ESP DAEWOO NUBIRA 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2545 of 2643

NUBIRA/LACETTIFRONT 4–11

3–2. REPAIR PROCEDURE

1. Remove the related parts.

S Parts to be removed when removing the front panel and

front wheelhouse.

S Parts on passenger side of dash panel lower which are

especially flammable.

S Instrument panel, wiring harness, related parts and oth-

ers.

Note : Remove according to part damaged.

2. Roughly pull out and straighten the damaged area to

approximately the original shape.

S Attach the car to the frame straightener by tightening the

underbody clamps at the horizontal pinch weld points.

S Before cutting off the damaged sections, pull them out

so that they are restored to the original shape.

S Roughly cut off the front longitudinal according to the ex-

tent of damage before roughly pulling out the damage

makes repair of the related parts difficult.

S Do not pull out more than necessary.

Note : Check the condition of the door and hinges.

3. Peel off the undercoat and sealer.

S Heat the undercoat and sealer at the welding areas of

the damaged parts with a gas torch and peel off the un-

dercoat and sealer with a steel spatula.

CAUTION : Be careful not to burn the fittings inside

the passenger compartment when heating.

4. Cut and pry off the front longitudinal.

Note : It’s not necessary to separate the wheelhouse

from the front longitudinal if the wheelhouse is to be re-

placed also.

S Center punch around the spot weld imprints on the

wheelhouse and other related parts.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the center punched areas.

S Cut off the front longitudinal with an air chisel, leaving the

welding flanges intact.

S Level and finish the burrs from the pried off spot welds

with a disc sander.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

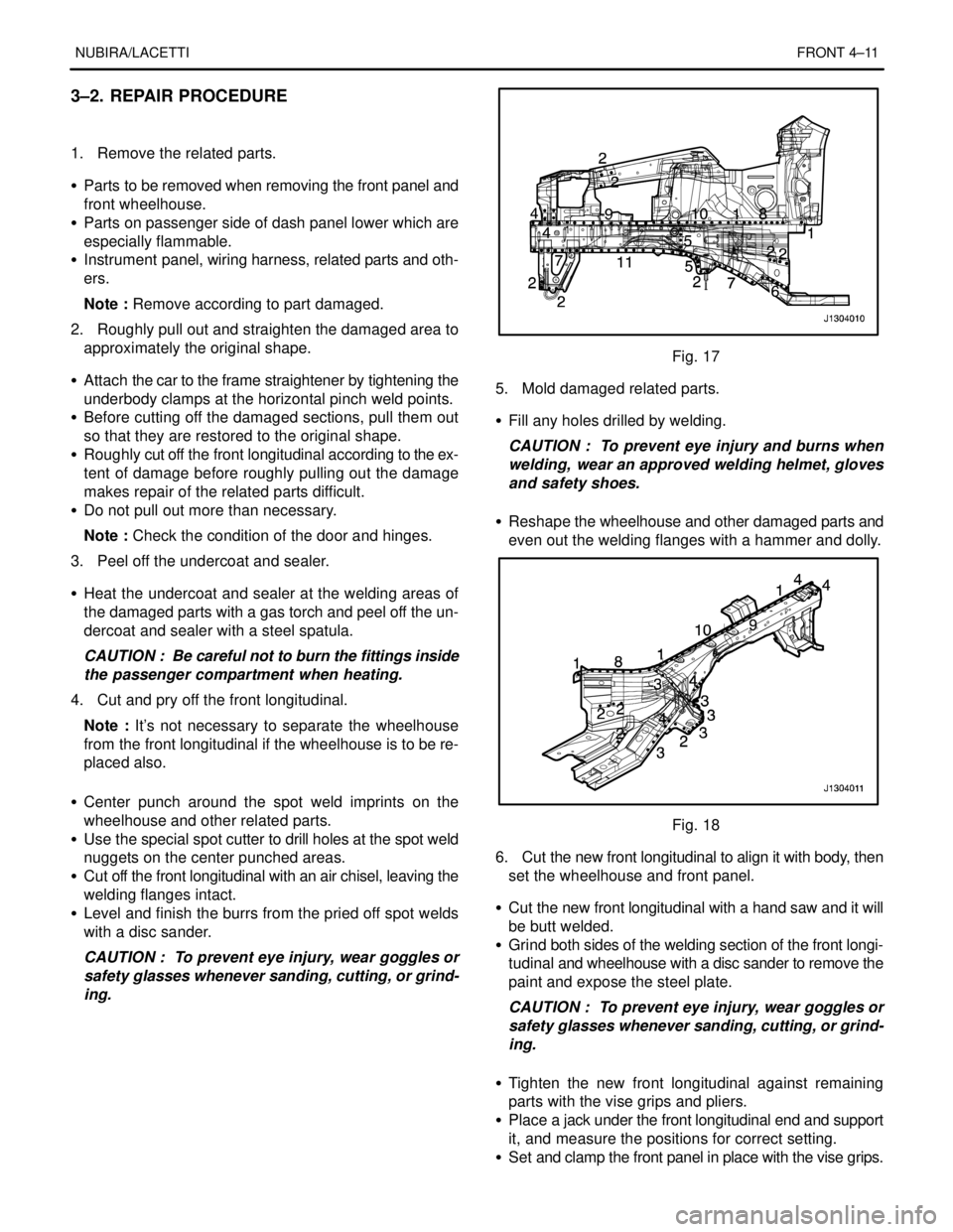

Fig. 17

5. Mold damaged related parts.

S Fill any holes drilled by welding.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Reshape the wheelhouse and other damaged parts and

even out the welding flanges with a hammer and dolly.

Fig. 18

6. Cut the new front longitudinal to align it with body, then

set the wheelhouse and front panel.

S Cut the new front longitudinal with a hand saw and it will

be butt welded.

S Grind both sides of the welding section of the front longi-

tudinal and wheelhouse with a disc sander to remove the

paint and expose the steel plate.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Tighten the new front longitudinal against remaining

parts with the vise grips and pliers.

S Place a jack under the front longitudinal end and support

it, and measure the positions for correct setting.

S Set and clamp the front panel in place with the vise grips.

