ECU DATSUN 510 1968 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 73 of 252

68

CHAPTER

SEVEN

Capacity

Test

Perform

the

capacity

test

only

when

the

statIc

pressiue

test

IS

withm

acceptable

lirmts

1

D

sconnect

the

fuellme

at

the

carburetor

2

Place

a

sUItable

container

at

the

end

of

the

fuellme

3

St

lrt

the

engm

and

run

at

OOO

rpm

4

The

fuel

pump

should

delIver

fuel

into

the

co

ntainer

at

a

rate

slightly

over

two

pints

per

minute

If

no

gasolme

or

only

a

lIttle

appears

the

fuel

lme

is

clogged

or

thefuel

pump

defectIve

Bef

removmg

the

fuel

pump

remove

the

gas

tank

filler

cap

dtsconnect

the

mlet

and

outlet

fuel

lmes

and

qlow

through

them

With

compressed

air

to

make

certam

they

are

clear

Reconnect

the

fuellmes

and

retest

the

flow

If

stIll

insufficient

the

fuel

p

mp

requires

servicmg

or

replacement

Fuel

Punip

Removal

and

Disassembly

1

Unscrew

the

two

mountIng

nuts

hOldmg

fuel

pump

to

the

cylmder

head

2

Disconnect

the

inlet

and

outlet

lines

3

Remove

the

fuel

pump

from

the

cylmder

head

4

Place

the

pump

on

a

work

bench

and

remove

the

screws

jommg

the

upper

and

lower

bodIes

5

Remove

the

cap

and

gasket

by

removing

the

cap

screws

6

Unscrew

the

elbow

and

connector

7

Remove

the

valve

retamer

by

unscrewmg

the

two

valve

retamer

screws

The

two

valves

are

then

easily

removed

8

To

remove

the

dIaphragm

spring

lower

body

seal

washer

and

lower

body

seal

from

the

lower

body

press

the

diaphragm

down

Wh1le

domg

thIS

cant

the

dIaphragm

so

that

the

rectangular

part

m

the

lower

end

of

the

pull

rod

unhooks

from

the

rocker

arm

lmk

ThIS

action

IS

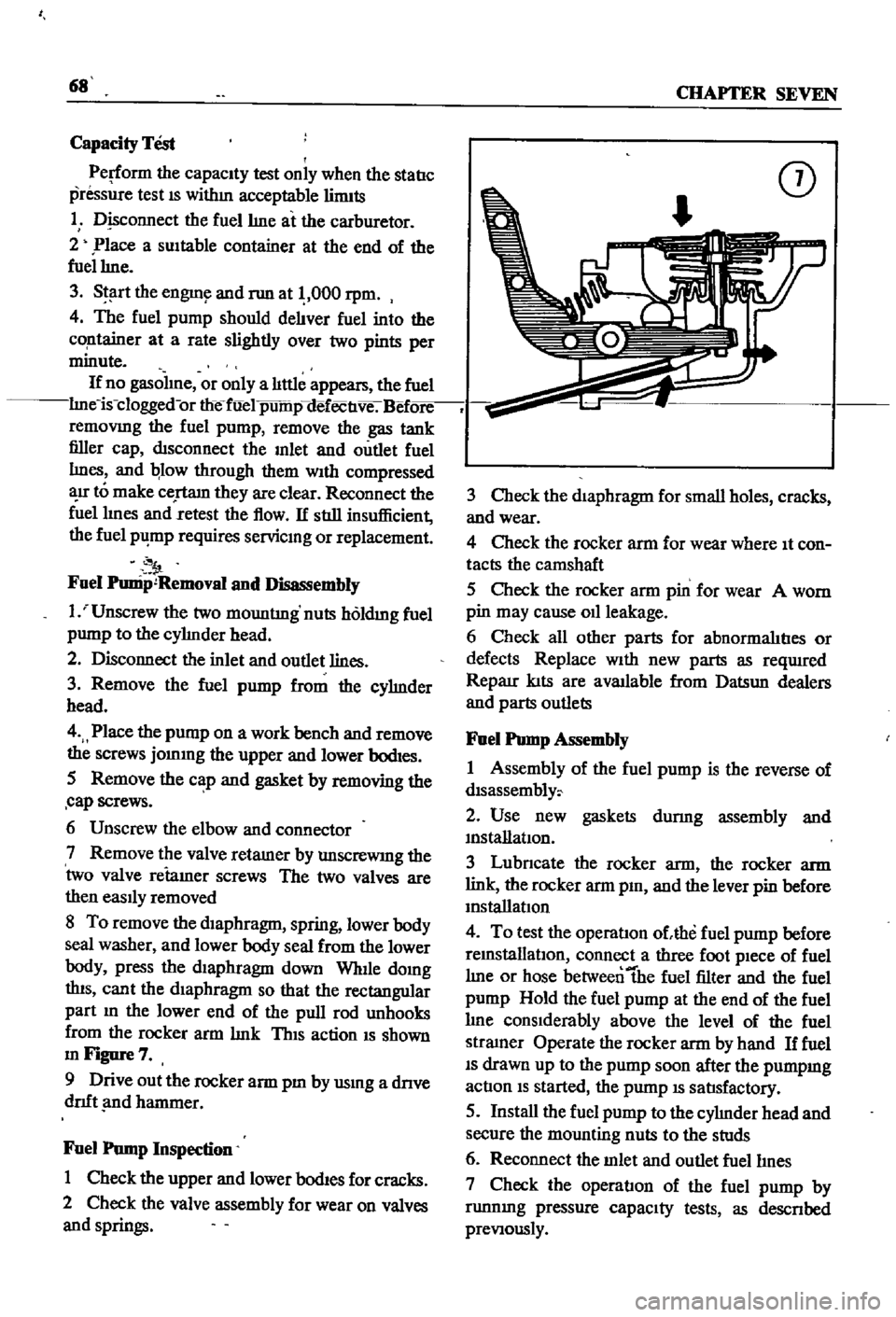

shown

mFigure7

9

Drive

out

the

rocker

arm

pm

by

usmg

a

dnve

dnft

nd

hammer

Fuel

Pump

Inspection

1

Check

the

upper

and

lower

bodIes

for

cracks

2

Check

the

valve

assembly

for

wear

on

valves

and

springs

CD

3

Check

the

diaphragm

for

small

holes

cracks

and

wear

4

Check

the

rocker

arm

for

wear

where

It

con

tacts

the

camshaft

5

Check

the

rocker

arm

pin

for

wear

A

worn

pin

may

cause

011

leakage

6

Check

all

other

parts

for

abnormalItIes

or

defects

Replace

With

new

parts

as

reqUlred

Reparr

kIts

are

available

from

Datsun

dealers

and

parts

outlets

Fuel

Pump

Assembly

1

Assembly

of

the

fuel

pump

is

the

reverse

of

dlsassembly

2

Use

new

gaskets

durmg

assembly

and

mstanatIon

3

Lubncate

the

rocker

arm

the

rocker

arm

link

the

rocker

arm

pm

and

the

lever

pin

before

mstallatIon

4

To

test

the

operatIon

ohhe

fuel

pump

before

remstallatlOn

connect

a

three

foot

pIece

of

fuel

lme

or

hose

betweentbe

fuel

filter

and

the

fuel

pump

Hold

the

fuel

pump

at

the

end

of

the

fuel

lme

conSIderably

above

the

level

of

the

fuel

stramer

Operate

the

rocker

arm

by

hand

If

fuel

IS

drawn

up

to

the

pump

soon

after

the

pumpmg

actIon

IS

started

the

pump

IS

satIsfactory

5

Install

the

fuel

pump

to

the

cylmder

head

and

secure

the

mounting

nuts

to

the

studs

6

Reconnect

the

mlet

and

outlet

fuellmes

7

Check

the

operatIon

of

the

fuel

pump

by

runnmg

