key DATSUN 510 1968 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 40 of 252

I

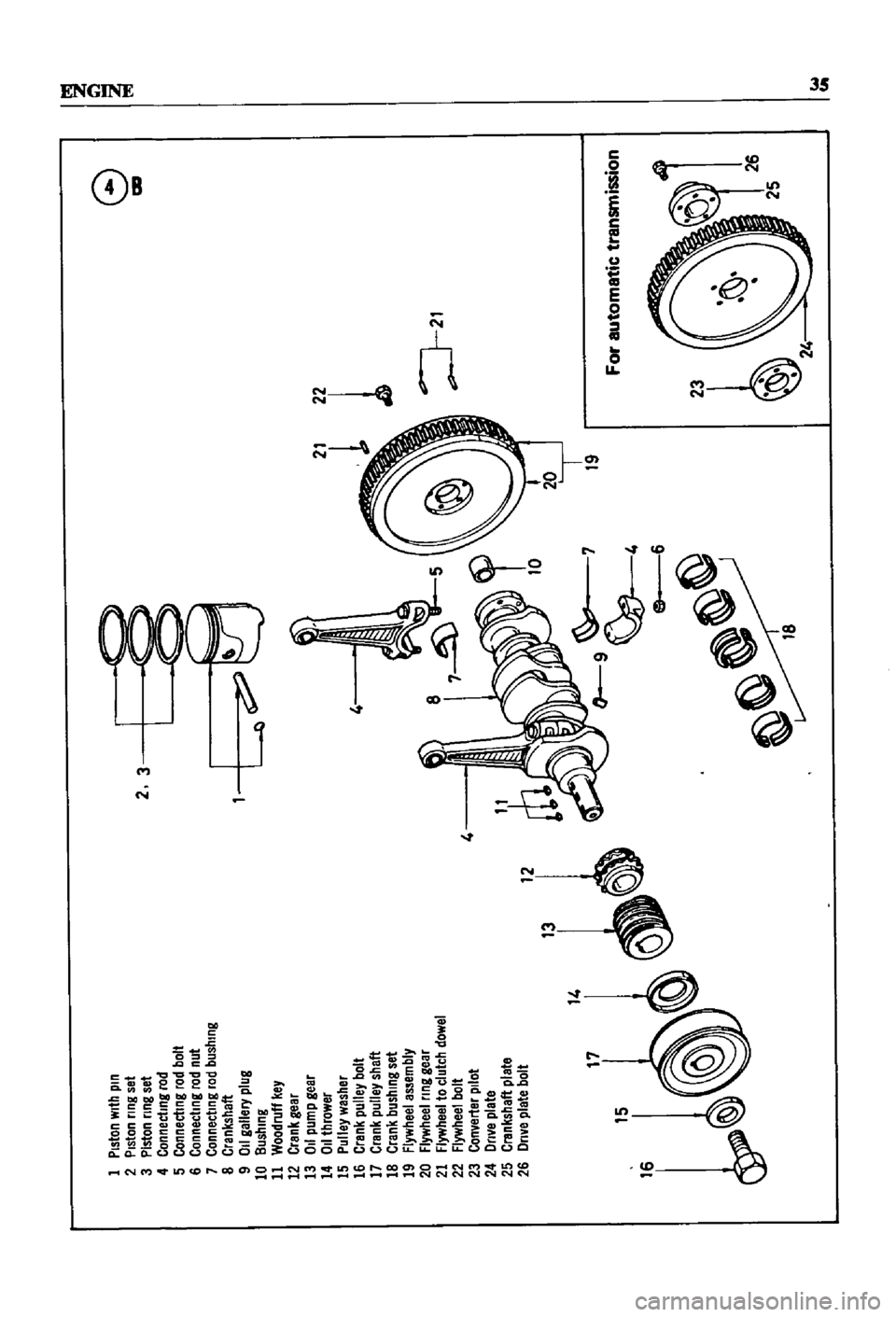

Piston

with

pin

2

Piston

nng

set

3

Piston

nng

set

4

Connecting

rod

5

Connecting

rod

bolt

6

Connecting

rod

nut

7

Connecting

rod

bushing

8

Crankshaft

9

011

gallery

plug

10

Bushing

11

Woodruff

key

12

Crank

gear

13

011

pump

gear

14

OJlthrower

15

Pulley

washer

16

Crank

pulley

bolt

17

Crank

pulley

shaft

18

Crank

bushing

set

19

Flywheel

assembly

20

Flywheel

nng

gear

21

Flywheel

to

clutch

dowel

22

Flywheel

bolt

4

23

Converter

pilot

24

Dnve

plate

25

Crankshaft

plate

26

Dnve

plate

bolt

13

I

14

17

15

2

3

l

L

4

8

9

6

19

1

J

21

2

24

8

ICD

I

For

automatic

transmission

W

lit

Page 48 of 252

ENGINE

43

@

0

00

o

mg

the

cham

tenslOner

to

the

block

to

free

the

sprIng

loaded

tenslOner

assembly

2

Remove

the

four

bolts

and

lockwashers

hold

mg

the

left

and

rIght

sIde

cham

guides

to

the

cylmder

block

Remove

the

guIdes

3

On

the

front

of

the

camshaft

remove

the

bolt

and

lockwasher

holdIng

the

fuel

pump

cam

as

sembly

and

the

eam

sprocket

to

the

eam

4

LIft

the

drIve

chaIn

asIde

and

remove

the

earn

sprocket

and

fuel

pump

cam

from

the

cam

shaft

as

shown

In

Figure

20

5

Remove

the

dnve

cham

from

the

crankshaft

drIve

spr6cket

Cylinder

Head

Removal

NOTE

Removal

of

the

cylinder

head

requires

a

special

tool

identified

as

DatsunST49010000

and

is

shown

In

FIGURE

21

@

I

USIng

the

specIal

tool

or

eqUIvalent

remove

ten

bolts

and

washers

holdIng

cylinder

head

to

cyhnder

block

See

Figure

22

2

Remove

head

from

block

and

dtscard

gasket

Oil

Pan

and

Strainer

Removal

I

Invert

the

engme

remove

22

bolts

and

wash

ers

secunng

pan

to

block

and

remove

011

pan

On

automatIc

transmission

models

tpe

pan

bolts

also

hold

the

oIl

cooler

hose

and

tube

clamps

in

place

DISCard

011

pan

gasket

3

Figure

23

shows

the

oIl

stramer

mOlJ

lted

m

the

block

Remove

two

bolts

and

washers

for

dISassembly

Crankshaft

Removal

I

Use

a

gear

