key battery DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 768 of 2643

1F – 522IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1106

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT HIGH

VOLTAGE

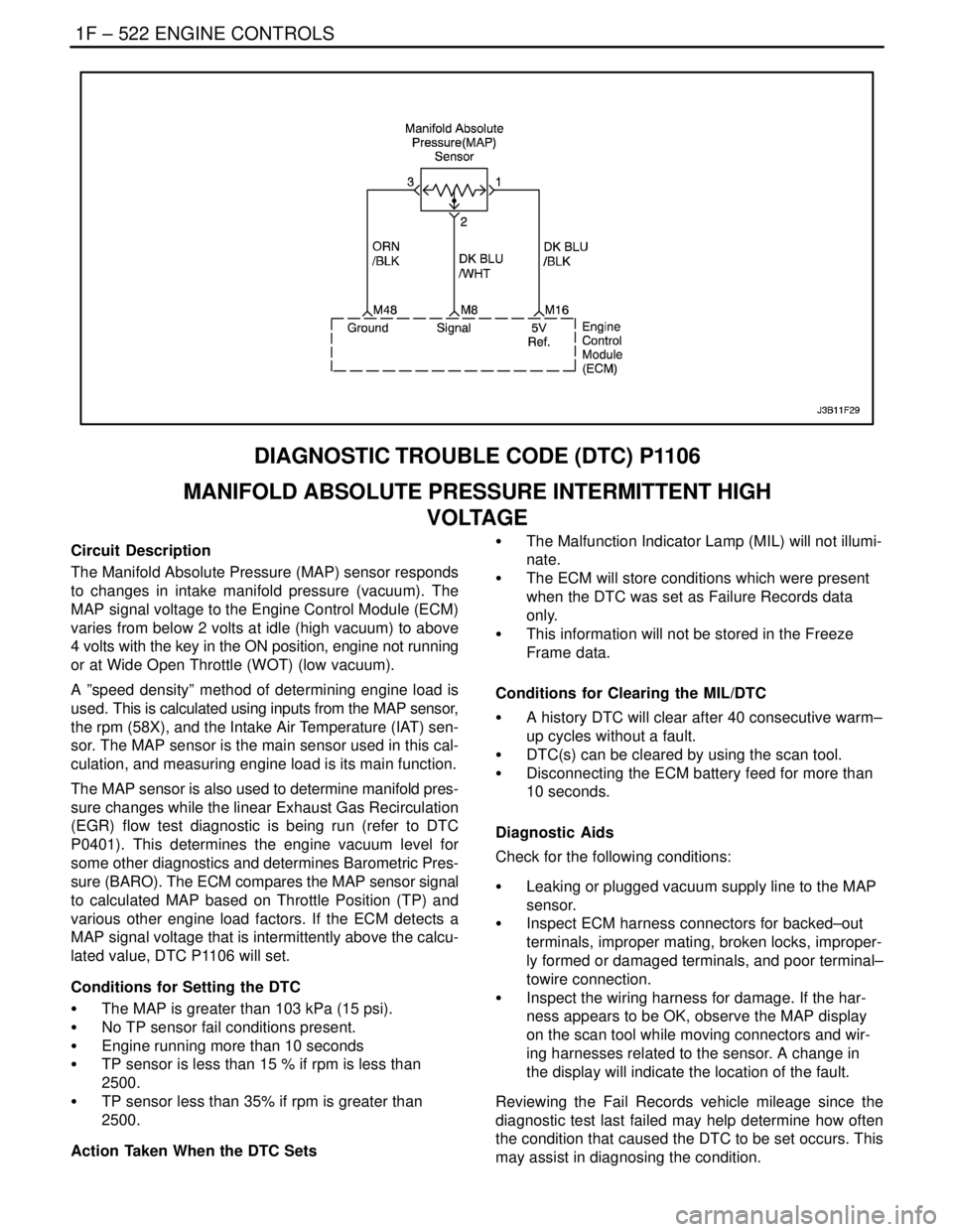

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently above the calcu-

lated value, DTC P1106 will set.

Conditions for Setting the DTC

S The MAP is greater than 103 kPa (15 psi).

S No TP sensor fail conditions present.

S Engine running more than 10 seconds

S TP sensor is less than 15 % if rpm is less than

2500.

