instrument cluster DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 253 of 2643

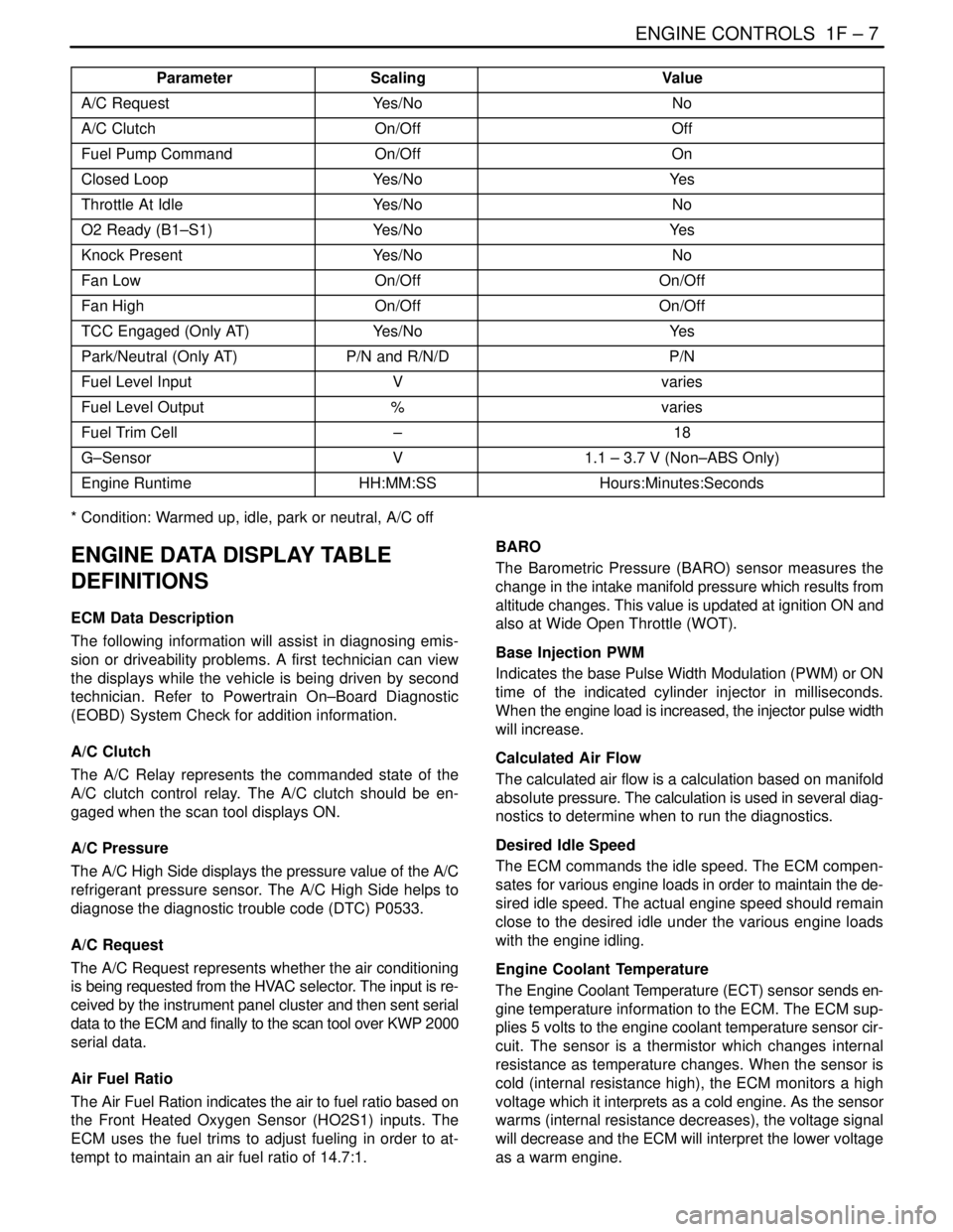

ENGINE CONTROLS 1F – 7

DAEWOO V–121 BL4

Parameter ValueScaling

A/C RequestYes/NoNo

A/C ClutchOn/OffOff

Fuel Pump CommandOn/OffOn

Closed LoopYes/NoYe s

Throttle At IdleYes/NoNo

O2 Ready (B1–S1)Yes/NoYe s

Knock PresentYes/NoNo

Fan LowOn/OffOn/Off

Fan HighOn/OffOn/Off

TCC Engaged (Only AT)Yes/NoYe s

Park/Neutral (Only AT)P/N and R/N/DP/N

Fuel Level InputVvaries

Fuel Level Output%varies

Fuel Trim Cell–18

G–SensorV1.1 – 3.7 V (Non–ABS Only)

Engine RuntimeHH:MM:SSHours:Minutes:Seconds

* Condition: Warmed up, idle, park or neutral, A/C off

ENGINE DATA DISPLAY TABLE

DEFINITIONS

ECM Data Description

The following information will assist in diagnosing emis-

sion or driveability problems. A first technician can view

the displays while the vehicle is being driven by second

technician. Refer to Powertrain On–Board Diagnostic

(EOBD) System Check for addition information.

A/C Clutch

The A/C Relay represents the commanded state of the

A/C clutch control relay. The A/C clutch should be en-

gaged when the scan tool displays ON.

A/C Pressure

The A/C High Side displays the pressure value of the A/C

refrigerant pressure sensor. The A/C High Side helps to

diagnose the diagnostic trouble code (DTC) P0533.

A/C Request

The A/C Request represents whether the air conditioning

is being requested from the HVAC selector. The input is re-

ceived by the instrument panel cluster and then sent serial

data to the ECM and finally to the scan tool over KWP 2000

serial data.

Air Fuel Ratio

The Air Fuel Ration indicates the air to fuel ratio based on

the Front Heated Oxygen Sensor (HO2S1) inputs. The

ECM uses the fuel trims to adjust fueling in order to at-

tempt to maintain an air fuel ratio of 14.7:1.BARO

The Barometric Pressure (BARO) sensor measures the

change in the intake manifold pressure which results from

altitude changes. This value is updated at ignition ON and

also at Wide Open Throttle (WOT).