puller

as

shown

III

Figure

24

to

pull

the

oIl

thrower

crankshaft

worm

gear

and

drive

cham

sprocket

from

the

crankshaft

The

above

parts

are

held

In

place

by

three

woodruff

keyS

2

DISconnect

the

pIston

and

connectrng

rod

assemblIes

from

the

crankshaft

by

removing

the

Page 60 of 252

ENGINE

55

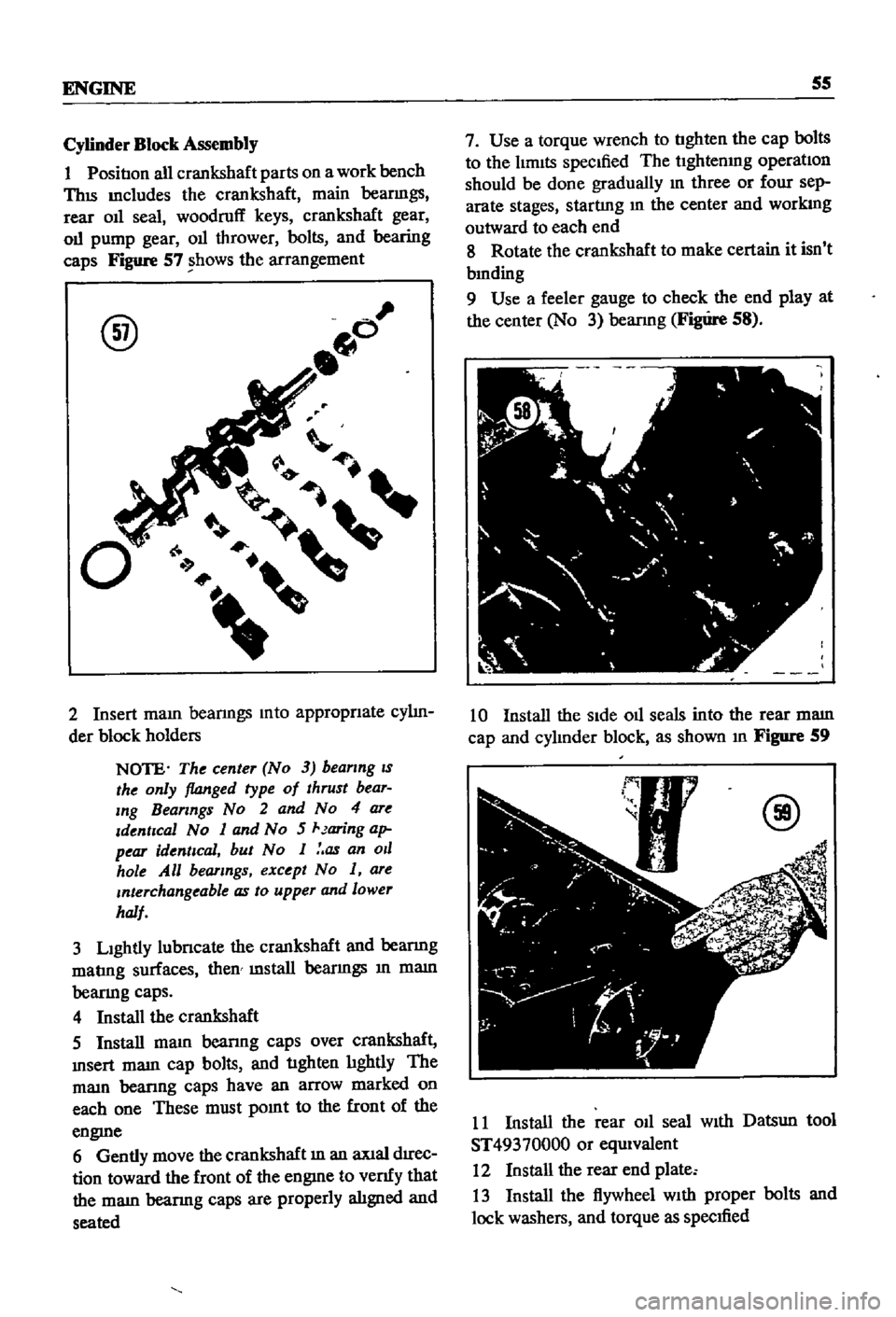

Cylinder

Block

Assembly

1

PositIon

all

crankshaft

parts

on

a

work

bench

ThIS

mcludes

the

crankshaft

main

beanngs

rear

011

seal

woodruff

keys

crankshaft

gear

011

pump

gear

011

thrower

bolts

and

bearing

caps

Figure

57

shows

the

arrangement

@

2

Insert

maIO

beanngs

mto

appropnate

cy1m

der

block

holders

NOTE

The

center

No

3

beanng

IS

the

only

flanged

type

of

thrust

bear

Ing

Bearings

No

2

and

No

4

are

Identical

No

1

and

No

5

Jaring

ap

pear

identical

but

No

1

as

an

011

hole

All

bearings

except

No

1

are

Interchangeable

as

to

upper

and

lower

half

3

LIghtly

lubncate

the

crankshaft

and

beanng

matmg

surfaces

then

mstall

beanngs

10

mam

beanng

caps

4

Install

the

crankshaft

5

Install

mam

beanng

caps

over

crankshaft

msert

mam

cap

bolts

and

tighten

hghtly

The

mam

beanng

caps

have

an

arrow

marked

on

each

one

These

must

pomt

to

the

front

of

the

engme

6

Gently

move

the

crankshaft

10

an

aXIal

drrec

don

toward

the

front

of

the

engme

to

venfy

that

the

mam

beanng

caps

are

properly

alIgned

and

seated

7

Use

a

torque

wrench

to

tighten

the

cap

bolts

to

the

hmlts

speCIfied

The

t1ghtenmg

operatIon

should

be

done

gradually

10

three

or

four

sep

arate

stages

starting

10

the

center

and

workmg

outward

to

each

end

8

Rotate

the

crankshaft

to

make

certain

it

isn

t

bmding

9

Use

a

feeler

gauge

to

check

the

end

play

at

the

center

No

3

beanng

Figure

58

10

Install

the

SIde

oll

seals

into

the

rear

mam

cap

and

cy1mder

block

as

shown

10

Figure

59

@

11

Install

the

rear

011

seal

WIth

Datsun

tool

ST49370000

or

equIvalent

12

Install

the

rear

end

plate

13

Install

the

flywheel

WIth

proper

bolts

and

lock

washers

