suspension DATSUN 510 1968 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 3 of 252

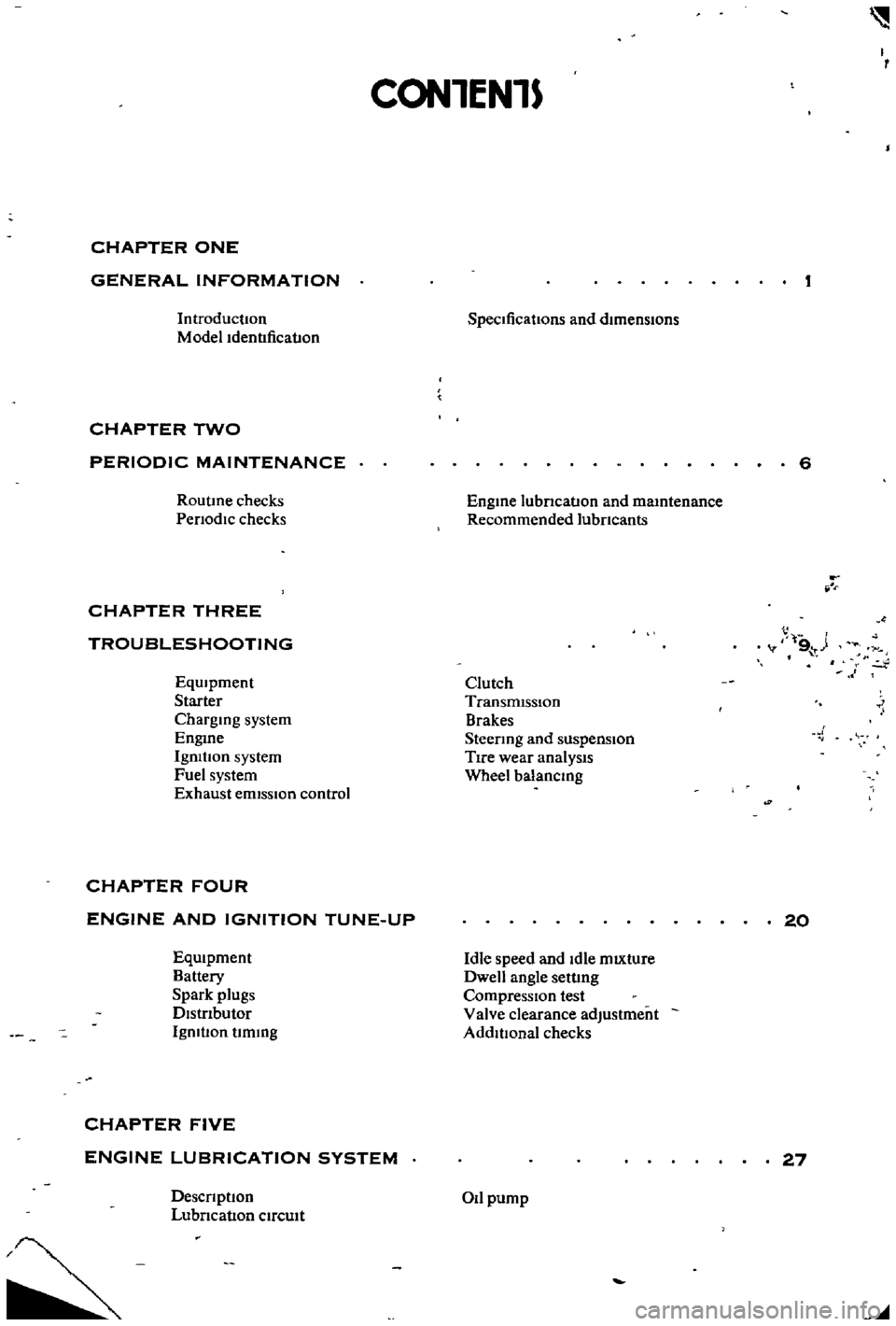

CON1EN1S

CHAPTER

ONE

GENERAL

INFORMATION

Introduction

Model

Identification

CHAPTER

TWO

PERIODIC

MAINTENANCE

RoutIne

checks

Pen

odic

checks

CHAPTER

THREE

TROUBLESHOOTING

EqUIpment

Starter

ChargIng

system

EngIne

Igmtlon

system

Fuel

system

Exhaust

emIssIon

control

CHAPTER

FOUR

ENGINE

AND

IGNITION

TUNE

UP

EqUIpment

Battery

Spark

plugs

DIstrIbutor

Igmtlon

timIng

CHAPTER

FIVE

ENGINE

LUBRICATION

SYSTEM

Descnptlon

Lubncation

cIrcuIt

SpecIficatiOns

and

dImensIons

EngIne

lubncation

and

maIntenance

Recommended

lubncants

Clutch

TransmIssiOn

Brakes

Steenng

and

suspension

TIre

wear

analysIs

Wheel

balancIng

Idle

speed

and

Idle

mIXture

Dwell

angle

setting

CompressIon

test

Valve

clearance

adjustment

AddlllOnal

checks

Oil

pump

I

6

t

1

4

V

9

t

1

20

27

Page 5 of 252

CHAPTER

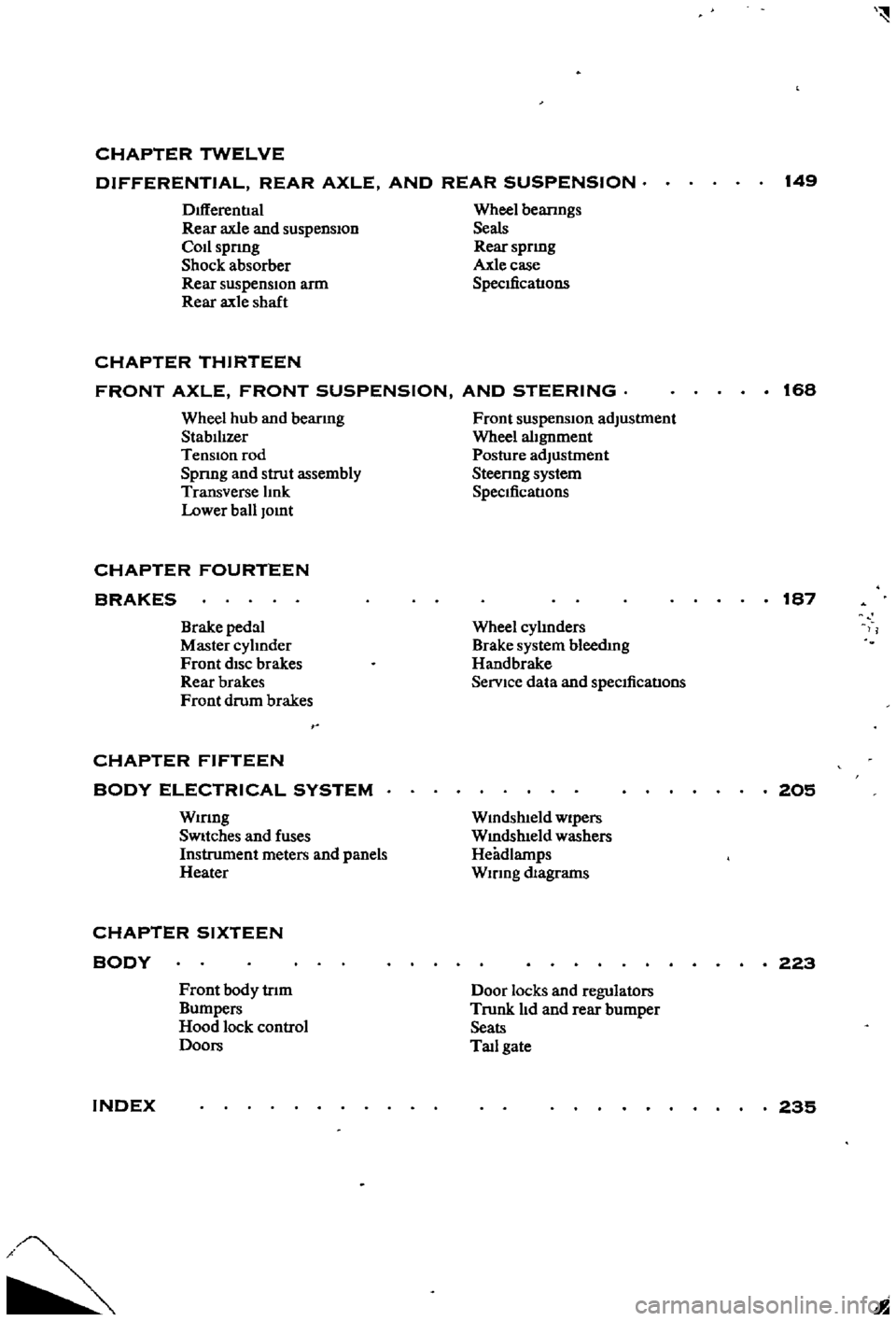

TWELVE

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

149

DIfferentIal

Rear

axle

and

suspension

Codspnng

Shock

absorber

Rear

suspensIOn

arm

Rear

axle

shaft

Wheel

beanngs

Seals

Rear

spnng

Axle

case

SpecificatIons

CHAPTER

THIRTEEN

FRONT

AXLE

FRONT

SUSPENSION

AND

STEERING

168

Wheel

hub

and

bearmg

StabilIzer

TenSion

rod

Spnng

and

strut

assembly

Transverse

lInk

Lower

ball

Jomt

Front

suspension

adjustment

Wheel

alignment

Posture

adJustment

Steenng

system

SpeCificatIons

CHAPTER

FOURTEEN

BRAKES

187

Brake

pedal

Master

cylInder

Front

diSC

brakes

Rear

brakes

Front

drum

brakes

Wheel

cylInders

Brake

system

bleedIng

Handbrake

Service

data

and

speCificatIons

CHAPTER

FIFTEEN

BODY

ELECTRICAL

SYSTEM

Wmng

SWitches

and

fuses

Instrument

meters

and

panels

Heater

205

Wmdshleld

wipers

Wmdslueld

washers

Headlamps

WIrIng

diagrams

CHAPTER

SIXTEEN

BODY

223

Front

body

trIm

Bumpers

Hood

lock

control

Doors

Door

locks

and

regulators

Trunk

lId

and

rear

bumper

Seats

Tad

gate

INDEX

235

I

Page 10 of 252

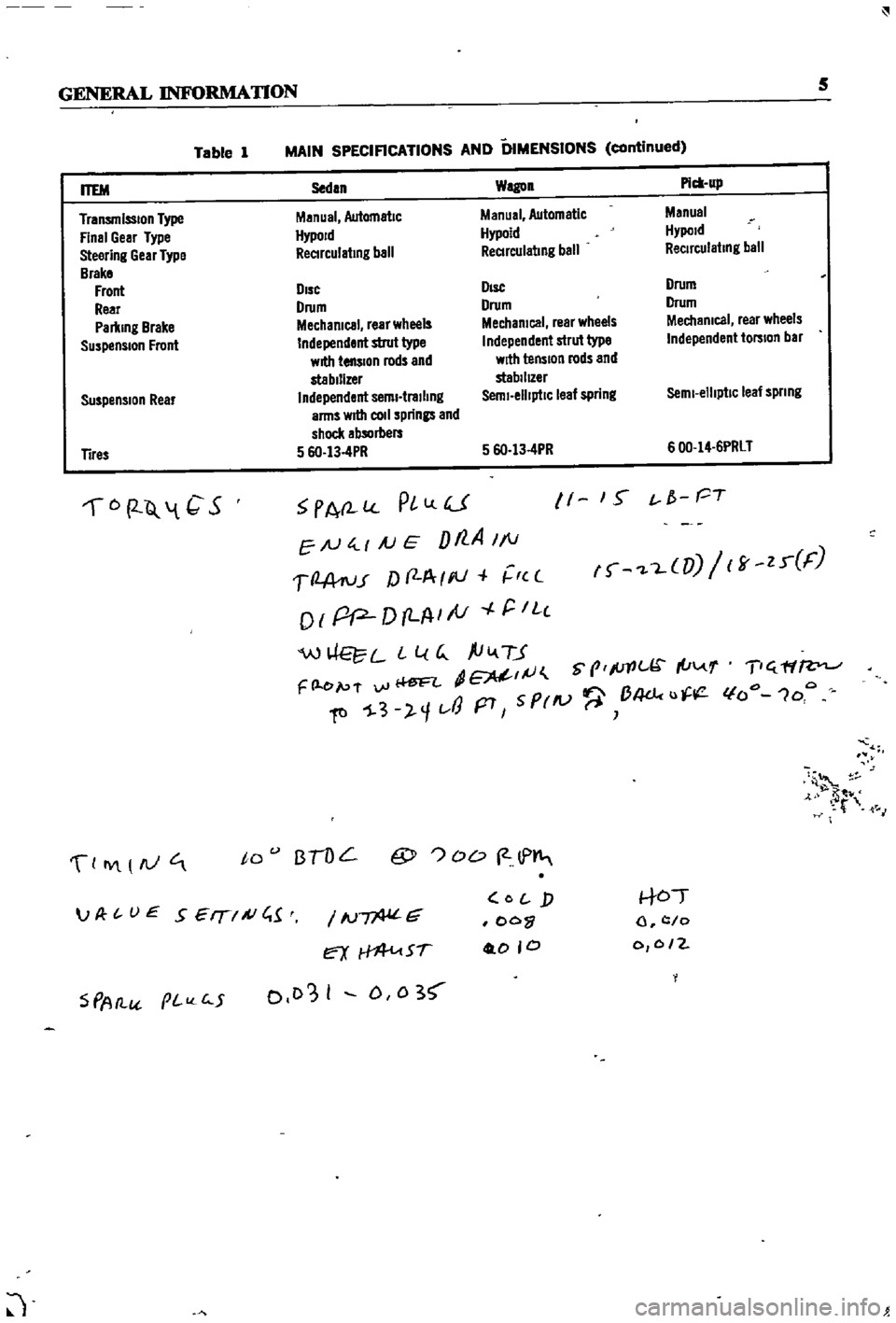

GENERAL

INFORMATION

5

Table

1

MAIN

SPECIFICATIONS

AND

DIMENSIONS

continued

Suspension

Rear

Sedan

Wagon

Pick

up

Manual

Automatic

Manual

Automatic

Manual

HypoJd

Hypoid

Hypold

ReCIrculating

ball

ReCIrculating

ball

ReCirculating

ball

DIsc

DIsc

Drum

Drum

Drum

Drum

Mechanical