Page 2546 of 2643

4–12 FRONTNUBIRA/LACETTI

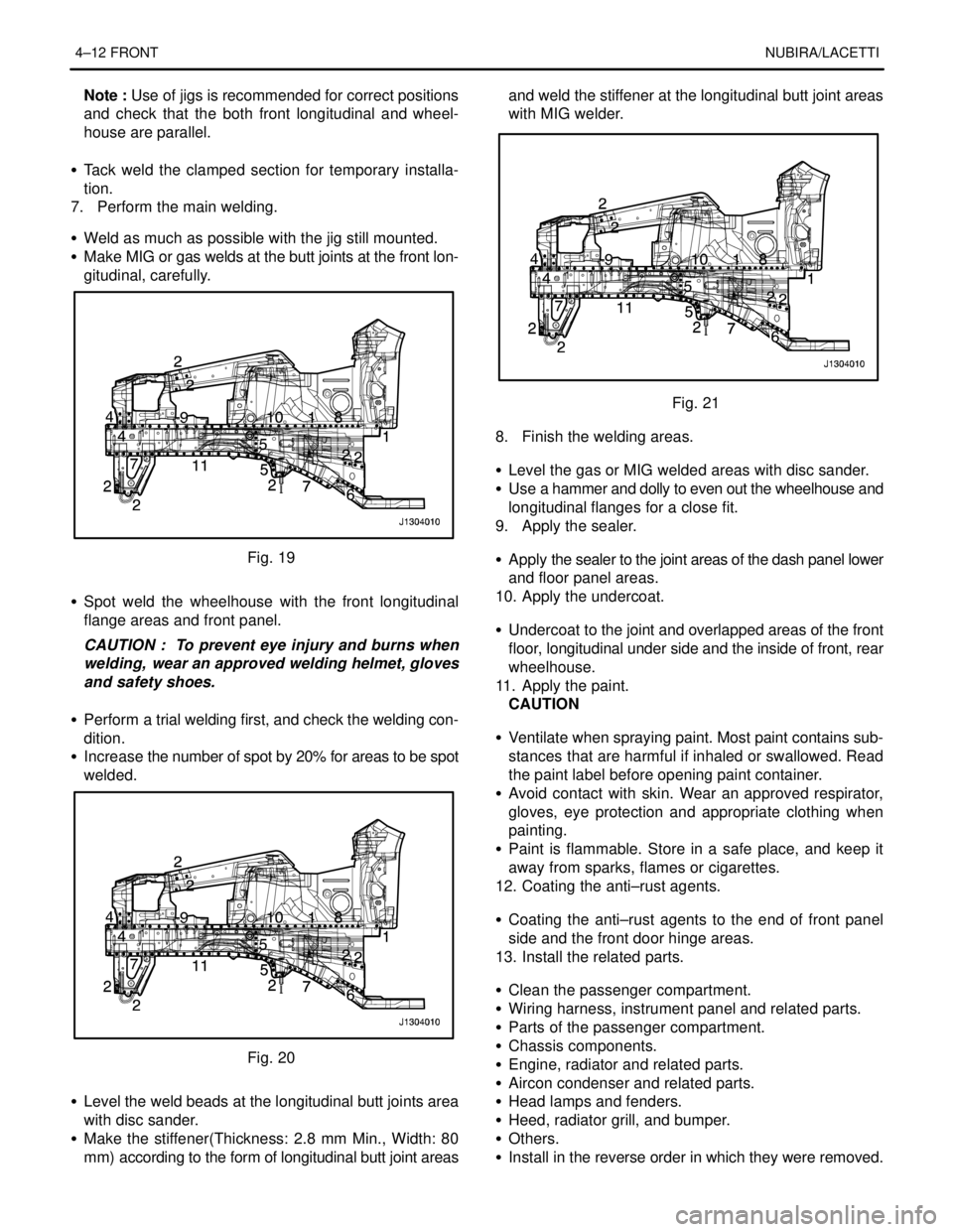

Note : Use of jigs is recommended for correct positions

and check that the both front longitudinal and wheel-

house are parallel.

S Tack weld the clamped section for temporary installa-

tion.

7. Perform the main welding.

S Weld as much as possible with the jig still mounted.

S Make MIG or gas welds at the butt joints at the front lon-

gitudinal, carefully.

Fig. 19

S Spot weld the wheelhouse with the front longitudinal

flange areas and front panel.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Perform a trial welding first, and check the welding con-

dition.

S Increase the number of spot by 20% for areas to be spot

welded.

Fig. 20

S Level the weld beads at the longitudinal butt joints area

with disc sander.

S Make the stiffener(Thickness: 2.8 mm Min., Width: 80

mm) according to the form of longitudinal butt joint areasand weld the stiffener at the longitudinal butt joint areas

with MIG welder.

Fig. 21

8. Finish the welding areas.

S Level the gas or MIG welded areas with disc sander.

S Use a hammer and dolly to even out the wheelhouse and

longitudinal flanges for a close fit.

9. Apply the sealer.

S Apply the sealer to the joint areas of the dash panel lower

and floor panel areas.

10. Apply the undercoat.

S Undercoat to the joint and overlapped areas of the front

floor, longitudinal under side and the inside of front, rear

wheelhouse.

11. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

12. Coating the anti–rust agents.

S Coating the anti–rust agents to the end of front panel

side and the front door hinge areas.

13. Install the related parts.

S Clean the passenger compartment.

S Wiring harness, instrument panel and related parts.

S Parts of the passenger compartment.

S Chassis components.

S Engine, radiator and related parts.

S Aircon condenser and related parts.

S Head lamps and fenders.

S Heed, radiator grill, and bumper.

S Others.

S Install in the reverse order in which they were removed.