pressure

capaCIty

tests

as

descnbed

preVIously

Page 76 of 252

FUEL

SYSTEM

71

Dash

Pot

Adjustment

The

adjustment

of

the

dash

pot

IS

done

by

warmmg

up

the

engme

properly

and

checkIng

If

the

throttle

lever

touches

th

dash

pot

stem

as

the

engine

reaches

1

800

and

2

000

rpm

under

no

load

conditIons

Proper

contact

between

the

throttle

lever

and

the

dash

pot

stem

produces

a

normal

dash

pot

performance

Should

a

normal

mcrease

m

engme

speed

not

occur

adjust

the

dash

pot

as

follows

1

Loosen

the

dash

pot

locknuts

2

Rotate

the

dash

pot

nght

and

then

left

3

Adjust

the

dash

pot

so

that

the

throttle

lever

hIts

the

stem

between

1

800

and

2

000

rpm

4

Fasten

the

lock

nuts

securely

5

The

clearance

between

the

throttle

valve

and

the

throttle

chamber

wall

should

be

0

0709

m

0

8mm

or

10

degrees

In

throttle

valve

angle

MAJOR

CARBURETOR

SERVICE

PROCEDURES

A

carburetor

m

good

operatIng

condition

will

delIver

the

pr

per

gasolme

and

aIr

ratIos

for

all

engme

runnmg

speeds

A

gradual

declme

In

smoothness

response

and

power

Will

occur

as

the

carburetor

slIps

from

adjustment

and

Its

delI

cate

parts

become

dirty

and

worn

Overhaul

should

only

be

attempted

by

an

expenenced

mechanic

Accurate

calIbratIon

of

passages

and

dIS

charge

hole

reqUIre

that

extreme

care

be

taken

In

dISassembly

cleanmg

and

reassembly

Use

only

a

hIgh

grade

carburetor

cleaner

and

com

pressed

arr

to

clean

parts

and

passages

Never

use

wire

or

other

pOInted

Instruments

for

clean

ing

CalIbratIon

of

the

carburetor

will

be

af

fected

The

procedures

below

are

generally

true

for

all

models

As

an

aId

Figures

13

and

14

are

typIcal

examples

of

the

carburetors

used

Carburetor

Removal

1

Remove

the

au

cleaner

by

dIsconnectIng

all

hoses

attached

to

It

remoVmg

the

two

bolts

holdmg

the

aIr

cleaner

to

the

support

and

loos

enmg

the

band

bolt

at

the

base

of

the

aIr

cleaner

2

DIsconnect

fuellme

vacuum

Ime

and

choke

wire

u

eqUIpped

from

the

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

holdmg

car

buretor

to

manIfold

5

Lift

carburetor

off

of

manuold

6

Remove

and

dIscard

carburetor

to

manuold

gasket

7

Place

carburetor

on

clean

workbench

Carburetor

Disassembly

1

The

maIn

Jets

slow

Jets

and

needle

valves

on

both

the

pnmary

and

secondary

systenIS

are

accessIble

from

outsIde

the

carburetor

Refer

to

FIgures

13

and

14

for

locatI

n

2

The

choke

chamber

can

be

detached

by

re

mOVIng

the

connectIng

rod

pump

connectIng

rod

return

sprmg

stop

pm

and

the

set

screws

I

that

hold

It

in

place

3

The

pnmary

and

secondary

emulSIon

tubes

can

be

disassembled

by

remOVIng

the

mam

air

bleeds

on

the

respectIve

SIdes

4

To

check

the

accelerator

pump

remove

the

cylInder

cover

Be

careful

not

to

lose

the

return

spnng

and

Inlet

valve

at

the

lower

part

of

the

pIston

durmg

dIsassembly

5

Detach

the

throttle

chamber

from

the

float

chamber

by

remOVIng

the

rod

lInkIng

the

dia

phragm

WIth

the

secondary

throttle

valve

and

the

four

screws

that

hold

It

However

It

IS

preferable

to

leave

the

