reset DAEWOO NUBIRA 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 655 of 2643

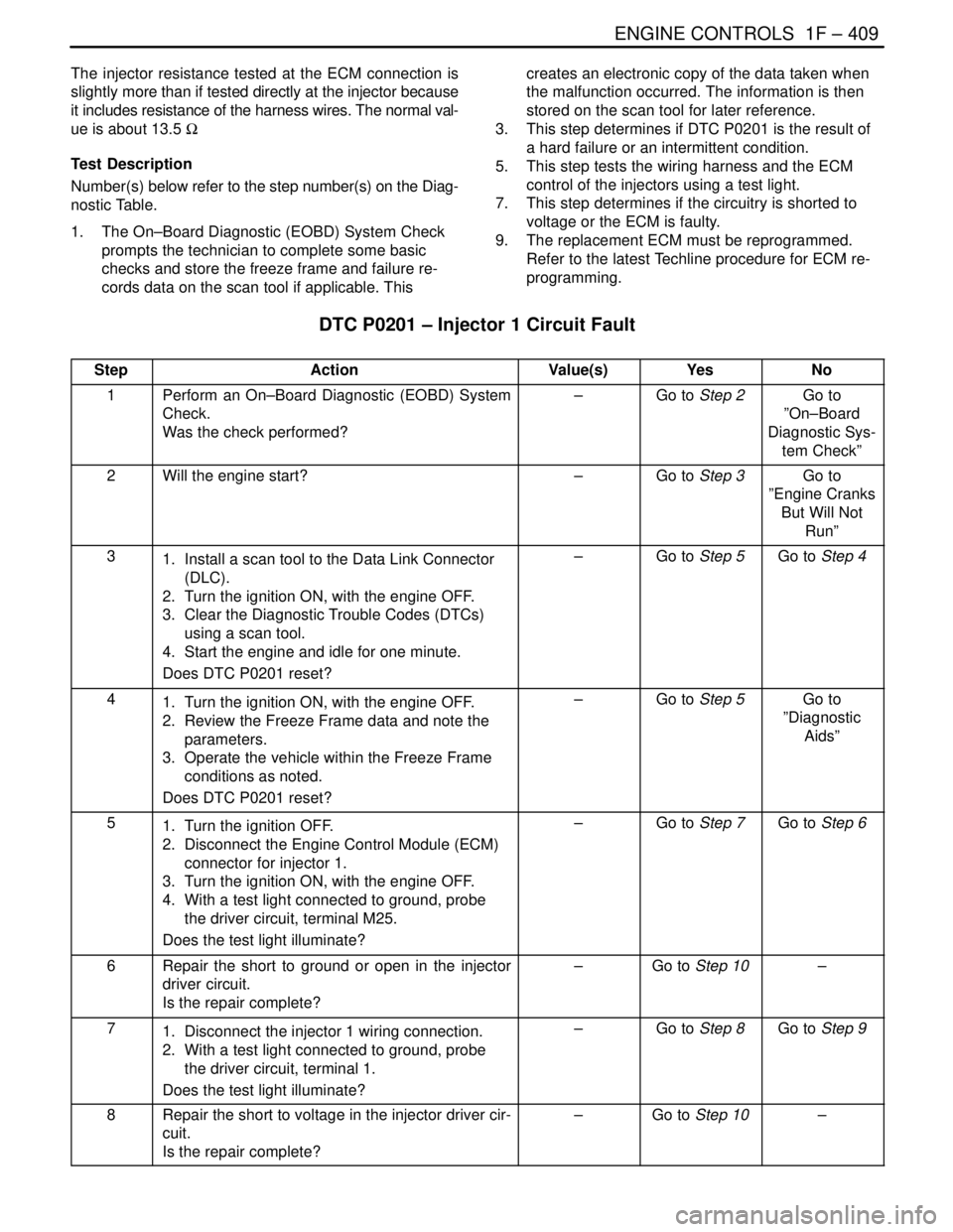

ENGINE CONTROLS 1F – 409

DAEWOO V–121 BL4

The injector resistance tested at the ECM connection is

slightly more than if tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5 Ω

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. Thiscreates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. This step determines if DTC P0201 is the result of

a hard failure or an intermittent condition.

5. This step tests the wiring harness and the ECM

control of the injectors using a test light.

7. This step determines if the circuitry is shorted to

voltage or the ECM is faulty.

9. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0201 – Injector 1 Circuit Fault

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Will the engine start?–Go to Step 3Go to

”Engine Cranks

But Will Not

Run”

31. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON, with the engine OFF.

3. Clear the Diagnostic Trouble Codes (DTCs)

using a scan tool.

4. Start the engine and idle for one minute.

Does DTC P0201 reset?–Go to Step 5Go to Step 4

41. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions as noted.

Does DTC P0201 reset?–Go to Step 5Go to

”Diagnostic

Aids”

51. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

connector for injector 1.

3. Turn the ignition ON, with the engine OFF.

4. With a test light connected to ground, probe

the driver circuit, terminal M25.

Does the test light illuminate?–Go to Step 7Go to Step 6

6Repair the short to ground or open in the injector

driver circuit.

Is the repair complete?–Go to Step 10–

71. Disconnect the injector 1 wiring connection.

2. With a test light connected to ground, probe

the driver circuit, terminal 1.

Does the test light illuminate?–Go to Step 8Go to Step 9

8Repair the short to voltage in the injector driver cir-

cuit.

