power steering fluid DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1911 of 2643

6B – 2IPOWER STEERING PUMP

DAEWOO V–121 BL4

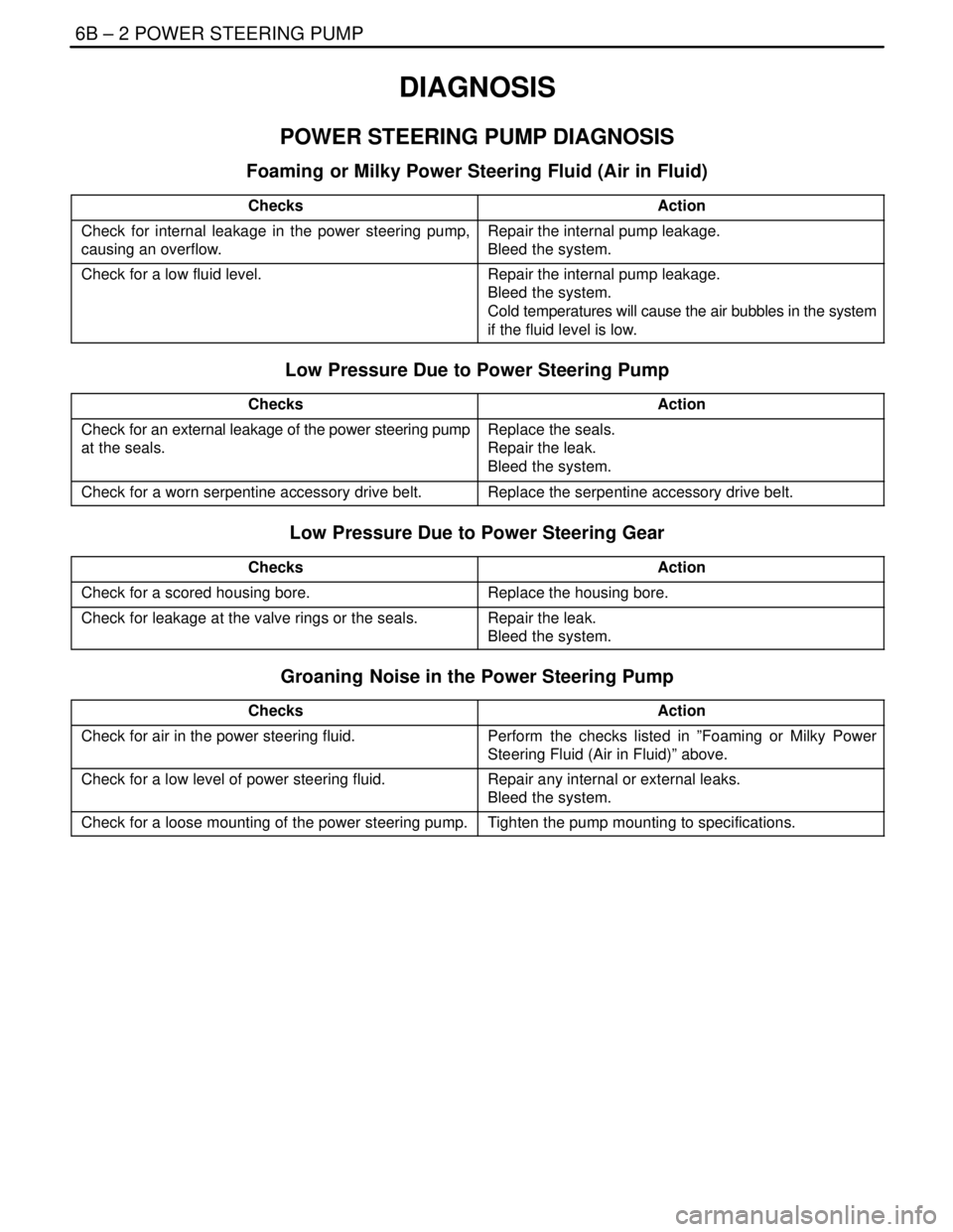

DIAGNOSIS

POWER STEERING PUMP DIAGNOSIS

Foaming or Milky Power Steering Fluid (Air in Fluid)

ChecksAction

Check for internal leakage in the power steering pump,

causing an overflow.Repair the internal pump leakage.

Bleed the system.

Check for a low fluid level.Repair the internal pump leakage.

Bleed the system.

Cold temperatures will cause the air bubbles in the system

if the fluid level is low.

Low Pressure Due to Power Steering Pump

ChecksAction

Check for an external leakage of the power steering pump

at the seals.Replace the seals.

Repair the leak.

Bleed the system.

Check for a worn serpentine accessory drive belt.Replace the serpentine accessory drive belt.

Low Pressure Due to Power Steering Gear

ChecksAction

Check for a scored housing bore.Replace the housing bore.

Check for leakage at the valve rings or the seals.Repair the leak.

Bleed the system.

Groaning Noise in the Power Steering Pump

ChecksAction

Check for air in the power steering fluid.Perform the checks listed in ”Foaming or Milky Power

Steering Fluid (Air in Fluid)” above.

Check for a low level of power steering fluid.Repair any internal or external leaks.

Bleed the system.

Check for a loose mounting of the power steering pump.Tighten the pump mounting to specifications.