throttle

valve

mtact

unless

absolutely

reqUired

If

It

IS

necessary

to

dlS

assemble

the

valve

It

should

be

Installed

so

that

the

secondary

throttle

valve

will

be

gap

free

OtherwIse

stable

Idle

and

good

slow

speed

performance

will

suffer

is

To

check

the

float

the

float

chamber

cover

must

be

removed

I

7

The

dIaphragm

IS

dIsassembled

by

removing

the

set

screws

holdmg

the

dIaphragm

chamber

cover

In

reassemblIng

the

diaphragm

be

careful

not

to

turn

the

edge

of

the

dIaphragm

up

8

In

dlsassemblmg

and

reassembling

the

mter

lockIng

lInks

take

care

so

that

each

lInkage

has

a

smooth

actIon

and

that

parts

are

not

forced

mto

pOSItIon

9

For

vehIcles

equipped

With

an

automatIc

choke

remove

the

brmetal

case

by

releasmg

the

set

screws

The

bimetal

1l

extremely

senSItIve

Page 90 of 252

COOLING

SYSTEM

8S

and

In

those

with

exhaust

and

evaporatIve

emIS

sion

control

devIces

a

fan

clutch

IS

combIned

WIth

the

thermostat

to

detect

temperature

m

the

engme

compartlnent

When

the

temperature

nses

the

thermostat

detects

the

change

an

the

fan

clutch

engages

thereby

helpmg

to

cool

the

engme

WATER

PUMP

Figure

2

page

86

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1970

to

1971

The

top

half

of

the

IllustratIon

applIes

to

those

models

WIth

exhaust

and

evaporatIve

emiSSIOn

control

systems

The

bottom

half

covers

models

WIth

a

crankcase

emiSSIon

control

deVIce

only

Figure

3

page

87

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1968

models

Without

exhaust

or

evaporatIve

controls

Figure

4

page

88

shows

the

1968

model

With

emISSIon

control

deVIce

As

can

be

seen

from

the

illustratIons

most

dIfferences

eXISt

withIn

the

fan

clutch

assembly

Water

Pump

Removal

1

Remove

upper

and

lower

radIator

hoses

from

the

thermostat

housmg

and

cylmder

block

re

spectIvely

Dram

coolant

from

rad1ator

and

cylInder

block

2

Loosen

the

alternator

mountlng

bolt

and

the

adjustIng

bolt

on

the

alternator

mountIng

bracket

3

Move

the

alternator

toward

the

cylinder

block

untIl

slack

IS

eVIdent

10

the

fan

belt

Re

move

fa

belt

fro

alternator

water

pump

and

crankshaft

pulley

4

It

IS

difficult

to

remove

the

water

pump

from

the

front

housmg

With

the

radiator

and

top

shroud

10

place

so

remove

them

5

Remove

the

bolts

holdmg

the

fan

assembly

to

the

water

pump

and

remove

the

fan

assembly

6

Remove

the

bolts

holdmg

the

water

pump

to

the

front

housmg

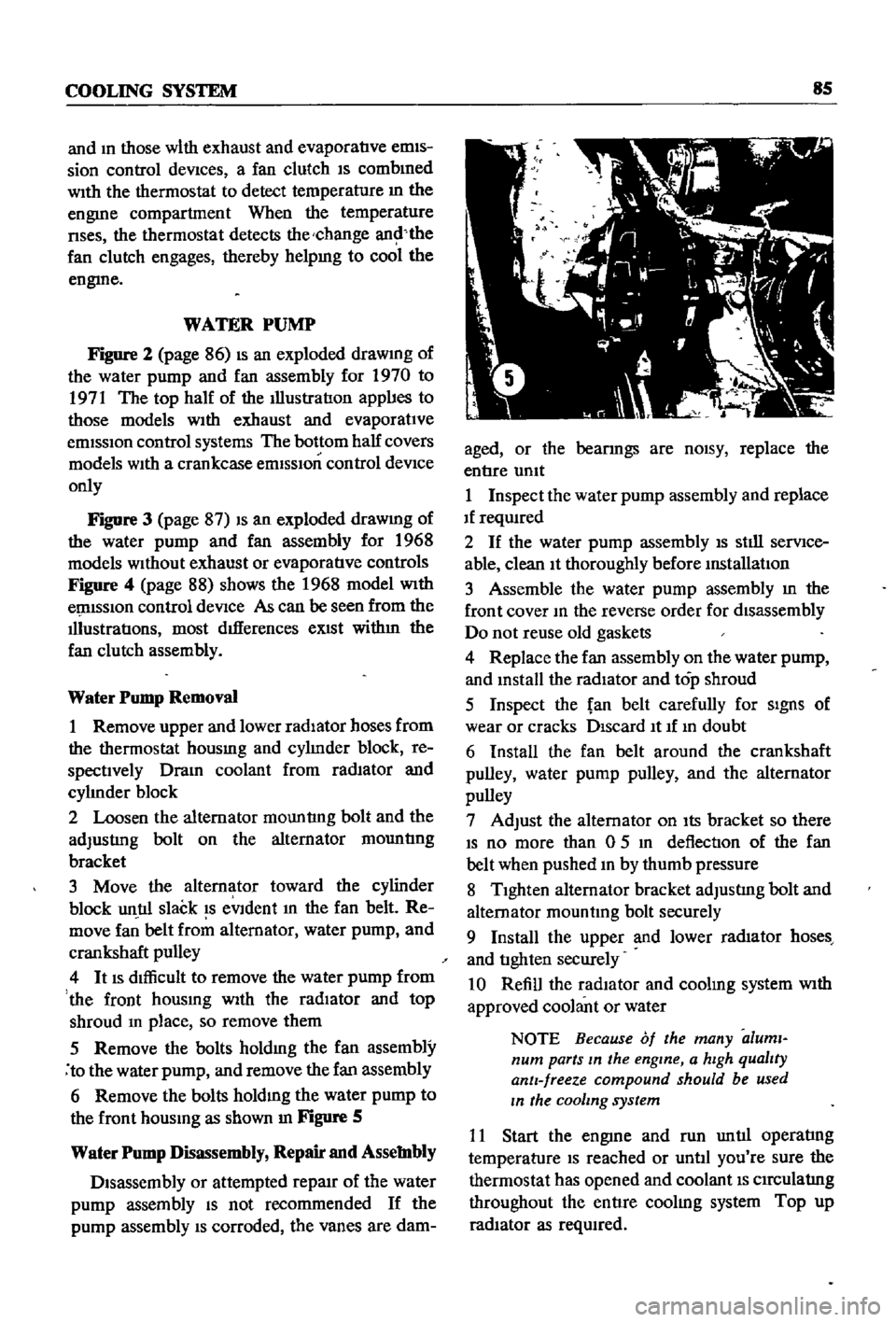

as

shown

In

Figure

S

Water

Pump

Disassembly

Repair

and

Assembly

Disassembly

or

attempted

repaIr

of

the

water

pump

assembly

IS

not

recommended

If

the

pump

assembly

IS

corroded

the

vanes

are

dam

aged

or

the

bearmgs

are

nOISY

replace

the

entIre

umt

1

Inspect

the

water

pump

assembly

and

replace

If

reqUIred

2

If

the

water

pump

assembly

IS

stIll

serVIce

able

clean

It

thoroughly

before

mstallatIon

3

Assemble

the

water

pump

assembly

m

the

front

cover

10

the

reverse

order

for

disassembly

Do

not

reuse

old

gaskets

4

Replace

the

fan

assembly

on

the

water

pump

and

mstall

the

radiator

and

top

shroud