Is the repair complete?–Go to Step 10–

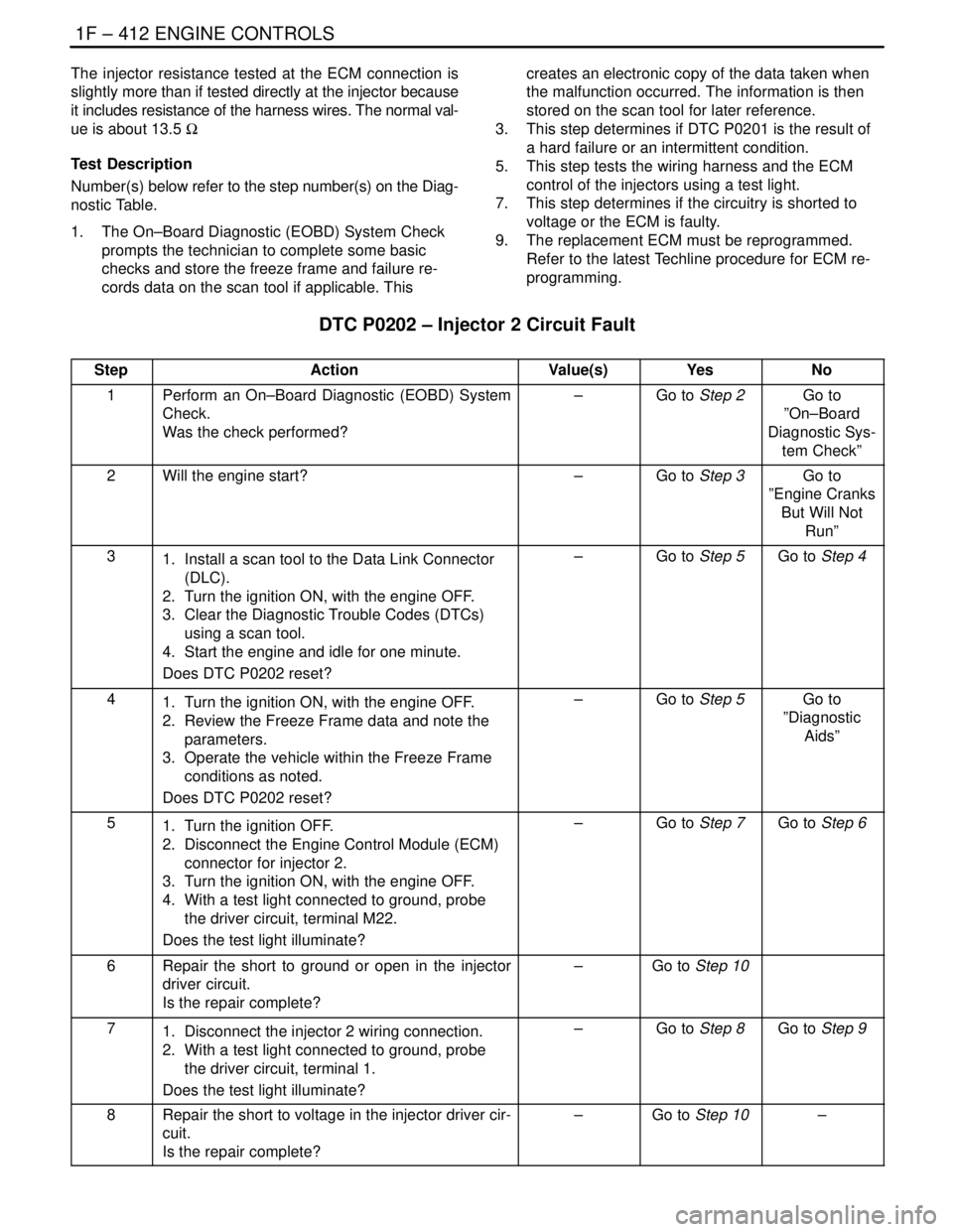

Page 658 of 2643

1F – 412IENGINE CONTROLS

DAEWOO V–121 BL4

The injector resistance tested at the ECM connection is

slightly more than if tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5 Ω

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. Thiscreates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. This step determines if DTC P0201 is the result of

a hard failure or an intermittent condition.

5. This step tests the wiring harness and the ECM

control of the injectors using a test light.

7. This step determines if the circuitry is shorted to

voltage or the ECM is faulty.

9. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0202 – Injector 2 Circuit Fault

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Will the engine start?–Go to Step 3Go to

”Engine Cranks

But Will Not

Run”

31. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON, with the engine OFF.

3. Clear the Diagnostic Trouble Codes (DTCs)

using a scan tool.

4. Start the engine and idle for one minute.

Does DTC P0202 reset?–Go to Step 5Go to Step 4

41. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions as noted.

Does DTC P0202 reset?–Go to Step 5Go to

”Diagnostic

Aids”

51. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

connector for injector 2.

3. Turn the ignition ON, with the engine OFF.

4. With a test light connected to ground, probe

the driver circuit, terminal M22.

Does the test light illuminate?–Go to Step 7Go to Step 6

6Repair the short to ground or open in the injector

driver circuit.

Is the repair complete?–Go to Step 10

71. Disconnect the injector 2 wiring connection.

2. With a test light connected to ground, probe

the driver circuit, terminal 1.

Does the test light illuminate?–Go to Step 8Go to Step 9

8Repair the short to voltage in the injector driver cir-

cuit.