Page 1914 of 2643

POWER STEERING PUMP 6B – 5

DAEWOO V–121 BL4

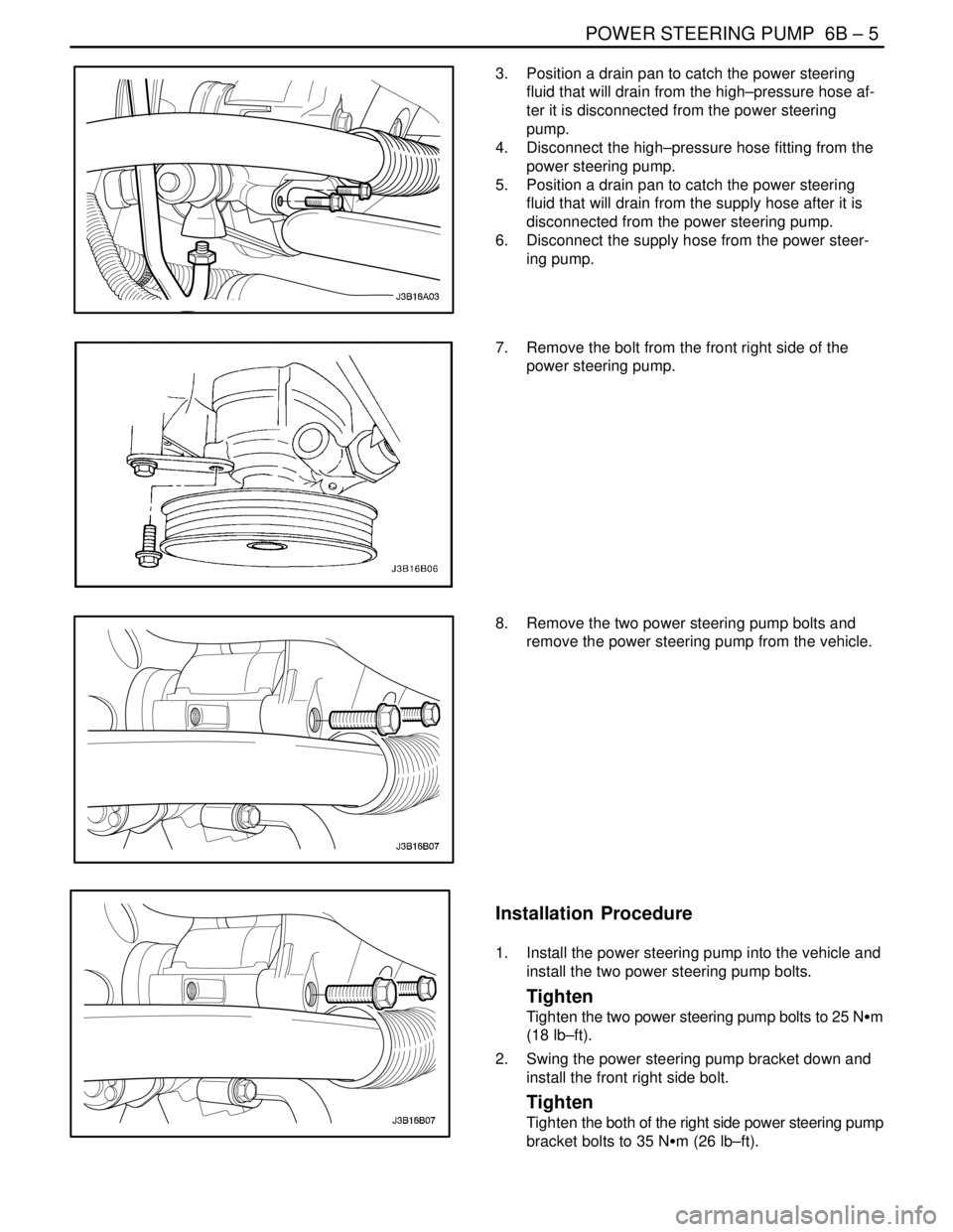

3. Position a drain pan to catch the power steering

fluid that will drain from the high–pressure hose af-

ter it is disconnected from the power steering

pump.

4. Disconnect the high–pressure hose fitting from the

power steering pump.

5. Position a drain pan to catch the power steering

fluid that will drain from the supply hose after it is

disconnected from the power steering pump.

6. Disconnect the supply hose from the power steer-

ing pump.

7. Remove the bolt from the front right side of the

power steering pump.

8. Remove the two power steering pump bolts and

remove the power steering pump from the vehicle.

Installation Procedure

1. Install the power steering pump into the vehicle and

install the two power steering pump bolts.

Tighten

Tighten the two power steering pump bolts to 25 NSm

(18 lb–ft).

2. Swing the power steering pump bracket down and

install the front right side bolt.

Tighten

Tighten the both of the right side power steering pump

bracket bolts to 35 NSm (26 lb–ft).

