engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 942 of 2643

FRONT SUSPENSION 2C – 25

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FRONT SUSPENSION

The front suspension for this vehicle is a combination of

a strut assembly and a knuckle assembly. The strut as-

sembly combines a strut dampener and spring mounted

to the body of the vehicle. The upper end of the strut is iso-

lated by a rubber mount and contains a bearing to allow the

strut to turn. The knuckle is attached to the strut assembly

and pivots on a ball joint bolted to the control arm. The con-

trol arms pivot from the body using rubber bushings.

The ball joint is fastened to the steering knuckle with a

pinch bolt and nut, and to the lower control arm with rivets.

The stabilizer bar interconnects both strut assemblies ofthe vehicle through the stabilizer link and is attached to the

front suspension crossmember. Jounce and rebound

movements affecting one wheel are partially transmitted

to the opposite wheel of the vehicle to stabilize body roll.

When servicing the control arm–to–body attachment and

the stabilizer shaft–to–body insulators, make sure the at-

taching bolts are loose until the control arms are moved to

the trim height, which is curb height. Trim height is the nor-

mal position to which the control arms move when the ve-

hicle is sitting on the ground. Refer to ”General Specifica-

tions” in this section.

The springs in the front suspension of engine family II are

stronger and the strut dampeners heavier than are the

springs and strut dampeners found in the front suspension

of engine family I.

