four wheel drive DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 745 of 2643

ENGINE CONTROLS 1F – 499

DAEWOO V–121 BL4

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent problem may be caused by a poor connec-

tion, rubbed–through wire insulation, or a wire that is bro-

ken inside the insulation.

VSS signal circuit should be thoroughly checked for the

following conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

S Physical damage to the wiring harness

Ensure the VSS is correctly tightened with proper torque

to the transmission housing.

Refer to ”Intermittents”in this section.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. The permanent magnet generator only produces a

signal if the drive wheels are turning greater than 5

mph (8 km/h). This step determines if DTC P0502

is the result of a hard failure or an intermittent con-

dition.

3. Proper engine loads cannot be achieved in a shop

environment to properly run the vehicle within the

Freeze Frame Data conditions. It will be necessary

to drive the vehicle on the road to obtain the proper

engine loads.

4. This step verifies that the ECM is receiving a signal

from the vehicle speed sensor.

5. Refer to service bulletin information for the latest

calibration update.

6. Refer to the latest Techline information for program-

ming procedures.

8. A resistance reading that is higher than the speci-

fied value indicates that the VSS circuitry is open.

10. If the displayed resistance is less than the 1300

ohms, the VSS high and low circuits are shorted

together.

11. This checks the resistance of the VSS if no opens

or shorts were found on the VSS high and low cir-

cuits.

13. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

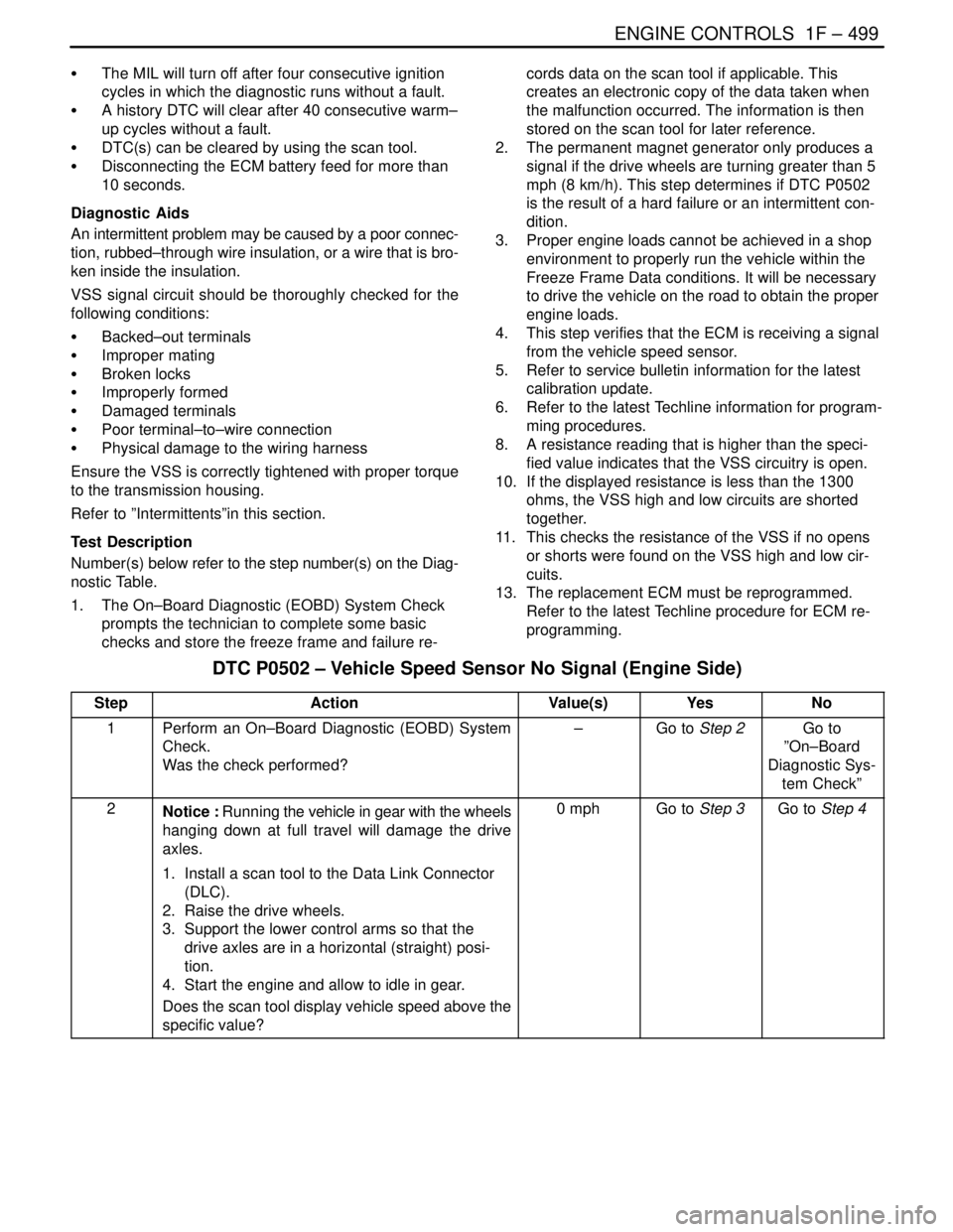

DTC P0502 – Vehicle Speed Sensor No Signal (Engine Side)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Notice : Running the vehicle in gear with the wheels

hanging down at full travel will damage the drive

axles.