Page 1915 of 2643

6B – 6IPOWER STEERING PUMP

DAEWOO V–121 BL4

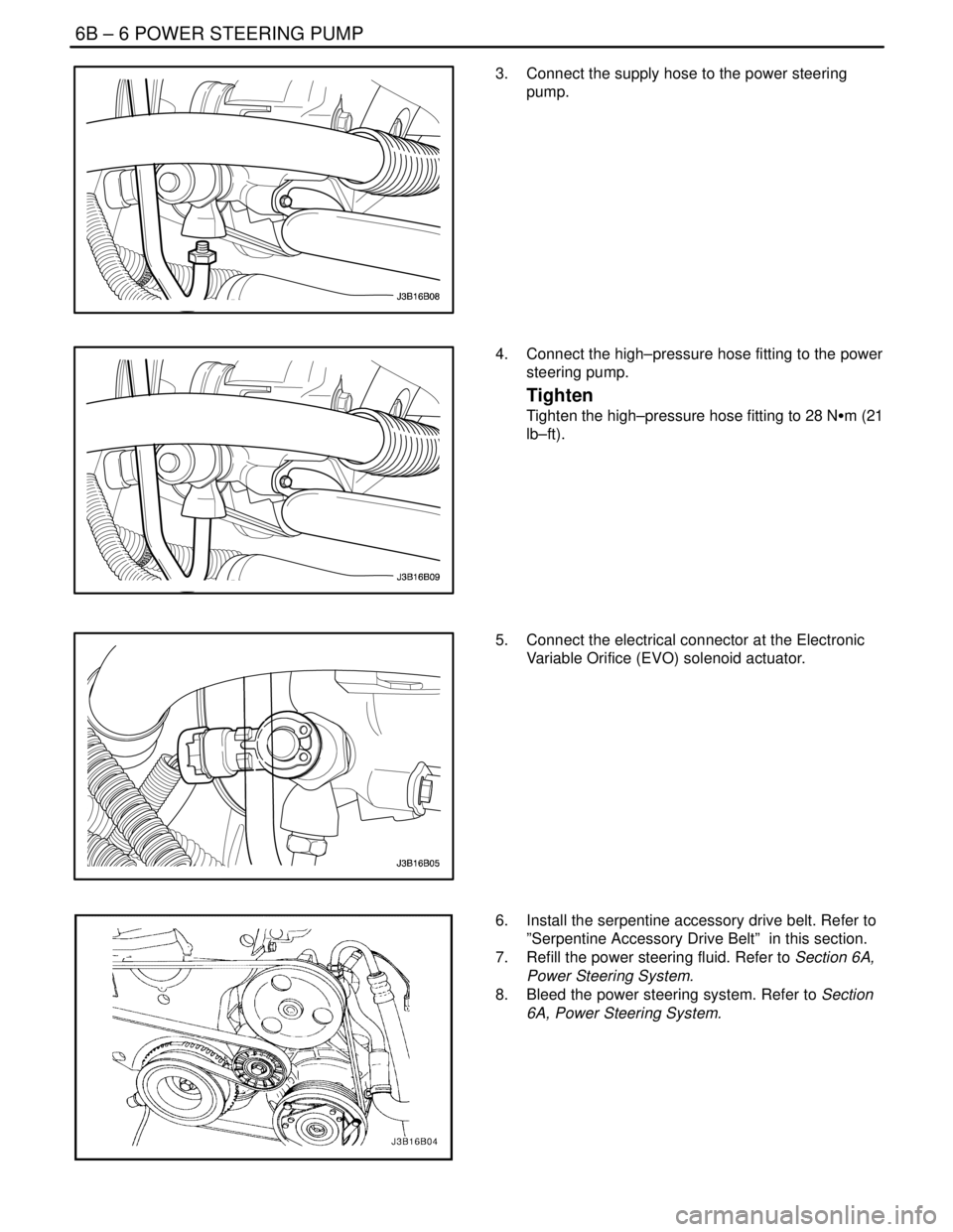

3. Connect the supply hose to the power steering

pump.

4. Connect the high–pressure hose fitting to the power

steering pump.

Tighten

Tighten the high–pressure hose fitting to 28 NSm (21

lb–ft).

5. Connect the electrical connector at the Electronic

Variable Orifice (EVO) solenoid actuator.

6. Install the serpentine accessory drive belt. Refer to

”Serpentine Accessory Drive Belt” in this section.

7. Refill the power steering fluid. Refer to Section 6A,

Power Steering System.

8. Bleed the power steering system. Refer to Section

6A, Power Steering System.

