gear shift DAEWOO NUBIRA 2004 Service Manual Online

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1672 of 2643

5A2 – 82IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

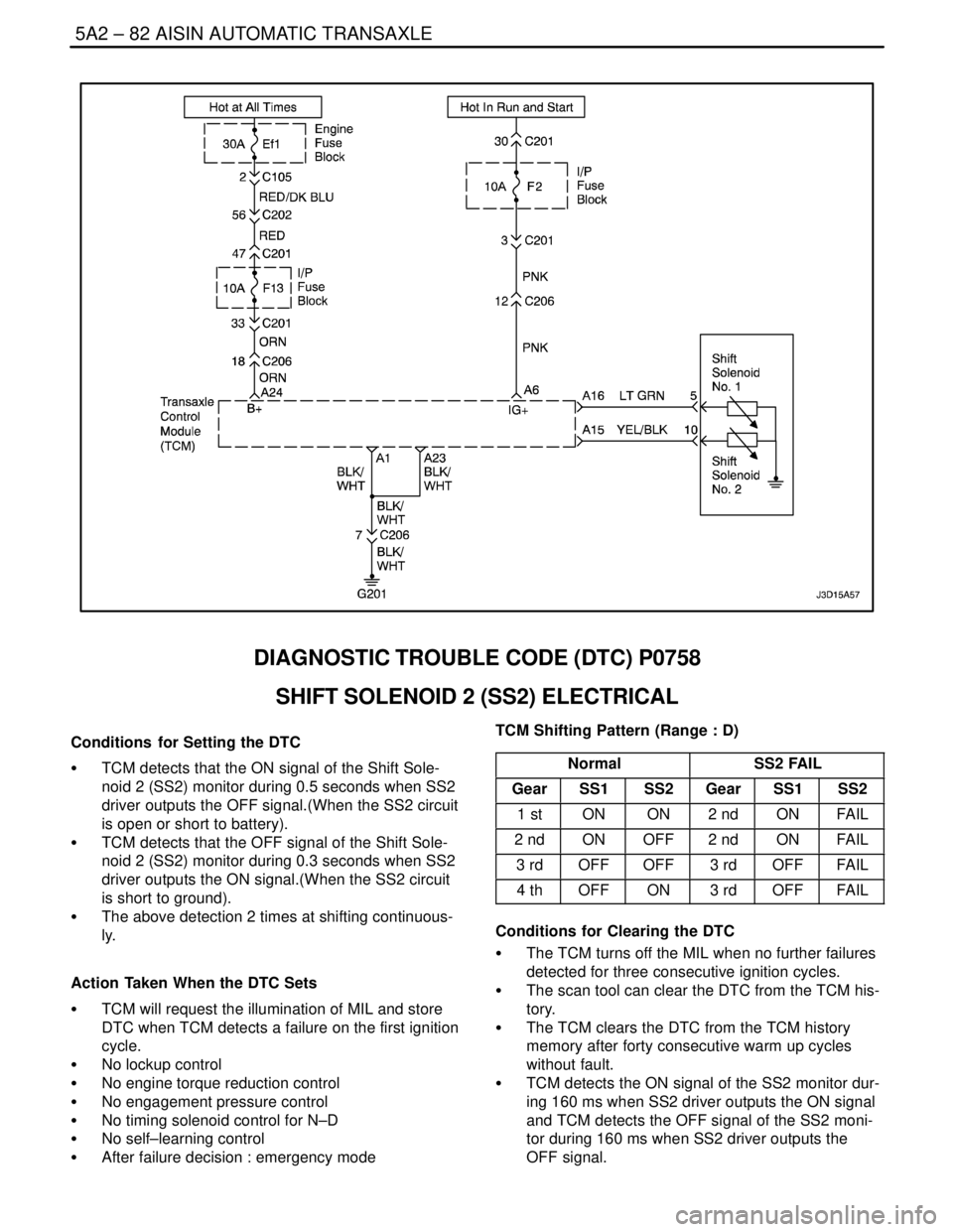

DIAGNOSTIC TROUBLE CODE (DTC) P0758

SHIFT SOLENOID 2 (SS2) ELECTRICAL

Conditions for Setting the DTC

S TCM detects that the ON signal of the Shift Sole-

noid 2 (SS2) monitor during 0.5 seconds when SS2

driver outputs the OFF signal.(When the SS2 circuit

is open or short to battery).

S TCM detects that the OFF signal of the Shift Sole-

noid 2 (SS2) monitor during 0.3 seconds when SS2

driver outputs the ON signal.(When the SS2 circuit

is short to ground).

S The above detection 2 times at shifting continuous-

ly.

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects a failure on the first ignition

cycle.

S No lockup control

S No engine torque reduction control

S No engagement pressure control

S No timing solenoid control for N–D

S No self–learning control

S After failure decision : emergency modeTCM Shifting Pattern (Range : D)

Normal

SS2 FAIL

GearSS1SS2GearSS1SS2

1 stONON2 ndONFAIL

2 ndONOFF2 ndONFAIL

3 rdOFFOFF3 rdOFFFAIL

4 thOFFON3 rdOFFFAIL

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

S TCM detects the ON signal of the SS2 monitor dur-

ing 160 ms when SS2 driver outputs the ON signal

and TCM detects the OFF signal of the SS2 moni-

tor during 160 ms when SS2 driver outputs the

OFF signal.