Is the repair complete?–Go to Step 10–

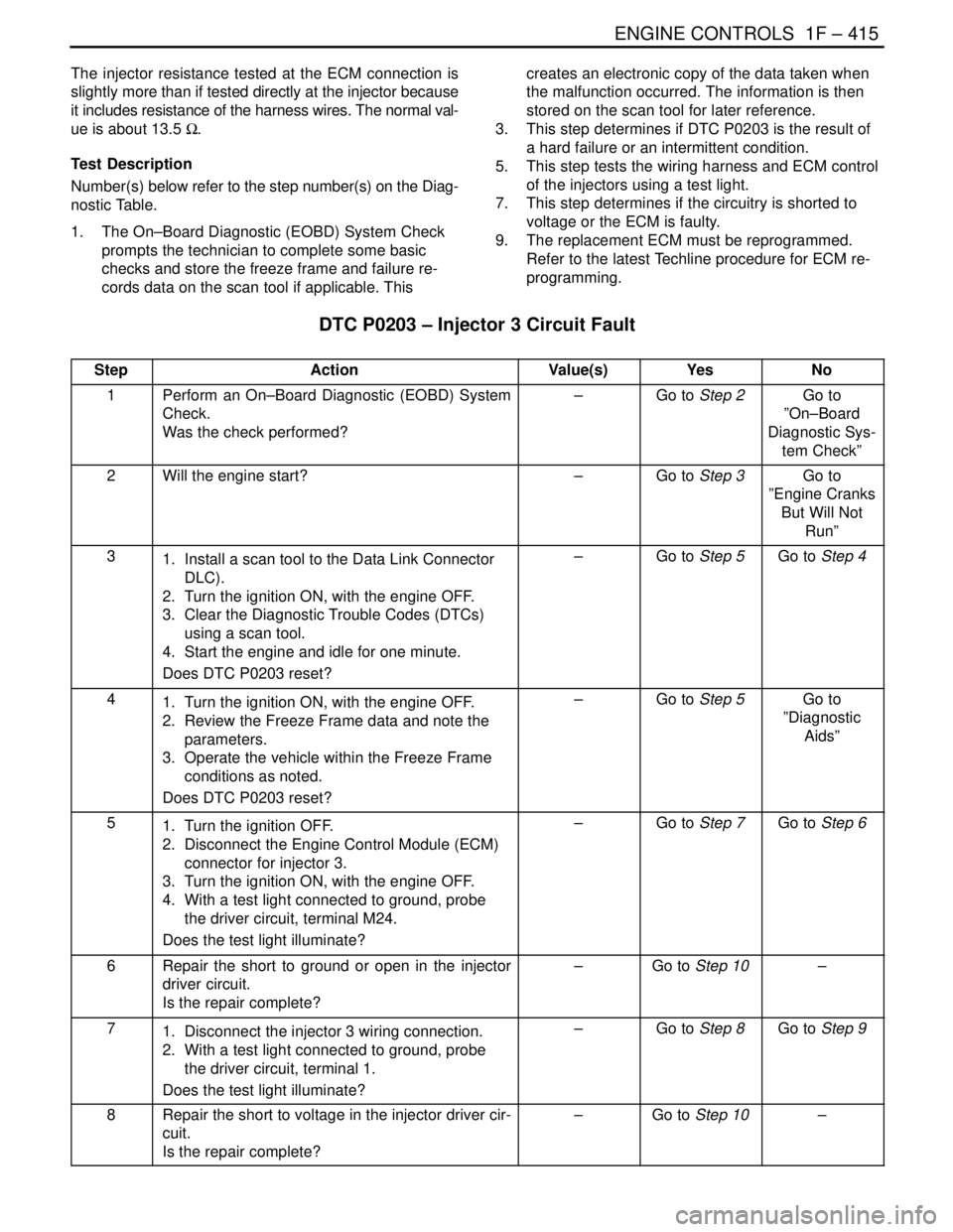

Page 661 of 2643

ENGINE CONTROLS 1F – 415

DAEWOO V–121 BL4

The injector resistance tested at the ECM connection is

slightly more than if tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5 Ω.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. Thiscreates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. This step determines if DTC P0203 is the result of

a hard failure or an intermittent condition.

5. This step tests the wiring harness and ECM control

of the injectors using a test light.

7. This step determines if the circuitry is shorted to

voltage or the ECM is faulty.

9. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0203 – Injector 3 Circuit Fault

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Will the engine start?–Go to Step 3Go to

”Engine Cranks

But Will Not

Run”

31. Install a scan tool to the Data Link Connector

DLC).

2. Turn the ignition ON, with the engine OFF.

3. Clear the Diagnostic Trouble Codes (DTCs)

using a scan tool.

4. Start the engine and idle for one minute.

Does DTC P0203 reset?–Go to Step 5Go to Step 4

41. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions as noted.

Does DTC P0203 reset?–Go to Step 5Go to

”Diagnostic

Aids”

51. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

connector for injector 3.

3. Turn the ignition ON, with the engine OFF.

4. With a test light connected to ground, probe

the driver circuit, terminal M24.

Does the test light illuminate?–Go to Step 7Go to Step 6

6Repair the short to ground or open in the injector

driver circuit.

Is the repair complete?–Go to Step 10–

71. Disconnect the injector 3 wiring connection.

2. With a test light connected to ground, probe

the driver circuit, terminal 1.

Does the test light illuminate?–Go to Step 8Go to Step 9

8Repair the short to voltage in the injector driver cir-

cuit.

Is the repair complete?–Go to Step 10–

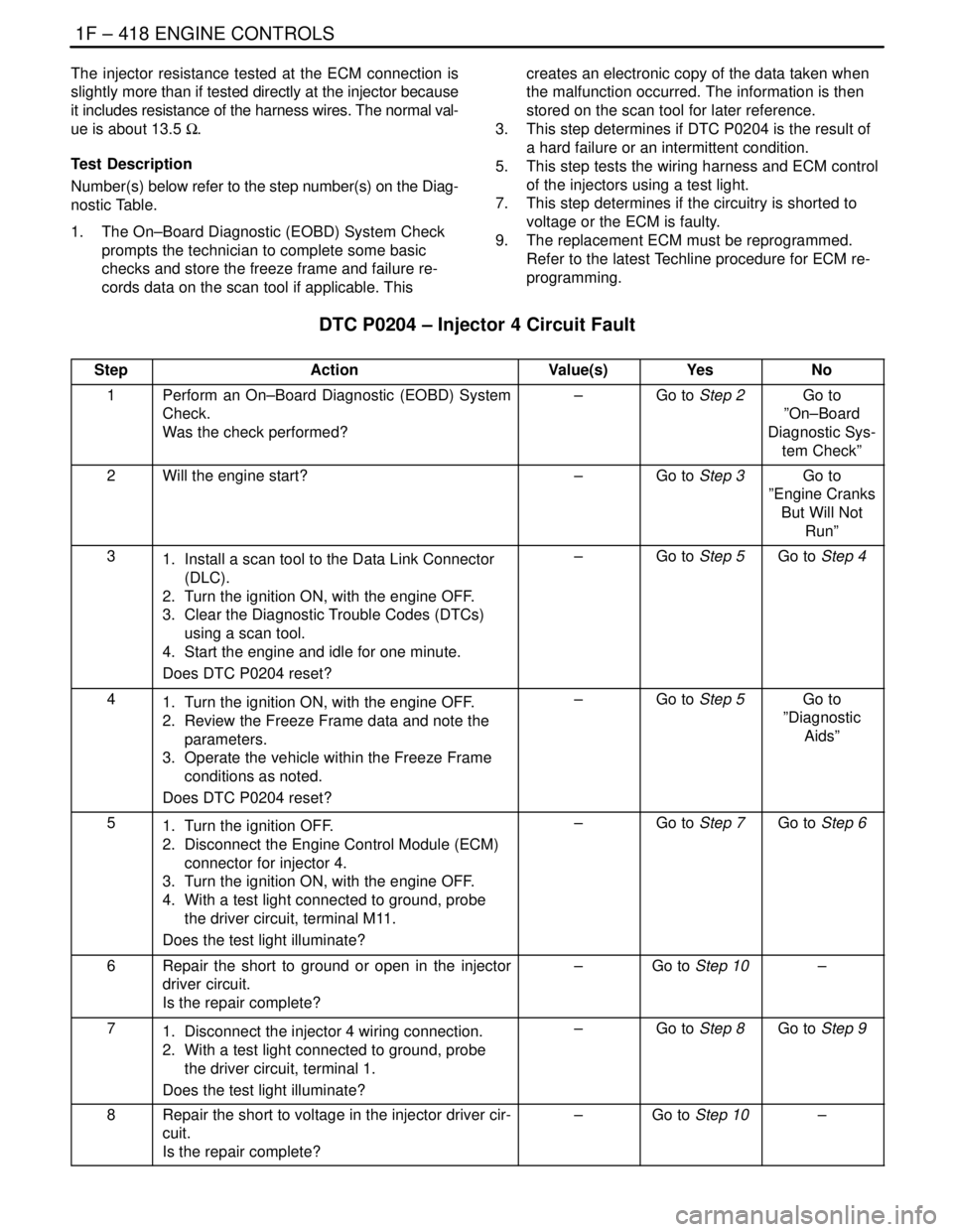

Page 664 of 2643

1F – 418IENGINE CONTROLS

DAEWOO V–121 BL4

The injector resistance tested at the ECM connection is

slightly more than if tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5 Ω.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. Thiscreates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

3. This step determines if DTC P0204 is the result of

a hard failure or an intermittent condition.