Page 1918 of 2643

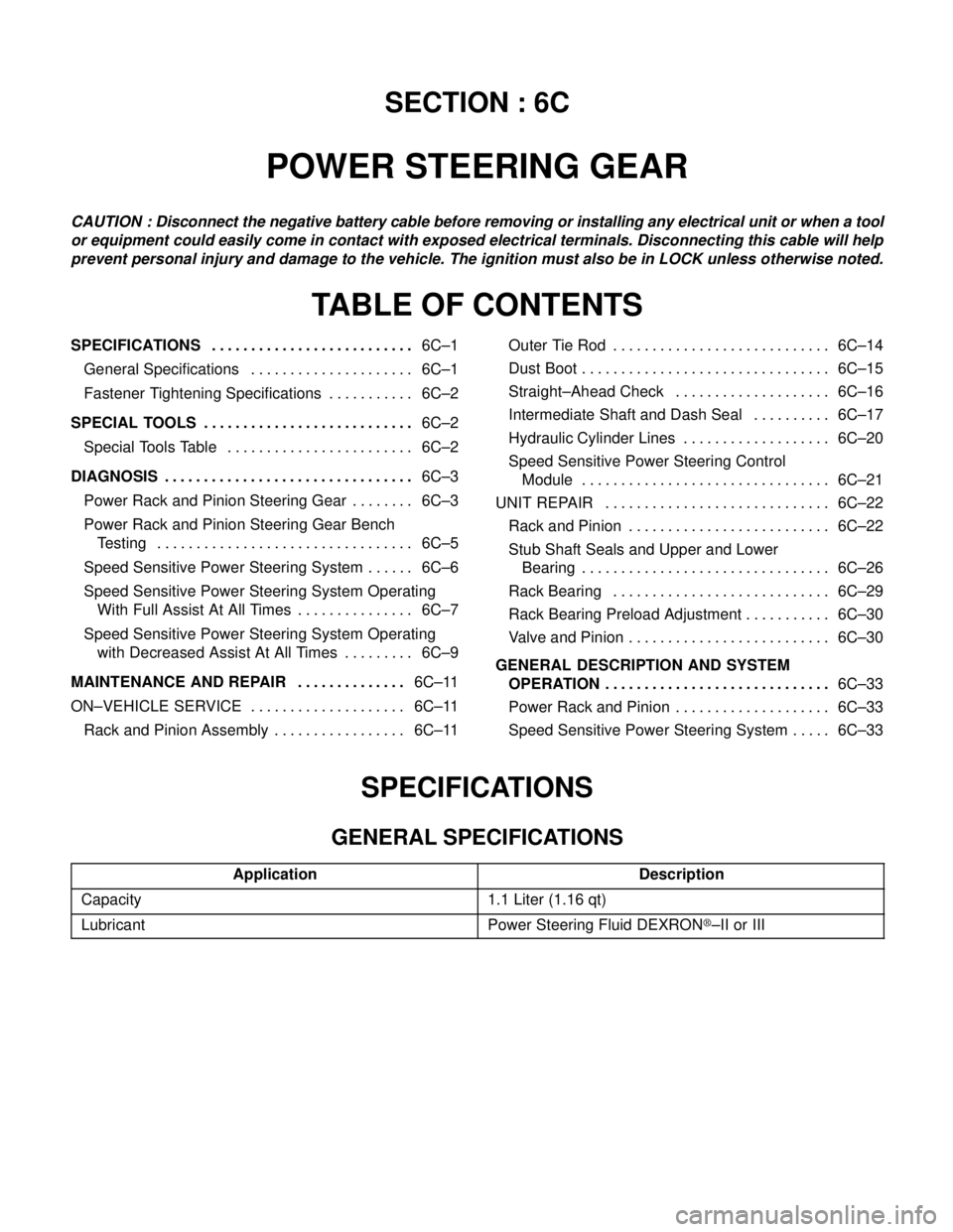

SECTION : 6C

POWER STEERING GEAR

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6C–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6C–1. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6C–2. . . . . . . . . . .

SPECIAL TOOLS6C–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6C–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6C–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion Steering Gear 6C–3. . . . . . . .

Power Rack and Pinion Steering Gear Bench

Testing 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–6. . . . . .

Speed Sensitive Power Steering System Operating

With Full Assist At All Times 6C–7. . . . . . . . . . . . . . .

Speed Sensitive Power Steering System Operating

with Decreased Assist At All Times 6C–9. . . . . . . . .

MAINTENANCE AND REPAIR6C–11 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6C–11. . . . . . . . . . . . . . . . . . . .

Rack and Pinion Assembly 6C–11. . . . . . . . . . . . . . . . . Outer Tie Rod 6C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dust Boot 6C–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Straight–Ahead Check 6C–16. . . . . . . . . . . . . . . . . . . .

Intermediate Shaft and Dash Seal 6C–17. . . . . . . . . .

Hydraulic Cylinder Lines 6C–20. . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering Control

Module 6C–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack and Pinion 6C–22. . . . . . . . . . . . . . . . . . . . . . . . . .

Stub Shaft Seals and Upper and Lower

Bearing 6C–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing 6C–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack Bearing Preload Adjustment 6C–30. . . . . . . . . . .

Valve and Pinion 6C–30. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6C–33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rack and Pinion 6C–33. . . . . . . . . . . . . . . . . . . .

Speed Sensitive Power Steering System 6C–33. . . . .

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationDescription

Capacity1.1 Liter (1.16 qt)

LubricantPower Steering Fluid DEXRON®–II or III

Page 1920 of 2643

POWER STEERING GEAR 6C – 3

DAEWOO V–121 BL4

DIAGNOSIS

POWER RACK AND PINION STEERING GEAR

Hissing Noise

ChecksAction

Check the intermediate shaft joints for looseness.Tighten the intermediate shaft joints.

Check the power steering hose for contact with other com-

ponents.Be sure the power steering hose is correctly fitted into the

hose clips.

Rattling Noise in Steering Gear

ChecksAction

Check the power steering hose for contact with the body.Be sure the power steering hose is correctly fitted into the

hose clips.

Check the steering gear for insufficient lubrication.Lubricate the steering gear.

Check the steering gear mounting for improper installa-

tion.Tighten the steering gear mounting bracket nuts and bolts.

Check the outer tie rods for improper installation.Tighten the outer tie rod joints. Replace the outer tie rods.

Poor Return of Steering Wheel to Center

ChecksAction

Check the steering wheel for contact with the turn signal

housing.Adjust the turn signal housing.

Check the intermediate shaft joints for binding or loose-

ness.Replace the intermediate shaft.

Check the power steering pump flow control valve for

sticking and improper alignment.Replace the power steering pump.

Check the wheel alignment.Align the wheels.

Check the wheel bearings for wear or damage.Replace the wheel bearings.

Check the intermediate shaft joints for improper installa-

tion.Adjust the intermediate shaft between the steering gear

and the steering column.

Replace the intermediate shaft.

Check the outer tie rods and the ball joints for binding or

looseness.Tighten the tie rods and the ball joints. Replace the tie rods

and the ball joints.

Check the steering gear adjustments.Perform a straight–ahead check.

Check the steering column shaft seal for rubbing on the

shaft.Replace the dash seal.

Check the steering shaft bearings for binding.Replace the stub shaft bearings.