Page 966 of 2643

2E – 4ITIRES AND WHEELS

DAEWOO V–121 BL4

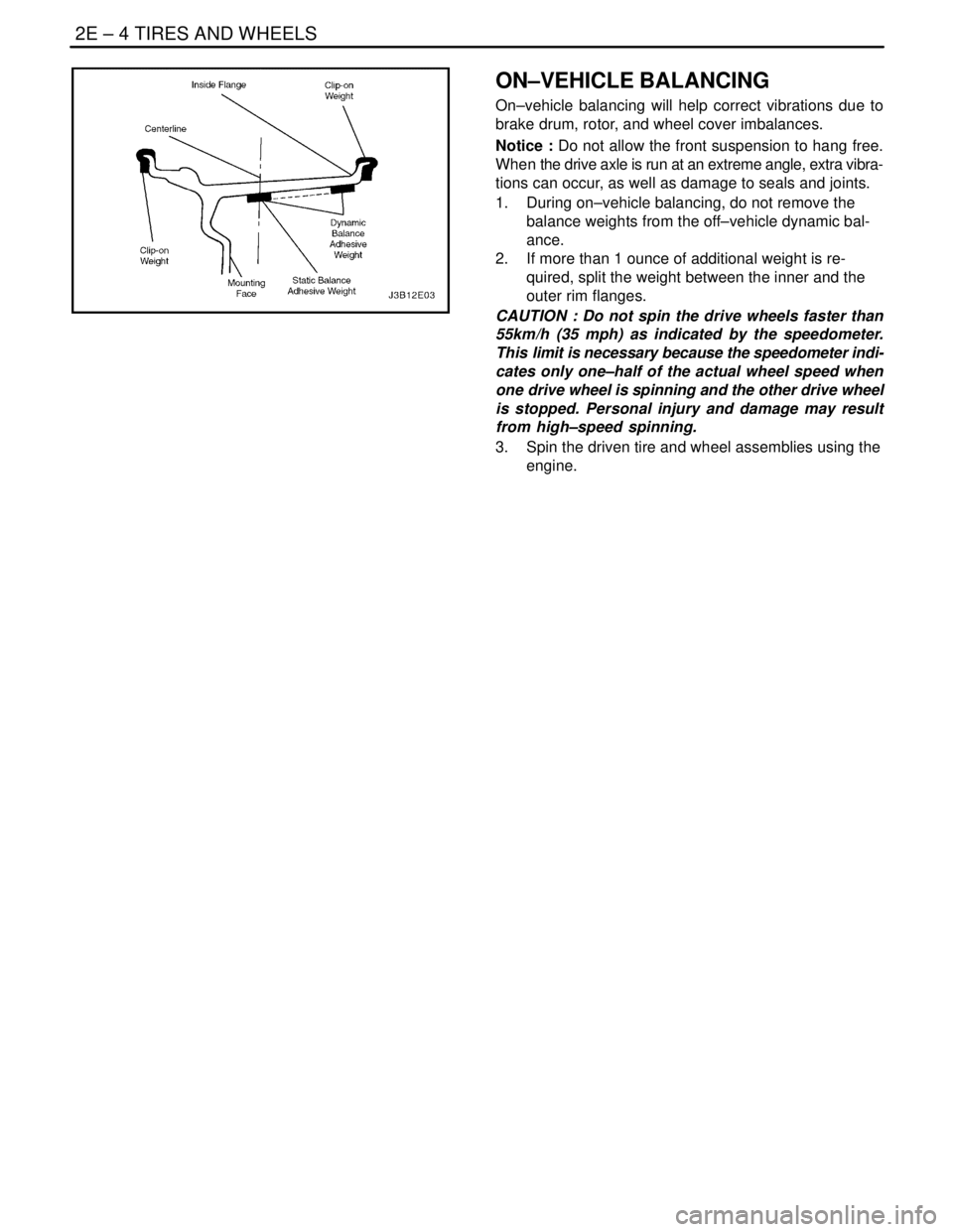

ON–VEHICLE BALANCING

On–vehicle balancing will help correct vibrations due to

brake drum, rotor, and wheel cover imbalances.

Notice : Do not allow the front suspension to hang free.

When the drive axle is run at an extreme angle, extra vibra-

tions can occur, as well as damage to seals and joints.

1. During on–vehicle balancing, do not remove the

balance weights from the off–vehicle dynamic bal-

ance.

2. If more than 1 ounce of additional weight is re-

quired, split the weight between the inner and the

outer rim flanges.

CAUTION : Do not spin the drive wheels faster than

55km/h (35 mph) as indicated by the speedometer.

This limit is necessary because the speedometer indi-

cates only one–half of the actual wheel speed when

one drive wheel is spinning and the other drive wheel

is stopped. Personal injury and damage may result

from high–speed spinning.

3. Spin the driven tire and wheel assemblies using the

engine.

Page 968 of 2643

2E – 6ITIRES AND WHEELS

DAEWOO V–121 BL4

S Amchem Alodine No. 1001. Stock No. DX50T or

equivalent coating chemical for alloys.

S Ditzler Delclear Acrylic Urethane Clear, Stock No.

DAU–75 or equivalent.

S Ditzler Delthane Ultra–Urethane Additive, Stock No.

DXR–80 or equivalent.

Before repairing the alloy damage or the clear coat dam-

age, prepare the wheels and the tires.

1. Remove the wheel from the vehicle.

2. Mark the location of the outboard weights and re-

move them.

3. Wash the wheel inside and out with a water–based,

all–purpose cleaner. Remove the grease and oil

with a solvent cleaner.

4. Mask the tire prior to painting.

5. Using a 400–grit wet or dry sandpaper, sand over

the painted areas that will not require recoloring.

Sanding will promote the adhesion of the clear coat.

Alloy Damage on Wheel Surface

1. Mount the wheel on a brake lathe and spin the as-

sembly slowly.

2. Sand the wheel with a backing block or pad. Hold

the backing block or pad flat to the surface of the

wheel and sand slowly back and forth from the cen-

ter to the outer edge of the tire to remove the dam-

age. Use the following sandpaper grits in the order

listed:

1) 80 grit.

2) 150 grit.

3) 240 grit.

Clear Coat Damage on Unpainted Wheels

1. Apply the chemical stripper Amchem Alumi Prep

No. 33. Use a small 1/4–inch detail brush to apply

the stripper around the perimeter and spoke–like

areas.

2. Remove the stripper according to the manufactur-

er’s recommendations.

CAUTION : To avoid serious personal injury, do not

use engine power to rotate the wheel while sanding.

3. Sand the wheel with 240–grit sandpaper by rotating

the wheel on a slow–spinning brake lathe or by

mounting the wheel on the car and spinning it by

hand. Sanding restores the machined appearance

and promotes adhesion.

After repairing the alloy or clear coat damage, the wheels

must be recoated.