Base Injection PWM

Indicates the base Pulse Width Modulation (PWM) or ON

time of the indicated cylinder injector in milliseconds.

When the engine load is increased, the injector pulse width

will increase.

Calculated Air Flow

The calculated air flow is a calculation based on manifold

absolute pressure. The calculation is used in several diag-

nostics to determine when to run the diagnostics.

Desired Idle Speed

The ECM commands the idle speed. The ECM compen-

sates for various engine loads in order to maintain the de-

sired idle speed. The actual engine speed should remain

close to the desired idle under the various engine loads

with the engine idling.

Engine Coolant Temperature

The Engine Coolant Temperature (ECT) sensor sends en-

gine temperature information to the ECM. The ECM sup-

plies 5 volts to the engine coolant temperature sensor cir-

cuit. The sensor is a thermistor which changes internal

resistance as temperature changes. When the sensor is

cold (internal resistance high), the ECM monitors a high

voltage which it interprets as a cold engine. As the sensor

warms (internal resistance decreases), the voltage signal

will decrease and the ECM will interpret the lower voltage

as a warm engine.

Page 255 of 2643

ENGINE CONTROLS 1F – 9

DAEWOO V–121 BL4

Spark Advance

This is a display of the spark advance Ignition Coil (IC) cal-

culation which the ECM is programming in the ignition sys-

tem. It computes the desired spark advance using data

such as engine temperature, rpm, engine load, vehicle

speed and operating mode.

TCC Engaged

When the brake pedal is applied, the Torque Converter

Clutch (TCC) brake switch sends a signal to the ECM to

disengage the TCC and disable the cruise control.

Total Misfire Current Counter

Indicates the total number of misfires that have been de-tected in all the cylinders after 100 engine cycles. One

cycle equals one complete 4 stroke cycle. The total misfire

only increments during the steady state cruise conditions.

TP Sensor

The ECM uses the TP Sensor in order to determine the

amount of the throttle demanded by the vehicle’s operator.

The TP Sensor reads between 0.36–0.96 volts at idle to

above 4 volts at WOT.

Vehicle Speed

The vehicle speed sensor signal is converted into mph or

km/h for display. The vehicle speed output from the ECM

is 4000 pulses per mile. The scan tool uses the KWP 2000

serial data from the ECM to obtain vehicle speed, while the

Instrument Panel Cluster (IPC), cruise control module and

the chime alarm module use the 4000 ppm output.

Page 305 of 2643

ENGINE CONTROLS 1F – 59

DAEWOO V–121 BL4

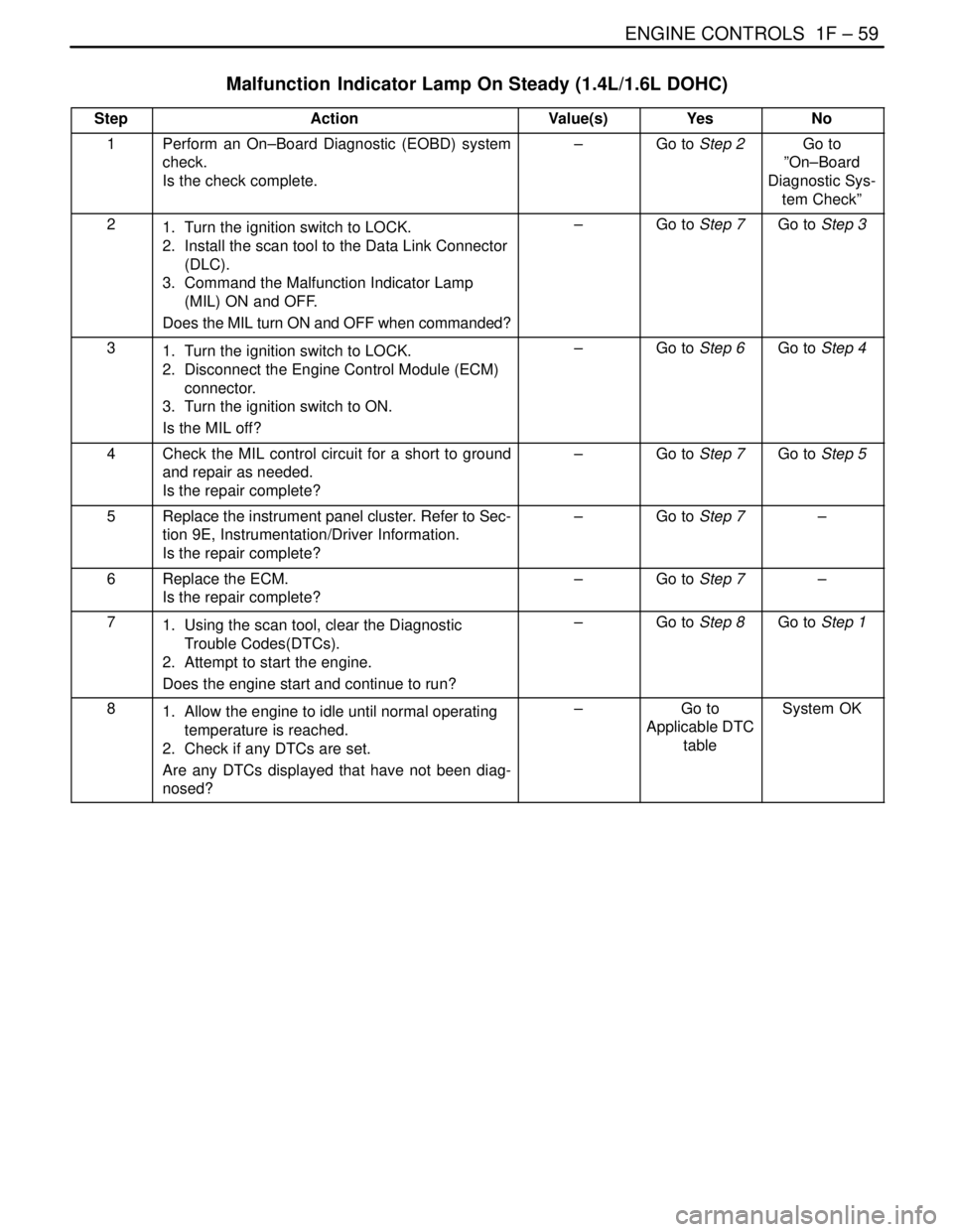

Malfunction Indicator Lamp On Steady (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Is the check complete.–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK.