rear

wheels

Mechanical

rear

wheels

Mechanical

rear

wheels

Independent

strut

type

Independent

strut

type

Independent

torsion

bar

with

tension

rods

and

with

tension

rods

and

stabilizer

stabilIZer

Independent

semi

trailing

Semi

elliptiC

leaf

spring

Semi

elliptic

leaf

spnng

arms

wrtII

coli

springs

and

shock

absorbers

5

6O

13

4PR

5

6O

13

4PR

600

14

6PRLT

ITEM

Transmission

Type

Final

Gear

Type

Steering

Gear

Type

Brake

Front

Rear

Parking

Brake

Suspension

Front

Tires

6

2

Q

1

C

S

PA

l

PlLlU

EN

4

1

AJ

E

Dt7

A

1

1

1

2

A

ru

r

f

f

A

I

III

r

c

o

I

pP

D

LA

I

tV

r

IL

c

W

L

L

l

G

ftiv

TJ

dE

IJ

S

prlc

I

u

F

l

e

p

f

vi

Ii

ftl

1

3

l

1t

J

p7

5

PrlV

B4dc

u

11

1

S

t

f

PT

f

L

UJ

ff

zr

F

T

ff

lfo

1oo

4

t

M

0

IY

AJ

to

BTOL

@

OD

2

lP

S

PAtl

pI

c

5

IN

G

ex

Sf

0103

I

D

0

3

O

j

oo

0

0

0

to

l

c

o

0

0

2

JP

t

UE

SEIT

A

C

1

J

Page 21 of 252

16

CHAPTER

TIlREE

sary

Also

check

all

parts

for

mlSaltgnment

and

uneven

wear

TRANSMISSION

1

Difficult

to

mesh

gears

Make

certam

the

clutch

pressure

plate

and

re

lease

beanng

are

m

good

condItion

The

trouble

can

be

caused

by

worn

gears

shaft

and

or

bear

mgs

DISassemble

and

repaIr

as

requIred

Also

can

be

caused

by

msufficlent

operatmg

stroke

due

to

worn

or

loose

sltdmg

parts

or

a

defective

synchronIZer

DIsassemble

carefully

InSpect

and

replace

as

requIred

2

Gears

slip

out

of

mesh

Generally

thIS

trouble

occurs

when

the

mterlock

plunger

check

ball

and

or

spnng

IS

weakened

or

worn

The

trouble

can

also

be

caused

by

worn

fork

rod

ball

groove

damaged

bearings

or

dam

aged

gears

DIsassemble

carefully

mspect

and

replace

as

required

3

NOIse

If

nOISes

are

heard

wIth

the

engme

idlmg

and

the

clutch

disengaged

the

nOIse

IS

probably

conung

from

the

transmISSIOn

Several

Items

can

cause

nOISes

either

smgly

or

m

combmatIon

Check

the

qualIty

and

quantity

of

lubrIcant

in

the

trans

mISSIon

Replace

or

replenISh

as

necessary

Worn

bearIngs

wIll

usually

produce

a

lugh

humming

at

hIgh

speed

and

a

cycltc

knockIng

sound

at

low

speed

Worn

or

damaged

splInes

and

bushmgs

will

also

cause

nOIse

BRAKES

1

Brake

pedal

goes

to

floor

There

are

numerous

causes

for

thIS

includIng

excessIvely

