check engine DATSUN 510 1968 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 59 of 252

54

CHAP1ER

SIX

2

Set

the

valve

spnng

seat

m

position

on

the

top

of

the

block

and

over

the

valve

stem

3

Place

the

oil

seal

over

the

valve

stem

4

Place

the

mner

and

outer

valve

spnngs

over

the

valve

stem

S

Place

the

spnng

retamer

over

the

springs

compress

spnngs

With

spring

compressor

Figure

55

and

mstall

valve

collets

around

valve

stem

so

that

they

lock

onto

stem

6

Release

spnng

compressor

If

collets

are

firm

ly

locked

onto

the

groove

m

the

valve

stem

assembly

IS

complete

7

Install

the

rocker

guIde

on

top

of

the

valve

stem

when

assemblmg

the

rocker

pivot

assembly

VaIve

Rocker

Pivot

Assembly

1

Thread

lock

nut

onto

valve

rocker

pivOt

and

place

rocker

retaIner

over

the

valve

rocker

pivOt

2

Thread

the

above

assembly

mto

the

rocker

bushIng

protrudIng

from

the

head

Camshaft

Assembly

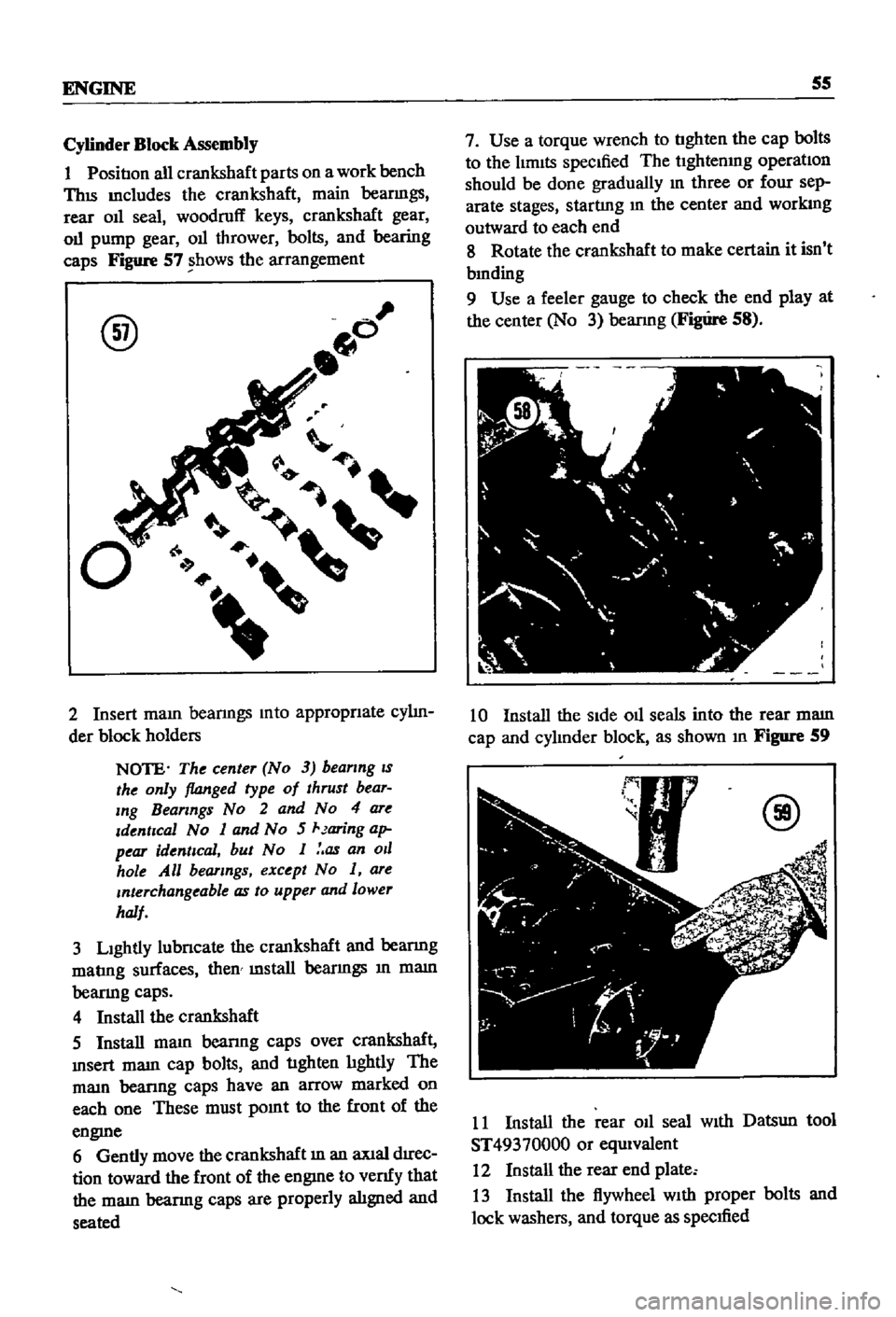

1

Mount

the

locatIng

plate

on

the

front

of

the

head

as

shown

m

FJgIlI

1

56

2

From

the

back

of

the

head

carefully

InSert

the

camshaft

through

the

four

camshaft

beanngs

being

ca

efu1

not

to

move

or

damage

the

bear

ings

NOTE

Install

the

CQJ7IShaft

sprocket

onto

the

camshaft

so

that

the

three

locating

holes

are

at

the

top

left

and

bottom

h

1

3

Install

the

camshaft

sprocket

and

fuel

pump

cam

onto

the

front

of

the

camshaft

and

torque

to

specificatIon

4

Check

the

camshaft

for

end

play

using

a

feeler

gauge

as

preViously

described

Rocker

Pivot

Assembly

1

Push

down

on

valve

spnng

with

screwdriver

and

insert

rocker

piVOt

arm

between

camshaft

and

valve

stem

Insert

rocker

valve

guide

onto

top

of

valve

stem

at

this

time

2

Install

valve

rocker

springs

over

top

of

rocker

pivot

arm

Piston

and

Connecting

Rod

Assembly

1

Assemble

the

four

pistons

pms

and

connect

mg

rods

Secure

piston

pm

The

connecting

rod

IS

press

fitted

onto

the

pISton

pin

With

from

1

to

3

tons

of

force

NOTE

The

pistons

are

marked

with

an

F

which

should

point

toward

the

front

of

the

engine

The

connecting

rods

must

be

installed

so

that

the

011

Jet

In

the

large

end

IS

positioned

to

ward

the

right

Side

of

the

tnglne

The

center

of

the

piston

pin

IS

oD

set

In

relation

to

the

center

of

the

piston

so

correct

assembly

is

cntical

2

Use

a

nng

expander

to

install

the

rings

onto

the

pistons

Install

the

top

and

rmddle

nngs

with

the

marks

up

3

Lubncate

the

rod

bearings

hghtly

and

mstall

them

into

their

respective

connectIng

rods

and

rod

caps

Page 60 of 252

ENGINE

55

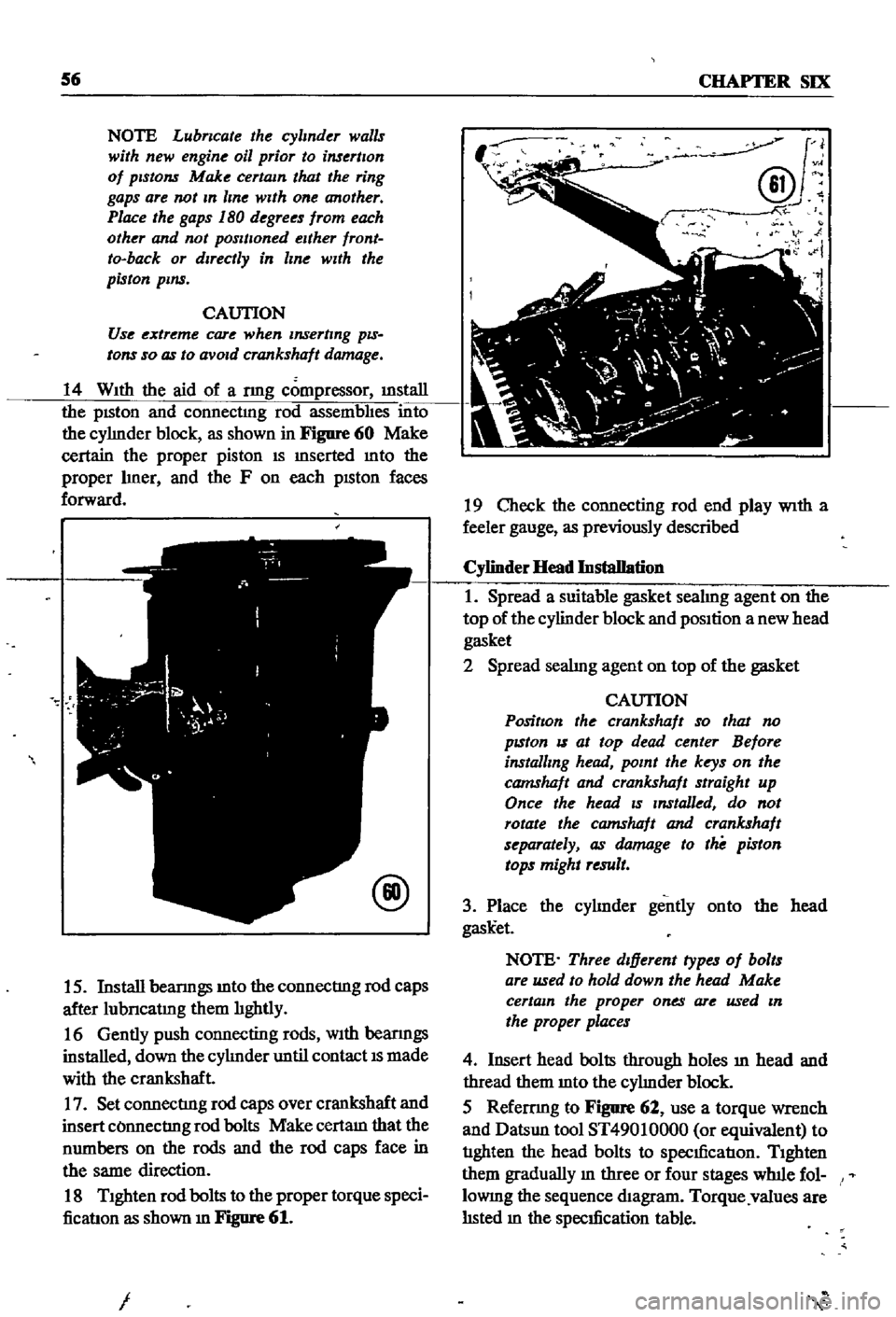

Cylinder

Block

Assembly

1

PositIon

all

crankshaft

parts

on

a

work