2. Install the scan tool to the Data Link Connector

(DLC).

3. Command the Malfunction Indicator Lamp

(MIL) ON and OFF.

Does the MIL turn ON and OFF when commanded?–Go to Step 7Go to Step 3

31. Turn the ignition switch to LOCK.

2. Disconnect the Engine Control Module (ECM)

connector.

3. Turn the ignition switch to ON.

Is the MIL off?–Go to Step 6Go to Step 4

4Check the MIL control circuit for a short to ground

and repair as needed.

Is the repair complete?–Go to Step 7Go to Step 5

5Replace the instrument panel cluster. Refer to Sec-

tion 9E, Instrumentation/Driver Information.

Is the repair complete?–Go to Step 7–

6Replace the ECM.

Is the repair complete?–Go to Step 7–

71. Using the scan tool, clear the Diagnostic

Trouble Codes(DTCs).

2. Attempt to start the engine.

Does the engine start and continue to run?–Go to Step 8Go to Step 1

81. Allow the engine to idle until normal operating

temperature is reached.

2. Check if any DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 307 of 2643

ENGINE CONTROLS 1F – 61

DAEWOO V–121 BL4

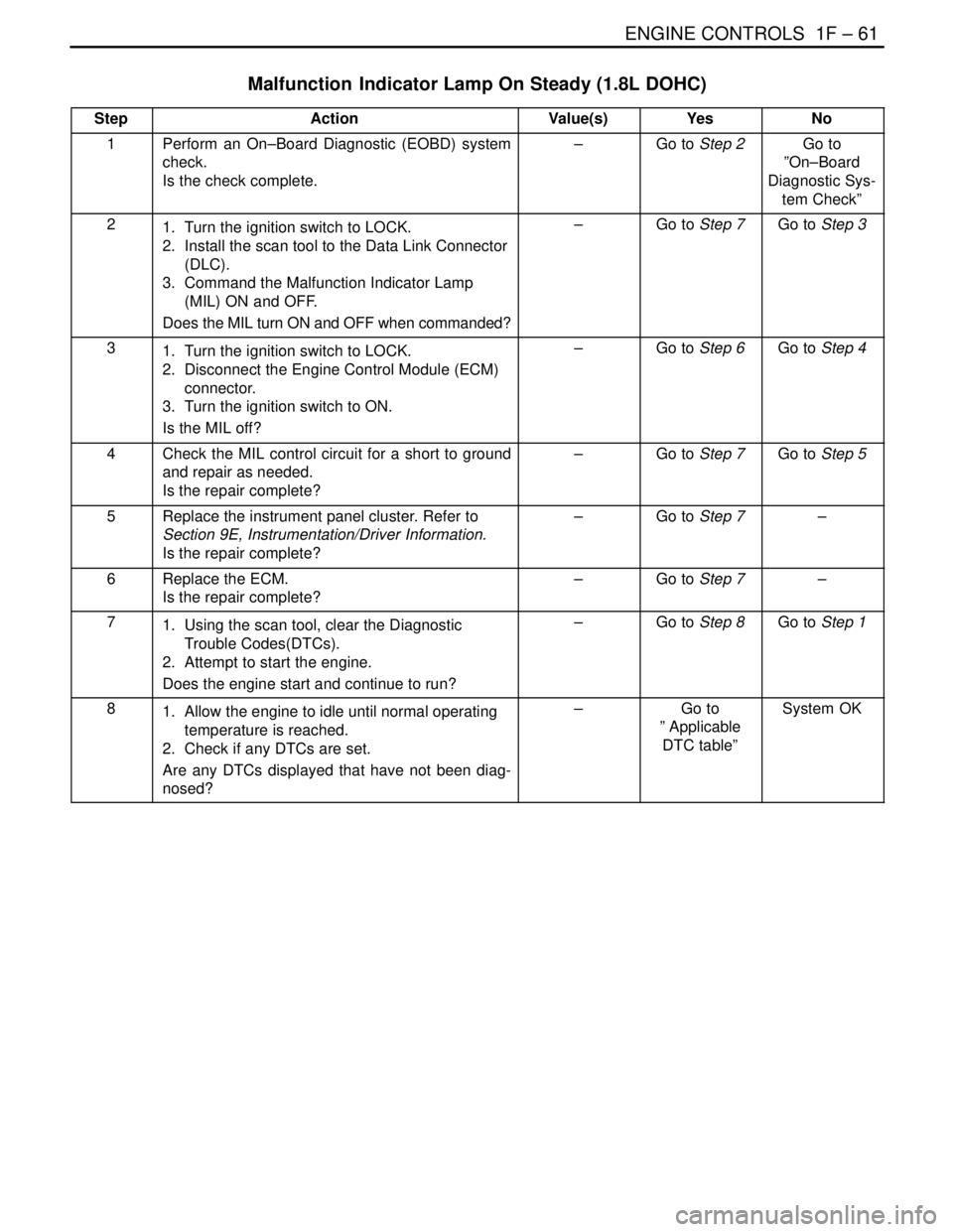

Malfunction Indicator Lamp On Steady (1.8L DOHC)

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) system

check.

Is the check complete.–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition switch to LOCK.

2. Install the scan tool to the Data Link Connector

(DLC).

3. Command the Malfunction Indicator Lamp

(MIL) ON and OFF.

Does the MIL turn ON and OFF when commanded?–Go to Step 7Go to Step 3

31. Turn the ignition switch to LOCK.

2. Disconnect the Engine Control Module (ECM)

connector.

3. Turn the ignition switch to ON.

Is the MIL off?–Go to Step 6Go to Step 4

4Check the MIL control circuit for a short to ground

and repair as needed.