5. This step tests the wiring harness and ECM control

of the injectors using a test light.

7. This step determines if the circuitry is shorted to

voltage or the ECM is faulty.

9. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

DTC P0204 – Injector 4 Circuit Fault

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Will the engine start?–Go to Step 3Go to

”Engine Cranks

But Will Not

Run”

31. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON, with the engine OFF.

3. Clear the Diagnostic Trouble Codes (DTCs)

using a scan tool.

4. Start the engine and idle for one minute.

Does DTC P0204 reset?–Go to Step 5Go to Step 4

41. Turn the ignition ON, with the engine OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions as noted.

Does DTC P0204 reset?–Go to Step 5Go to

”Diagnostic

Aids”

51. Turn the ignition OFF.

2. Disconnect the Engine Control Module (ECM)

connector for injector 4.

3. Turn the ignition ON, with the engine OFF.

4. With a test light connected to ground, probe

the driver circuit, terminal M11.

Does the test light illuminate?–Go to Step 7Go to Step 6

6Repair the short to ground or open in the injector

driver circuit.

Is the repair complete?–Go to Step 10–

71. Disconnect the injector 4 wiring connection.

2. With a test light connected to ground, probe

the driver circuit, terminal 1.

Does the test light illuminate?–Go to Step 8Go to Step 9

8Repair the short to voltage in the injector driver cir-

cuit.

Is the repair complete?–Go to Step 10–

Page 815 of 2643

ENGINE CONTROLS 1F – 569

DAEWOO V–121 BL4

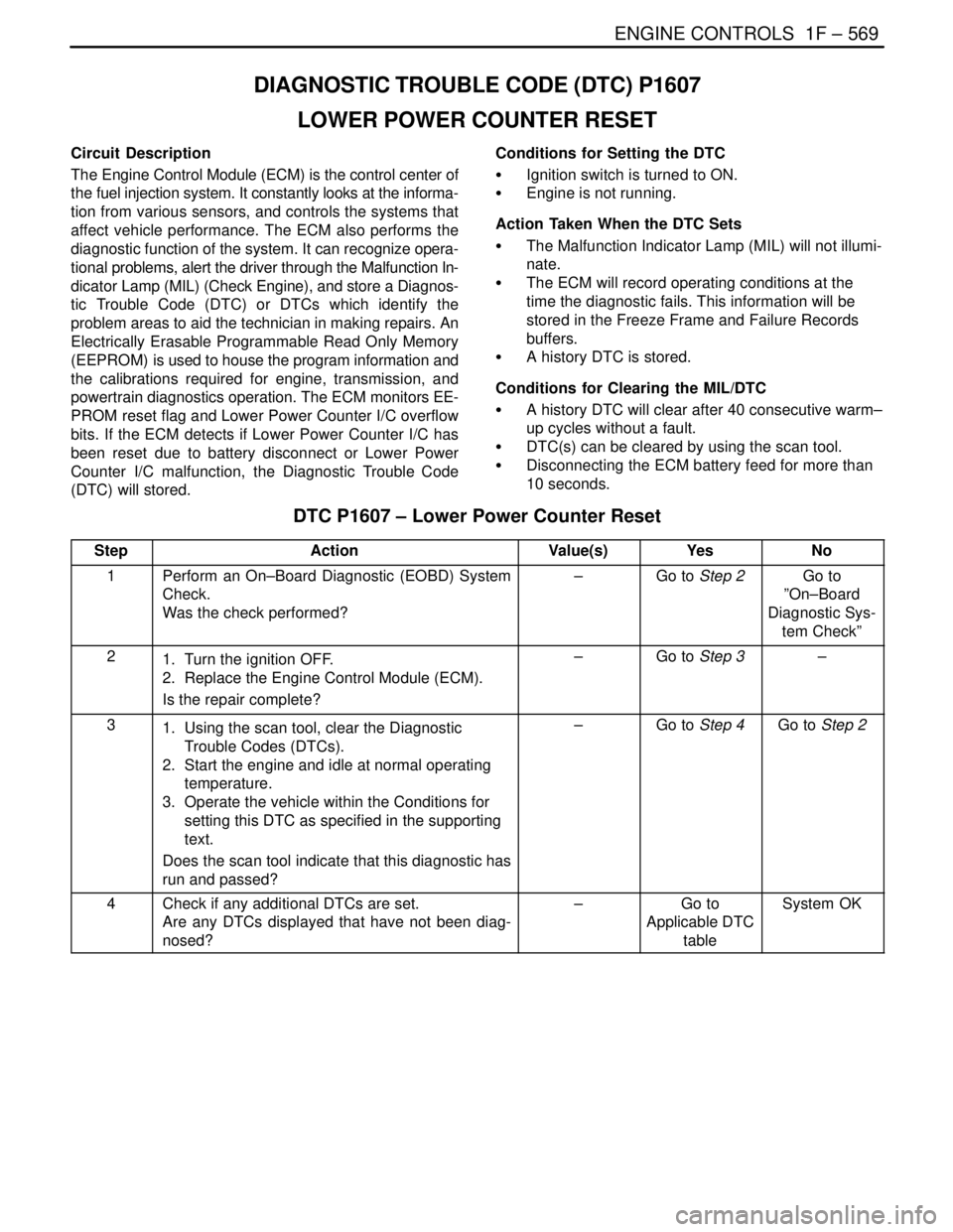

DIAGNOSTIC TROUBLE CODE (DTC) P1607

LOWER POWER COUNTER RESET

Circuit Description

The Engine Control Module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

affect vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL) (Check Engine), and store a Diagnos-

tic Trouble Code (DTC) or DTCs which identify the

problem areas to aid the technician in making repairs. An

Electrically Erasable Programmable Read Only Memory

(EEPROM) is used to house the program information and

the calibrations required for engine, transmission, and

powertrain diagnostics operation. The ECM monitors EE-

PROM reset flag and Lower Power Counter I/C overflow

bits. If the ECM detects if Lower Power Counter I/C has

been reset due to battery disconnect or Lower Power

Counter I/C malfunction, the Diagnostic Trouble Code

(DTC) will stored.Conditions for Setting the DTC

S Ignition switch is turned to ON.