bench

ThIS

mcludes

the

crankshaft

main

beanngs

rear

011

seal

woodruff

keys

crankshaft

gear

011

pump

gear

011

thrower

bolts

and

bearing

caps

Figure

57

shows

the

arrangement

@

2

Insert

maIO

beanngs

mto

appropnate

cy1m

der

block

holders

NOTE

The

center

No

3

beanng

IS

the

only

flanged

type

of

thrust

bear

Ing

Bearings

No

2

and

No

4

are

Identical

No

1

and

No

5

Jaring

ap

pear

identical

but

No

1

as

an

011

hole

All

bearings

except

No

1

are

Interchangeable

as

to

upper

and

lower

half

3

LIghtly

lubncate

the

crankshaft

and

beanng

matmg

surfaces

then

mstall

beanngs

10

mam

beanng

caps

4

Install

the

crankshaft

5

Install

mam

beanng

caps

over

crankshaft

msert

mam

cap

bolts

and

tighten

hghtly

The

mam

beanng

caps

have

an

arrow

marked

on

each

one

These

must

pomt

to

the

front

of

the

engme

6

Gently

move

the

crankshaft

10

an

aXIal

drrec

don

toward

the

front

of

the

engme

to

venfy

that

the

mam

beanng

caps

are

properly

alIgned

and

seated

7

Use

a

torque

wrench

to

tighten

the

cap

bolts

to

the

hmlts

speCIfied

The

t1ghtenmg

operatIon

should

be

done

gradually

10

three

or

four

sep

arate

stages

starting

10

the

center

and

workmg

outward

to

each

end

8

Rotate

the

crankshaft

to

make

certain

it

isn

t

bmding

9

Use

a

feeler

gauge

to

check

the

end

play

at

the

center

No

3

beanng

Figure

58

10

Install

the

SIde

oll

seals

into

the

rear

mam

cap

and

cy1mder

block

as

shown

10

Figure

59

@

11

Install

the

rear

011

seal

WIth

Datsun

tool

ST49370000

or

equIvalent

12

Install

the

rear

end

plate

13

Install

the

flywheel

WIth

proper

bolts

and

lock

washers

and

torque

as

specified

Page 61 of 252

56

CHAPTER

SIX

NOTE

Lubncate

the

cylinder

walls

with

new

engine

oil

prior

to

insertIOn

of

pistOns

Make

certain

that

the

ring

gaps

are

not

In

line

wIth

one

another

Place

the

gaps

180

degrees

from

each

other

and

not

posltloned

either

front

to

back

or

dIrectly

in

line

with

the

piston

pIns

CAUTION

Use

extreme

care

when

Inserting

pzs

tons

so

as

to

avoId

crankshaft

damage

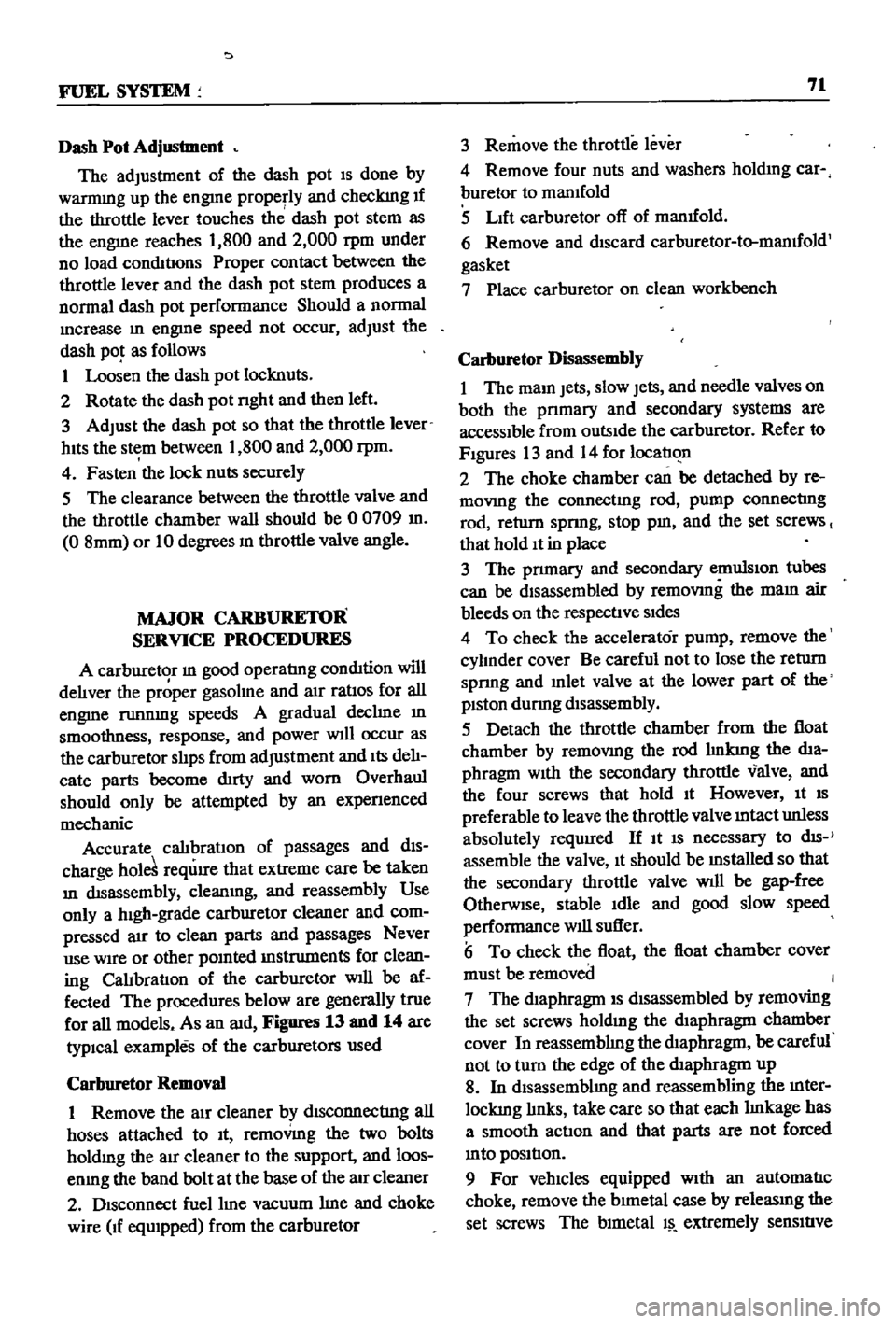

14

With

the

aid

of

a

nng

compressor

illStaIl

the

pISton

and

connectmg

rod

assembhes

into

the

cyhnder

block

as

shown

in

Figure

60

Make

certain

the

proper

piston

IS

mserted

mto

the

proper

hner

and

the

F

on

each

pISton

faces

forward

@

15

Install

beanngs

mto

the

connectIng

rod

caps

after

lubncatmg

them

hghtly

16

Gently

push

connecting

rods

With

beanngs

installed

down

the

cyhnder

until

contact

IS

made

with

the

crankshaft

17

Set

connectIng

rod

caps

over

crankshaft

and

insert

COnnectIng

rod

bolts

Make

certam

that

the

numbers

on

the

rods

and

the

rod

caps

face

in

the

