Five speed manual transaxle clutch DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 5 of 2643

v

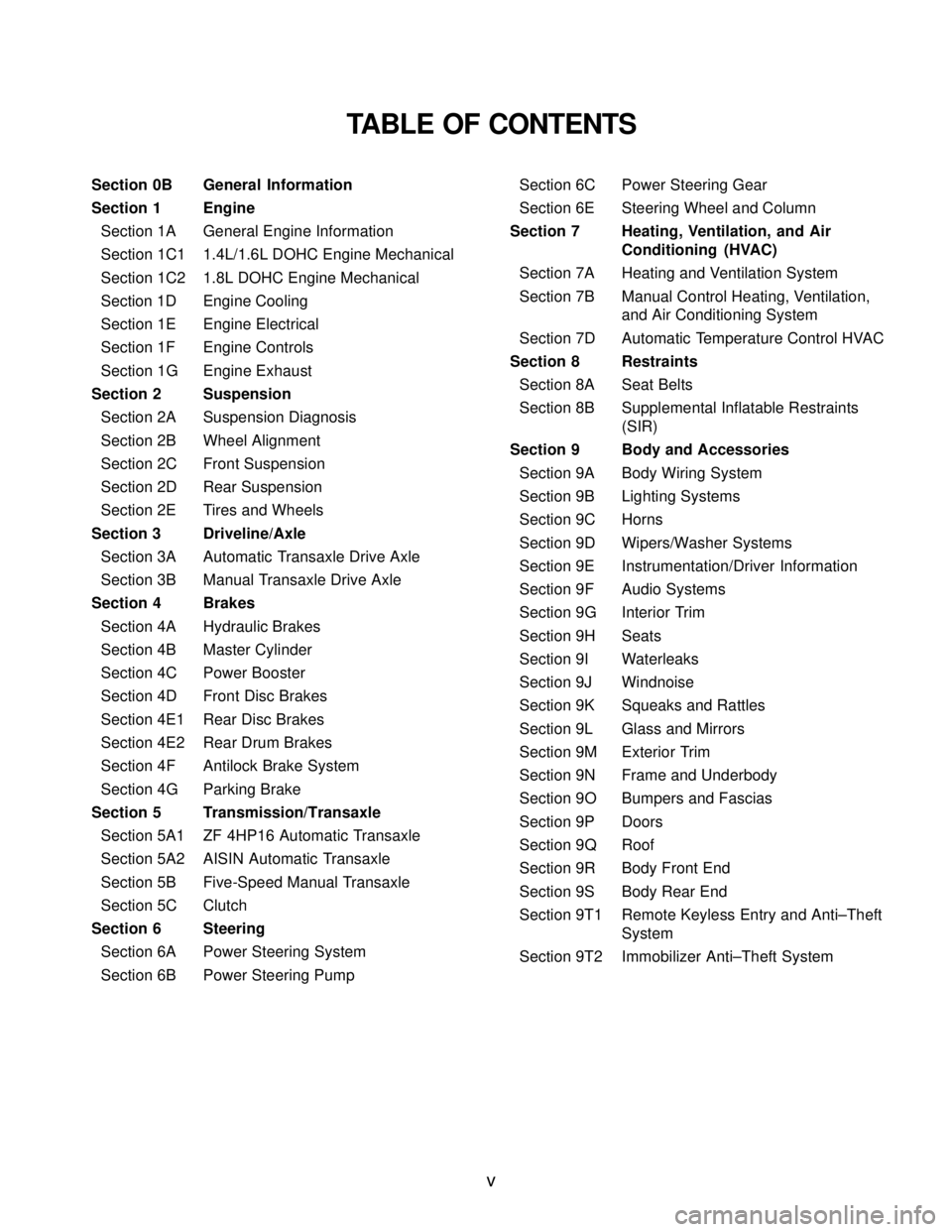

TABLE OF CONTENTS

Section 0B General Information

Section 1 Engine

Section 1A General Engine Information

Section 1C1 1.4L/1.6L DOHC Engine Mechanical

Section 1C2 1.8L DOHC Engine Mechanical

Section 1D Engine Cooling

Section 1E Engine Electrical

Section 1F Engine Controls

Section 1G Engine Exhaust

Section 2 Suspension

Section 2A Suspension Diagnosis

Section 2B Wheel Alignment

Section 2C Front Suspension

Section 2D Rear Suspension

Section 2E Tires and Wheels

Section 3 Driveline/Axle

Section 3A Automatic Transaxle Drive Axle

Section 3B Manual Transaxle Drive Axle

Section 4 Brakes

Section 4A Hydraulic Brakes

Section 4B Master Cylinder

Section 4C Power Booster

Section 4D Front Disc Brakes

Section 4E1 Rear Disc Brakes

Section 4E2 Rear Drum Brakes

Section 4F Antilock Brake System

Section 4G Parking Brake

Section 5 Transmission/Transaxle

Section 5A1 ZF 4HP16 Automatic Transaxle

Section 5A2 AISIN Automatic Transaxle

Section 5B Five-Speed Manual Transaxle

Section 5C Clutch

Section 6 Steering

Section 6A Power Steering System

Section 6B Power Steering PumpSection 6C Power Steering Gear

Section 6E Steering Wheel and Column

Section 7 Heating, Ventilation, and Air

Conditioning (HVAC)

Section 7A Heating and Ventilation System

Section 7B Manual Control Heating, Ventilation,

and Air Conditioning System

Section 7D Automatic Temperature Control HVAC

Section 8 Restraints

Section 8A Seat Belts

Section 8B Supplemental Inflatable Restraints

(SIR)