S TP sensor less than 35% if rpm is greater than

2500.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

towire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 770 of 2643

1F – 524IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1107

MANIFOLD ABSOLUTE PRESSURE INTERMITTENT LOW

VOLTAGE

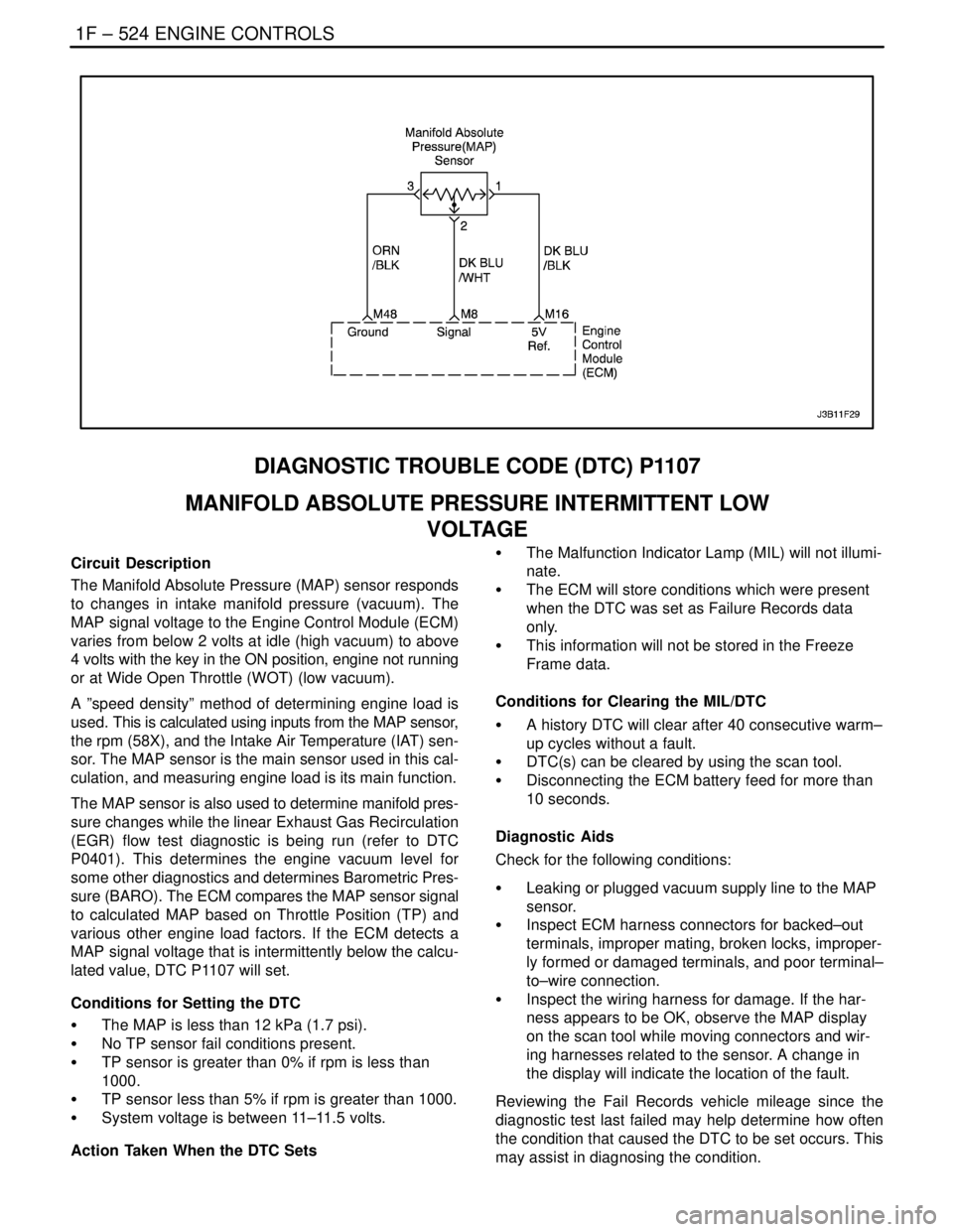

Circuit Description

The Manifold Absolute Pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP signal voltage to the Engine Control Module (ECM)

varies from below 2 volts at idle (high vacuum) to above

4 volts with the key in the ON position, engine not running

or at Wide Open Throttle (WOT) (low vacuum).

A ”speed density” method of determining engine load is

used. This is calculated using inputs from the MAP sensor,

the rpm (58X), and the Intake Air Temperature (IAT) sen-

sor. The MAP sensor is the main sensor used in this cal-

culation, and measuring engine load is its main function.

The MAP sensor is also used to determine manifold pres-

sure changes while the linear Exhaust Gas Recirculation

(EGR) flow test diagnostic is being run (refer to DTC

P0401). This determines the engine vacuum level for

some other diagnostics and determines Barometric Pres-

sure (BARO). The ECM compares the MAP sensor signal

to calculated MAP based on Throttle Position (TP) and

various other engine load factors. If the ECM detects a

MAP signal voltage that is intermittently below the calcu-

lated value, DTC P1107 will set.

Conditions for Setting the DTC

S The MAP is less than 12 kPa (1.7 psi).

S No TP sensor fail conditions present.

S TP sensor is greater than 0% if rpm is less than

1000.

S TP sensor less than 5% if rpm is greater than 1000.

S System voltage is between 11–11.5 volts.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Check for the following conditions:

S Leaking or plugged vacuum supply line to the MAP

sensor.

S Inspect ECM harness connectors for backed–out

terminals, improper mating, broken locks, improper-

ly formed or damaged terminals, and poor terminal–

to–wire connection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe the MAP display

on the scan tool while moving connectors and wir-

ing harnesses related to the sensor. A change in

the display will indicate the location of the fault.

Reviewing the Fail Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 1014 of 2643

4–2WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

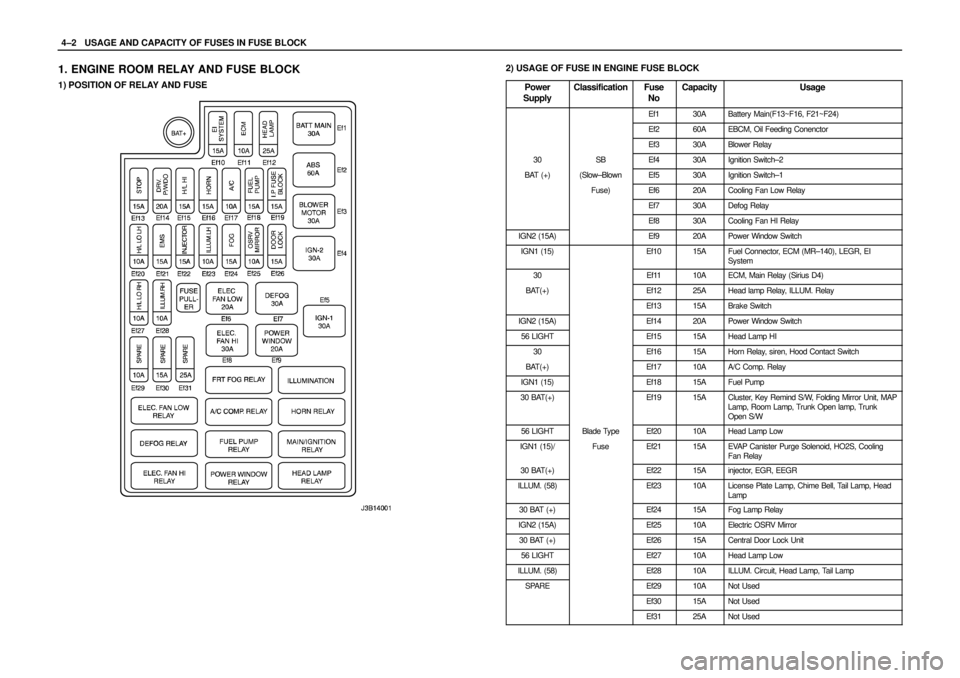

1. ENGINE ROOM RELAY AND FUSE BLOCK

1) POSITION OF RELAY AND FUSE

2) USAGE OF FUSE IN ENGINE FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

Ef130ABattery Main(F13~F16, F21~F24)

