engine DATSUN 610 1969 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 18 of 171

h

W

and

connecting

rod

assemblies

Use

a

piston

ring

compressor

to

install

the

pistons

through

the

top

of

the

cylbder

bore

Make

sure

that

the

pistons

and

rings

and

the

cylinder

bores

are

lubricated

with

clean

engine

oil

The

pistons

should

be

arranged

so

that

the

F

mark

faces

to

the

front

and

with

the

piston

ring

gaps

positioned

at

1800

to

each

other

Each

piston

must

be

refitted

into

its

original

bore

NOTE

Single

inlet

valve

springs

are

used

on

the

1400

cc

engine

double

valve

springs

are

used

on

the

1600cc

and

1800

cc

engines

Screw

the

valve

rocker

pivots

with

the

locknuts

into

the

pivot

bushing

Set

the

camshaft

locating

plate

and

install

the

camshaft

in

the

cylinder

head

with

the

groove

in

the

locating

plate

directed

to

the

front

of

the

engine

Install

the

camshaft

sprocket

and

tighten

it

together

with

the

fuel

pump

earn

to

a

torque

reading

of

12

16

kgm

86

116

IbJt

a

eck

that

the

camshaft

end

play

is

within

the

specified

limits

Install

the

rocker

arms

using

a

screwdriver

to

press

down

the

valve

springs

and

fit

the

valve

rocker

springs

Gean

the

joint

faces

of

the

cylinder

block

and

head

thoroughly

before

installing

the

cylinder

head

Turn

the

crank

shaft

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

and

make

sure

that

the

camshaft

sprocket

notch

and

the

oblong

groove

in

the

locating

plate

are

correctly

positioned

Care

should

be

taken

to

ensure

that

the

valves

are

clear

from

the

heads

of

the

pistons

The

crankshaft

and

camshaft

must

not

be

rotated

separately

or

the

valves

will

strike

the

heads

of

the

pistons

Temporarily

tighten

the

two

cylinder

head

bolts

1

and

2

in

Fig

A

37

to

a

torque

reading

of

2

kgm

14

5

lb

ft

Fit

the

crankshaft

sprocket

and

distributor

drive

gear

and

install

the

oil

thrower

Ensure

that

the

mating

marks

on

the

crankshaft

sprocket

face

towards

the

front

Install

the

timing

chain

making

sure

that

the

crankshaft

and

camshaft

keys

are

XJinting

upwards

The

marks

on

the

timing

chain

must

be

aligned

with

the

marks

on

the

right

hand

side

of

the

crankshaft

and

camshaft

sprockets

It

should

be

noted

that

three

location

holes

are

provided

in

the

camshaft

sprocket

See

Fig

A

38

The

camshaft

sprocket

being

set

to

the

No

2

location

hole

by

the

manufacturers

A

stretched

chain

will

however

affect

the

valve

timing

and

if

this

occurs

it

will

be

necessary

to

set

the

camshaft

to

the

No

3

location

hole

in

the

camshaft

sprocket

The

chain

can

be

checked

by

turning

the

engine

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

In

this

position

adjustment

will

be

required

if

the

location

notch

on

the

camshaft

sprocket

is

to

the

left

of

the

groove

on

the

camshaft

locating

plate

as

shown

in

the

illustration

The

correction

is

made

by

setting

the

camshaft

on

the

No

3

location

hole

in

the

camshaft

sprocket

the

No

3

notch

should

then

be

to

the

right

of

the

groove

and

the

valve

timing

will

have

to

be

set

using

the

No

3

timing

mark

Install

the

chain

guide

and

chain

tensioner

when

the

chain

is

located

correctly

There

should

be

no

protrusion

of

the

chain

tensioner

spindle

See

Fig

A

39

A

new

tensioner

must

be

fitted

if

the

spindle

protrudes

Press

a

new

oil

seal

into

the

timing

cover

and

fit

the

cover

into

position

using

a

new

gasket

Apply

sealing

compound

to

the

front

of

the

cylinder

block

and

to

the

gasket

and

to

the

top

of

the

timing

cover

Ensure

that

the

difference

in

height

between

the

top

of

the

timing

cover

and

the

upper

face

of

the

cylinder

block

does

not

exceed

0

15

mm

0

006

in

Two

sizes

of

timing

cover

bolts

are

used

the

size

M8

0

315

in

must

be

tightened

to

a

torque

reading

of

1

0

1

6

kgm

7

2

17

Ib

ft

and

the

size

M6

0

236

in

to

a

torque

reading

of

0

4

0

8

kgm

2

9

81b

ft

Install

the

crankshaft

pulley

and

water

pump

tighten

the

pulley

nut

to

a

torque

reading

of

12

16

kgm

86

8

115

7Ib

ft

then

set

the

No

1

piston

at

T

D

C

on

its

compression

stroke

Finally

tighten

the

cylinder

head

bolts

to

the

specified

torque

reading

in

accordance

with

the

tightening

sequence

shown

in

Fig

A

3

The

bolts

should

be

tightened

in

three

stages

as

follows

First

stage

Second

stage

Third

stage

4

kgm

28

9

lbJt

6

kgm

43

4

IbJ

t

6

5

85

kgm

47

0

61

5lb

ft

The

cylinder

head

bolts

should

be

retightened

if

necessary

after

the

engine

has