S Engine is not running.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1607 – Lower Power Counter Reset

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 909 of 2643

2B – 2IWHEEL ALIGNMENT

DAEWOO V–121 BL4

DIAGNOSIS

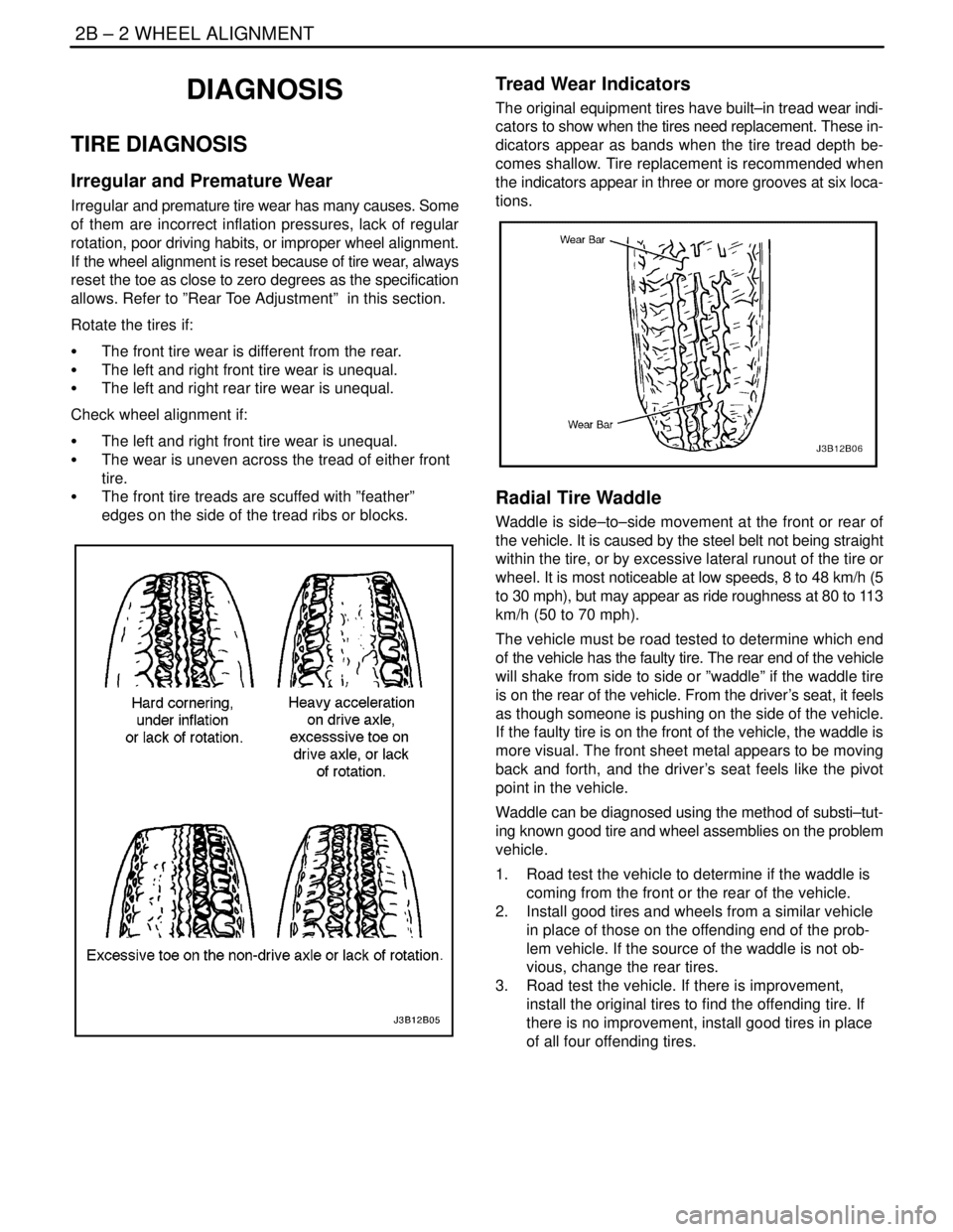

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes. Some

of them are incorrect inflation pressures, lack of regular

rotation, poor driving habits, or improper wheel alignment.

If the wheel alignment is reset because of tire wear, always

reset the toe as close to zero degrees as the specification

allows. Refer to ”Rear Toe Adjustment” in this section.

Rotate the tires if:

S The front tire wear is different from the rear.

S The left and right front tire wear is unequal.

S The left and right rear tire wear is unequal.

Check wheel alignment if:

S The left and right front tire wear is unequal.

S The wear is uneven across the tread of either front

tire.

S The front tire treads are scuffed with ”feather”

edges on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built–in tread wear indi-

cators to show when the tires need replacement. These in-

dicators appear as bands when the tire tread depth be-

comes shallow. Tire replacement is recommended when

the indicators appear in three or more grooves at six loca-

tions.

Radial Tire Waddle

Waddle is side–to–side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire or

wheel. It is most noticeable at low speeds, 8 to 48 km/h (5

to 30 mph), but may appear as ride roughness at 80 to 113

km/h (50 to 70 mph).

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the vehicle

will shake from side to side or ”waddle” if the waddle tire

is on the rear of the vehicle. From the driver’s seat, it feels

as though someone is pushing on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle is

more visual. The front sheet metal appears to be moving

back and forth, and the driver’s seat feels like the pivot

point in the vehicle.

Waddle can be diagnosed using the method of substi–tut-

ing known good tire and wheel assemblies on the problem

vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the prob-

lem vehicle. If the source of the waddle is not ob-

vious, change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no improvement, install good tires in place

of all four offending tires.

Page 1103 of 2643

4F – 22IANTILOCK BRAKE SYSTEM

DAEWOO V–121 BL4

SELF–DIAGNOSTICS

Important : The electronic brake control module (EBCM)

turns the valve relay off when a diagnostic trouble code

(DTC) is set. The scan tool will indicate that the valve relay

is off when it is used to monitor the data list. This is normal

and should not be considered a malfunction.

