torque DATSUN 510 1968 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 64 of 252

ENGINE

59

2

Coat

the

pan

gasket

on

both

sides

With

gasket

compound

and

attach

the

oil

pan

to

the

cyhnder

block

Torque

as

specIfied

Manifold

and

Carburetor

Installation

1

Install

the

mtake

and

exhaust

manIfolds

WIth

associated

gasket

to

the

cylmder

head

2

Mount

the

carburetor

and

gasket

to

the

mtake

manIfold

2

Adjust

all

mtake

and

exhaust

valves

to

the

specIfied

clearance

for

a

cold

engme

Clutch

Assembly

Installation

CAUTION

Take

extreme

care

not

to

get

grease

or

011

on

the

clutch

or

flywheel

frlc

hon

contact

surfaces

1

Place

the

clutch

disc

assembly

on

the

flywheel

With

the

longer

chamfered

splmed

end

of

the

dISC

toward

the

transmISSion

2

Visually

align

or

use

a

dummy

splmed

dnve

shaft

to

ahgn

the

diSC

assembly

With

the

flywheel

pilot

beanng

3

Install

and

tighten

the

SIX

bolts

holdmg

the

clutch

cover

assembly

to

the

flywheel

Tighten

the

bolts

a

turn

each

tune

by

diagonal

pattern

until

they

are

tight

Tlghtenmg

torque

should

be

174

to

188ft

lbs

24

to

2

6

kg

m

NOTE

There

are

two

dowels

on

the

flywheel

to

locate

the

clutch

cover

4

Remove

dummy

shaft

If

used

after

the

above

bolts

are

fully

tightened

5

Refit

the

release

bearing

and

translI11Ssion

case

Miscellaneous

Installation

1

Connect

the

fuel

hose

on

the

front

part

of

the

engme

to

the

fuel

pump

and

to

the

carburetor

2

Gap

the

spark

plugs

and

mstall

them

usmg

new

gaskets

3

Coat

the

rocker

arm

cover

gasket

With

sealer

and

position

It

on

the

cylmder

head

4

Install

the

rocker

arm

cover

and

tighten

the

two

thumb

screws

that

hold

it

m

place

5

Install

distrIbutor

makmg

certam

that

the

notch

on

the

distributor

shaft

assembly

mates

With

the

drive

spmdle

Ahgn

the

location

marks

made

dunng

disassembly

so

that

the

distrIbutor

is

positioned

as

before

6

Install

and

tighten

the

bolts

which

hold

the

dIStributor

to

the

front

cover

7

Install

pomts

condenser

and

rotor

8

Replace

distrIbutor

cap

and

attach

spark

plug

Wires

m

the

correct

sequence

Make

certain

that

all

wires

are

firmly

seated

m

the

distrIbutor

cap

and

attached

securely

to

the

spark

plugs

9

HOISt

the

engme

assembly

from

the

work

stand

10

Install

the

alternator

bracket

alternator

and

engme

mounts

to

the

block

11

Install

the

IgnItIon

coil

oil

filter

oil

pressure

SWitch

dipstick

and

water

drain

plug

12

Connect

the

vacuum

Ime

between

the

dis

trIbutor

and

carburetor

13

Connect

the

transIDlSSlOn

to

the

engine

prior

to

mstallatIon

m

the

vehicle

Engine

Installation

Installation

is

the

reverse

of

the

procedures

followed

m

removal

Be

certaIn

thatlall

battery

connections

are

made

that

water

hoses

are

se

cured

wmng

IS

connected

properly

and

that

all

required

bolts

and

mounts

are

mstalled

and

tightened

Replace

the

radiator

fan

belts

and

radiator

shroud

Fill

the

engme

With

the

proper

grade

of

oil

and

the

radiator

With

recommended

coolant

Install

the

hood

to

the