5

Inspect

the

fan

belt

carefully

for

SIgnS

of

wear

or

cracks

DIscard

It

If

10

doubt

6

Install

the

fan

belt

around

the

crankshaft

pulley

water

pump

pulley

and

the

alternator

pulley

7

Adjust

the

alternator

on

Its

bracket

so

there

IS

no

more

than

0

5

10

deflection

of

the

fan

belt

when

pushed

10

by

thumb

pressure

8

TIghten

alternator

bracket

adjustIng

bolt

and

alternator

mountmg

bolt

securely

9

Install

the

upper

and

lower

rad1ator

hoses

and

tIghten

securely

10

Refill

the

radIator

and

coolmg

system

With

approved

coolant

or

water

NOTE

Because

of

the

many

aluml

num

parts

In

the

engine

a

hIgh

qualIty

antI

freeze

compound

should

be

used

In

the

cooling

system

11

Start

the

engme

and

run

untIl

operatIng

temperature

IS

reached

or

untIl

you

re

sure

the

thermostat

has

opened

and

coolant

IS

CIrCulatIng

throughout

the

entIre

coolIng

system

Top

up

radIator

as

reqUIred

Page 95 of 252

90

CHAPTER

EIGHT

degrees

C

The

maXImum

WIdth

of

the

thermo

stat

openIng

should

be

0315

In

8mm

3

If

the

thermostat

IS

defectIve

or

If

you

have

an

doubts

about

It

mstall

a

new

one

4

When

Installmg

the

thermostat

m

the

hous

Ing

be

certaIn

to

place

the

spnng

end

down

Coat

both

SIdes

of

the

gasket

WIth

sealer

to

pre

vent

leaks

and

tIghten

the

mountlng

nuts

securely

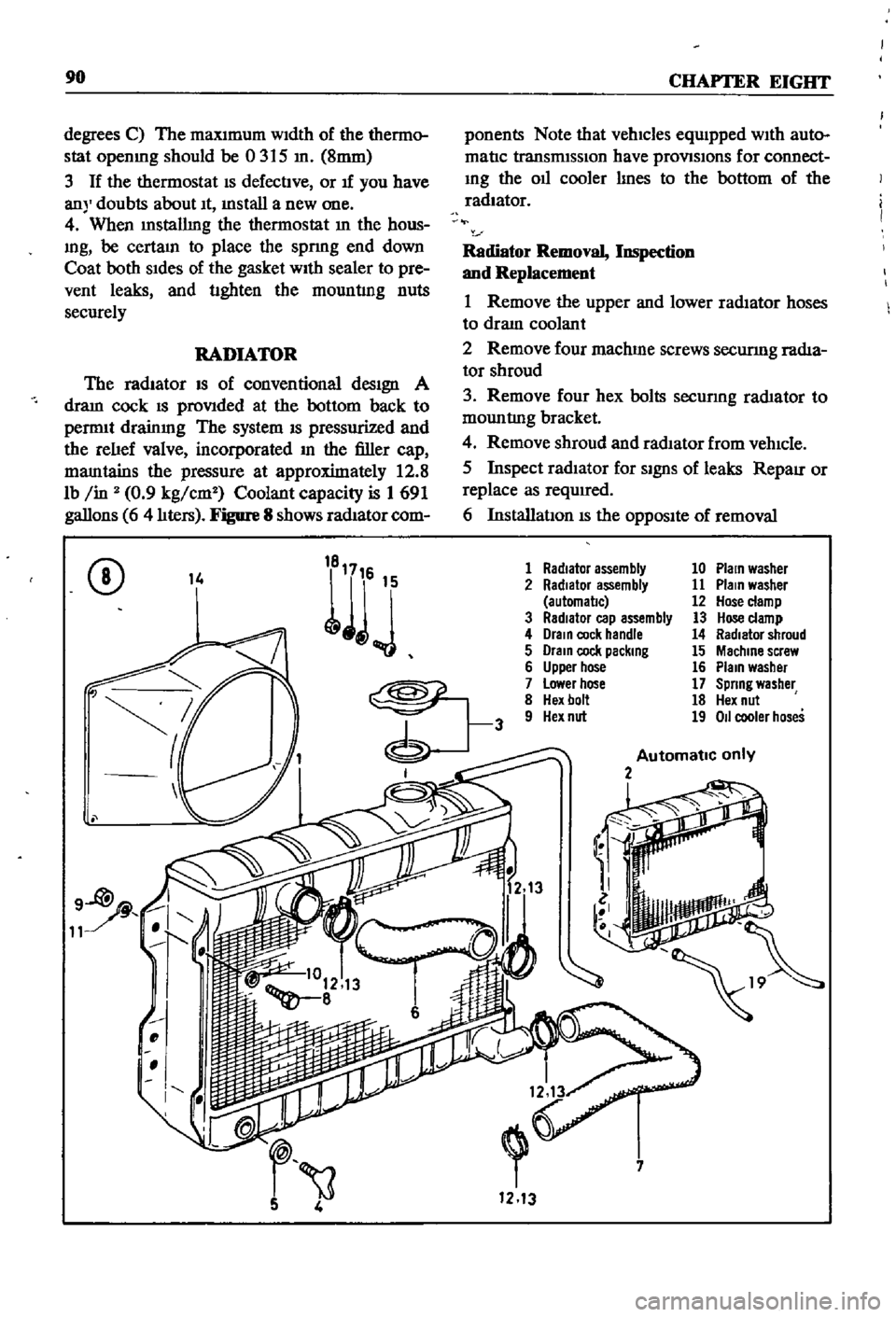

RADIATOR

The

radIator

IS

of

conventional

desIgn

A

draIn

cock

IS

proVIded

at

the

bottom

back

to

perrmt

drainIng

The

system

IS

pressurized

and

the

rehef

valve

incorporated

In

the

filler

cap

mamtains

the

pressure

at

approximately

12

8

Ib

in

0

9

kg

cm

Coolant

capacity

is

1

691

gallons

6

4

lIters

Figure

8

shows

radIator

com

ponents

Note

that

vehicles

equIpped

WIth

auto

matIc

transmISSIon

have

provlSlons

for

connect

Ing

the

011

cooler

lInes

to

the

bottom

of

the

radiator

Radiator

Removal

Inspection

and

Replacement

1

Remove

the

upper

and

lower

radIator

hoses

to

draIn

coolant

2

Remove

four

machme

screws

securmg

radIa

tor

shroud

3

Remove

four

hex

bolts

secunng

rad1ator

to

mountlng

bracket

4

Remove

shroud

and

radIator

from

vehIcle

5

Inspect

radIator

for

SignS

of

leaks

RepaIr

or

replace

as

required

6

InstallatIon

IS

the

OppOSIte

of

removal

CD

14

1

Radiator

assembly

10

Plain

washer

2

Radiator

assembly

11

Plain

washer

automal1c

12

Hose

clamp

3

RadIator

cap

assembly

13

Hose

clamp

4

Drain

cock

handle

14

Radiator

shroud

5

Drain

cock

packing

15

Machine

screw

6

Upper

hose

16

Plain

washer

7

Lower

hose

17

Spring

washer

8

Hex

bolt

18

Hex

nut

9

Hex

nut

19

011

cooler

hoses

Automatic

only

2

i

7

1213

Page 97 of 252

91

CHAPTER

NINE

bon

the

serIes

coll

demagnetizes

agatnst

the

shunt

cOIl

The

return

spnng

causes

the

plunger

to

return

to

the

origmal

posItIon

stoppmg

the

starter

The

overrunnmg

clutch

provIdes

for

positIve

meshmg

and

unmeshmg

of

the

pmlOn

gear

and

flywheerrmg

gear

and

perinitStlie

pmlon

to

overrun

the

armature

after

the

engme

has

started

CONSTRUCIlON

A

typical

Datsun

starter

motor

is

shown

m

Figure

3

The

example

is

for

