automatic transaxle DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1903 of 2643

6A – 2IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

KM–354–B Pressure Test Gauge Kit

Check the fluid pressure as follows to determine whether

the trouble is in the pump or the gear unit.

Test Procedure

1. Check the power steering fluid level and the power

steering pump belt tension. Refer to ”Checking and

Adding Fluid” in this section and Section 6B, Power

Steering Pump.

2. Disconnect the high pressure line at the pump. Use

a small container to catch any fluid.

3. Connect the hose of the pressure test gauge kit

KM–354–B to the power steering pressure hose

from the power steering pump.

4. Place the gear selector lever in PARK (automatic

transaxle–equipped vehicles) or NEUTRAL (manual

transaxle–equipped vehicles). Set the parking

brake.

5. Open the gauge valve fully.

6. Start the engine and let it idle.

7. Turn the steering wheel from lock to lock several

times to warm the fluid to operating temperature.

8. Increase the engine speed to 1,500 rpm.

Notice : The power steering pump could be damaged if

the valve is fully closed for more than 5 seconds.

9. Close the gauge valve fully, and read the pressure.

The pump pressure with the valve closed should be

between 8,330 kPa to 8,820 kPa (1,208 psi to

1,279 psi). With electronic variable orifice, the pres-

sure should be between 8,500 kPa to 8,960 kPa

(1,233 psi to 1,299 psi).

10. Immediately open the gauge valve fully.

11. Turn the steering wheel all the way to the left and

the right. If the pressure is within the specified lim-

its, the problem is not in the pump. Check the pow-

er steering gear for leaks.

POWER STEERING SYSTEM LEAK

TEST

General Procedure

Inspect the following:

S The fluid reservoir for overfill.

S Fluid for aeration and overflow.

S The hoses for loose connections.

S The torsion bar, stub shaft and adjuster seals for

leaks.

S The component sealing surfaces for damage.

Important : Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the point

at which the system is leaking. When service is required,

clean the leak area upon disassembly, replace the leaking

seal, check the component sealing surfaces for damage

and reset the torque bolt to specifications, where required.

External Leak Check

The purpose of this procedure is to pinpoint the location of

the leak. In some cases, the leak can be easily located, but

seepage–type leaks may be harder to find. To locate seep-

age leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary. Refer

to ”Checking and Adding Fluid” in this section.

