLUMN

CAUTION : To ensure the energy–absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy–absorbing column is designed to compress in

a front–end collision to lessen the chance of driver injury.

The ignition switch and the lock are mounted on the col-

umn, allowing the ignition and steering operations to be

locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.The tilt steering column uses telescopic function to allow

the steering wheel to tilt up and down in and out. This en-

ables the driver to adjust the steering wheel to a comfort-

able position.

Notice : Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled easi-

ly.IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key is

still in the ignition when the driver attempts to exit the ve-

hicle.

An internal switch in the ignition lock cylinder supplies bat-

tery voltage to the reminder chime module when all of the

following conditions are true:

S The key is in the ignition switch.

S The ignition is OFF.

S The driver’s door is open.

For information on removal and installation of the reminder

chime module, refer to Section 9E, Instrumentation/Driver

Information.

Page 1975 of 2643

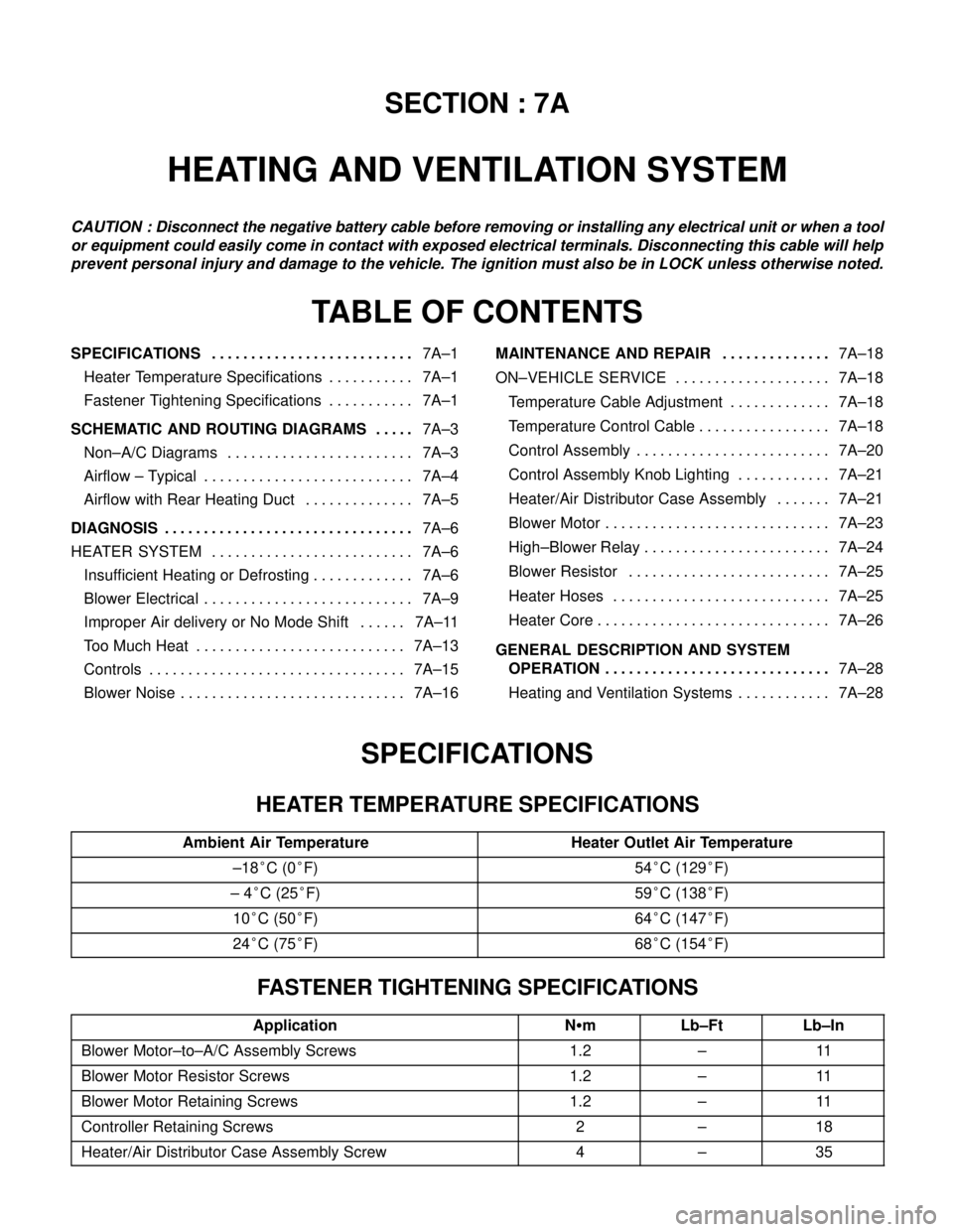

SECTION : 7A

HEATING AND VENTILATION SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS7A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Temperature Specifications 7A–1. . . . . . . . . . .