Is the repair complete?–Go to Step 7Go to Step 5

5Replace the instrument panel cluster. Refer to

Section 9E, Instrumentation/Driver Information.

Is the repair complete?–Go to Step 7–

6Replace the ECM.

Is the repair complete?–Go to Step 7–

71. Using the scan tool, clear the Diagnostic

Trouble Codes(DTCs).

2. Attempt to start the engine.

Does the engine start and continue to run?–Go to Step 8Go to Step 1

81. Allow the engine to idle until normal operating

temperature is reached.

2. Check if any DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

” Applicable

DTC table”System OK

Page 352 of 2643

1F – 106IENGINE CONTROLS

DAEWOO V–121 BL4

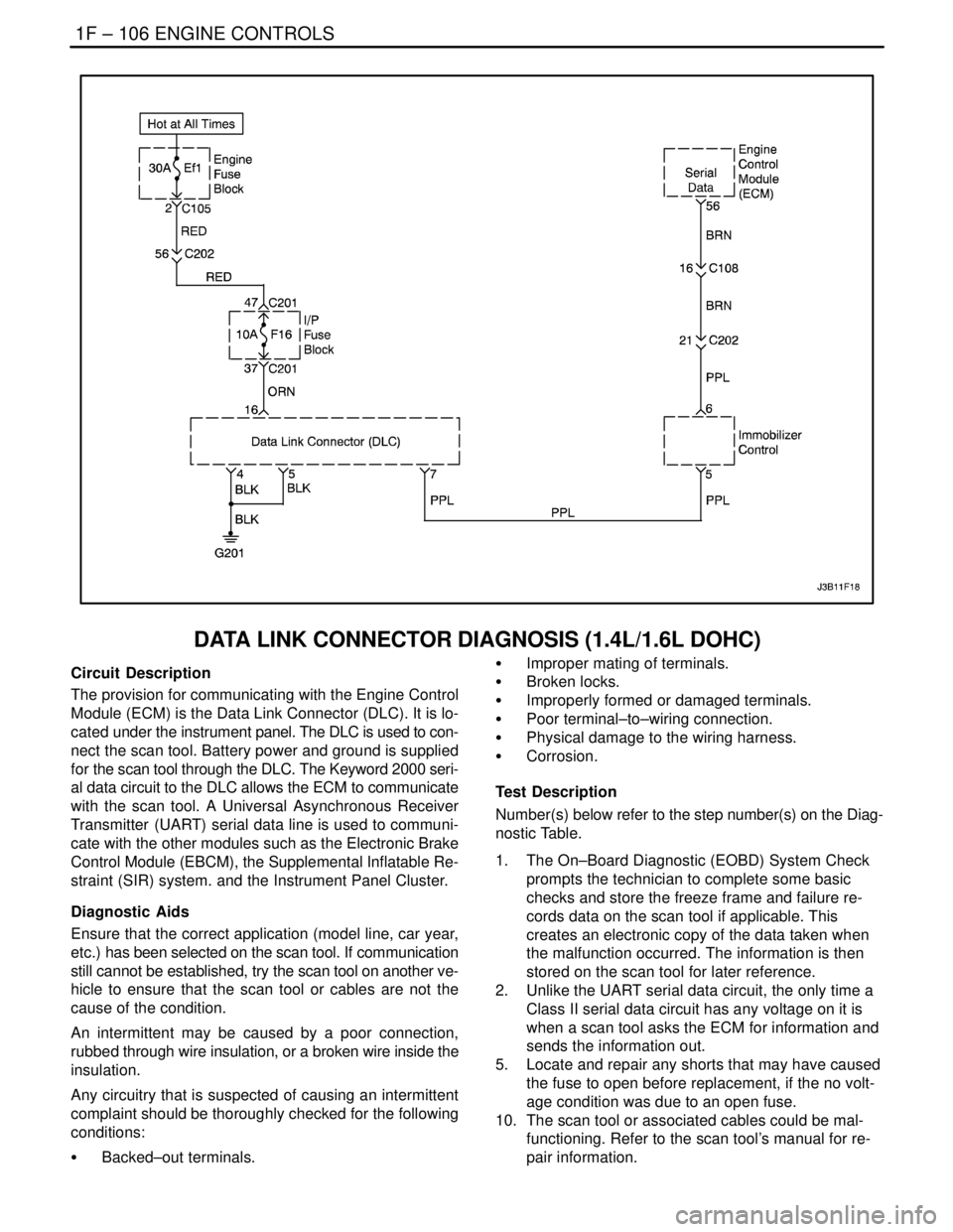

DATA LINK CONNECTOR DIAGNOSIS (1.4L/1.6L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 354 of 2643