1. Install a scan tool to the Data Link Connector

(DLC).

2. Raise the drive wheels.

3. Support the lower control arms so that the

drive axles are in a horizontal (straight) posi-

tion.

4. Start the engine and allow to idle in gear.

Does the scan tool display vehicle speed above the

specific value?0 mphGo to Step 3Go to Step 4

Page 796 of 2643

1F – 550IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1336

58X CRANK POSITION TOOTH ERROR NOT LEARNED

Circuit Description

In order to detect engine misfire at higher engine speeds,

the Engine Control Module (ECM) must know of any varia-

tion between the crankshaft sensor pulses. Most varia-

tions are due to the machining of the crankshaft reluctor

wheel. However, other sources of variation are also pos-

sible. A Crankshaft Position (CKP) system variation learn-

ing procedure must be performed any time a change is

made to the crankshaft sensor to crankshaft relationship

of if the ECM is replaced or reprogrammed. The ECM

measures the variations and then calculates compensa-

tion factors needed to enable the ECM to accurately de-

tect engine misfire at all speeds and loads. A scan tool

must be used to command the ECM to learn these varia-

tions. If for any reason the ECM is unable to learn these

variations or they are out of an acceptable range, the ECM

will set Diagnostic Trouble Code (DTC) P1336. An ECM

that has not had the CKP system variation learning proce-

dure performed due to replacement or reprogramming will

also set DTC P1336.

Conditions for Setting the DTC

S Tooth error not learned if the manufacture enable

counter is set to zero.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0132, P0201, P0202, P0203,

P0204, P0325 , 0327, P0336, P0337, P0341,

P0342, P0351, P0352, P0402, P1404, P0404,

P0405, P0406 and P0502 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffer.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn OFF after four consecutive igni-

tion cycles in which the diagnostic runs without a

fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Disconnecting the ECM battery feed for more than

10 seconds.

S DTC(s) can be cleared by using the scan tool.Diagnostic Aids

CAUTION : To avoid personal injury when performing

the crankshaft position system variation learning

procedure, always set the vehice parking brake and

block the drive wheels. Release the throttle immedi-

ately when the engine starts to decelerate. Once the

learn procedure is completed, engine control will be

returned to the operator, and the engine will respond

to throttle position.

DTC P1336 will only set if the ECM has not learned the

CKP system variation. The ECM only needs to learn this

variation once per life cycle of the vehicle unless the crank

sensor to crankshaft relationship is disturbed. Removing

a part is considered a disturbance. A fully warmed engine

is critical to learning the variation correctly. If a valid learn

occurs, no other learns can be completed that ignition

cycle.

If the engine cuts out before the specified learn procedure

engine speed or at normal fuel cutoff rpm, the ECM is not

in the learn procedure mode.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the fault occurred. The information is then stored on

the scan tool for later reference.

2. Engine temperature is critical to properly learn the

CKP system variation. Failure to properly warm the

engine before performing this procedure will result

in an inaccurate measurement of the CKP system

variation. The ECM learns this variation as the en-

gine is decelerating and then allows engine control

to be returned to the operator. All accessories must

be OFF when learning the CKP system angle varia-

tion. If the A/C is not disabled when the learn pro-

cedure is enabled, the ECM will disable the A/C.

3. If after the specified number attempts the ECM

cannot learn the CKP system variation, then the

variation is too large and no further attempts should

be made until the variation problem is corrected.

4. Being unable to learn the procedure indicates that

the variation is out of range.

5. After the CKP system variation has been learned,

wait above 10 seconds with ignition switch OFF to

prevent being cleared the learned value.