hInges

according

to

the

marks

made

dUrIng

removal

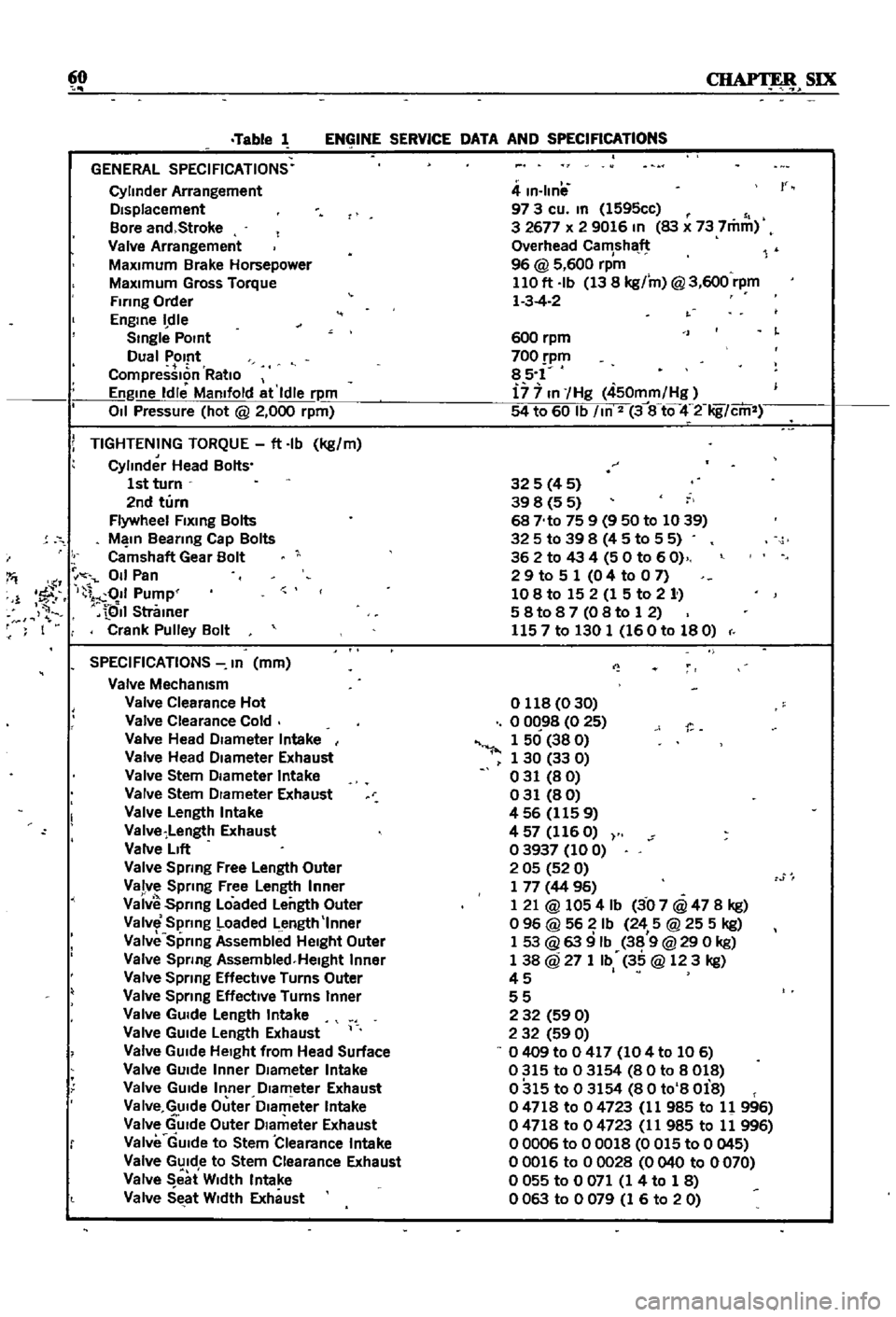

SERVICE

DATA

AND

SPECIFICATIONS

Table

1

covers

servIce

data

and

engme

Speci

fications

Page 65 of 252

60

SIX

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Cylinder

Arrangement

DIsplacement

Bore

and

Stroke

Valve

Arrangement

MaxImum

Brake

Horsepower

MaxImum

Gross

Torque

Firing

Order

Engme

dle

Smgle

POint

Dual

Pomt

CompressIon

RatIo

Engme

Idle

Mamfold

at

Idle

rpm

011

Pressure

hot

@

2

000

rpm

i

TIGHTENING

TORQUE

ft

Ib

kg

m

Cylinder

Head

Bolts

1st

turn

2nd

turn

Flywheel

Flxmg

Bolts

M

In

Beanng

Cap

Bolts

Camshaft

Gear

Bolt

I

011

Pan

1

1

fF

I

011

Pump

QII

Stramer

F

I

Crank

Pulley

Bolt

SPECIFICATIONS

In

mm

Valve

Mechamsm

Valve

Clearance

Hot

Valve

Clearance

Cold

Valve

Head

DIameter

Intake

Valve

Head

DIameter

Exhaust

Valve

Stem

DIameter

Intake

Valve

Stem

DIameter

Exhaust

Valve

Length

Intake

Valve

Length

Exhaust

Valve

LIft

Valve

Spring

Free

Length

Outer

Valve

Sprmg

Free

Length

Inner

Vaiv

Spnng

Loaded

Length

Outer

Valve

Spring

Loaded

Length

Inner

Valve

Sprmg

Assembllld

HeIght

Outer

Valve

Spnng

Assembled

Helght

Inner

Valve

Spnng

Effective

Turns

Outer

Valve

Sprmg

EffectIve

Turns

Inner

Valve

GUIde

Length

Intake

Valve

GUIde

Length

Exhaust

Valve

GUIde

HeIght

from

Head

Surface

Valve

GUIde

Inner

DIameter

Intake

Valve

GUIde

Inner

DIameter

Exhaust

Va

Ive

GUIde

Outer

Dlam

eter

Intake

Valve

GUIde

Outer

DIameter

Exhaust

Valve

GUIde

to

Stem

Clearance

Intake

Valve

GUIde

to

Stem

Clearance

Exhaust

Valve

eat

W

dth

Intake

Valve

SEtat

WIdth

Exhaust

4

m

Ilnil

97

3

cu

m

1595cc

3

2677

x

2

9016

In

83

x

73

7mm

Overhead

Camshaft

96

@

5

600

rpm

110

ft

Ib

13

8

kg

m

@

3

600

rpm

1

3

4

2

r

600

rpm

700

pm

85

1

i7

7

In

Hg

450mm

Hg

54

to

60

Ib

m

2

3

8

tQ

4

2

Iig

cm

325

4

5

39

8

5

5

68

No

75

9

9

50

to

1039

325

to

39

8

4

5

to

5

5

362

to

43

4

50

to

60

2

9

to

5

1

0

4

to

0

7

108

to

15

2

1

5

to

2

1

58t087

08to

12

1157

to

130

1

160

to

180

o

118

0

30

o

0C

98

0

25

1

50

38

0

1

30

33

0

031

80

031

80

456

1159

4

57

116

O

03937

100

2

05

52

0

1

77

44

96

1

21

@

1054

Ib

3

07

@

47

8

kg

o

96

@

56

Ib

24

5

@

25

5

kg

1

53

@

63

9

Ib

38

9

@

29

0

kg

1

38

@

27

1

Ib

35

@

123

kg

45

I

55

2

32

59

0

2

32

59

0

0409

to

0

417

104

to

106

0315

to

03154

80

to

8018

0315

to

03154

80

to

8

Oi8

04718

to

04723

11

985

to

11

996

04718

to

04723

11

985

to

11

996

00006

to

00018

0

015

to

0

045

00016

to

00028

0040

to

0070

o

055

to

0

071

1

4

to

1

8

0063

to

0079

1

6

to

20

Page 101 of 252

96

CHAFTER

NINE

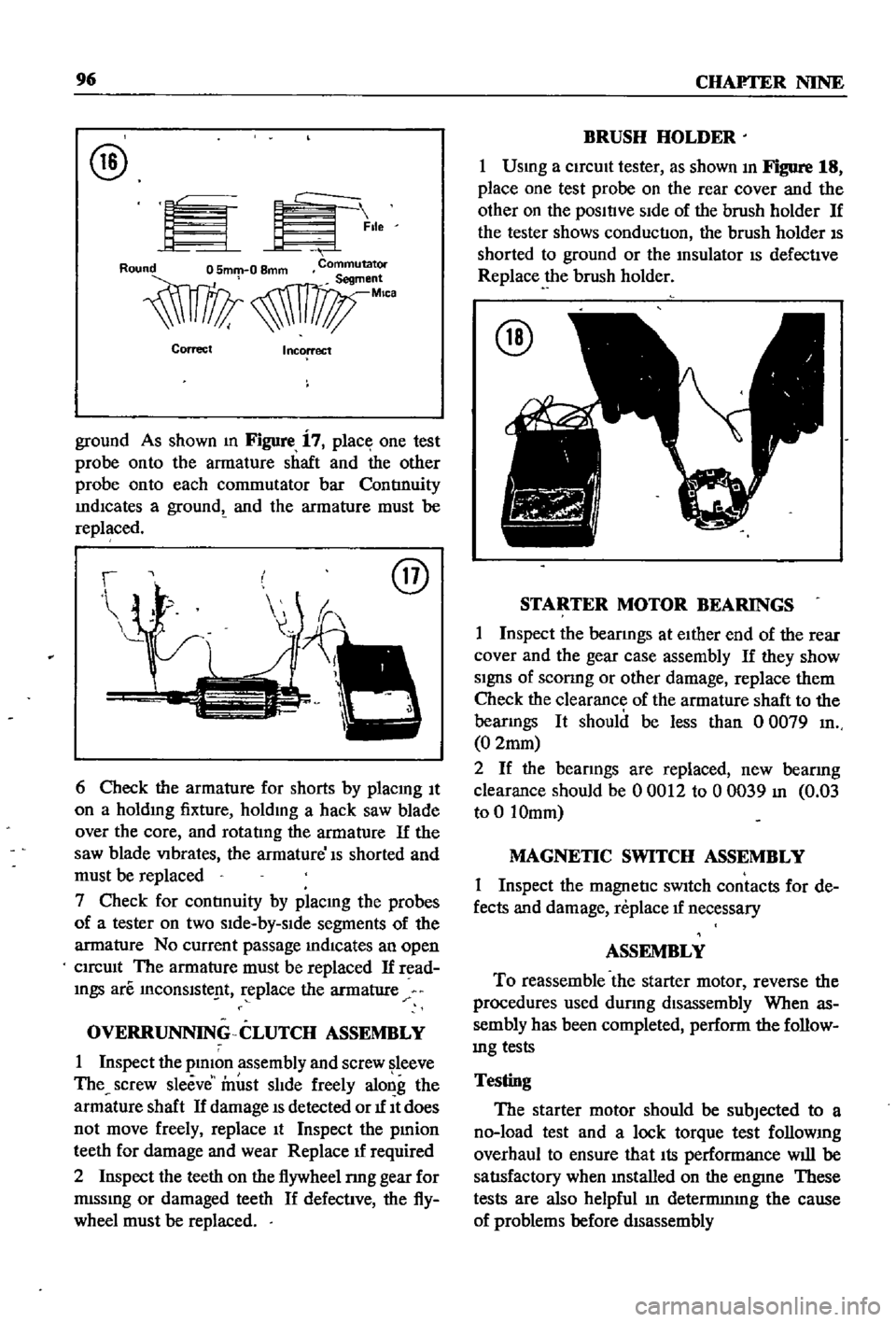

@

EK

lle

Correct

Incorrect

ground

As

shown

m

Figure

i

7

place

one

test

probe

onto

the

armature

shaft

and

the

other

probe

onto

each

commutator

bar

ContInuity

IndICates

a

groundt

and

the

armature

must

be

replaced

@

6

Check

the

armature

for

shorts

by

placmg

It

on

a

holdmg

fixture

holdmg

a

hack

saw