Page 1681 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 91

DAEWOO V–121 BL4

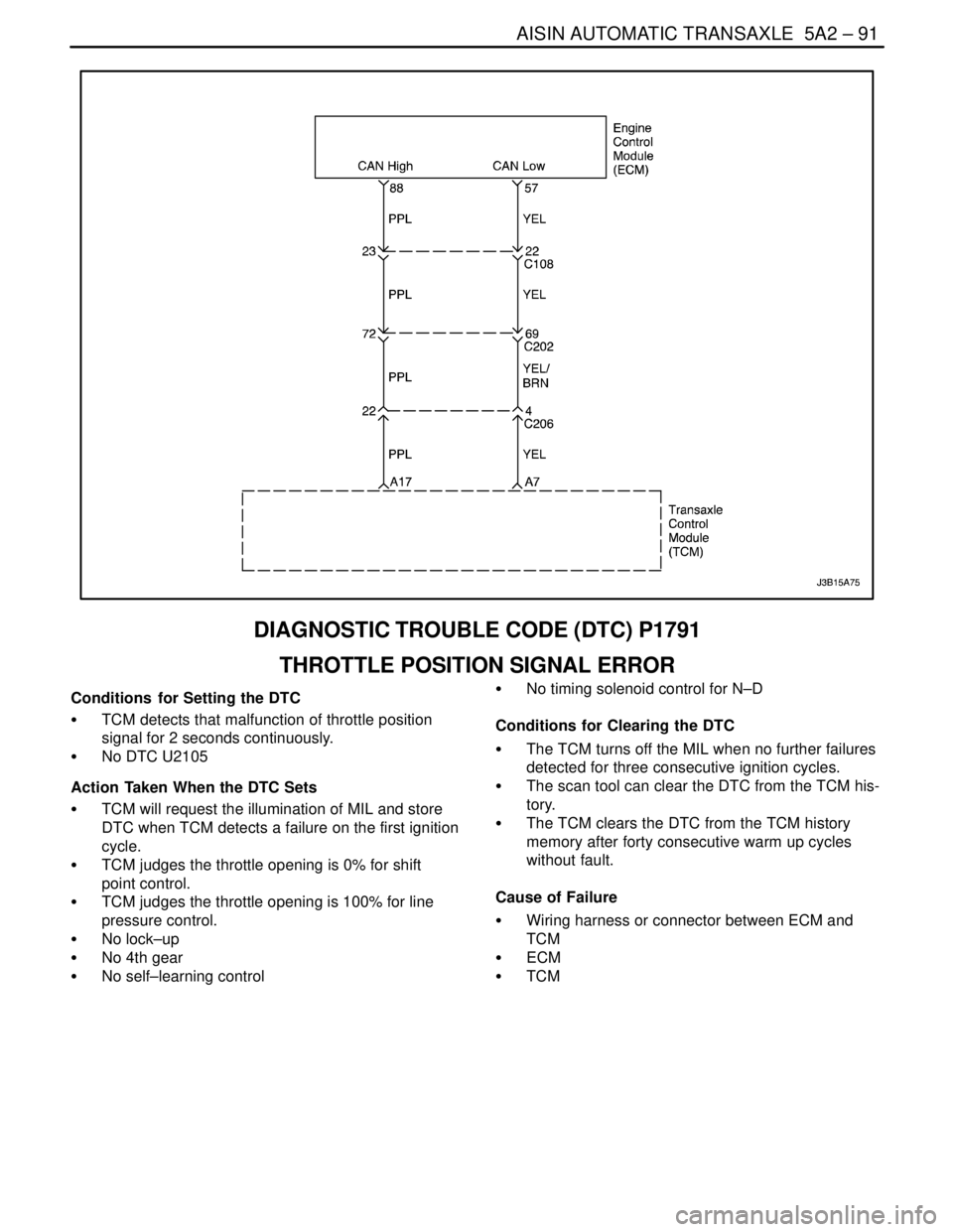

DIAGNOSTIC TROUBLE CODE (DTC) P1791

THROTTLE POSITION SIGNAL ERROR

Conditions for Setting the DTC

S TCM detects that malfunction of throttle position

signal for 2 seconds continuously.

S No DTC U2105

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects a failure on the first ignition

cycle.

S TCM judges the throttle opening is 0% for shift

point control.

S TCM judges the throttle opening is 100% for line

pressure control.

S No lock–up

S No 4th gear

S No self–learning controlS No timing solenoid control for N–D

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Wiring harness or connector between ECM and