Page 2551 of 2643

NUBIRA/LACETTIFRONT 4–17

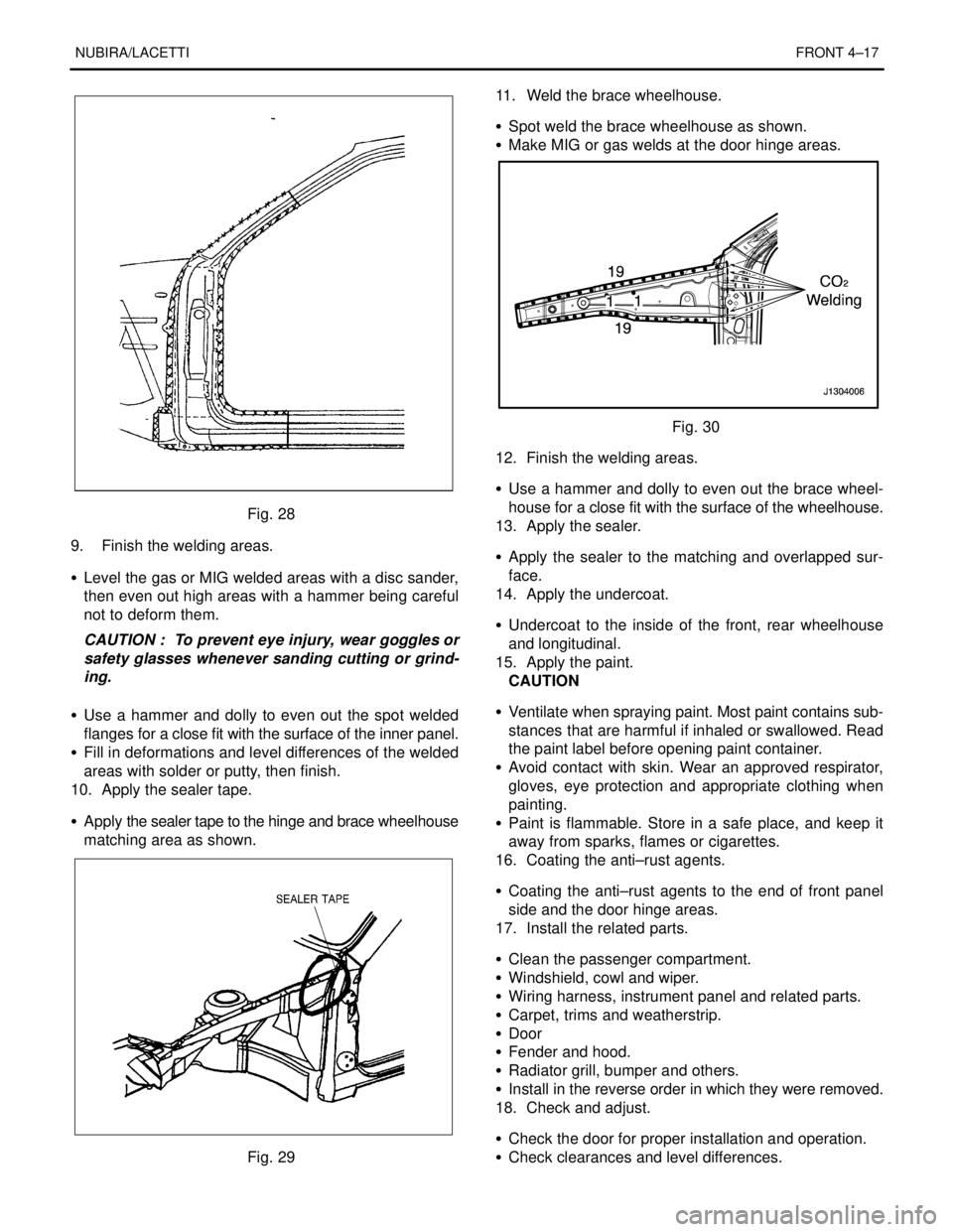

Fig. 28

9. Finish the welding areas.

S Level the gas or MIG welded areas with a disc sander,

then even out high areas with a hammer being careful

not to deform them.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding cutting or grind-

ing.

S Use a hammer and dolly to even out the spot welded

flanges for a close fit with the surface of the inner panel.

S Fill in deformations and level differences of the welded

areas with solder or putty, then finish.

10. Apply the sealer tape.

S Apply the sealer tape to the hinge and brace wheelhouse

matching area as shown.

Fig. 2911. Weld the brace wheelhouse.

S Spot weld the brace wheelhouse as shown.

S Make MIG or gas welds at the door hinge areas.

Fig. 30

12. Finish the welding areas.

S Use a hammer and dolly to even out the brace wheel-

house for a close fit with the surface of the wheelhouse.

13. Apply the sealer.

S Apply the sealer to the matching and overlapped sur-

face.

14. Apply the undercoat.

S Undercoat to the inside of the front, rear wheelhouse

and longitudinal.

15. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

16. Coating the anti–rust agents.

S Coating the anti–rust agents to the end of front panel

side and the door hinge areas.

17. Install the related parts.

S Clean the passenger compartment.

S Windshield, cowl and wiper.

S Wiring harness, instrument panel and related parts.

S Carpet, trims and weatherstrip.

S Door

S Fender and hood.

S Radiator grill, bumper and others.

S Install in the reverse order in which they were removed.

18. Check and adjust.

S Check the door for proper installation and operation.

S Check clearances and level differences.