Ef260AEBCM, Oil Feeding Conenctor

Ef330ABlower Relay

30SBEf430AIgnition Switch–2

BAT (+)(Slow–BlownEf530AIgnition Switch–1

Fuse)Ef620ACooling Fan Low Relay

Ef730ADefog Relay

Ef830ACooling Fan HI Relay

IGN2 (15A)Ef920APower Window Switch

IGN1 (15)Ef1015AFuel Connector, ECM (MR–140), LEGR, EI

System

30Ef1110AECM, Main Relay (Sirius D4)

BAT(+)Ef1225AHead lamp Relay, ILLUM. Relay

Ef1315ABrake Switch

IGN2 (15A)Ef1420APower Window Switch

56 LIGHTEf1515AHead Lamp HI

30Ef1615AHorn Relay, siren, Hood Contact Switch

BAT(+)Ef1710AA/C Comp. Relay

IGN1 (15)Ef1815AFuel Pump

30 BAT(+)Ef1915ACluster, Key Remind S/W, Folding Mirror Unit, MAP

Lamp, Room Lamp, Trunk Open lamp, Trunk

Open S/W

56 LIGHTBlade TypeEf2010AHead Lamp Low

IGN1 (15)/FuseEf2115AEVAP Canister Purge Solenoid, HO2S, Cooling

Fan Relay

30 BAT(+)Ef2215Ainjector, EGR, EEGR

ILLUM. (58)Ef2310ALicense Plate Lamp, Chime Bell, Tail Lamp, Head

Lamp

30 BAT (+)Ef2415AFog Lamp Relay

IGN2 (15A)Ef2510AElectric OSRV Mirror

30 BAT (+)Ef2615ACentral Door Lock Unit

56 LIGHTEf2710AHead Lamp Low

ILLUM. (58)Ef2810AILLUM. Circuit, Head Lamp, Tail Lamp

SPAREEf2910ANot Used

Ef3015ANot Used

Ef3125ANot Used

Page 1955 of 2643

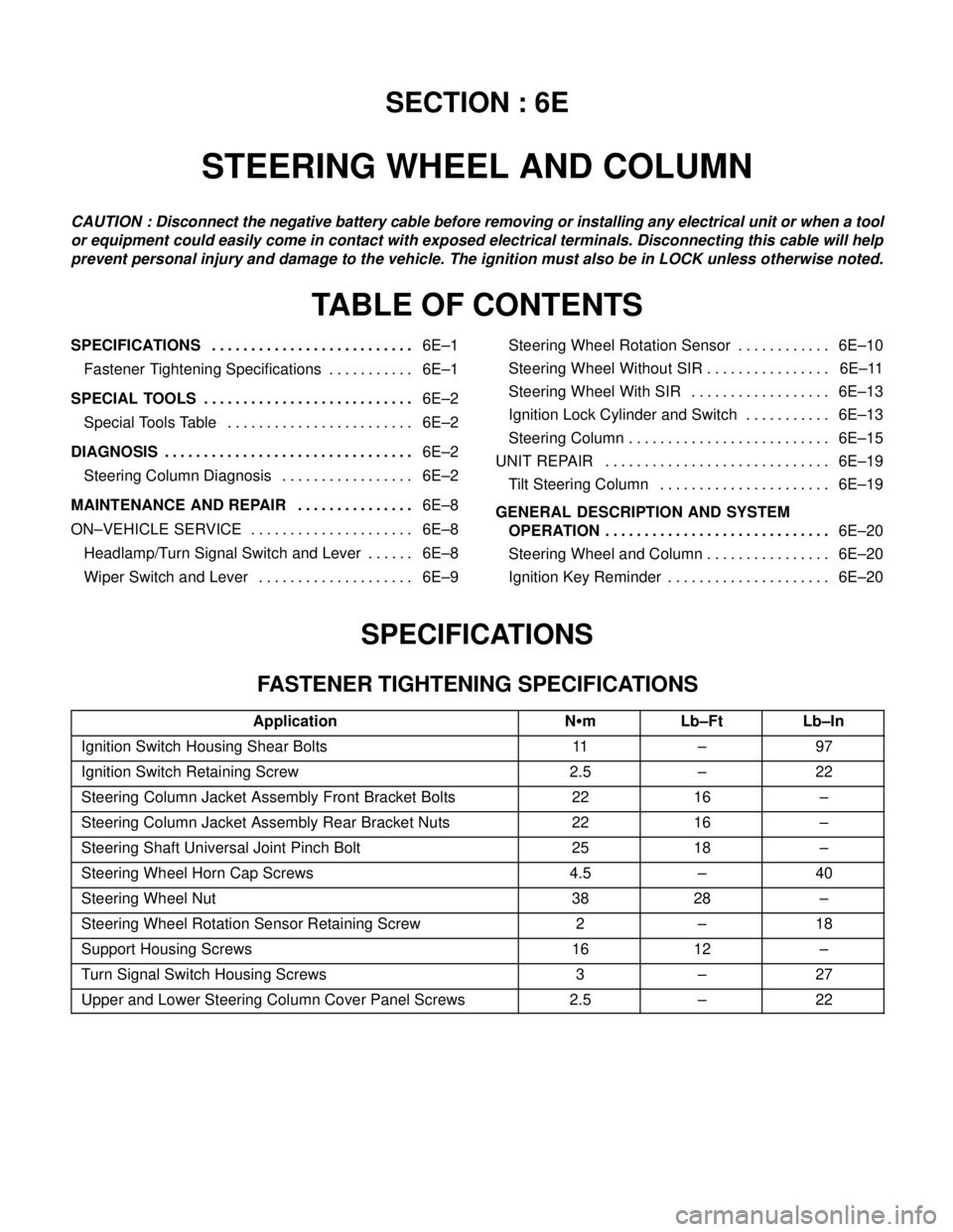

SECTION : 6E

STEERING WHEEL AND COLUMN

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6E–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6E–1. . . . . . . . . . .

SPECIAL TOOLS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6E–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column Diagnosis 6E–2. . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR6E–8 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6E–8. . . . . . . . . . . . . . . . . . . . .

Headlamp/Turn Signal Switch and Lever 6E–8. . . . . .

Wiper Switch and Lever 6E–9. . . . . . . . . . . . . . . . . . . . Steering Wheel Rotation Sensor 6E–10. . . . . . . . . . . .