1971

models

but

about

the

only

dIfferences

existing

between

It

and

other

models

are

the

number

of

elements

used

in

the

dust

cover

and

the

number

of

thrust

washers

Removal

1

DIsconnect

the

battery

ground

cable

2

Disconnect

the

black

yellow

wire

from

the

magnetIc

sWitch

tennmal

on

the

solenoid

3

Disconnect

the

black

battery

cable

and

red

wire

from

the

battery

tennmal

on

the

solenOId

4

Remove

two

bolts

holdmg

the

startmg

motor

to

flywheel

hOUSIng

The

battery

ground

cable

is

attached

to

the

flywheel

hOUSIng

bottom

bolt

5

Pull

starter

motor

toward

front

of

engme

and

remove

Disassembly

1

Remove

the

nut

holdIng

the

electrIc

WIre

to

the

magnetIc

sWItch

M

tennmal

DIsconnect

the

WIre

2

Remove

three

screws

securmg

magnetic

switch

assembly

to

yoke

Remove

magnetic

sWItch

assembly

and

dust

cover

s

Figure

4

3

Remove

two

through

bolts

and

brush

cover

assembly

as

shown

m

Figure

5

4

Remove

the

yoke

assembly

by

tappmg

lIghtly

as

In

Figure

6

5

Remove

bolt

nut

and

washers

at

base

of

yoke

to

free

shut

lever

WIthdraw

the

armatlIre

and

shut

lever

as

shown

m

Figure

7

6

Remove

the

pInIOn

stop

nng

located

at

the

end

of

the

armature

shaft

To

remove

the

stop

nng

push

the

stop

nng

to

the

clutch

SIde

remove

the

snap

nng

and

Withdraw

the

stop

nng

and

CD

c

0

I

CD

Ml

ml

CD

a

I

II

0

l

g

I

o

Page 112 of 252

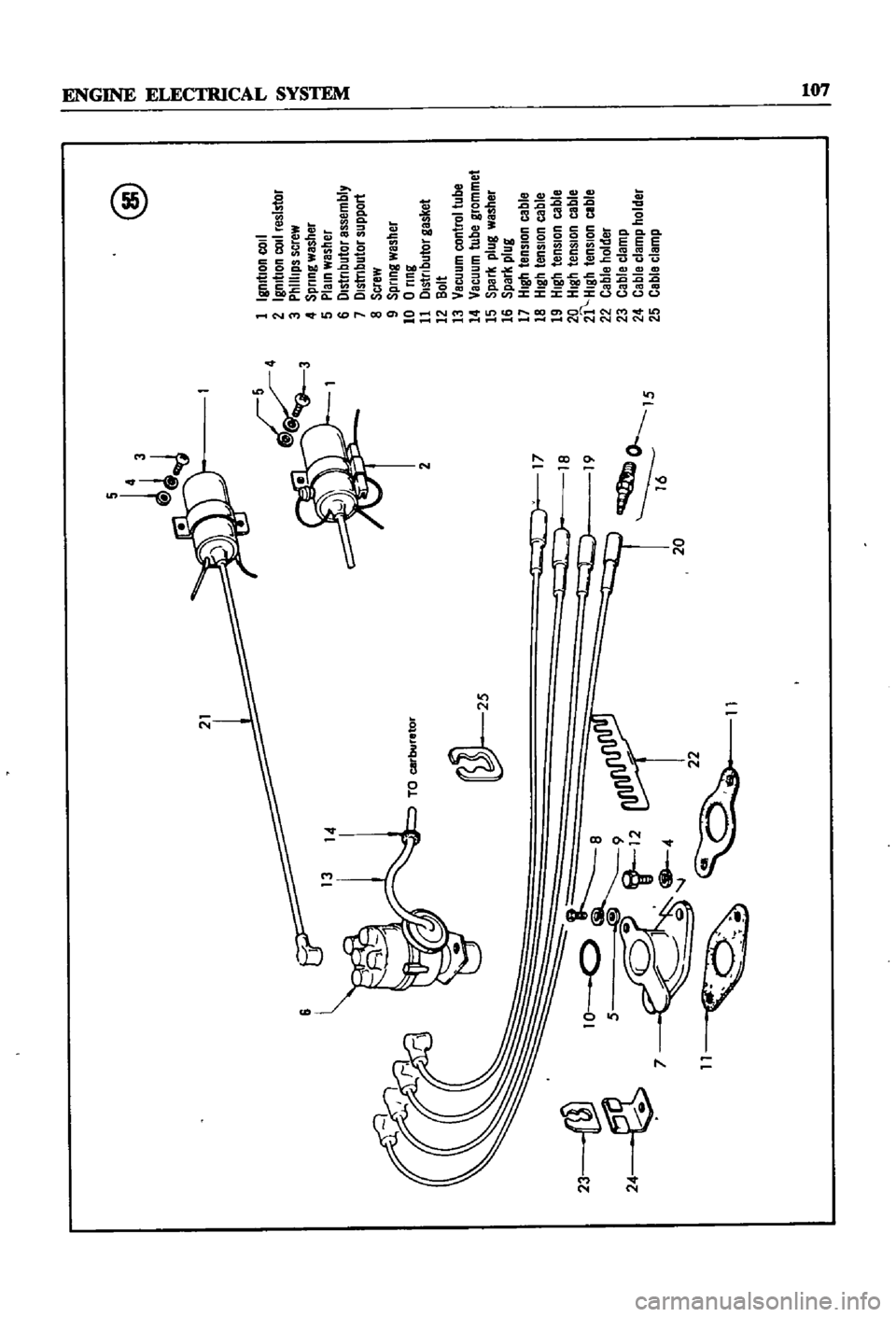

24

21

TO

oto

25

1

17

18

19

o

15

16

20

@

1

IgnItIon

coIl

2

Ignlllon

COIl

resls

Ol

3

p

II

lS

sere

ll

4

spnng

lles1

Br

5

PlaIn

wesner

6

illstl

OUtor

assembly

1

illstllbu

Ol

sUP

rt

II

sere

ll

9

spnng

wesner

10

0

ling

11

Ills

nbutor

gasket

12

llolt

13

VaCUum

control

tube

14

Vecuum

tube

grommet

IS

spar

plug

IIeslIer

1

sperll

plug

11

111gb

tenSIon

cable

18

IIlglllenSIOn

cable

19

lI

gll

tensIon

cable

20

IIlgII

tensIon

cable

ii

lIlgII

tenSion

cable

22

Ceble

older

23

Cable

c1emp

24

cable

clempllOlder

25

Ceble

clemp

J

Page 115 of 252

110

CHAPTER

NINE

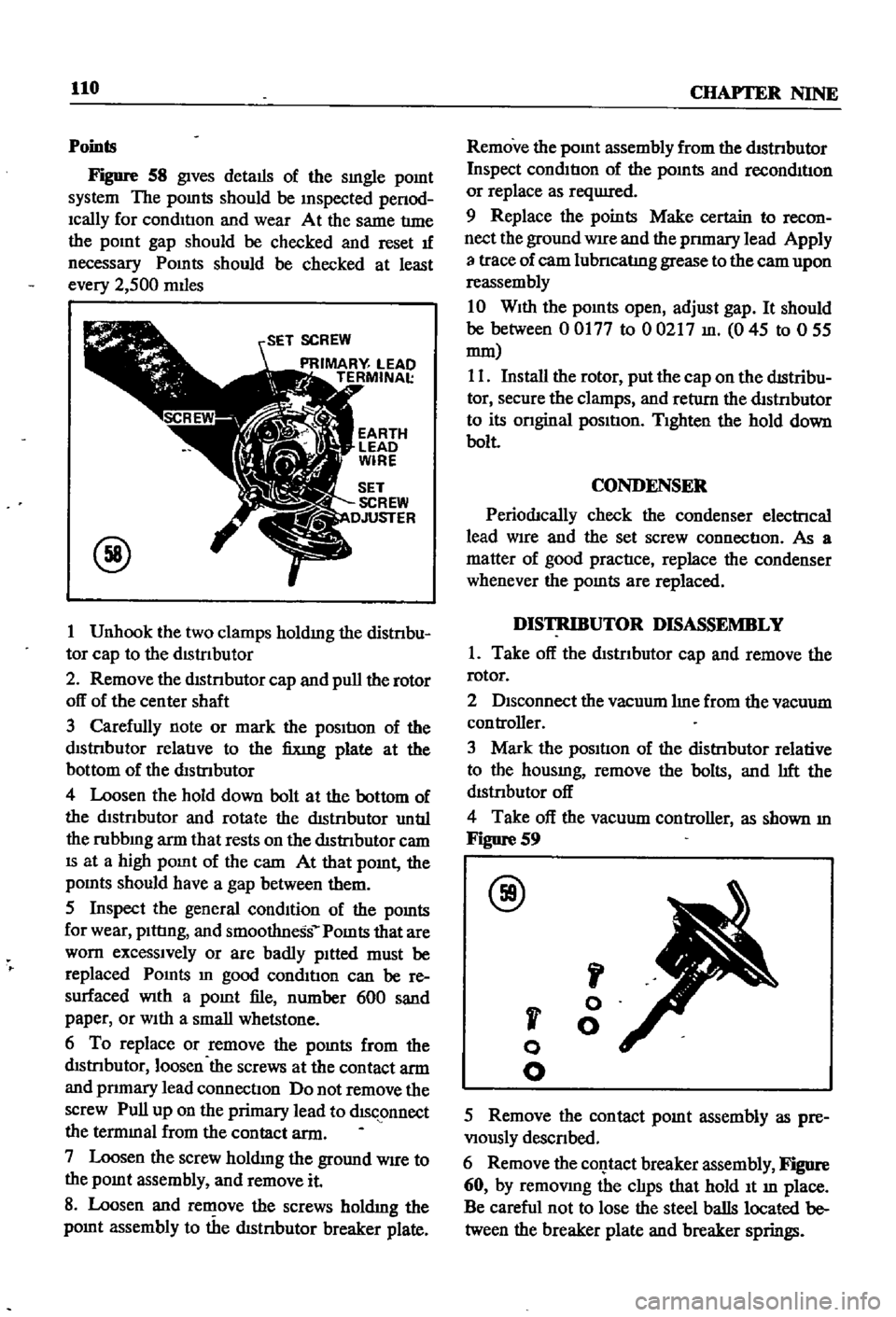

Points

Figure

S8

gives

details

of

the

sIngle

pomt

system

The

pomts

should

be

Inspected

penod

Ically

for

condItIon

and

wear

At

the

same

tlme

the

pOInt

gap

should

be

checked

and

reset

1f

necessary

Pomts

should

be

checked

at

least

every

2

500

mIles

SET

SCREW

PRIMARY

LEAD

TERMINAl

@

1

Unhook

the

two

clamps

holdmg

the

distnbu

tor

cap

to

the

dIStrIbutor

2

Remove

the

dlstnbutor

cap

and

pull

the

rotor

off

of

the

center

shaft

3

Carefully

note

or

mark

the

pOSItIon

of

the

dIStrIbutor

relatIve

to

the

fixmg

plate

at

the

bottom

of

the

distrIbutor

4

Loosen

the

hold

down

bolt

at

the

bottom

of

the

dlstnbutor

and

rotate

the

dIStnbutor

untIl

the

rubbmg

arm

that

rests

on

the

dIStrIbutor

cam

IS

at

a

high

pomt

of

the

cam

At

that

pomt

the

pomts

should

have

a

gap

between

them

5

Inspect

the

general

condItion

of

the

pomts

for

wear

pIttIng

and

smoot1mess

Pomts

that

are

worn

excessIvely

or

are

badly

pItted

must

be

replaced

Pomts

In

good

condItIon

can

be

re

surfaced

With

a

pOInt

file