Page 2557 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–5

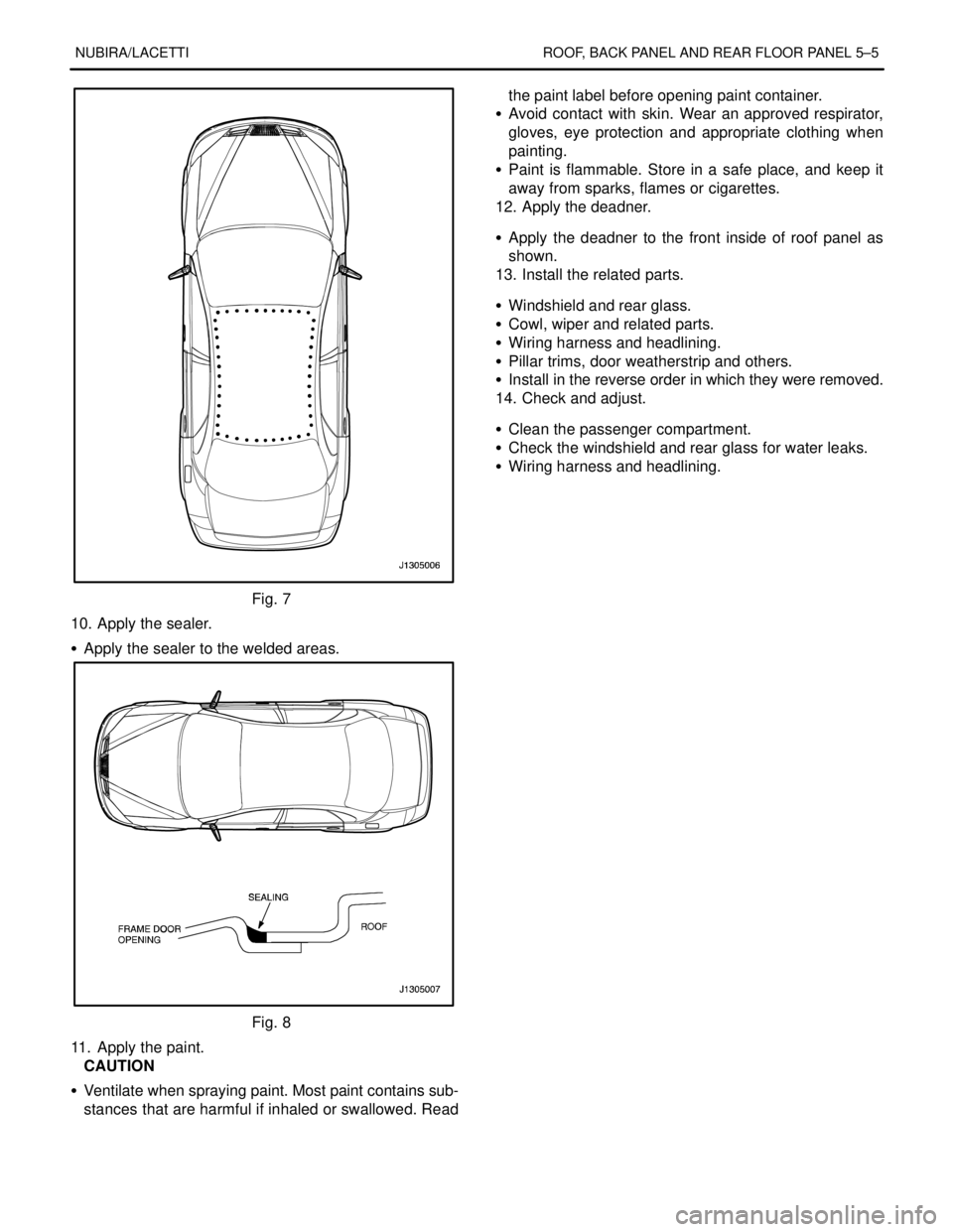

Fig. 7

10. Apply the sealer.

S Apply the sealer to the welded areas.

Fig. 8

11. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Readthe paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

12. Apply the deadner.

S Apply the deadner to the front inside of roof panel as

shown.

13. Install the related parts.

S Windshield and rear glass.

S Cowl, wiper and related parts.

S Wiring harness and headlining.

S Pillar trims, door weatherstrip and others.

S Install in the reverse order in which they were removed.

14. Check and adjust.

S Clean the passenger compartment.

S Check the windshield and rear glass for water leaks.

S Wiring harness and headlining.

Page 2560 of 2643

5–8 ROOF, BACK PANEL AND REAR FLOOR PANEL NUBIRA/LACETTI

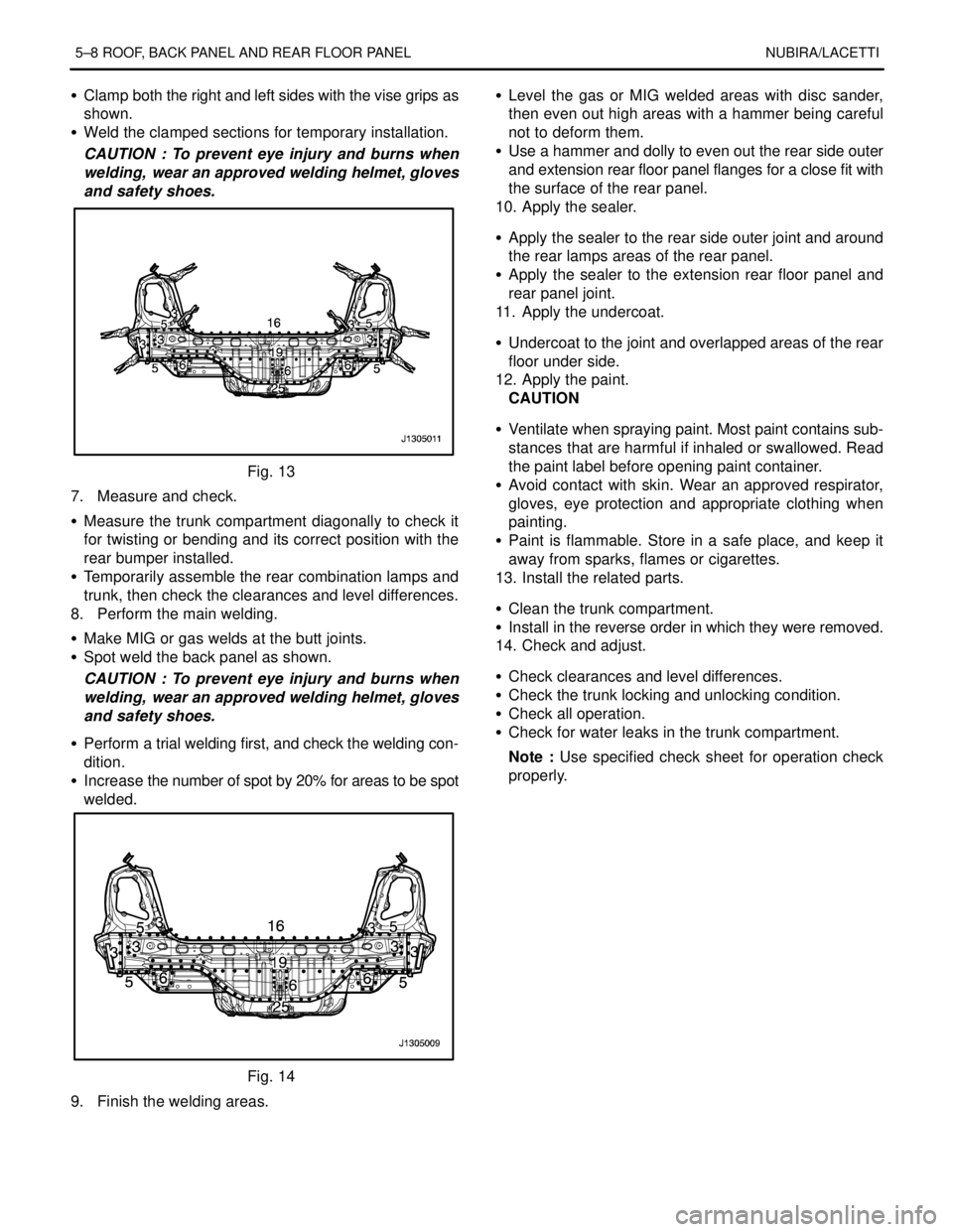

S Clamp both the right and left sides with the vise grips as

shown.

S Weld the clamped sections for temporary installation.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

Fig. 13

7. Measure and check.

S Measure the trunk compartment diagonally to check it

for twisting or bending and its correct position with the

rear bumper installed.

S Temporarily assemble the rear combination lamps and

trunk, then check the clearances and level differences.

8. Perform the main welding.

S Make MIG or gas welds at the butt joints.