Section 9 Body and Accessories

Section 9A Body Wiring System

Section 9B Lighting Systems

Section 9C Horns

Section 9D Wipers/Washer Systems

Section 9E Instrumentation/Driver Information

Section 9F Audio Systems

Section 9G Interior Trim

Section 9H Seats

Section 9I Waterleaks

Section 9J Windnoise

Section 9K Squeaks and Rattles

Section 9L Glass and Mirrors

Section 9M Exterior Trim

Section 9N Frame and Underbody

Section 9O Bumpers and Fascias

Section 9P Doors

Section 9Q Roof

Section 9R Body Front End

Section 9S Body Rear End

Section 9T1 Remote Keyless Entry and Anti–Theft

System

Section 9T2 Immobilizer Anti–Theft System

Page 1826 of 2643

5B – 2IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

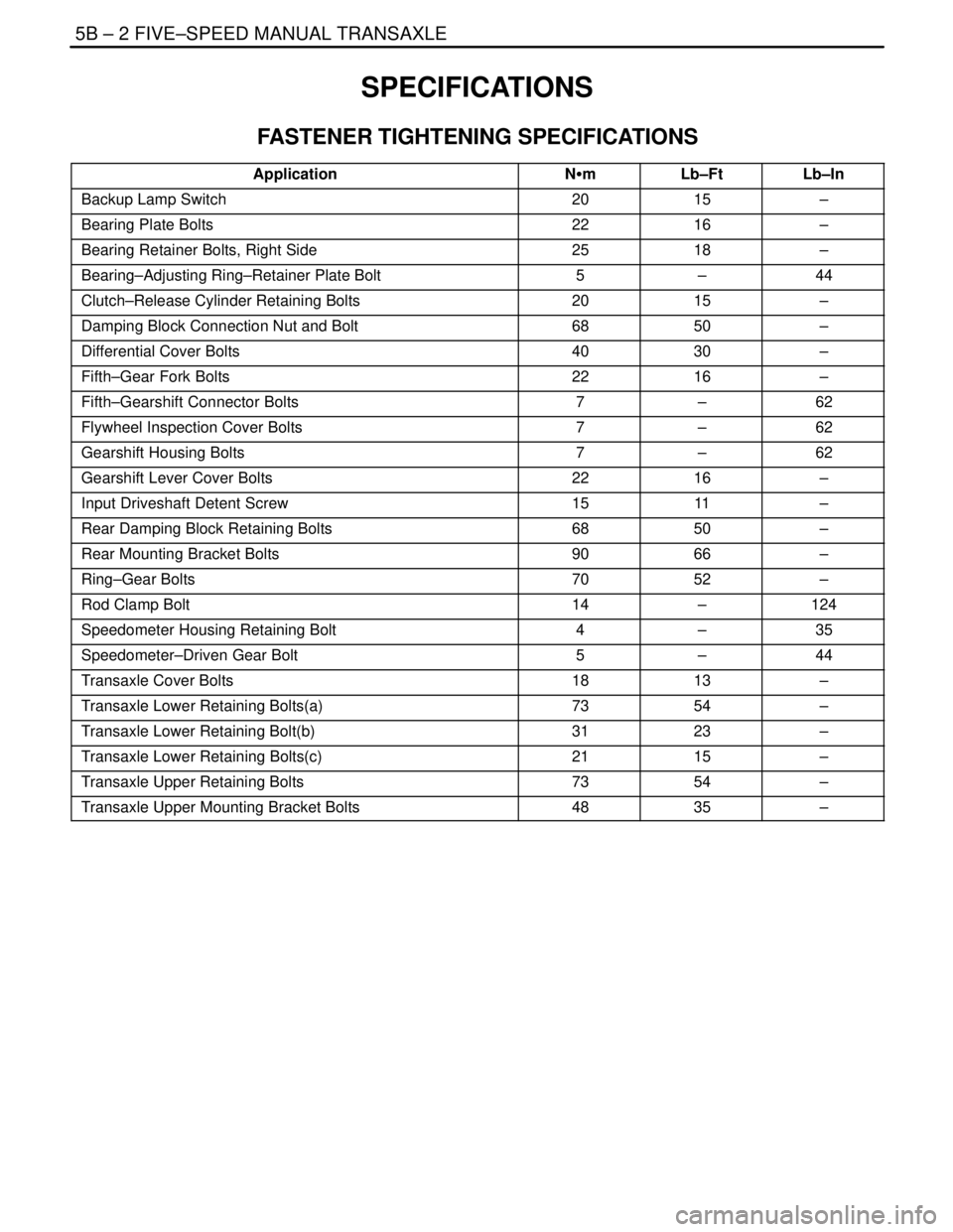

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Backup Lamp Switch2015–

Bearing Plate Bolts2216–

Bearing Retainer Bolts, Right Side2518–

Bearing–Adjusting Ring–Retainer Plate Bolt5–44

Clutch–Release Cylinder Retaining Bolts2015–

Damping Block Connection Nut and Bolt6850–

Differential Cover Bolts4030–

Fifth–Gear Fork Bolts2216–

Fifth–Gearshift Connector Bolts7–62

Flywheel Inspection Cover Bolts7–62

Gearshift Housing Bolts7–62

Gearshift Lever Cover Bolts2216–

Input Driveshaft Detent Screw1511–

Rear Damping Block Retaining Bolts6850–

Rear Mounting Bracket Bolts9066–

Ring–Gear Bolts7052–

Rod Clamp Bolt14–124

Speedometer Housing Retaining Bolt4–35

Speedometer–Driven Gear Bolt5–44

Transaxle Cover Bolts1813–

Transaxle Lower Retaining Bolts(a)7354–

Transaxle Lower Retaining Bolt(b)3123–

Transaxle Lower Retaining Bolts(c)2115–

Transaxle Upper Retaining Bolts7354–

Transaxle Upper Mounting Bracket Bolts4835–

Page 1829 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 5

DAEWOO V–121 BL4

DIAGNOSIS

ISOLATE NOISE

Identify the cause of any noise before attempting to repair

the clutch, the transaxle, or their related link–ages.

Symptoms of trouble with the clutch or the manual trans-

axle include:

S A great effort required to shift gears.

S The sound of gears clashing and grinding.

S Gear blockout.

Any of these conditions requires a careful analysis. Make

the following checks before disassembling the clutch or

the transaxle for repairs.

Road Travel Noise

Many noises that appear to come from the transaxle may

actually originate with other sources such as the:

S Tires.

S Road surfaces.

S Wheel bearings.

S Engine.

S Exhaust system.

These noises may vary according to the:

S Size of the vehicle.

S Type of the vehicle.

S Amount of insulation used in the body of the ve-

hicle.

Transaxle Noise

Transaxle gears, like any mechanical device, are not ab-

solutely quiet and will make some noise during normal op-

eration.