TCM

S ECM

S TCM

Page 1685 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 95

DAEWOO V–121 BL4

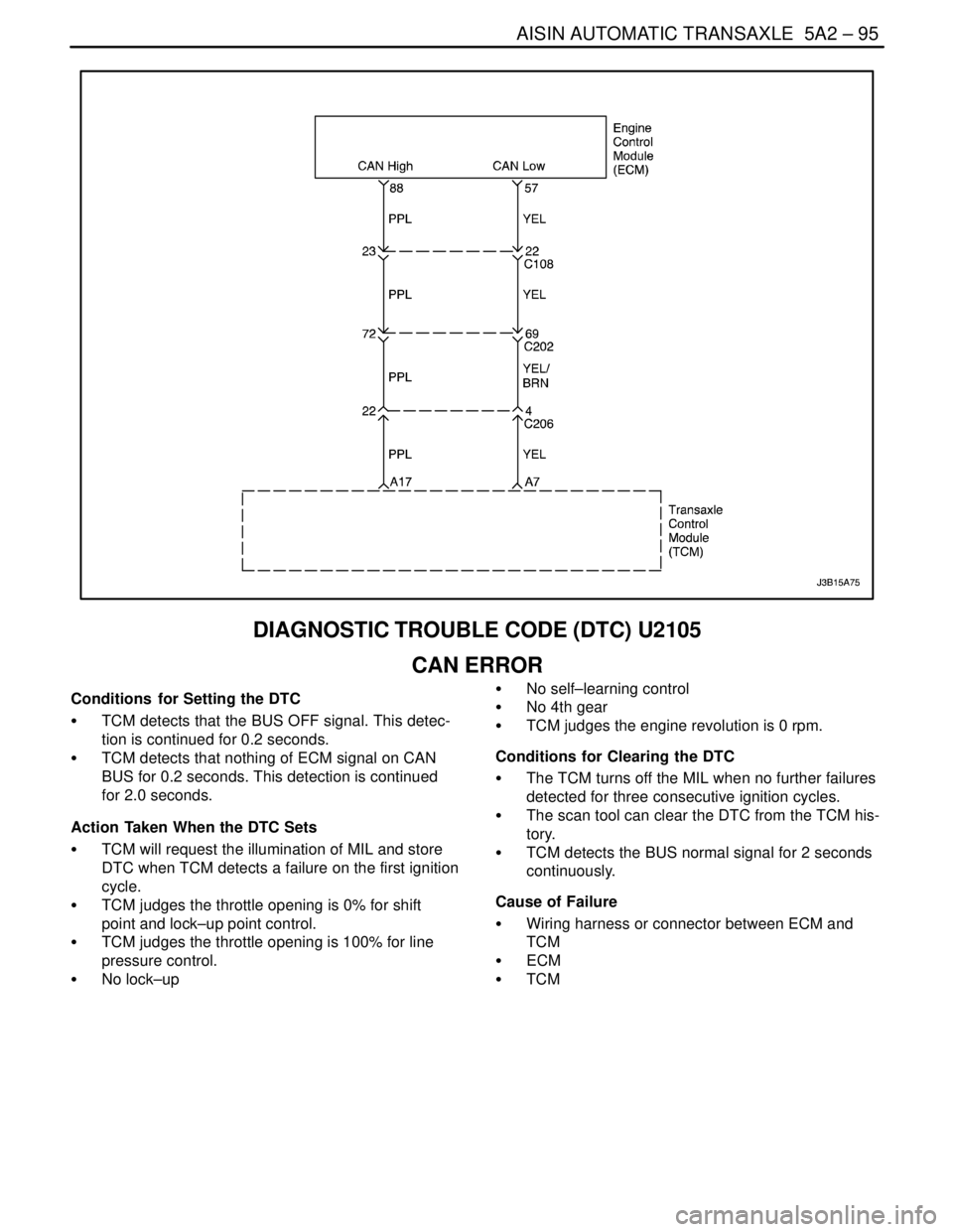

DIAGNOSTIC TROUBLE CODE (DTC) U2105

CAN ERROR

Conditions for Setting the DTC

S TCM detects that the BUS OFF signal. This detec-

tion is continued for 0.2 seconds.

S TCM detects that nothing of ECM signal on CAN

BUS for 0.2 seconds. This detection is continued

for 2.0 seconds.

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects a failure on the first ignition

cycle.

S TCM judges the throttle opening is 0% for shift

point and lock–up point control.

S TCM judges the throttle opening is 100% for line

pressure control.

S No lock–upS No self–learning control

S No 4th gear

S TCM judges the engine revolution is 0 rpm.

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S TCM detects the BUS normal signal for 2 seconds

continuously.

Cause of Failure

S Wiring harness or connector between ECM and

TCM

S ECM

S TCM

Page 1688 of 2643

5A2 – 98IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

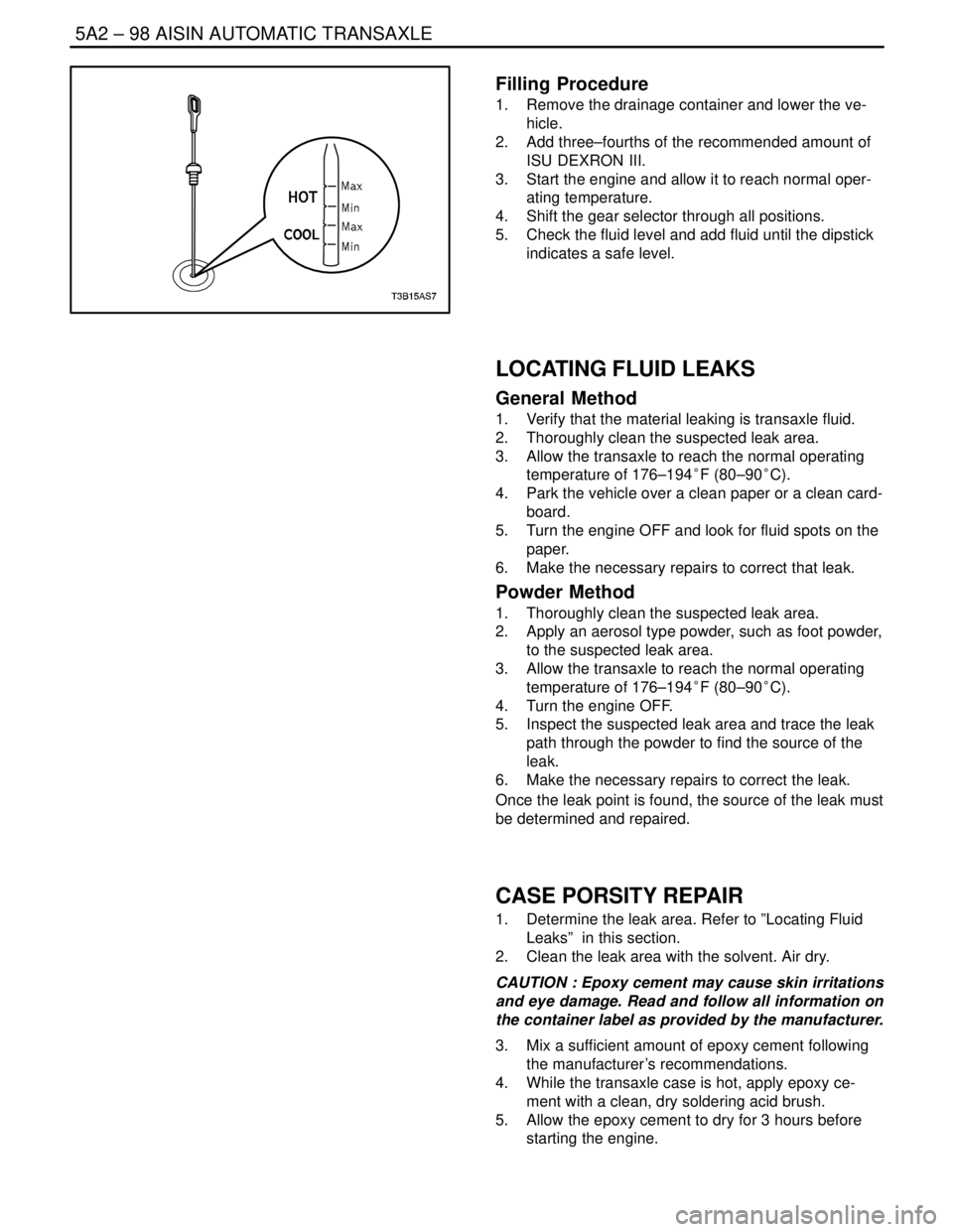

Filling Procedure

1. Remove the drainage container and lower the ve-

hicle.