Fastener Tightening Specifications 7A–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS7A–3 . . . . .

Non–A/C Diagrams 7A–3. . . . . . . . . . . . . . . . . . . . . . . .

Airflow – Typical 7A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Airflow with Rear Heating Duct 7A–5. . . . . . . . . . . . . .

DIAGNOSIS7A–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEATER SYSTEM 7A–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Insufficient Heating or Defrosting 7A–6. . . . . . . . . . . . .

Blower Electrical 7A–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Improper Air delivery or No Mode Shift 7A–11. . . . . .

Too Much Heat 7A–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 7A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Noise 7A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAINTENANCE AND REPAIR7A–18 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 7A–18. . . . . . . . . . . . . . . . . . . .

Temperature Cable Adjustment 7A–18. . . . . . . . . . . . .

Temperature Control Cable 7A–18. . . . . . . . . . . . . . . . .

Control Assembly 7A–20. . . . . . . . . . . . . . . . . . . . . . . . .

Control Assembly Knob Lighting 7A–21. . . . . . . . . . . .

Heater/Air Distributor Case Assembly 7A–21. . . . . . .

Blower Motor 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High–Blower Relay 7A–24. . . . . . . . . . . . . . . . . . . . . . . .

Blower Resistor 7A–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Hoses 7A–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Core 7A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION7A–28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating and Ventilation Systems 7A–28. . . . . . . . . . . .

SPECIFICATIONS

HEATER TEMPERATURE SPECIFICATIONS

Ambient Air TemperatureHeater Outlet Air Temperature

–18°C (0°F)54°C (129°F)

– 4°C (25°F)59°C (138°F)

10°C (50°F)64°C (147°F)

24°C (75°F)68°C (154°F)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Blower Motor–to–A/C Assembly Screws1.2–11