Page 909 of 2643

2B – 2IWHEEL ALIGNMENT

DAEWOO V–121 BL4

DIAGNOSIS

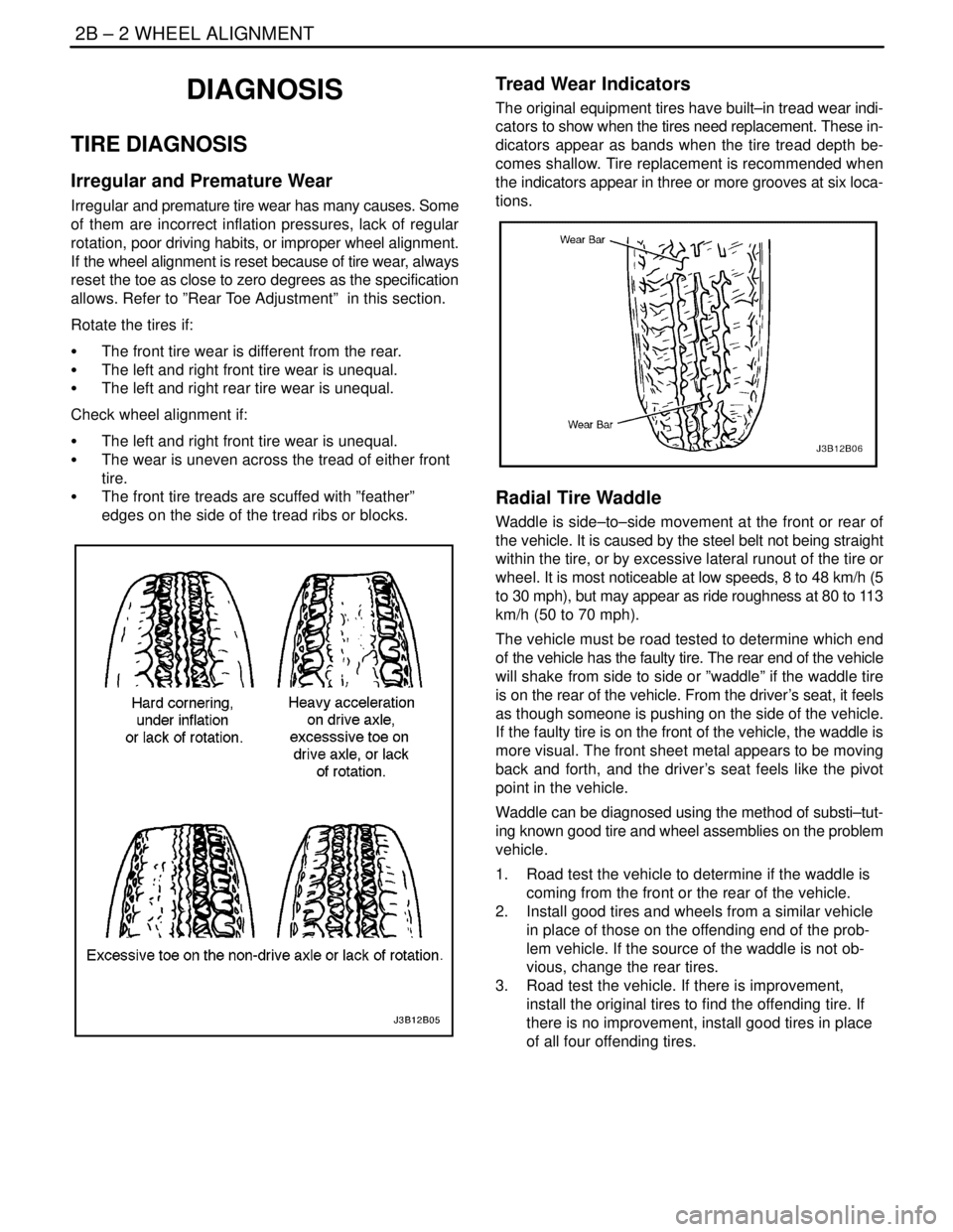

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes. Some

of them are incorrect inflation pressures, lack of regular

rotation, poor driving habits, or improper wheel alignment.

If the wheel alignment is reset because of tire wear, always

reset the toe as close to zero degrees as the specification

allows. Refer to ”Rear Toe Adjustment” in this section.

Rotate the tires if:

S The front tire wear is different from the rear.

S The left and right front tire wear is unequal.

S The left and right rear tire wear is unequal.

Check wheel alignment if:

S The left and right front tire wear is unequal.

S The wear is uneven across the tread of either front

tire.

S The front tire treads are scuffed with ”feather”

edges on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built–in tread wear indi-

cators to show when the tires need replacement. These in-

dicators appear as bands when the tire tread depth be-

comes shallow. Tire replacement is recommended when

the indicators appear in three or more grooves at six loca-

tions.

Radial Tire Waddle

Waddle is side–to–side movement at the front or rear of

the vehicle. It is caused by the steel belt not being straight

within the tire, or by excessive lateral runout of the tire or

wheel. It is most noticeable at low speeds, 8 to 48 km/h (5

to 30 mph), but may appear as ride roughness at 80 to 113

km/h (50 to 70 mph).

The vehicle must be road tested to determine which end

of the vehicle has the faulty tire. The rear end of the vehicle

will shake from side to side or ”waddle” if the waddle tire

is on the rear of the vehicle. From the driver’s seat, it feels

as though someone is pushing on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle is

more visual. The front sheet metal appears to be moving

back and forth, and the driver’s seat feels like the pivot

point in the vehicle.