2. Add three–fourths of the recommended amount of

ISU DEXRON III.

3. Start the engine and allow it to reach normal oper-

ating temperature.

4. Shift the gear selector through all positions.

5. Check the fluid level and add fluid until the dipstick

indicates a safe level.

LOCATING FLUID LEAKS

General Method

1. Verify that the material leaking is transaxle fluid.

2. Thoroughly clean the suspected leak area.

3. Allow the transaxle to reach the normal operating

temperature of 176–194°F (80–90°C).

4. Park the vehicle over a clean paper or a clean card-

board.

5. Turn the engine OFF and look for fluid spots on the

paper.

6. Make the necessary repairs to correct that leak.

Powder Method

1. Thoroughly clean the suspected leak area.

2. Apply an aerosol type powder, such as foot powder,

to the suspected leak area.

3. Allow the transaxle to reach the normal operating

temperature of 176–194°F (80–90°C).

4. Turn the engine OFF.

5. Inspect the suspected leak area and trace the leak

path through the powder to find the source of the

leak.

6. Make the necessary repairs to correct the leak.

Once the leak point is found, the source of the leak must

be determined and repaired.

CASE PORSITY REPAIR

1. Determine the leak area. Refer to ”Locating Fluid

Leaks” in this section.

2. Clean the leak area with the solvent. Air dry.

CAUTION : Epoxy cement may cause skin irritations

and eye damage. Read and follow all information on

the container label as provided by the manufacturer.

3. Mix a sufficient amount of epoxy cement following

the manufacturer’s recommendations.

4. While the transaxle case is hot, apply epoxy ce-

ment with a clean, dry soldering acid brush.

5. Allow the epoxy cement to dry for 3 hours before

starting the engine.

Page 1808 of 2643

5A2 – 218IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

TRANSAXLE DESCRIPTION

The new automatic transmission is an electronically con-

trolled 4–speed automatic transmission with Lock–up

mechanism.

The transmission is mainly composed of the torque con-

verter with lock up clutch, newly developed 4–speed plan-

etary gear unit, the hydraulic control system and the elec-

tric control system.

ELECTRONICAL COMPONENTS

Transmission Control Module (TCM)

The TCM primarily controls shift points and lockup en-

gagement. It is located on the driver side under the instru-

ment panel.

The transmission is controlled by an electronic shift sys-

tem. The Transmission Control Module (TCM) processes

input signals. From the information received, the TCM

controls the transmission hydraulic system.

The electronic shift system consists of the following :

S Transmission control module (TCM)

S Shift solenoids (SS1 and SS2)

S Pressure control solenoid (PCS)

S Lockup solenoid

S Input shaft speed (ISS) sensor

S Output shaft speed (OSS) sensor

S Transmission Fluid Temperature (TFT) sensor

S Transmission Range (TR) Switch

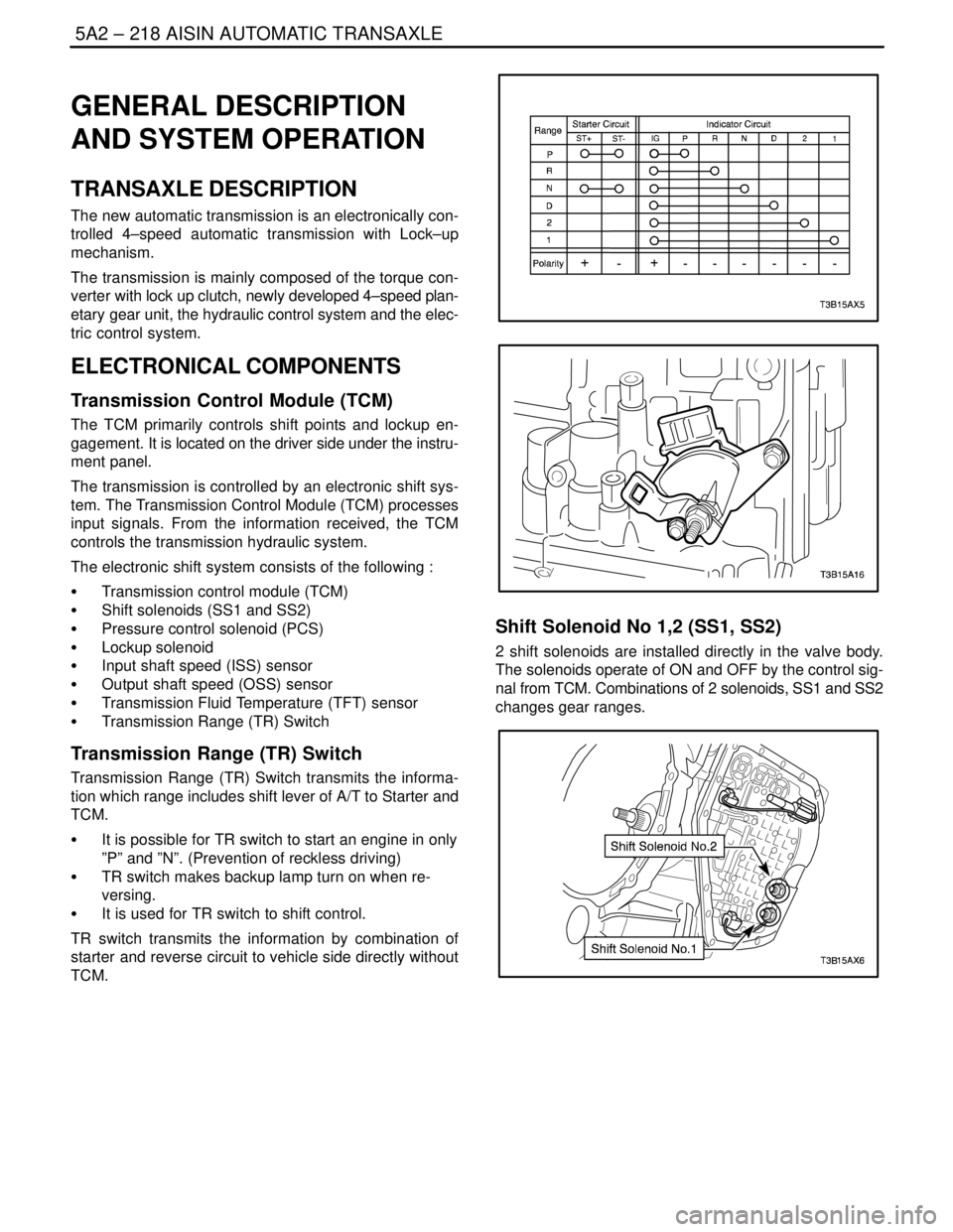

Transmission Range (TR) Switch

Transmission Range (TR) Switch transmits the informa-

tion which range includes shift lever of A/T to Starter and

TCM.