been

run

for

several

minutes

Install

the

oil

pump

and

distributor

drive

spindle

into

the

front

cover

as

described

under

Engine

Lubrication

System

r

rf

i

Install

the

fuel

pump

water

inlet

elbow

and

front

engine

slinger

Fit

the

oil

strainer

into

position

coat

the

oil

sump

gasket

with

sealing

compound

and

fit

the

gasket

and

oil

sump

to

the

cylinder

block

Tighten

the

oil

sump

bolts

in

a

diagonal

pattern

to

a

torque

reading

of

0

6

0

9

kgm

4

3

6

5

IbJt

Adjust

the

valve

clearances

to

the

specified

cold

engine

ftgures

following

the

procedures

described

under

the

appropriate

heading

Final

adjustments

will

be

carried

out

after

the

engine

has

been

assembled

completely

and

warmed

up

to

its

nonnal

temperature

Install

the

rear

engine

slinger

exhaust

manifold

and

inlet

manifold

Refit

the

distributor

and

carburettor

assemblies

as

described

in

their

relevant

sections

Install

the

fuel

pipes

and

vacuum

hose

making

sure

that

they

are

securely

cl

ped

Refit

the

thermostat

housing

thermostat

and

water

outlet

together

with

the

gasket

Bond

the

rocker

cover

gasket

to

the

rocker

cover

using

sealant

and

fit

the

rocker

cover

to

the

cylinder

head

Install

the

spark

plugs

and

connect

the

high

tension

leads

Fit

the

left

hand

engine

mounting

bracket

and

install

the

clutch

assembly

using

the

alignment

tool

ST20600000

to

fit

the

clutch

to

the

flywheel

as

described

in

the

section

ClUfCR

Lift

the

engine

away

from

the

mounting

stand

and

into

the

engine

compartment

Install

the

alternator

bracket

adjusting

bar

alternator

fan

pulley

fan

and

fan

belt

in

the

order

given

Check

the

tension

of

the

fan

belt

by

depressing

the

belt

at

a

point

midw

y

between

the

pulleys

The

tension

is

correct

if

the

belt

is

deflected

by

8

12

mm

0

3

0

4

in

under

thumb

pressure

Fit

the

right

hand

engine

mounting

bracket

the

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

Take

care

not

to

overtighten

the

oil

nIter

or

leakage

will

occur

Fill

the

engine

and

gearbox

to

the

correct

levels

with

recommended

lubricant

and

refill

the

cooling

system

Adjust

the

ignition

timing

and

carburettor

as

described

in

the

appro

priate

sections

17

Page 19 of 171

inter

lmi

@

jl

Fig

A

41

Engine

lubrication

circuit

i

Punch

rmrk

Oil

hole

L

Fig

A

44

Aligning

the

oil

pump

spindle

18

II

l

o

CD

I

Fig

A

42

Component

parts

of

the

oil

pump

L

Pump

body

2

Inner

rotor

and

wft

3

OutO

rotor

4

Pump

coper

5

Reliefvalve

6

Relief

valve

Jpring

7

Washer

8

S

alp

9

ConT

613ut

I

Sideclruance

2

TIp

clearance

3

Guier

10

00

body

clearance

t

4

Rotor

to

bottom

cover

cleatance

Fig

A

43

Checking

the

rotor

clearance

Page 20 of 171

VALVE

CLEARANCES

Adjusting

Incorrect

valve

clearance

will

affect

the

performance

of

the

engine

and

may

damage

the

valves

and

valve

seats

Insuf

ficient

valve

clearance

will

result

in

loss

of

power

and

may

prevent

the

valve

from

seating

properly

Excessive

clearance

causes

the

valve

to

seat

and

reduces

the

amount

of

valve

lift

This

will

result

in

noisy

operation

with

damage

to

the

valves

and

seats

Adjustment

is

made

with

the

engine

switched

off

and

should

be

carried

out

initially

with

the

engine

cold

to

allow

the

engine

to

run

Final

adjustments

are

made

after

wanning

up

the

engine

to

its

Donnal

operating

temperature

The

engine

can

be

rotated

by

removing

the

sparking

plugs

to

release

the

cylinder

compressions

then

selecting

top

gear

and

pushing

the

vehicle

backwards

and

forwards

The

cold

valve

clearances

should

be

set

to

0

20

mm

0

0079

in

for

the

inlet

valves

and

0

25

mm

0

0098

in

for

the

exhaust

valves

Check

the

clearance

between

the

valve

and

rocker

using

a

feeler

gauge

as

shown

in

Fig

A

40

Slacken

the

locknut

and

turn

the

adjusting

screw

until

the

specified

clearance

is

obtained

then

tighten

the

locknut

and

recheck

the

clearance

The

feeler

gauge

should

just

be

free

to

move

between

the

rocker

and

valve

When

the

cold

valve

clearances

have

been

set

run

the

engine

until

it

reaches

its

normal

operating

temperature

then

switch

off

and

adjust

the

valve

clearances

with

the

engine

warm

to

0

25

mm

0

0098

in

for

the

inlet

valves

and

0

30

mm

0

0118

in

for

the

exhaust

valves

ENGINE

LUBRICATION

SYSTEM

Fig

A

41

OIL

PUMP

Removal

and

Dismantling

The

rotor

type

oil

pump

is

mounted

at

the

bottom

of

the

front

timing

cover

and

driven

by

the

distributor

drive

shaft

assembly

Overhaul

of

the

pump

will

require

careful