Waddle can be diagnosed using the method of substi–tut-

ing known good tire and wheel assemblies on the problem

vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the prob-

lem vehicle. If the source of the waddle is not ob-

vious, change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no improvement, install good tires in place

of all four offending tires.

Page 917 of 2643

2B – 10IWHEEL ALIGNMENT

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FOUR WHEEL ALIGNMENT

The first responsibility of engineering is to design safe

steering and suspension systems. Each component must

be strong enough to withstand and absorb extreme pun-

ishment. Both the steering system and the front and the

rear suspension must function geometrically with the body

mass.

The steering and the suspension systems require that the

front wheels self–return and that the tire rolling effort and

the road friction be held to a negligible force in order to al-

low the customer to direct the vehicle with the least effort

and the most comfort.

A complete wheel alignment check should include mea-

surements of the rear toe and camber.

Four–wheel alignment assures that all four wheels will be

running in precisely the same direction.

When the vehicle is geometrically aligned, fuel economy

and tire life are at their peak, and steering and perfor-

mance are maximized.

TOE

Toe–in is the turning in of the tires, while toe–out is the

turning out of the tires from the geometric centerline or

thrust line. The toe ensures parallel rolling of the wheels.

The toe serves to offset the small deflections of the wheel

support system which occur when the vehicle is rolling for-

ward. The specified toe angle is the setting which achieves

0 degrees of toe when the vehicle is moving.

Incorrect toe–in or toe–out will cause tire wear and re-

duced fuel economy. As the individual steering and sus-

pension components wear from vehicle mileage, addition-

al toe will be needed to compensate for the wear.

Always correct the toe dimension last.

CASTER

Caster is the tilting of the uppermost point of the steering

axis either forward or backward from the vertical when

viewed from the side of the vehicle. A backward tilt is posi-

tive, and a forward tilt is negative. Caster influences direc-

tional control of the steering but does not affect tire wear.

Weak springs or overloading a vehicle will affect caster.

One wheel with more positive caster will pull toward the

center of the car. This condition will cause the car to move

or lean toward the side with the least amount of positive

caster. Caster is measured in degrees and is not adjust-

able.

CAMBER

Camber is the tilting of the top of the tire from the vertical

when viewed from the front of the vehicle. When the tires

tilt outward, the camber is positive. When the tires tilt in-

ward, the camber is negative. The camber angle is mea-

sured in degrees from the vertical. Camber influences

both directional control and tire wear.

If the vehicle has too much positive camber, the outside

shoulder of the tire will wear. If the vehicle has too much

negative camber, the inside shoulder of the tire will wear.

Camber is not adjustable.

STEERING AXIS INCLINATION

Steering Axis Inclination (SAI) is the tilt at the top of the

steering knuckle from the vertical. Measure the SAI angle

from the true vertical to a line through the center of the strut

and the lower ball joint as viewed from the front of the ve-

hicle.

SAI helps the vehicle track straight down the road and as-

sists the wheel back into the straight ahead position. SAI

on front wheel drive vehicles should be negative.

INCLUDED ANGLE

The included angle is the angle measured from the cam-

ber angle to the line through the center of the strut and the

lower ball joint as viewed from the front of the vehicle.

The included angle is calculated in degrees. Most align-

ment racks will not measure the included angle directly. To

determine the included angle, subtract the negative or add

the positive camber readings to the Steering Axis Inclina-

tion (SAI).

SCRUB RADIUS

The scrub radius is the distance between true vertical and

the line through the center of the strut and lower ball joint

to the road surface. Scrub radius is built into the design of

the vehicle. Scrub radius is not adjustable.

SETBACK

The setback is the distance in which one front hub and

bearing assembly may be rearward of the other front hub

and bearing assembly. Setback is primarily caused by a

road hazard or vehicle collision.

TURNING ANGLE

The turning angle is the angle of each front wheel to the

vertical when the vehicle is making a turn.

Page 1152 of 2643

ANTILOCK BRAKE SYSTEM 4F – 71

DAEWOO V–121 BL4

TIRES AND ABS/EBD

Replacement Tires

Tire size is important for proper performance of the ABS

system. Replacement tires should be the same size, load

range, and construction as the original tires. Replace tires

in axle sets and only with tires of the same tire perfor-

mance criteria (TPC) specification number. Use of any

other size or type may seriously affect the ABS operation.

TIRES AND ABS/EBD

Notice : There is no serviceable or removable EEPROM.

The EBCM must be replaced as an assembly.

The EBCM is attached to the hydraulic unit in the engine

compartment. The controlling element of ABS 5.3 is a mi-

croprocessor–based EBCM. Inputs to the system include

the four wheel speed sensors, the stoplamp switch, the

ignition switch, and the unswitched battery voltage. There

is an output to a bi–directional serial data link, located in

pin K of Data Link Connector (DLC) for service diagnostic

tools and assembly plant testing.