S Spot weld the back panel as shown.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Perform a trial welding first, and check the welding con-

dition.

S Increase the number of spot by 20% for areas to be spot

welded.

Fig. 14

9. Finish the welding areas.S Level the gas or MIG welded areas with disc sander,

then even out high areas with a hammer being careful

not to deform them.

S Use a hammer and dolly to even out the rear side outer

and extension rear floor panel flanges for a close fit with

the surface of the rear panel.

10. Apply the sealer.

S Apply the sealer to the rear side outer joint and around

the rear lamps areas of the rear panel.

S Apply the sealer to the extension rear floor panel and

rear panel joint.

11. Apply the undercoat.

S Undercoat to the joint and overlapped areas of the rear

floor under side.

12. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

13. Install the related parts.

S Clean the trunk compartment.

S Install in the reverse order in which they were removed.

14. Check and adjust.

S Check clearances and level differences.

S Check the trunk locking and unlocking condition.

S Check all operation.

S Check for water leaks in the trunk compartment.

Note : Use specified check sheet for operation check

properly.

Page 2565 of 2643

NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–13

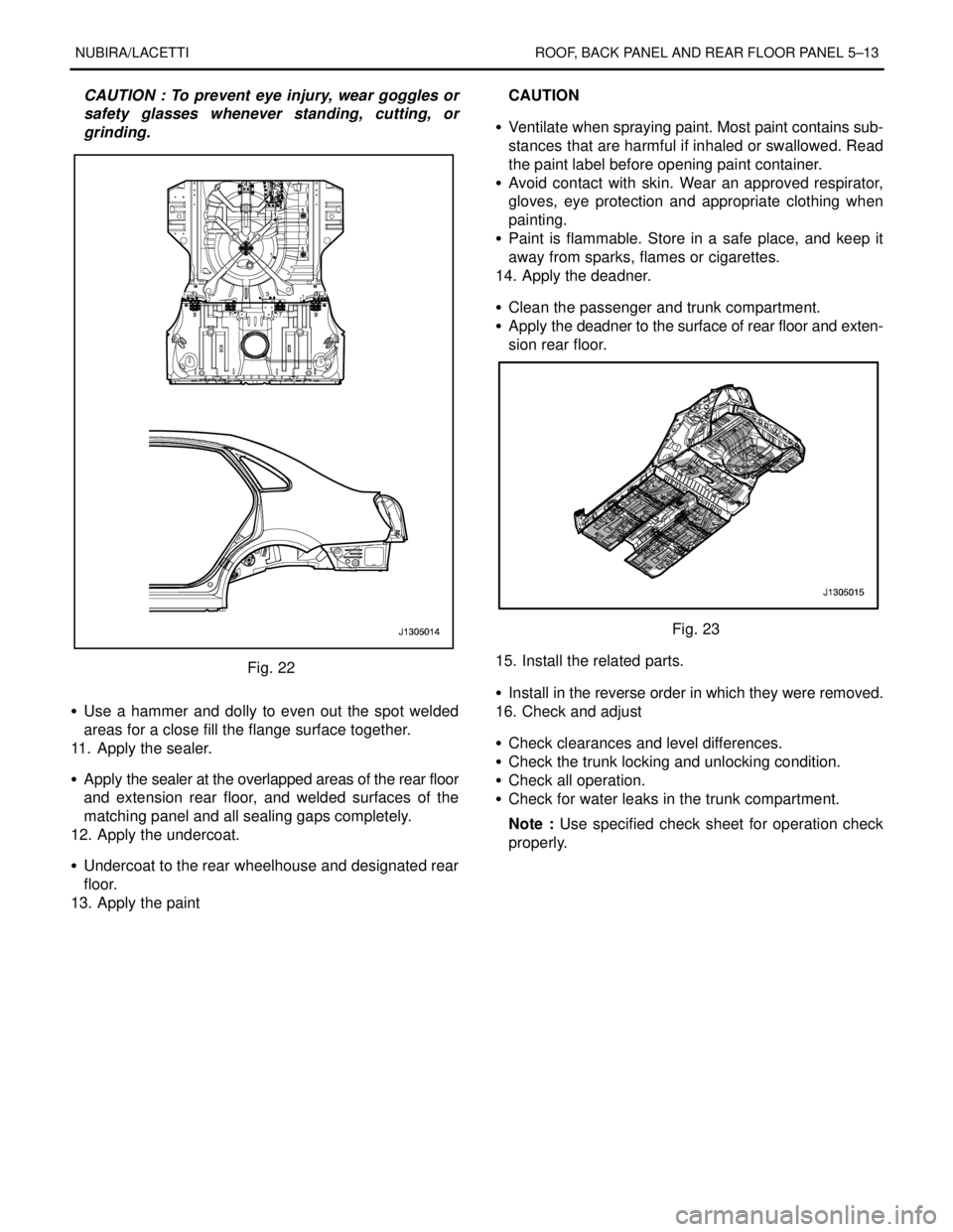

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever standing, cutting, or

grinding.

Fig. 22

S Use a hammer and dolly to even out the spot welded

areas for a close fill the flange surface together.

11. Apply the sealer.

S Apply the sealer at the overlapped areas of the rear floor

and extension rear floor, and welded surfaces of the

matching panel and all sealing gaps completely.

12. Apply the undercoat.

S Undercoat to the rear wheelhouse and designated rear

floor.

13. Apply the paintCAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

14. Apply the deadner.

S Clean the passenger and trunk compartment.

S Apply the deadner to the surface of rear floor and exten-

sion rear floor.

Fig. 23

15. Install the related parts.

S Install in the reverse order in which they were removed.

16. Check and adjust

S Check clearances and level differences.

S Check the trunk locking and unlocking condition.

S Check all operation.

S Check for water leaks in the trunk compartment.

Note : Use specified check sheet for operation check

properly.