measurement

of

the

various

clearances

to

determine

the

amount

of

wear

which

has

taken

place

If

any

part

is

found

to

be

worn

it

may

be

neces

sary

to

replace

the

entire

oil

pump

assembly

To

remove

the

oil

pump

from

the

engine

proceed

as

follows

1

Remove

the

distributor

assembly

as

described

in

the

section

IGNITION

SYSTEM

Remove

the

oil

sump

drain

plug

and

drain

off

the

engine

oil

See

under

the

heading

CHANGING

THE

ENGINE

OIL

2

Remove

the

front

stabiliser

and

the

splash

shield

board

3

Withdraw

the

securing

bolts

and

detach

the

oil

pump

body

together

with

the

drive

gear

spindle

Take

out

the

bolts

securing

the

pump

cover

to

the

pump

body

and

withdraw

the

rotors

and

drive

shaft

See

Fig

A

42

The

pin

securing

the

driven

shaft

and

inner

rotor

must

not

00

taken

out

as

the

shaft

is

press

fitted

to

the

rotor

and

the

pin

is

caulked

Unscrew

the

threaded

plug

and

withdraw

the

regulator

valve

and

spring

Oean

each

part

thoroughly

and

examine

for

signs

of

damage

or

wear

Use

a

feeler

gauge

to

check

the

side

clearances

between

the

outer

and

inner

rotors

the

clearances

at

the

tips

of

the

rotors

and

the

clearance

between

the

outer

rotor

and

the

pump

body

See

Technical

Data

for

the

relevant

clearances

The

clearances

can

be

checked

using

a

straight

edge

as

shown

in

Fig

A

43

OIL

PUMP

Assembly

and

Installation

Assembly

is

a

reversal

of

the

dismantling

procedure

Before

installing

the

oil

pump

in

the

engine

it

will

be

necessary

to

rotate

the

engine

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

Fill

the

pump

housing

with

engine

oil

and

align

the

punch

mark

on

the

spindle

with

the

hole

in

the

oil

pump

as

shown

in

Fig

A

44

Install

the

pump

with

a

new

gasket

and

tighten

the

securing

bolts

to

a

torque

reading

of

1

1

1

5

kgm

8

1

Ilb

ft

Replace

the

splash

shield

board

and

the

front

stabiliser

refill

the

engine

with

the

specified

amount

of

engine

oil

OIL

FILTER

The

cartridge

type

oil

filter

can

be

removed

with

the

special

tool

ST

19320000

or

a

suitable

filter

remover

Interior

cleaning

is

not

necessary

but

the

ftIter

body

and

element

must

be

repiaced

every

10

000

km

6000

miles

Be

care

ul

not

to

overtighten

the

filter

when

replacing

or

oil

leakage

may

occur

CHANGING

THE

ENGINE

OIL

After

the

fIrst

oil

change

which

should

take

place

at

1000

km

600

miles

the

oil

should

be

changed

regularly

at

5000

km

3000

miles

intervals

Draining

is

more

easily

accomplished

after

a

lengthy

run

when

the

oil

being

thoroughly

warm

will

flow

quite

freely

Stand

the

vehicle

on

level

ground

and

place

a

suitable

container

under

the

drain

plug

Remove

the

drain

plug

carefully

as

the

hot

oil

may

spurt

out

with

considerable

force

When

refIlling

the

engine

make

sure

that

the

oil

is

to

the

H

mark

on

the

dipstick

19

Page 21 of 171

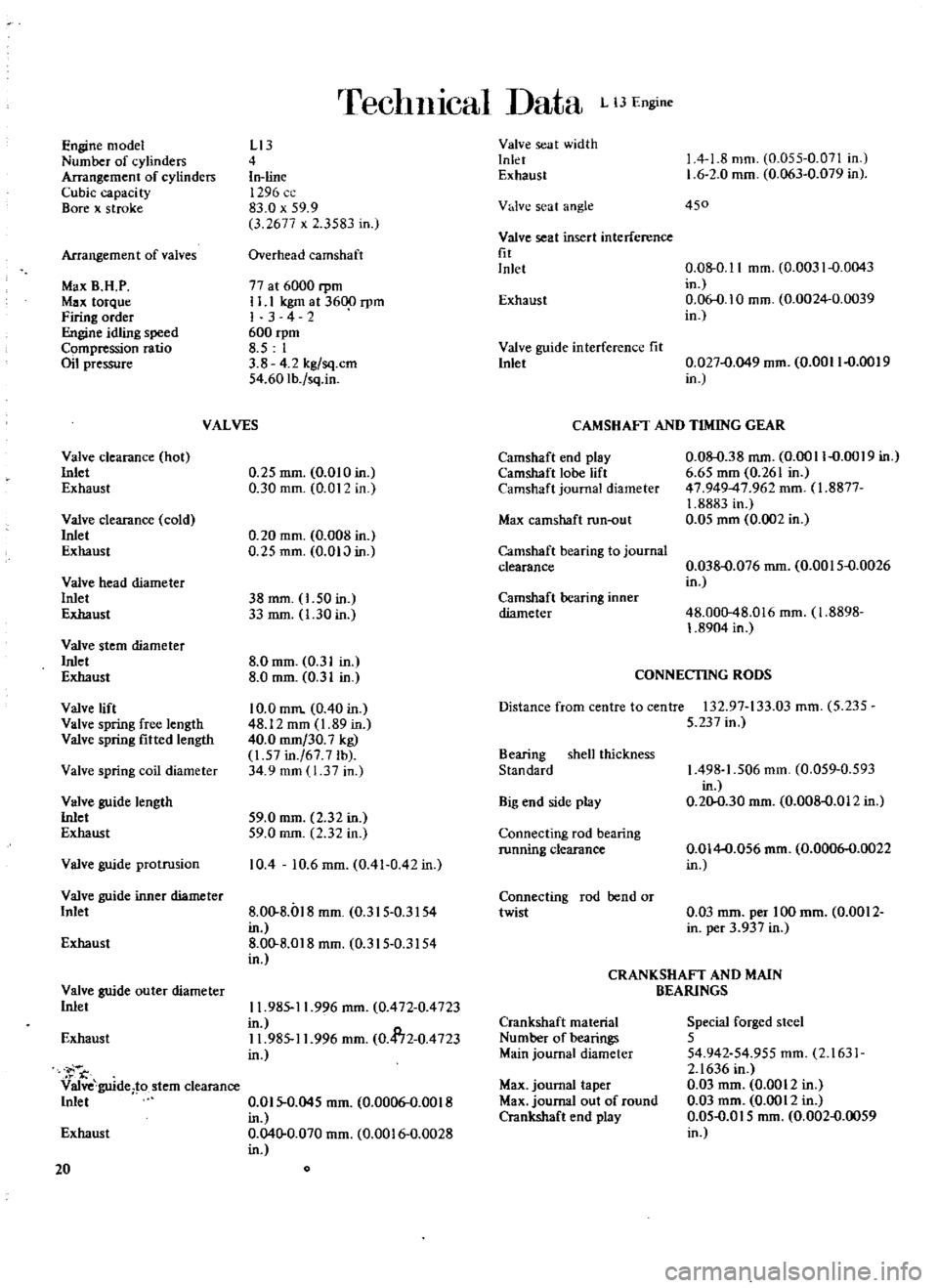

Engine

model

Number

of

cylinders

Arrangement

of

cylinders

Cubic

capaci

ty

Bore

x

stroke

Arrangemen

t

of

valves

Max

B

H

P

Max

torque

Firing

order

eidlingspeed

Compression

ratio

Oil

pressure

Valve

clearance

hot

Inlet

Exhaust

Valve

clearance

cold

Inlet

Exhaust

Valve

head

diameter

Inlet

Exhaust

Valve

stem

diameter

Inlet

Exhaust

Valve

lift

Valve

spring

free

length

Valve

spring

fitted

length

Valve

spring

coil

diameter

Valve

guide

length

Inlet

Exhaust

Valve

guide

protrusion

rreclll11cal

ata

L

lJEngine

LI3

4

In

line

1296

83

0

x

59

9

3

2677

x

3583

in

Overhead

camshaft

77

at

6000

rpm

II

1

kgm

at

3600

rpm

I

342

600

rpm

8

5

1

3

8

4

2

kg

sq

em

54

60Ib

sq

in

VALVES

0

25

mm

0

010

in

0

30

mm

0

01

in

0

20

mm

0

008

in

0

25

mm

O

OIJ

in

38

mm

1

50

in

33

mm

1

30

in

8

0

mm

0

31

in

8

0

mm

0

31

in

10

0

mm

0

40

in

48

12

mm

1

89

in

40

0

mm

30

7

kg

1

57

in

67

7

lb

34

9

mm

1

37

in

59

0

mm

2

32

in

59

0

mm

2

32

in

10

4

10

6

mm

0

41

0

42

in

Valve

guide

inner

diameter

Inlet

8

00

8

l

8

mm

0

315

0

3154

in

Exhaust

8

00

8

018

mm

0

315

0

3154

in

Valve

guide

outer

diameter

Inlet

Exhaust

Valve

guide

to

stem

clearance

Inlet

Exhaust

20

11

985

11

996

mm

0

472

0

4723

in

11

985

11

996

mm

0

4172

0

4723

in

0

015

0

045

mm

0

0006

0

0018

in

0

040

0

070

mm

0

0016

0

0028

in

Valve

seat

width

Inlet

Exhaust

V

lve

seat

angle

Valve

seat

insert

interference

fit

Inlet

Exhaust

Valve

guide

interference

fit

Inlet

1

4

1

8

mm

0

055

0

071

in

1

6

2

0

mm

0

063

0

079

in

450

0

08

0

11

mm