worn

Itnmgs

aIr

in

the

hydraultc

sys

tem

leaky

brake

lmes

leaky

wheel

cylmders

or

leaky

or

worn

master

cylmder

Check

for

leaks

and

thIn

brake

linmgs

Bleed

and

adjust

the

brakes

If

thIS

doesn

t

cure

the

trouble

rebwld

wheel

cylmders

a

nd

or

master

cylmder

2

Spongy

pedal

Normally

caused

by

aIr

m

the

system

blee

d

and

adjust

the

brakes

3

Brakes

pull

Check

brake

adjustment

Also

check

for

contam

inated

brake

Itmngs

from

leaks

leaky

wheel

cyltnders

loose

caltpers

frozen

or

seIZed

pIstons

and

restrIcted

brake

lmes

or

hoses

In

addItion

check

front

end

alignment

and

suspensIOn

dam

age

such

as

broken

front

or

rear

sprmgs

shocks

etc

Check

condItIon

of

tIres

4

Brakes

squeal

or

chatter

Check

brake

lmmg

thickness

and

brake

drum

roundness

Ensure

that

the

shoes

have

cham

ferred

ends

and

are

not

loose

Inspect

the

condI

tion

of

the

rotors

on

the

front

wheel

dISC

brakes

to

make

certain

they

are

not

scored

or

damaged

Clean

away

all

dIrt

on

shoes

pads

rotors

or

drums

5

Draggmg

brakes

Check

brake

adjustment

includmg

handbrake

Check

for

broken

or

weak

shoe

return

springs

swollen

rubber

parts

due

to

unproper

brake

flUId

or

other

contammatIon

Clean

or

replace

de

fectIve

parts

6

Hard

pedal

Check

brake

linmgs

for

contammation

Also

check

for

restrIcted

brake

lines

and

hoses

7

High

speed

fade

Check

for

dIstorted

or

out

of

round

drums

and

contamInated

brake

lmmgs

Make

certam

the

recommended

brake

flUId

IS

used

Dram

entIre

system

and

refill

If

In

doubt

8

Pulsatmg

pedal

Check

for

dIStorted

or

out

of

round

drums

or

rotors

Check

for

excessIVe

brake

dISC

run

out

STEERING

AND

SUSPENSION

NOTE

Unusual

steermg

pullmg

or

wandermg

IS

usually

caused

by

bent

or

otherwise

mIsaligned

suspenszon

parts

Because

of

the

speCialized

equIp

ment

reqUired

to

evaluate

and

correct

these

faults

It

IS

recommended

t

tat

servIce

to

the

steermg

and

suspension

system

be

referred

to

your

Datsun

dealer

oca

quallfied

specrallst

m

thiS

field

1

VibratIOn

felt

m

steermg

wheel

VIbratIon

can

be

caused

by

several

thmgs

includ

ing

lll1proper

aIr

pressure

m

tIres

uneven

wear

Page 22 of 252

TROUBLESHOOTING

17

of

tIre

loose

wheels

unproper

adjustment

or

wear

of

front

wheel

bearIngs