and

torque

as

specified

Page 61 of 252

56

CHAPTER

SIX

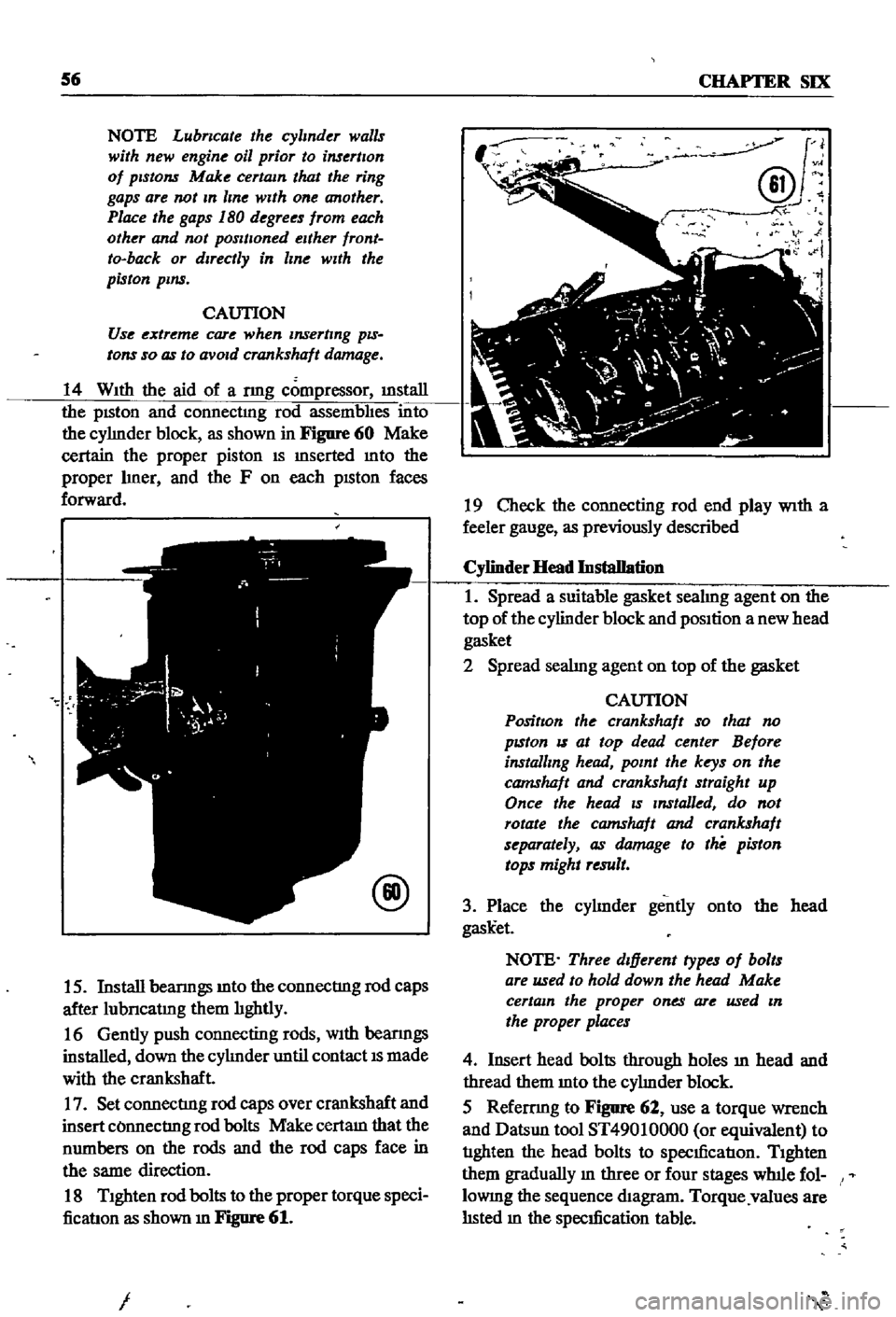

NOTE

Lubncate

the

cylinder

walls

with

new

engine

oil

prior

to

insertIOn

of

pistOns

Make

certain

that

the

ring

gaps

are

not

In

line

wIth

one

another

Place

the

gaps

180

degrees

from

each

other

and

not

posltloned

either

front

to

back

or

dIrectly

in

line

with

the

piston

pIns

CAUTION

Use

extreme

care

when

Inserting

pzs

tons

so

as

to

avoId

crankshaft

damage

14

With

the

aid

of

a

nng

compressor

illStaIl

the

pISton

and

connectmg

rod

assembhes

into

the

cyhnder

block

as

shown

in

Figure

60

Make

certain

the

proper

piston

IS

mserted

mto

the

proper

hner

and

the

F

on

each

pISton

faces

forward

@

15

Install

beanngs

mto

the

connectIng

rod

caps

after

lubncatmg

them

hghtly

16

Gently

push

connecting

rods

With

beanngs

installed

down

the

cyhnder

until

contact

IS

made

with

the

crankshaft

17

Set

connectIng

rod

caps

over

crankshaft

and

insert

COnnectIng

rod

bolts

Make

certam

that

the

numbers

on

the

rods

and

the

rod

caps

face

in

the

same

direction

18

Tighten

rod

bolts

to

the

proper

torque

speci

ficatIon

as

shown

m

Figure

61

I

J

@v

N

i

19

Check

the

connecting

rod

end

play

With

a

feeler

gauge

as

previously

described

Cylinder

Head

Installation

1

Spread

a

suitable

gasket

seahng

agent

on

the

top

of

the

cylinder

block

and

position

a

new

head

gasket

2

Spread

seahng

agent

on

top

of

the

gasket

CAUTION

PositIon

the

crankshaft

so

that

no

pzston

IS

at

top

dead

center

Before

installing

head

point

the

keys

on

the

camshaft

and

crankshaft

straight

up

Once

the

head

zs

Installed

do

not

rotate

the

camshaft

and

crankshaft

separately

as

damage

to

the

piston

tops

might

result

3

Place

the

cyhnder

gently

onto

the

head

gask

et

NOTE

Three

dIfferent

types

of

bolts

are

used

to

hold

down

the

head

Make

certain

the

proper

ones

are

used

In

the

proper

places

4

Insert

head

bolts

through

holes

ill

head

and

thread

them

mto

the

cyhnder

block

5

Refemng

to

Figure