Important : For safety reasons it is recommended that the

vehicle not be driven with test equipment connected. Ex-

ception : for testing of wheel speeds provided the test reg-

ulations are met.

The EBCM performs system self–diagnostics and can de-

tect and often isolate system malfunctions. When it de-

tects a malfunction, the EBCM sets a DTC that represents

the malfunction, turns ON the ABS and/or the EBD indica-

tors in most instances, and may disable the ABS and/or

the EBD functions as necessary for the duration of the igni-

tion cycle.

Once each ignition cycle, the EBCM performs an automat-

ic test when the vehicle speed > 6 km/h and the brake ped-

al is not actuated or when the vehicle speed > 15 km/h and

the brake pedal is actuated. In the course of this test, the

system cycles each valve solenoid and the pump motor,

along with the necessary relays, to check component op-

eration. If the EBCM detects any malfunctions, it will set

a DTC as described above.

DISPLAYING DTCS

Tools Required

Scan Tool

DTCs can be read through the use of the scan tool.

CLEARING DTCS

Tools Required

Scan Tool

The diagnostic trouble codes (DTCs) in the electronic

brake control module (EBCM) memory are erased:S Use the scan tool ”Clear DTCs” selection.

The method is detailed below. Be sure to verify proper sys-

tem operation and absence of DTCs when the clearing

procedure is completed.

The EBCM will not permit DTC clearing until all DTCs have

been displayed. Also, DTCs cannot be cleared by discon-

necting the EBCM, disconnecting the battery cables, or

turning the ignition switch to LOCK.

Scan Tool Method

The scan tool can clear ABS system DTCs using the mass

storage cartridge.

1. Install the scan tool and the mass storage cartridge.

2. Select ”Fault Memory.”

3. Select ”Clear Fault Memory.”

Clearing the fault memory cannot reset a valve relay which

was shut down when the fault was recognized. Changes

are possible only after the fault has been eliminated and

the next ignition cycle has begun.

INTERMITTENTS AND POOR

CONNECTIONS

As with most electronic systems, intermittent malfunctions

may be difficult to diagnose accurately. The following is a

method to try to isolate an intermittent malfunction, espe-

cially in wheel speed circuitry.

If an ABS malfunction occurs, the ABS indicator will illumi-

nate during the ignition cycle in which the malfunction was

detected. If it is an intermittent problem which seems to

have corrected itself (ABS indicator off), a history DTC will

be stored. Also stored will be the history data of the DTC

at the time the malfunction occurred. Use the scan tool

modular diagnostic system to read ABS history data.

Most intermittents are caused by faulty electrical connec-

tions or wiring, although a sticking relay or solenoid can oc-

casionally be at fault.

Page 1132 of 2643

ANTILOCK BRAKE SYSTEM 4F – 51

DAEWOO V–121 BL4

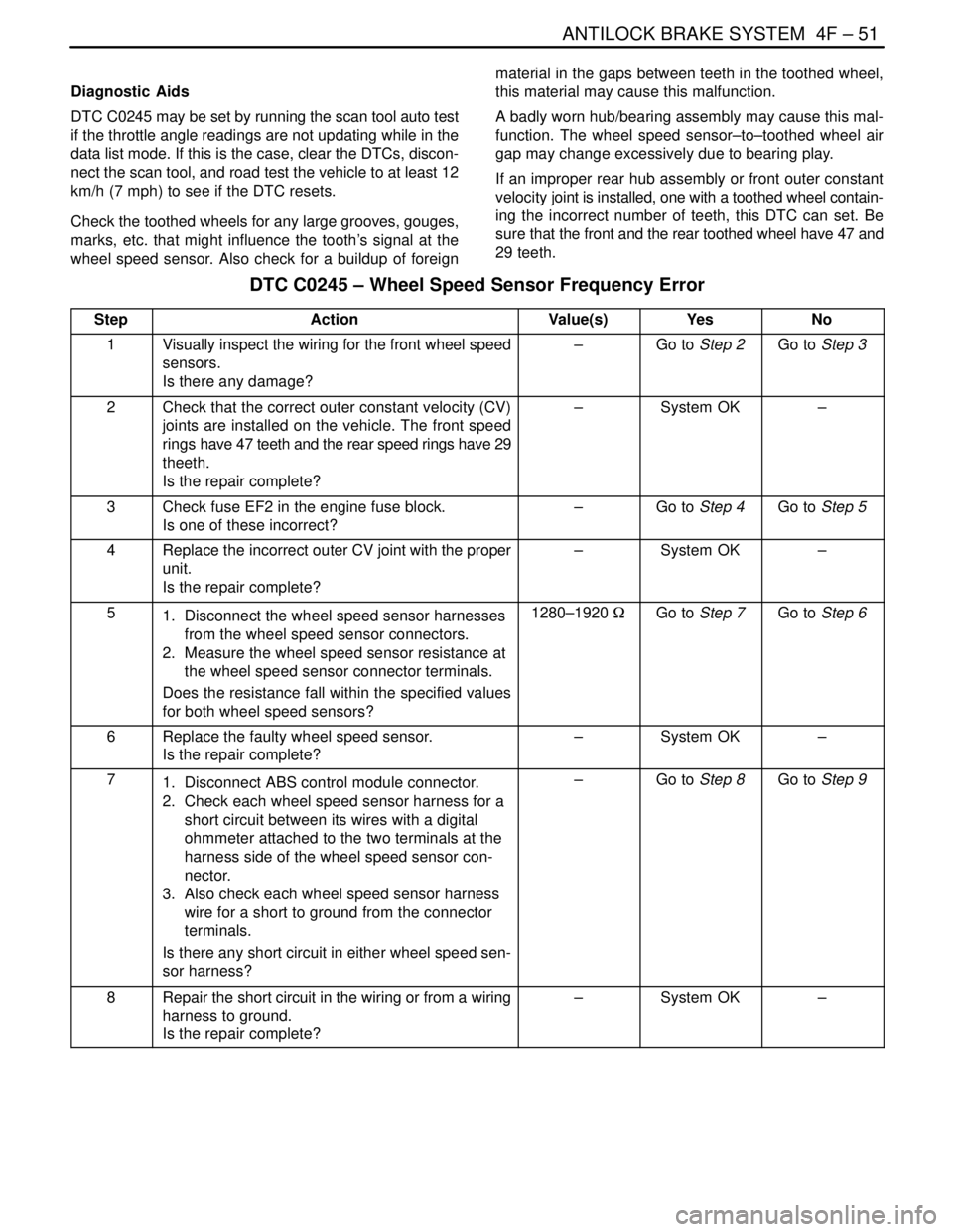

Diagnostic Aids

DTC C0245 may be set by running the scan tool auto test

if the throttle angle readings are not updating while in the

data list mode. If this is the case, clear the DTCs, discon-

nect the scan tool, and road test the vehicle to at least 12

km/h (7 mph) to see if the DTC resets.