Momentary Increase in Effort When Turning the Wheel Quickly

ChecksAction

Check the power steering pump for internal leaks.Replace the power steering pump.

Check the hoses for damage or restricted flow.Replace the power steering hoses and/or pipes.

Check the power steering fluid level.Fill the power steering fluid reservoir.

Check the power steering pump flow control valve for

sticking and improper operation.Replace the power steering pump.

Page 1922 of 2643

POWER STEERING GEAR 6C – 5

DAEWOO V–121 BL4

POWER RACK AND PINION

STEERING GEAR BENCH TESTING

Removal, Setup and Testing Procedure

Notice : Pressure checks or pressure and flow checks

may also be conducted using this set–up.

1. Disconnect and remove the power steering gear.

Refer to ”Rack and Pinion Assembly” in this sec-

tion.

2. Place the power steering gear on a bench next to

the vehicle.

3. Disconnect the pressure line at the point where the

hose connects to the pipe. Extend this line in order

to reach the power steering gear on the bench.

4. Disconnect the return line from the the power steer-

ing fluid reservoir. Extend this line in order to reach

the power steering gear on the bench.

5. Connect the power steering pipes to the power

steering gear.6. Start the engine and allow it to idle for 10 seconds.

7. Check the power steering fluid level. Refer to Sec-

tion 6A, Power Steering System.

8. Start the engine and turn the rack and pinion stub

shaft to a full turn in each direction. Hold the shaft

against each stop for 5 seconds.

9. Inspect for possible leak points. Refer to Section

6A, Power Steering System.

Installation Procedure

1. Stop the engine.

2. Disconnect the power steering pipes from the pow-

er steering gear.

3. Remove the extensions and reconnect the pressure

and return lines.

4. Install and connect the power steering gear. Refer

to ”Rack and Pinion Assembly” in this section.

5. Start the engine and stay idle for 10 seconds.

6. Check the power steering fluid level. Refer to Sec-

tion 6A, Power Steering System.

Page 1928 of 2643

POWER STEERING GEAR 6C – 11

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

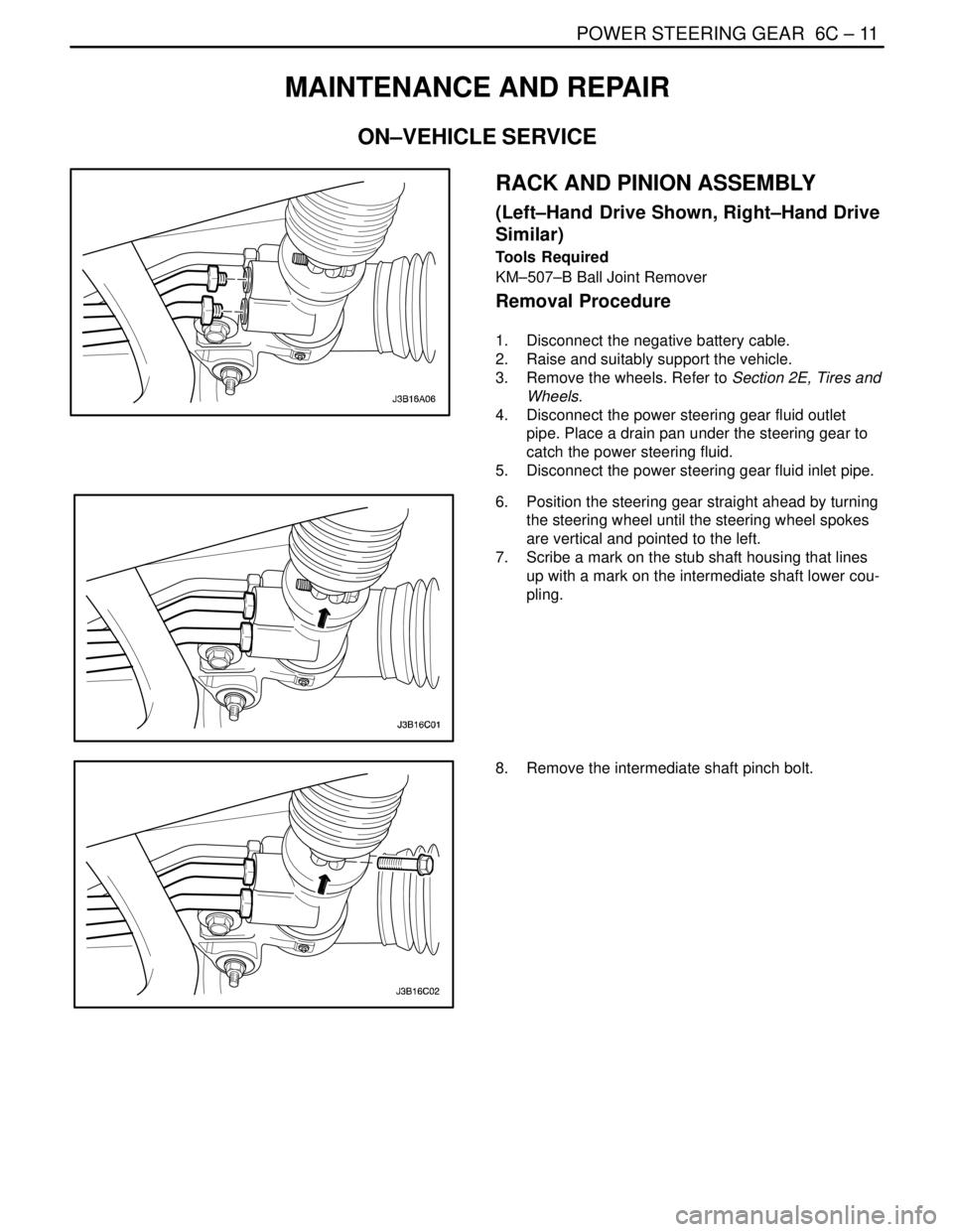

RACK AND PINION ASSEMBLY

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Disconnect the negative battery cable.