Blower Motor Resistor Screws1.2–11

Blower Motor Retaining Screws1.2–11

Controller Retaining Screws2–18

Heater/Air Distributor Case Assembly Screw4–35

Page 1984 of 2643

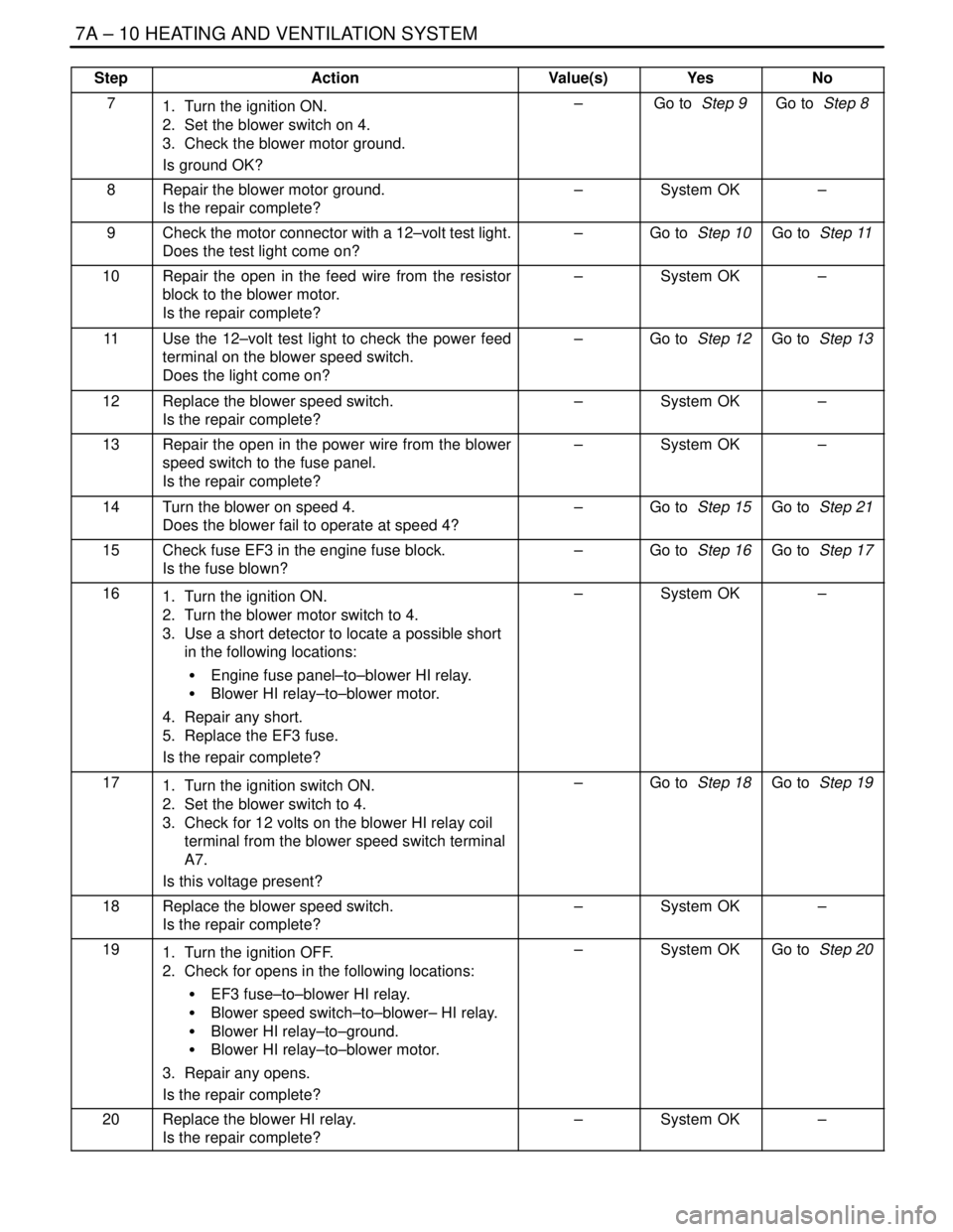

7A – 10IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

71. Turn the ignition ON.

2. Set the blower switch on 4.

3. Check the blower motor ground.

Is ground OK?–Go to Step 9Go to Step 8

8Repair the blower motor ground.

Is the repair complete?–System OK–

9Check the motor connector with a 12–volt test light.

Does the test light come on?–Go to Step 10Go to Step 11

10Repair the open in the feed wire from the resistor

block to the blower motor.

Is the repair complete?–System OK–

11Use the 12–volt test light to check the power feed

terminal on the blower speed switch.

Does the light come on?–Go to Step 12Go to Step 13

12Replace the blower speed switch.

Is the repair complete?–System OK–

13Repair the open in the power wire from the blower

speed switch to the fuse panel.

Is the repair complete?–System OK–

14Turn the blower on speed 4.

Does the blower fail to operate at speed 4?–Go to Step 15Go to Step 21

15Check fuse EF3 in the engine fuse block.

Is the fuse blown?–Go to Step 16Go to Step 17

161. Turn the ignition ON.

2. Turn the blower motor switch to 4.

3. Use a short detector to locate a possible short

in the following locations:

S Engine fuse panel–to–blower HI relay.

S Blower HI relay–to–blower motor.

4. Repair any short.

5. Replace the EF3 fuse.

Is the repair complete?–System OK–

171. Turn the ignition switch ON.

2. Set the blower switch to 4.

3. Check for 12 volts on the blower HI relay coil

terminal from the blower speed switch terminal

A7.

Is this voltage present?–Go to Step 18Go to Step 19

18Replace the blower speed switch.

Is the repair complete?–System OK–

191. Turn the ignition OFF.

2. Check for opens in the following locations:

S EF3 fuse–to–blower HI relay.

S Blower speed switch–to–blower– HI relay.

S Blower HI relay–to–ground.

S Blower HI relay–to–blower motor.

3. Repair any opens.

Is the repair complete?–System OKGo to Step 20

20Replace the blower HI relay.