62

use

a

torque

wrench

and

Datsun

tool

ST49010000

or

equivalent

to

tIghten

the

head

bolts

to

specIficatIon

Tighten

them

gradually

m

three

or

four

stages

wlnle

fol

lOWIng

the

sequence

diagram

Torque

values

are

hsted

m

the

specIfication

table

Page 62 of 252

ENGINE

57

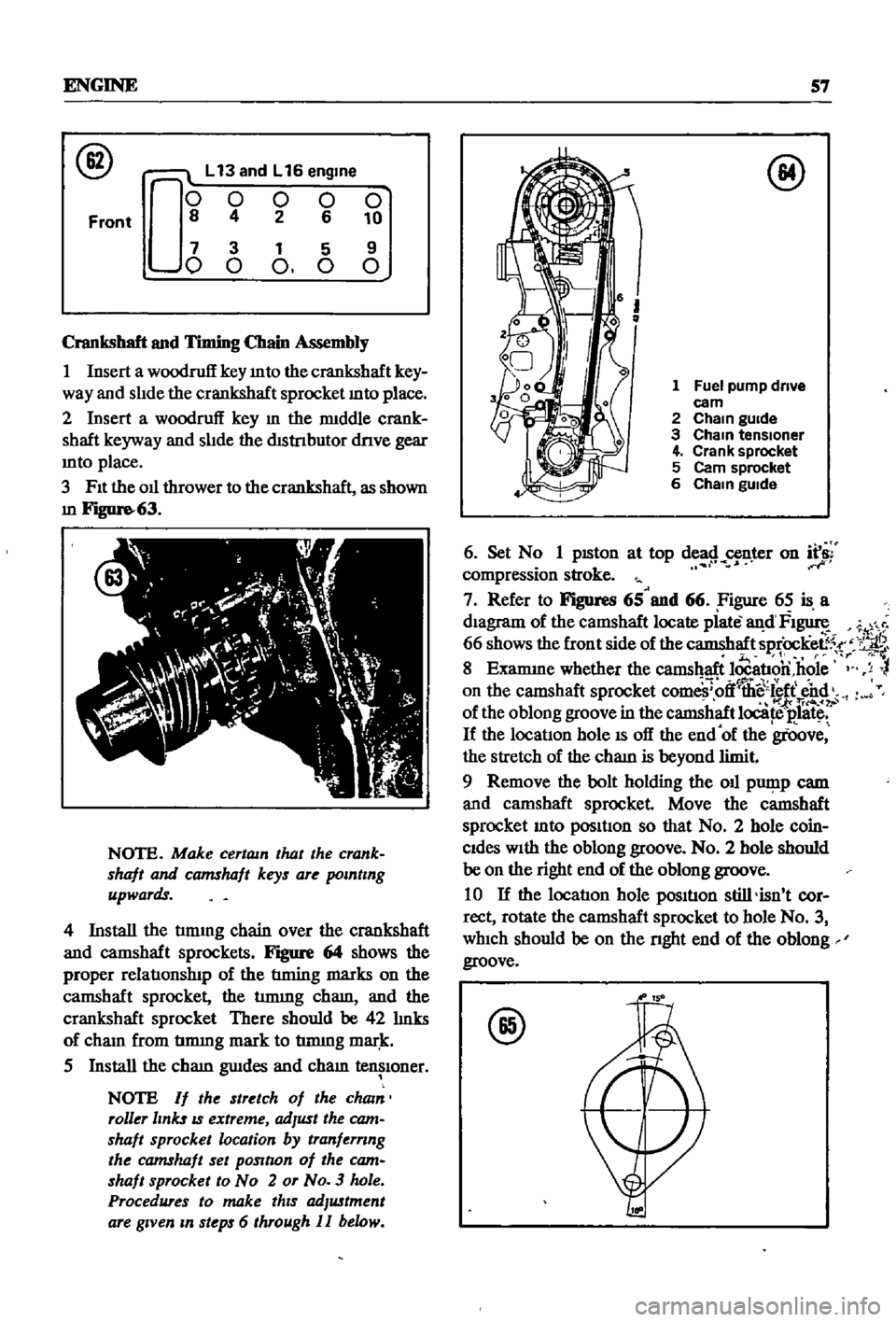

@

L

13

and

L

16

engme

000000

8

4

2

6

10

7

3

1

5

9

o

0

0

0

0

Front

Crankshaft

and

Timing

Chain

Assembly

1

Insert

a

woodruff

key

mto

the

crankshaft

key

way

and

slide

the

crankshaft

sprocket

mto

place

2

Insert

a

woodruff

key

m

the

Illiddle

crank

shaft

keyway

and

slide

the

dIstnbutor

dnve

gear

mto

place

3

FIt

the

oil

thrower

to

the

crankshaft

as

shown

m

Figure

63

NOTE

Make

certam

that

the

crank

shaft

and

camshaft

keys

are

polntlng

upwards

4

Install

the

tmung

chain

over

the

crankshaft

and

camshaft

sprockets

Figure

64

shows

the

proper

relatIonslnp

of

the

tIming

marks

on

the

camshaft

sprocket

the

tmung

cham

and

the

crankshaft

sprocket

There

should

be

42

hnks

of

cham

from

tmung

mark

to

tmung

mar

k

5

Install

the

cham

gwdes

and

cham

tensIoner

NOTE

If

the

stretch

of

the

cham

roller

links

IS

extreme

adJust

the

cam

shaft

sprocket

location

by

tranfernng

the

camshaft

set

pOSltlon

of

the

cam

shaft

sprocket

to

No

2

or

No

3

hole

Procedures

to

make

thIS

adJustment

are

gIVen

m

steps

6

through

II

below

@

1

Fuel

pump

drive

eam

2

Cham

gUide

3

Cham

tensloner

4

Crank

sprocket

5

Cam

sprocket

6

Cham

gUide

6

Set

N

1

pISton

at

top

de

8

n

r

on

f

compressIon

stroke

7

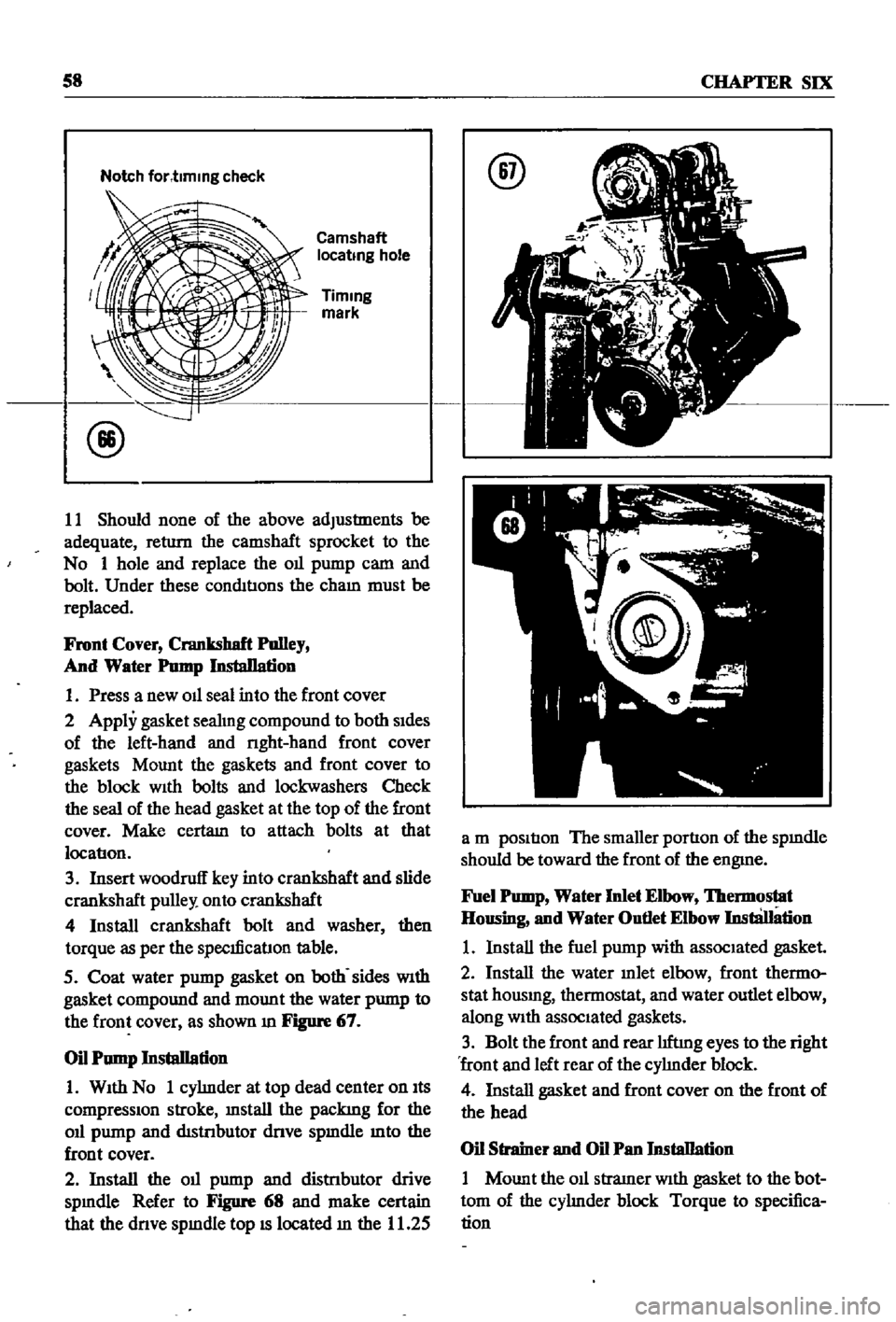

Refer

to

Figures

65

and

66

Figure

65

is

a

dIagram

of

the

camshaft

locate

piate

an

d

FI

1

66

shows

the

front

side

of

the

camshaft

sprOcKee5

r

11

r

If

8

Examme

whether

the

camshaft

locatIon

hole

y

on

the

camshaft

sprocket

com

ff

llii

sl

ff

end

foI

tri4o

of

the

oblong

groove

in

the

camshaft

locate

E

1litc

If

the

locatIon

hole

IS

off

the

end

of

the

groove

the

stretch

of

the

cham

is

beyond

limit

9

Remove