same

direction

18

Tighten

rod

bolts

to

the

proper

torque

speci

ficatIon

as

shown

m

Figure

61

I

J

@v

N

i

19

Check

the

connecting

rod

end

play

With

a

feeler

gauge

as

previously

described

Cylinder

Head

Installation

1

Spread

a

suitable

gasket

seahng

agent

on

the

top

of

the

cylinder

block

and

position

a

new

head

gasket

2

Spread

seahng

agent

on

top

of

the

gasket

CAUTION

PositIon

the

crankshaft

so

that

no

pzston

IS

at

top

dead

center

Before

installing

head

point

the

keys

on

the

camshaft

and

crankshaft

straight

up

Once

the

head

zs

Installed

do

not

rotate

the

camshaft

and

crankshaft

separately

as

damage

to

the

piston

tops

might

result

3

Place

the

cyhnder

gently

onto

the

head

gask

et

NOTE

Three

dIfferent

types

of

bolts

are

used

to

hold

down

the

head

Make

certain

the

proper

ones

are

used

In

the

proper

places

4

Insert

head

bolts

through

holes

ill

head

and

thread

them

mto

the

cyhnder

block

5

Refemng

to

Figure

62

use

a

torque

wrench

and

Datsun

tool

ST49010000

or

equivalent

to

tIghten

the

head

bolts

to

specIficatIon

Tighten

them

gradually

m

three

or

four

stages

wlnle

fol

lOWIng

the

sequence

diagram

Torque

values

are

hsted

m

the

specIfication

table

Page 76 of 252

FUEL

SYSTEM

71

Dash

Pot

Adjustment

The

adjustment

of

the

dash

pot

IS

done

by

warmmg

up

the

engme

properly

and

checkIng

If

the

throttle

lever

touches

th

dash

pot

stem

as

the

engine

reaches

1

800

and

2

000

rpm

under

no

load

conditIons

Proper

contact

between

the

throttle

lever

and

the

dash

pot

stem

produces

a

normal

dash

pot

performance

Should

a

normal

mcrease

m

engme

speed

not

occur

adjust

the

dash

pot

as

follows

1

Loosen

the

dash

pot

locknuts

2

Rotate

the

dash

pot

nght

and

then

left

3

Adjust

the

dash

pot

so

that

the

throttle

lever

hIts

the

stem

between

1

800

and

2

000

rpm

4

Fasten

the

lock

nuts

securely

5

The

clearance

between

the

throttle

valve

and

the

throttle

chamber

wall

should

be

0

0709

m

0

8mm

or

10

degrees

In

throttle

valve

angle

MAJOR

CARBURETOR

SERVICE

PROCEDURES

A

carburetor

m

good

operatIng

condition

will

delIver

the

pr

per

gasolme

and

aIr

ratIos

for

all

engme

runnmg

speeds

A

gradual

declme

In

smoothness

response

and

power

Will

occur

as

the

carburetor

slIps

from

adjustment

and

Its

delI

cate

parts

become

dirty

and

worn

Overhaul

should

only

be

attempted

by

an

expenenced

mechanic

Accurate

calIbratIon

of

passages

and

dIS

charge

hole

reqUIre

that

extreme

care

be

taken

In

dISassembly

cleanmg

and

reassembly

Use

only

a

hIgh

grade

carburetor

cleaner

and

com

pressed

arr

to

clean

parts

and

passages

Never

use

wire

or

other

pOInted

Instruments

for

clean