Notice : Do not hold the steering wheel at a stop for any

length of time as this can damage the power steering

pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1929 of 2643

6C – 12IPOWER STEERING GEAR

DAEWOO V–121 BL4

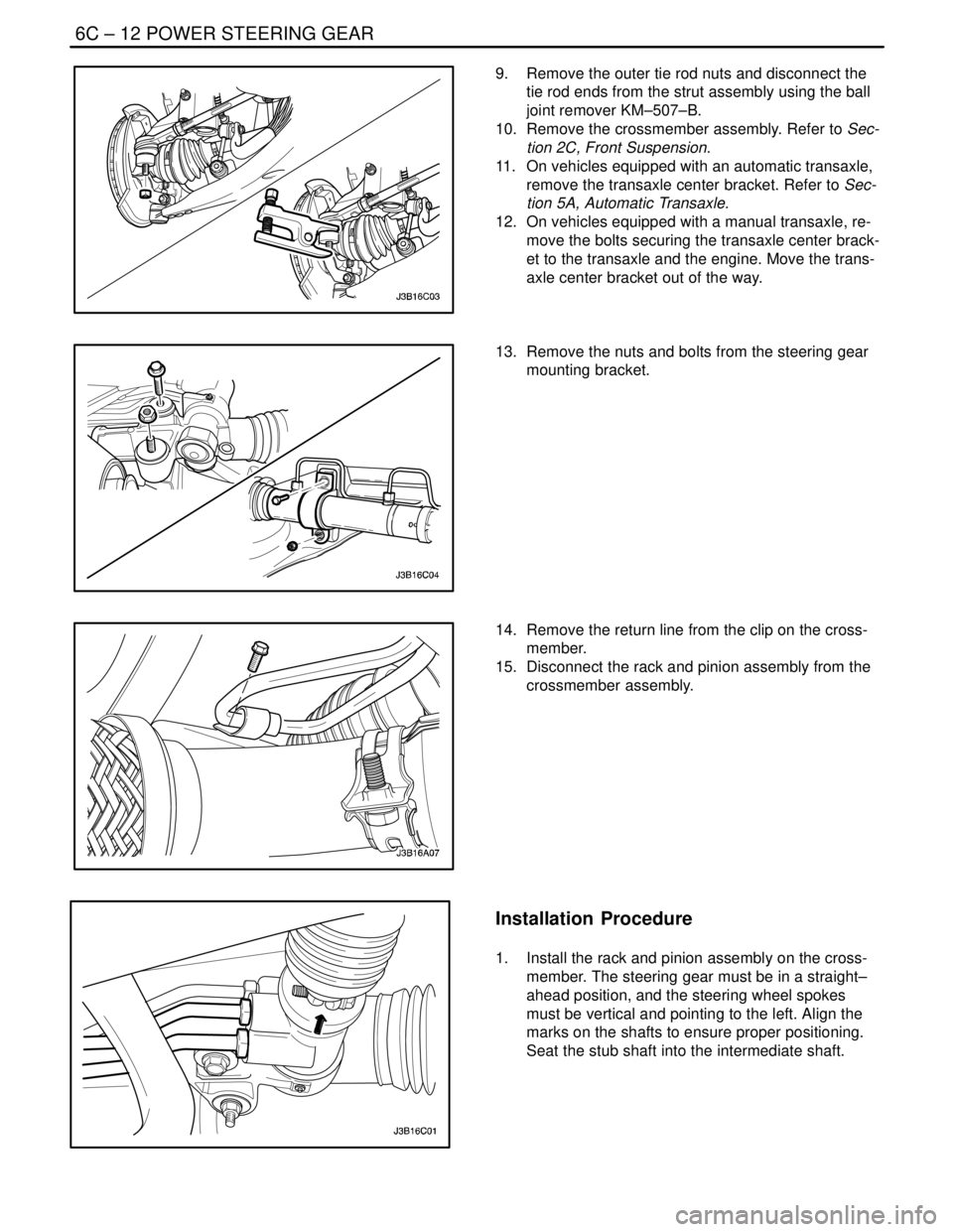

9. Remove the outer tie rod nuts and disconnect the

tie rod ends from the strut assembly using the ball

joint remover KM–507–B.

10. Remove the crossmember assembly. Refer to Sec-

tion 2C, Front Suspension.

11. On vehicles equipped with an automatic transaxle,

remove the transaxle center bracket. Refer to Sec-

tion 5A, Automatic Transaxle.

12. On vehicles equipped with a manual transaxle, re-

move the bolts securing the transaxle center brack-

et to the transaxle and the engine. Move the trans-

axle center bracket out of the way.

13. Remove the nuts and bolts from the steering gear

mounting bracket.

14. Remove the return line from the clip on the cross-

member.

15. Disconnect the rack and pinion assembly from the

crossmember assembly.