the

bolt

holding

the

oil

pwp

p

cam

and

camshaft

sprocket

Move

the

camshaft

sprocket

mto

posItIon

so

that

No

2

hole

coin

Cides

With

the

oblong

groove

No

2

hole

should

be

on

the

right

end

of

the

oblong

groove

10

If

the

locatIon

hole

posItIon

still

isn

t

cor

rect

rotate

the

camshaft

sprocket

to

hole

No

3

which

should

be

on

the

nght

end

of

the

oblong

groove

@

Page 63 of 252

58

CHAPTER

SIX

Notch

for

t1mmg

check

Camshaft

locatmg

hole

Timmg

mark

11

Should

none

of

the

above

adjustments

be

adequate

return

the

camshaft

sprocket

to

the

No

1

hole

and

replace

the

Oll

pump

cam

and

bolt

Under

these

conditIons

the

cham

must

be

replaced

Front

Cover

Crankshaft

Polley

And

Water

Pomp

InstaDation

1

Press

a

new

Oll

seal

into

the

front

cover

2

Apply

gasket

seahng

compound

to

both

sides

of

the

left

hand

and

nght

hand

front

cover

gaskets

Mount

the

gaskets

and

front

cover

to

the

block

With

bolts

and

lockwashers

Check

the

seal

of

the

head

gasket

at

the

top

of

the

front

cover

Make

certam

to

attach

bolts

at

that

locatlon

3

Insert

woodruff

key

into

crankshaft

and

slide

crankshaft

pulley

onto

crankshaft

4

Install

crankshaft

bolt

and

washer

then

torque

as

per

the

speclficatlon

table

5

Coat

water

pump

gasket

on

both

sides

With

gasket

compound

and

mount

the

water

pump

to

the

front

cover

as

shown

m

Figure

67

Oil

Pump

Installation

1

With

No

1

cyhnder

at

top

dead

center

on

Its

compressIOn

stroke

mstall

the

packing

for

the

Oll

pump

and

distnbutor

dnve

spmdle

mto

the

front

cover

2

Install

the

Oll

pump

and

distnbutor

drive

spmdle

Refer

to

Figure

68

and

make

certain

that

the

dnve

spmdle

top

IS

located

m

the

11

25

@

a

m

position

The

smaller

portion

of

the

spmdle

should

be

toward

the

front

of

the

engme

Fuel

Pomp

Water

Inlet

Elbow

lbermostat

Housing

and

Water

Outlet

Elbow

InstliJIation

1

Install

the

fuel

pump

with

associated

gasket

2

Install

the

water

mlet

elbow

front

thermo

stat

housmg

thermostat

and

water

outlet

elbow