faulty

wheel

align

ment

or

wear

of

transverse

lInk

and

tension

rod

bushings

Inspect

all

parts

carefully

for

wear

or

damage

Replace

or

replUI

parts

as

required

2

Shock

transmltled

through

steering

wheel

This

is

usually

most

noticeable

when

traveling

over

bad

roads

at

relatively

high

speeds

Causes

Include

damage

to

the

idler

ann

insuffiCient

tIghtening

of

steenng

gear

box

wear

of

the

steer

Ing

linkage

and

wear

of

the

suspension

ball

joint

Inspect

all

parts

for

wear

or

damage

Refer

to

Chapter

ThIrteen

for

service

or

repair

you

can

perform

and

for

procedures

which

should

be

referred

to

your

deal

r

3

Shlmmymg

This

is

usually

most

noticeable

when

a

specIfic

speed

IS

attained

and

will

normally

repeat

at

that

speed

Causes

are

generally

unbalanced

wheels

unproper

adjustment

of

steenng

gear

insuffi

cient

backlash

malfunction

of

the

shock

ab

sorbers

or

loose

bolts

for

the

strut

mountIng

Reparr

or

replace

defective

parts

as

required

Refer

to

Chapter

Thirteen

4

Wandermg

of

car

m

one

dlrectlOnl

This

problem

can

be

caused

by

improper

air

pressure

loose

wheel

nuts

difference

in

tire

tread

wear

from

left

to

right

side

Incorrect

adjustment

of

wheel

bearings

defectIve

wheel

beanngs

collapsing

or

twistIng

of

front

spnng

or

Incorrect

wheel

alignment

Also

binding

of

the

brake

shoes

worn

bushings

in

the

transverse

link

or

the

tension

rod

and

deformation

of

s

enng

lInkage

and

suspension

link

can

cause

wander

Carefully

iuspect

all

parts

for

looseness

and

wear

and

re

place

or

repaIr

as

required

In

some

c

ases

a

de

fective

rear

suspension

may

also

cause

the

vehicle

to

wander

5

InstabIlity

Instability

can

be

caused

by

unproper

tIre

pres

sures

worn

bushings

in

the

transverse

link

and

tension

rod

mcorrect

wheel

alignment

worn

steenng

linkage

Incorrect

adjustment

of

steer

ing

gear

and

unbalanced

wheels

Inspect

all

parts

carefully

for

wear

and

damage

Adjust

repair

or

replace

as

required

6

Heavy

feelmg

m

steering

This

can

be

caused

by

improper

tIre

pressures

insuffiCient

or

contamInated

lubncant

in

gear

box

damage

or

insuffiCient

grease

In

suspeuslon

ball

Joint

damaged

or

badly

adjusted

wheel

bearIngs

worn

or

damaged

steermg

gear

dam

age

of

upper

strut