Page 974 of 2643

SECTION 3

WIRING DIAGRAM FOR POWER SUPPLIES

CONTENTS

1. IGNITION SWITCH CIRCUIT3–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. 30 TER ”BAT+” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. 15 TER ”IGN 1” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. 15A TER ”IGN2”, 15C TER ”ACC” POWER SUPPLY CIRCUIT(I.P FUSE BLOCK) 3–4. . . . . . . . . . . . . . . . . . . . . .

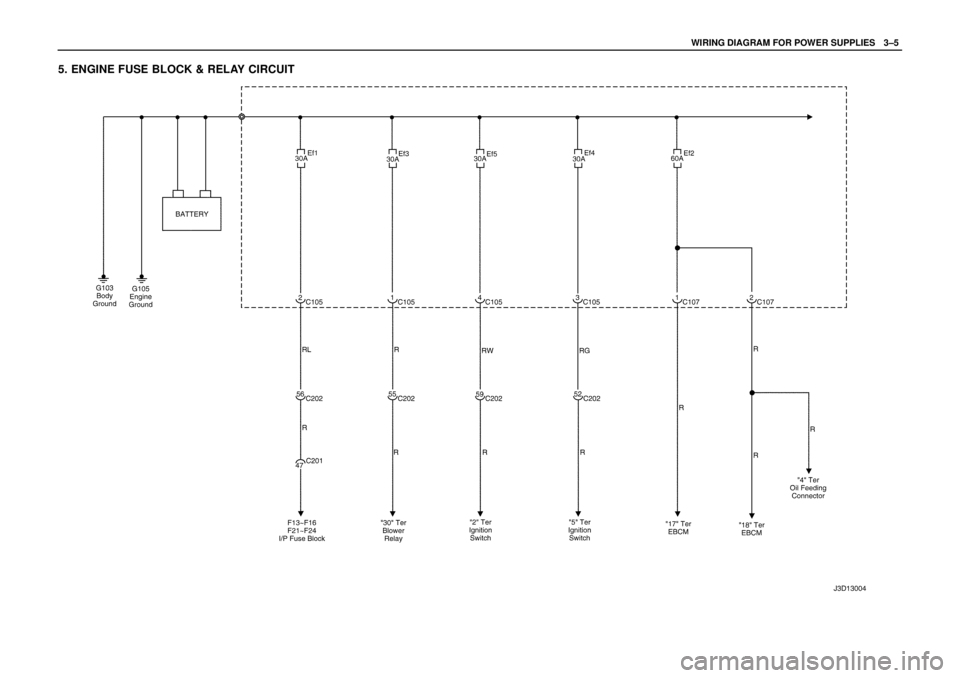

5. ENGINE FUSE BLOCK & RELAY CIRCUIT 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 978 of 2643

WIRING DIAGRAM FOR POWER SUPPLIESW3–5

5. ENGINE FUSE BLOCK & RELAY CIRCUIT

Page 1013 of 2643

SECTION 4

USAGE AND CAPACITY OF FUSES IN FUSE BLOCK

CONTENTS

1. ENGINE ROOM RELAY AND FUSE BLOCK 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. I.P FUSE BLOCK4–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. POSITION OF CONTROL UNIT, RELAY AND PART NUMBER 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 1014 of 2643