1F – 108IENGINE CONTROLS

DAEWOO V–121 BL4

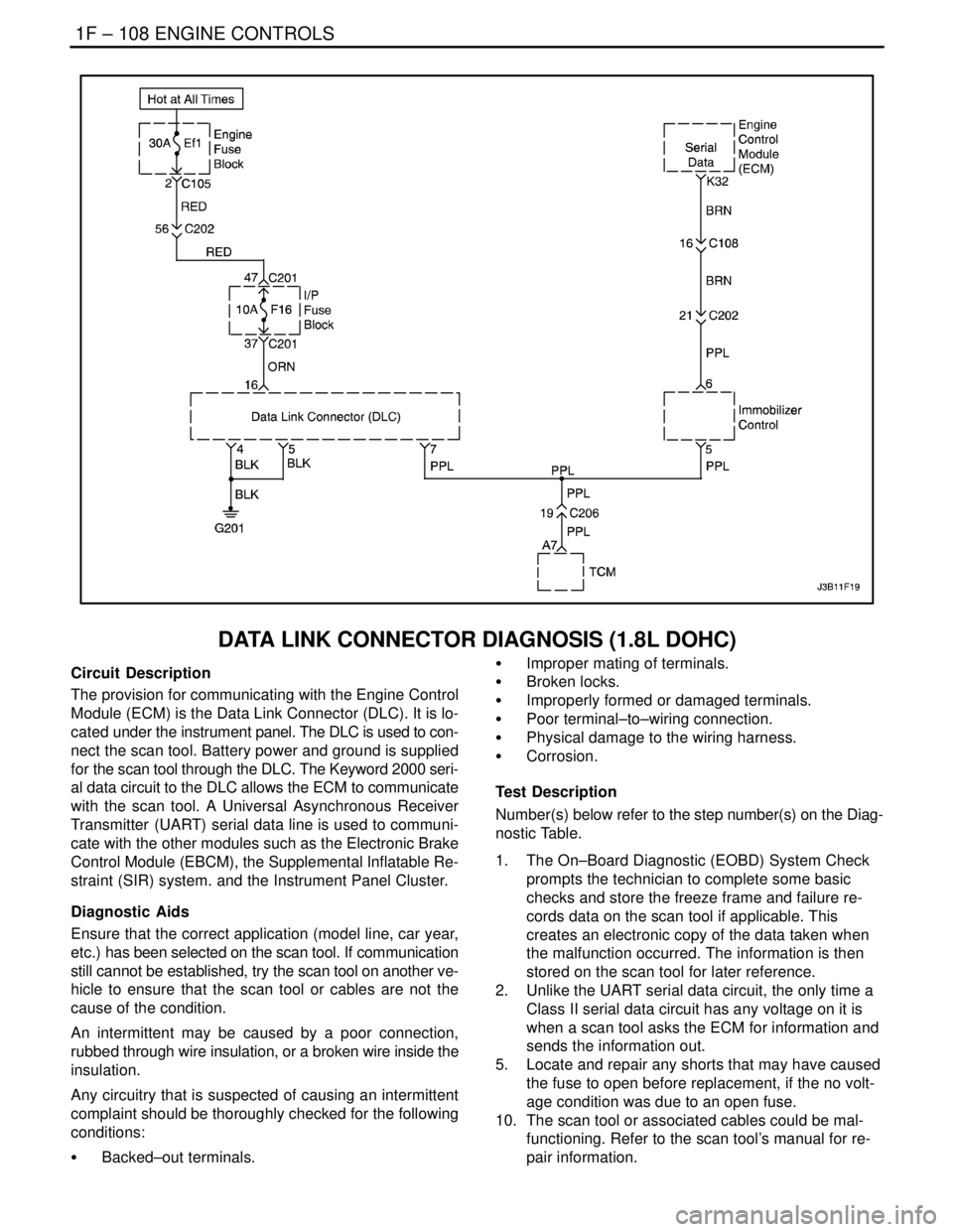

DATA LINK CONNECTOR DIAGNOSIS (1.8L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 1021 of 2643

HYDRAULIC BRAKES 4A – 5

DAEWOO V–121 BL4

DIAGNOSIS

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy, or

covered with loose dirt whereby all tires do not grip the

road equally. Testing will also be adversely affected if the

roadway is crowned so as to throw the weight so roughly

that the wheels tend to bounce.

Test the brakes at different vehicle speeds with both light

and heavy pedal pressure; however, avoid locking the

brakes and sliding the tires. Locked brakes and sliding

tires do not indicate brake efficiency since heavily braked,

but turning, wheels will stop the vehicle in less distance

than locked brakes. More tire–to–road friction is present

with a heavily–braked, turning tire than with a sliding tire.

Because of the high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

There are three major external conditions that affect brake

performance:

S Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

S Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

S Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pressure

on the pedal with the engine running at idle and the shift

lever in NEUTRAL. If the pedal gradually falls away with

the constant pressure, the hydraulic system may be leak-

ing. Perform a visual check to confirm any suspected

leaks.

Check the master cylinder fluid level. While a slight drop

in the reservoir level results from normal lining wear, an ab-

normally low level indicates a leak in the system. The hy-

draulic system may be leaking either internally or external-

ly. Refer to the procedure below to check the master

cylinder. Also, the system may appear to pass this test

while still having a slight leak. If the fluid level is normal,

check the vacuum booster pushrod length. If an incorrect

pushrod length is found, adjust or replace the rod.

Check the master cylinder using the following procedure:

S Check for a cracked master cylinder casting or

brake fluid leaking around the master cylinder.

Leaks are indicated only if there is at least one drop

of fluid. A damp condition is not abnormal.S Check for a binding pedal linkage and for an incor-

rect pushrod length. If both of these parts are in

satisfactory condition, disassemble the master cyl-

inder and check for an elongated or swollen primary

cylinder or piston seals. If swollen seals are found,

substandard or contaminated brake fluid should be

suspected. If contaminated brake fluid is found, all

the components should be disassembled and

cleaned, and all the rubber components should be

replaced. All of the pipes must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration of

the rubber components. If the primary piston cups in the

master cylinder are swollen, then the rubber parts have

deteriorated. This deterioration may also be evidenced by

swollen wheel cylinder piston seals on the drum brake

wheels.

If deterioration of rubber is evident, disassemble all the hy-

draulic parts and wash the parts with alcohol. Dry these

parts with compressed air before reassembly to keep alco-

hol out of the system. Replace all the rubber parts in the

system, including the hoses. Also, when working on the

brake mechanisms, check for fluid on the linings. If exces-

sive fluid is found, replace the linings.

If the master cylinder piston seals are in satisfactory condi-

tion, check for leaks or excessive heat conditions. If these

conditions are not found, drain the fluid, flush the master

cylinder with brake fluid, refill the master cylinder, and

bleed the system. Refer to ”Manual Bleeding the Brakes”

or”Pressure Bleeding the Brakes” in this section.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be checked

for road hazard damage, cracks, chafing of the outer cov-

er, and for leaks or blisters. Inspect the hoses for proper

routing and mounting. A brake hose that rubs on a suspen-

sion component will wear and eventually fail. A light and

a mirror may be needed for an adequate inspection. If any

of the above conditions are observed on the brake hose,

adjust or replace the hose as necessary.

WARNING LAMP OPERATION

This brake system uses a BRAKE warning lamp located

in the instrument panel cluster. When the ignition switch

is in the START position, the BRAKE warning lamp should

glow and go OFF when the ignition switch returns to the

RUN position.