To verify suspected transaxle noises:

1. Select a smooth, level asphalt road to reduce tire

and resonant body noise.

2. Drive the vehicle far enough to warm up all the lu-

bricants thoroughly.

3. Record the speed and the gear range of the trans-

axle when the noise occurs.

4. Check for noises with the vehicle stopped, but with

the engine running.

5. Determine if the noise occurs while the vehicle op-

erates in:

S Drive – under a light acceleration or a heavy

pull.

S Float – maintaining a constant speed with a light

throttle on a level road.

S Coast – with the transaxle in gear and the

throttle partly or fully closed.

S All of the above.

Bearing Noise

Differential Side Bearing Noise

Differential side bearing noise and wheel bearing noise

can be confused easily. Since side bearings are pre–

loaded, a differential side bearing noise should not dimin-

ish much when the differential/transaxle is run with the

wheels off the ground.

Wheel Bearing Noise

Wheel bearings produce a rough growl or grating sound

that will continue when the vehicle is coasting and the

transaxle is in NEUTRAL. Since wheel bearings are not

pre–loaded, a wheel bearing noise should diminish con-

siderably when the wheels are off the ground.

Other Noise

Brinelling

A brinelled bearing causes a ”knock” or ”click” approxi-

mately every second revolution of the wheel because the

bearing rollers do not travel at the same speed as the

wheel. In operation, the effect is characterized by a low–

pitched noise.

A brinelled bearing is caused by excessive thrust which

pushes the balls up on the pathway and creates a triangu-

lar–shaped spot in the bearing race. A brinelled bearing

can also be caused from pressing one race into position

by applying pressure on the other race.

A false indication of a brinelled bearing occurs as a result

of vibration near the area where the bearing is mounted.

Brinelling is identified by slight indentations, resulting in a

washboard effect in the bearing race.

Lapping

Lapped bearing noise occurs when fine particles of abra-

sive materials such as scale, sand, or emery circulate

through the oil in the vehicle, causing the surfaces of the

roller and the race to wear away. Bearings that wear loose

but remain smooth, without spalling or pitting, are the re-

sult of dirty oil.

Locking

Large particles of foreign material wedged between the

roller and the race usually causes one of the races to turn,

creating noise from a locked bearing. Pre–loading regular

taper roller bearings to a value higher than that specified

also can result in locked bearings

Pitting

Pitting on the rolling surface comes from normal wear and

the introduction of foreign materials.

Spalling

Spalled bearings have flaked or pitted rollers or races

caused by an overload or an incorrect assembly that re-

sults in a misalignment, a cocking of bearings, or adjust-

ments that are too tight.

After completing these checks, refer to the ”Diagnosis

Chart” in this section.

Page 1830 of 2643

5B – 6IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

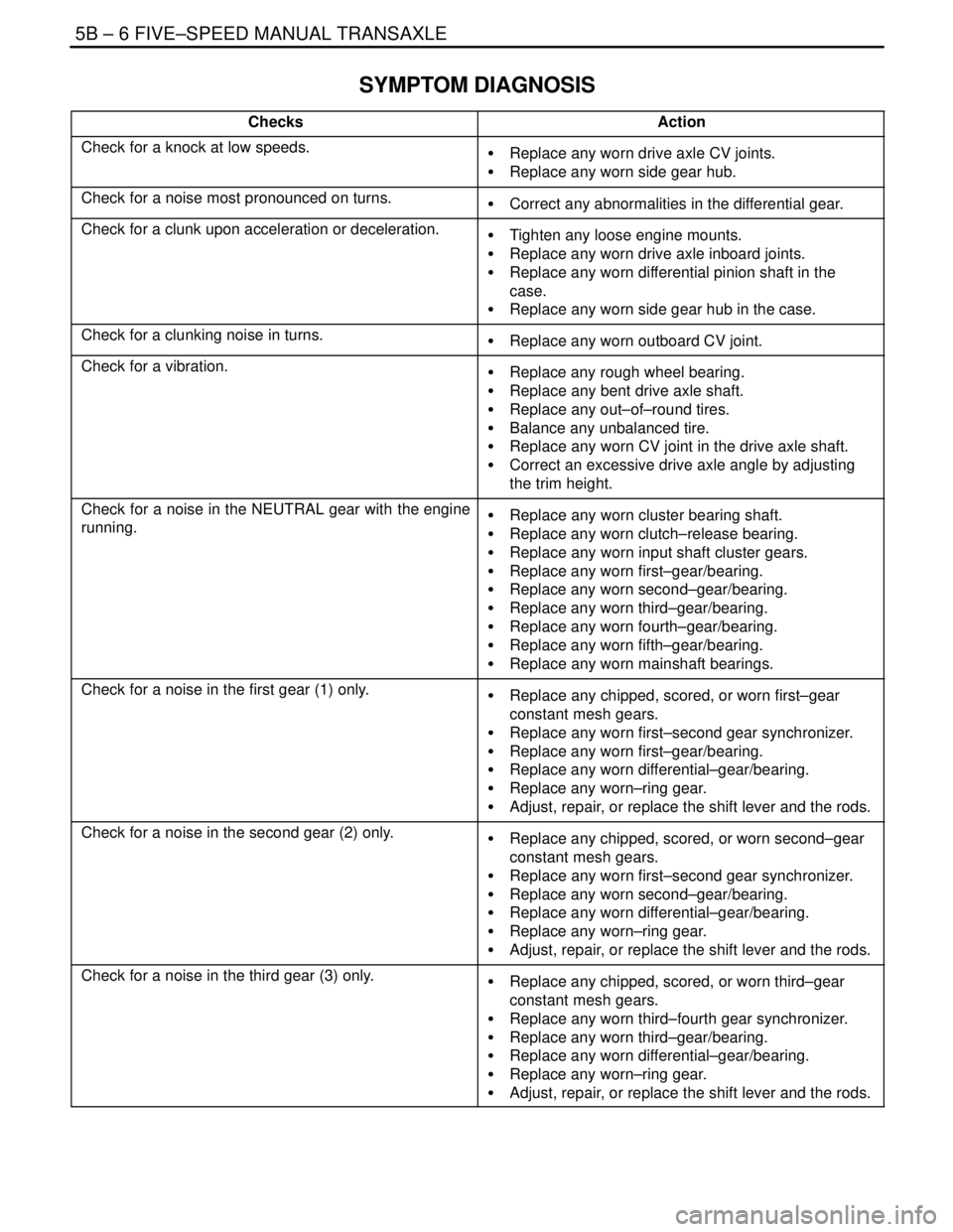

SYMPTOM DIAGNOSIS

ChecksAction

Check for a knock at low speeds.S Replace any worn drive axle CV joints.