2. Raise and suitably support the vehicle.

3. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

4. Disconnect the power steering gear fluid outlet

pipe. Place a drain pan under the steering gear to

catch the power steering fluid.

5. Disconnect the power steering gear fluid inlet pipe.

6. Position the steering gear straight ahead by turning

the steering wheel until the steering wheel spokes

are vertical and pointed to the left.

7. Scribe a mark on the stub shaft housing that lines

up with a mark on the intermediate shaft lower cou-

pling.

8. Remove the intermediate shaft pinch bolt.

Page 1931 of 2643

6C – 14IPOWER STEERING GEAR

DAEWOO V–121 BL4

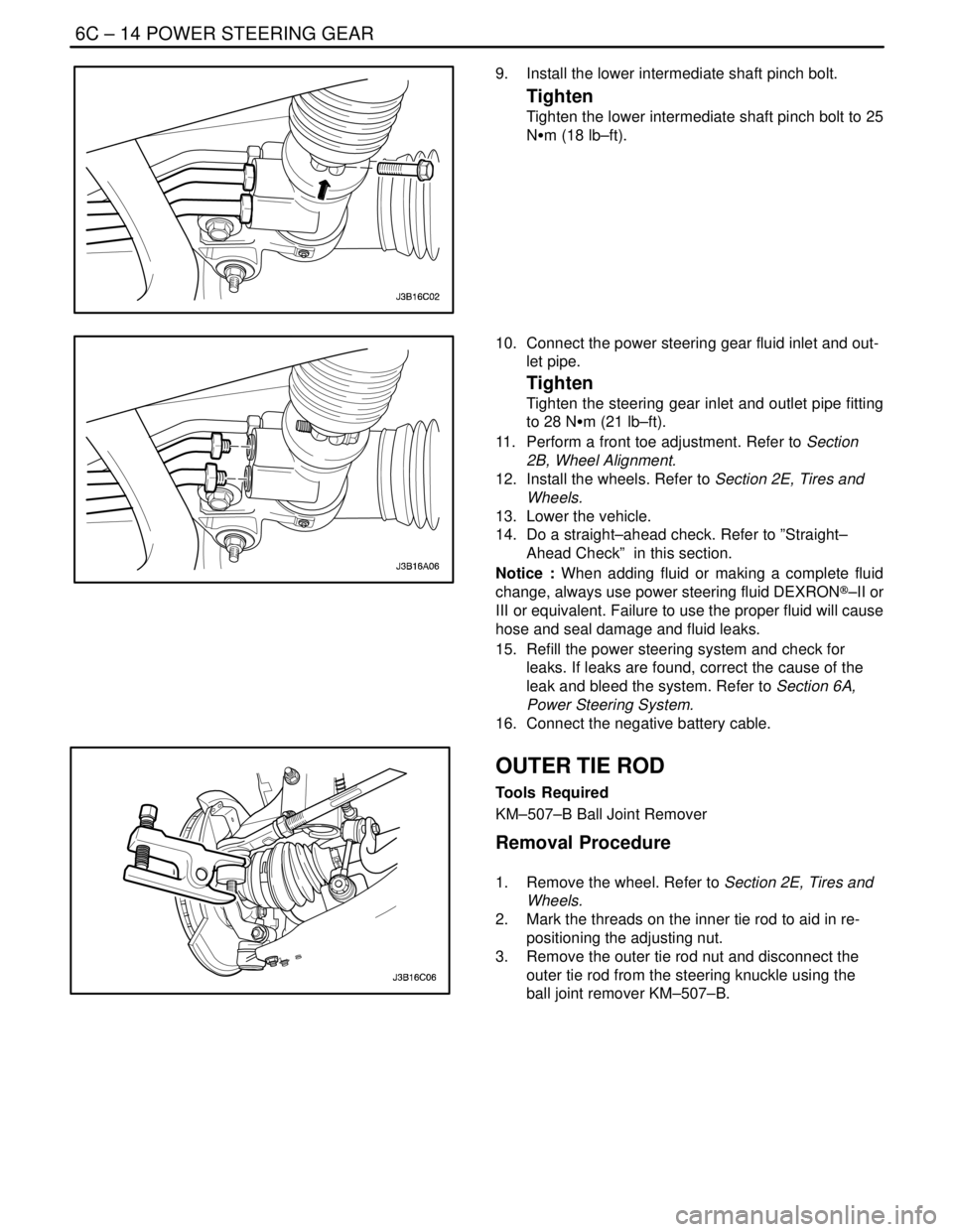

9. Install the lower intermediate shaft pinch bolt.

Tighten

Tighten the lower intermediate shaft pinch bolt to 25

NSm (18 lb–ft).

10. Connect the power steering gear fluid inlet and out-

let pipe.

Tighten

Tighten the steering gear inlet and outlet pipe fitting

to 28 NSm (21 lb–ft).

11. Perform a front toe adjustment. Refer to Section

2B, Wheel Alignment.

12. Install the wheels. Refer to Section 2E, Tires and

Wheels.