along

With

associated

gaskets

3

Bolt

the

front

and

rear

hftmg

eyes

to

the

right

front

and

left

rear

of

the

cyhnder

block

4

Install

gasket

and

front

cover

on

the

front

of

the

head

Oil

Strainer

and

Oil

Pan

Installation

1

Mount

the

011

stramer

With

gasket

to

the

bot

tom

of

the

cyhnder

block

Torque

to

specifica

tion

Page 96 of 252

CHAPTER

NINE

ENGINE

ELECTRICAL

SYSTEM

The

electrIcal

system

has

undergone

slIght

yearly

changes

the

most

SignIficant

being

ill

the

distrIbutor

Some

models

have

a

smgle

contact

pomt

whIle

others

have

a

dual

pomt

system

De

talls

are

covered

m

the

dIstrIbutor

sectlon

The

electrIcal

system

IS

a

12

volt

negatIve

type

OPERATION

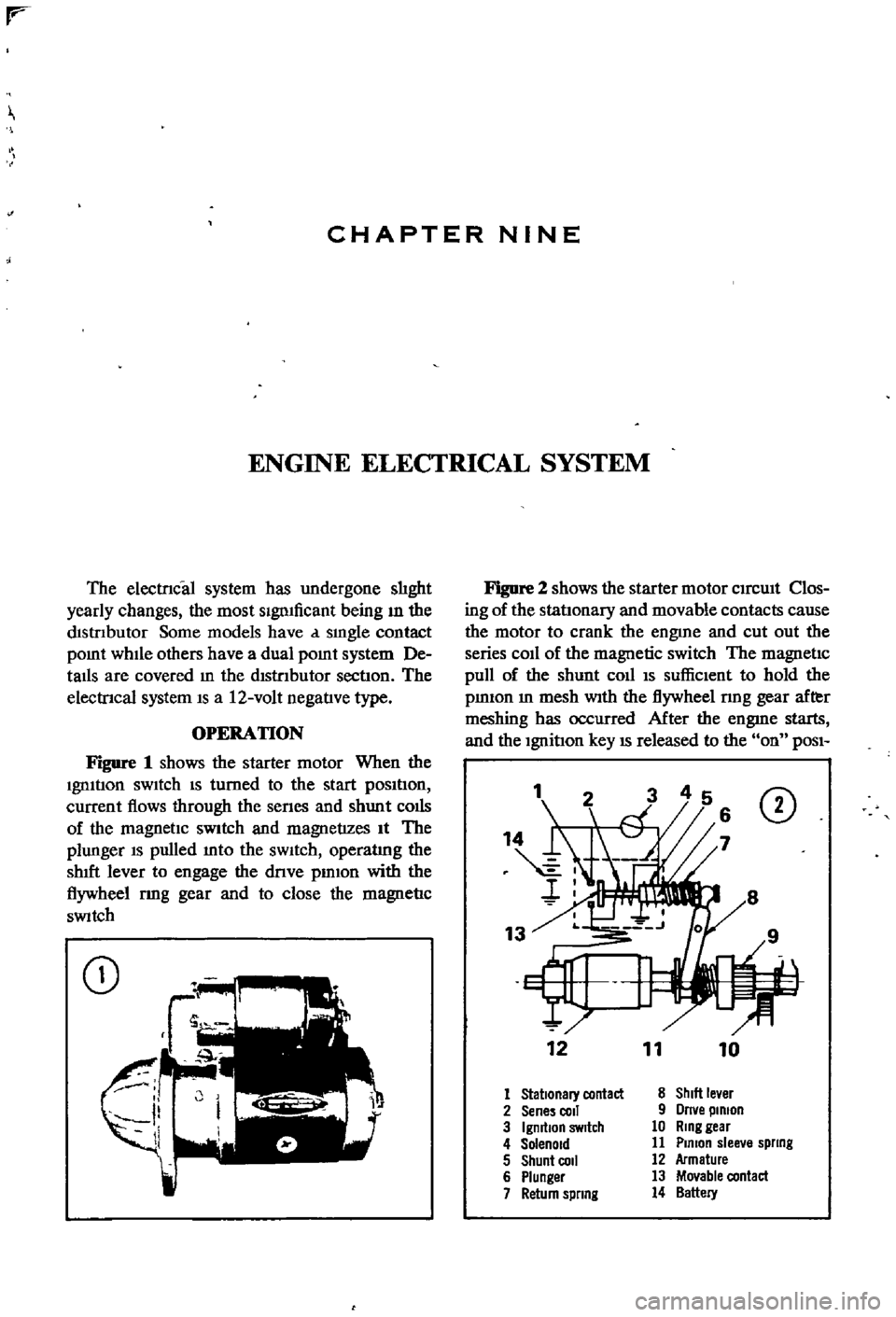

Figure

1

shows

the

starter

motor

When

the

Ignltlon

sWItch

IS

turned

to

the

start

pOSItIon

current

flows

through

the

senes

and

shunt

colis

of

the

magnetIc

SWitch

and

magnetizes

It

The

plunger

IS

pulled

mto

the

sWItch

operatlng

the

shIft

lever

to

engage

the

dnve

pmlon

with

the

flywheel

rmg

gear

and

to

close

the

magnetIc

SWitch

CD

Figure

2

shows

the

starter

motor

CIrcUIt

Clos

ing

of

the

statlonary

and

movable

contacts

cause

the

motor

to

crank

the

engme

and

cut

out

the

series

coIl

of

the

magnetic

switch

The

magnetic

pull

of

the

shunt

coll

IS

suffiCIent

to

hold

the

pmIOn

m

mesh

With

the

flywheel

nng

gear

after

meshing

has

occurred

After

the

engme

starts

and

the

Ignition

key

IS

released

to

the

on

POSI

1

CD

12

11

10

1

Stationary

contact

8

ShIlt

le

er

2

Sene

coli

9

Orne

pinion

3

IgmtlOn

SWitch

10

Ring

gear

4

Solenoid

11

Plmon

slee

e

spllng

5

Shunt

COil

12

Armature

6

Plunger

13

Movable

contact

7

Return

spllng

14

Battery

Page 104 of 252

ENGINE

ELECfRlCAL

SYSTEM

99

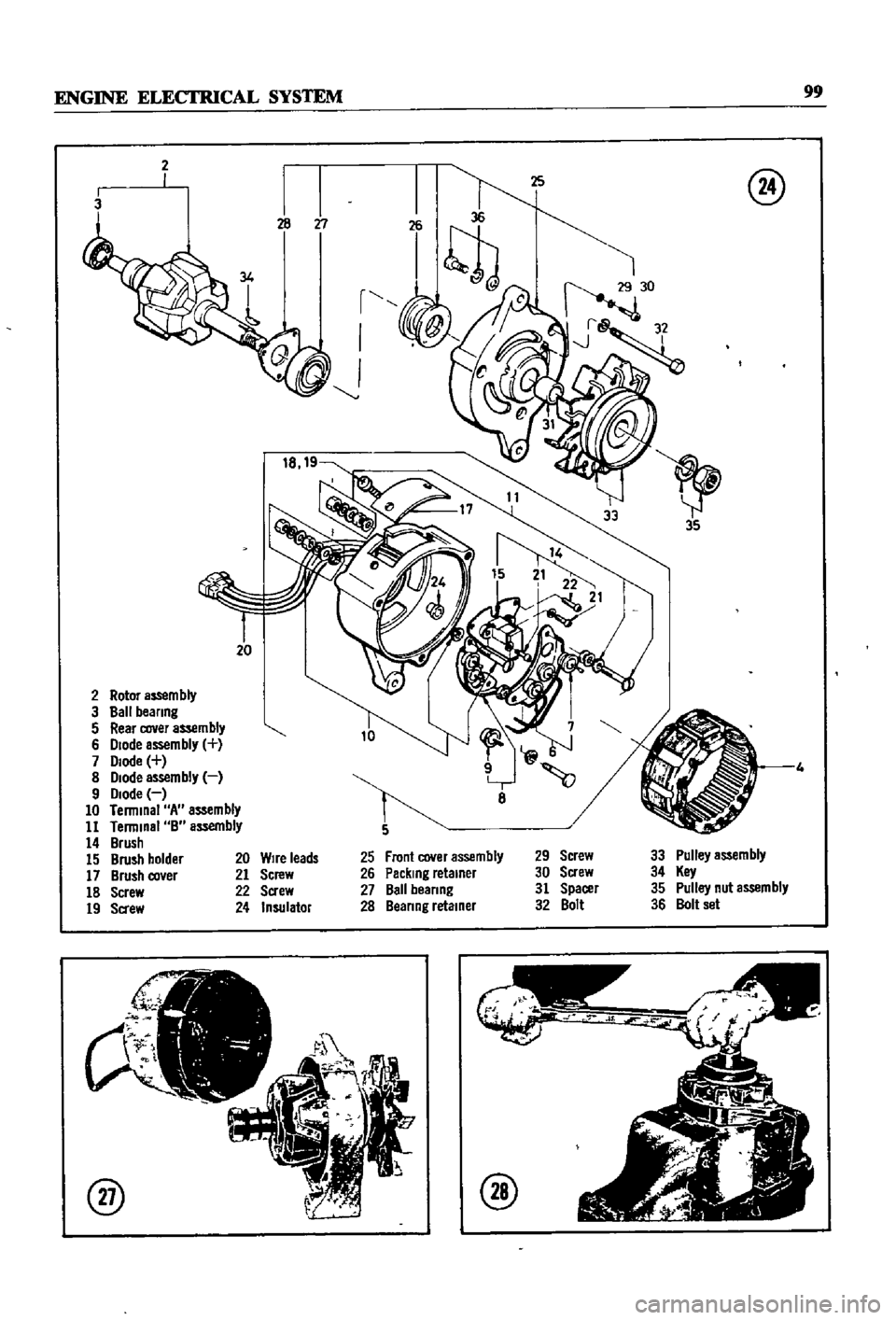

2

3

r

I

J

20

2

Rotor

aS5em

bly

3

Ball

beanng

5

Rear

cover

assembly

6

Diode

assembly

7

Diode

8

Diode

assembly

9

Diode

10

Terminal

A

assembly

11

Terminal

B

assembly

14

Brush

15

Brush

holder

17

Brush

co

er

18

Screw

19

Sa

ew