Installation Procedure

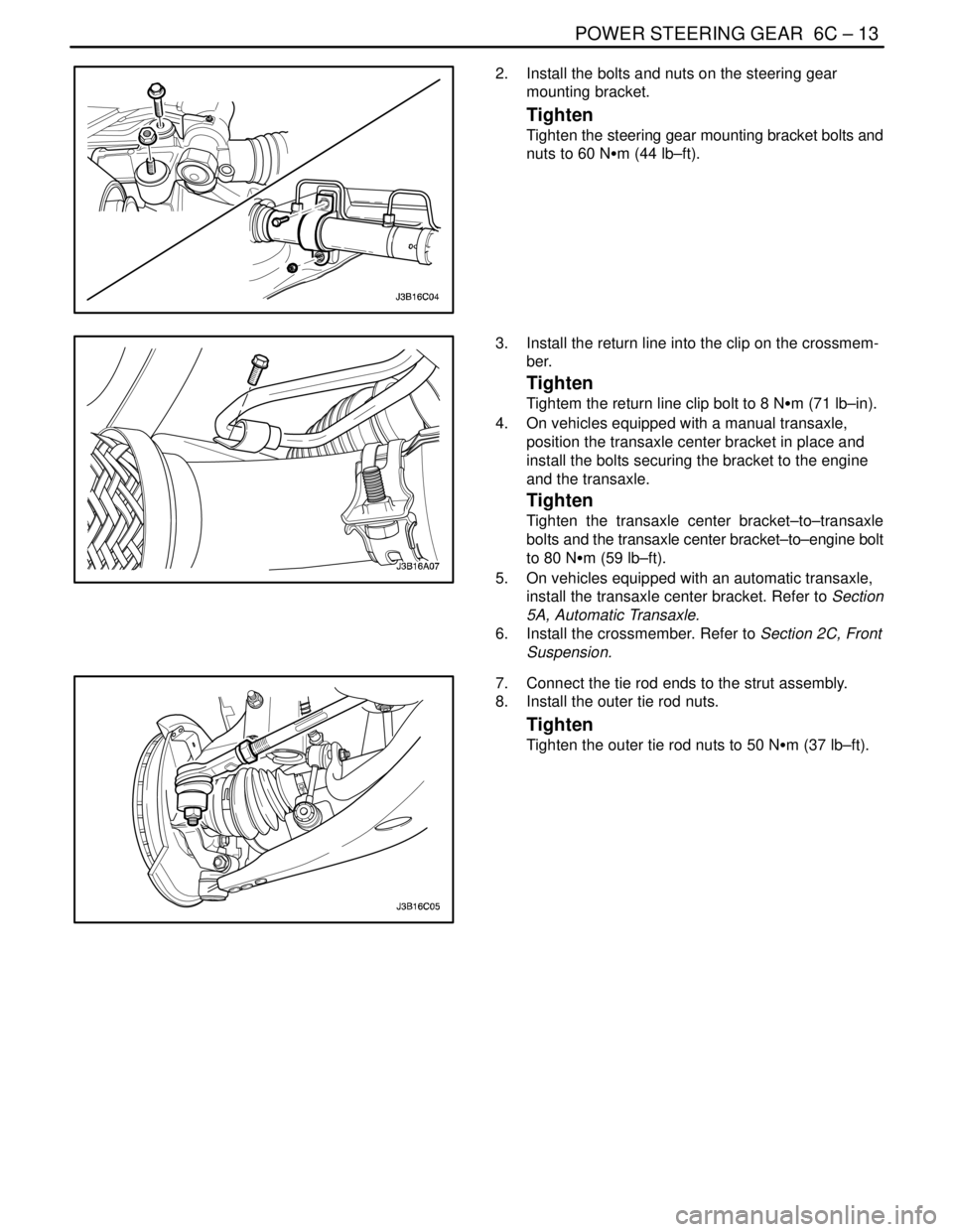

1. Install the rack and pinion assembly on the cross-

member. The steering gear must be in a straight–

ahead position, and the steering wheel spokes

must be vertical and pointing to the left. Align the

marks on the shafts to ensure proper positioning.

Seat the stub shaft into the intermediate shaft.

Page 1930 of 2643

POWER STEERING GEAR 6C – 13

DAEWOO V–121 BL4

2. Install the bolts and nuts on the steering gear

mounting bracket.

Tighten

Tighten the steering gear mounting bracket bolts and

nuts to 60 NSm (44 lb–ft).

3. Install the return line into the clip on the crossmem-

ber.

Tighten

Tightem the return line clip bolt to 8 NSm (71 lb–in).

4. On vehicles equipped with a manual transaxle,

position the transaxle center bracket in place and

install the bolts securing the bracket to the engine

and the transaxle.

Tighten

Tighten the transaxle center bracket–to–transaxle

bolts and the transaxle center bracket–to–engine bolt

to 80 NSm (59 lb–ft).

5. On vehicles equipped with an automatic transaxle,

install the transaxle center bracket. Refer to Section

5A, Automatic Transaxle.

6. Install the crossmember. Refer to Section 2C, Front

Suspension.

7. Connect the tie rod ends to the strut assembly.

8. Install the outer tie rod nuts.

Tighten

Tighten the outer tie rod nuts to 50 NSm (37 lb–ft).