ing

CalIbratIon

of

the

carburetor

will

be

af

fected

The

procedures

below

are

generally

true

for

all

models

As

an

aId

Figures

13

and

14

are

typIcal

examples

of

the

carburetors

used

Carburetor

Removal

1

Remove

the

au

cleaner

by

dIsconnectIng

all

hoses

attached

to

It

remoVmg

the

two

bolts

holdmg

the

aIr

cleaner

to

the

support

and

loos

enmg

the

band

bolt

at

the

base

of

the

aIr

cleaner

2

DIsconnect

fuellme

vacuum

Ime

and

choke

wire

u

eqUIpped

from

the

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

holdmg

car

buretor

to

manIfold

5

Lift

carburetor

off

of

manuold

6

Remove

and

dIscard

carburetor

to

manuold

gasket

7

Place

carburetor

on

clean

workbench

Carburetor

Disassembly

1

The

maIn

Jets

slow

Jets

and

needle

valves

on

both

the

pnmary

and

secondary

systenIS

are

accessIble

from

outsIde

the

carburetor

Refer

to

FIgures

13

and

14

for

locatI

n

2

The

choke

chamber

can

be

detached

by

re

mOVIng

the

connectIng

rod

pump

connectIng

rod

return

sprmg

stop

pm

and

the

set

screws

I

that

hold

It

in

place

3

The

pnmary

and

secondary

emulSIon

tubes

can

be

disassembled

by

remOVIng

the

mam

air

bleeds

on

the

respectIve

SIdes

4

To

check

the

accelerator

pump

remove

the

cylInder

cover

Be

careful

not

to

lose

the

return

spnng

and

Inlet

valve

at

the

lower

part

of

the

pIston

durmg

dIsassembly

5

Detach

the

throttle

chamber

from

the

float

chamber

by

remOVIng

the

rod

lInkIng

the

dia

phragm

WIth

the

secondary

throttle

valve

and

the

four

screws

that

hold

It

However

It

IS

preferable

to

leave

the

throttle

valve

mtact

unless

absolutely

reqUired

If

It

IS

necessary

to

dlS

assemble

the

valve

It

should

be

Installed

so

that

the

secondary

throttle

valve

will

be

gap

free

OtherwIse

stable

Idle

and

good

slow

speed

performance

will

suffer

is

To

check

the

float

the

float

chamber

cover

must

be

removed

I

7

The

dIaphragm

IS

dIsassembled

by

removing

the

set

screws

holdmg

the

dIaphragm

chamber

cover

In

reassemblIng

the

diaphragm

be

careful

not

to

turn

the

edge

of

the

dIaphragm

up

8

In

dlsassemblmg

and

reassembling

the

mter

lockIng

lInks

take

care

so

that

each

lInkage

has

a

smooth

actIon

and

that

parts

are

not

forced

mto

pOSItIon

9

For

vehIcles

equipped

With

an

automatIc

choke

remove

the

brmetal

case

by

releasmg

the

set

screws

The

bimetal

1l

extremely

senSItIve

Page 94 of 252

COOLING

SYSTEM

89

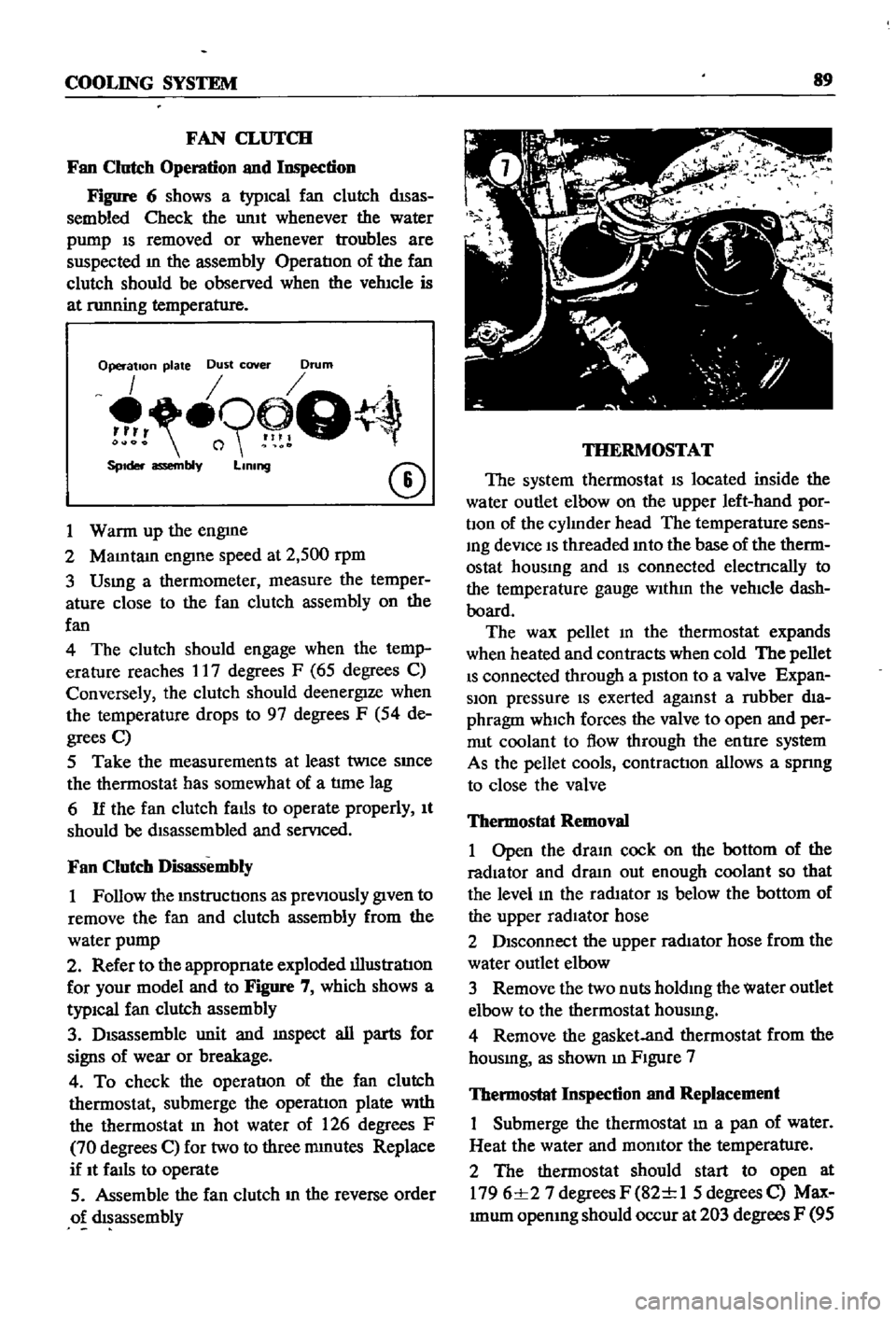

FAN

CLUTCH

Fan

Clutch

Operation

and

Inspection

Figure

6

shows

a

typICal

fan

clutch

dISas

sembled

Check

the

umt

whenever

the

water

pump

IS

removed

or

whenever

troubles

are

suspected

m

the

assembly

OperatIon

of

the

fan

clutch

should

be

observed