@

8

Front

cover

assembly

Packing

retainer

Ball

beanng

Beanng

retainer

29

Screw

30

Screw

31

Spacer

32

Bolt

33

Pulley

assembly

34

Key

35

Pulley

nut

assembly

36

Bolt

set

20

Wire

leads

21

Screw

22

Screw

24

Insulator

@

@

Page 153 of 252

148

CHAPTER

ELEVEN

1

Insert

key

in

IgnItion

switch

and

turn

to

first

posltlon

2

Depress

accelerator

pedal

fully

LISten

for

the

solenOId

to

click

If

a

clIck

is

heard

the

solenoid

is

operating

correctly

3

Replace

solenoid

if

click

IS

not

heard

Before

replacing

solenoid

dram

apprOlumately

2

pInts

of

transmission

011

from

tranSmISsion

Re

fill

when

solenoid

replacement

is

complete

4

If

solenoId

IS

operatlng

correctly

but

trouble

persISts

check

WIres

for

continuity

With

electri

cal

tester

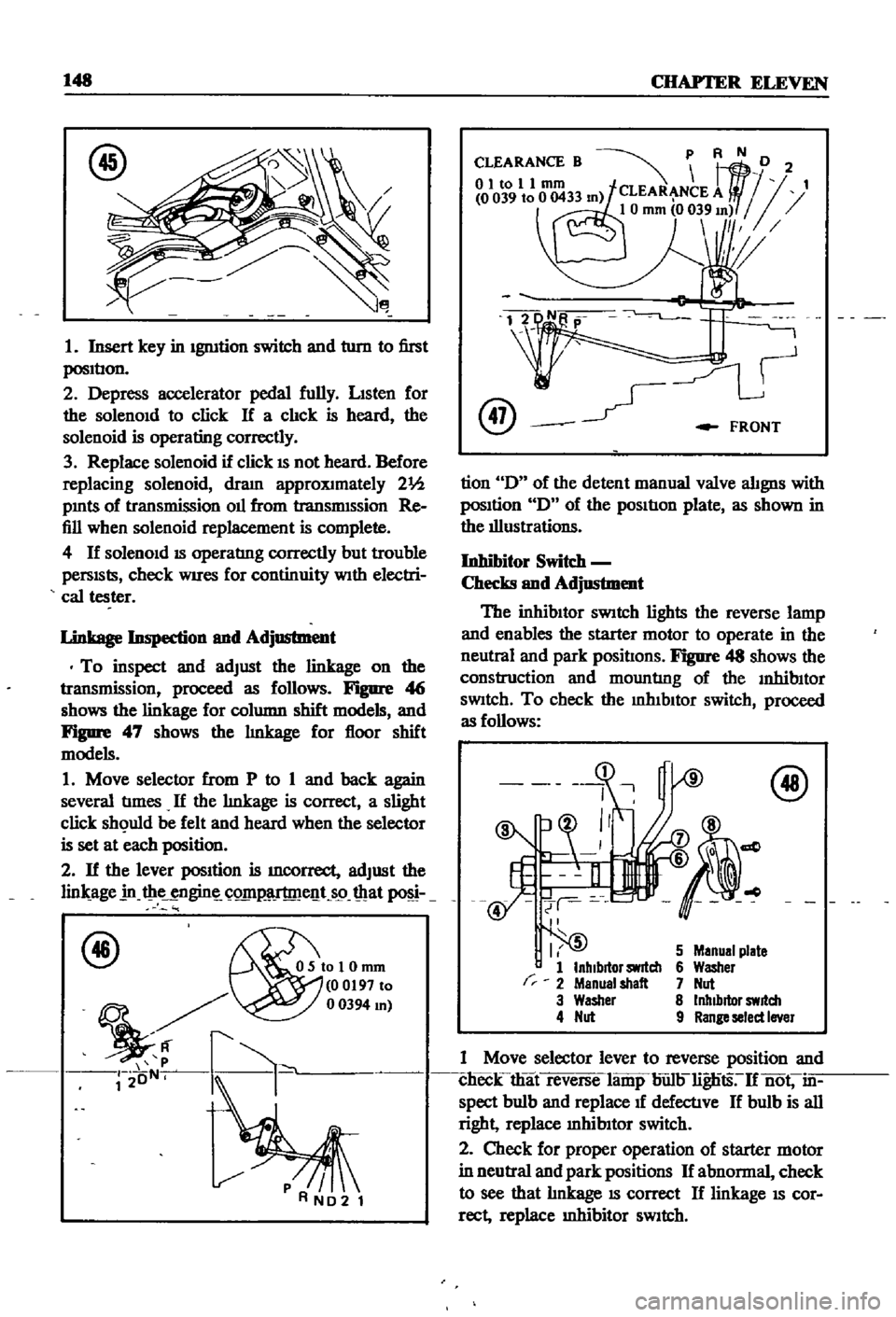

Linkage

Inspection

and

Adjustment

To

inspect

and

adjust

the

linkage

on

the

transmission

proceed

as

follows

Figure

4

j

shows

the

linkage

for

column

shift

models

and

Figure

47

shows

the

lInkage

for

floor

shift

models

1

Move

selector

from

P

to

1

and

back

again

several

tImes

If

the

lInkage

is

correct

a

slight

click

sh

uld

be

felt

and

heard

when

the

selector

is

set

at

each

position

2

If

the

lever

position

is

mcorrect

adjust

the

lin

age

in

t

ie

ngin

C

Q1I1

lT

me

t

s9

mat

f46

OSIoI0mm

00197

to

mJ

r2

oN

k

@

FRONT

tion

D

of

the

detent

manual

valve

alignS

with

posItion

D

of

the

pOSItIon

plate

as

shown

in

the

illustrations

Inhibitor

Switc

h

Checks

and

Adjustment

The

inhibItor

SWitch

lights

the

reverse

lamp

and

enables

the

starter

motor

to

operate

in

the

neutral

and

park

positIons

Figure

48

shows

the

construction

and

mountlng

of

the

InhibItor

SWitch

To

check

the

mhIbltor

switch

proceed

as

follows

r

I

5

1

InhIbitor

switch

2

Menual

shalt

3

Washer

4

Nut

5

Manual

plate

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

Iner

1

Move

selector

lever

to

reverse

position

and

clieck

that

reverse

lamp

bun

lignts

If

not

in

spect

bulb

and

replace

1f

defectlve

If

bulb

is

all