Page 2569 of 2643

6–4 FRAME DOOR OPENING, DOOR AND SIDE PANEL OUTER NUBIRA/LACETTI

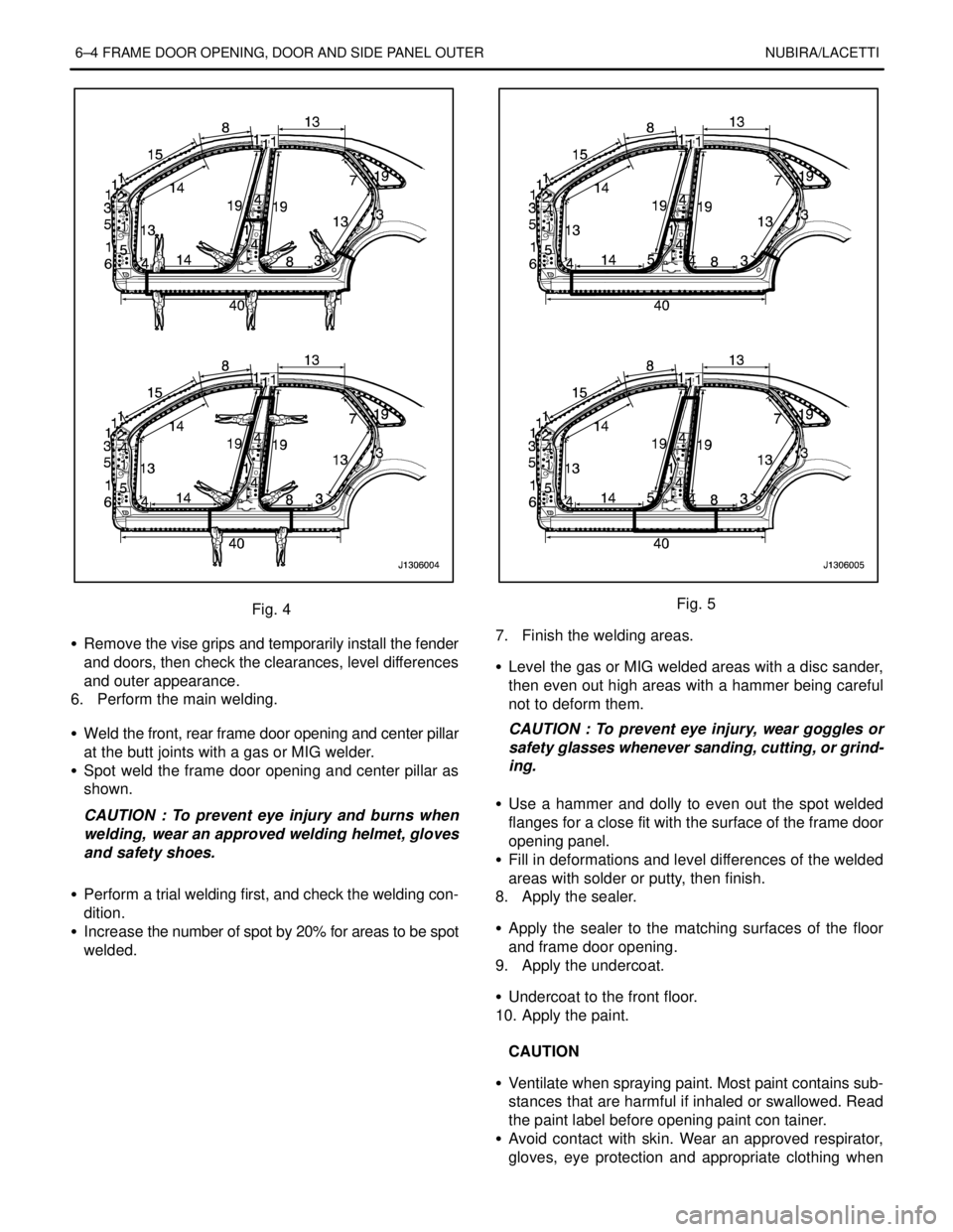

Fig. 4

S Remove the vise grips and temporarily install the fender

and doors, then check the clearances, level differences

and outer appearance.

6. Perform the main welding.

S Weld the front, rear frame door opening and center pillar

at the butt joints with a gas or MIG welder.

S Spot weld the frame door opening and center pillar as

shown.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Perform a trial welding first, and check the welding con-

dition.

S Increase the number of spot by 20% for areas to be spot

welded.Fig. 5

7. Finish the welding areas.

S Level the gas or MIG welded areas with a disc sander,

then even out high areas with a hammer being careful

not to deform them.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Use a hammer and dolly to even out the spot welded

flanges for a close fit with the surface of the frame door

opening panel.

S Fill in deformations and level differences of the welded

areas with solder or putty, then finish.

8. Apply the sealer.

S Apply the sealer to the matching surfaces of the floor

and frame door opening.

9. Apply the undercoat.

S Undercoat to the front floor.

10. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint con tainer.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