when

the

vehIcle

is

at

nmning

temperature

Operation

plate

Dust

cover

Drum

o9

Q

SpIder

assembly

LIning

CD

1

Warm

up

the

engme

2

MaIntam

engIne

speed

at

2

500

rpm

3

Usmg

a

thermometer

measure

the

temper

ature

close

to

the

fan

clutch

assembly

on

the

fan

4

The

clutch

should

engage

when

the

temp

erature

reaches

17

degrees

F

65

degrees

C

Conversely

the

clutch

should

deenergIze

when

the

temperature

drops

to

97

degrees

F

54

de

grees

C

5

Take

the

measurements

at

least

twice

SInce

the

thermostat

has

somewhat

of

a

tlme

lag

6

If

the

fan

clutch

falls

to

operate

properly

It

should

be

dIsassembled

and

servIced

Fan

Clutch

Disassembly

1

Follow

the

mstructIons

as

prevIOusly

gIven

to

remove

the

fan

and

clutch

assembly

from

the

water

pump

2

Refer

to

the

appropnate

exploded

illustratIon

for

your

model

and

to

Figure

7

which

shows

a

typiCal

fan

clutch

assembly

3

DIsassemble

unit

and

mspect

all

parts

for

signs

of

wear

or

breakage

4

To

check

the

operatIon

of

the

fan

clutch

thermostat

submerge

the

operatIon

plate

With

the

thermostat

In

hot

water

of

126

degrees

F

70

degrees

C

for

two

to

three

mmutes

Replace

if

It

faIls

to

operate

5

Assemble

the

fan

clutch

m

the

reverse

order

o

dIsassembly

THERMOSTAT

The

system

thermostat

IS

located

inside

the

water

outlet

elbow

on

the

upper

left

hand

por

bon

of

the

cylInder

head

The

temperature

sens

Ing

deVice

IS

threaded

Into

the

base

of

the

therm

ostat

housmg

and

IS

connected

electrlcally

to

the

temperature

gauge

WIthIn

the

vehIcle

dash

board

The

wax

pellet

m

the

thermostat

expands

when

heated

and

contracts

when

cold

The

pellet

IS

connected

through

a

pIston

to

a

valve

Expan

sion

pressure

IS

exerted

agalUst

a

rubber

dIa

phragm

which

forces

the

valve

to

open

and

per

rrut

coolant

to

flow

through

the

entIre

system

As

the

pellet

cools

contractIOn

allows

a

spnng

to

close

the

valve

Thermostat

Removal

1

Open

the

draIn

cock

on

the

bottom

of

the

radiator

and

dram

out

enough

coolant

so

that

the

level

In

the

radIator

IS

below

the

bottom

of

the

upper

radIator

hose

2

DIsconnect

the

upper

radIator

hose

from

the

water

outlet

elbow

3

Remove

the

two

nuts

holdIng

the

water

outlet

elbow

to

the

thermostat

housmg

4

Remove

the

gasket

and

thermostat

from

the

housmg

as

shown

m

FIgure

7

Thermostat

Inspection

and

Replacement

Submerge

the

thermostat

In

a

pan

of

water

Heat

the

water

and

momtor

the

temperature

2

The

thermostat

should

start

to

open

at

1796

1

27

degrees

F

82

1

1

5

degrees

C

Max

Imum

opemng

should

occur

at

203

degrees

F

95

Page 100 of 252

ENGINE

ELECI

RlCAL

SYSTEM

9S

@

@

4

Test

the

COIls

for

shorts