blade

over

the

core

and

rotatIng

the

armature

If

the

saw

blade

VIbrates

the

armature

Is

shorted

and

must

be

replaced

7

Check

for

contInuity

by

placmg

the

probes

of

a

tester

on

two

sIde

by

slde

segments

of

the

armature

No

current

passage

mdlcates

an

open

CIrcUIt

The

armature

must

be

replaced

If

read

mgs

are

InCOnslste

t

replace

the

armature

OVERRUNNING

CLUTCH

ASSEMBLY

1

Inspect

the

plmon

assembly

and

screw

leeve

The

screw

sleeve

must

slIde

freely

along

the

armature

shaft

If

damage

IS

detected

or

1f

It

does

not

move

freely

replace

It

Inspect

the

pmion

teeth

for

damage

and

wear

Replace

1f

required

2

Inspect

the

teeth

on

the

flywheel

nng

gear

for

mlssmg

or

damaged

teeth

If

defective

the

fly

wheel

must

be

replaced

BRUSH

HOLDER

1

Usmg

a

CirCUIt

tester

as

shown

In

Figure

18

place

one

test

probe

on

the

rear

cover

and

the

other

on

the

posltlve

SIde

of

the

brush

holder

If

the

tester

shows

conduction

the

brush

holder

IS

shorted

to

ground

or

the

msulator

IS

defective

Replace

the

brush

holder

@

STARTER

MOTOR

BEARINGS

1

Inspect

the

bearmgs

at

eIther

end

of

the

rear

cover

and

the

gear

case

assembly

If

they

show

SignS

of

sconng

or

other

damage

replace

them

Check

the

clearance

of

the

armature

shaft

to

the

bearmgs

It

should

be

less

than

0

0079

In

0

2mm

2

If

the

bearings

are

replaced

new

bearing

clearance

should

be

00012

to

00039

In

0

03

to

0

10mm

MAGNETIC

SWITCH

ASSEMBLY

1

Inspect

the

magnetic

sWItch

contacts

for

de

fects

and

damage

replace

1f

necessary

ASSEMBLY

To

reassemble

the

starter

motor

reverse

the

procedures

used

dUring

disassembly

When

as

sembly

has

been

completed

perform

the

follow

mg

tests

Testing

The

starter

motor

should

be

subjected

to

a

no

load

test

and

a

lock

torque

test

follOWIng

overhaul

to

ensure

that

Its

performance

will

be

satIsfactory

when

mstalled

on

the

engme

These

tests

are

also

helpful

In

detennmIng

the

cause

of

problems

before

dIsassembly

Page 102 of 252

ENGINE

ELECI

RlCAL

SYSTEM

97

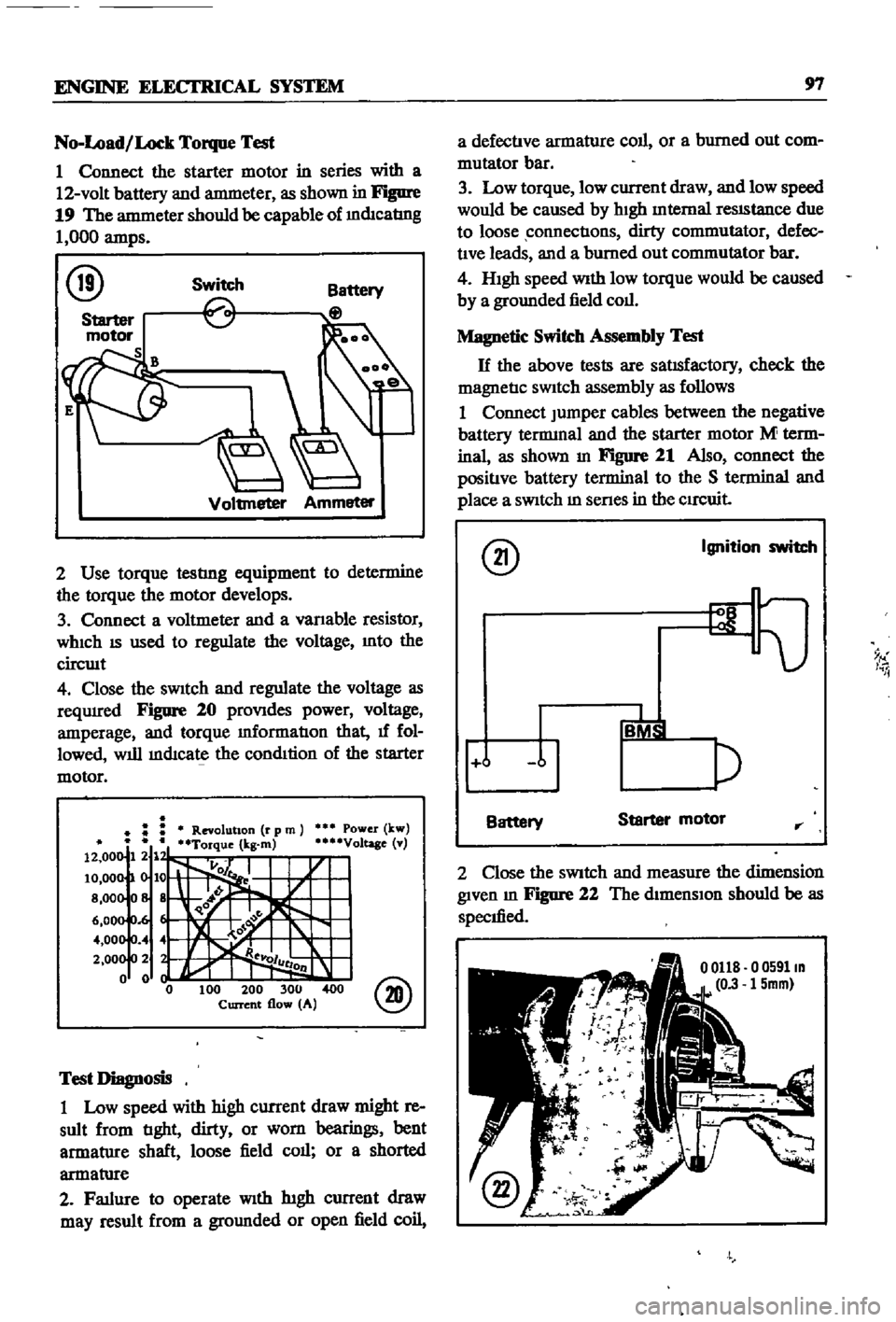

No

Load

Lock

Torque

Test

1

Connect

the

starter

motor

in

series

with

a

12

volt

battery

and

antmeter

as

shown

in

Figure

19

The

antmeter

should

be

capable

of

mdIcatIng

1

000

amps

@

Switch

Voltmeter

Ammeter

2

Use

torque

testlng

equipment

to

determine

the

torque

the

motor

develops

3

Connect

a

voltmeter

and

a

vanable

resistor

WhICh

IS

used

to

regulate

the

voltage

Into

the

circwt

4

Close

the

sWitch

and

regulate

the

voltage

as

reqUIred

Figure

20

proVIdes

power

voltage

amperage

and

torque

mformatIon

that

1f

fol

lowed

will

mdIcate

the

condItion

of

the

starter

motor

Power

kw

Voltage

v

@

Test

Diagnosis

1

Low

speed

with

high

current

draw

might

re

sult

from

tIght

dirty

or

worn

bearings

bent

armatlIre

shaft

loose

field

call

or

a

shorted

armatlIre

2

Fatlure

to

operate

With

htgh

current

draw

may

result

from

a

gromlded

or

open

field

coil

a

defectIve

armature

coll

or

a

burned

out

com

mutator

bar

3

Low