The EBCM monitors the speed of each wheel. If any wheel

begins to approach lockup and the brake switch is closed

(brake pedal depressed), the EBCM controls the sole-

noids to reduce brake pressure to the wheel approaching

lockup. Once the wheel regains traction, brake pressure

is increased until the wheel again begins to approach lock-

up. This cycle repeats until either the vehicle comes to a

stop, the brake pedal is released, or no wheels approach

lockup.

Additionally, the EBCM monitors itself, each input (except

the serial data link), and each output for proper operation.

If it detects any system malfunction, the EBCM will store

a DTC in nonvolatile memory (EEPROM) (DTCs will not

disappear if the battery is disconnected). Refer to ”Self

Diagnostics” in this section for more detailed information.

FRONT WHEEL SPEED SENSOR

The front wheel speed sensors are of a variable reluctance

type. Each sensor is attached to the steering knuckle,

close to a toothed ring. The result, as teeth pass by the

sensor, is an AC voltage with a frequency proportional to

the speed of the wheel. The magnitude of the voltage and

frequency increase with increasing speed. The sensor is

not repairable, nor is the air gap adjustable.

FRONT WHEEL SPEED SENSOR

RINGS

The toothed ring mentioned above is pressed onto the

wheel–side (outer) constant velocity joint. Each ring con-

tains 47 equally spaced teeth. Exercise care during ser-

vice procedures to avoid prying or contacting this ring. Ex-cessive contact may cause damage to one or more teeth.

If the ring is damaged, the wheel–side constant velocity

joint must be replaced.

REAR WHEEL SPEED SENSOR AND

RINGS

The rear wheel speed sensors operate in the same man-

ner as the front wheel speed sensors. They incorporate a

length of flexible harness with the connector attached to

the end of the harness. The rear wheel speed rings are in-

corporated into the hub assemblies and cannot be re-

placed separately, but require replacement of the rear

hub/bearing assembly.

VALUE RELAY AND PUMP MOTOR

RELAY

The valve relay and the motor pump relay are located in-

side the electronic brake control module (EBCM) and are

not replaceable. If one should fail, replace the EBCM.

WIRING HARNESS

The wiring harness is the mechanism by which the elec-

tronic brake control module (EBCM) is electrically con-

nected to power and to ground, to the wheel speed sen-

sors, the fuses, the switches, the indicators, and the serial

communications port. The components, considered part

of the wiring harness, are the wires that provide electrical

interconnection, and connectors (terminals, pins, con-

tacts, or lugs) that provide an electrical/mechanical inter-

face from the wire to a system component.

INDICATORS

The electronic brake control module (EBCM) continuously

monitors itself and the other ABS components. If the

EBCM detects a problem with the system, the amber ABS

indicator will light continuously to alert the driver to the

problem. An illuminated ABS indicator indicates that the

ABS system has detected a problem that affects the op-

eration of ABS. No antilock braking will be available. Nor-

mal, non–antilock brake performance will remain. In order

to regain ABS braking ability, the ABS must be serviced.

The red BRAKE indicator will be illuminated when the sys-

tem detects a low brake fluid level in the master cylinder

or when the parking brake switch is closed (the parking

brake is engaged) or EBD system is diabled.

WARNING : EBD INDICATOR LAMP WIRING IS CON-

NECTED TO THE PARKING BRAKE LAMP. IF THE

PARKING BRAKE LAMP IS TURNED ON WHEN YOU

DRIVING, CHECKING ON WHETHER THE PARKING

BRAKE LEVER IS ENAGED OR THE BRAKE FLUID

LEVEL IS LOW. IF THE SYSTEM HAS NO PROBLEM,

THE EBD SYSTEM IS WORKING IMPROPERLY. THE

EBD SYSTEM MUST BE SERVICED.

Page 1352 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 3

DAEWOO V–121 BL4

Important Measurement/Adjustment 5A1–230. . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION5A1–232 . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical Components 5A1–232. . . . . . . . . . . . . . . . .

Electronical Components 5A1–236. . . . . . . . . . . . . . . .

TCM Inputs That Affect the 4HP 16

Transaxle 5A1–241. . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION

ZF 4HP 16 AUTOMATIC TRANSAXLE

The ZF 4 HP 16 is a four–speed automatic transaxle de-

signed for cars with front–wheel drive and a transversely

mounted engine.

The transaxle has a hydrodynamic torque converter with

a controlled slip lock–up clutch.

A planetary gear train establishes the mechanical gear ra-

tios. The integral constant ratio can be adapted to the en-

gine’s power output and the vehicle’s weight. The elec-

tronic–hydraulic control makes controlled power shifts and

various shift programs possible. In selector lever position

”P”, the output is locked mechanically.The special feature of this transaxle is that it operates with-

out freewheels. Shifting between individual gears takes

place by means of overlapping clutch engagement and re-

lease.