S It is possible for TR switch to start an engine in only

”P” and ”N”. (Prevention of reckless driving)

S TR switch makes backup lamp turn on when re-

versing.

S It is used for TR switch to shift control.

TR switch transmits the information by combination of

starter and reverse circuit to vehicle side directly without

TCM.

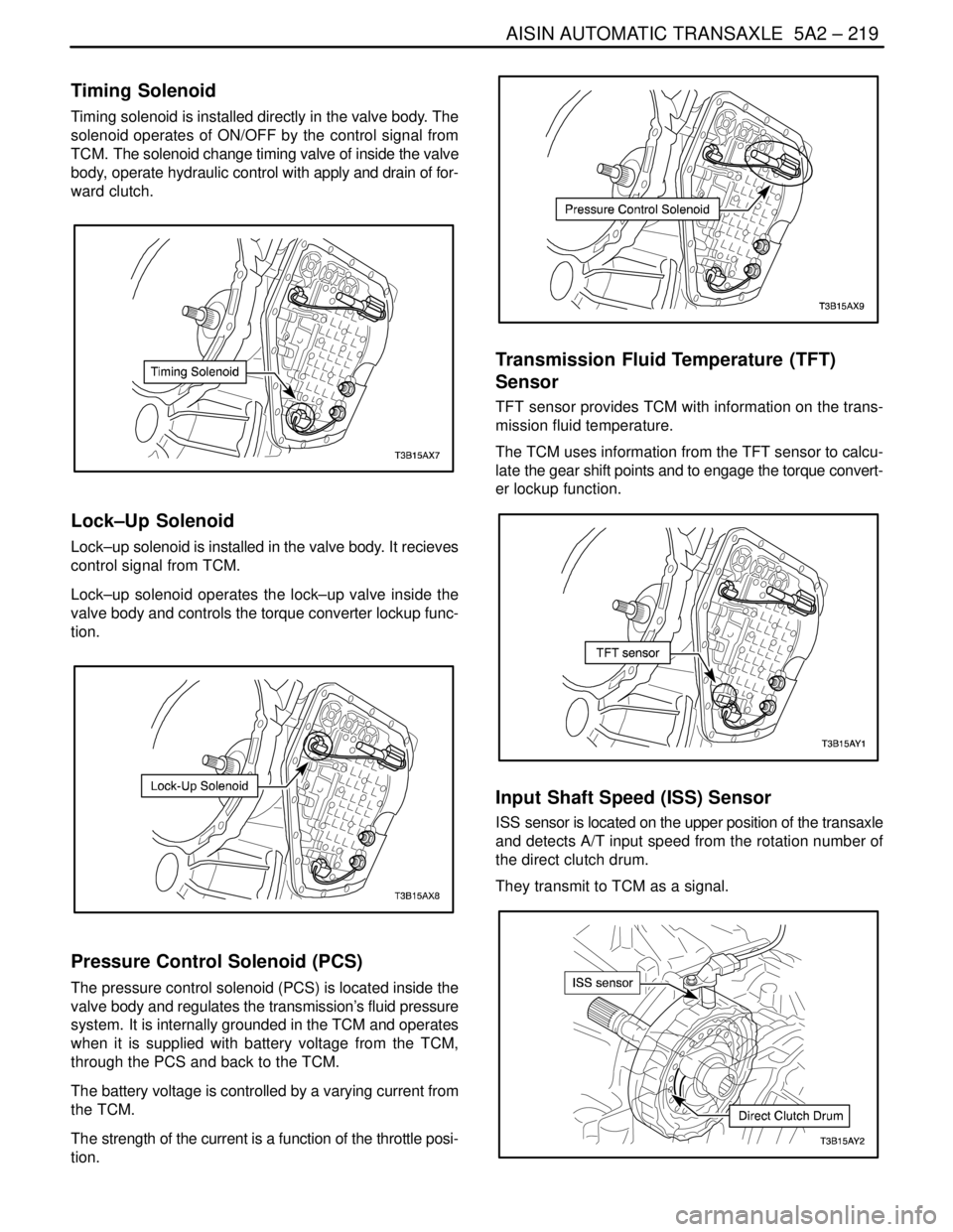

Shift Solenoid No 1,2 (SS1, SS2)

2 shift solenoids are installed directly in the valve body.

The solenoids operate of ON and OFF by the control sig-

nal from TCM. Combinations of 2 solenoids, SS1 and SS2

changes gear ranges.

Page 1809 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 219

DAEWOO V–121 BL4

Timing Solenoid

Timing solenoid is installed directly in the valve body. The

solenoid operates of ON/OFF by the control signal from

TCM. The solenoid change timing valve of inside the valve

body, operate hydraulic control with apply and drain of for-

ward clutch.

Lock–Up Solenoid

Lock–up solenoid is installed in the valve body. It recieves

control signal from TCM.

Lock–up solenoid operates the lock–up valve inside the

valve body and controls the torque converter lockup func-

tion.

Pressure Control Solenoid (PCS)

The pressure control solenoid (PCS) is located inside the

valve body and regulates the transmission’s fluid pressure

system. It is internally grounded in the TCM and operates

when it is supplied with battery voltage from the TCM,

through the PCS and back to the TCM.

The battery voltage is controlled by a varying current from

the TCM.

The strength of the current is a function of the throttle posi-

tion.

Transmission Fluid Temperature (TFT)

Sensor

TFT sensor provides TCM with information on the trans-

mission fluid temperature.