S Replace any worn side gear hub.

Check for a noise most pronounced on turns.S Correct any abnormalities in the differential gear.

Check for a clunk upon acceleration or deceleration.S Tighten any loose engine mounts.

S Replace any worn drive axle inboard joints.

S Replace any worn differential pinion shaft in the

case.

S Replace any worn side gear hub in the case.

Check for a clunking noise in turns.S Replace any worn outboard CV joint.

Check for a vibration.S Replace any rough wheel bearing.

S Replace any bent drive axle shaft.

S Replace any out–of–round tires.

S Balance any unbalanced tire.

S Replace any worn CV joint in the drive axle shaft.

S Correct an excessive drive axle angle by adjusting

the trim height.

Check for a noise in the NEUTRAL gear with the engine

running.S Replace any worn cluster bearing shaft.

S Replace any worn clutch–release bearing.

S Replace any worn input shaft cluster gears.

S Replace any worn first–gear/bearing.

S Replace any worn second–gear/bearing.

S Replace any worn third–gear/bearing.

S Replace any worn fourth–gear/bearing.

S Replace any worn fifth–gear/bearing.

S Replace any worn mainshaft bearings.

Check for a noise in the first gear (1) only.S Replace any chipped, scored, or worn first–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn first–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the second gear (2) only.S Replace any chipped, scored, or worn second–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn second–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the third gear (3) only.S Replace any chipped, scored, or worn third–gear

constant mesh gears.

S Replace any worn third–fourth gear synchronizer.

S Replace any worn third–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Page 1831 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 7

DAEWOO V–121 BL4

Checks Action

Check for a noise in the fourth gear (4) only.S Replace any chipped, scored, or worn fourth gear or

output gear.

S Replace any worn third–fourth gear synchronizer.

S Replace any worn fourth–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the fifth gear (5) only.S Replace any chipped, scored, or worn fifth gear or

output gear.

S Repair any worn fifth–gear synchronizer.

S Replace any worn fifth–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the reverse (R) gear only.S Replace any chipped, scored, or worn reverse idler

gear, idler–gear bushing, input gear, or output gear.

S Replace any worn first–second gear synchronizer.

S Replace any worn output gear.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

Check for a noise in all gears.S Add sufficient lubricant.

S Replace any worn bearings.

S Replace any chipped, scored, or worn input–gear

shaft or output–gear shaft.

Check for the transaxle slipping out of gear.S Adjust or replace the linkage, as needed.

S Adjust, repair, or replace any binding shift linkage.

S Tighten or replace the input–gear bearing retainer, as

needed.

S Repair or replace any worn or bent shift fork.

Check for a leak in the area of the clutch.S Repair the transaxle casing.

S Replace any damaged release bearing guide.

Check for a leak at the center of the transaxle.S Repair the transaxle casing.

S Repair the shift mechanism.

S Replace the damaged backup lamp switch.

Check for a leak at the differential.S Adjust or replace the bearing retainers.

S Tighten or replace the differential cover.

S Adjust or replace the drive axle shaft seals.

Page 1832 of 2643

5B – 8IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

Checks Action

Check for a hard shift.S Replace any damaged release–bearing guide.

S Adjust, repair, or replace the shift mechanism.

S Adjust, repair, or replace the clutch–release system.

S Replace any chipped, scored, or worn fifth–gear syn-

chronizer.

S Replace any chipped, scored, or worn first–second

gear synchronizer.

S Replace any worn third–fourth gear synchronizer.

S Adjust, repair, or replace the shift lever and the rods.

Check for a clashing of gears.S Replace any damaged release–bearing guide.

S Adjust, repair, or replace the clutch–release system.

S Replace the chipped, scored, or worn input shaft/

gear–cluster gears.

S Replace any worn fifth–gear synchronizer.

S Replace any worn fifth–gear/bearing.

S Replace any worn first–gear/bearing.

S Replace any worn first–second gear synchronizer.

S Replace any worn second–gear/bearing.

S Replace any worn third–gear/bearing.

S Replace any worn third–fourth synchronizer.

S Replace any worn fourth–gear/bearing.

S Replace any worn reverse–idler gear.