The advantage of overlap shifting is as follows:

– The transaxle can be of more compact design

and is lighter on account of the absence of free-

wheels and the lower number of shift elements

– Lower drag losses, i.e. higher efficiency

– Lower peak torques acting on the components

and driveline.

However, overlap shifting necessitates high–performance

hardware and software, and precision engine signals.

Page 1354 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 5

DAEWOO V–121 BL4

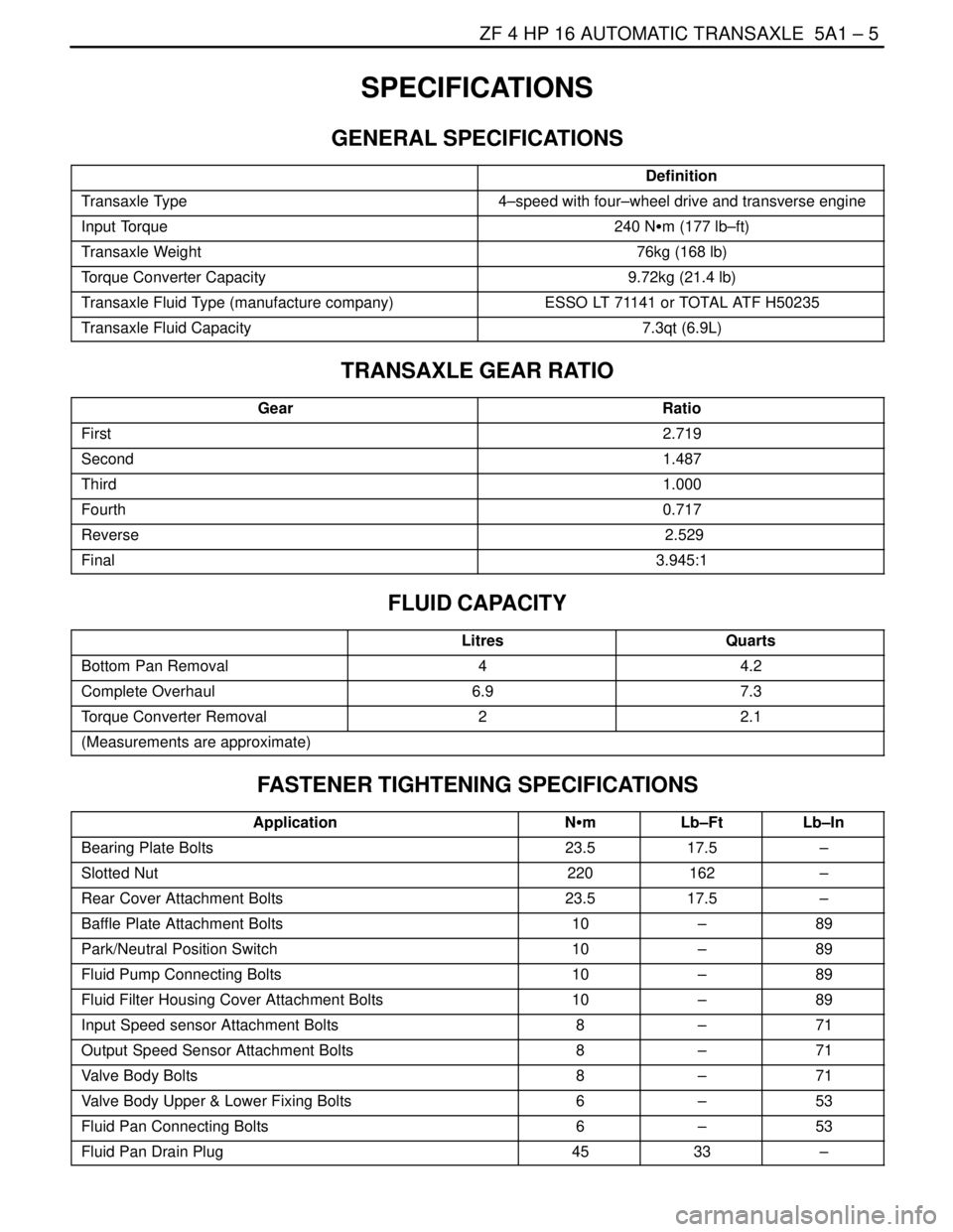

SPECIFICATIONS

GENERAL SPECIFICATIONS

Definition

Transaxle Type4–speed with four–wheel drive and transverse engine

Input Torque240 NSm (177 lb–ft)

Transaxle Weight76kg (168 lb)

Torque Converter Capacity9.72kg (21.4 lb)

Transaxle Fluid Type (manufacture company)ESSO LT 71141 or TOTAL ATF H50235

Transaxle Fluid Capacity7.3qt (6.9L)