by

unsoldermg

the

connectIons

of

each

coIl

and

repeatlng

the

test

given

m

step

3

If

a

defectIve

coil

IS

found

It

must

be

replaced

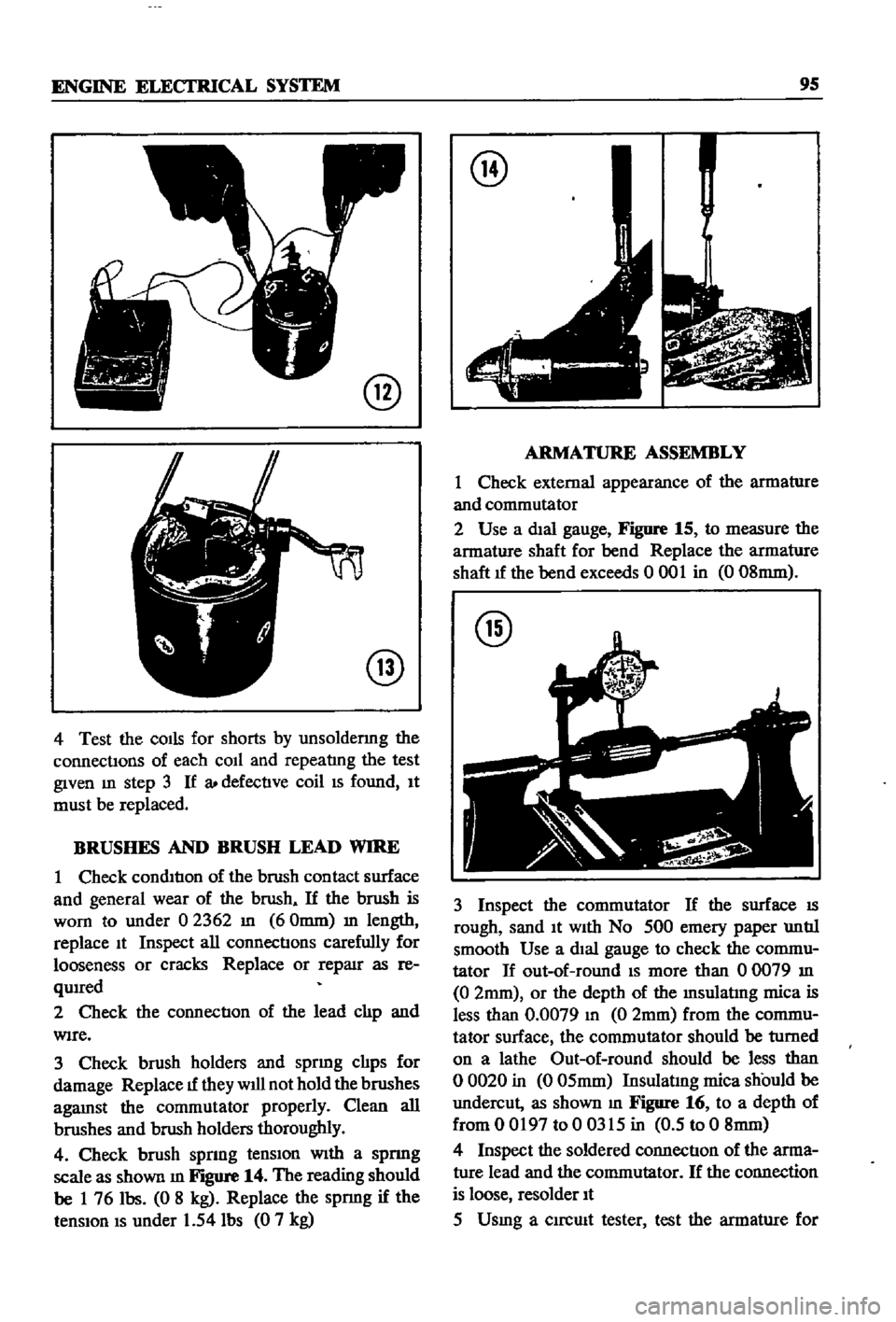

BRUSHES

AND

BRUSH

LEAD

WIRE

1

Check

condItIon

of

the

brush

contact

surface

and

general

wear

of

the

brush

If

the

brush

is

worn

to

under

02362

In

60mm

m

length

replace

It

Inspect

all

connectIons

carefully

for

looseness

or

cracks

Replace

or

reparr

as

re

qUIred

2

Check

the

connectIon

of

the

lead

clIp

and

WIre

3

Check

brush

holders

and

sprmg

clIps

for

damage

Replace

1f

they

will

not

hold

the

brushes

agaInst

the

commutator

properly

Clean

all

brushes

aIld

brush

holders

thoroughly

4

Check

brush

sprmg

tenSIon

WIth

a

spnng

scale

as

shown

m

Figure

14

The

reading

should

be

1

76

Ibs

0

8

kg

Replace

the

spnng

if

the

tenSIon

IS

under

1

54

Ibs

0

7

kg

@

ARMATURE

ASSEMBLY

1

Check

external

appearance

of

the

armature

and

commutator

2

Use

a

dIal

gauge

Figure

15

to

measure

the

armature

shaft

for

bend

Replace

the

armature

shaft

1f

the

bend

exceeds

0

001

in

0

08mm

@

3

Inspect

the

commutator

If

the

surface

IS

rough

sand

It

With

No

500

emery

paper

untIl

smooth

Use

a

dIal

gauge

to

check

the

commu

tator

If

out

of

round

IS

more

than

00079

In

0

2mm

or

the

depth

of

the

Insulatlng

mica

is

less

than

0

0079

In

0

2mm

from

the

commu

tator

surface

the

commutator

should

be

turned

on

a

lathe

Out

of

round

should

be

less

than

o

0020

in

0

05mm

Insulatmg

mica

should

be

undercut

as

shown

m

Figure

16

to

a

depth

of

from

0

0197

to

0

0315

in

0

5

to

0

8mm

4

Inspect

the

soldered

connectIon

of

the

arma

ture

lead

and

the

commutator

If

the

connection

is

loose

resolder

It

5

Usmg

a

clrcmt

tester

test

the

armature

for

Page 102 of 252

ENGINE

ELECI

RlCAL

SYSTEM

97

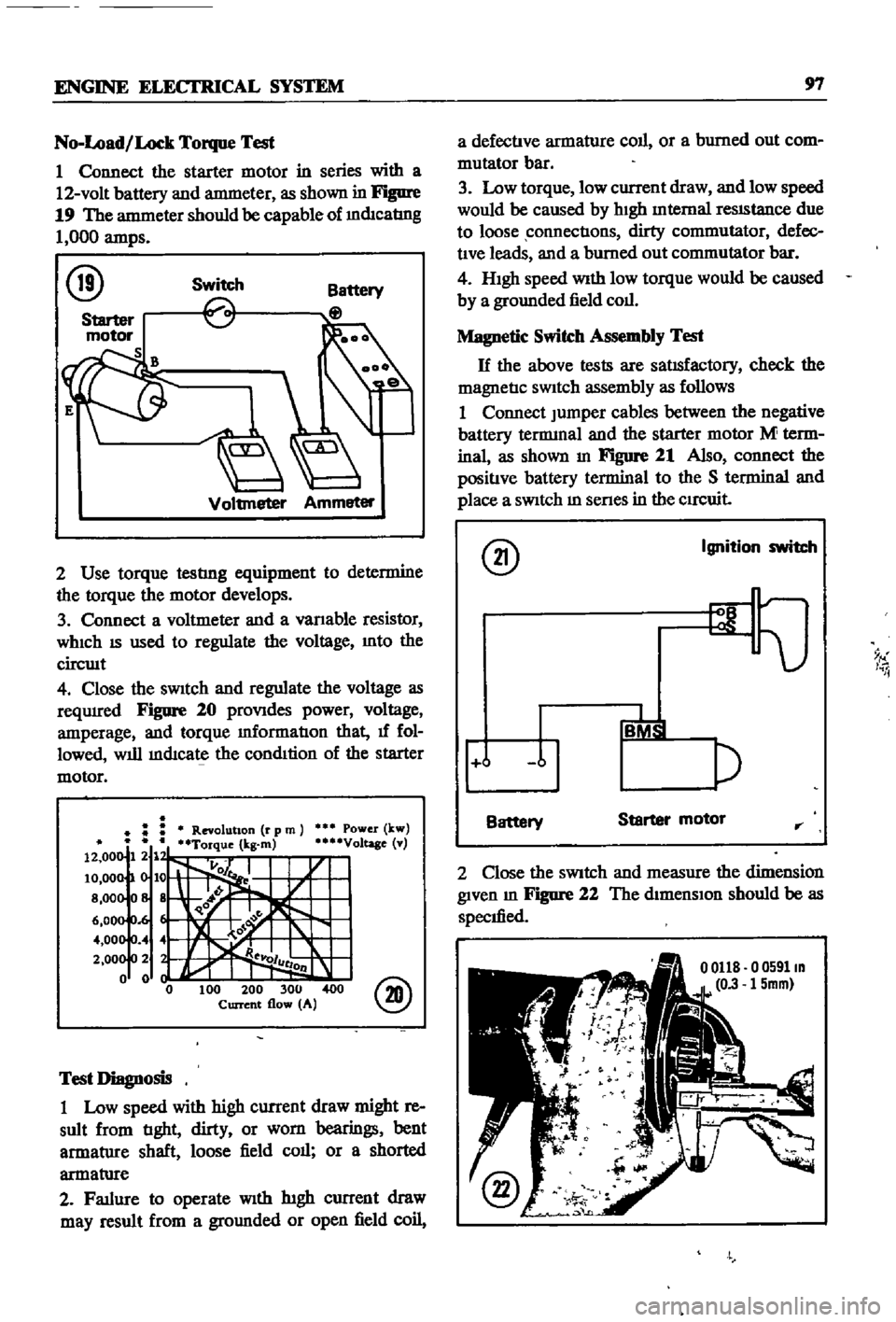

No

Load

Lock

Torque

Test

1

Connect

the

starter

motor

in

series

with

a

12

volt

battery

and

antmeter

as

shown

in

Figure

19

The

antmeter

should

be

capable

of

mdIcatIng

1

000

amps

@

Switch

Voltmeter

Ammeter

2

Use

torque

testlng

equipment

to

determine

the

torque

the

motor

develops

3

Connect

a

voltmeter

and

a

vanable

resistor

WhICh

IS

used

to

regulate

the

voltage

Into

the

circwt

4

Close

the

sWitch

and

regulate

the

voltage

as

reqUIred

Figure

20

proVIdes

power

voltage

amperage

and

torque

mformatIon

that

1f

fol

lowed

will

mdIcate

the

condItion

of

the

starter

motor

Power

kw

Voltage

v

@

Test

Diagnosis

1

Low

speed

with

high

current

draw

might

re

sult

from

tIght

dirty

or

worn

bearings

bent

armatlIre

shaft

loose

field

call

or

a

shorted

armatlIre

2

Fatlure

to

operate

With

htgh

current