bearing

and

mterference

of

steenng

column

With

turn

signal

SWitch

Inspect

all

parts

carefully

for

wear

and

damage

Adjust

repair

or

replace

as

required

7

ExceSSIve

play

m

steermg

wheel

This

is

usually

caused

by

Incorrect

adjustment

of

the

steenng

gear

worn

bushings

in

the

steering

linkage

or

Idler

arm

mcorrect

adjustment

of

the

front

wheel

bearings

worn

bushIngs

in

the

trans

verse

lInk

and

tension

rod

Carefully

inspect

all

parts

for

wear

or

damage

Adjust

repair

or

re

place

as

reqUIred

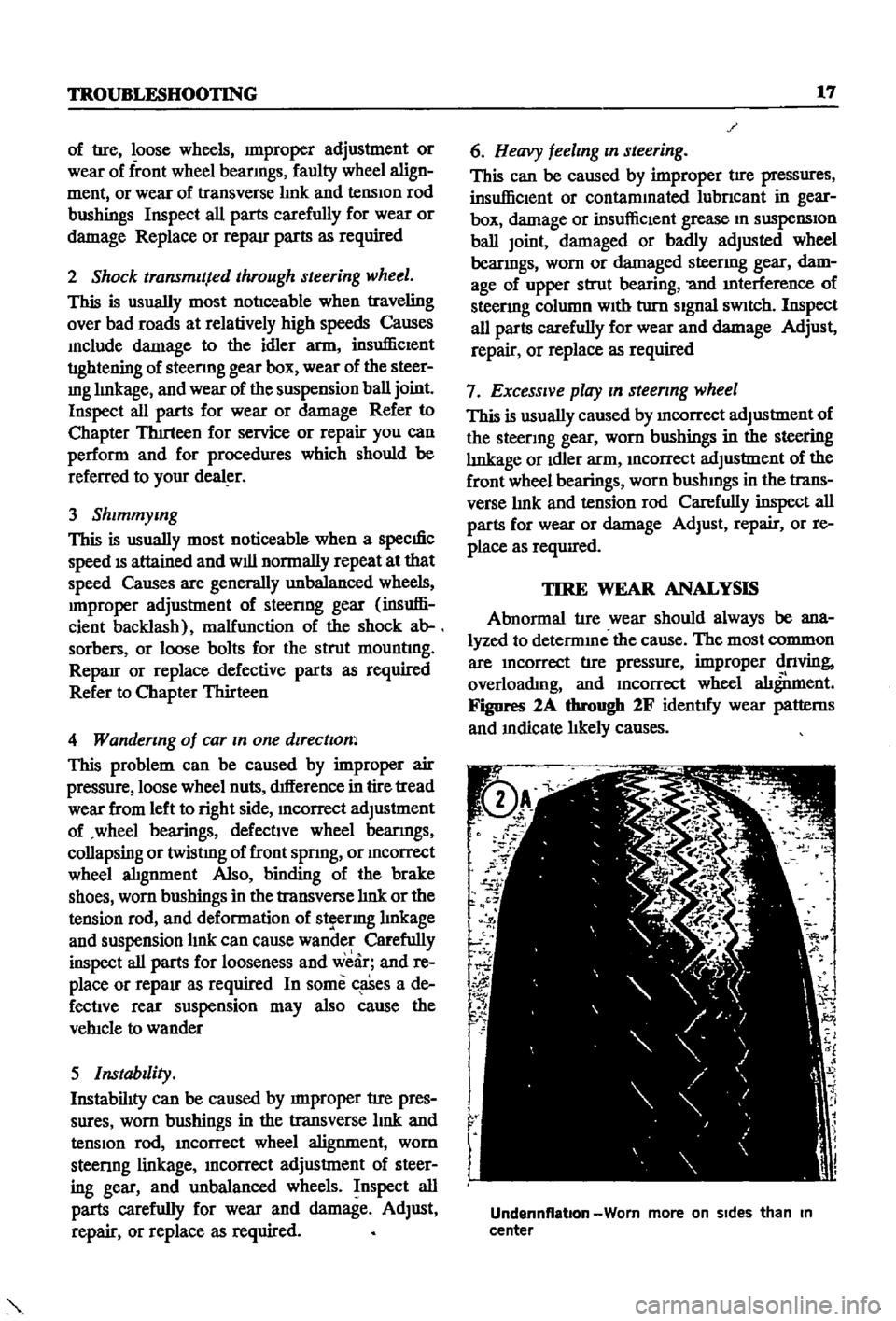

TIRE

WEAR

ANALYSIS

Abnormal

tIre

wear

should

always

be

ana

lyzed

to

deternune

the

cause

The

most

common

are

Incorrect

tIre

pressure

improper

dnving

overloading

and

Incorrect

wheel

ahgDment

Figures

2A

through

2F

identify

wear

patterns

and

mdicate

likely

causes

Of

I

1

l

D

1

Undennflatlon

Worn

more

on

Sides

than

In

center

Page 154 of 252

CHAPTER

TWELVE

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

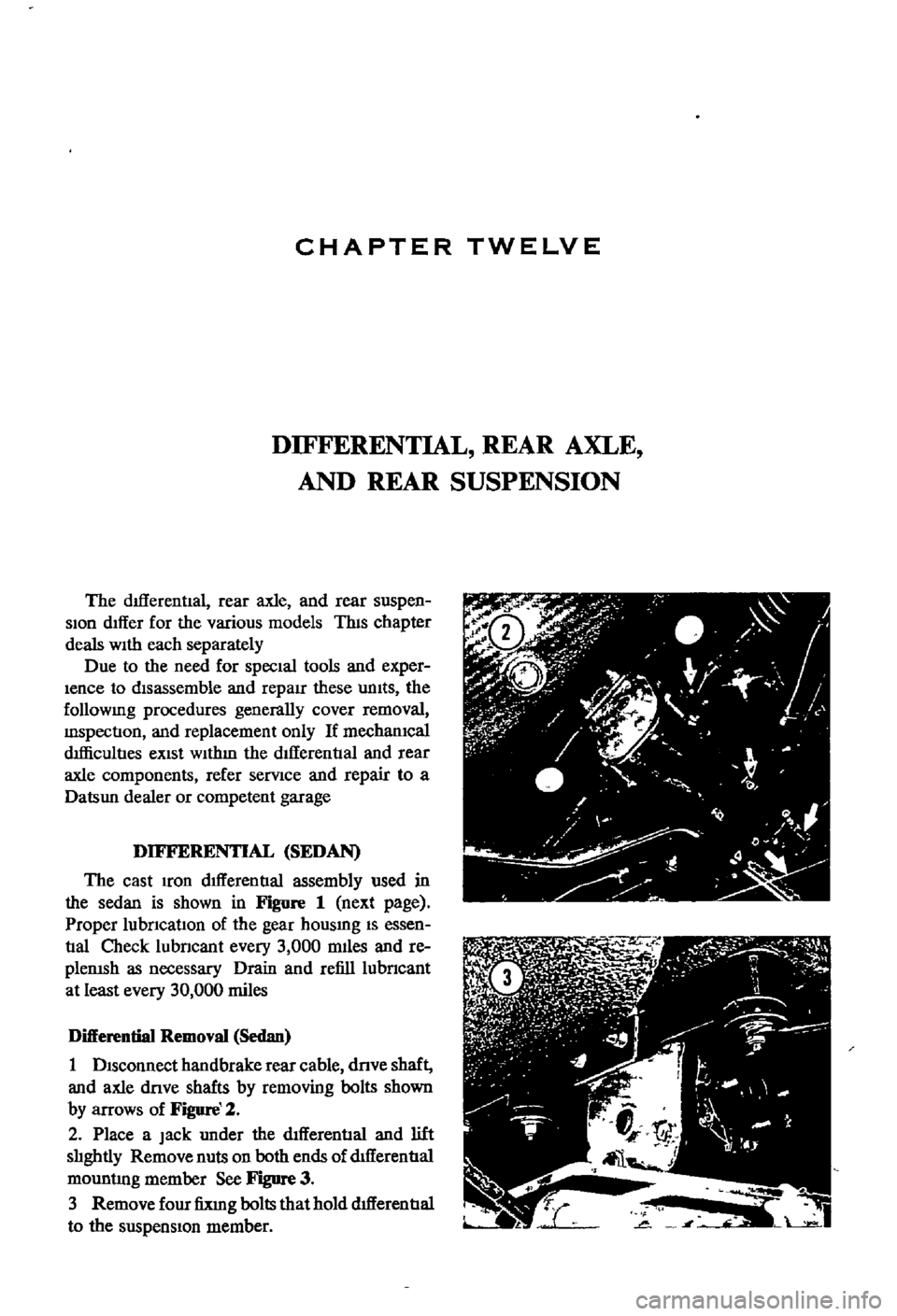

The

dIfferential

rear

axle

and

rear

suspen

sIon

dIffer

for

the

various

models

ThIS

chapter

deals

WIth

each

separately

Due

to

the

need

for

SpecIal

tools

and

exper

Ience

to

dIsassemble

and

repaIr

these

unItS

the

followmg

procedures

generally

cover

removal

InspectIon

and

replacement

only

If

mechanIcal

dIfficultIes

eXIst

WIthIn

the

dIfferentIal

and

rear

axle

components

refer

servIce

and

repair

to

a

Datsun

dealer

or

competent

garage

DIFFERENTIAL

SEDAN

The

cast

Iron

dIfferentIal

assembly

used

in

the

sedan

is

shown

in

Figure

1

next

page

Proper

lubncatlOn

of

the

gear

housmg

IS

essen

tIal

Check

lubncant

every

3

000

mlles

and

re

plenISh

as

necessary

Drain

and

refill

lubncant

at

least

every

30

000

miles

Differential

Removal

Sedan

1

DISconnect

handbrake

rear

cable

dnve

shaft

and

axle

dove

shafts

by

removing

bolts

shown

by

arrows

of

Figure

2

2

Place

a

Jack

under

the

dIfferential

and

lift

slIghtly

Remove

nuts

on

both

ends

of

dtfferentIal

mountlng

member

See

Figure

3

3

Remove

four

fixIng

bolts

that

hold

dIfferentIal

to

the

suspensIon

member

Page 156 of 252

DIFFERENTIAL

REAR

AXLE

AND

REAR

SUSPENSION

151

4

Lower

the

Jack

and

r

move

dIfferentIal

from

rear

of

vehIcle

See

Figure

4

After

removal

sup

port