right

replace

mhibItor

switch

2

Check

for

proper

operation

of

starter

motor

in

neutral

and

park

positions

If

abnormal

check

to

see

that

lInkage

IS

correct

If

linkage

IS

cor

rect

replace

Inhibitor

SWitch

Page 215 of 252

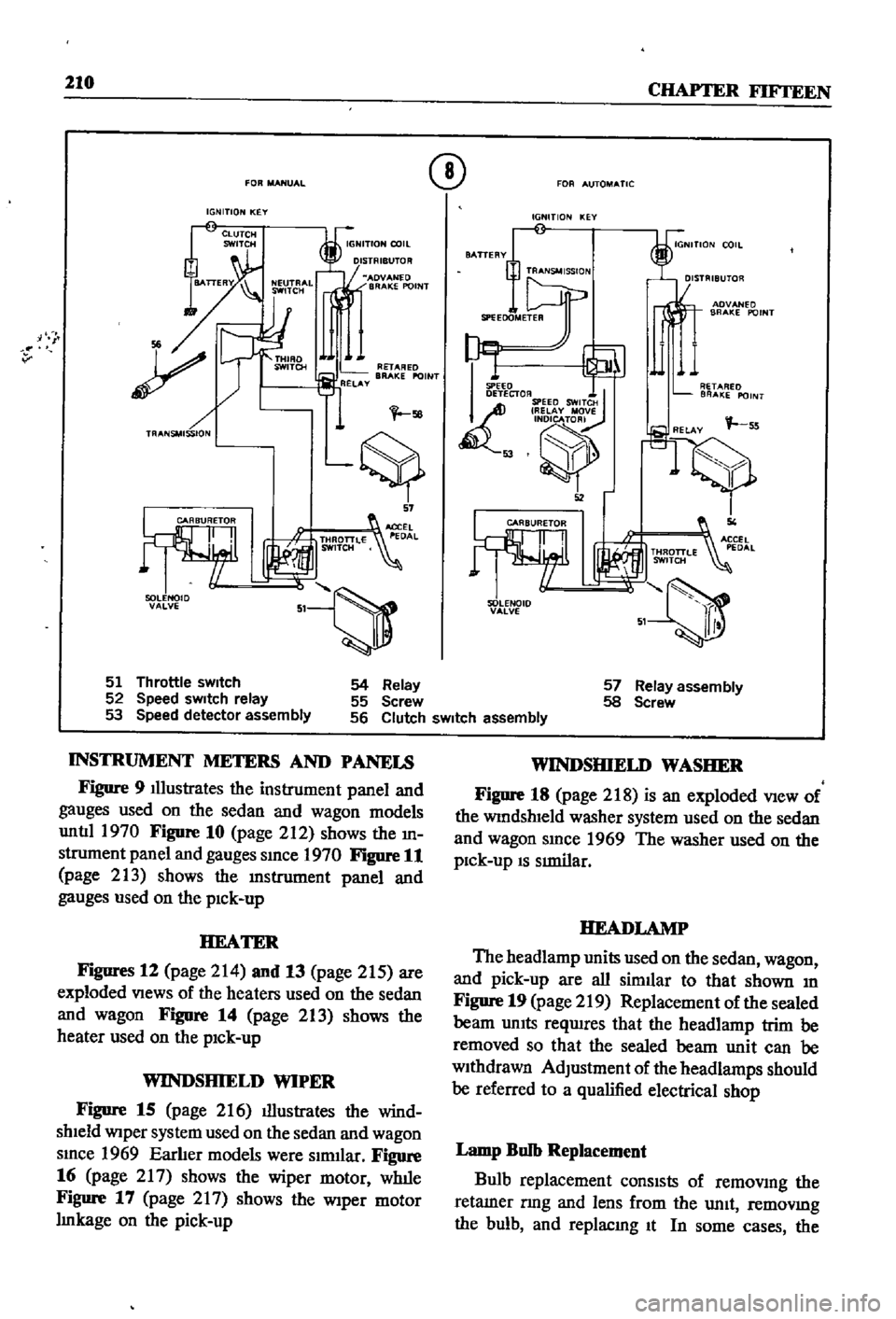

110

CHAPTER

FIFTEEN

FOR

MANUAL

IGNITION

KEY

i

I

MADV

Nf

D

BRAKE

POINT

v

sa

tS

57

51

Th

rottle

sWItch

52

Speed

sWItch

relay

53

Speed

detector

assembly

Q

FOR

AUTOMATIC

IGNITION

KEY

AOVANEO

BRAKE

POINT

I

SPEED

DETECTOR

SPEED

SWITCH

I

RELAY

MJsr

I

IQ

52

SOLENOID

VALVE

54

Relay

55

Screw

56

Clutch

sWItch

assembly

57

Relay

assembly

58

Screw

INSTRUMENT

METERS

AND

PANELS

Figure

9

Illustrates

the

instrument

panel

and

gauges

used

on

the

sedan

and

wagon

models

untIl

1970

Figure

10

page

212

shows

the

m

strument

panel

and

gauges

smce

1970

Figure

11

page

213

shows

the

lDstrument

panel

and

gauges

used

on

the

pick

up

HEATER

Figures

12

page

214

and

13

page

215

are

exploded

Views

of

the

heaters

used

on

the

sedan

and

wagon

FigDre

14

page

213

shows

the

heater

used

on

the

pick

up

WINDSHIELD

WIPER

Figure

15

page

216

illustrates

the

wind

shield

Wiper

system

used

on

the

sedan

and

wagon

smce

1969

Earlier

models

were

slrmlar

Figure

16

page

217

shows

the

wiper

motor

wlule

Figure

17

page

2

I

7

shows

the

Wiper

motor

Imkage

on

the

pick

up

WINDSHIELD

WASHER

Figure

18

page

218

is

an

exploded

View

of

the

WindshIeld

washer

system

used

on

the

sedan

and

wagon

smce

1969

The

washer

used

on

the

pick

up

IS

SImilar

HEADLAMP

The

headlamp

units

used

on

the

sedan

wagon

and

pick

up

are

all

similar

to

that

shown

m

Figure

19

page

219

Replacement

of

the

sealed

beam

UnIts

reqwres

that

the

headlamp

trim

be

removed

so

that

the

sealed

beam

unit

can

be

withdrawn

AdJustment

of

the

headlamps

should

be

referred

to

a

qualified

electrical

shop

Lamp

Bulb

Replacement

Bulb

replacement

consIsts

of

removmg

the

retamer

nng

and

lens

from

the

unit

removmg

the

bulb

and

replacmg

It

In

some

cases

the