draw

may

result

from

a

gromlded

or

open

field

coil

a

defectIve

armature

coll

or

a

burned

out

com

mutator

bar

3

Low

torque

low

current

draw

and

low

speed

would

be

caused

by

hIgh

Internal

reSIStance

due

to

loose

connectIons

dirty

commutator

defec

tIve

leads

and

a

burned

out

commutator

bar

4

HIgh

speed

With

low

torque

would

be

caused

by

a

grounded

field

coll

Magnetic

Switch

Assembly

Test

H

the

above

tests

are

satIsfactory

check

the

magnetIc

SWitch

assembly

as

follows

1

Connect

Jumper

cables

between

the

negative

battery

tennmal

and

the

starter

motor

M

term

inal

as

shown

In

Figure

21

Also

connect

the

positIve

battery

terminal

to

the

S

terminal

and

place

a

SWitch

m

senes

in

the

CIrCuit

@

Ignition

switch

9

I

i

j

Battery

Starter

motor

rr

2

Close

the

SWitch

and

measure

the

dimension

given

m

Figure

22

The

dimensIon

should

be

as

specIfied

o

0591m

15mm

Page 108 of 252

ENGINE

ELECTRICAL

SYSTEM

103

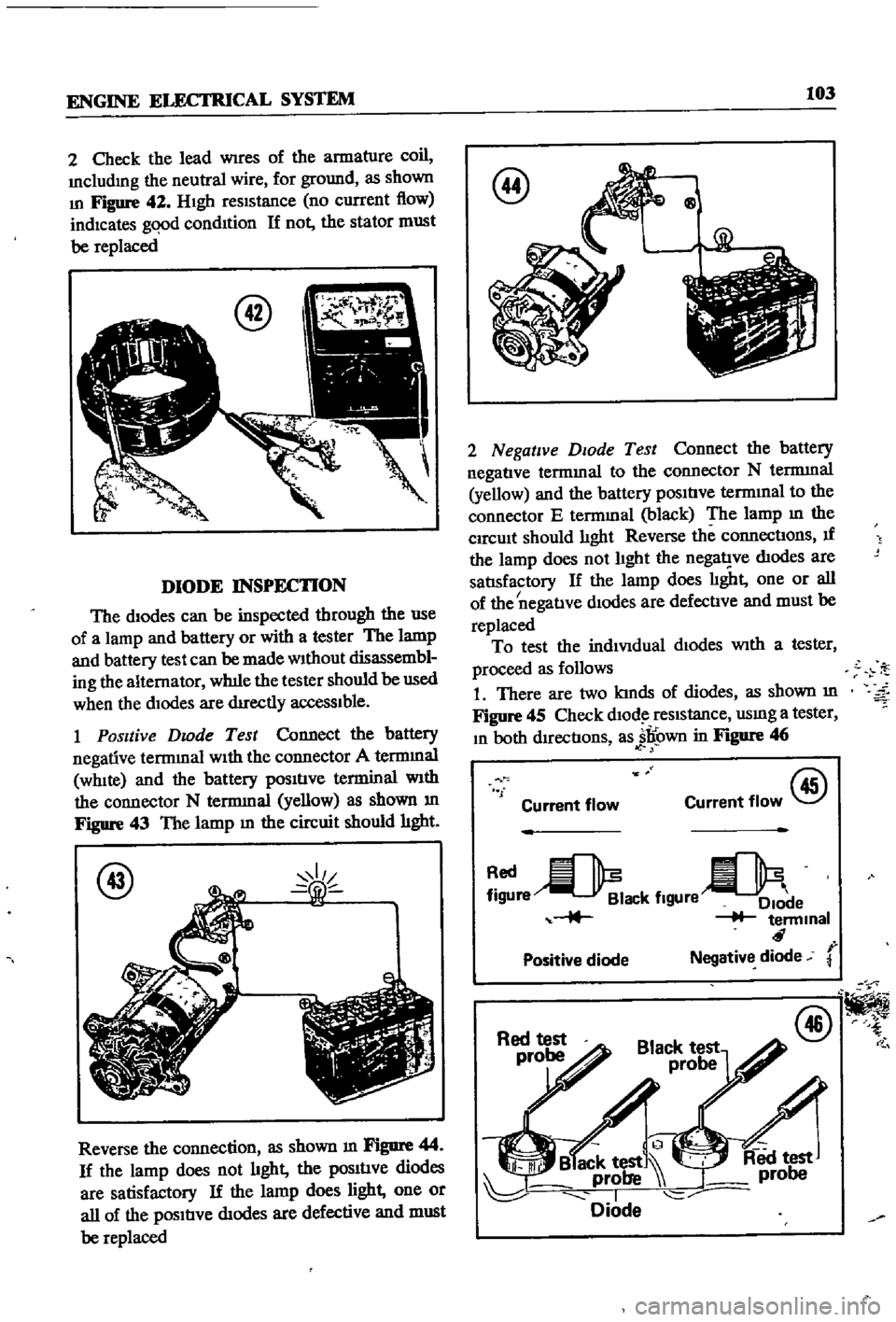

2

Check

the

lead

Wires

of

the

armature

coil

Includmg

the

neutral

wire

for

ground

as

shown

In

Figure

42

HIgh

reSIStance

no

current

flow

indicates

gqod

condItion

If

not

the

stator

must

be

replaced

DIODE

INSPECTION

The

diodes

can

be

inspected

through

the

use

of

a

lamp

and

battery

or

with

a

tester

The

lamp

and

battery

test

can

be

made

Without

disassembl

ing

the

alternator

wh1le

the

tester

should

be

used

when

the

dIodes

are

dIrectly

acceSSIble

1

Positive

Dwde

Test

Connect

the

battery

negative

terrmnal

WIth

the

connector

A

terrmnal

WhIte

and

the

battery

pOSItIve

terminal

With

the

connector

N

terrmnal

yellow

as

shown

m

Figure

43

The

lamp

m

the

circuit

should

hght

@

Reverse

the

connection

as

shown

m

Figure

44

If

the

lamp

does

not

hght

the

pOSItIve

diodes

are

satisfactory

If

the

lamp

does

light

one

or

all

of

the

pOSItIve

dIodes

are

defective

and

must

be

replaced

@

Qg

2

Negative

DIOde

Test

Connect

the

battery

negatIve

termmal

to

the

connector

N

terrmnal

yellow

and

the

battery

pOSItIve

termInal

to

the

connector

E

termmal

black

The

lamp

m

the

CIrcUit

should

lIght

Reverse

the

connectIons

If

the

lamp

does

not

lIght

the

nega1

ve

dIodes

are

satlsfactory

If

the

lamp

does

lIght

one

or

all

I

of

the

negatIve

dIodes

are

defectIve

and

must

be

replaced

To

test

the

indiVIdual

dIodes

With

a

tester

proceed

as

follows

1

There

are

two

kInds

of

diodes

as

shown

m

Figure

45

Check

dlOd

reSIstance

usmg

a

tester

In

both

dIrectIons

as

jl

own

in

Figure

46

f

Current

flow

@

Current

flow

re

ack

flgUre

e

terminal

r

Positive

diode

Negative

diode

@

Page 111 of 252

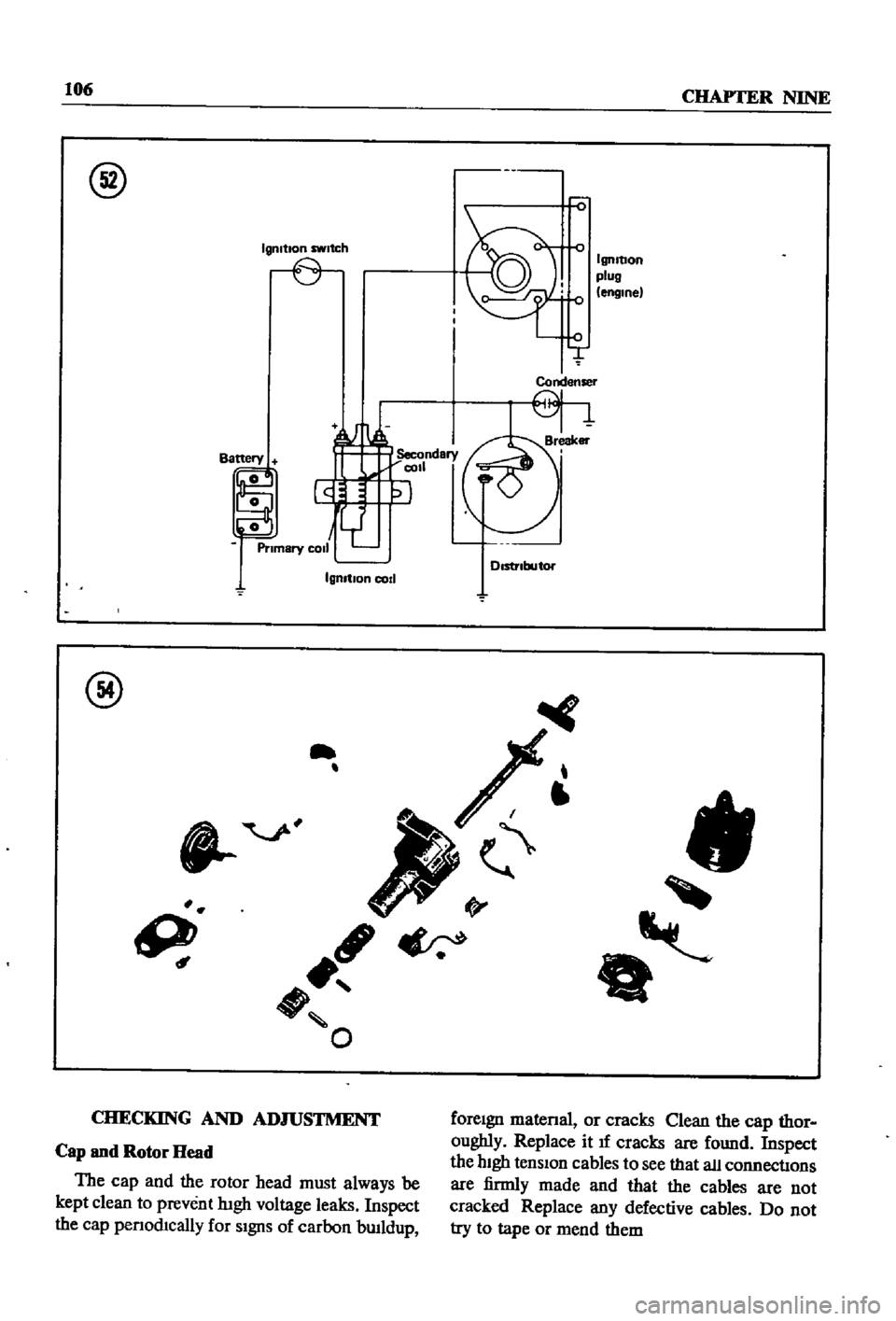

106

CHAPTER

NINE

@