Page 1839 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 15

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

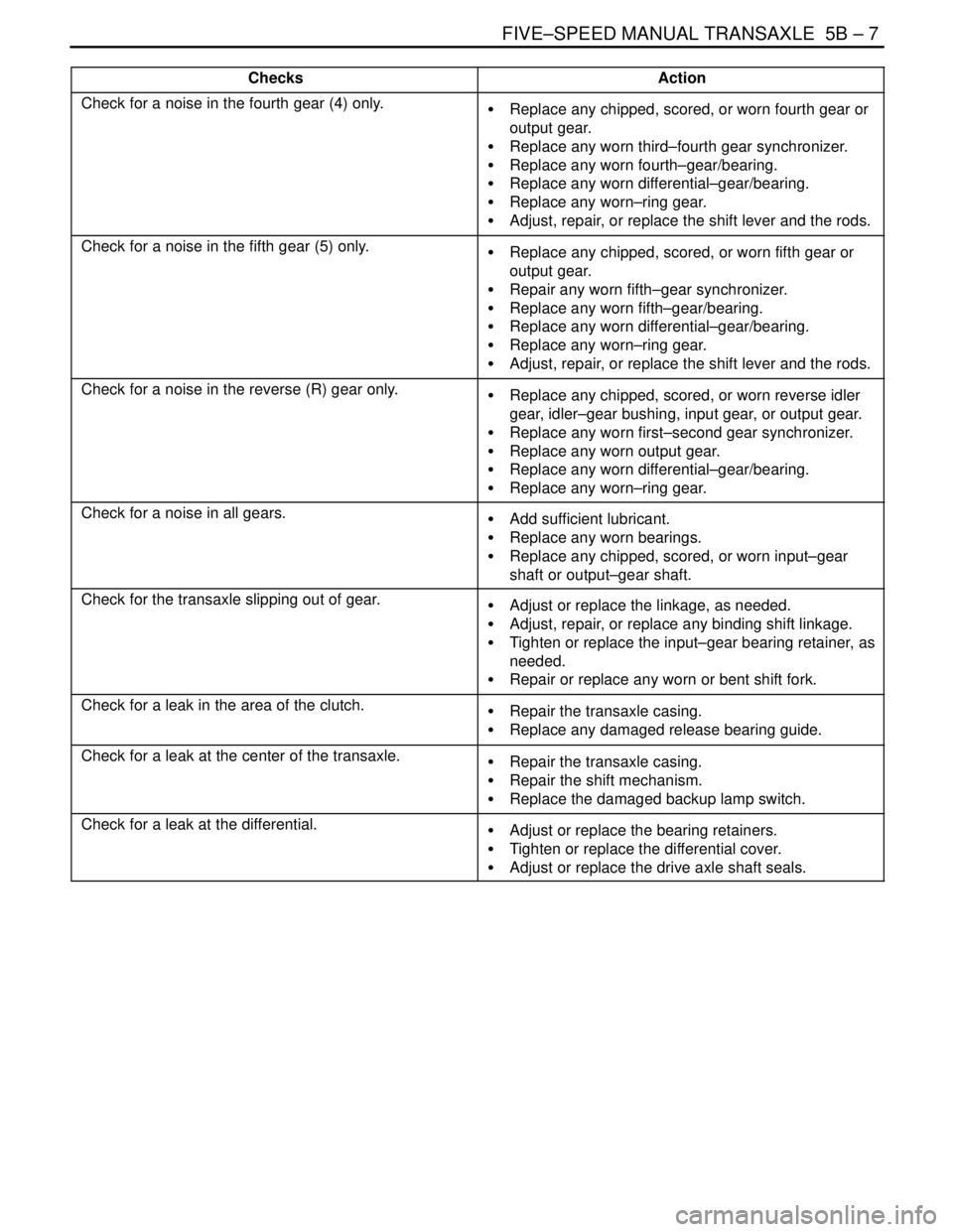

CHECKING FLUID LEVEL

1. With the vehicle on a level surface and the fluid in

the transaxle cold, remove the filler plug and check

the fluid level. The fluid should come to the bottom

edge of the plug hole.

2. If the level is low, add SAE 80 manual transaxle

fluid through the filler plug hole until the fluid begins

to run out.

3. Reinstall the filler plug and tighten it securely.

4. If the fluid is contaminated, drain the oil after re-

moving the differential gear cover.

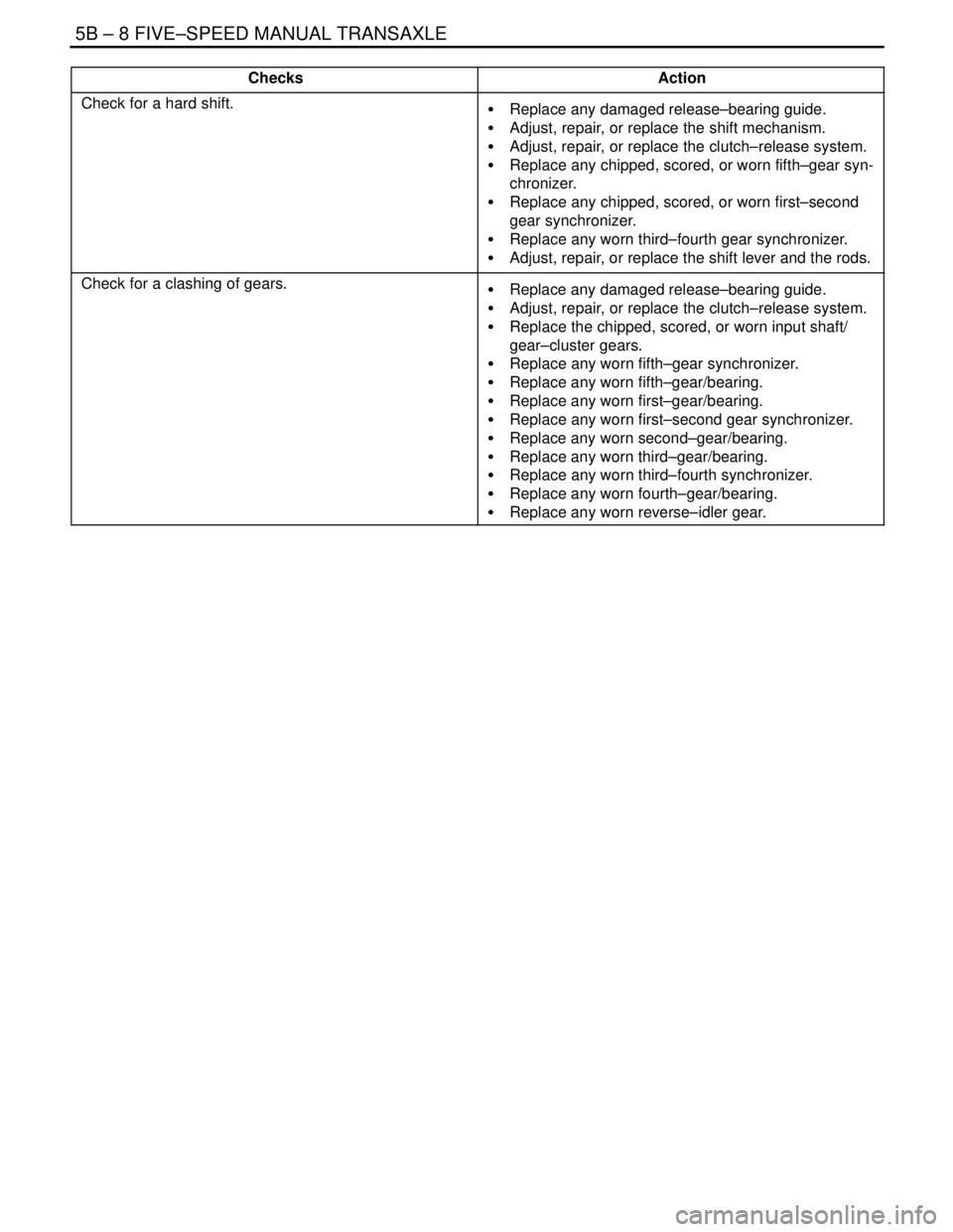

SHIFT LINKAGE ADJUSTMENT

(LEFT–HAND DRIVE SHOWN,

RIGHT–HAND DRIVE SIMILAR)

1. Disconnect the negative battery cable.

2. Position the gearshift lever into NEUTRAL.

Important : All the gears must be easy to engage when

the vehicle is stationary, the engine is running, and the

clutch is disengaged.