0

0031

0

0043

in

0

06

0

10

mm

0

0024

0

0039

in

0

027

0

049

mm

0

0011

0

0019

in

CAMSHAFT

AND

TIMING

GEAR

Camshaft

end

play

Camshaft

lobe

lift

Camshaft

journal

diameter

Max

camshaft

run

out

Camshaft

bearing

to

journal

clearance

Camshaft

bearing

inner

diameter

0

08

0

38

mm

0

0011

0

0019

in

6

65

mm

0

261

in

47

949

47

962

mm

fI

8877

1

8883

in

0

05

mm

0

002

in

0

038

0

076

mm

0

0015

0

0026

in

48

000

48

016

mm

1

8898

1

8904

in

CONNECTING

RODS

Distance

from

centre

to

centre

132

97

133

03

mm

5

235

5

237

in

Bearing

shell

thickness

Standard

Big

end

side

play

Connecting

rod

bearing

running

clearance

Connecting

rod

rend

or

twist

1

498

1

506

mm

0

059

0

593

in

0

20

0

30

mm

0

008

0

012

in

0

014

0

056

mm

0

0006

0

0022

in

0

03

mm

per

100

mm

0

0012

in

per

3

937

in

CRANKSHAFT

AND

MAIN

BEARINGS

Crankshaft

material

Number

of

bearings

Main

journal

diameter

Max

journal

taper

Max

journal

out

of

round

Crankshaft

end

play

Special

forged

steel

5

54

942

54

955

mm

2

1631

2

1636

in

0

03

mm

0

0012

in

0

03

mm

0

0012

in

0

05

0

015

mm

0

002

0

0059

in

Page 22 of 171

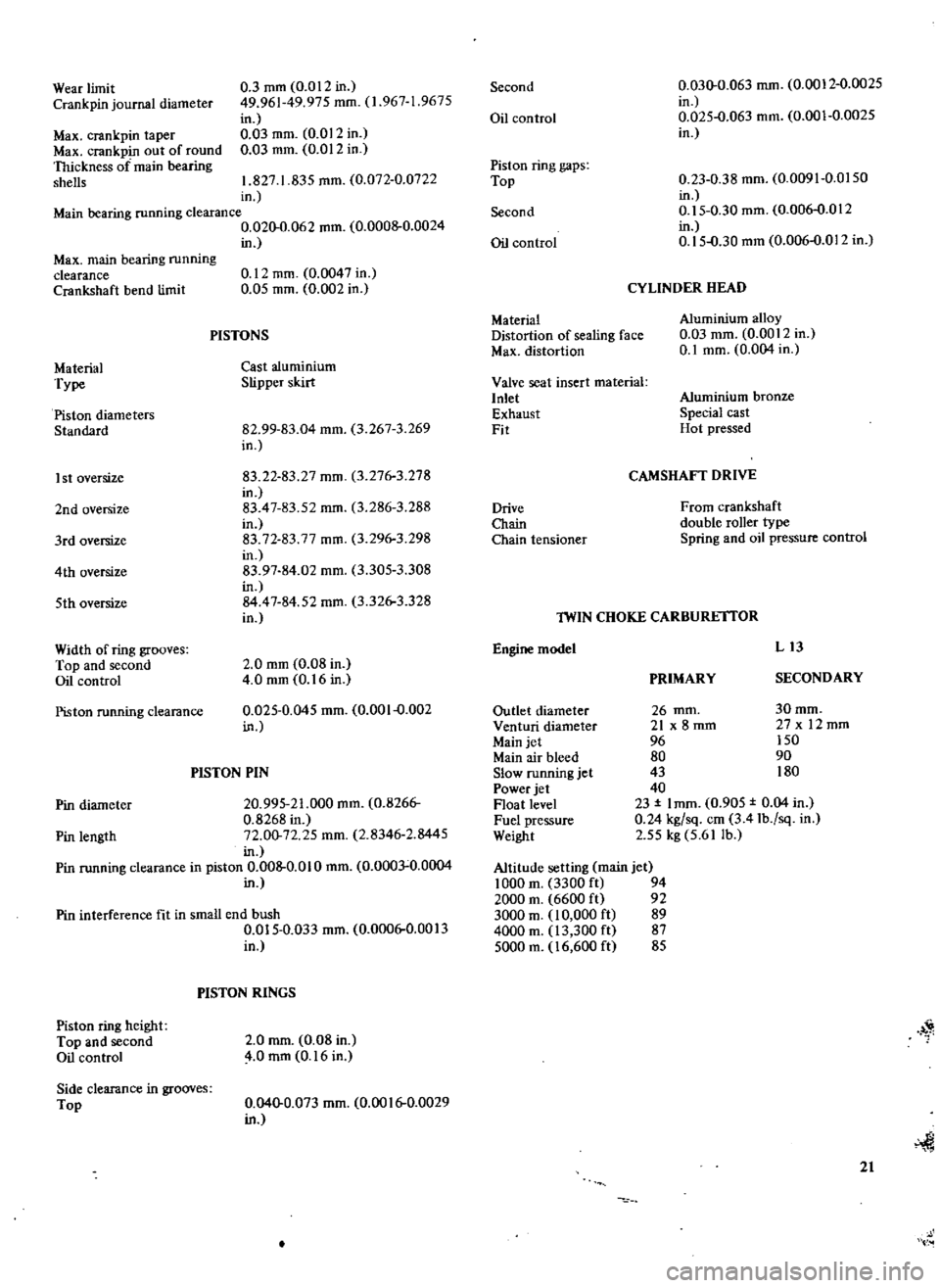

Wear

limit

Crank

pin

journal

diameter

Max

crankpin

taper

Max

crankpin

out

of

round

Thickness

of

main

bearing

shells

0

3

mm

0

012

in

49

961

49

975

mm

1

967

1

9675

in

0

03

mm

0

012

in

0

03

mm

0

012

in

1

827

1

835

mm

0

072

0

0722

in

Main

bearing

running

clearance

0

020

0

062

mm

0

0008

0

0024

in

Max

main

bearing

running

clearance

Crankshaft

bend

limit

Material

Type

Piston

diameters

Standard

I

st

oversize

2nd

oversize

3rd

oversize

4th

oversize

5th

oversize

Width

of

ring

grooves

Top

and

second

Oil

control

Piston

running

clearance

0

12

mm

0

0047

in

0

05

mm

0

002

in

PISTONS

Cast

aluminium

Slipper

skirt

82

99

83

04

mm

3

267

3

269

in

83

22

83

27

mm

3

276

3

278

in

83

47

83

52

mm

3

286

3

288

in

83

72

83

77

mm

3

296

3

298

in

83

97

84

02

mm

3

305

3

308

in

84

47

84

52

mm

3

326

3

328

in

2

0

mm

0

08

in

4

0

mm

0

16

in

0

025

0

045

mm

0

001

0

002

in

PISTON

PIN

Pin

diameter

20

995

21

000

mm

0

8266

0

8268

in

Pin

length

72

00

72

25

mm

2

8346

2

8445

in

Pin

running

clearance

in

piston

0

008

0

010

mm

0

0003

0

0004

in

Pin

interference

fit

in

small

end

bush

0

015

0

033

mm

0

0006

0

0013

in

Piston

ring

height

Top

and

second

Oil

control

Side

clearance

in

grooves

Top

PISTON

RINGS

2

0

mm

0

08

in

4

0

mm

0

16

in

0

040

0

073

mm

0

0016

0

0029

in

Second

Oil

control

Piston

ring

gaps

Top

Second

Oil

control

Material

Distortion

of

sealing

face

Max

distortion

Valve

seat

insert

material

Inlet

Exhaust

Fit

Drive

Chain

Chain

tensioner

0

030

0

063

mm

0

0012

0

0025

in

0

025

0

063

mm

0

001

0

0025

in

0

23

0

38

mm

0

0091

0

0150

in

0

15

0

30

mm

0

006

0

012

in

0

15

0

30

mm

0

006

0

012

in

CYLINDER

HEAD

Aluminium

alloy

0

03

mm

0

0012

in

0

1

mm

0

004

in

Aluminium

bronze

Special

cast

Hot

pressed

CAMSHAFT

DRIVE

From

crankshaft

double

roller

type

Spring

and

oil

pressure

control

Engine

model

lWIN

CHOKE

CARBURE

ITOR

Outlet

diameter

Venturi

diameter

Main

jet

Main

air

bleed

Slow

running

jet

Power

jet

Float

level

Fuel

pressure

Weight

Altitude

setting

main

jet

1000

m

3300

ft

94

2000

m

6600

ft

92

3000

m

10

000

ft

89

4000

m

13

300

ft

87

5000

m

16

600

ft

85

PRIMARY

L13

SECONDARY

30mm

27x

12mm

150

90

180

26

mm

21

x

8

mm

96

80

43

40

23

I

mm

0

905

0

04

in

0

24

kg

sq

em

3

41b

sq

in

2

55

kg

5

61

lb

1

21

Page 23 of 171

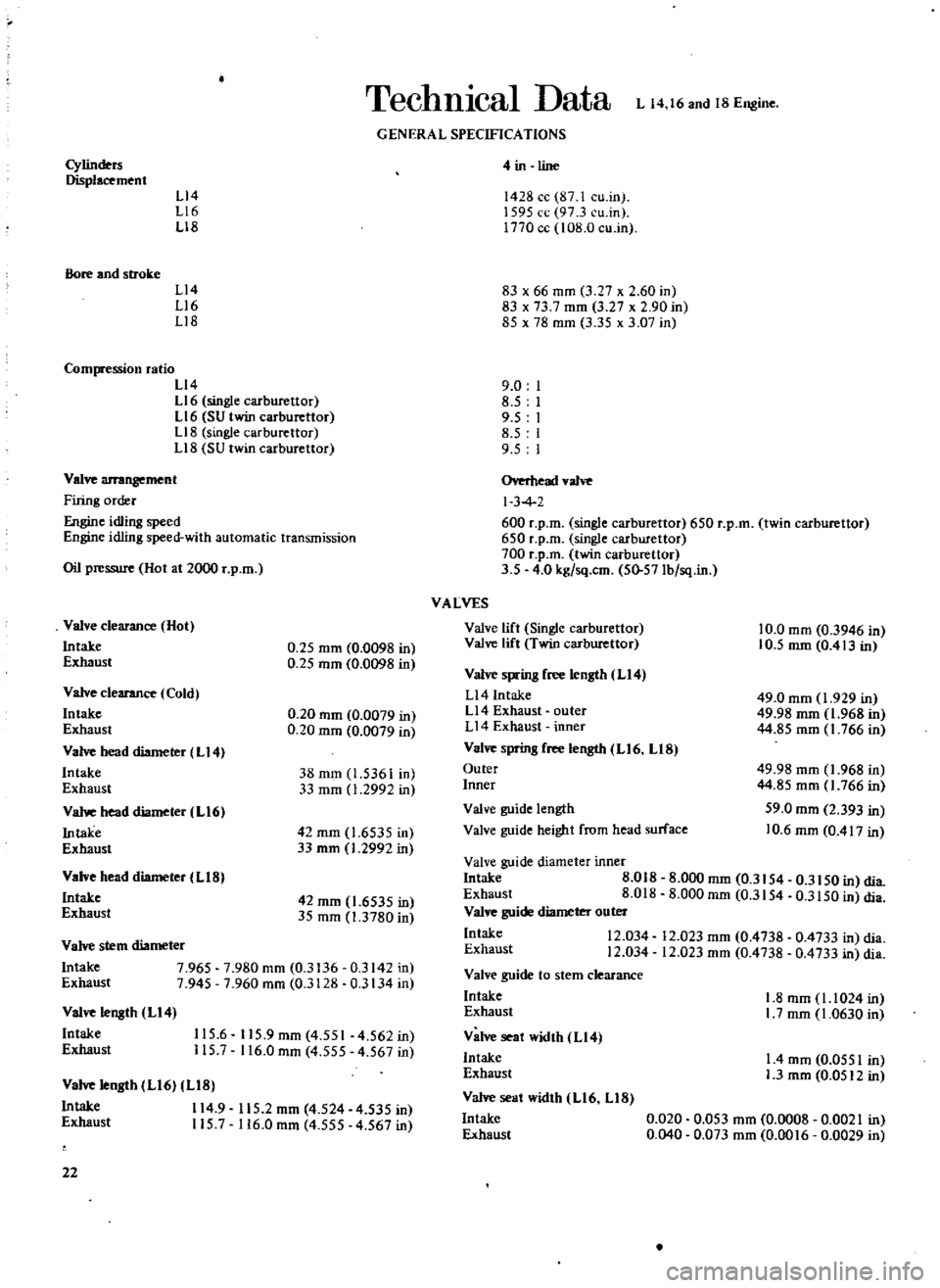

TechnIcal

Data

L

14

16

and

18

Engine

GENERAL

SPECIFICATIONS

Cylinders

Displacement

L14

L16

L18

Bore

and

stroke

L14

L16

Ll8

Compression

ratio

L14

L16

single

carburettor

L16

SU

twin

carburettor

L18

single

carburettor

Ll8

SU

twin

carburettor

Valve

arrangement

Firing

order

e

idling

speed

Engine

idling

speed

with

automatic

transmission

Oil

pressure

Hot

at

2000

r

p

m

Valve

clearance

Hot

Intake

Exhaust

0

25

mm

0

0098

in

0

25

mm

0

0098

in

Valve

clearance

Cold

Intake

Exhaust

Va

head

diameter

L14

Intake

Exhaust

Vahoe

head

diameter

L16

Intake

Exhaust

0

20

mm

0

0079

in

0

20

mm

0

0079

in

38

mm

1

5361

in

33

mm

1

2992

in

42

mm

1

6535

in

33

rom

1

2992

in

Valve

head

diameter

L18

Intake

Exhaust

42

mm

1

6535

in

35

mm

1

3780

in

Valve

stem

diameter

Intake

7

965

7

980

mm

0

3136

0

3142

in

Exhaust

7

945

7

960

mm

0

3128

0