Steering Wheel Without SIR 6E–11. . . . . . . . . . . . . . . .

Steering Wheel With SIR 6E–13. . . . . . . . . . . . . . . . . .

Ignition Lock Cylinder and Switch 6E–13. . . . . . . . . . .

Steering Column 6E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Steering Column 6E–19. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6E–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel and Column 6E–20. . . . . . . . . . . . . . . .

Ignition Key Reminder 6E–20. . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ignition Switch Housing Shear Bolts11–97

Ignition Switch Retaining Screw2.5–22

Steering Column Jacket Assembly Front Bracket Bolts2216–

Steering Column Jacket Assembly Rear Bracket Nuts2216–

Steering Shaft Universal Joint Pinch Bolt2518–

Steering Wheel Horn Cap Screws4.5–40

Steering Wheel Nut3828–

Steering Wheel Rotation Sensor Retaining Screw2–18

Support Housing Screws1612–

Turn Signal Switch Housing Screws3–27

Upper and Lower Steering Column Cover Panel Screws2.5–22

Page 1968 of 2643

6E – 14ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

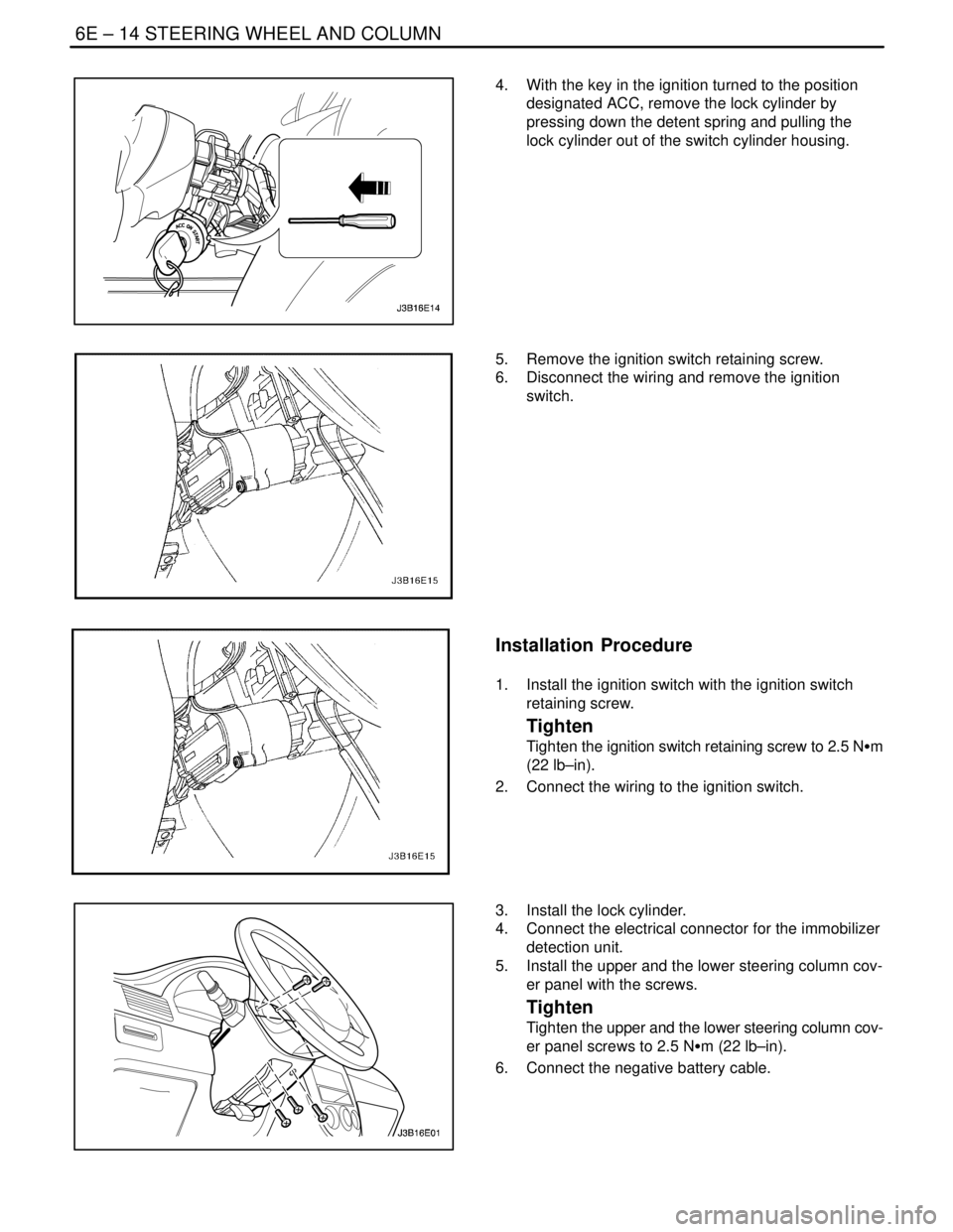

4. With the key in the ignition turned to the position

designated ACC, remove the lock cylinder by

pressing down the detent spring and pulling the

lock cylinder out of the switch cylinder housing.