13. Lower the vehicle.

14. Do a straight–ahead check. Refer to ”Straight–

Ahead Check” in this section.

Notice : When adding fluid or making a complete fluid

change, always use power steering fluid DEXRON®–II or

III or equivalent. Failure to use the proper fluid will cause

hose and seal damage and fluid leaks.

15. Refill the power steering system and check for

leaks. If leaks are found, correct the cause of the

leak and bleed the system. Refer to Section 6A,

Power Steering System.

16. Connect the negative battery cable.

OUTER TIE ROD

Tools Required

KM–507–B Ball Joint Remover

Removal Procedure

1. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

2. Mark the threads on the inner tie rod to aid in re-

positioning the adjusting nut.

3. Remove the outer tie rod nut and disconnect the

outer tie rod from the steering knuckle using the

ball joint remover KM–507–B.

Page 1937 of 2643

6C – 20IPOWER STEERING GEAR

DAEWOO V–121 BL4

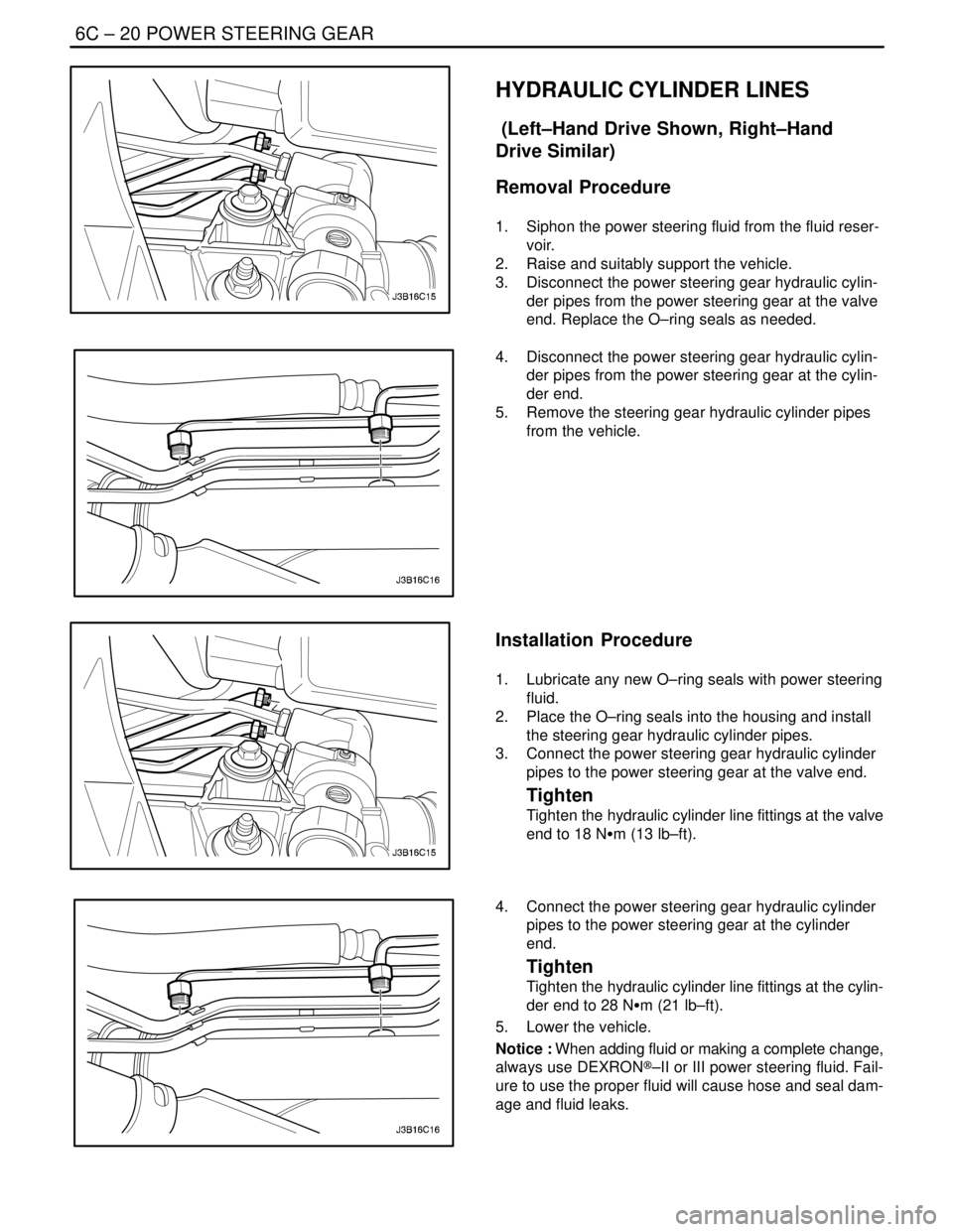

HYDRAULIC CYLINDER LINES

(Left–Hand Drive Shown, Right–Hand

Drive Similar)

Removal Procedure

1. Siphon the power steering fluid from the fluid reser-

voir.

2. Raise and suitably support the vehicle.

3. Disconnect the power steering gear hydraulic cylin-

der pipes from the power steering gear at the valve

end. Replace the O–ring seals as needed.

4. Disconnect the power steering gear hydraulic cylin-

der pipes from the power steering gear at the cylin-

der end.

5. Remove the steering gear hydraulic cylinder pipes

from the vehicle.

Installation Procedure

1. Lubricate any new O–ring seals with power steering

fluid.

2. Place the O–ring seals into the housing and install

the steering gear hydraulic cylinder pipes.