The following conditions will activate the BRAKE lamp:

S Parking brake applied. The light should be ON

whenever the parking brake is applied and the igni-

tion switch is ON.

S Low fluid level. A low fluid level in the master cylin-

der will turn the BRAKE lamp ON.

S EBD system is disabled. The light should be ON

when the EBD system is malfunctioning.

Page 1022 of 2643

4A – 6IHYDRAULIC BRAKES

DAEWOO V–121 BL4

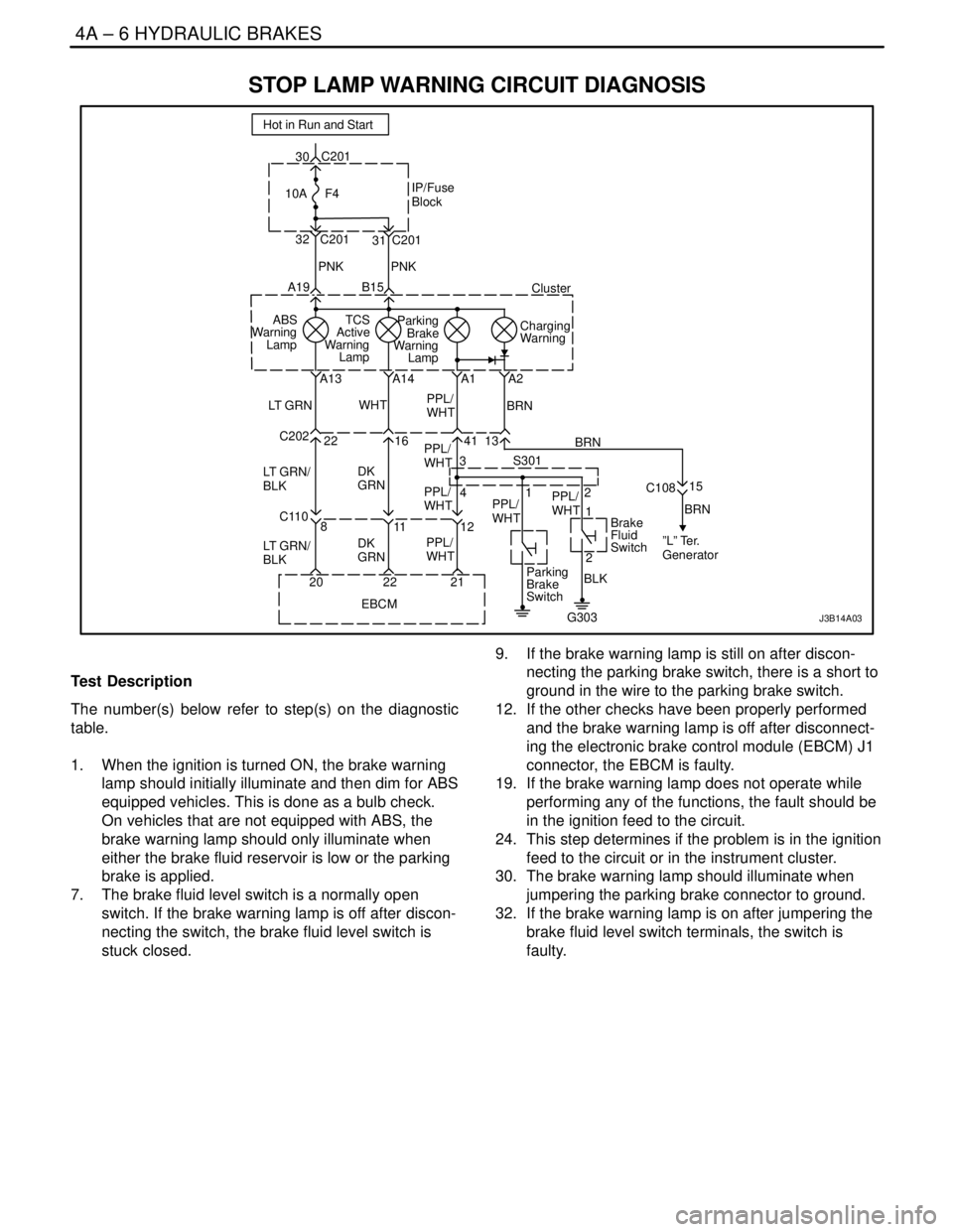

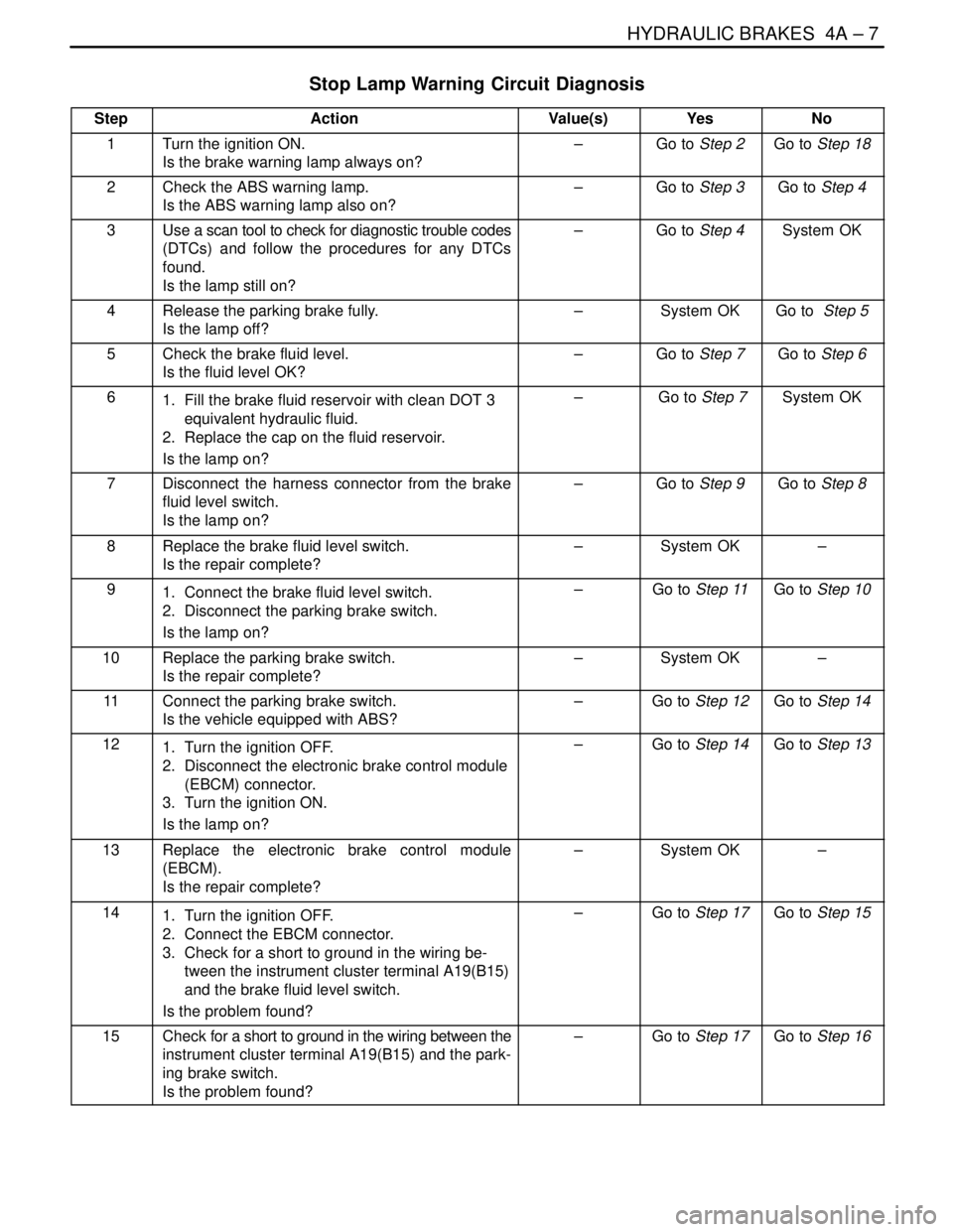

STOP LAMP WARNING CIRCUIT DIAGNOSIS

J3B14A03

10A30

F4

32

A19

A13 A14 A1 A2B15 C201

31C201IP/Fuse

Block C201

C202

C110C108 S301 WHT

BRN

BRN

Parking

Brake

SwitchBrake

Fluid

Switch

BLKBRN LT GRN

DK

GRN

DK

GRN LT GRN/

BLK

LT GRN/

BLKPPL/

WHT

PPL/

WHT

PPL/

WHTPPL/

WHT PPL/

WHT

PPL/

WHT ABS

Warning

Lamp TCS

Active

Warning

Lamp Parking

Brake

Warning

Lamp Charging

Warning

Hot in Run and Start

PNK

Cluster PNK

EBCM”L” Ter.

Generator 1 12

2

20 2222 16 41 13

3

4

11 1 215

8

21

G303

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

1. When the ignition is turned ON, the brake warning

lamp should initially illuminate and then dim for ABS

equipped vehicles. This is done as a bulb check.

On vehicles that are not equipped with ABS, the

brake warning lamp should only illuminate when

either the brake fluid reservoir is low or the parking

brake is applied.

7. The brake fluid level switch is a normally open

switch. If the brake warning lamp is off after discon-

necting the switch, the brake fluid level switch is

stuck closed.9. If the brake warning lamp is still on after discon-

necting the parking brake switch, there is a short to

ground in the wire to the parking brake switch.

12. If the other checks have been properly performed

and the brake warning lamp is off after disconnect-

ing the electronic brake control module (EBCM) J1

connector, the EBCM is faulty.

19. If the brake warning lamp does not operate while

performing any of the functions, the fault should be

in the ignition feed to the circuit.

24. This step determines if the problem is in the ignition

feed to the circuit or in the instrument cluster.

30. The brake warning lamp should illuminate when

jumpering the parking brake connector to ground.

32. If the brake warning lamp is on after jumpering the

brake fluid level switch terminals, the switch is

faulty.