3134

in

Valve

length

L14

Intake

Exhaust

115

6

115

9mm

4

551

4

562in

115

7

116

0

mm

4

555

4

567

in

Valve

length

L16

LIB

Intake

114

9

115

2

mm

4

524

4

535

in

Exhaust

115

7

116

0

mm

4

555

4

567

in

22

4

in

line

1428

cc

87

1

cu

in

1595

cc

97

3

cu

in

1770

cc

108

0

cu

in

83

x

66

mm

3

27

x

2

60

in

83

x

73

7

mm

3

27

x

2

90

in

85

x

7B

mm

3

35

x

3

07

in

9

0

8

5

9

5

8

5

9

5

Overhead

valve

I

3

4

600

r

p

m

single

carburettor

650

r

p

m

twin

carburettor

650

r

p

m

single

carburettor

700

r

p

m

twin

carburettor

3

5

4

0

kg

sq

cm

50

57Ib

sq

in

VALVES

Valve

lift

Single

carburettor

Valve

lift

Twin

carburettor

10

0

mm

0

3946

in

10

5

mm

0

413

in

Valve

spring

free

length

LI4

Ll4

Intake

Ll4

Exhaust

outer

L14

Exhaust

inner

Valve

sprin8

free

length

L16

LIB

Outer

Inner

49

0

mm

1

929

in

49

98

mm

1

968

in

44

85

mm

1

766

in

49

98

mm

1

968

in

44

85

mm

1

766

in

59

0

mm

2

393

in

10

6

mm

0

417

in

Valve

guide

length

Valve

guide

height

from

head

surface

Valve

guide

diameter

inner

Intake

8

018

Exhaust

8

018

Valve

guide

diameter

outer

Intake

12

034

Exhaust

12

034

Valve

guide

to

stem

clearance

Intake

Exhaust

Valve

seat

width

L14

Intake

Exhaust

Valve

seat

width

L16

LIB

Intake

Exhaust

8

000

mm

0

3154

0

3150

in

clia

8

000

mm

0

3154

0

3150

in

clia

12

023

mm

0

4738

0

4733

in

clia

12

023

mm

0

4738

0

4733

in

clia

1

8

mm

1

1024

in

I

7

mm

1

0630

in

I

4

mm

0

0551

in

1

3

mm

0

0512

in

0

020

0

053

mm

0

0008

0

0021

in

0

040

0

073

mm

0

0016

0

0029

in

Page 26 of 171

CoolIng

System

GENERAL

FAN

BELT

TENSION

FLUSHING

AND

DRAINING

THE

SYSTEM

THERMOSTAT

Testing

RADlA

TOR

Removal

GENERAL

The

cooling

system

is

pressurised

and

incorporates

a

water

pump

corrugated

fin

type

radiator

fan

and

a

pellet

type

thermostat

The

water

pump

is

of

the

centrifugal

type

and

has

an

aluminium

die

cast

body

The

volute

chamber

is

built

into

the

front

cover

assembly

and

a

high

pressure

sealing

mechanism

prevents

water

leakage

and

noise

The

fan

pulley

is

driven

by

the

V

belt

from

a

pulley

on

the

crankshaft

he

pellct

type

thermostat

enables

the

engine

to

warm

up

rapidlY

and

also

regulates

the

temperature

of

the

coolant

When

the

wax

pellet

in

the

thermostat

is

heated

it

expands

and

exerts

pressure

against

a

rubber

diaphragm

causing

the

valve

to

open

and

allow

the

coolant

to

flow

from

the

cylinder

head

back

to

the

radiator

As

the

pellet

is

cooled

itcontractsand

allows

the

spring

to

close

the

valve

thereby

preventing

coolant

from

leaving

the

cylinder

head

The

rad

ator

is

of

the

down

flow

type

with

an

expansion

tank

The

relIef

valve

in

the

radiator

filler

cap

controls

the

pressure

at

approximately

0

9

kg

sq

cm

l3Ib

sq

in

Always

try

to

avoid

removing

the

filler

cap

when

the

engine

is

hot

as

coolant

may

spray

out

and

cause

scalding

If

the

cap

must

be

removed

in

these

circumstances

use

a

lar

e

pic

c

of

cloth

to

hold

the

cap

and

turn

the

cap

sli

htlY

Walt

until

all

pressure

has

been

released

before

lifting

off

the

cap

F

AN

BELT

TENSION

The

fan

belt

drives

the

water

pump

and

alternator

as

well

as

the

fan

and

its

correct

adjustment

is

most

essential

A

loose

fan

belt

will

sl

ip

and

Y

e

r

and

most

probably

cause

overheating

alternatively

If

the

belt

IS

too

tight

the

pump

and

alternator

bearings

will

be

overloaded

The

belt

is

correctly

tensioned

if

it

can

be

depressed

by

approximately

10

mm

1

2

in

at

a

point

midway

between

the

fan

and

alternator

pulleys

See

Fig

R2

If

adjustment

is

neces

ary

slacken

the

alternator

mounting

and

adjustment

bolts

and

pivot

the

alternator

away

from

the

engine

to

tighten

the

belt

to

towards

the

engine

if

the

belt

is

to

be

slackened

NOTE

Always

apply

leverage

to

the

drive

end

housing

when

pivoting

the

alternator

and

never

to

the

diode

end

housing

or

the

alternator

will

be

damaged

Retighten

the

alternator

bolts

and

make

SUfe

that

the

belt

is

correctly

tensioned

FLUSHING

AND

DRAINING

THE

SYSTEM

The

radiator

and

water

passages

should

be

flushed

out

periodically

to

remove

the

accumulated

scale

or

sediment

Reverse

flushing

equipment

should

be

used

to

carry

out

a

completely

thorough

flushing

operation

but

the

owner

drivef

not

possessing

this

type

of

equipment

can

flush

out

the

system

in

the

following

manner

Drain

the

system

by

removing

the

radiator

filler

cap

and

opening

the

radiator

and