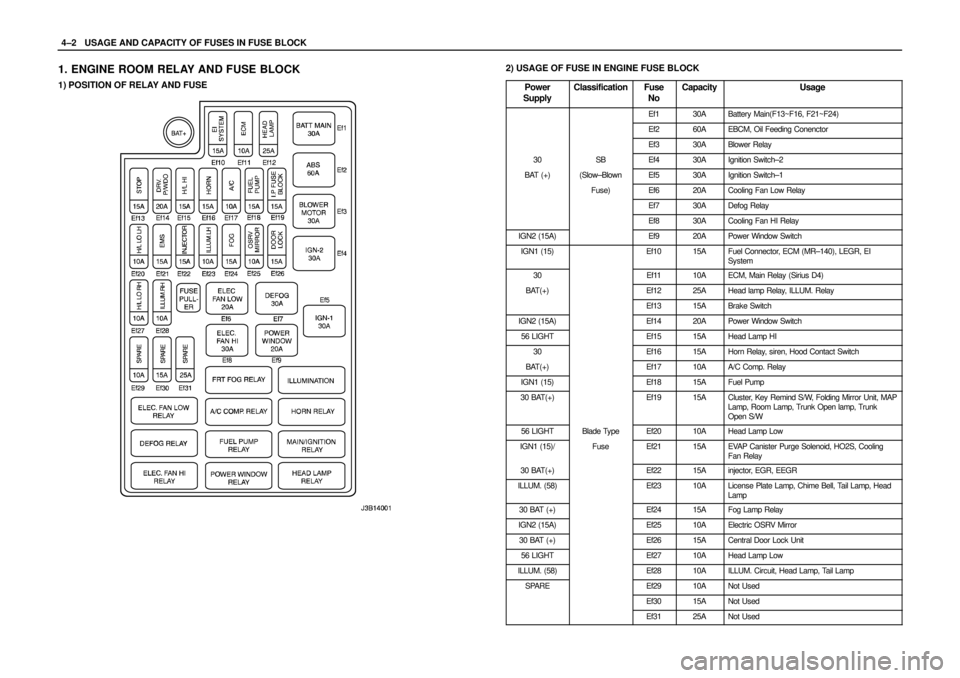

4–2WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

1. ENGINE ROOM RELAY AND FUSE BLOCK

1) POSITION OF RELAY AND FUSE

2) USAGE OF FUSE IN ENGINE FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

Ef130ABattery Main(F13~F16, F21~F24)

Ef260AEBCM, Oil Feeding Conenctor

Ef330ABlower Relay

30SBEf430AIgnition Switch–2

BAT (+)(Slow–BlownEf530AIgnition Switch–1

Fuse)Ef620ACooling Fan Low Relay

Ef730ADefog Relay

Ef830ACooling Fan HI Relay

IGN2 (15A)Ef920APower Window Switch

IGN1 (15)Ef1015AFuel Connector, ECM (MR–140), LEGR, EI

System

30Ef1110AECM, Main Relay (Sirius D4)