torque

low

current

draw

and

low

speed

would

be

caused

by

hIgh

Internal

reSIStance

due

to

loose

connectIons

dirty

commutator

defec

tIve

leads

and

a

burned

out

commutator

bar

4

HIgh

speed

With

low

torque

would

be

caused

by

a

grounded

field

coll

Magnetic

Switch

Assembly

Test

H

the

above

tests

are

satIsfactory

check

the

magnetIc

SWitch

assembly

as

follows

1

Connect

Jumper

cables

between

the

negative

battery

tennmal

and

the

starter

motor

M

term

inal

as

shown

In

Figure

21

Also

connect

the

positIve

battery

terminal

to

the

S

terminal

and

place

a

SWitch

m

senes

in

the

CIrCuit

@

Ignition

switch

9

I

i

j

Battery

Starter

motor

rr

2

Close

the

SWitch

and

measure

the

dimension

given

m

Figure

22

The

dimensIon

should

be

as

specIfied

o

0591m

15mm

Page 134 of 252

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

129

scratches

on

the

pressure

plate

may

be

removed

with

crocus

cloth

If

the

source

of

clutch

trouble

IS

still

not

evl

dent

take

the

pressure

plate

and

disc

to

a

compe

tent

garage

to

check

the

pressure

plate

finger

release

height

and

nmout

Never

attempt

to

ad

just

the

fingers

or

dismantle

the

pressure

plate

Without

proper

tools

and

experience

Check

the

release

bearing

by

holdmg

the

Inner

race

and

rotatmg

the

outer

race

With

hght

pres

sure

applied

If

the

bearing

is

rough

or

noisy

replace

it

CAUTION

Never

clean

the

release

bearing

In

solvent

It

IS

prelubriCflted

at

the

fac

tory

Simply

wipe

with

a

Unt

free

cloth

If

the

release

bearing

shows

any

signs

of

loss

of

lubncant

install

a

new

bearing

Replace

the

sleev

lu

SignS

of

wear

are

evident

Clutch

Reassembly

1

Be

sure

your

hands

are

clean

for

the

initIal

assembly

2

Inspect

the

clutch

facings

pressure

plate

and

flywheel

to

be

sure

they

are

free

from

grease

oil

and

other

foreIgn

material

3

TIghtly

fit

release

bearmg

onto

the

bearing

sleeve

When

beanng

IS

mstalled

turn

bearmg

With

a

finger

to

make

sure

It

operates

smoothly

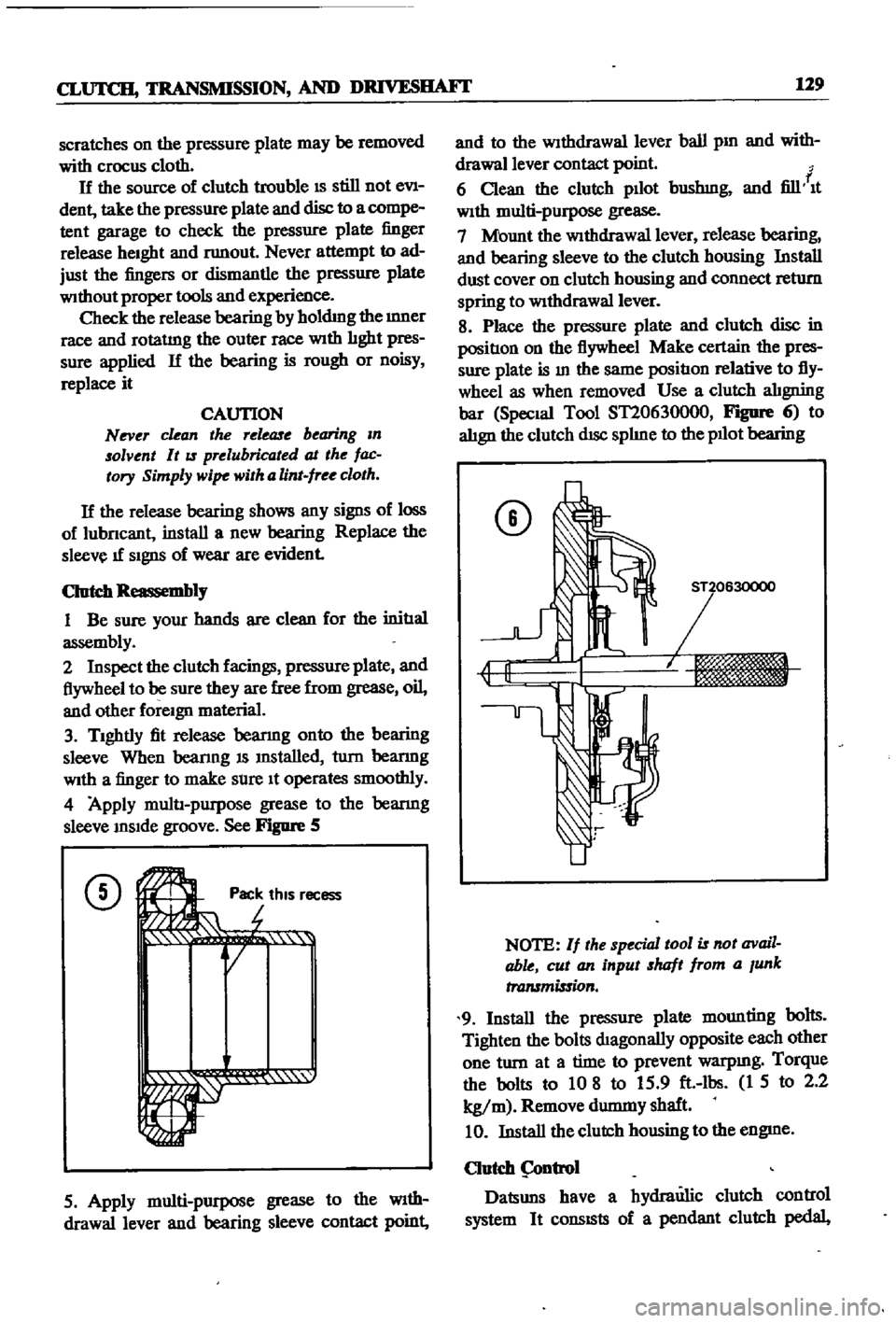

4

Apply

multI

purpose

grease

to

the

bearmg

sleeve

InSIde

groove

See

Figure

5

CD

Ji

rot

Pac

thiS

r

r

r

1

1i

QI

ecess

5

Apply

multi

purpose

grease

to

the

WIth

drawallever

and

bearing

sleeve

contact

point

and

to

the

Withdrawal

lever

ball

pm

and

with

drawallever

contact

point

f

6

Clean

the

clutch

pllot

bushmg

and

fill

It

With

multi

purpose

grease

7

Mount

the

WithdraWal

lever

release

bearing

and

bearing

sleeve

to

the

clutch

housing

Install

dust

cover

on

clutch

housing

and

connect

return

spring

to

WithdraWal

lever

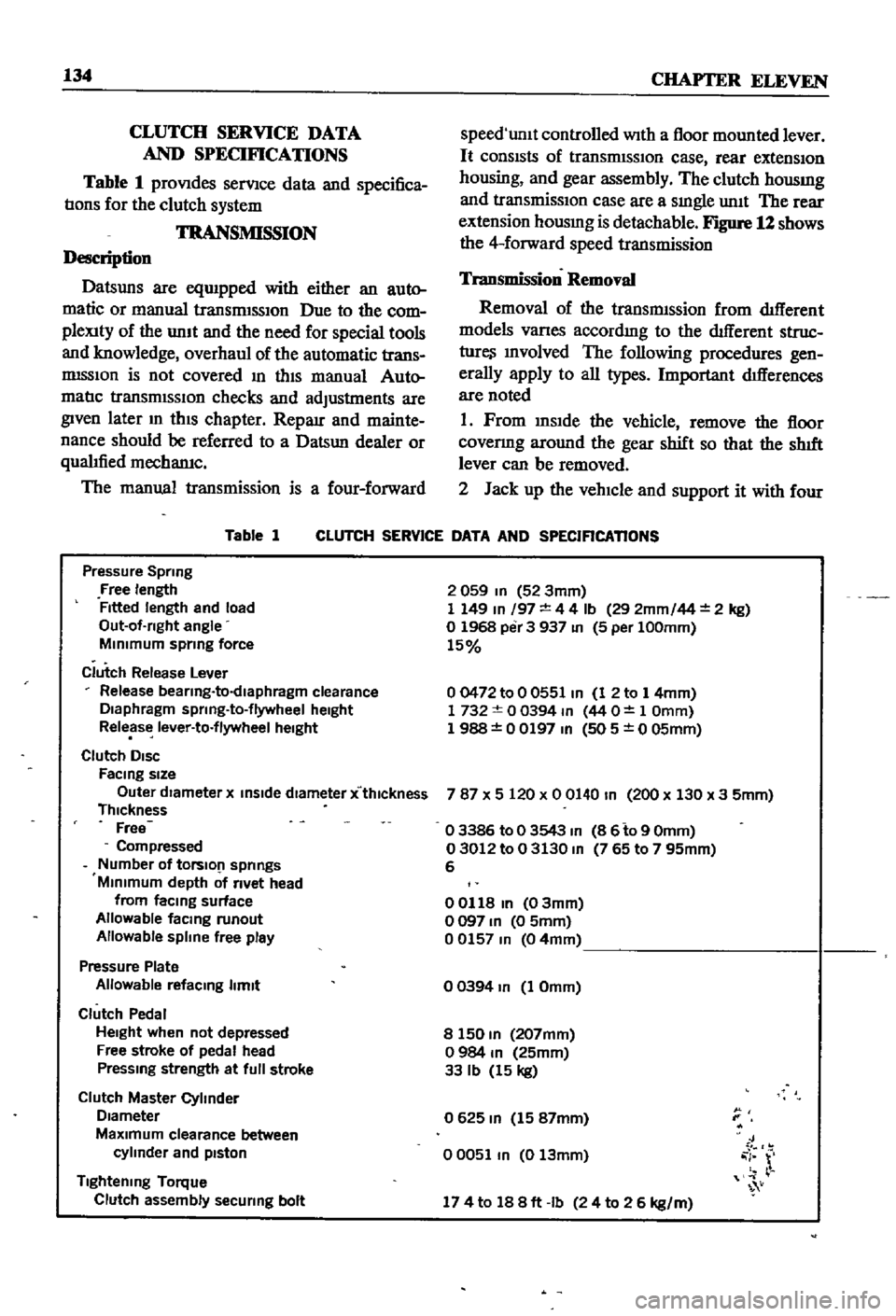

8

Place

the

pressure

plate

and

clutch

disc

in

positIon

on

the

flywheel

Make

certain

the

pres

sure

plate

is

In

the

same

positIon

relative

to

fly

wheel

as

when

removed

Use

a

clutch

alIgning

bar

Special

Tool

ST20630000

FIgDfe

6

to

alIgn

the

clutch

dISc

splIne

to

the

pllot

bearing

CD

NOTE

If

the

special

tool

is

not

avail

able

cut

an

input

shaft

from

a

Junk

transmission

9

Install

the