number

600

sand

paper

or

WIth

a

small

whetstone

6

To

replace

or

remove

the

pomts

from

the

dIStrIbutor

loosen

the

screws

at

the

contact

arm

and

pnmary

lead

connectIOn

Do

not

remove

the

screw

Pull

up

on

the

primary

lead

to

dISc

onnect

the

termmal

from

the

contact

arm

7

Loosen

the

screw

holdmg

the

ground

WIre

to

the

pOInt

assembly

and

remove

it

S

Loosen

and

rell

ove

the

screws

holdIng

the

pomt

assembly

to

the

dIStnbutor

breaker

plate

Remove

the

pOInt

assembly

from

the

dIStrIbutor

Inspect

condItIon

of

the

pOInts

and

reconditIon

or

replace

as

reqUIred

9

Replace

the

points

Make

certain

to

recon

nect

the

ground

WIre

and

the

pnmary

lead

Apply

3

trace

of

cam

lubncatlng

grease

to

the

cam

upon

reassembly

10

WIth

the

pOInts

open

adjust

gap

It

should

be

between

00177

to

00217

In

045

to

055

mm

11

Install

the

rotor

put

the

cap

on

the

dIStribu

tor

secure

the

clamps

and

return

the

dtstrIbutor

to

its

onginal

pOSItIon

TIghten

the

hold

down

bolt

CONDENSER

PeriodJcally

check

the

condenser

electrIcal

lead

wire

and

the

set

screw

connectIon

As

a

matter

of

good

practIce

replace

the

condenser

whenever

the

pomts

are

replaced

DISTRIBUTOR

DISASSEMBLY

1

Take

off

the

dIstrIbutor

cap

and

remove

the

rotor

2

DIsconnect

the

vacuum

me

from

the

vacuum

con

troller

3

Mark

the

pOSItIon

of

the

distrIbutor

relative

to

the

housmg

remove

the

bolts

and

lIft

the

dIstrIbutor

off

4

Take

off

the

vacuum

controller

as

shown

m

F1gDre

S9

@

J

I

v

o

o

o

o

5

Remove

the

contact

pOInt

assembly

as

pre

VIously

descnbed

6

Remove

the

c01Jtact

breaker

assembly

Figure

60

by

remOVIng

the

clIps

that

hold

It

m

place

Be

careful

not

to

lose

the

steel

balls

located

be

tween

the

breaker

plate

and

breaker

springs

Page 127 of 252

122

CHAPTER

TEN

1

Start

the

engIne

and

bnng

It

up

to

normal

operatIng

temperature

2

Inspect

all

hoses

and

connectIons

for

leaks

and

detenoratIon

Shut

off

the

engme

Replace

any

defectIve

hoses

3

Remove

the

hose

attached

to

the

check

valve

4

VIsually

Inspect

the

posItIon

of

the

valve

plate

InsIde

the

valve

body

See

Figure

10

It

should

be

lIghtly

posItIoned

agaInst

the

valve

seat

away

from

the

aIr

dlstnbutor

manifold

5

Insert

a

probe

Into

the

valve

connectIon

on

the

check

valve

Depress

the

valve

plate

It

should

return

freely

agaInst

the

valve

seat

when

released

6

Leave

the

hose

dISconnected

and

start

the

engme

7

Slowly

Increase

engine

speed

to

1

500

rpm

Watch

for

exhaust

gas

leakage

at

the

check

valve

There

should

not

be

any

The

valve

may

flutter

or

VIbrate

at

Idle

speeds

ThIS

IS

normal

Replace

the

valve

u

defecuve

Anti

Backfire

Valve

1

Start

the

engme

and

bnng

to

operating

temperature

2

Inspect

all

hoses

and

hose

connectIons

for

leaks

and

detenoratIon

Replace

as

required

3

DIsconnect

the

hose

at

the

antI

backfire

valve

leading

to

the

Intake

manuold

Insert

a

plug

ill

the

hose

and

fasten

securely

4

Open

and

close

the

throttle

valve

rapidly

See

Figure

11

Place

a

finger

over

the

valve

outlet

to

the

m

take