Page 2571 of 2643

6–6 FRAME DOOR OPENING, DOOR AND SIDE PANEL OUTER NUBIRA/LACETTI

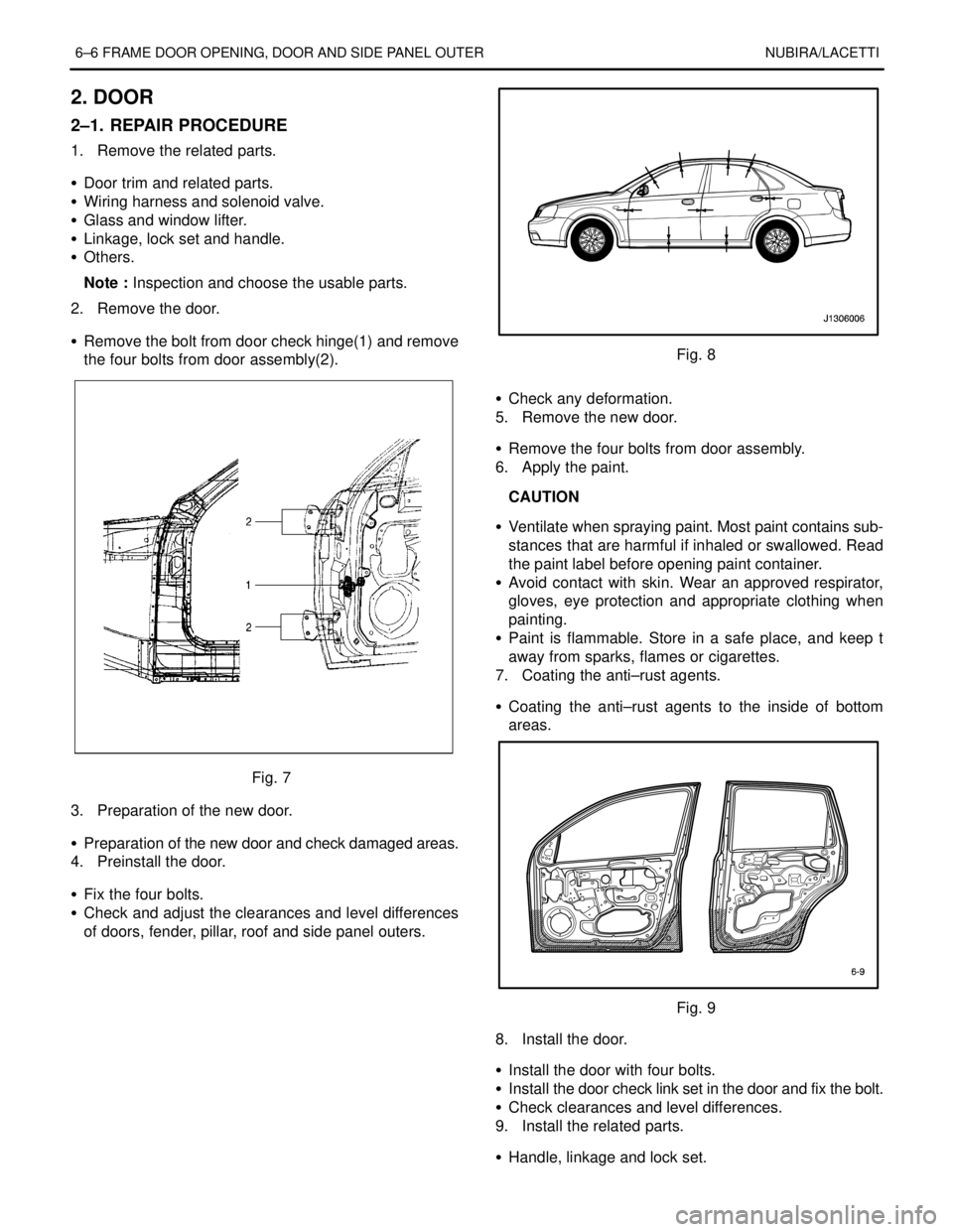

2. DOOR

2–1. REPAIR PROCEDURE

1. Remove the related parts.

S Door trim and related parts.

S Wiring harness and solenoid valve.

S Glass and window lifter.

S Linkage, lock set and handle.

S Others.

Note : Inspection and choose the usable parts.

2. Remove the door.

S Remove the bolt from door check hinge(1) and remove

the four bolts from door assembly(2).

Fig. 7

3. Preparation of the new door.

S Preparation of the new door and check damaged areas.

4. Preinstall the door.

S Fix the four bolts.

S Check and adjust the clearances and level differences

of doors, fender, pillar, roof and side panel outers.

Fig. 8

S Check any deformation.

5. Remove the new door.

S Remove the four bolts from door assembly.

6. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed. Read

the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep t

away from sparks, flames or cigarettes.

7. Coating the anti–rust agents.

S Coating the anti–rust agents to the inside of bottom

areas.

Fig. 9

8. Install the door.

S Install the door with four bolts.

S Install the door check link set in the door and fix the bolt.

S Check clearances and level differences.

9. Install the related parts.

S Handle, linkage and lock set.

Page 2573 of 2643

6–8 FRAME DOOR OPENING, DOOR AND SIDE PANEL OUTER NUBIRA/LACETTI

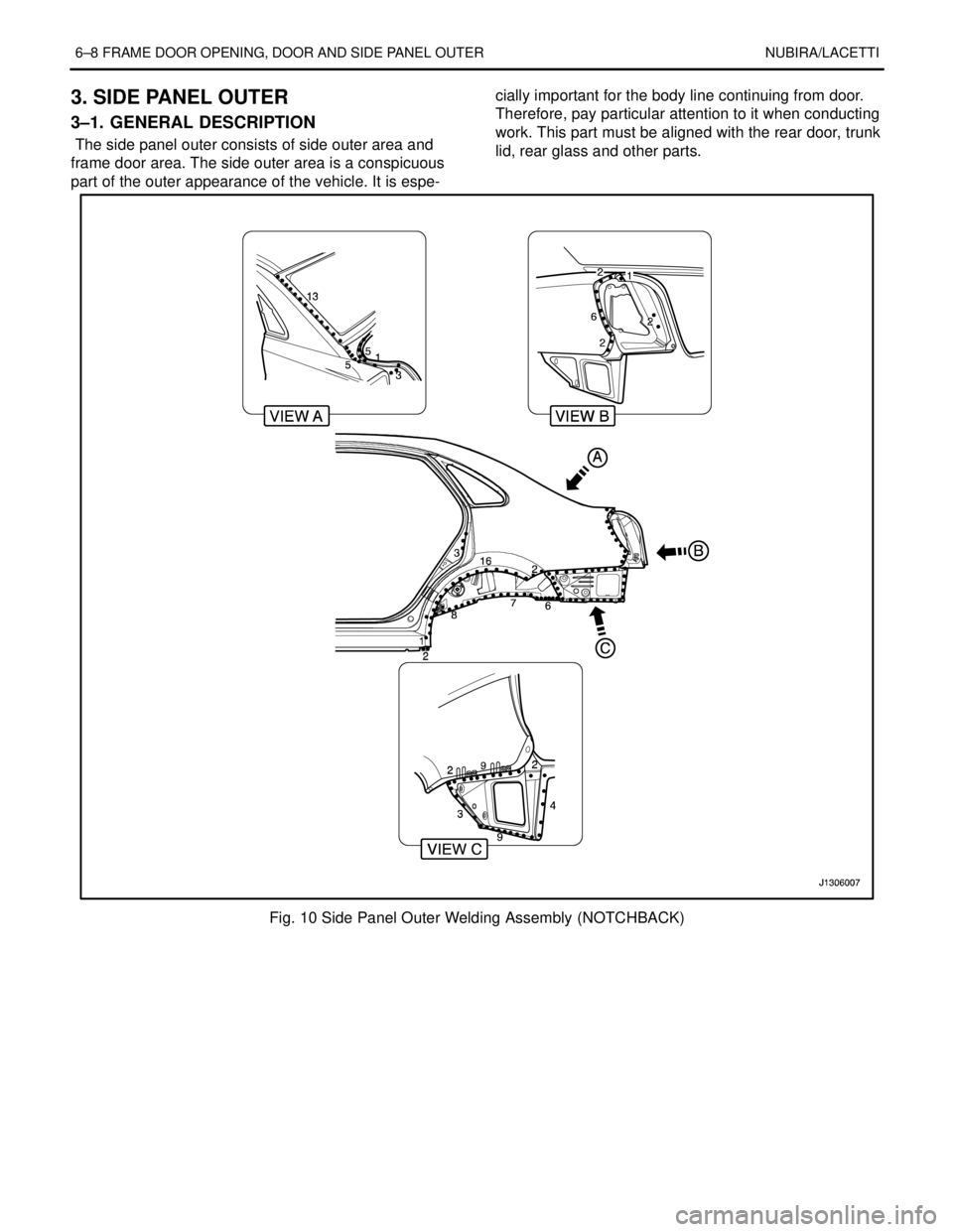

3. SIDE PANEL OUTER

3–1. GENERAL DESCRIPTION

The side panel outer consists of side outer area and

frame door area. The side outer area is a conspicuous

part of the outer appearance of the vehicle. It is espe-cially important for the body line continuing from door.