pressure

plate

mounting

bolts

Tighten

the

bolts

dIagonally

opposite

each

other

one

turn

at

a

time

to

prevent

warpmg

Torque

the

bolts

to

10

8

to

15

9

ft

lbs

1

5

to

2

2

kg

m

Remove

durmny

shaft

10

Install

the

clutch

housing

to

the

engme

Clutch

ntrol

Datsuns

have

a

hydraulic

clutch

control

system

It

consISts

of

a

pendant

clutch

pedal

Page 139 of 252

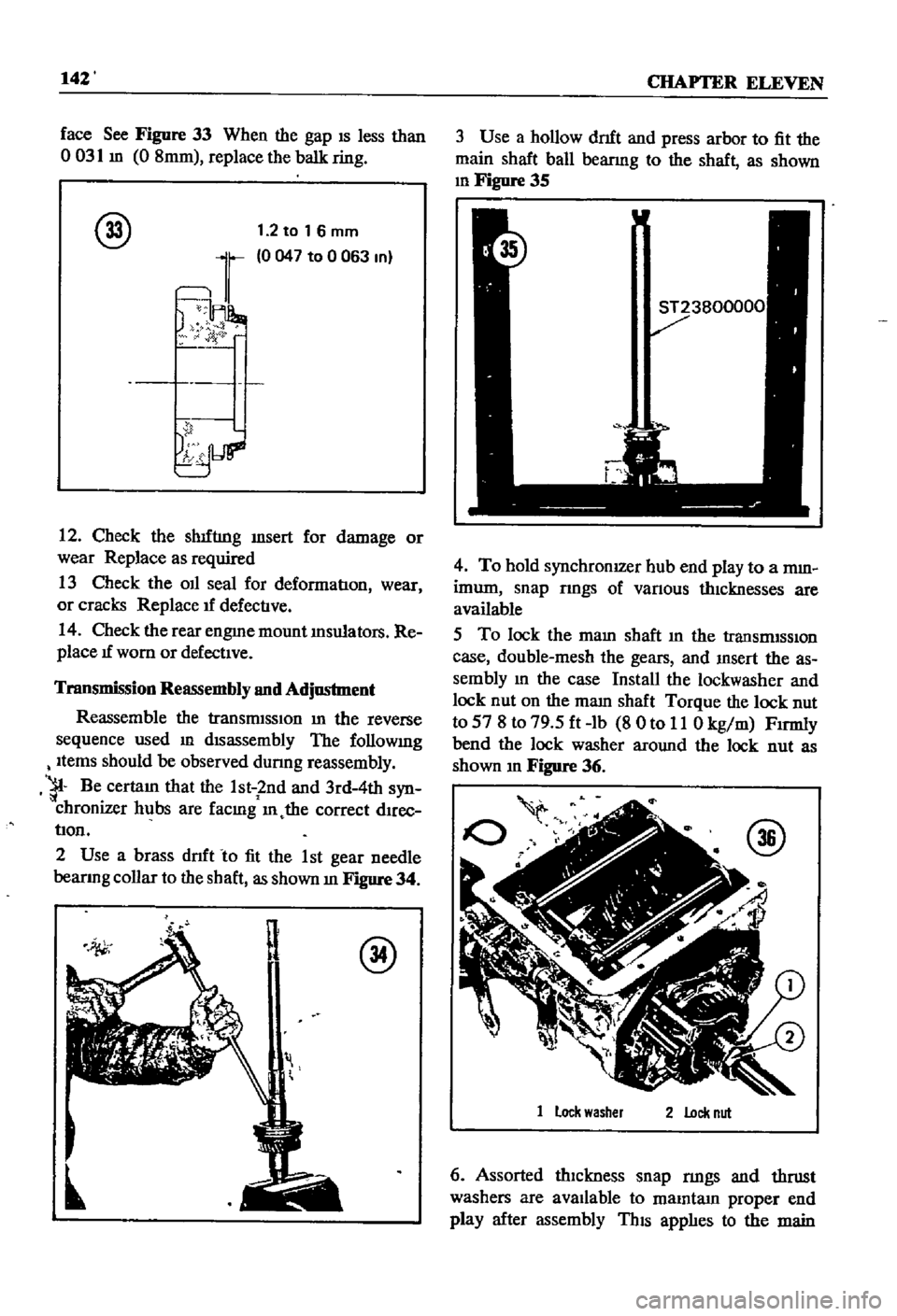

134

CHAPTER

ELEVEN

CLUTCH

SERVICE

DATA

AND

SPECIF1CATIONS

Table

1

proVIdes

serVIce

data

and

specifica

tIons

for

the

clutch

system

TRANSMISSION

Description

Datsuns

are

eqUIpped

with

either

an

auto

matic

or

manual

transrmSSIOn

Due

to

the

com

pleXity

of

the

unIt

and

the

need

for

special

tools

and

knowledge

overhaul

of

the

automatic

trans

mISSIon

is

not

covered

In

thIS

manual

Auto

matIc

transmISSIOn

checks

and

adjustments

are

given

later

m

thIS

chapter

Reparr

and

mainte

nance

should

be

referred

to

a

Datsun

dealer

or

qualIfied

mechamc

The

manual

transmission

is

a

four

forward

Table

1

speed

unlt

controlled

With

a

floor

mounted

lever

It

consIsts

of

transrmSSIOn

case

rear

extensIOn

housing

and

gear

assembly

The

clutch

housmg

and

transmissIOn

case

are

a

sIngle

unIt

The

rear

extension

housmg

is

detachable

Figure

12

shows

the

4

forward

speed

transmission

Transmission

Removal

Removal

of

the

transmIssion

from

dIfferent

models

Varles

accordmg

to

the

dIfferent

struc

ture

Involved

The

following

procedures

gen

erally

apply

to

all

types

Important

dIfferences

are

noted

1

Prom

InsIde

the

vehicle

remove

the

floor

covenng

around

the

gear

shift

so

that

the

shIft

lever

can

be

removed

2

Jack

up

the

vehIcle

and

support

it

with

four

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Pressure

Spring

Free

length

Fitted

length

and

load

Out

of

rlght

angle

MInimum

sprmg

force

Clutch

Release

Lever

Release

bearlng

to

dlaphragm

clearance

Diaphragm

sprlng

to

flywheel

height

Release

lever

to

flywheel

height

Clutch

DISC

FaCing

size

Outer

dIameter

x

inSide

diameter

x

thlckness

Thickness

Free

Compressed

Number

of

tOrslO

1

springs

Minimum

depth

of

rivet

head

from

faCing

surface

Allowable

facmg

runout

Allowable

spline

free

play

Pressure

Plate

Allowable

refacmg

limit

Clutch

Pedal

Height

when

not

depressed

Free

stroke

of

pedal

head

Pressmg

strength

at

full

stroke

Clutch

Master

Cylinder

Diameter

MaXimum

clearance

between

cylinder

and

pIston

Tightening

Torque

Clutch

assembly

securing

bolt

2

059

In

52

3mm

1

149

In

197

4

4

Ib

29

2mm

44

2

kg

o

1968

per

3

937

In

5

per

100mm

15

00472

to

0

0551

In

1

2

to

1

4mm

1732

0

0394

m

44

O

1

Omm

1

988

0

0197

In

505

0

05mm

787

X

5

120

x

0

0140

In

200

x

130

x

3

5mm

o

3386

to

0

3543

m

8

6

to

9

Omm

03012

to

0

3130

m

765

to

7

95mm

6

00118

In

03mm

o

097

In

0

5mm

00157

m

04mm

o

0394

In

1

Omm

8

150

m

207mm

o

984

m

25mm

33

Ib

15

kg

0625

m

15

87mm

00051

m

0

13mm

J

i

r

174

to

188ft

Ib

24

to

2

6

kg

m

Page 147 of 252

142

CHAPTER

ELEVEN

face

See