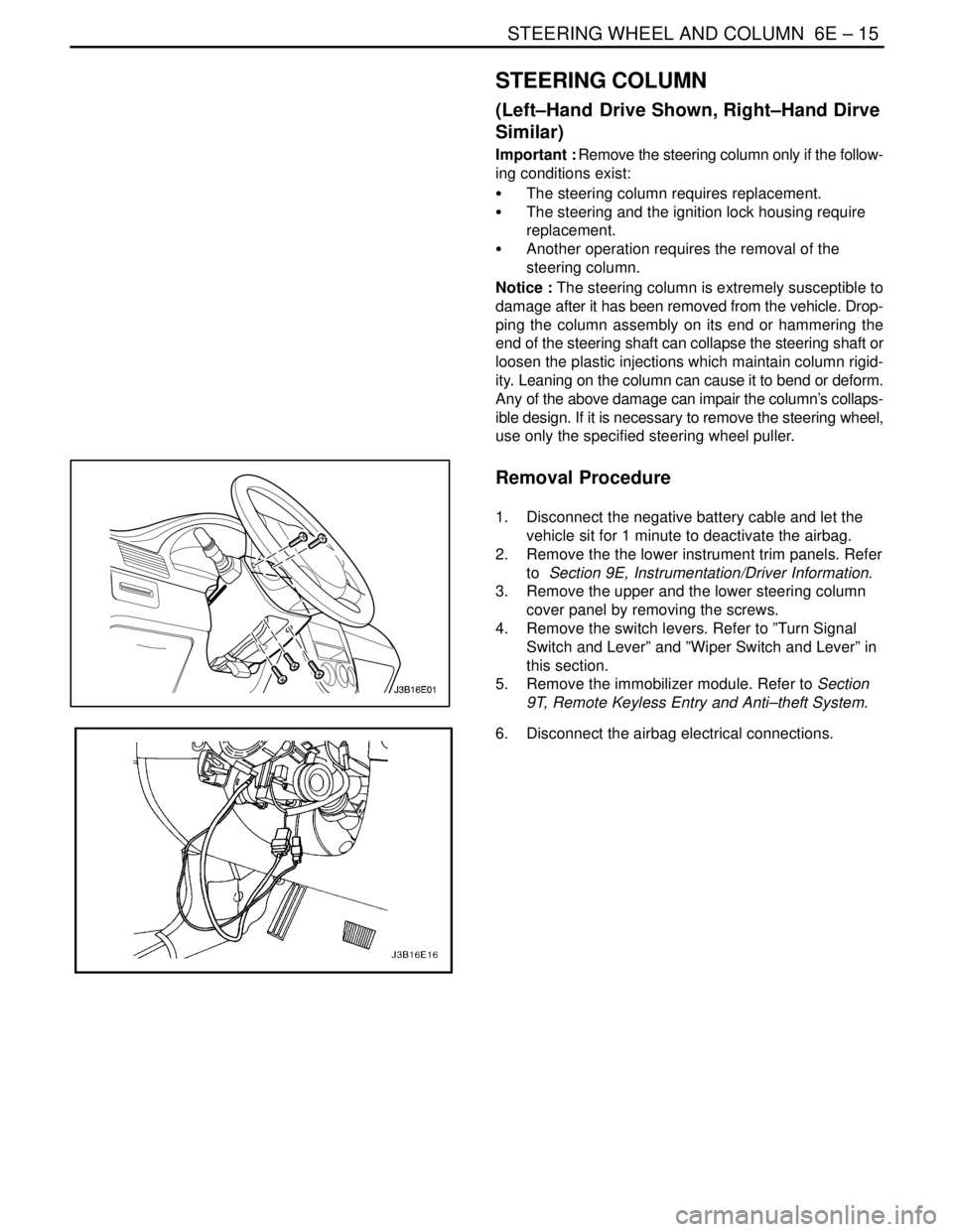

5. Remove the ignition switch retaining screw.

6. Disconnect the wiring and remove the ignition

switch.

Installation Procedure

1. Install the ignition switch with the ignition switch

retaining screw.

Tighten

Tighten the ignition switch retaining screw to 2.5 NSm

(22 lb–in).

2. Connect the wiring to the ignition switch.

3. Install the lock cylinder.

4. Connect the electrical connector for the immobilizer

detection unit.

5. Install the upper and the lower steering column cov-

er panel with the screws.

Tighten

Tighten the upper and the lower steering column cov-

er panel screws to 2.5 NSm (22 lb–in).