3. Loosen the rod clamp bolt.

Page 1845 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 21

DAEWOO V–121 BL4

TRANSAXLE ASSEMBLY

Tools Required

J–28467–B Engine Support Fixture

Removal Procedure

1. Install the engine support fixture J–28467–B.

2. Remove the battery and battery tray. Refer to Sec-

tion 1E, ENGINE ELETRICAL.

3. Remove the shift linkage assembly. Refer to ”Shift

Linkage Adjustment” in this section.

4. Remove the drive axle shaft. Refer to Section 3B,

Manual Transaxle Drive Axle.

5. Disconnect the backup lamp switch electrical con-

nector.

6. Disconnect the speedometer speed sensor electri-

cal connector.

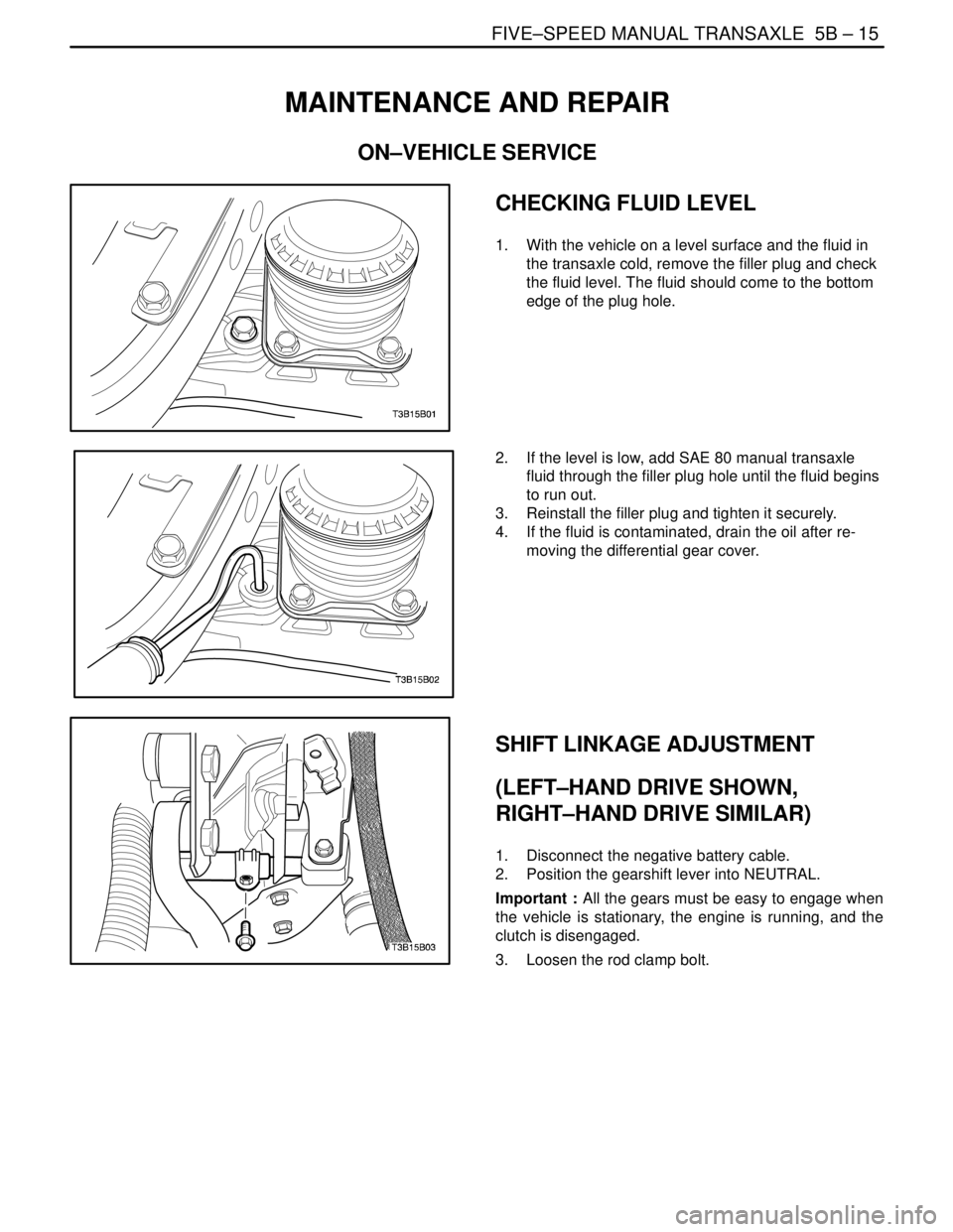

7. Remove the pin and the clutch release cylinder

pipe.