Figure

33

When

the

gap

IS

less

than

o

031

m

0

8mm

replace

the

balk

ring

@

1

2

to

1

6

mm

0047

to

0

063

In

12

Check

the

sh1fnng

msert

for

damage

or

wear

Replace

as

required

13

Check

the

OIl

seal

for

deformatIon

wear

or

cracks

Replace

1f

defectIve

14

Check

the

rear

engme

mount

Insulators

Re

place

1f

worn

or

defectIve

Transmission

Reassembly

and

Adjustment

Reassemble

the

transmISSIon

In

the

reverse

sequence

used

ill

dIsassembly

The

followmg

Items

should

be

observed

dunng

reassembly

1

Be

certaIn

that

the

1st

2nd

and

3rd

4th

syn

chronizer

hubs

are

facmg

ill

the

correct

dIrec

tIon

2

Use

a

brass

dnft

to

fit

the

1

st

gear

needle

bearlOg

collar

to

the

shaft

as

shown

In

Figure

34

il

@

3

Use

a

hollow

dnft

and

press

arbor

to

fit

the

main

shaft

ball

bearmg

to

the

shaft

as

shown

10

Figure

35

4

To

hold

synchronIZer

hub

end

play

to

a

mm

imum

snap

rmgs

of

vanous

thIcknesses

are

available

5

To

lock

the

malO

shaft

m

the

transrmSSlOn

case

double

mesh

the

gears

and

msert

the

as

sembly

10

the

case

Install

the

lockwasher

and

lock

nut

on

the

mam

shaft

Torque

the

lock

nut

to

57

8

to

79

5

ft

lb

8

0

to

11

0

kg

m

Fumly

bend

the

lock

washer

around

the

lock

nut

as

shown

In

Figure

36

1

lock

washer

2

Lock

nut

6

Assorted

thIckness

snap

nngs

and

thrust

washers

are

avallable

to

malOtam

proper

end

play

after

assembly

ThIS

applIes

to

the

main

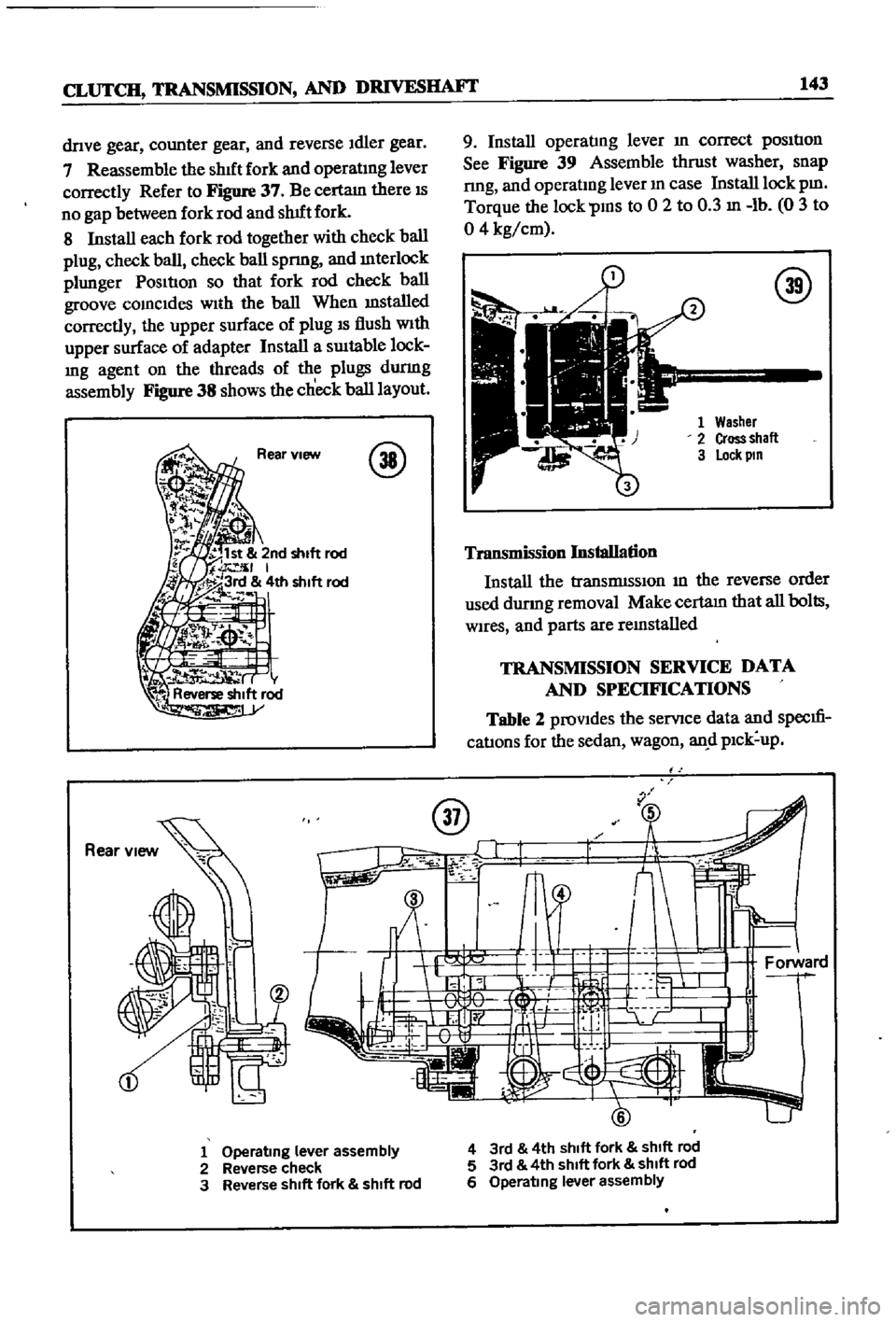

Page 148 of 252

CLUTCH

TRANSMISSION

AND

DRlVESHAFI

143

dnve

gear

counter

gear

and

reverse

Idler

gear

7

Reassemble

the

shIft

fork

and

operatIng

lever

correctly

Refer

to

Figure

37

Be

certam

there

IS

no

gap

between

fork

rod

and

shUt

fork

8

Install

each

fork

rod

together

with

check

ball

plug

check

ball

check

ball

spnng

and

mterlock

plunger

PosItIon

so

that

fork

rod

check

ball

groove

comcldes

wIth

the

ball

When

mstalled

correctly

the

upper

surface

of

plug

IS

flush

With

upper

surface

of

adapter

Install

a

sUItable

lock

Ing

agent

on

the

threads

of

the

plugs

durmg

assembly

Figure

38

shows

the

check

ball

layout

@

9

Install

operatIng

lever

In

correct

pOSItIon

See

Figure

39

Assemble

thrust

washer

snap

nng

and

operatlDg

lever

m

case

Install

lock

pm

Torque

the

lock

PIDS

to

0

2

to

0

3

In

lb

0

3

to

04

kg

cm

@

Washer

Cross

shall

lock

pm

Transmission

Installation

Install

the

tranSmISSIon

m

the

reverse

order

used

durmg

removal

Make

certam

that

all

bolts

Wires

and

parts

are

remstalled

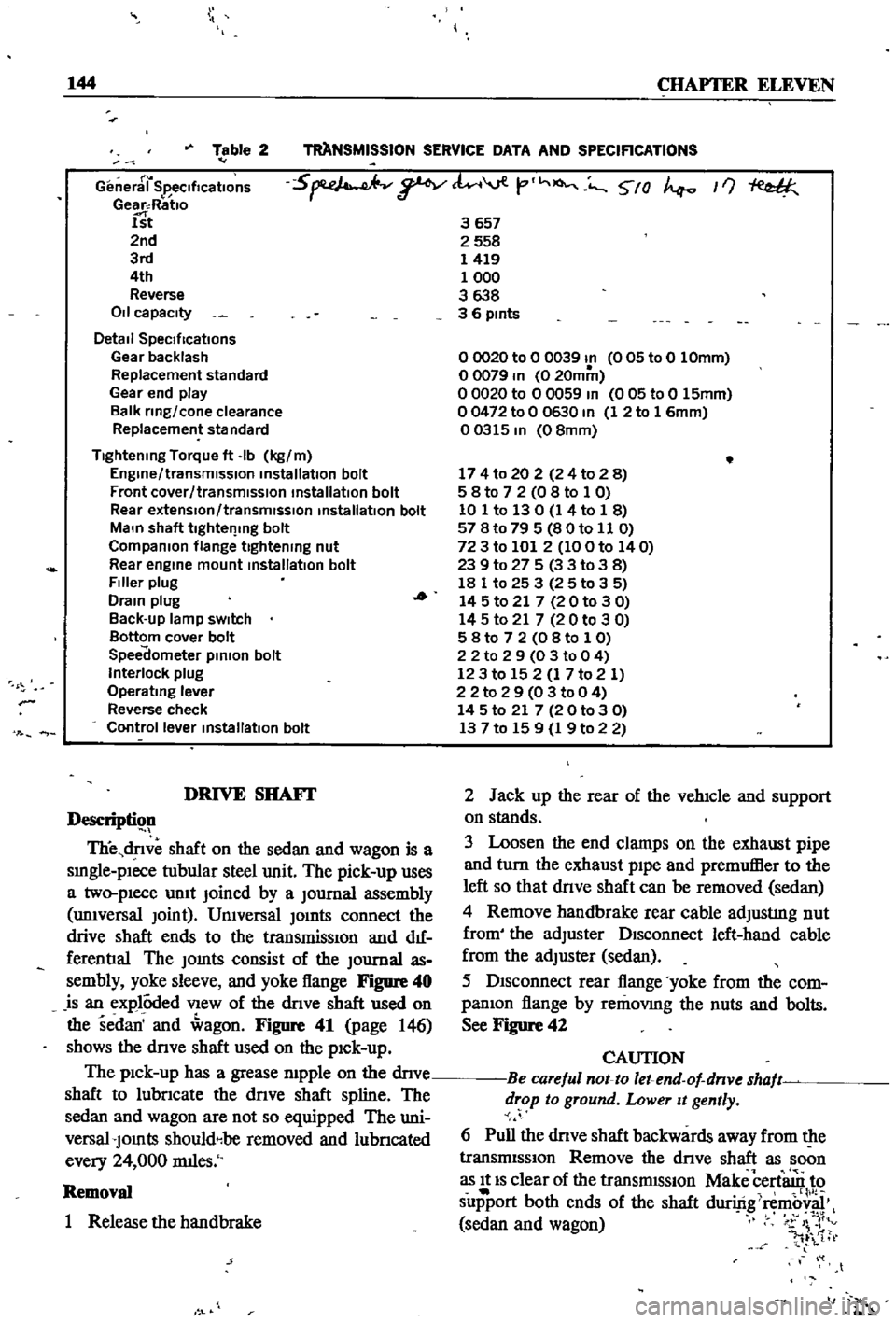

TRANSMISSION

SERVICE

DATA

AND

SPECIFICATIONS

Table

2

proVIdes

the

servlce

data

and

specm

catIons

for

the

sedan

wagon

an

d

pIck

up

u

1

Operating

lever

assembly

2

Reverse

check

3

Reverse

shift

fork

shift

rod

4

3rd

4th

shift

fork

shift

rod

5

3rd

4th

shIft

fork

shift

rod

6

Operating

lever

assembly

Page 149 of 252

144

CHAPTER

ELEVEN

TAANSMISSlON

SERVICE

DATA

AND

SPECIRCATIONS

Table

2

r

General

SpecificatIOns

Gear

Ratlo

1st

2nd

3rd

4th

Reverse

011

capacity