The TCM uses information from the TFT sensor to calcu-

late the gear shift points and to engage the torque convert-

er lockup function.

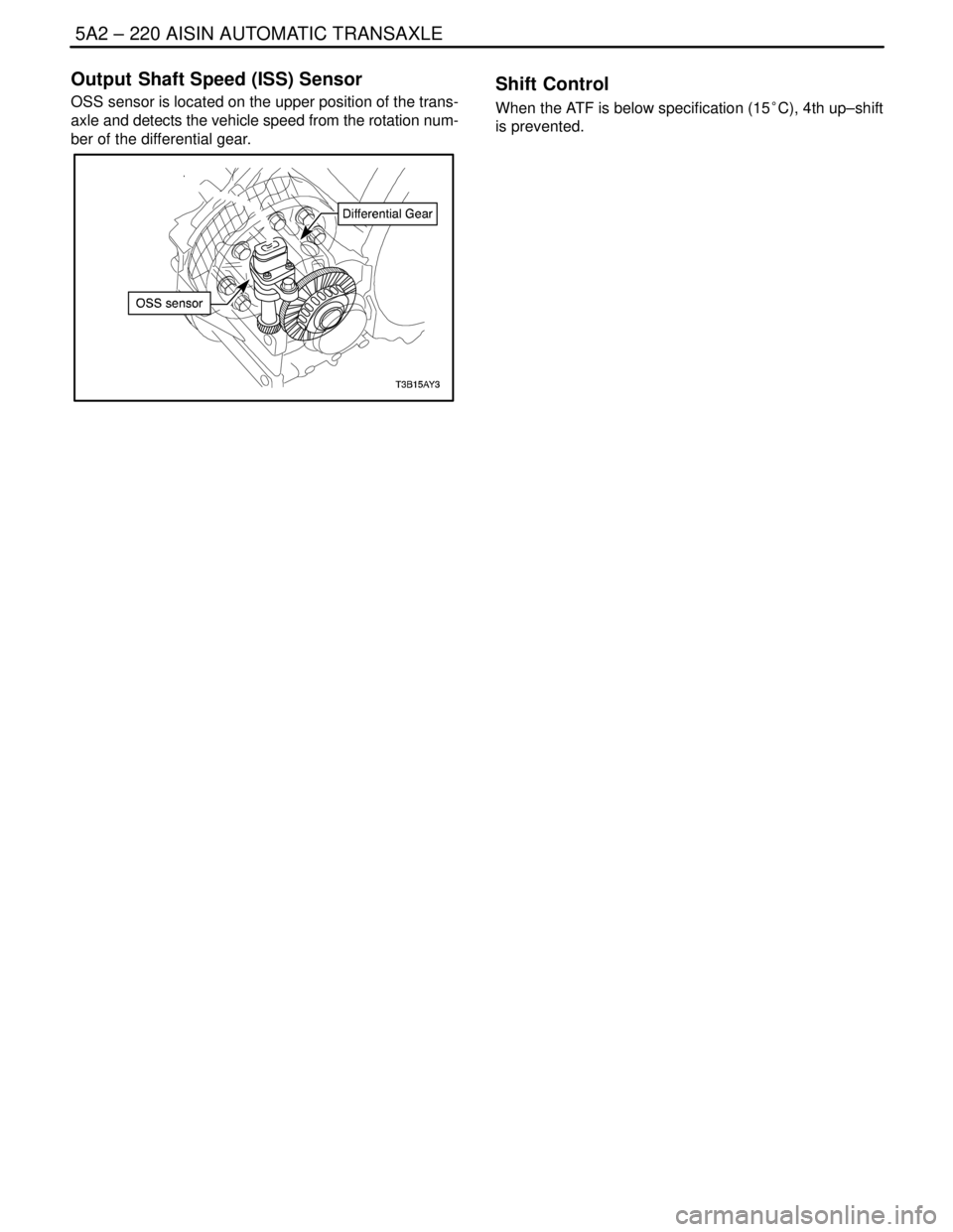

Input Shaft Speed (ISS) Sensor

ISS sensor is located on the upper position of the transaxle

and detects A/T input speed from the rotation number of

the direct clutch drum.

They transmit to TCM as a signal.

Page 1810 of 2643

5A2 – 220IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

Output Shaft Speed (ISS) Sensor

OSS sensor is located on the upper position of the trans-

axle and detects the vehicle speed from the rotation num-

ber of the differential gear.

Shift Control

When the ATF is below specification (15°C), 4th up–shift

is prevented.