Therefore, pay particular attention to it when conducting

work. This part must be aligned with the rear door, trunk

lid, rear glass and other parts.

Fig. 10 Side Panel Outer Welding Assembly (NOTCHBACK)

Page 2576 of 2643

NUBIRA/LACETTI FRAME DOOR OPENING, DOOR AND SIDE PANEL OUTER 6–11

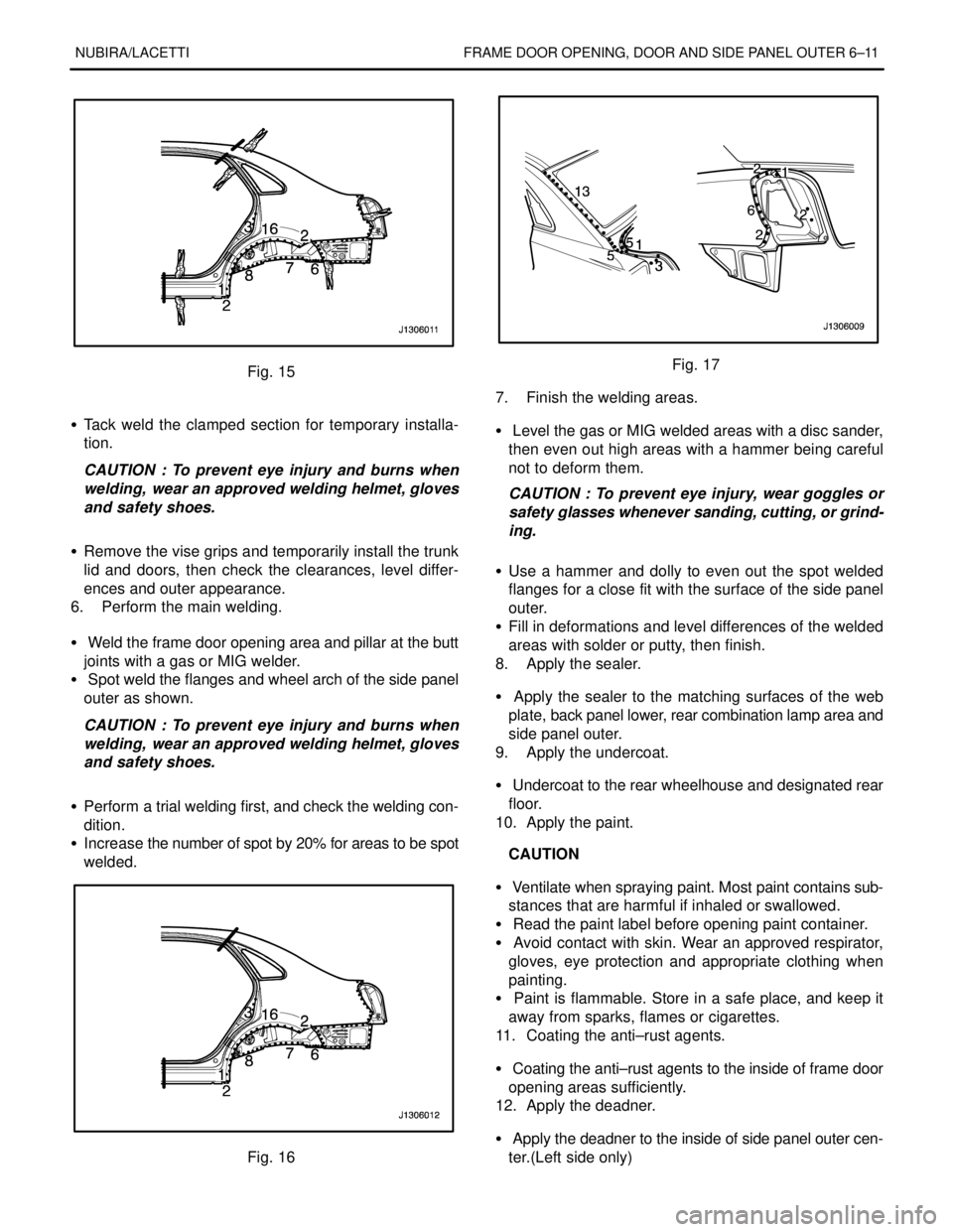

Fig. 15

S Tack weld the clamped section for temporary installa-

tion.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Remove the vise grips and temporarily install the trunk

lid and doors, then check the clearances, level differ-

ences and outer appearance.

6. Perform the main welding.

S Weld the frame door opening area and pillar at the butt

joints with a gas or MIG welder.

S Spot weld the flanges and wheel arch of the side panel

outer as shown.

CAUTION : To prevent eye injury and burns when

welding, wear an approved welding helmet, gloves

and safety shoes.

S Perform a trial welding first, and check the welding con-

dition.

S Increase the number of spot by 20% for areas to be spot

welded.

Fig. 16

Fig. 17

7. Finish the welding areas.

S Level the gas or MIG welded areas with a disc sander,

then even out high areas with a hammer being careful

not to deform them.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

S Use a hammer and dolly to even out the spot welded

flanges for a close fit with the surface of the side panel

outer.

S Fill in deformations and level differences of the welded

areas with solder or putty, then finish.

8. Apply the sealer.

S Apply the sealer to the matching surfaces of the web

plate, back panel lower, rear combination lamp area and

side panel outer.

9. Apply the undercoat.

S Undercoat to the rear wheelhouse and designated rear

floor.

10. Apply the paint.

CAUTION

S Ventilate when spraying paint. Most paint contains sub-

stances that are harmful if inhaled or swallowed.

S Read the paint label before opening paint container.

S Avoid contact with skin. Wear an approved respirator,

gloves, eye protection and appropriate clothing when

painting.

S Paint is flammable. Store in a safe place, and keep it

away from sparks, flames or cigarettes.

11. Coating the anti–rust agents.

S Coating the anti–rust agents to the inside of frame door

opening areas sufficiently.

12. Apply the deadner.

S Apply the deadner to the inside of side panel outer cen-

ter.(Left side only)