TRANSAXLE GEAR RATIO

GearRatio

First2.719

Second1.487

Third1.000

Fourth0.717

Reverse 2.529

Final3.945:1

FLUID CAPACITY

LitresQuarts

Bottom Pan Removal44.2

Complete Overhaul6.97.3

Torque Converter Removal22.1

(Measurements are approximate)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Bearing Plate Bolts23.517.5–

Slotted Nut220162–

Rear Cover Attachment Bolts23.517.5–

Baffle Plate Attachment Bolts10–89

Park/Neutral Position Switch10–89

Fluid Pump Connecting Bolts10–89

Fluid Filter Housing Cover Attachment Bolts10–89

Input Speed sensor Attachment Bolts8–71

Output Speed Sensor Attachment Bolts8–71

Valve Body Bolts8–71

Valve Body Upper & Lower Fixing Bolts6–53

Fluid Pan Connecting Bolts6–53

Fluid Pan Drain Plug4533–

Page 1581 of 2643

5A1 – 232IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

The ZF 4HP 16 automatic transaxle consists primarily of

the following components.

Mechanical

S Torque converter with TCC

S Drive link assembly

S Two multiple disk clutch assemblies : Clutch B,E

S Three multiple brake assemblies : Brake C,D,F

S Lock–up clutch valve

S Two planetary gear sets

S One oil pump

S Final drive and differential assembly

Electronic

S Two shift solenoid valve(sol.1,2)

S Four pressure control solenoid valve(EDS)

S Two speed sensors : A/T ISS and A/T OSS

S Fluid temperature sensor

S Automatic transaxle control module(TCM)

S Wiring harness assembly

MECHANICAL COMPONENTS

Torque Converter

The converter consists of the impeller, the turbine wheel,

the reaction member (stator) and the oil to transmit torque.

The impeller, which is driven by the engine, causes the oil

in the converter to flow in a circular pattern. This oil flow

meets the turbine wheel, where is direction of flow is de-

flected. At the hub, the oil leaves the turbine and reaches

the reaction member (stator), where it is once again de-

flected so that it reaches the impeller at the correct angle

of flow.

The reversal effect generates movement in the stator, the

reaction torque then amplifies the turbine torque.

The ratio between turbine torque and torque is referred to

as torque multiplication.

The greater the difference is speed between the pump and

turbine, the greater the torque multiplication; it is at its

highest when the turbine is at a standstill. The higher the

speed of the turbine, the lower the torque multiplication.

When the turbine speed reaches about 85%of the pump

speed, torque multiplication=1, i.e. the turbine torque

equivalent to pump torque.

The stator, which bears against the housing via the free-

wheel, is then rotating freely in the oil flow and the free-

wheel is over–come. From this point onwards, the con-

verter acts as a straightforward fluid coupling.

Space Behind Lock–up Clutch Piston

1. Friction lining

2. Lock–up clutch piston

3. Converter cover

4. Turbine wheel

5. Impeller

6. Stator

7. Turbine hub

8. Torque converter impeller hub

Torque Converter Lock–up Clutch (TCC)

The converter lock–up clutch is a device, which eliminates

converter slip and thus helps to improve fuel consumption.

The previous control principle for converter lock–up clutch

operation has been replaced by a controlling function on

the 4 HP 16. The converter lock–up clutch is engaged and

released in a controlled manner. During the controlled

phase, a slight speed difference between the impeller and

turbine wheel is established. This ensures that the en-

gine’s rotating vibration is not phased on to the transaxle.

The result is optimum shift quality.

An electronic pressure–regulating valve determines pres-

sure regulation of the lock–up converter clutch’s piston.

When open (conversion range), the oil pressure behind

the converter lock–up clutch piston and in the turbine zone

is equal. The direction of flow is through the turbine shaft

and through the space behind the piston, to the turbine

chamber.