Igmtlon

switch

IgnItion

plug

engine

Condenser

IgnItIon

cod

@

II

9

ft

O

CHECKING

AND

ADJUSTMENT

foreIgn

matenal

or

cracks

Qean

the

cap

thor

oughly

Replace

it

If

cracks

are

found

Inspect

the

hIgh

tensIon

cables

to

see

that

all

connectIons

are

firmly

made

and

that

the

cables

are

not

cracked

Replace

any

defective

cables

Do

not

try

to

tape

or

mend

them

Cap

and

Rotor

Head

The

cap

and

the

rotor

head

must

always

be

kept

clean

to

prevent

lugh

voltage

leaks

Inspect

the

cap

penod1cally

for

SIgnS

of

carbon

bwldup

Page 119 of 252

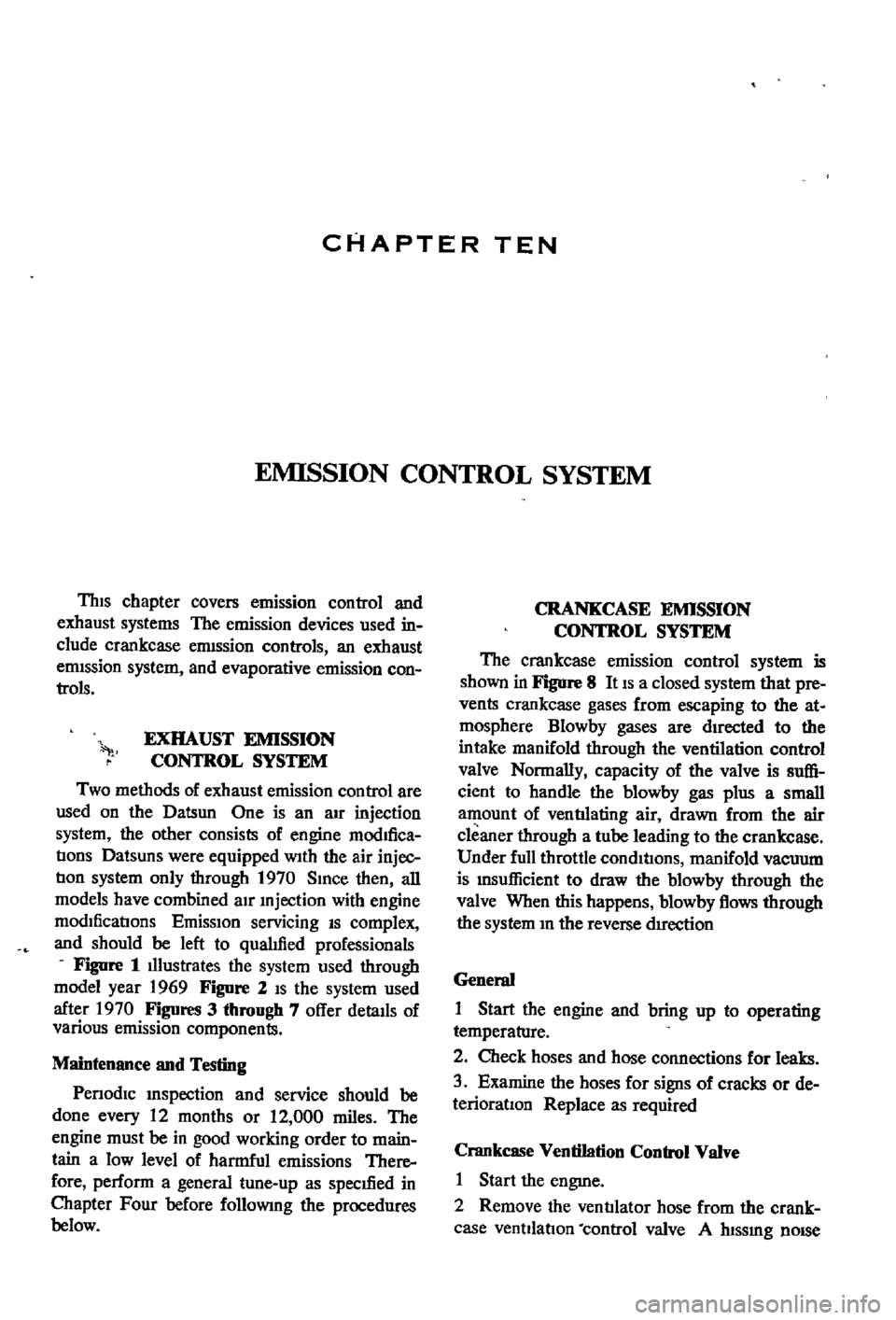

CHAPTER

TEN

EMISSION

CONTROL

SYSTEM

ThIs

chapter

covers

emission

control

and

exhaust

systems

The

emission

devices

used

in

clude

crankcase

ermssion

controls

an

exhaust

ermssion

system

and

evaporative

emission

con

trols

EXHAUST

EMISSION

CONTROL

SYSTEM

Two

methods

of

exhaust

emission

control

are

used

on

the

Datsun

One

is

an

aIr

injection

system

the

other

consists

of

engine

modifica

tIons

Datsuns

were

equipped

With

the

air

injec

tIon

system

only

through

1970

SInce

then

all

models

have

combined

aIr

mjection

with

engine

modIficatIons

EmisSIon

servicing

IS

complex

and

should

be

left

to

qualIfied

professionals

Figure

1

Illustrates

the

system

used

through

model

year

1969

Figure

2

IS

the

system

used

after

1970

Figures

3

through

7

offer

detaIls

of

various

emission

components

Maintenance

and

Testing

Penodlc

mspection

and

service

should

be

done

every

12

months

or

12

000

miles

The

engine

must

be

in

good

working

order

to

main

tain

a

low

level

of

harmful

emissions

There

fore

perform

a

general

tune

up

as

spec1fied

in

Chapter

Four

before

followmg

the

procedures

below

CRANKCASE

EMISSION

CONTROL

SYSTEM

The

crankcase

emission

control

system

is

shown

in

FlgDre

8

It

IS

a

closed

system

that

pre

vents

crankcase

gases

from

escaping

to

the

at

mosphere

Blowby

gases

are

dIrected

to

the

intake

manifold

through

the

ventilation

control

valve

Normally

capacity

of

the

valve

is

suffi

cient

to

handle

the

blowby

gas

plus

a

small

amount

of

ventIlating

air

drawn

from

the

air

cleaner

through

a

tube

leading

to

the

crankcase

Under

fun

throttle

condItIons

manifold

vacuum

is

Insufficient

to

draw

the

blowby

through

the

valve

When

this

happens

b10wby

flows

through

the

system

In

the

reverse

dIrection

General

1

Start

the

engine

and

bring

up

to

operating

temperature

2

Check

hoses

and

hose

connections

for

leaks

3

Examine

the

hoses

for

signs

of

cracks

or

de

terioraoon

Replace

as

required

Crankcase

Ventilation

Control

Valve

1

Start

the

engme

2

Remove

the

ventIlator

hose

from

the

crank

case

ventilatIon

control

valve

A

htssmg

nOISe