manuold

If

arr

flow

IS

felt

for

one

to

two

seconds

the

valve

IS

functIonIng

properly

If

there

s

no

aIr

or

If

the

flow

is

felt

for

more

than

two

seconds

the

valve

IS

defectIve

and

must

be

replaced

5

Connect

the

alr

hose

to

the

mtake

manuold

after

remOVIng

the

plug

6

DIsconnect

the

aIr

mlet

hose

from

the

air

pump

at

the

antI

backfire

valve

If

the

engine

Idle

speed

changes

excessIvely

the

valve

is

de

fectIve

and

must

be

replaced

Air

Pump

1

Check

the

atr

InjectIon

pump

belt

tension

DeflectIon

of

the

belt

should

be

0

5

In

when

pushed

In

by

thumb

pressure

Adjust

belt

u

necessary

2

Operate

the

engme

untIl

normal

temperature

IS

reached

3

Inspect

all

hoses

hose

connectIons

and

the

arr

gallery

for

SIgnS

of

leaks

or

detenoratIon

Replace

as

required

4

DIsconnect

the

air

supply

hose

at

the

check

valve

5

Insert

the

open

pipe

end

of

a

pressure

test

gauge

adapter

Into

the

air

supply

hose

See

Fig

ure

12

Clamp

the

adapter

firmly

to

the

hose

Install

the

pressure

test

gauge

to

the

adapter

PosItIon

the

adapter

and

test

gauge

so

that

the

alr

blast

emitted

through

the

dnlled

pipe

plug

Will

be

harmlessly

dislppated

6

Install

a

tachometer

on

the

engme

WIth

the

engIne

speed

set

to

1

500

rpm

observe

the

pres

sure

readmg

AIr

pressure

should

be

0

47

m

Hg

16mm

Hg

Page 139 of 252

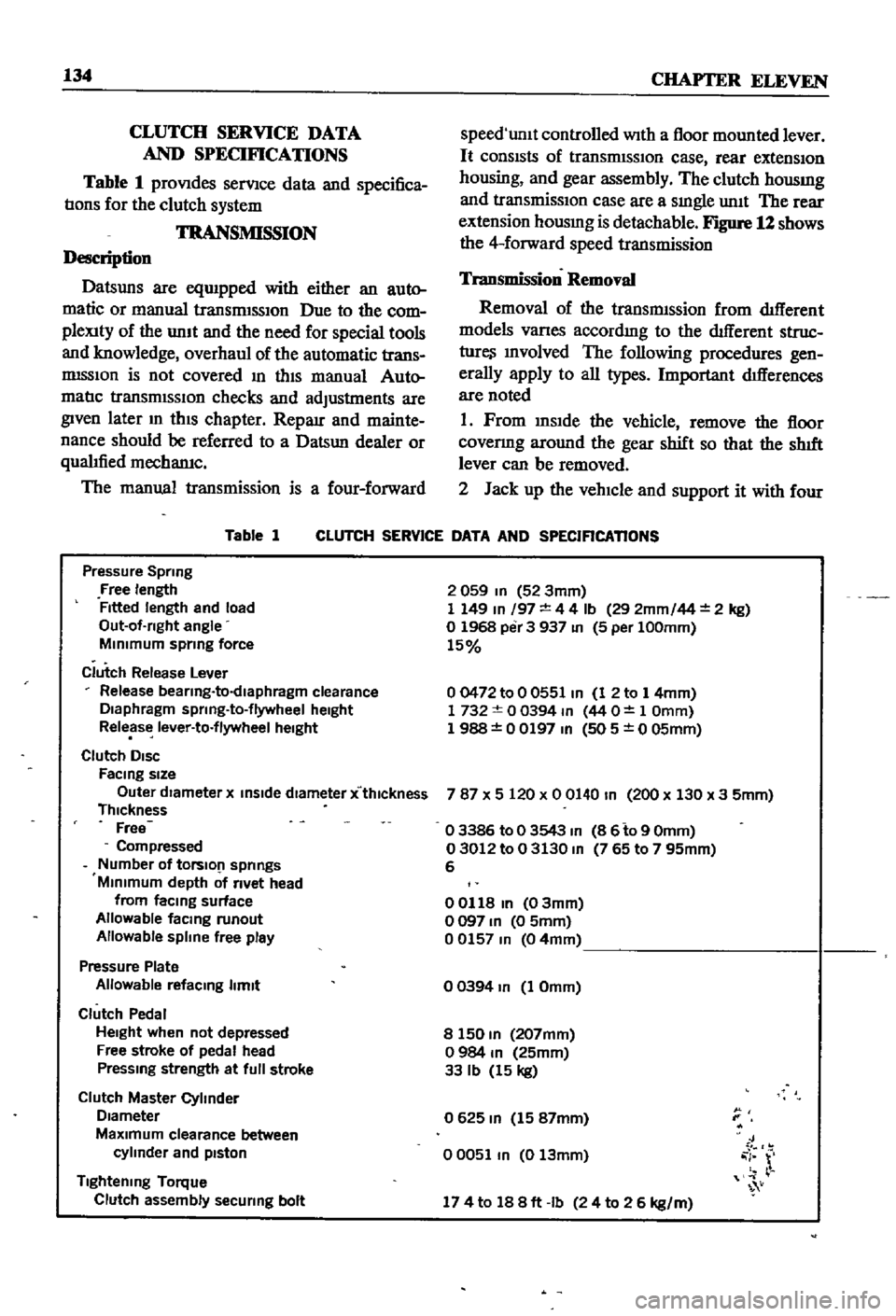

134

CHAPTER

ELEVEN

CLUTCH

SERVICE

DATA

AND

SPECIF1CATIONS

Table

1

proVIdes

serVIce

data

and

specifica

tIons

for

the

clutch

system

TRANSMISSION

Description

Datsuns

are

eqUIpped

with

either

an

auto

matic

or

manual

transrmSSIOn

Due

to

the

com

pleXity

of

the

unIt

and

the

need

for

special

tools

and

knowledge

overhaul

of

the

automatic

trans

mISSIon

is

not

covered

In

thIS

manual

Auto

matIc

transmISSIOn

checks

and

adjustments

are

given

later

m

thIS

chapter

Reparr

and

mainte

nance

should

be

referred

to

a

Datsun

dealer

or

qualIfied

mechamc

The

manual

transmission

is

a

four

forward

Table

1

speed

unlt

controlled

With

a

floor

mounted

lever

It

consIsts

of

transrmSSIOn

case

rear

extensIOn

housing

and

gear

assembly

The

clutch

housmg

and

transmissIOn

case

are

a

sIngle

unIt

The

rear

extension

housmg

is

detachable

Figure

12

shows

the

4

forward

speed

transmission

Transmission

Removal

Removal

of

the

transmIssion

from

dIfferent

models

Varles

accordmg

to

the

dIfferent

struc

ture

Involved

The

following

procedures

gen

erally

apply

to

all

types

Important

dIfferences

are

noted

1

Prom

InsIde

the

vehicle

remove

the

floor

covenng

around

the

gear

shift

so

that

the

shIft

lever

can

be

removed

2

Jack

up

the

vehIcle

and

support

it

with

four

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Pressure

Spring

Free

length

Fitted

length

and

load

Out

of

rlght

angle

MInimum

sprmg

force

Clutch

Release

Lever

Release

bearlng

to

dlaphragm

clearance

Diaphragm

sprlng

to

flywheel

height

Release

lever

to

flywheel

height

Clutch

DISC

FaCing

size

Outer

dIameter

x

inSide

diameter

x

thlckness

Thickness

Free

Compressed

Number

of

tOrslO

1

springs

Minimum