suspensIon

member

wIth

a

stand

to

prevent

distortlon

and

damage

to

the

Insulators

Differential

Inspection

Sedan

The

followmg

mspectIon

can

be

done

WIthout

disassembly

of

the

dIfferential

If

abnormalitIes

or

damage

eXiSts

refer

further

servIce

and

reparr

to

your

dealer

1

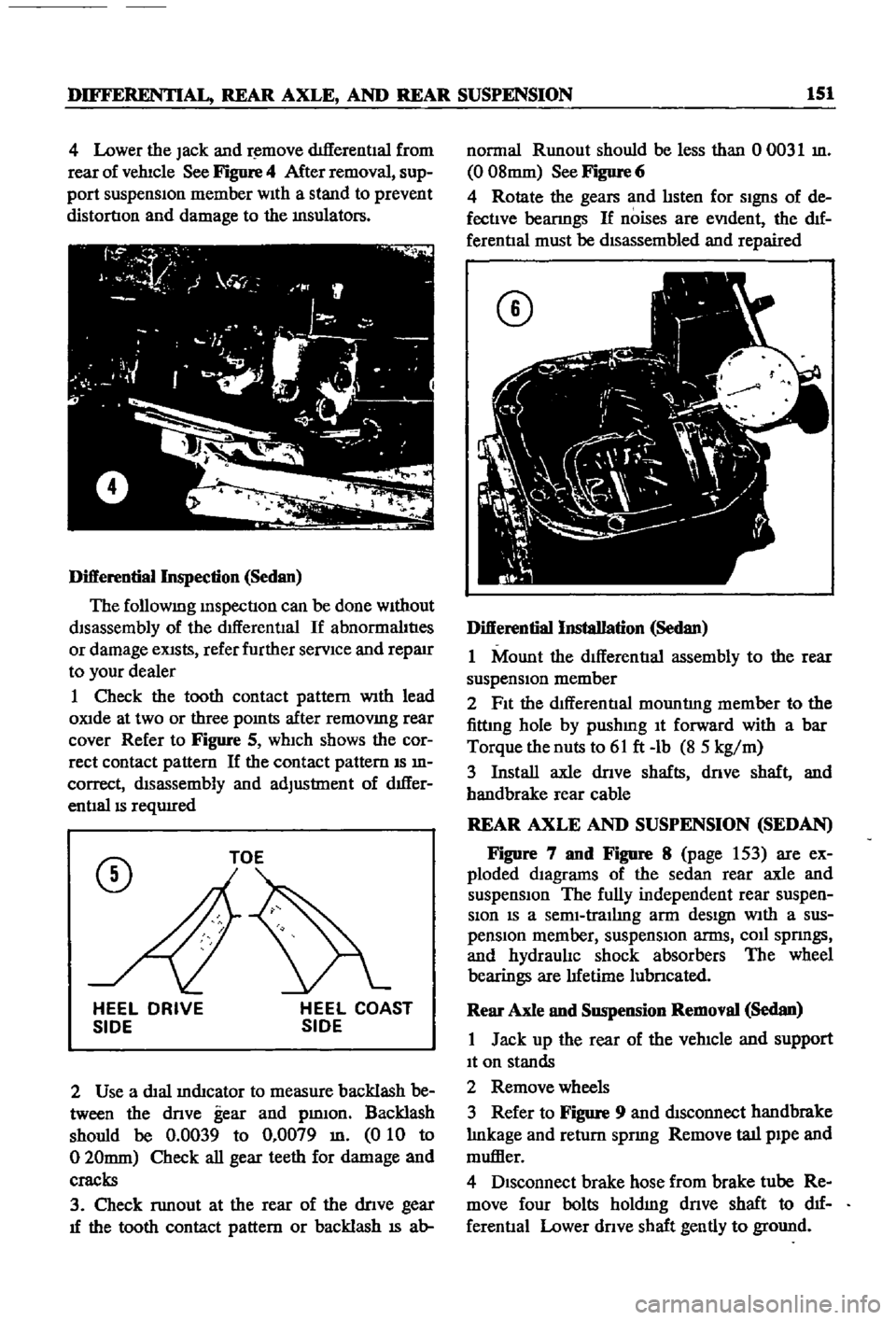

Check

the

tooth

contact

pattern

With

lead

oXide

at

two

or

three

pomts

after

removmg

rear

cover

Refer

to

Figure

5

which

shows

the

cor

rect

contact

pattern

If

the

contact

pattern

IS

m

correct

dIsassembly

and

adjustment

of

dIffer

entlalls

reqUIred

CD

TOE

HEEL

DRIVE

SIDE

HEEL

COAST

SIDE

2

Use

a

dIal

mdtcator

to

measure

backlash

be

tween

the

dnve

gear

and

pmIOn

Backlash

should

be

0

0039

to

0

0079

m

0

10

to

o

20mm

Check

all

gear

teeth

for

damage

and

cracks

3

Check

runout

at

the

rear

of

the

dnve

gear

If

the

tooth

contact

pattern

or

backlash

IS

ab

normal

Runout

should

be

less

than

00031

m

0

08mm

See

Figure

6

4

Rotate

the

gears

and

lIsten

for

SignS

of

de

fective

bearmgs

If

noises

are

eVIdent

the

dIf

ferential

must

be

dIsassembled

and

repaired

CD

Diflerentiallnstallation

Sedan

1

Mount

the

dIfferentIal

assembly

to

the

rear

suspensIOn

member

2

FIt

the

dIfferentIal

mountlng

member

to

the

fittmg

hole

by

pushIng

It

forward

with

a

bar

Torque

the

nuts

to

61

ft

lb

8

5

kg

m

3

Install

axle

dnve

shafts

dnve

shaft

and

handbrake

rear

cable

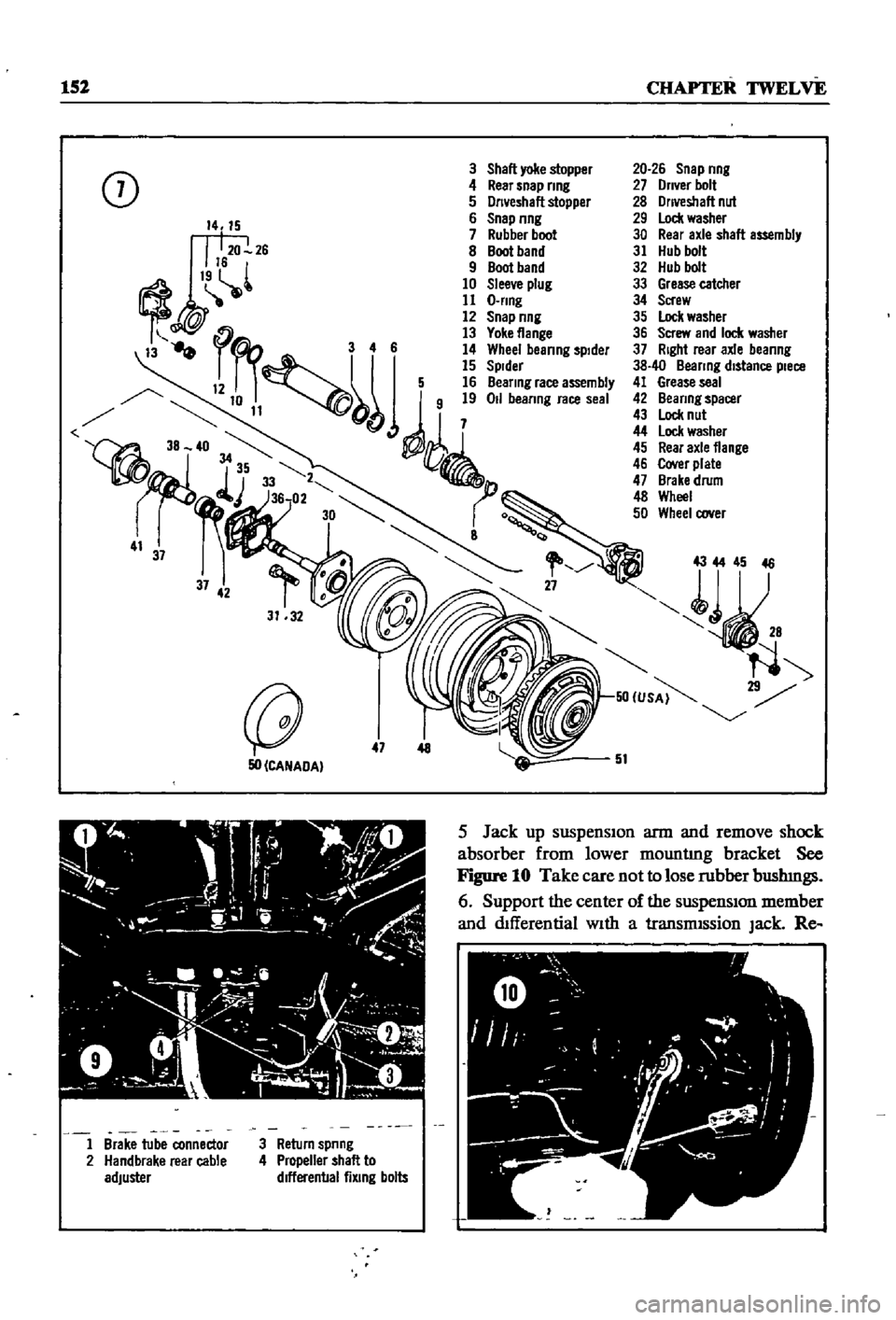

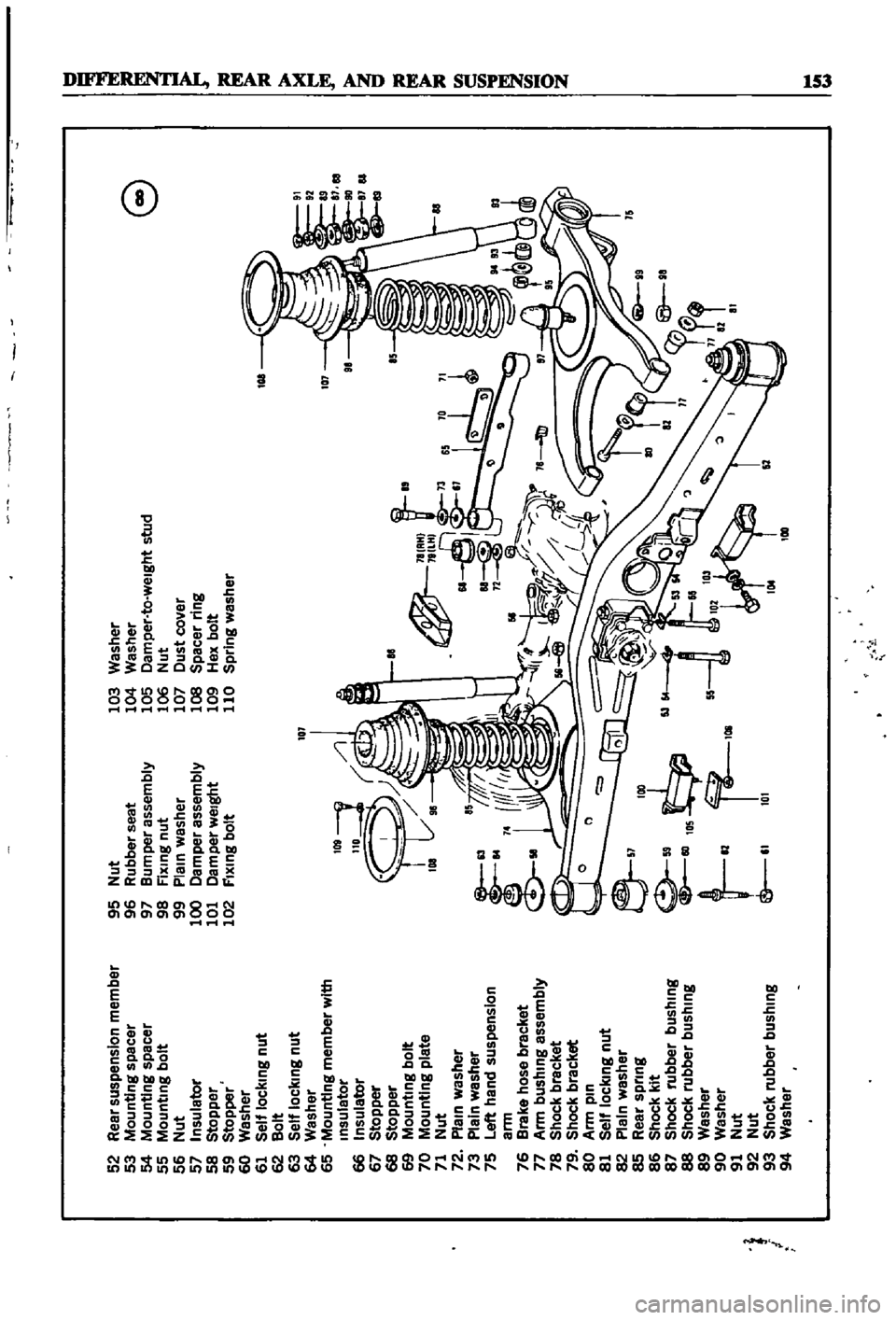

REAR

AXLE

AND

SUSPENSION

SEDAN

Figure

7

and

Figure

8

page

153

are

ex

ploded

dIagrams

of

the

sedan

rear

axle

and

suspensIOn

The

fully

independent

rear

suspen

SIon

IS

a

semI

traIlIng

arm

deSIgn

With

a

sus

penSIOn

member

suspensIOn

arms

coIl

spnngs

and

hydraulIc

shock

absorbers

The

wheel

bearings

are

lIfetime

lubncated

Rear

Axle

and

Suspension

Removal

Sedan

1

Jack

up

the

rear

of

the

veh1cle

and

support

It

on

stands

2

Remove

wheels

3

Refer

to

Figure

9

and

dtsconnect

handbrake

lInkage

and

rerum

sprmg

Remove

tall

pIpe

and

muffler

4

DISconnect

brake

hose

from

brake

tube

Re

move

four

bolts

holdmg

dnve

shaft

to

dIf

ferential

Lower

dnve

shaft

gently

to

ground

Page 157 of 252

152

CHAPTER

TWELVE

3

Shall

yoke

stopper

0

4

Rear