cylinder

block

drain

taps

Close

the

taps

again

and

refill

the

radiator

Run

the

engine

for

a

ShOft

period

and

then

rc

open

the

drain

taps

Continue

this

sequence

until

the

water

flowing

from

the

taps

is

clean

then

close

the

taps

and

refill

the

radiator

An

anti

freeze

mixture

should

always

be

used

in

Winter

time

The

Niss3n

long

life

coolant

L

L

c

is

an

ethylene

glycol

solution

containing

a

corrosion

preventative

which

can

remain

in

the

vehicle

throughout

the

year

but

must

not

be

mixed

with

other

products

It

is

advisable

to

check

the

radiator

and

heater

hoses

when

filling

with

anti

freeze

and

renew

them

if

signs

of

deterioration

are

apparent

WATER

PUMP

Replacement

The

water

pump

must

not

be

dismantled

and

should

be

renewed

if

it

becomes

faulty

The

pump

can

be

removed

in

the

following

manner

Drain

the

cooling

system

2

Take

the

fan

belt

off

the

pulley

3

Remove

the

fan

and

pulley

4

Remove

the

retaining

nuts

and

withdraw

the

water

pump

See

Fig

B

3

lnstallation

of

the

pump

is

a

reversal

of

the

removal

procedures

rERMOST

ATTesting

The

thermostat

is

located

in

the

water

outlet

passage

See

Fig

B

4

To

remove

the

unit

drain

the

cooling

system

remove

the

radiator

hose

and

the

water

outlet

elbow

Take

out

the

thermostat

25

Page 28 of 171

The

thermostat

can

be

tested

by

suspending

it

with

a

thermometer

in

a

container

ftlled

with

water

Heat

the

water

gradually

and

stir

it

to

obtain

a

uniform

temperature

Maintain

a

constant

check

of

the

temperature

and

make

sure

that

neither

the

thermostat

or

thermometer

touch

the

sides

of

the

container

or

false

readings

will

be

obtained

The

thermostat

should

begin

to

open

at

a

temperature

of

820C

1

50C

179

60F

2

70Fj

and

should

be

fully

open

with

a

maximum

valve

lift

of

8

mm

0

315

in

at

a

temperature

of

950C

2030F

When

installing

the

thermostat

apply

adhesive

to

both

sides

of

the

gasket

before

refitting

the

water

outlet

elbow

RADIATOR

Removal

Drain

the

cooling

system

as

previously

described

and

remove

the

front

grille

2

Disconnect

the

radiator

upper

hose

lower

hose

and

hose

to

the

reservoir

tank

3

Remove

the

radiator

securing

bolts

and

lift

out

the

radiator

Fig

B

4

It

should

be

noted

that

cars

fitted

with

automatic

transmission

incorporate

a

transmission

oil

cooler

which

must

be

disconnected

Installation

is

a

reversal

of

the

removal

procedure

refill

the

system

as

previously

described

FLUID

COUPLING

The

water

pump

is

equipped

with

a

fluid

coupling

on

vehicles

fitted

with

an

air

conditioner

The

fluid

coupling

Limits

the

maximum

fan

speed

to

approximately

3000

r

p

ro

and

eliminates

noise

and

loss

of

power

at

high

engine

speeds

A

fault

in

the

coupling

may

be

caused

by

the

entry

of

foreign

matter

If

a

fault

developes

the

oupling

must

be

removed

and

dismantled

and

the

interior

cleaned

by

washing

in

solvent

The

condition

of

the

seal

and

bearing

must

be

care

fully

checked

and

the

coupling

replaced

if

the

latter

items

have

become

blackened

If

oil

leaks

occur

it

will

be

necessary

to

replace

the

water

pump

assembly

with

the

coupling

After

cleaning

the

unit

refill

with

11

5

cc

silicon

oil

using

a

suitable

syringe

TechnIcal

Data

Radiator

Radiator

cap

working

pressure

Radiator

core

heightxwidth

x

thickness

1400

and

1600

cc

engines

510

body

1600

and

1800

cc

engines

610

body

Corrugated

fin

type

0

9

kg

sq

cm

13Ib

sq

in

280x488x38mm

I

LOx

19

2x

1

49

in

360x502x32mm

l4

2x19

8x1

26

in

Thermostat

valve

opening

temperature

Standard

B20C

l

BOOF

Cold

climates

880C

1900F

Tropical

climates

76

50C

l700F

Max

valve

lift

Cooling

system

capacity

With

heater

Without

heater

Cooling

system

capacity

With

heater

Above

8

mm

0

31

in

6

8litres

1

75

US

gall

1

5

Imp

gall

6

4litres

1

75

US

gall

1

375

Imp

gall

1600

and

1800

cc

engines

610

body

6

5litres

l

7

US

gall

1

375

Imp

gall

6

0

Iitres

1

625

US

gall

1

375

Imp

gall

Without

heater

27

Page 30 of 171

IgnItIon

System

DESCRII

TION

IGNITION

TIMING

IGNITION

DISTRIBUTOR

Maintenance

ADJUSTING

THE

CONTACT

BREAKER

GAP

CENTRIFUGAL

ADVANCE

MECHANISM

VACUUM

ADVANCE

MECHANISM

IGNITION

DISTRIBUTOR

Removal

and

Dismantling

IGNITION

DISTRIBUTOR

Assembling

and

Installation

SPARKING

PLUGS

DESCRII

TION

The

ignition

circuit

comprises

the

distributor

ignition

coil

ignition

switch

spark

plugs

high

tension

lead

and

the

battery

See

Fig

C

1

The

Hitachi

distributor

is

shown

in

exploded

form

in

Fig

C

2

19niton