Detail

SpeCIfications

Gear

backlash

Replacement

standard

Gear

end

play

Balk

ring

cone

clearance

Replacement

standard

5

tl

viV

t

O

5

0

If

3657

2558

1419

1000

3638

3

6

pints

Tightening

Torque

ft

Ib

kg

m

Engine

transmission

installation

bolt

Front

cover

transmission

installation

bolt

Rear

extensIon

transmIssion

installation

bolt

Main

shaft

tlghtel

lng

bolt

Companion

flange

tightening

nut

Rear

engine

mount

installation

bolt

Filler

plug

Drain

plug

Back

up

lamp

sWItch

Bottom

cover

bolt

Speedometer

pinion

bolt

Interlock

plug

Operating

lever

Reverse

check

Control

lever

installatIOn

bolt

00020

to

0

0039

In

005

to

0

10mm

o

0079

In

0

20mm

o

0020

to

0

0059

In

0

05

to

0

15mm

00472

to

0

0630

In

1

2

to

1

6mm

00315

In

08mm

174

to

20

2

24

to

2

8

5

8

to

7

2

0

8

to

1

0

10

1

to

130

1

4

to

1

8

57

8t079

5

80to

11

0

72

3

to

101

2

100

to

140

239

to

27

5

3

3

to

38

18

1

to

25

3

25

to

3

5

14

5

to

21

7

20

to

3

0

14

5

to

21

7

2

0

to

3

0

5

8

to

7

2

0

8

to

1

0

2

2

to

2

9

03

to

0

4

123

to

15

2

1

7

to

2

1

22

to

2

9

0

3

to

0

4

14

5

to

21

7

20

to

3

0

13

7

to

15

9

1

9

to

2

2

DRIVE

SHAFf

Descripti

ll

TIie

dnve

shaft

on

the

sedan

and

wagon

is

a

smgle

plece

tubular

steel

unit

The

pick

up

uses

a

two

pIece

umt

Joined

by

a

Journal

assembly

unIversal

Joint

UnIversal

Jomts

connect

the

drive

shaft

ends

to

the

transmissIOn

and

d1f

ferentIal

The

Jomts

consist

of

the

Journal

as

sembly

yoke

sleeve

and

yoke

flange

Figure

40

is

an

explOded

VIew

of

the

dnve

shaft

used

on

the

sedan

and

agon

Figure

41

page

146

shows

the

dnve

shaft

used

on

the

pIck

up

The

pIck

up

has

a

grease

mpple

on

the

dnve

shaft

to

lubncate

the

dnve

shaft

spline

The

sedan

and

wagon

are

not

so

equipped

The

uni

versal

Jomts

shouldebe

removed

and

lubncated

every

24

000

rmles

Removal

1

Release

the

handbrake

j

2

Jack

up

the

rear

of

the

vehIcle

and

support

on

stands

3

Loosen

the

end

clamps

on

the

exhaust

pipe

and

turn

the

exhaust

pIpe

and

premuffier

to

the

left

so

that

dnve

shaft

can

be

removed

sedan

4

Remove

handbrake

rear

cable

adjustIng

nut

from

the

adjuster

DIsconnect

left

hand

cable

from

the

adjuster

sedan

5

DIsconnect

rear

flange

yoke

from

the

com

panIon

flange

by

removmg

the

nuts

and

bolts

See

Figure

42

CAUTION

Be

careful

not

to

let

end

of

dnve

shaft

drop

to

ground

Lower

It

gently

6

Pull

the

dnve

shaft

backwards

away

from

the

transmISSIon

Remove

the

dnve

shaft

as

soon

as

It

IS

clear

of

the

transmISSIon

Make

cert

n

to

support

both

ends

of

the

shaft

duriftgi

mb

sedan

and

wagon

v

4

1tr

l

t

t

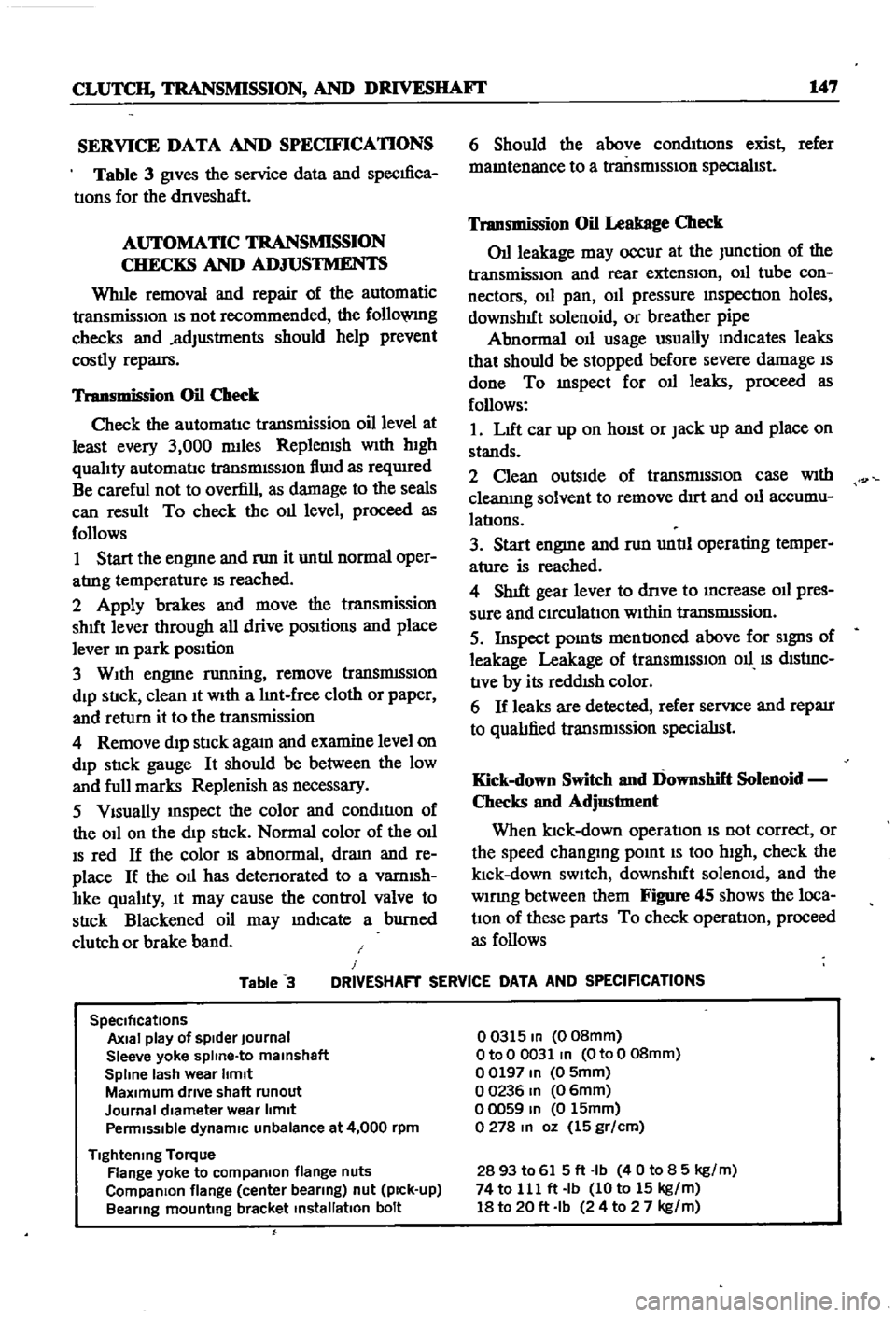

Page 152 of 252

CLUTCH

TRANSMISSION

AND

DRIVESHAFI

147

SERVICE

DATA

AND

SPECIFICATIONS

Table

3

gives

the

service

data

and

specIfica

tIons

for

the

dnveshaft

AUTOMATIC

TRANSMISSION

CHECKS

AND

ADJUSTMENTS

Whlle

removal

and

repair

of

the

automatic

transmisSIOn

IS

not

recommended

the

follo

VlIlg

checks