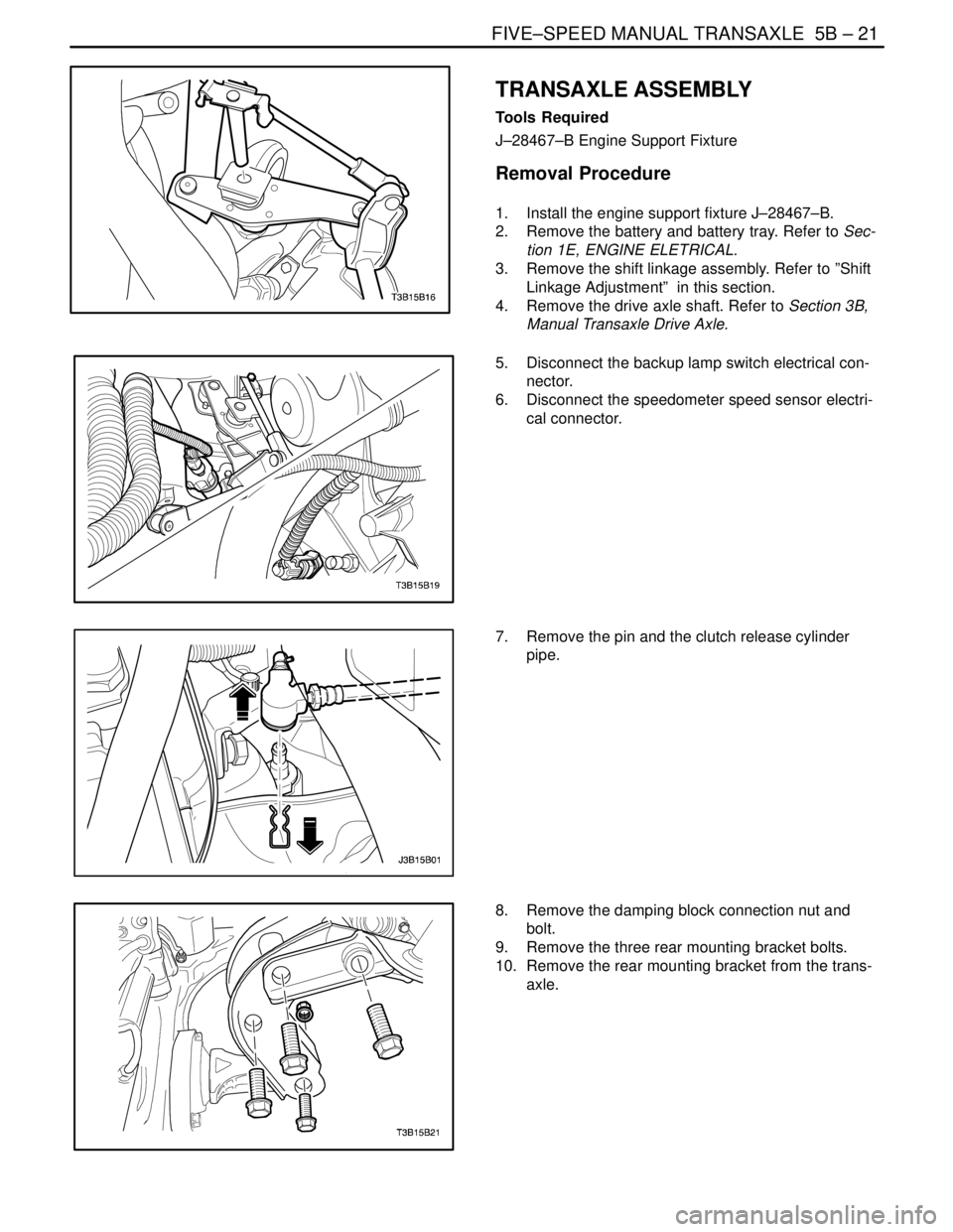

8. Remove the damping block connection nut and

bolt.

9. Remove the three rear mounting bracket bolts.

10. Remove the rear mounting bracket from the trans-

axle.