BAT(+)Ef1225AHead lamp Relay, ILLUM. Relay

Ef1315ABrake Switch

IGN2 (15A)Ef1420APower Window Switch

56 LIGHTEf1515AHead Lamp HI

30Ef1615AHorn Relay, siren, Hood Contact Switch

BAT(+)Ef1710AA/C Comp. Relay

IGN1 (15)Ef1815AFuel Pump

30 BAT(+)Ef1915ACluster, Key Remind S/W, Folding Mirror Unit, MAP

Lamp, Room Lamp, Trunk Open lamp, Trunk

Open S/W

56 LIGHTBlade TypeEf2010AHead Lamp Low

IGN1 (15)/FuseEf2115AEVAP Canister Purge Solenoid, HO2S, Cooling

Fan Relay

30 BAT(+)Ef2215Ainjector, EGR, EEGR

ILLUM. (58)Ef2310ALicense Plate Lamp, Chime Bell, Tail Lamp, Head

Lamp

30 BAT (+)Ef2415AFog Lamp Relay

IGN2 (15A)Ef2510AElectric OSRV Mirror

30 BAT (+)Ef2615ACentral Door Lock Unit

56 LIGHTEf2710AHead Lamp Low

ILLUM. (58)Ef2810AILLUM. Circuit, Head Lamp, Tail Lamp

SPAREEf2910ANot Used

Ef3015ANot Used

Ef3125ANot Used

Page 1016 of 2643

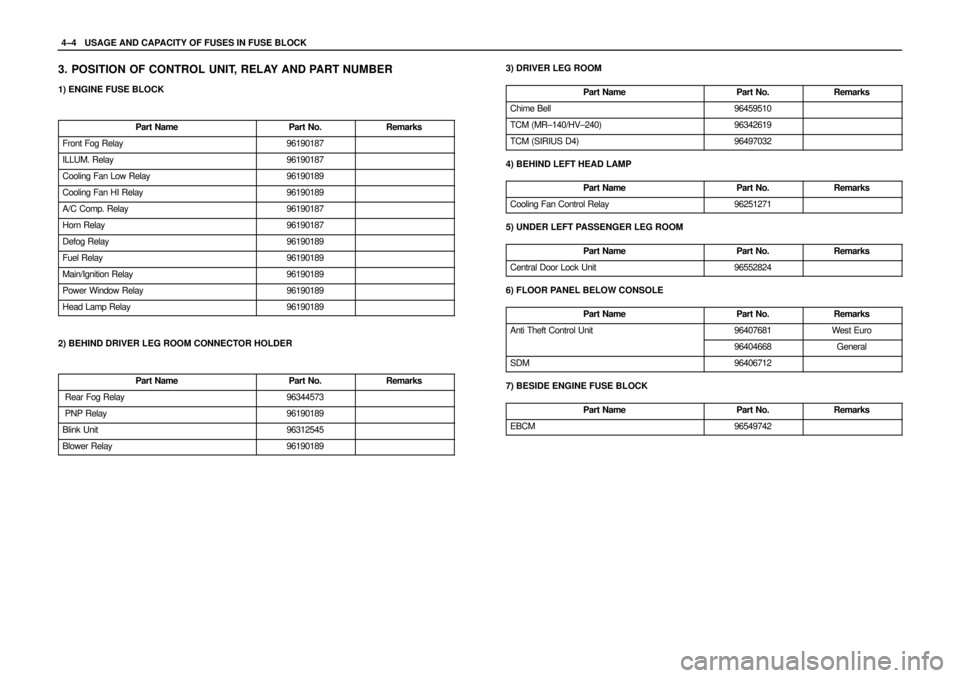

4–4WUSAGE AND CAPACITY OF FUSES IN FUSE BLOCK

3. POSITION OF CONTROL UNIT, RELAY AND PART NUMBER

1) ENGINE FUSE BLOCK

Part Name

Part No.Remarks

Front Fog Relay96190187

ILLUM. Relay96190187

Cooling Fan Low Relay96190189

Cooling Fan HI Relay96190189

A/C Comp. Relay96190187

Horn Relay96190187

Defog Relay96190189

Fuel Relay96190189

Main/Ignition Relay96190189

Power Window Relay96190189

Head Lamp Relay96190189

2) BEHIND DRIVER LEG ROOM CONNECTOR HOLDER

Part Name

Part No.Remarks

Rear Fog Relay96344573

PNP Relay96190189

Blink Unit96312545

Blower Relay96190189

3) DRIVER LEG ROOM

Part Name

Part No.Remarks

Chime Bell96459510

TCM (MR–140/HV–240)96342619

TCM (SIRIUS D4)96497032

4) BEHIND LEFT HEAD LAMP

Part Name

Part No.Remarks

Cooling Fan Control Relay96251271

5) UNDER LEFT PASSENGER LEG ROOM

Part Name