Page 1830 of 2643

5B – 6IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

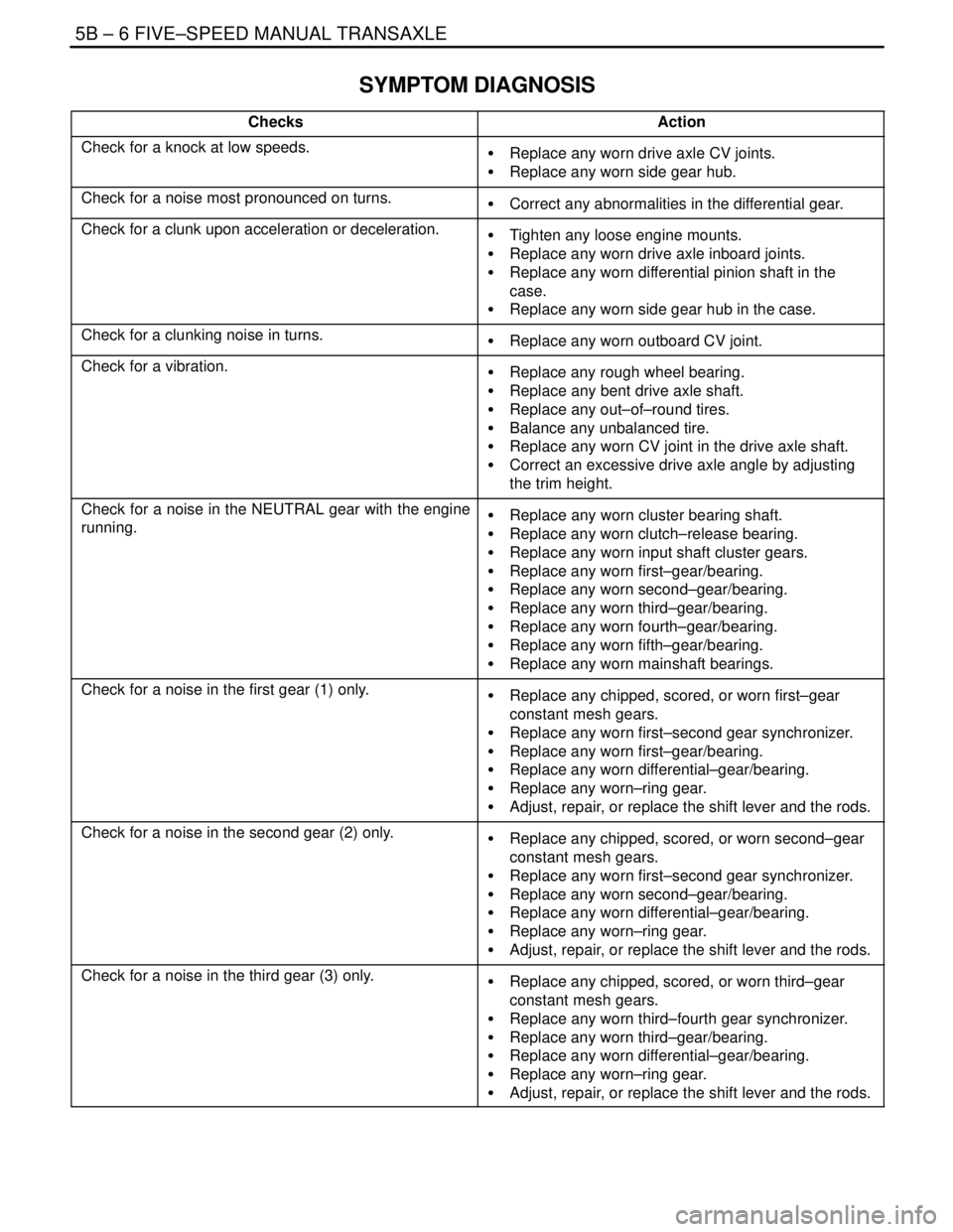

SYMPTOM DIAGNOSIS

ChecksAction

Check for a knock at low speeds.S Replace any worn drive axle CV joints.

S Replace any worn side gear hub.

Check for a noise most pronounced on turns.S Correct any abnormalities in the differential gear.

Check for a clunk upon acceleration or deceleration.S Tighten any loose engine mounts.

S Replace any worn drive axle inboard joints.

S Replace any worn differential pinion shaft in the

case.

S Replace any worn side gear hub in the case.

Check for a clunking noise in turns.S Replace any worn outboard CV joint.

Check for a vibration.S Replace any rough wheel bearing.

S Replace any bent drive axle shaft.

S Replace any out–of–round tires.

S Balance any unbalanced tire.

S Replace any worn CV joint in the drive axle shaft.

S Correct an excessive drive axle angle by adjusting

the trim height.

Check for a noise in the NEUTRAL gear with the engine

running.S Replace any worn cluster bearing shaft.

S Replace any worn clutch–release bearing.

S Replace any worn input shaft cluster gears.

S Replace any worn first–gear/bearing.

S Replace any worn second–gear/bearing.

S Replace any worn third–gear/bearing.

S Replace any worn fourth–gear/bearing.

S Replace any worn fifth–gear/bearing.

S Replace any worn mainshaft bearings.

Check for a noise in the first gear (1) only.S Replace any chipped, scored, or worn first–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn first–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the second gear (2) only.S Replace any chipped, scored, or worn second–gear

constant mesh gears.

S Replace any worn first–second gear synchronizer.

S Replace any worn second–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.

Check for a noise in the third gear (3) only.S Replace any chipped, scored, or worn third–gear

constant mesh gears.

S Replace any worn third–fourth gear synchronizer.

S Replace any worn third–gear/bearing.

S Replace any worn differential–gear/bearing.

S Replace any worn–ring gear.

S Adjust, repair, or replace the shift lever and the rods.