Page 1847 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 23

DAEWOO V–121 BL4

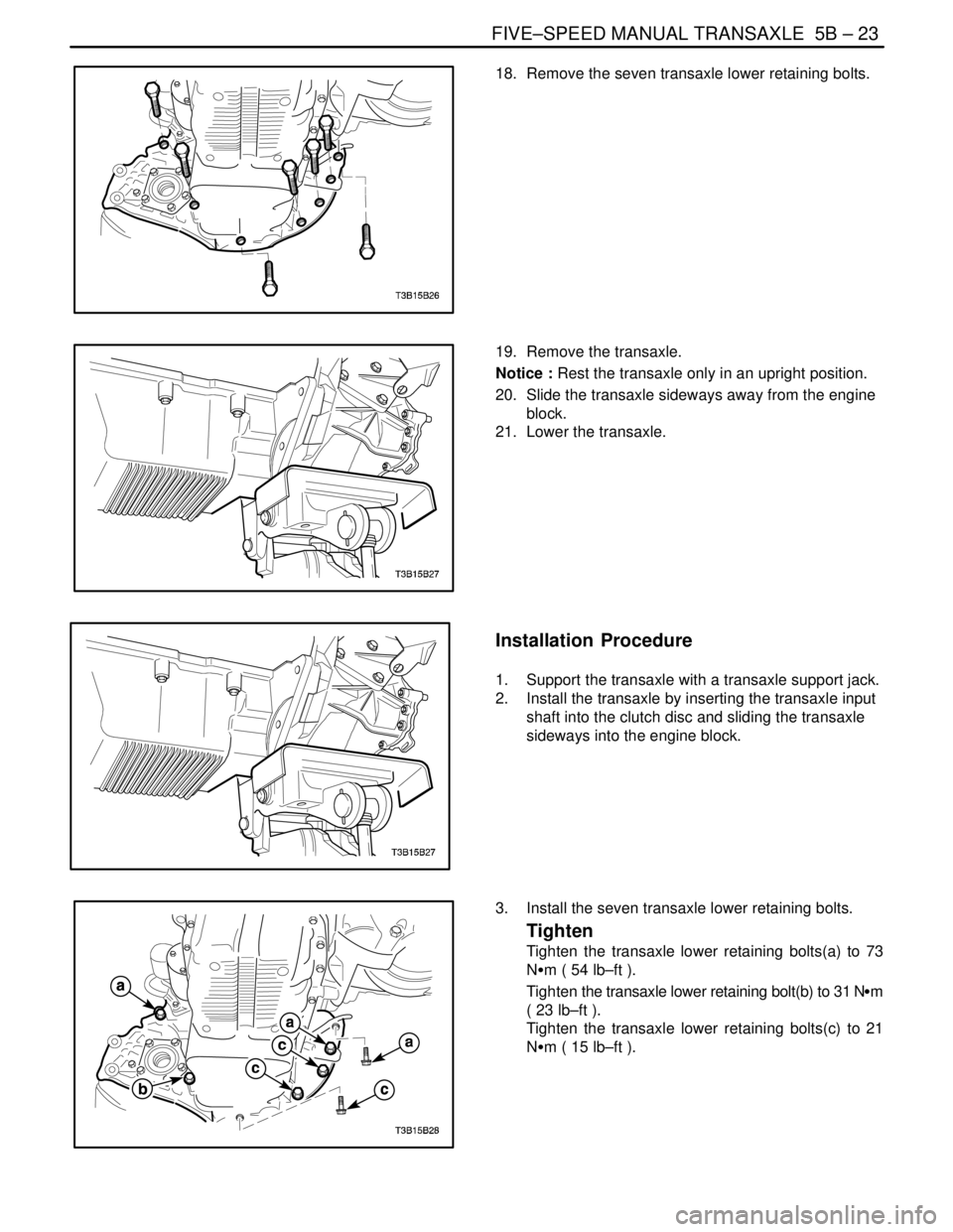

18. Remove the seven transaxle lower retaining bolts.

19. Remove the transaxle.

Notice : Rest the transaxle only in an upright position.

20. Slide the transaxle sideways away from the engine

block.

21. Lower the transaxle.

Installation Procedure

1. Support the transaxle with a transaxle support jack.

2. Install the transaxle by inserting the transaxle input

shaft into the clutch disc and sliding the transaxle

sideways into the engine block.

3. Install the seven transaxle lower retaining bolts.

Tighten

Tighten the transaxle lower retaining bolts(a) to 73

NSm ( 54 lb–ft ).

Tighten the transaxle lower retaining bolt(b) to 31 NSm

( 23 lb–ft ).

Tighten the transaxle lower retaining bolts(c) to 21

NSm ( 15 lb–ft ).

Page 1849 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 25

DAEWOO V–121 BL4

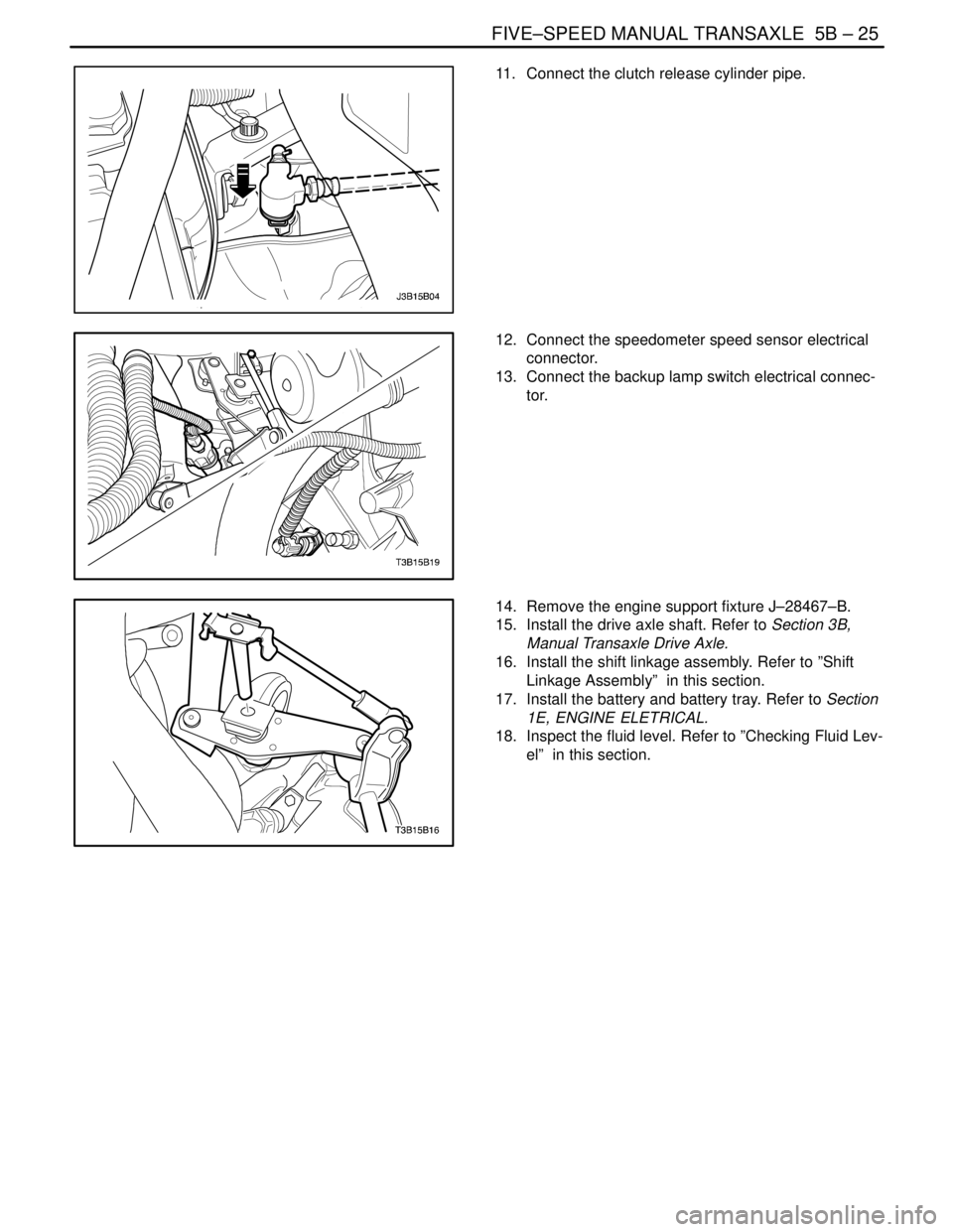

11. Connect the clutch release cylinder pipe.

12. Connect the speedometer speed sensor electrical

connector.

13. Connect the backup lamp switch electrical connec-

tor.

14. Remove the engine support fixture J–28467–B.

15. Install the drive axle shaft. Refer to Section 3B,

Manual Transaxle Drive Axle.

16. Install the shift linkage assembly. Refer to ”Shift

Linkage Assembly” in this section.

17. Install the battery and battery tray. Refer to Section

1E, ENGINE ELETRICAL.

18. Inspect the fluid level. Refer to ”Checking Fluid Lev-

el” in this section.