6. Connect the negative battery cable.

Page 1969 of 2643

STEERING WHEEL AND COLUMN 6E – 15

DAEWOO V–121 BL4

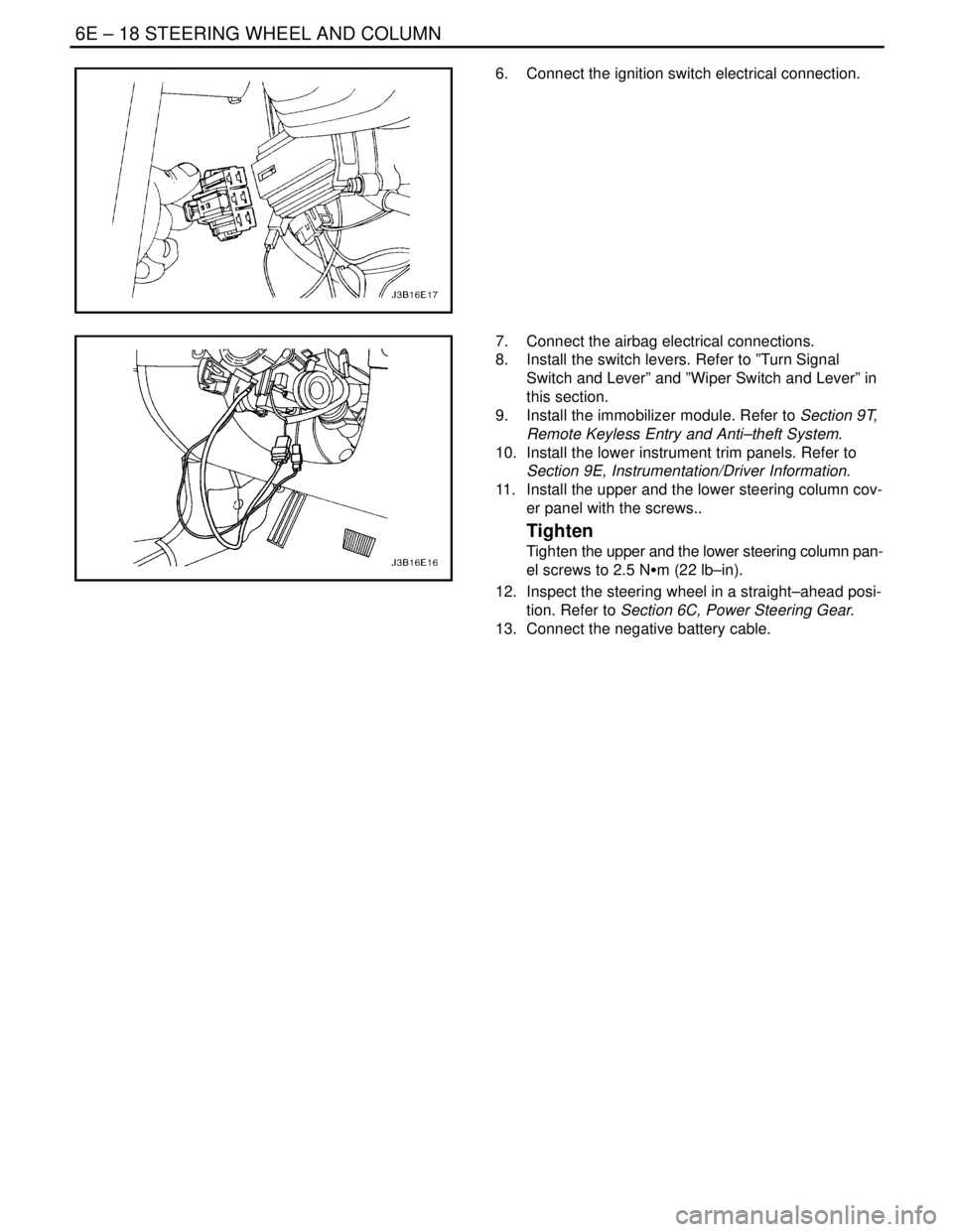

STEERING COLUMN

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Important : Remove the steering column only if the follow-

ing conditions exist:

S The steering column requires replacement.

S The steering and the ignition lock housing require

replacement.

S Another operation requires the removal of the

steering column.

Notice : The steering column is extremely susceptible to

damage after it has been removed from the vehicle. Drop-

ping the column assembly on its end or hammering the

end of the steering shaft can collapse the steering shaft or

loosen the plastic injections which maintain column rigid-

ity. Leaning on the column can cause it to bend or deform.

Any of the above damage can impair the column’s collaps-

ible design. If it is necessary to remove the steering wheel,

use only the specified steering wheel puller.

Removal Procedure

1. Disconnect the negative battery cable and let the

vehicle sit for 1 minute to deactivate the airbag.

2. Remove the the lower instrument trim panels. Refer

to Section 9E, Instrumentation/Driver Information.

3. Remove the upper and the lower steering column

cover panel by removing the screws.

4. Remove the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

5. Remove the immobilizer module. Refer to Section

9T, Remote Keyless Entry and Anti–theft System.

6. Disconnect the airbag electrical connections.

Page 1972 of 2643

6E – 18ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

6. Connect the ignition switch electrical connection.

7. Connect the airbag electrical connections.

8. Install the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

9. Install the immobilizer module. Refer to Section 9T,

Remote Keyless Entry and Anti–theft System.

10. Install the lower instrument trim panels. Refer to

Section 9E, Instrumentation/Driver Information.

11. Install the upper and the lower steering column cov-

er panel with the screws..

Tighten

Tighten the upper and the lower steering column pan-

el screws to 2.5 NSm (22 lb–in).

12. Inspect the steering wheel in a straight–ahead posi-

tion. Refer to Section 6C, Power Steering Gear.

13. Connect the negative battery cable.

Page 2219 of 2643

BODY WIRING SYSTEM 9A – 13

DAEWOO V–121 BL4

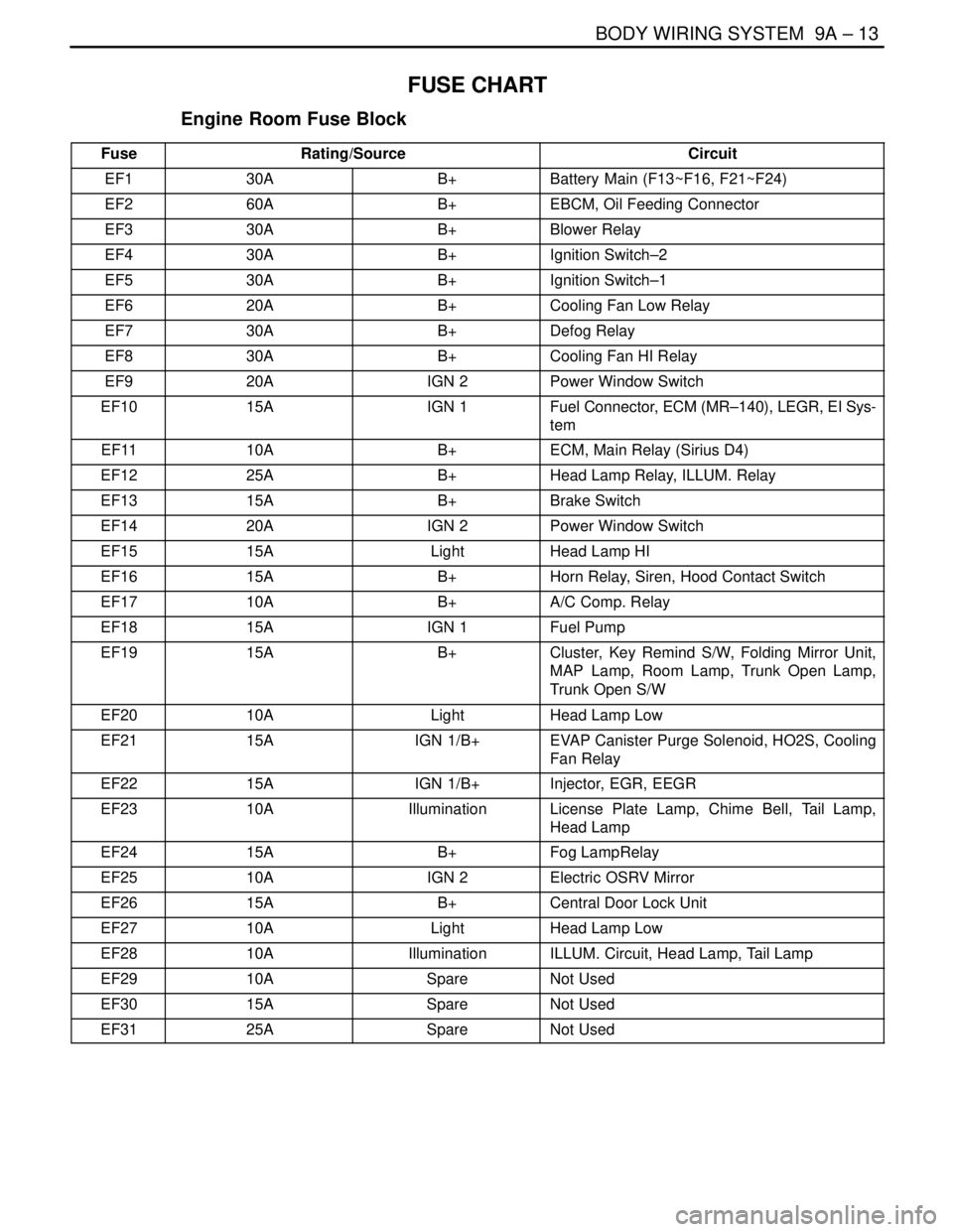

FUSE CHART

Engine Room Fuse Block

FuseRating/SourceCircuit

EF130AB+Battery Main (F13~F16, F21~F24)