Check the toothed wheels for any large grooves, gouges,

marks, etc. that might influence the tooth’s signal at the

wheel speed sensor. Also check for a buildup of foreignmaterial in the gaps between teeth in the toothed wheel,

this material may cause this malfunction.

A badly worn hub/bearing assembly may cause this mal-

function. The wheel speed sensor–to–toothed wheel air

gap may change excessively due to bearing play.

If an improper rear hub assembly or front outer constant

velocity joint is installed, one with a toothed wheel contain-

ing the incorrect number of teeth, this DTC can set. Be

sure that the front and the rear toothed wheel have 47 and

29 teeth.

DTC C0245 – Wheel Speed Sensor Frequency Error

StepActionValue(s)YesNo

1Visually inspect the wiring for the front wheel speed

sensors.

Is there any damage?–Go to Step 2Go to Step 3

2Check that the correct outer constant velocity (CV)

joints are installed on the vehicle. The front speed

rings have 47 teeth and the rear speed rings have 29

theeth.

Is the repair complete?–System OK–

3Check fuse EF2 in the engine fuse block.

Is one of these incorrect?–Go to Step 4Go to Step 5

4Replace the incorrect outer CV joint with the proper

unit.

Is the repair complete?–System OK–

51. Disconnect the wheel speed sensor harnesses

from the wheel speed sensor connectors.

2. Measure the wheel speed sensor resistance at

the wheel speed sensor connector terminals.

Does the resistance fall within the specified values

for both wheel speed sensors?1280–1920 WGo to Step 7Go to Step 6

6Replace the faulty wheel speed sensor.

Is the repair complete?–System OK–

71. Disconnect ABS control module connector.

2. Check each wheel speed sensor harness for a

short circuit between its wires with a digital

ohmmeter attached to the two terminals at the

harness side of the wheel speed sensor con-

nector.

3. Also check each wheel speed sensor harness

wire for a short to ground from the connector

terminals.

Is there any short circuit in either wheel speed sen-

sor harness?–Go to Step 8Go to Step 9

8Repair the short circuit in the wiring or from a wiring

harness to ground.

Is the repair complete?–System OK–

Page 1138 of 2643

ANTILOCK BRAKE SYSTEM 4F – 57

DAEWOO V–121 BL4

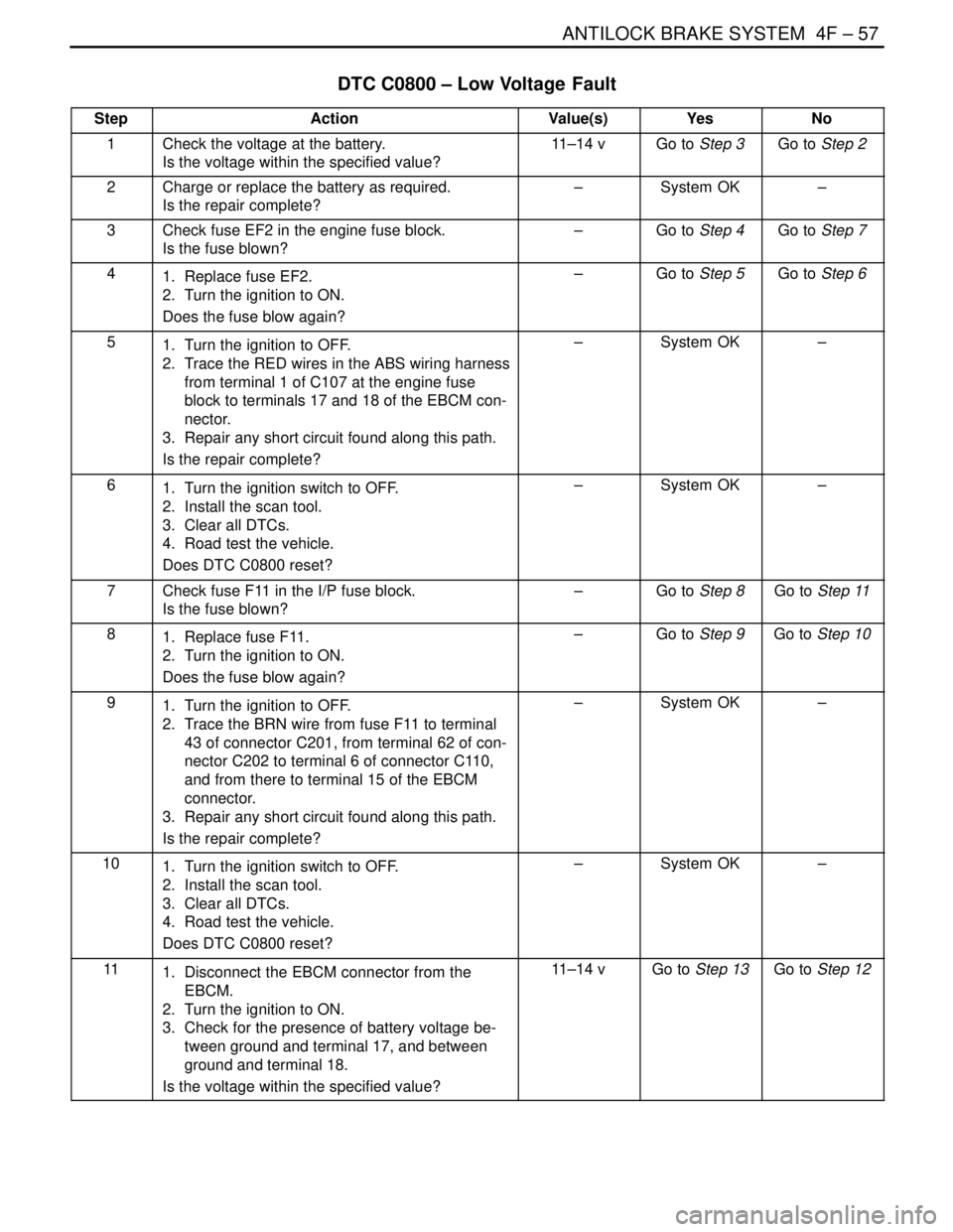

DTC C0800 – Low Voltage Fault

StepActionValue(s)YesNo

1Check the voltage at the battery.