Page 2252 of 2643

9B – 26ILIGHTING SYSTEMS

DAEWOO V–121 BL4

Backup Lamps Inoperative

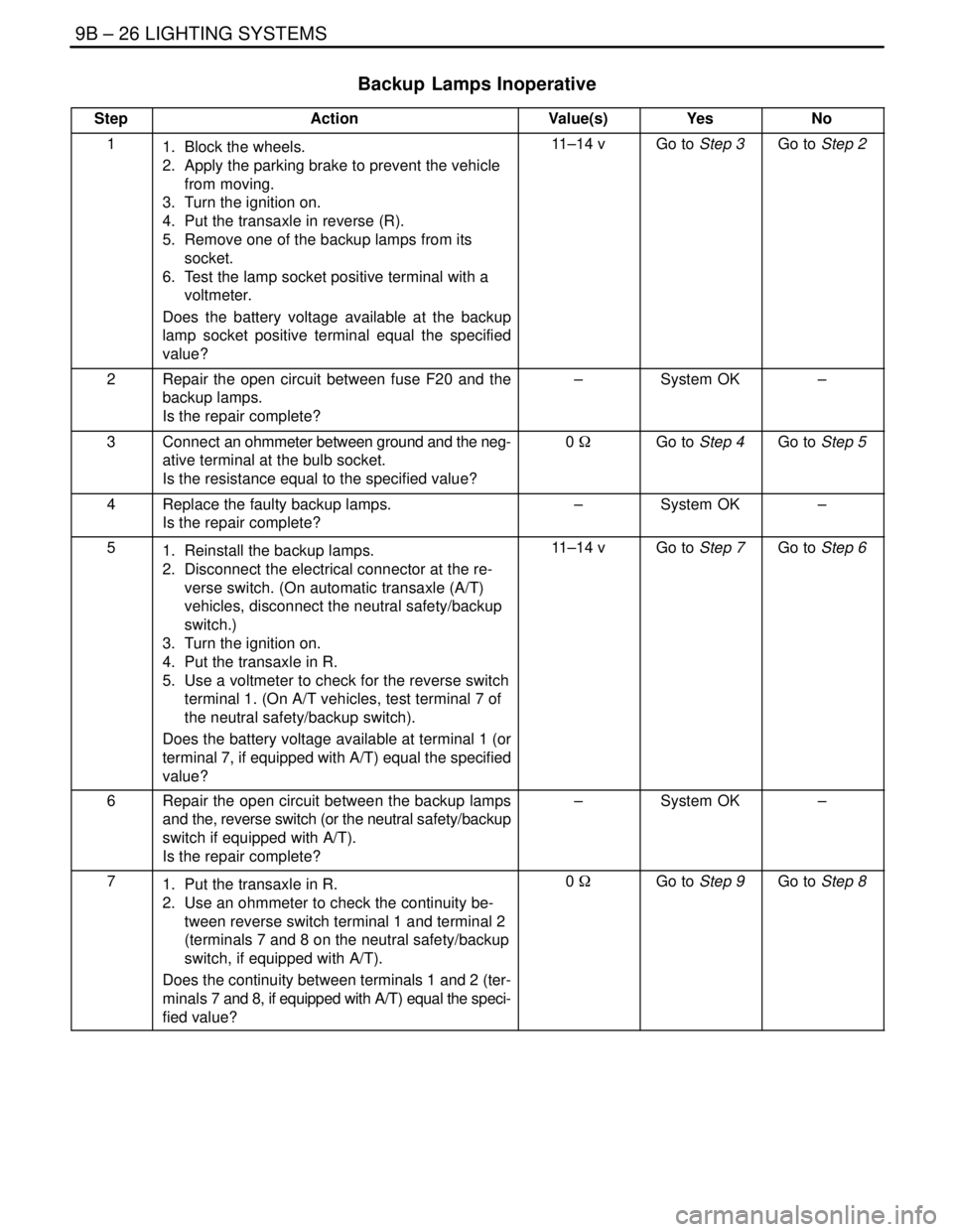

StepActionValue(s)YesNo

11. Block the wheels.

2. Apply the parking brake to prevent the vehicle

from moving.

3. Turn the ignition on.

4. Put the transaxle in reverse (R).

5. Remove one of the backup lamps from its

socket.

6. Test the lamp socket positive terminal with a

voltmeter.

Does the battery voltage available at the backup

lamp socket positive terminal equal the specified

value?11–14 vGo to Step 3Go to Step 2

2Repair the open circuit between fuse F20 and the

backup lamps.

Is the repair complete?–System OK–

3Connect an ohmmeter between ground and the neg-

ative terminal at the bulb socket.

Is the resistance equal to the specified value?0 WGo to Step 4Go to Step 5

4Replace the faulty backup lamps.

Is the repair complete?–System OK–

51. Reinstall the backup lamps.

2. Disconnect the electrical connector at the re-

verse switch. (On automatic transaxle (A/T)

vehicles, disconnect the neutral safety/backup

switch.)

3. Turn the ignition on.

4. Put the transaxle in R.

5. Use a voltmeter to check for the reverse switch

terminal 1. (On A/T vehicles, test terminal 7 of

the neutral safety/backup switch).

Does the battery voltage available at terminal 1 (or

terminal 7, if equipped with A/T) equal the specified

value?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between the backup lamps

and the, reverse switch (or the neutral safety/backup

switch if equipped with A/T).

Is the repair complete?–System OK–

71. Put the transaxle in R.

2. Use an ohmmeter to check the continuity be-

tween reverse switch terminal 1 and terminal 2

(terminals 7 and 8 on the neutral safety/backup

switch, if equipped with A/T).

Does the continuity between terminals 1 and 2 (ter-

minals 7 and 8, if equipped with A/T) equal the speci-

fied value?0 WGo to Step 9Go to Step 8

Page 2273 of 2643

LITHING SYSTEMS 9B – 47

DAEWOO V–121 BL4

BACKUP LAMPS

The backup lamps are located in the rear combination

lamps They will come on when the transaxle is shifted into

reverse. On a vehicle with an automatic transaxle, the

backup lamps are activated by the neutral safety backup

(NSBU) switch. On a vehicle with a manual transaxle, they

are activated by a reverse switch which is part of the trans-

axle.