timing

is

automatically

regulated

by

the

distributor

centrifugal

advance

mechanism

or

vacuum

advance

mechanism

depending

upon

the

demand

made

on

the

engine

The

vacuum

advance

mechanism

operates

under

part

throttle

only

and

uses

intake

manifold

depression

to

advance

the

ignition

timing

When

the

engine

speed

is

increased

the

vacuum

is

inoperative

and

ignition

timing

is

regulated

by

the

centrifugal

advance

mechanism

The

centrifugal

advance

mechanism

uses

a

system

of

governor

weights

and

springs

which

turn

the

carn

assembly

in

on

anti

clockwise

direction

to

advance

the

ignition

timing

As

the

engine

speed

is

decreased

the

weights

move

back

and

allow

the

cam

to

return

thereby

retarding

the

ignition

timing

The

ignition

coil

is

an

oil

filled

unit

comprising

a

coil

around

which

is

wound

the

secondary

and

primary

windings

The

number

of

turns

in

the

primary

winding

provide

a

high

secondary

voltage

throughout

the

speed

range

The

resistor

is

automatically

by

passed

at

the

moment

of

starting

and

allows

the

ignition

coil

to

be

directly

connected

to

the

battery

This

applies

the

full

battery

voltage

to

the

coil

to

give

the

necessary

staTting

boost

When

the

starter

switch

is

released

the

current

flows

through

the

resistor

and

the

voltage

through

the

coil

is

dropped

for

normal

running

purposes

IGNITION

TIMING

The

ignition

timing

can

be

accurately

checked

using

a

stroboscopic

timing

light

which

should

be

connected

in

accor

dance

with

the

manufacturers

instructions

Make

sure

that

the

timing

marks

on

the

crankshaft

pulley

are

visible

if

they

are

not

visible

mark

them

with

chalk

or

white

paint

Each

mark

represents

a

50

division

of

the

crank

angle

Disconnect

the

distributor

vacuum

line

start

the

engine

and

allow

it

to

run

at

normal

idling

speed

or

slightly

below

Point

the

timing

light

at

the

timing

pointer

on

the

front

cover

Fig

C

3

The

crankshaft

pulley

groove

should

appear

to

be

stationery

and

aligned

with

the

pointer

on

the

front

cover

The

top

dead

centre

mark

is

located

at

the

extreme

right

as

shown

in

the

illustration

If

the

setting

requires

adjustment

the

distributor

flange

bolts

must

be

slackened

and

the

distributor

body

turned

clockwise

to

advance

or

anti

clockwise

to

retard

the

timing

See

Technical

Data

for

timing

settings

After

adjusting

the

timing

tighten

the

distributor

flange

bolts

and

recheck

the

timing

IGNITION

DISTRIBUTOR

Maintenance

Remove

the

distributor

cap

by

easing

away

the

two

clamps

and

examine

the

points

for

signs

of

burning

or

pitting

The

points

can

be

cleaned

if

necessary

using

a

fine

grade

of

oilstone

or

file

The

faces

of

the

points

must

be

completely

flat

and

parallel

and

all

abrasive

dust

removed

with

compressed

air

If

the

points

are

excessively

pitted

they

must

be

renewed

and

grease

applied

to

the

moving

contact

pivot

and

the

surface

of

the

cam

Ensure

that

the

distributor

cap

is

thoroughly

clean

both

inside

and

outside

A

contaminated

cap

will

promote

tracking

indicated

by

black

lines

and

caused

by

electrical

leakage

between

the

segments

on

the

inside

of

the

cap

Make

sure

that

the

carbon

button

is

not

worn

Both

the

distributor

cap

and

rotor

must

be

renewed

if

they

are

cracked

or

damaged

IGNITION

DISTRIBUTOR

Adjusting

the

contact

breaker

gap

To

adjust

the

contact

breaker

points

remove

the

distributor

cap

and

pull

the

rotor

off

the

cam

spindle

Turn

the

engine

until

the

heel

of

the

contact

breaker

arm

is

positioned

on

the

cam

lobe

the

contact

breaker

gap

is

set

to

the

maximum

in

this

position

Slacken

the

adjusting

screw

Fig

CA

insert

a

feeler

gauge

between

the

points

and

adjust

the

breaker

plate

until

the

re

quired

gap

of

0

45

0

55

mm

0

0177

0

0217

in

is

obtained

Tighten

the

adjusting

screw

and

recheck

the

setting

After

the

contact

breaker

gap

has

been

adjusted

check

the

ignition

timing

as

previously

described

The

tension

of

the

contact

breaker

should

be

0

5

0

65

kg

I

I

I

4

lb

Measure

the

tension

with

a

gauge

and

at

900

to

the

contact

breaker

arm

29

Page 32 of 171

CENTRIFUGAL

ADVANCE

MECHANISM

Special

equipment

is

required

to

check

the

advance

characteristics

It

is

possible

however

to

carry

out

an

exam

ination

of

the

caffi

assembly

and

the

weights

and

springs

to

ensure

that

the

earn

is

not

seizing

Lift

off

the

distributor

cap

and

turn

the

rotor

anti

clock

wise

When

the

rotor

is

released

is

should

return

to

the

fully

retarded