Is the repair complete?–System OK–

Page 1985 of 2643

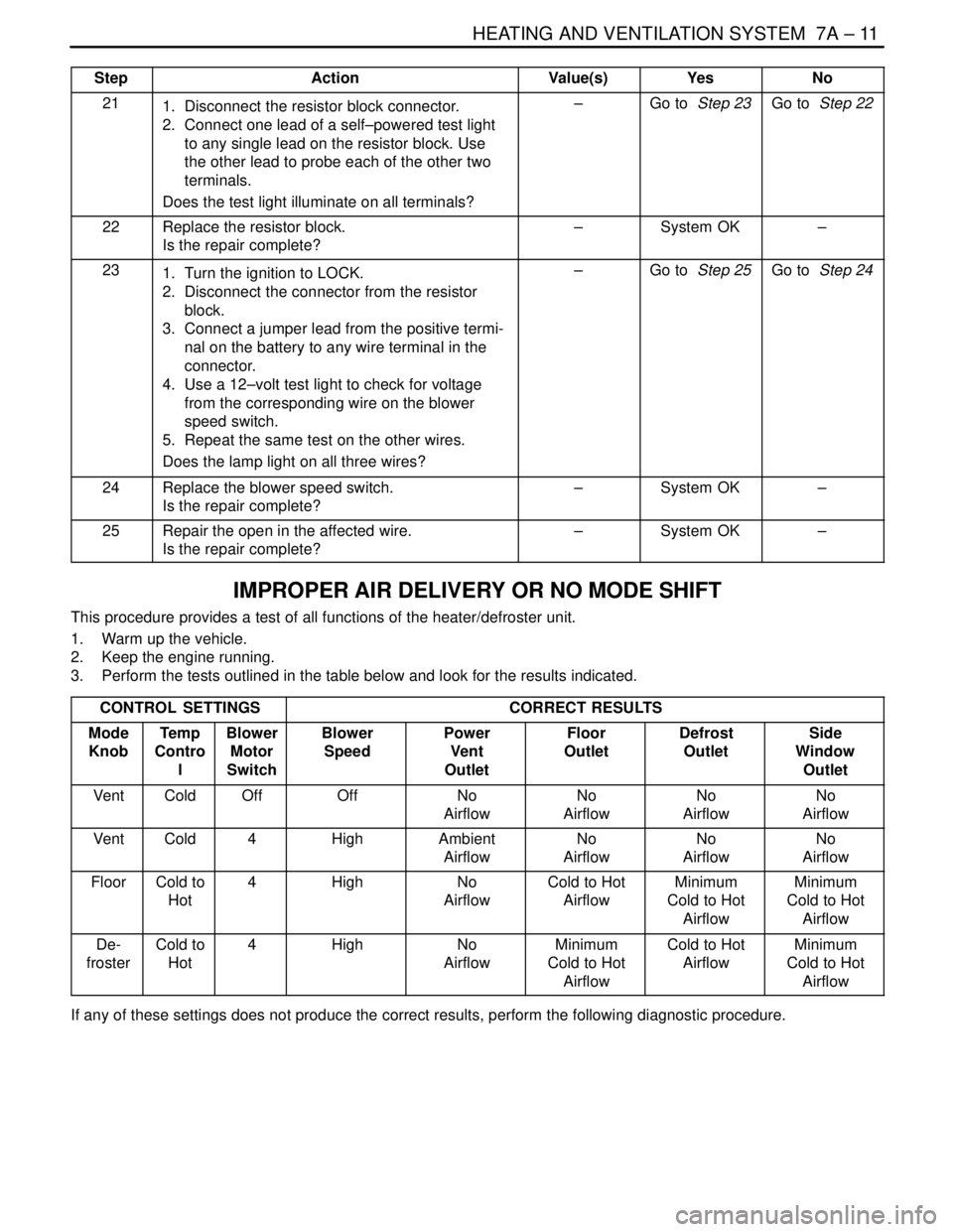

HEATING AND VENTILATION SYSTEM 7A – 11

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

211. Disconnect the resistor block connector.

2. Connect one lead of a self–powered test light

to any single lead on the resistor block. Use

the other lead to probe each of the other two

terminals.

Does the test light illuminate on all terminals?–Go to Step 23Go to Step 22

22Replace the resistor block.

Is the repair complete?–System OK–

231. Turn the ignition to LOCK.

2. Disconnect the connector from the resistor

block.

3. Connect a jumper lead from the positive termi-

nal on the battery to any wire terminal in the

connector.

4. Use a 12–volt test light to check for voltage

from the corresponding wire on the blower

speed switch.

5. Repeat the same test on the other wires.

Does the lamp light on all three wires?–Go to Step 25Go to Step 24

24Replace the blower speed switch.

Is the repair complete?–System OK–

25Repair the open in the affected wire.

Is the repair complete?–System OK–

IMPROPER AIR DELIVERY OR NO MODE SHIFT

This procedure provides a test of all functions of the heater/defroster unit.

1. Warm up the vehicle.

2. Keep the engine running.

3. Perform the tests outlined in the table below and look for the results indicated.

CONTROL SETTINGS

CORRECT RESULTS

Mode

KnobTe m p

Contro

lBlower

Motor

SwitchBlower

SpeedPower

Vent

OutletFloor

OutletDefrost

OutletSide

Window

Outlet

VentColdOffOffNo

AirflowNo

AirflowNo

AirflowNo

Airflow

VentCold4HighAmbient

AirflowNo

AirflowNo

AirflowNo

Airflow

FloorCold to

Hot4HighNo

AirflowCold to Hot

AirflowMinimum

Cold to Hot

AirflowMinimum

Cold to Hot

Airflow

De-

frosterCold to

Hot4HighNo

AirflowMinimum

Cold to Hot

AirflowCold to Hot

AirflowMinimum

Cold to Hot

Airflow

If any of these settings does not produce the correct results, perform the following diagnostic procedure.