EF260AB+EBCM, Oil Feeding Connector

EF330AB+Blower Relay

EF430AB+Ignition Switch–2

EF530AB+Ignition Switch–1

EF620AB+Cooling Fan Low Relay

EF730AB+Defog Relay

EF830AB+Cooling Fan HI Relay

EF920AIGN 2Power Window Switch

EF1015AIGN 1Fuel Connector, ECM (MR–140), LEGR, EI Sys-

tem

EF1110AB+ECM, Main Relay (Sirius D4)

EF1225AB+Head Lamp Relay, ILLUM. Relay

EF1315AB+Brake Switch

EF1420AIGN 2Power Window Switch

EF1515ALightHead Lamp HI

EF1615AB+Horn Relay, Siren, Hood Contact Switch

EF1710AB+A/C Comp. Relay

EF1815AIGN 1Fuel Pump

EF1915AB+Cluster, Key Remind S/W, Folding Mirror Unit,

MAP Lamp, Room Lamp, Trunk Open Lamp,

Trunk Open S/W

EF2010ALightHead Lamp Low

EF2115AIGN 1/B+EVAP Canister Purge Solenoid, HO2S, Cooling

Fan Relay

EF2215AIGN 1/B+Injector, EGR, EEGR

EF2310AIlluminationLicense Plate Lamp, Chime Bell, Tail Lamp,

Head Lamp

EF2415AB+Fog LampRelay

EF2510AIGN 2Electric OSRV Mirror

EF2615AB+Central Door Lock Unit

EF2710ALightHead Lamp Low

EF2810AIlluminationILLUM. Circuit, Head Lamp, Tail Lamp

EF2910ASpareNot Used

EF3015ASpareNot Used

EF3125ASpareNot Used

Page 2305 of 2643

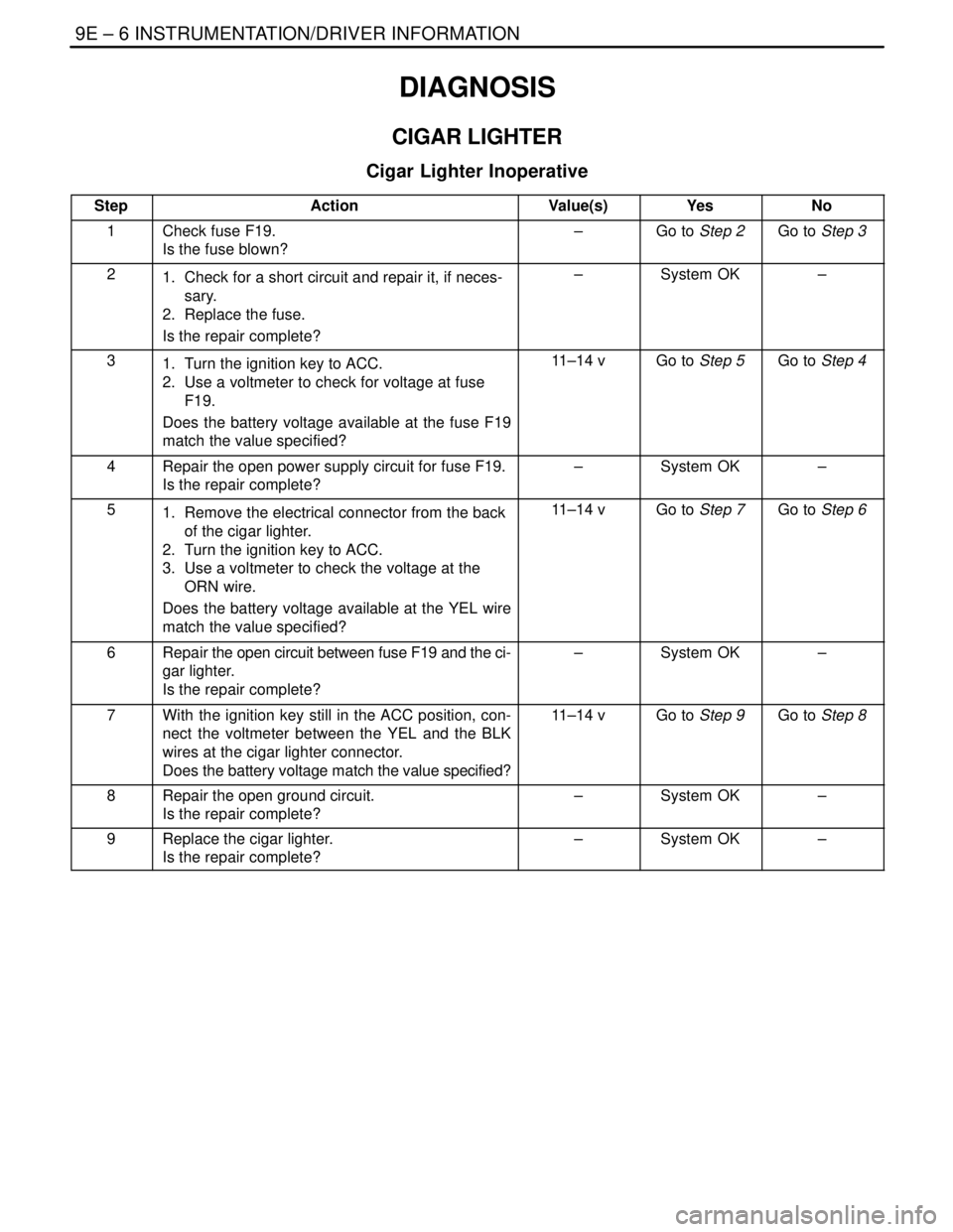

9E – 6IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

DIAGNOSIS

CIGAR LIGHTER

Cigar Lighter Inoperative

StepActionValue(s)YesNo

1Check fuse F19.