Page 1815 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 225

DAEWOO V–121 BL4

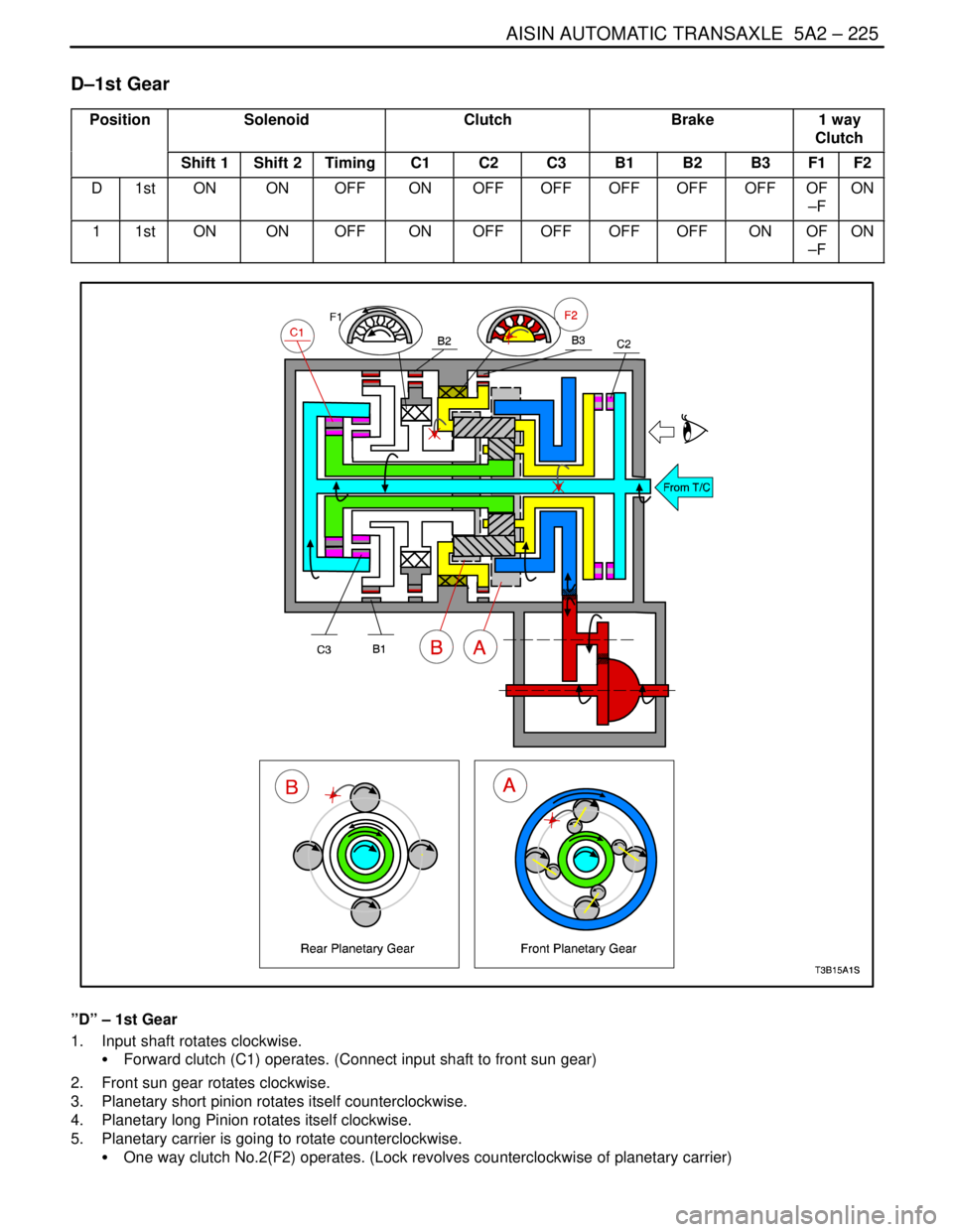

D–1st Gear

PositionSolenoidClutchBrake1 way

Clutch

Shift 1Shift 2TimingC1C2C3B1B2B3F1F2

D1stONONOFFONOFFOFFOFFOFFOFFOF

–FON

11stONONOFFONOFFOFFOFFOFFONOF

–FON

”D” – 1st Gear

1. Input shaft rotates clockwise.

S Forward clutch (C1) operates. (Connect input shaft to front sun gear)

2. Front sun gear rotates clockwise.

3. Planetary short pinion rotates itself counterclockwise.

4. Planetary long Pinion rotates itself clockwise.

5. Planetary carrier is going to rotate counterclockwise.

S One way clutch No.2(F2) operates. (Lock revolves counterclockwise of planetary carrier)