Part No.Remarks

Central Door Lock Unit96552824

6) FLOOR PANEL BELOW CONSOLE

Part Name

Part No.Remarks

Anti Theft Control Unit96407681Wes t Euro

96404668General

SDM96406712

7) BESIDE ENGINE FUSE BLOCK

Part Name

Part No.Remarks

EBCM96549742

Page 1018 of 2643

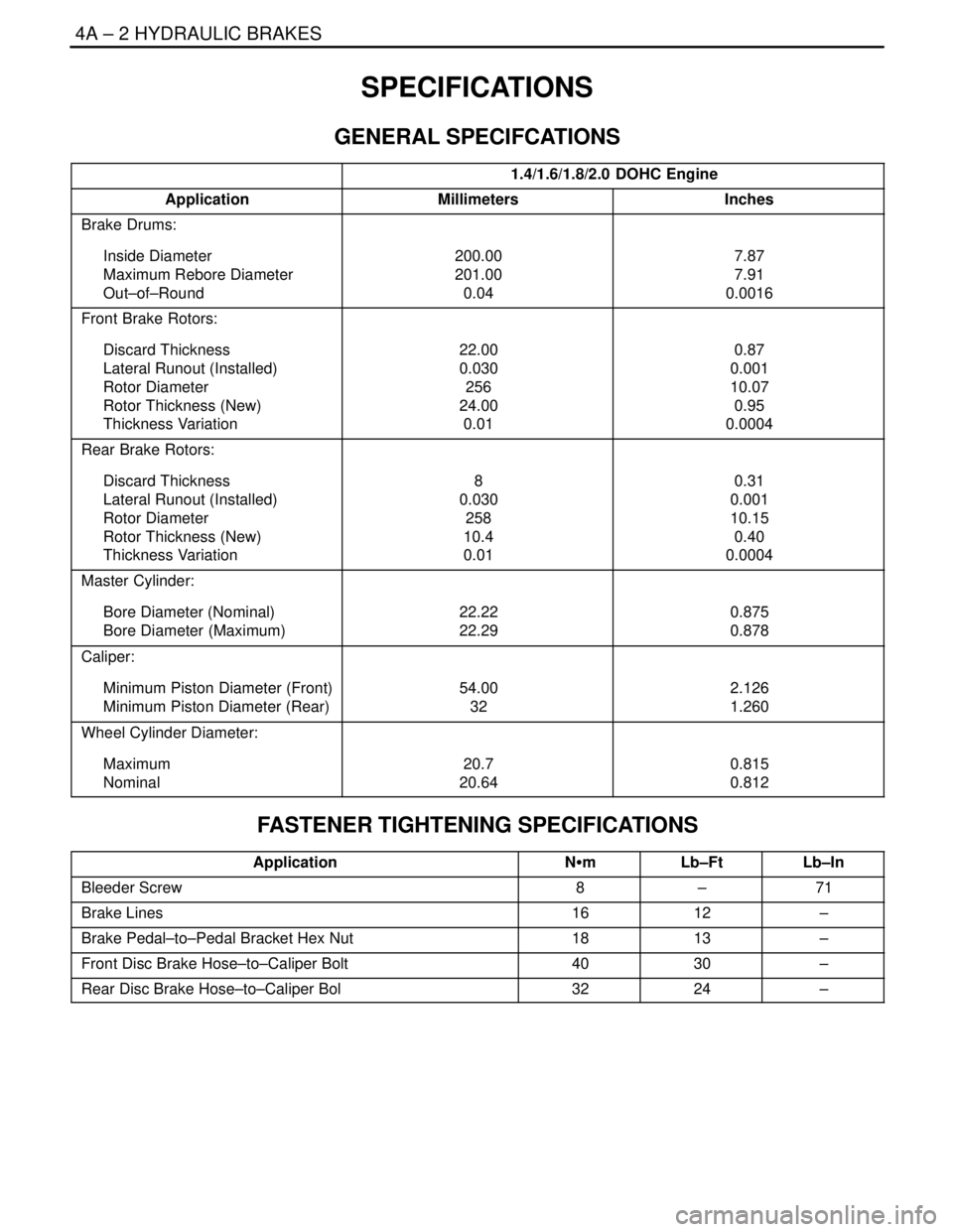

4A – 2IHYDRAULIC BRAKES

DAEWOO V–121 BL4

SPECIFICATIONS

GENERAL SPECIFCATIONS

1.4/1.6/1.8/2.0 DOHC Engine

ApplicationMillimetersInches

Brake Drums:

Inside Diameter

Maximum Rebore Diameter

Out–of–Round200.00

201.00

0.047.87

7.91

0.0016

Front Brake Rotors:

Discard Thickness

Lateral Runout (Installed)

Rotor Diameter

Rotor Thickness (New)

Thickness Variation22.00

0.030

256

24.00

0.010.87

0.001

10.07

0.95

0.0004

Rear Brake Rotors:

Discard Thickness

Lateral Runout (Installed)

Rotor Diameter

Rotor Thickness (New)

Thickness Variation8

0.030

258

10.4

0.010.31

0.001

10.15

0.40

0.0004

Master Cylinder:

Bore Diameter (Nominal)

Bore Diameter (Maximum)22.22

22.290.875

0.878

Caliper:

Minimum Piston Diameter (Front)

Minimum Piston Diameter (Rear)54.00

322.126

1.260

Wheel Cylinder Diameter:

Maximum

Nominal20.7

20.640.815

0.812

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Bleeder Screw8–71

Brake Lines1612–

Brake Pedal–to–Pedal Bracket Hex Nut1813–

Front Disc Brake Hose–to–Caliper Bolt4030–

Rear Disc Brake Hose–to–Caliper Bol3224–

Page 1021 of 2643

HYDRAULIC BRAKES 4A – 5

DAEWOO V–121 BL4

DIAGNOSIS

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy, or

covered with loose dirt whereby all tires do not grip the

road equally. Testing will also be adversely affected if the

roadway is crowned so as to throw the weight so roughly

that the wheels tend to bounce.