Is the voltage within the specified value?11–14 vGo to Step 3Go to Step 2

2Charge or replace the battery as required.

Is the repair complete?–System OK–

3Check fuse EF2 in the engine fuse block.

Is the fuse blown?–Go to Step 4Go to Step 7

41. Replace fuse EF2.

2. Turn the ignition to ON.

Does the fuse blow again?–Go to Step 5Go to Step 6

51. Turn the ignition to OFF.

2. Trace the RED wires in the ABS wiring harness

from terminal 1 of C107 at the engine fuse

block to terminals 17 and 18 of the EBCM con-

nector.

3. Repair any short circuit found along this path.

Is the repair complete?–System OK–

61. Turn the ignition switch to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Road test the vehicle.

Does DTC C0800 reset?–System OK–

7Check fuse F11 in the I/P fuse block.

Is the fuse blown?–Go to Step 8Go to Step 11

81. Replace fuse F11.

2. Turn the ignition to ON.

Does the fuse blow again?–Go to Step 9Go to Step 10

91. Turn the ignition to OFF.

2. Trace the BRN wire from fuse F11 to terminal

43 of connector C201, from terminal 62 of con-

nector C202 to terminal 6 of connector C110,

and from there to terminal 15 of the EBCM

connector.

3. Repair any short circuit found along this path.

Is the repair complete?–System OK–

101. Turn the ignition switch to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Road test the vehicle.

Does DTC C0800 reset?–System OK–

111. Disconnect the EBCM connector from the

EBCM.

2. Turn the ignition to ON.

3. Check for the presence of battery voltage be-

tween ground and terminal 17, and between

ground and terminal 18.

Is the voltage within the specified value?11–14 vGo to Step 13Go to Step 12

Page 1429 of 2643

5A1 – 80IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

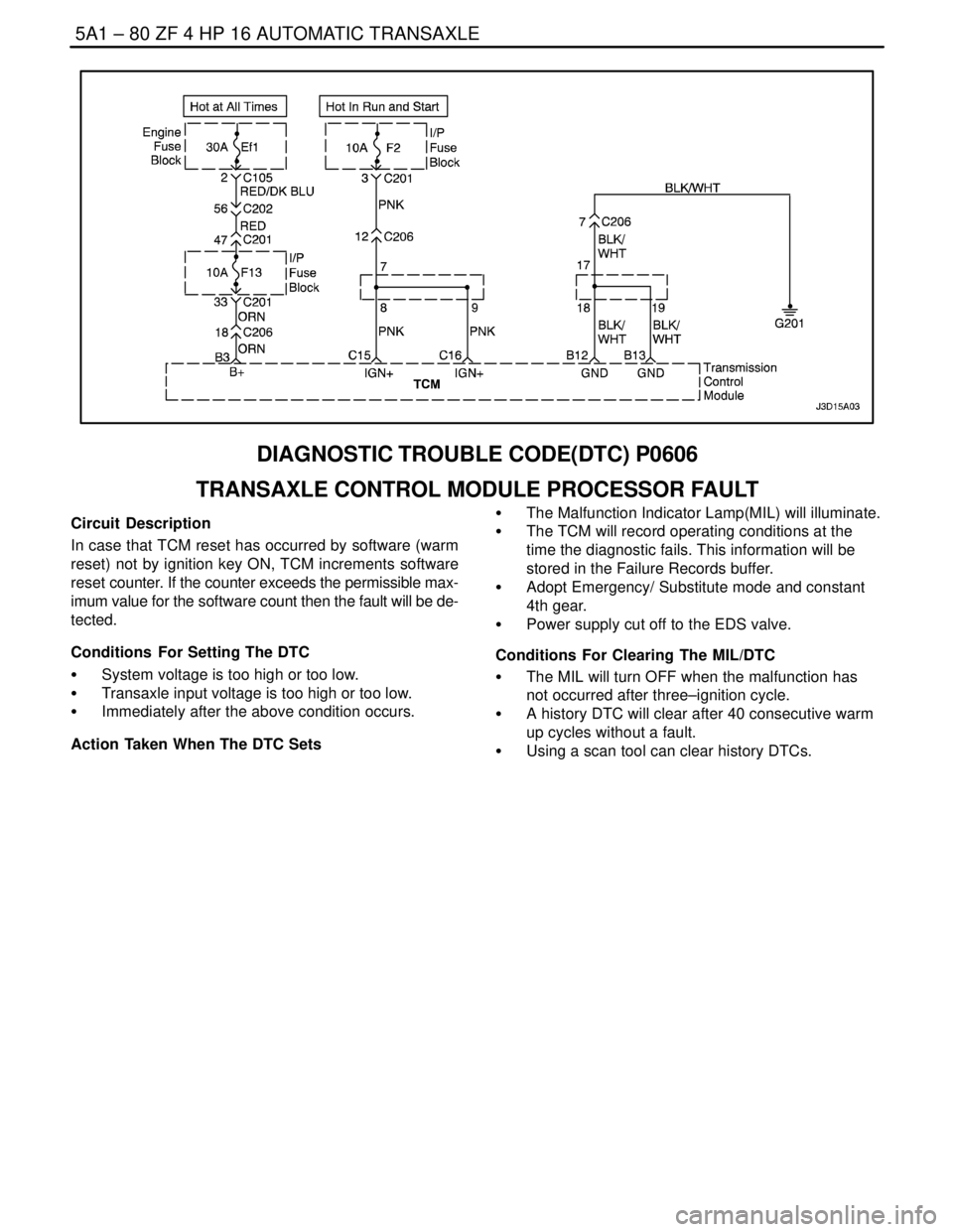

DIAGNOSTIC TROUBLE CODE(DTC) P0606

TRANSAXLE CONTROL MODULE PROCESSOR FAULT

Circuit Description

In case that TCM reset has occurred by software (warm

reset) not by ignition key ON, TCM increments software

reset counter. If the counter exceeds the permissible max-

imum value for the software count then the fault will be de-

tected.

Conditions For Setting The DTC

S System voltage is too high or too low.

S Transaxle input voltage is too high or too low.

S Immediately after the above condition occurs.

Action Taken When The DTC SetsS The Malfunction Indicator Lamp(MIL) will illuminate.

S The TCM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Failure Records buffer.

S Adopt Emergency/ Substitute mode and constant

4th gear.

S Power supply cut off to the EDS valve.

Conditions For Clearing The MIL/DTC

S The MIL will turn OFF when the malfunction has

not occurred after three–ignition cycle.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using a scan tool can clear history DTCs.