snap

nng

J

5

Dn

eshall

stopper

6

Snap

nng

7

Rubber

boot

8

Boot

band

9

Boot

band

10

Slee

e

plug

11

O

nng

12

Snap

nng

13

Yoke

flange

3

4

6

14

Whee

beanng

spIder

15

Spider

12

5

16

Beanng

race

assembly

j

50

CANADA

47

AtO

C

J

ty

9

1

Y

4

i

l

A

I

ii

1

o

l

J

Il

h

o

20

J

I

1

Brake

tube

connector

2

Handbrake

rear

cable

adjuster

3

Return

spnng

4

Propeller

shall

to

dlfferenballixlng

bolts

20

26

Snap

nng

27

Dn

er

bolt

28

Onveshall

nut

29

Lock

washer

30

Rear

axle

shall

assembly

31

Hub

bolt

32

Hub

bolt

33

Grease

catcher

34

Screw

35

Lock

washer

36

Screw

and

Ioc

l

washer

37

Right

rear

axle

beanng

38

40

Beanng

distance

piece

41

Grease

seal

42

Beanng

spacer

43

Lock

nut

44

lock

washer

45

Rear

axle

flange

46

Cover

plate

47

Brake

drum

48

Wheel

50

Wheel

oover

43

44

45

46

51

5

Jack

up

suspenSIon

arm

and

remove

shock

absorber

from

lower

mountlng

bracket

See

Figure

10

Take

care

not

to

lose

rubber

bushmgs

6

Support

the

center

of

the

suspensIon

member

and

dIfferential

With

a

transmISsion

Jack

Re

Page 158 of 252

p

52

Rear

suspension

member

95

Nut

103

Washer

53

Mounting

spacer

96

Rubber

seat

104

Washer

e

54

Mounting

spacer

97

Bumper

assembly

105

Damper

to

weight

stud

55

Mounting

bolt

98

Fixmg

nut

106

Nut

56

Nut

99

Plain

washer

107

Dust

cover

57

Insulator

100

Damper

assembly

lOS

Spacer

ring

58

Stopper

101

Damper

weight

109

Hex

bolt

E

59

Stopper

102

FIxing

bolt

110

Spring

washer

60

Washer

61

Self

locking

nut

62

Bolt

63

Self

locking

nut

101

64

Washer

65

Mounting

member

with

Insulator

109

1

l

66

Insulator

110

67

Stopper

w

68

Stopper

E

69

Mountmg

bolt

70

Mounting

plate

@

8IAH

loa

9

181lH

71

Nut

a

72

Plain

washer

73

Plain

washer

75

Left

hand

suspension

a

12

I

ann

t

76

Brake

hose

bracket

77

Arm

bushing

assembly

Ik

I

f

I

f

78

Shock

bracket

M

@

79

Shock

bracket

80

Ann

pin

81

Self

locking

nut

82

Plain

washer

e

85

Rear

spring

v

IDO

86

Shock

kit

M

4r

87

Shock

rubber

bushing

88

Shock

rubber

bushing

105

l1

89

Washer

t

81

r

D9

55

90

Washer

91

Nut

I

Sf

l

I

81

I

92

Nut

93

Shock

rubber

bushing

e

81

101

94

Washer

t

L

Page 159 of 252

154

CHAPTER

tWELVE

move

two

nuts

attachmg

dtfferenual

suspension