Is the fuse blown?–Go to Step 2Go to Step 3

21. Check for a short circuit and repair it, if neces-

sary.

2. Replace the fuse.

Is the repair complete?–System OK–

31. Turn the ignition key to ACC.

2. Use a voltmeter to check for voltage at fuse

F19.

Does the battery voltage available at the fuse F19

match the value specified?11–14 vGo to Step 5Go to Step 4

4Repair the open power supply circuit for fuse F19.

Is the repair complete?–System OK–

51. Remove the electrical connector from the back

of the cigar lighter.

2. Turn the ignition key to ACC.

3. Use a voltmeter to check the voltage at the

ORN wire.

Does the battery voltage available at the YEL wire

match the value specified?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between fuse F19 and the ci-

gar lighter.

Is the repair complete?–System OK–

7With the ignition key still in the ACC position, con-

nect the voltmeter between the YEL and the BLK

wires at the cigar lighter connector.

Does the battery voltage match the value specified?11–14 vGo to Step 9Go to Step 8

8Repair the open ground circuit.

Is the repair complete?–System OK–

9Replace the cigar lighter.

Is the repair complete?–System OK–

Page 2482 of 2643

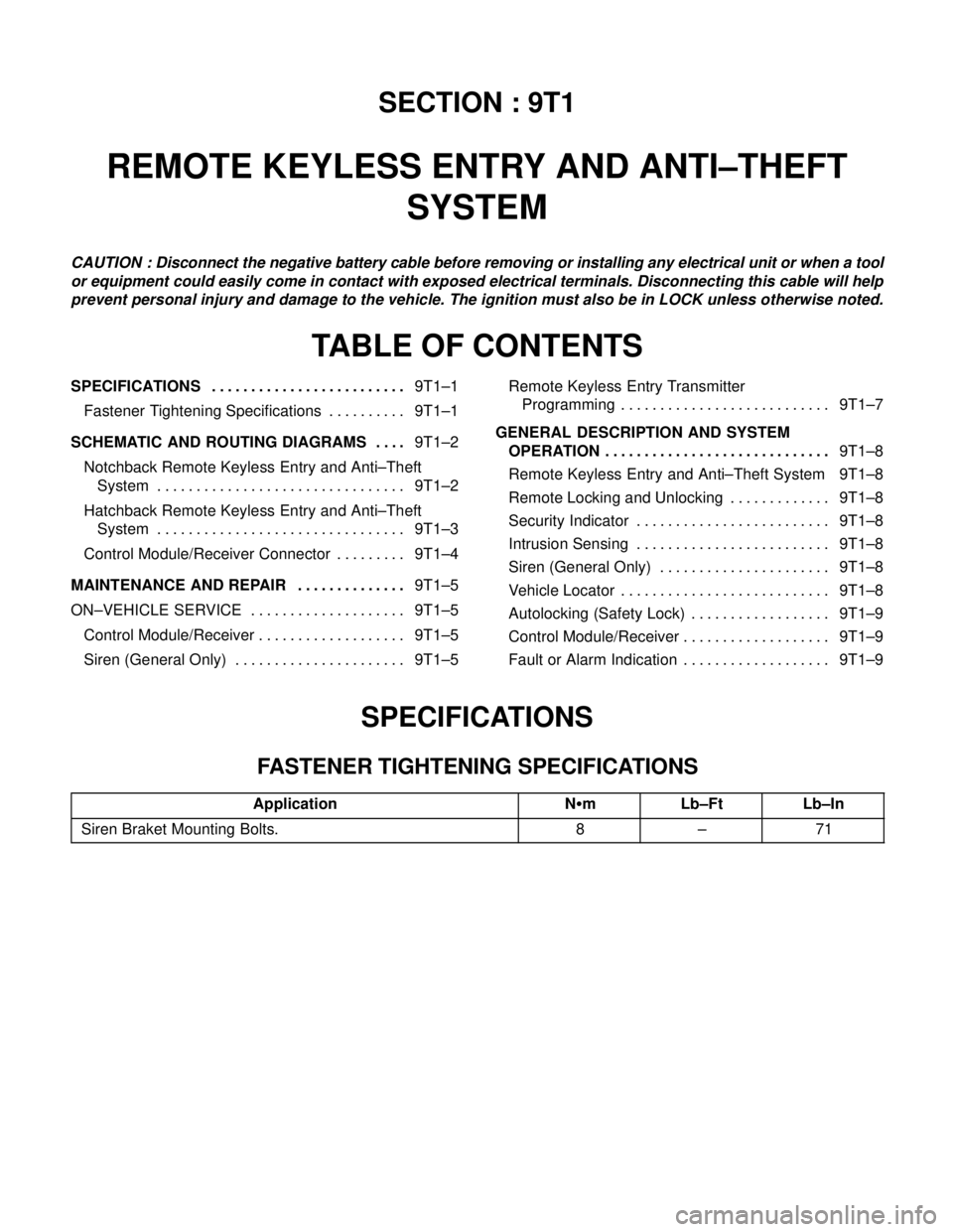

SECTION : 9T1

REMOTE KEYLESS ENTRY AND ANTI–THEFT

SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS 9T1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9T1–1. . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS9T1–2 . . . .

Notchback Remote Keyless Entry and Anti–Theft

System 9T1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Remote Keyless Entry and Anti–Theft

System 9T1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Module/Receiver Connector 9T1–4. . . . . . . . .

MAINTENANCE AND REPAIR9T1–5 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9T1–5. . . . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–5. . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–5. . . . . . . . . . . . . . . . . . . . . . Remote Keyless Entry Transmitter

Programming 9T1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9T1–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keyless Entry and Anti–Theft System 9T1–8

Remote Locking and Unlocking 9T1–8. . . . . . . . . . . . .

Security Indicator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Intrusion Sensing 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . .

Siren (General Only) 9T1–8. . . . . . . . . . . . . . . . . . . . . .

Vehicle Locator 9T1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Autolocking (Safety Lock) 9T1–9. . . . . . . . . . . . . . . . . .

Control Module/Receiver 9T1–9. . . . . . . . . . . . . . . . . . .

Fault or Alarm Indication 9T1–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Siren Braket Mounting Bolts.8–71