and

adjustments

should

help

prevent

costly

repatrs

Transmission

Oil

Check

Check

the

automatIc

transmission

oil

level

at

least

every

3

000

mlles

Replemsh

With

hIgh

qualIty

automatIc

transmISSIon

flUId

as

reqUIred

Be

careful

not

to

overfill

as

damage

to

the

seals

can

result

To

check

the

011

level

proceed

as

follows

1

Start

the

engme

and

nm

it

untIl

normal

oper

atrng

temperature

IS

reached

2

Apply

brakes

and

move

the

transmission

shut

lever

through

all

drive

pOSItions

and

place

lever

In

park

position

3

WIth

engme

running

remove

tranSmISSIon

dIp

StIck

clean

It

WIth

a

lInt

free

cloth

or

paper

and

return

it

to

the

transmission

4

Remove

dIp

stIck

agam

and

examine

level

on

dIp

stIck

gauge

It

should

be

between

the

low

and

full

marks

Replenish

as

necessary

5

VIsually

InSpect

the

color

and

condItIon

of

the

OIl

on

the

dIp

stIck

Normal

color

of

the

OIl

IS

red

If

the

color

IS

abnormal

dram

and

re

place

If

the

011

has

detenorated

to

a

vamlsh

lIke

qualIty

It

may

cause

the

control

valve

to

stIck

Blackened

oil

may

mdlcate

a

burned

clutch

or

brake

band

6

Should

the

above

condItIons

exist

refer

mamtenance

to

a

transmISSIon

specIalIst

Transmission

Oil

Leakage

Check

011

leakage

may

occur

at

the

Junction

of

the

transmissIon

and

rear

extensIon

011

tube

con

nectors

011

pan

OIl

pressure

mspectIon

holes

downshIft

solenoid

or

breather

pipe

Abnormal

OIl

usage

usually

mdlcates

leaks

that

should

be

stopped

before

severe

damage

IS

done

To

mspect

for

011

leaks

proceed

as

follows

1

LIft

car

up

on

hOISt

or

Jack

up

and

place

on

stands

2

Clean

outsIde

of

transmISSIon

case

With

cleanIng

solvent

to

remove

dIrt

and

011

accumu

latIons

3

Start

engme

and

nm

untIl

operating

temper

ature

is

reached

4

ShIft

gear

lever

to

dnve

to

Increase

011

pres

sure

and

CIrculatIon

WIthin

tranSmISsion

5

Inspect

pOInts

mentIoned

above

for

SIgnS

of

leakage

Leakage

of

transrmSSIOn

011

IS

dIStrnC

tIve

by

its

reddISh

color

6

If

leaks

are

detected

refer

servIce

and

reparr

to

qualIfied

transrmssion

specialISt

Kick

down

Switch

and

Downshift

Solenoid

Checks

and

Adjustment

When

ktck

down

operatIon

IS

not

correct

or

the

speed

changmg

pomt

IS

too

high

check

the

klck

down

SWItch

downshIft

solenOId

and

the

wlDng

between

them

Figure

45

shows

the

loca

tIOn

of

these

parts

To

check

operatIon

proceed

as

follows

Table

3

J

DRIVESHAFT

SERVICE

DATA

AND

SPECIFICATIONS

SpeCifications

Axial

play

of

spider

Journal

Sleeve

yoke

spltne

to

malnshaft

Spline

lash

wear

Itmlt

MaXimum

drive

shaft

runout

Journal

diameter

wear

limit

Penmlsslble

dynamiC

unbalance

at

4

000

rpm

Tightening

Torque

Flange

yoke

to

compaRlon

flange

nuts

CompaRlon

flange

center

bearing

nut

pick

up

Bearing

mounting

bracket

installation

bolt

00315

In

008mm

OtoO

0031

In

OtoO

08mm

00197

In

0

5mm

00236

In

06mm

00059

In

0

15mm

0278

In

oz

15

gr

cm

2893

to

615ft

Ib

40

to

8

5

kg

m

74

to

111

ft

Ib

10

to

15

kg

m

18

to

20

ft

Ib

24

to

2

7

kg

m