Test the brakes at different vehicle speeds with both light

and heavy pedal pressure; however, avoid locking the

brakes and sliding the tires. Locked brakes and sliding

tires do not indicate brake efficiency since heavily braked,

but turning, wheels will stop the vehicle in less distance

than locked brakes. More tire–to–road friction is present

with a heavily–braked, turning tire than with a sliding tire.

Because of the high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

There are three major external conditions that affect brake

performance:

S Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

S Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

S Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pressure

on the pedal with the engine running at idle and the shift

lever in NEUTRAL. If the pedal gradually falls away with

the constant pressure, the hydraulic system may be leak-

ing. Perform a visual check to confirm any suspected

leaks.

Check the master cylinder fluid level. While a slight drop

in the reservoir level results from normal lining wear, an ab-

normally low level indicates a leak in the system. The hy-

draulic system may be leaking either internally or external-

ly. Refer to the procedure below to check the master

cylinder. Also, the system may appear to pass this test

while still having a slight leak. If the fluid level is normal,

check the vacuum booster pushrod length. If an incorrect

pushrod length is found, adjust or replace the rod.

Check the master cylinder using the following procedure:

S Check for a cracked master cylinder casting or

brake fluid leaking around the master cylinder.

Leaks are indicated only if there is at least one drop

of fluid. A damp condition is not abnormal.S Check for a binding pedal linkage and for an incor-

rect pushrod length. If both of these parts are in

satisfactory condition, disassemble the master cyl-

inder and check for an elongated or swollen primary

cylinder or piston seals. If swollen seals are found,

substandard or contaminated brake fluid should be

suspected. If contaminated brake fluid is found, all

the components should be disassembled and

cleaned, and all the rubber components should be

replaced. All of the pipes must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration of

the rubber components. If the primary piston cups in the

master cylinder are swollen, then the rubber parts have

deteriorated. This deterioration may also be evidenced by

swollen wheel cylinder piston seals on the drum brake

wheels.

If deterioration of rubber is evident, disassemble all the hy-

draulic parts and wash the parts with alcohol. Dry these

parts with compressed air before reassembly to keep alco-

hol out of the system. Replace all the rubber parts in the

system, including the hoses. Also, when working on the

brake mechanisms, check for fluid on the linings. If exces-

sive fluid is found, replace the linings.

If the master cylinder piston seals are in satisfactory condi-

tion, check for leaks or excessive heat conditions. If these

conditions are not found, drain the fluid, flush the master

cylinder with brake fluid, refill the master cylinder, and

bleed the system. Refer to ”Manual Bleeding the Brakes”

or”Pressure Bleeding the Brakes” in this section.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be checked

for road hazard damage, cracks, chafing of the outer cov-

er, and for leaks or blisters. Inspect the hoses for proper

routing and mounting. A brake hose that rubs on a suspen-

sion component will wear and eventually fail. A light and

a mirror may be needed for an adequate inspection. If any

of the above conditions are observed on the brake hose,

adjust or replace the hose as necessary.

WARNING LAMP OPERATION

This brake system uses a BRAKE warning lamp located

in the instrument panel cluster. When the ignition switch

is in the START position, the BRAKE warning lamp should

glow and go OFF when the ignition switch returns to the

RUN position.

The following conditions will activate the BRAKE lamp:

S Parking brake applied. The light should be ON

whenever the parking brake is applied and the igni-

tion switch is ON.

S Low fluid level. A low fluid level in the master cylin-

der will turn the BRAKE lamp ON.

S EBD system is disabled. The light should be ON

when the EBD system is malfunctioning.