member

to

the

body

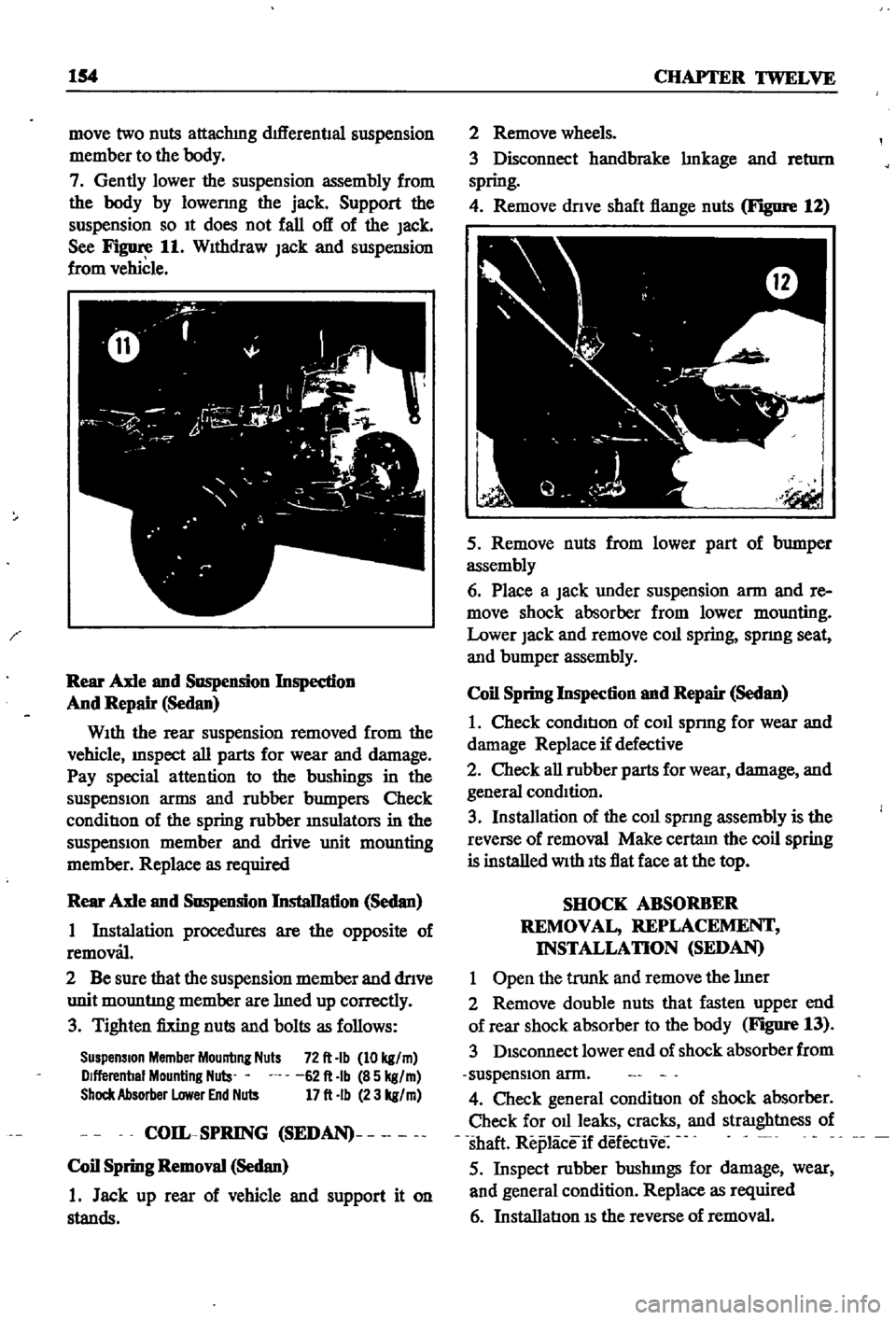

7

Gently

lower

the

suspension

assembly

from

the

body

by

10wermg

the

jack

Support

the

suspension

so

It

does

not

fall

off

of

the

Jack

See

Figure

11

WIthdraw

Jack

and

suspension

from

vehicle

Rear

Axle

and

Suspension

Inspedion

And

Repair

Sedan

WIth

the

rear

suspension

removed

from

the

vehicle

InSpect

all

parts

for

wear

and

damage

Pay

special

attention

to

the

bushings

in

the

suspensIon

arms

and

robber

bumpers

Check

conditIon

of

the

spring

robber

msulators

in

the

suspensIOn

member

and

drive

unit

mounting

member

Replace

as

required

Rear

Axle

and

Suspension

InstaDation

Sedan

1

Instalation

procedures

are

the

opposite

of

removal

2

Be

sure

that

the

suspension

member

and

dnve

unit

mountmg

member

are

med

up

correctly

3

Tighten

fixing

nuts

and

bolts

as

follows

Suspension

Member

Mounting

Nuts

72

It

Ib

10

kg

m

Dlfferenbal

Mounting

Nuls

62

It

Ib

85

kg

m

Shock

Absorber

Lower

End

Nuts

17

It

Ib

23

kg

m

COIL

SPRING

SEDAN

Coil

Spring

Removal

Sedan

1

Jack

up

rear

of

vehicle

and

support

it

on

stands

2

Remove

wheels

3

Disconnect

handbrake

mkage

and

retl1rn

spring

4

Remove

dnve

shaft

flange

nuts

Figure

12

5

Remove

nuts

from

lower

part

of

bumper

assembly

6

Place

a

Jack

under

suspension

arm

and

re

move

shock

absorber

from

lower

mounting

Lower

Jack

and

remove

coll

spring

spnng

seat

and

bumper

assembly

Coil

Spring

Inspection

and

Repair

Sedan

1

Check

condItIon

of

coll

sprmg

for

wear

and

damage

Replace

if

defective

2

Check

all

robber

parts

for

wear

damage

and

general

condItion

3

Installation

of

the

coll

spnng

assembly

is

the

reverse

of

removal

Make

certam

the

coil

spring

is

installed

With

Its

flat

face

at

the

top

SHOCK

ABSORBER

REMOVAL

REPLACEMENT

INSTALLATION

SEDAN

1

Open

the

trunk

and

remove

the

mer

2

Remove

double

nuts

that

fasten

upper

end

of

rear

shock

absorber

to

the

body

Figure

13

3

DIsconnect

lower

end

of

shock

absorber

from

suspensIon

arm

4

Check

general

conditIon

of

shock

absorber

Check

for

011

leaks

cracks

and

straIghtness

of

shaft

Replaceif

defectIve

5

Inspect

robber

bushmgs

for

damage

wear

and

general

condition

Replace

as

required

6

InstallatIon

IS

the

reverse

of

removal