position

without

sticking

If

it

does

not

return

to

the

fully

retarded

position

it

will

be

necessary

to

check

for

dirt

and

weak

springs

It

should

be

noted

that

any

wear

in

the

mechanism

or

lose

of

spring

tension

will

upset

the

advance

characteristics

and

cause

unsatisfactory

engine

running

performance

over

the

speed

range

VACUUM

ADVANCE

MECHANISM

The

diaphragm

of

the

vacuum

advance

mechanism

is

mechanically

connected

to

the

contact

breaker

plate

The

rise

and

fall

of

inlet

manifold

depression

causes

the

diaphragm

to

move

the

contact

breaker

plate

to

advance

or

retard

the

ignition

If

the

vacuum

control

unit

fails

to

function

correctly

a

check

can

be

carried

out

to

ensure

that

the

contact

breaker

plate

is

moving

freely

and

that

the

three

steel

balls

at

the

top

and

oottom

of

the

plate

are

adequately

lubricated

Also

make

sure

that

the

vacuum

inlet

pipe

is

not

blocked

or

leaking

and

is

securely

tightened

Leakage

may

be

due

to

a

defective

diaphragm

which

should

be

renewed

along

with

any

other

faulty

part

of

the

mechanism

IGNITION

DlSTRffiUTOR

Removal

and

Dismantling

Disconnect

the

battery

leads

2

Disconnect

the

high

tension

lead

at

the

coil

3

Withdraw

the

high

tension

leads

from

the

distributor

cap

4

Detach

the

suction

pipe

from

the

vacuum

control

unit

5

Mark

the

position

of

the

distributor

and

rotor

remove

the

flange

mounting

bolts

and

withdraw

the

distributor

To

dismantle

the

distributor

proceed

as

follows

Take

off

the

distributor

cap

and

remove

the

rotor

Slacken

the

two

set

screws

holding

the

contact

breaker

upper

plate

Remove

the

primary

cable

terminals

and

withdraw

the

contact

set

from

the

distributor

Fig

C

S

Remove

the

vacuum

control

unit

c

Remove

the

two

screws

and

lift

out

the

contact

breaker

plate

detach

the

clamp

the

terminal

and

the

lead

To

remove

the

cam

take

out

the

centre

screw

as

shown

in

Fig

e

6

Drive

out

the

drive

pinion

retaining

pin

with

a

drift

and

hammer

Fig

e

and

remove

the

pinion

and

washer

Take

care

not

to

stretch

or

deform

the

governor

springs

when

detaching

them

from

the

weights

IGNITION

DISTRIBUTOR

Assembling

and

Installing

Assembly

is

a

reversal

of

the

dismantling

procedure

Lubricate

the

moving

contact

pivot

and

smear

the

lobes

of

the

cam

with

multi

purpose

grease

If

the

centrifugal

advance

mechanism

has

been

dismantled

the

governor

springs

and

cams

must

be

refitted

as

shown

in

Fig

e

8

The

governor

weight

pin

6

should

be

fitted

into

the

longer

of

the

two

slots

leaving

a

certain

amount

of

clearance

for

the

start

and

end

of

the

centrifugal

advance

movement

When

installing

the

distributor

take

care

to

align

the

body

and

rotor

with

the

marks

made

during

removal

The

rotor

must

be

positioned

in

its

original

location

it

will

turn

slightly

when

the

distributor

is

inserted

and

the

gear

teeth

mesh

Remove

and

replace

the

distributor

if

the

rotor

does

not

point

to

the

align

ment

mark

until

both

distributor

body

and

rotor

are

correctly

aligned

SPARKING

PLUGS

The

sparking

plugs

should

be

inspected

and

cleaned

at

regular

intervals

not

exceeding

every

10

000

km

6000

miles

New

sparking

plugs

should

be

fitted

at

approximately

20

000

km

12

000

miles

Remove

the

plugs

and

check

the

amount

of

electrode

wear

and

type

of

deposits

Brown

to

greyish

tan

deposits

with

slight

electrode

wear

indicate

that

the

plugs

are

satisfactory

and

working

in

the

correct

heat

range

Dry

fluffy

carbon

deposits

are

caused

by

too

rich

a

mixture

dirty

air

cleaner

excessive

idling

or

faulty

ignition

In

this

case

it

is

advisable

to

replace

the

plugs

with

plugs

having

a

higher

heat

range

Oily

wet

black

deposits

are

an

indication

of

oil

in

the

combustion

chambers

through

worn

pistons

and

rings

or

excessive

clearance

between

valve

guides

and

stems

The

engine

should

be

overhauled

and

hotter

plugs

installed

A

white

or

light

grey

centre

electrode

and

bluish

burned

side

electrode

indicates

engine

overheating

incorrect

ignition

timing

loose

plugs

low

fuel

pump

pressure

or

incorrect

grade

of

fuel

Colder

sparking

plugs

should

be

fitted

The

plugs

should

be

cleaned

on

a

blasting

machine

and

tested

Dress

the

electrodes

with

a

small

file

so

that

the

surfaces

of

both

electrodes

are

flat

and

parallel

Adjust

the

spark

plug

gap

to

0

8

0

9

mm

0

031

0

035

in

by

bending

the

earth

electrode

Refit

the

plugs

and

tighten

them

to

a

torque

reading

of

1

5

2

5

kgm

II

15Ib

ft

31