3. Connect the power steering gear hydraulic cylinder

pipes to the power steering gear at the valve end.

Tighten

Tighten the hydraulic cylinder line fittings at the valve

end to 18 NSm (13 lb–ft).

4. Connect the power steering gear hydraulic cylinder

pipes to the power steering gear at the cylinder

end.

Tighten

Tighten the hydraulic cylinder line fittings at the cylin-

der end to 28 NSm (21 lb–ft).

5. Lower the vehicle.

Notice : When adding fluid or making a complete change,

always use DEXRON®–II or III power steering fluid. Fail-

ure to use the proper fluid will cause hose and seal dam-

age and fluid leaks.

Page 1938 of 2643

POWER STEERING GEAR 6C – 21

DAEWOO V–121 BL4

6. Fill the fluid reservoir with power steering fluid.

7. Inspect for leaks. If there are leaks, correct the

cause of the leaks and bleed the system. Refer to

”Bleeding the Power Steering System” in this sec-

tion.

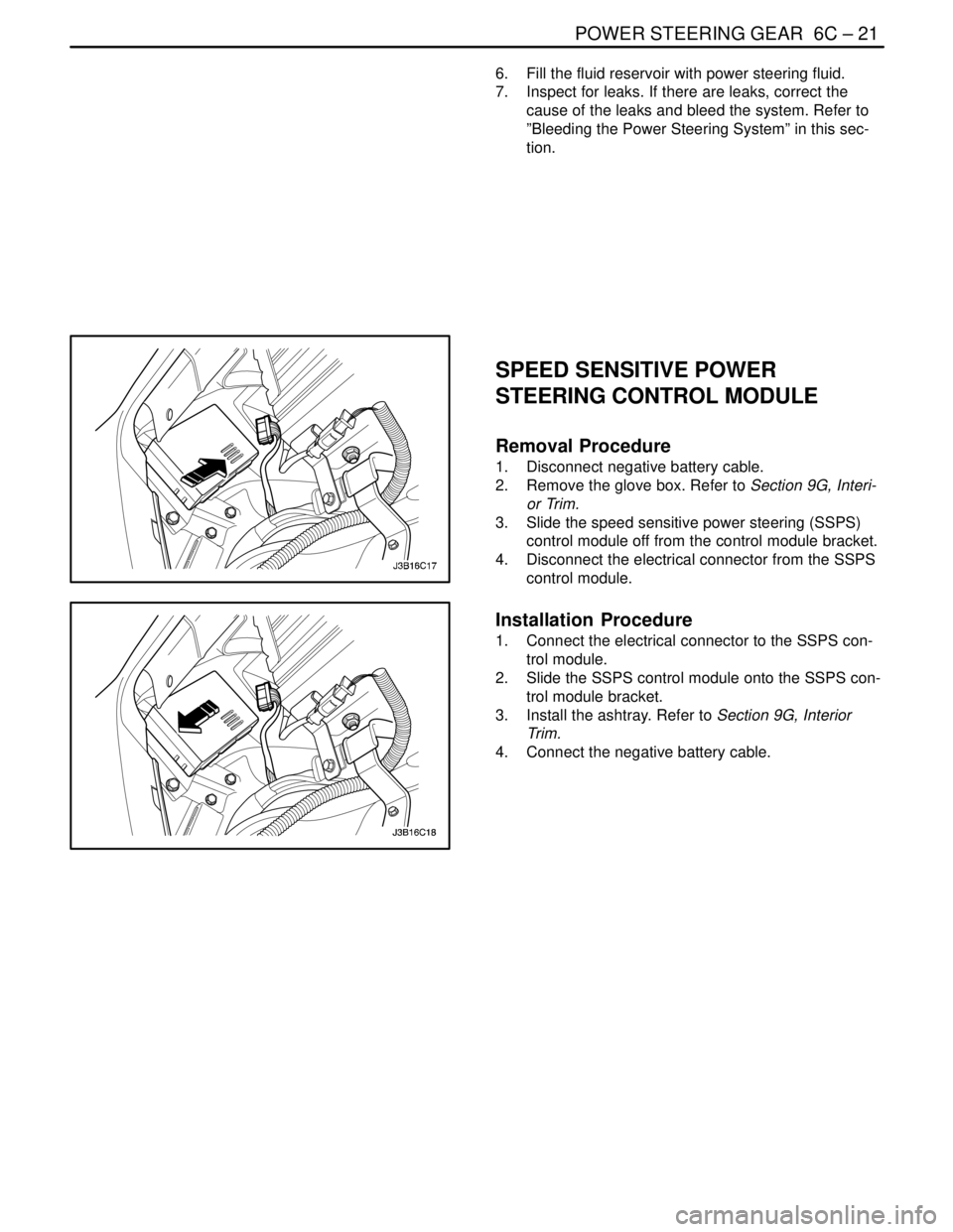

SPEED SENSITIVE POWER

STEERING CONTROL MODULE

Removal Procedure

1. Disconnect negative battery cable.

2. Remove the glove box. Refer to Section 9G, Interi-

or Trim.

3. Slide the speed sensitive power steering (SSPS)

control module off from the control module bracket.

4. Disconnect the electrical connector from the SSPS

control module.

Installation Procedure

1. Connect the electrical connector to the SSPS con-

trol module.

2. Slide the SSPS control module onto the SSPS con-

trol module bracket.

3. Install the ashtray. Refer to Section 9G, Interior

Trim.

4. Connect the negative battery cable.