Page 1817 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 227

DAEWOO V–121 BL4

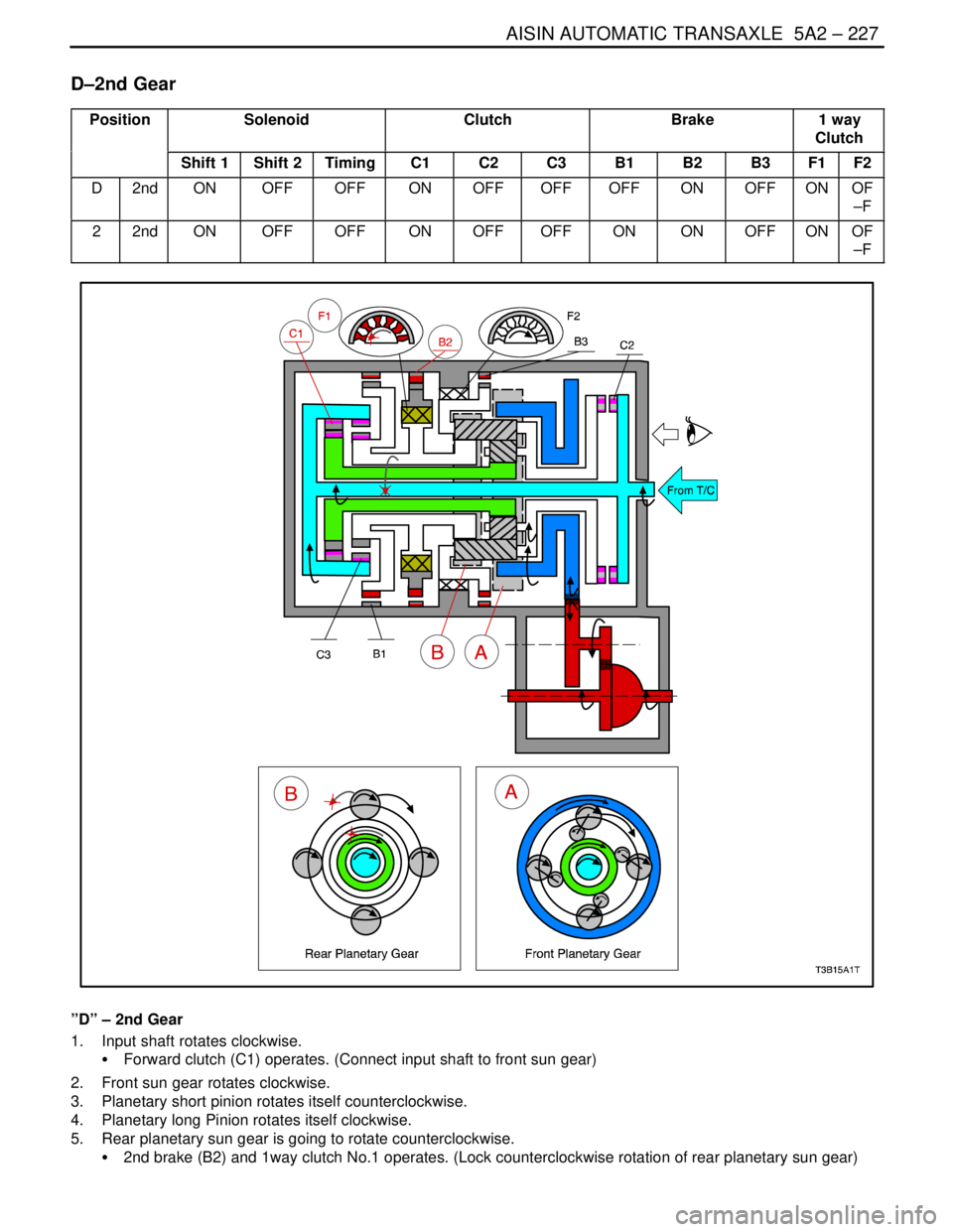

D–2nd Gear

PositionSolenoidClutchBrake1 way

Clutch

Shift 1Shift 2TimingC1C2C3B1B2B3F1F2

D2ndONOFFOFFONOFFOFFOFFONOFFONOF

–F

22ndONOFFOFFONOFFOFFONONOFFONOF

–F

”D” – 2nd Gear

1. Input shaft rotates clockwise.

S Forward clutch (C1) operates. (Connect input shaft to front sun gear)

2. Front sun gear rotates clockwise.

3. Planetary short pinion rotates itself counterclockwise.

4. Planetary long Pinion rotates itself clockwise.

5. Rear planetary sun gear is going to rotate counterclockwise.

S 2nd brake (B2) and 1way clutch No.1 operates. (Lock counterclockwise rotation of rear planetary sun gear)

Page 1819 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 229

DAEWOO V–121 BL4

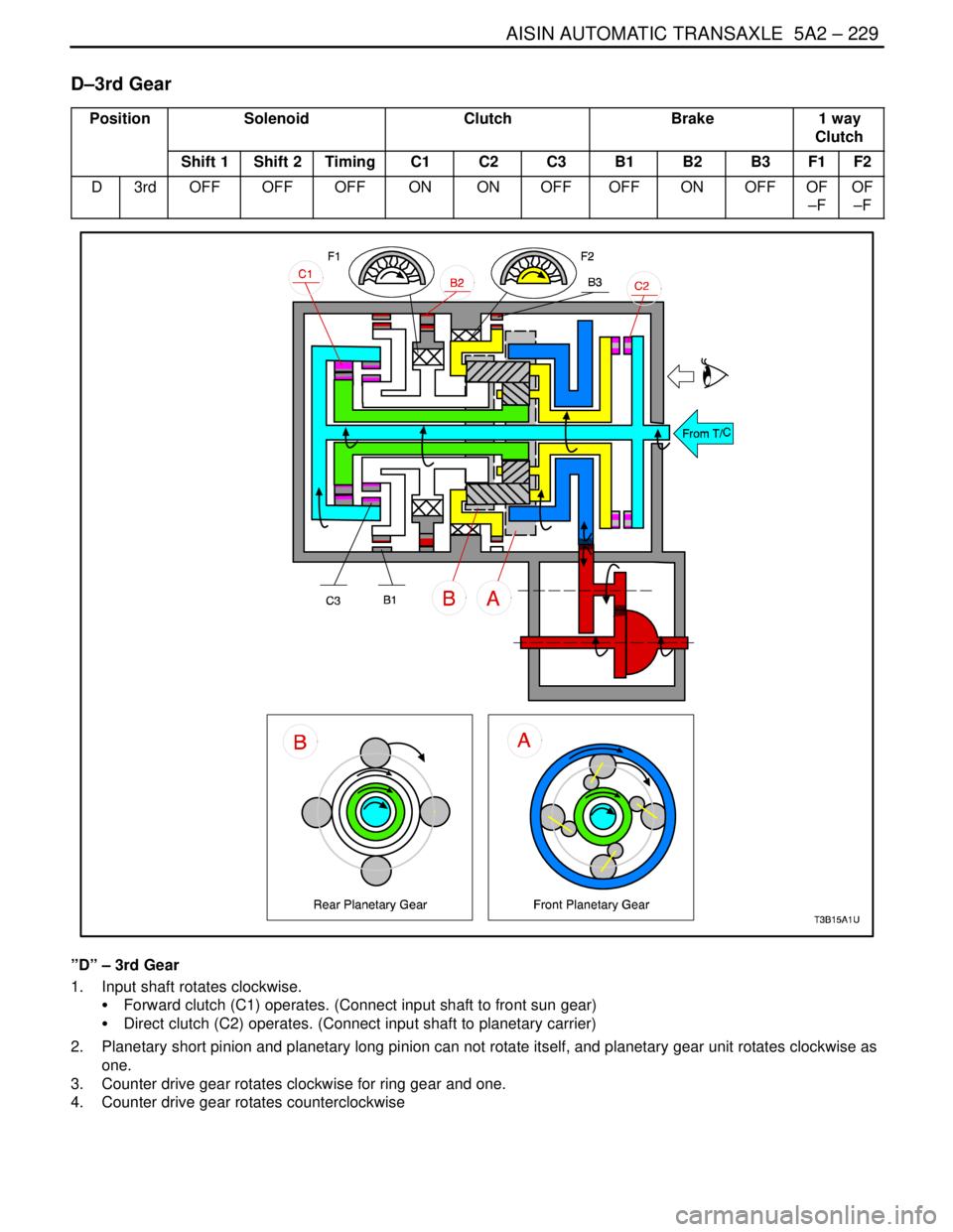

D–3rd Gear

PositionSolenoidClutchBrake1 way

Clutch

Shift 1Shift 2TimingC1C2C3B1B2B3F1F2

D3rdOFFOFFOFFONONOFFOFFONOFFOF

–FOF

–F

”D” – 3rd Gear

1. Input shaft rotates clockwise.

S Forward clutch (C1) operates. (Connect input shaft to front sun gear)

S Direct clutch (C2) operates. (Connect input shaft to planetary carrier)

2. Planetary short pinion and planetary long pinion can not rotate itself, and planetary gear unit rotates clockwise as

one.

3. Counter drive gear rotates clockwise for ring gear and one.

4. Counter drive gear rotates counterclockwise