Page 1023 of 2643

HYDRAULIC BRAKES 4A – 7

DAEWOO V–121 BL4

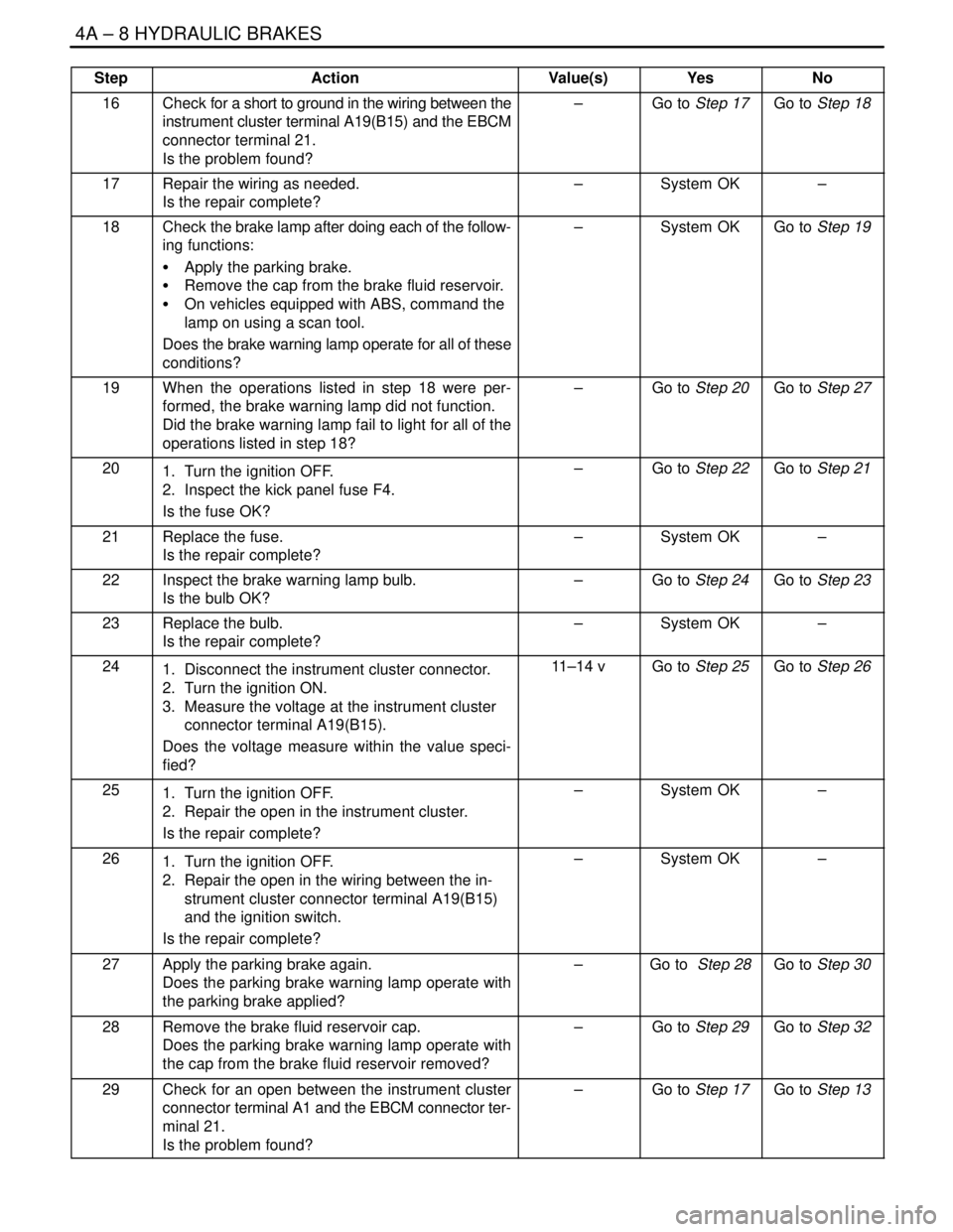

Stop Lamp Warning Circuit Diagnosis

StepActionValue(s)YesNo

1Turn the ignition ON.

Is the brake warning lamp always on?–Go to Step 2Go to Step 18

2Check the ABS warning lamp.

Is the ABS warning lamp also on?–Go to Step 3Go to Step 4

3Use a scan tool to check for diagnostic trouble codes

(DTCs) and follow the procedures for any DTCs

found.

Is the lamp still on?–Go to Step 4System OK

4Release the parking brake fully.

Is the lamp off?–System OKGo to Step 5

5Check the brake fluid level.

Is the fluid level OK?–Go to Step 7Go to Step 6

61. Fill the brake fluid reservoir with clean DOT 3

equivalent hydraulic fluid.

2. Replace the cap on the fluid reservoir.

Is the lamp on?– Go to Step 7System OK

7Disconnect the harness connector from the brake

fluid level switch.

Is the lamp on?–Go to Step 9Go to Step 8

8Replace the brake fluid level switch.

Is the repair complete?–System OK–

91. Connect the brake fluid level switch.

2. Disconnect the parking brake switch.

Is the lamp on?–Go to Step 11Go to Step 10

10Replace the parking brake switch.

Is the repair complete?–System OK–

11Connect the parking brake switch.

Is the vehicle equipped with ABS?–Go to Step 12Go to Step 14

121. Turn the ignition OFF.

2. Disconnect the electronic brake control module

(EBCM) connector.

3. Turn the ignition ON.

Is the lamp on?–Go to Step 14Go to Step 13

13Replace the electronic brake control module

(EBCM).

Is the repair complete?–System OK–

141. Turn the ignition OFF.

2. Connect the EBCM connector.

3. Check for a short to ground in the wiring be-

tween the instrument cluster terminal A19(B15)

and the brake fluid level switch.

Is the problem found?–Go to Step 17Go to Step 15

15Check for a short to ground in the wiring between the

instrument cluster terminal A19(B15) and the park-

ing brake switch.

Is the problem found?–Go to Step 17Go to Step 16

Page 1024 of 2643

4A – 8IHYDRAULIC BRAKES

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

16Check for a short to ground in the wiring between the

instrument cluster terminal A19(B15) and the EBCM

connector terminal 21.

Is the problem found?–Go to Step 17Go to Step 18

17Repair the wiring as needed.

Is the repair complete?–System OK–

18Check the brake lamp after doing each of the follow-

ing functions:

S Apply the parking brake.

S Remove the cap from the brake fluid reservoir.

S On vehicles equipped with ABS, command the

lamp on using a scan tool.

Does the brake warning lamp operate for all of these

conditions?–System OKGo to Step 19

19When the operations listed in step 18 were per-

formed, the brake warning lamp did not function.

Did the brake warning lamp fail to light for all of the

operations listed in step 18?–Go to Step 20Go to Step 27

201. Turn the ignition OFF.

2. Inspect the kick panel fuse F4.

Is the fuse OK?–Go to Step 22Go to Step 21

21Replace the fuse.

Is the repair complete?–System OK–

22Inspect the brake warning lamp bulb.

Is the bulb OK?–Go to Step 24Go to Step 23

23Replace the bulb.

Is the repair complete?–System OK–

241. Disconnect the instrument cluster connector.

2. Turn the ignition ON.

3. Measure the voltage at the instrument cluster

connector terminal A19(B15).

Does the voltage measure within the value speci-

fied?11–14 vGo to Step 25Go to Step 26

251. Turn the ignition OFF.

2. Repair the open in the instrument cluster.

Is the repair complete?–System OK–

261. Turn the ignition OFF.

2. Repair the open in the wiring between the in-

strument cluster connector terminal A19(B15)

and the ignition switch.

Is the repair complete?–System OK–

27Apply the parking brake again.

Does the parking brake warning lamp operate with

the parking brake applied?–Go to Step 28Go to Step 30

28Remove the brake fluid reservoir cap.

Does the parking brake warning lamp operate with

the cap from the brake fluid reservoir removed?–Go to Step 29Go to Step 32

29Check for an open between the instrument cluster

connector terminal A1 and the EBCM connector ter-

minal 21.

Is the problem found?–Go to Step 17Go to Step 13