depth

of

rivet

head

from

faCing

surface

Allowable

facmg

runout

Allowable

spline

free

play

Pressure

Plate

Allowable

refacmg

limit

Clutch

Pedal

Height

when

not

depressed

Free

stroke

of

pedal

head

Pressmg

strength

at

full

stroke

Clutch

Master

Cylinder

Diameter

MaXimum

clearance

between

cylinder

and

pIston

Tightening

Torque

Clutch

assembly

securing

bolt

2

059

In

52

3mm

1

149

In

197

4

4

Ib

29

2mm

44

2

kg

o

1968

per

3

937

In

5

per

100mm

15

00472

to

0

0551

In

1

2

to

1

4mm

1732

0

0394

m

44

O

1

Omm

1

988

0

0197

In

505

0

05mm

787

X

5

120

x

0

0140

In

200

x

130

x

3

5mm

o

3386

to

0

3543

m

8

6

to

9

Omm

03012

to

0

3130

m

765

to

7

95mm

6

00118

In

03mm

o

097

In

0

5mm

00157

m

04mm

o

0394

In

1

Omm

8

150

m

207mm

o

984

m

25mm

33

Ib

15

kg

0625

m

15

87mm

00051

m

0

13mm

J

i

r

174

to

188ft

Ib

24

to

2

6

kg

m

Page 144 of 252

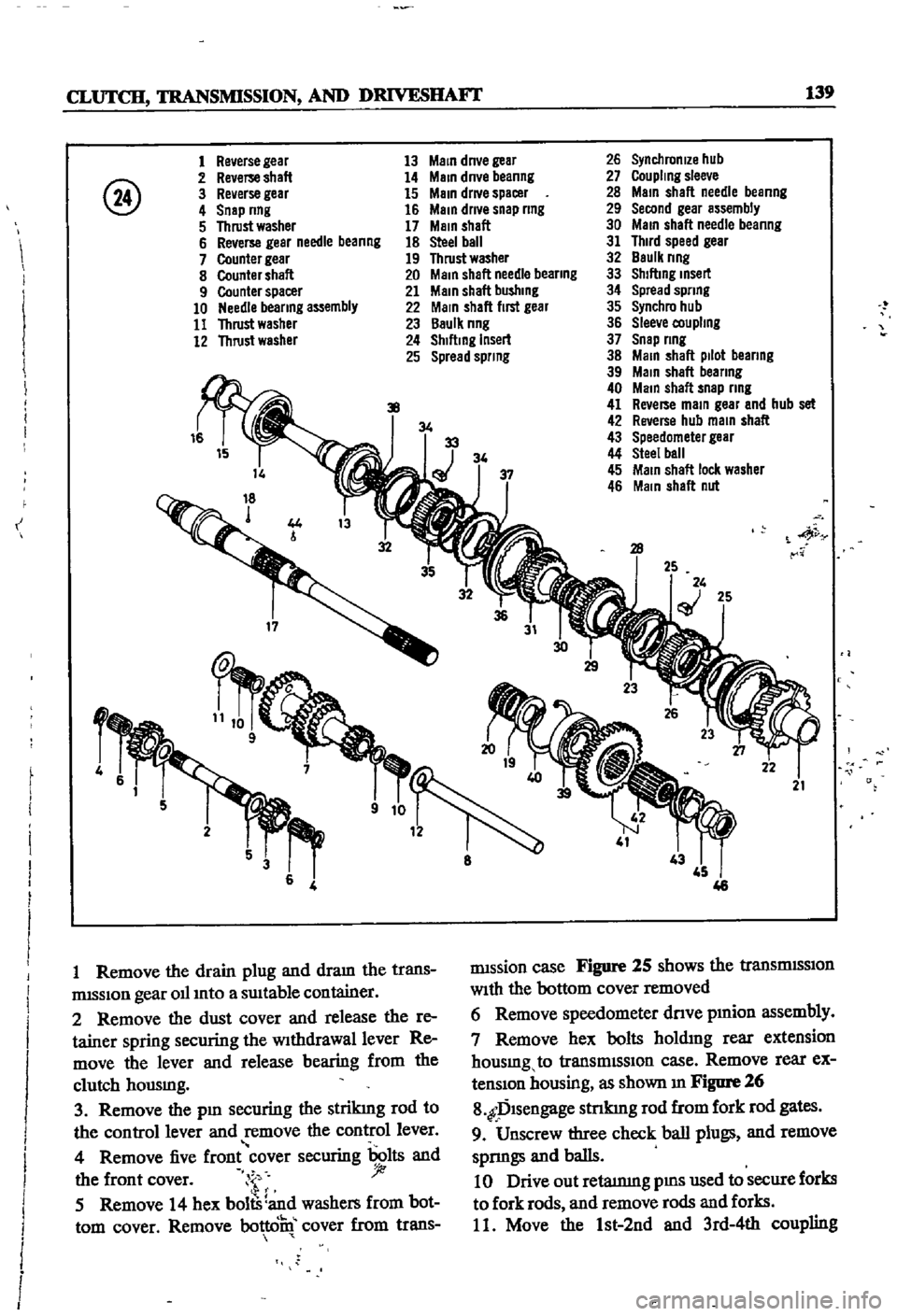

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

139

@

1

Re

erse

gear

2

Re

erse

shaft

3

Reverse

gear

4

Snep

nng

5

Thrust

washer

6

Reverse

gear

needle

beanng

7

Counter

gear

8

Counter

shaft

9

Counter

spacer

10

Needle

bearing

assembly

11

Thrust

washer

12

Thrust

washer

J

f

I

I

I

I

I

I

I

I

I

I

J

I

I

i

I

f

4

rm

9

13

MaIO

dnve

gear

14

MaIO

dn

e

beanng

15

MaIO

drl

e

spacer

16

MelO

drl

e

snap

ring

17

MaIO

shaft

18

steel

ball

19

Thrust

washer

20

MaIO

shaft

needle

bearing

21

Meln

shaft

bushlOg

22

MaIO

shaft

flm

gear

23

Baulk

nng

24

Sh

ftlOg

Insert

25

Spread

sprlOg

9

1

Remove

the

drain

plug

and

dram

the

trans

rmSSlon

gear

011

Into

a

SUItable

container

2

Remove

the

dust

cover

and

release

the

re

tainer

spring

securing

the

Withdrawal

lever

Re

move

the

lever

and

release

bearing

from

the

clutch

housmg

3

Remove

the

pIn

securing

the

strikmg

rod

to

the

control

lever

and

remove

the

control

lever

4

Remove

five

front

cover

securing

bolts

and

the

front

cover

i

j

5

Remove

14

hex

bolts

and

washers

from

bot

tom

cover

Remove

bottcifu

cover

from

trans

I

I

I

I

I

I

i

i

J

34

34

26

Synchronize

hub

27

CoupllOg

slee

e

28

MaIO

shaft

needle

beanng

29

Second

gear

assembly

30

MaIO

shaft

needle

beanng

31

Third

speed

gear

32

Baulk

nng

33

ShlftlOg

IOsert

34

Spread

spring

35

Synchro

hub

36

Slee

e

coupllOg

37

Snep

nng

38

MaIO

shaft

pilot

beanng

39

Main

shaft

bearing

40

MaIO

shaft

snap

ring

41

Re

erse

maIO

gear

and

hub

set

42

Rwerse

hub

maIO

shaft

43

Speedometer

gear

44

Steel

ball

45

MaIO

sheft

loc

l

washer

46

MaIO

shaft

nut

28

iy

25

25

21

rmssion

case

Figure

25

shows

the

tranSmISSIon

With

the

bottom

cover

removed

6

Remove

speedometer

dnve

pmion

assembly

7

Remove

hex

bolts

holdmg

rear

extension

housmg

to

transmISSIon

case

Remove

rear

ex

tenSIon

housing

as

shown

m

Figure

26

8

fDlsengage

stnkmg

rod

from

fork

rod

gates

9

Unscrew

three

check

ball

plugs

and

remove

sprmgs

and

balls

10

Drive

out

retatnmg

pms

used

to

secure

forks

to

fork

rods

and

remove

rods

and

forks

11

Move

the

1st

2nd

and

3rd

4th

coupling