ignition DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 4 of 171

inteN

j

@IP

B

Index

ENGINE

COOLING

SYSTE

l

IGNITION

SYSTE

I

FUEL

SYSTBl

CLUTCH

GEARUOX

PROPELLER

SHAFT

Id

DIFFERENTIAL

REAR

AXLE

nd

REAR

SUSPENSION

FRONT

SUSPENSION

STEERING

BRAKING

SYSTEM

ELECTRICAL

EQUIP

JENT

WIRING

JAGRA

IS

TROUBLE

SHOOTING

TIGHTENING

TORQUES

SERIES

C

30

MODEL

SUPPLEMENT

AUTOSERVlCE

DATA

CHART

PART

NA

ES

nd

ALTERNATIVES

CONVERSION

TABLES

S

15

2S

33

43

51

62

7S

83

91

9S

lOB

liB

I2S

129

51

End

of

manuir

IntroductIon

OUf

intention

in

writing

this

Manual

is

to

provide

the

reader

with

all

the

data

and

in

formation

required

to

maintain

and

repair

the

vehicle

However

it

must

be

realised

that

special

equipment

and

skills

arc

required

in

some

caseS

to

carry

out

the

work

detailed

in

the

text

and

we

do

not

recommend

that

such

work

be

attempted

unless

the

reader

possesses

the

necessary

skill

and

equipment

It

would

be

better

to

have

an

AUTHQRISED

DEALER

to

carry

out

the

work

using

the

special

tools

and

equipment

available

to

his

trained

staff

He

will

also

be

in

possession

of

the

genuine

spare

parts

which

may

be

needed

for

replacement

The

information

in

the

Manual

has

been

checked

against

that

provided

by

the

vehicle

manufacturer

and

any

peculiarities

have

been

mentioned

if

they

depart

rom

usual

work

shop

practice

A

fault

finding

and

trouble

shooting

chart

has

been

inserted

at

the

end

of

the

Manual

to

enable

the

reader

to

pin

point

faults

and

so

save

time

As

it

is

impossible

to

include

every

malfunction

only

the

more

usual

ones

have

been

included

A

composite

conversion

table

has

also

been

included

at

the

end

of

the

manual

and

we

would

recommend

that

wherever

possible

for

greater

accuracy

the

metric

system

units

are

used

Brevity

and

simplicity

have

been

our

aim

in

compiling

this

Manual

relying

on

the

number

ous

illustrations

and

clear

text

to

inform

and

instruct

the

reader

At

the

request

of

the

many

users

of

our

Manuals

we

have

slanted

the

book

towards

repair

and

overhaul

rather

than

maintenance

Although

every

care

has

been

taken

to

ensure

that

the

information

and

data

are

correct

WE

CANNOT

ACCEPT

ANY

LIABILITY

FOR

INACCURACIES

OR

OMISSIONS

OR

FOR

DAMAGE

OR

MALFUNCTIONS

ARISING

FROM

THE

USE

OF

THIS

BOOK

NO

MATTER

HOW

CAUSED

I

3

Page 6 of 171

EngIne

INTRODUCTION

ENGINE

Removal

ENGINE

DismantUng

ENGINE

Inspection

and

Overhaul

VALVES

VALVE

GUIDES

VALVE

SEAT

INSERTS

CAMSHAFT

AND

CAMSHAFT

BEARINGS

Checking

CYliNDER

BLOCK

PtSTONS

AND

CONNECTING

RODS

INTRODUCTION

The

1400

1600

cc

and

1800

cc

engines

are

four

cylinder

in

line

units

with

a

single

overhead

camshaft

and

fully

balanced

five

bearing

crankshaft

The

valves

are

operated

through

rockers

which

are

directly

activated

by

the

earn

mechanism

The

crankshaft

is

a

special

steel

forging

with

the

centre

main

bearing

equipped

with

thrust

washers

to

take

up

the

end

thrust

of

the

crankshaft

The

special

aluminium

pistons

are

of

the

strut

construction

to

control

thermal

expansion

and

have

two

compression

rings

and

one

combined

oil

ring

The

gudgeon

pins

have

special

hollow

steel

shafts

and

are

a

fully

floating

fit

in

the

pistons

and

a

press

fit

in

the

connecting

rods

The

aluminium

alloy

cylinder

head

contains

wedge

type

combustion

chambers

and

is

fitted

with

aluminium

bronze

valve

seats

for

the

intake

valves

and

heat

resistant

steel

valve

seats

for

the

exhaust

valves

The

cast

iron

camshaft

is

driven

by

a

double

row

roller

chain

from

the

crankshaft

pulley

The

engine

is

pressure

lubricated

by

a

rotor

type

oil

pump

which

draws

oil

through

an

oil

strainer

into

the

pump

housing

and

then

forces

it

through

a

full

flow

oil

filter

into

the

main

oil

gallery

ENGINE

Removal

Place

alignment

marks

on

the

bonnet

and

hinges

remove

the

bonnet

from

the

vehicle

2

Drain

the

cooling

system

and

engine

and

transmission

lubricant

Remove

the

radiator

grille

3

Discon

ect

the

battery

cables

and

lift

out

the

battery

4

Detach

the

upper

and

lower

radiator

hoses

remove

the

radiator

mounting

bolts

and

lift

the

radiator

away

from

the

vehicle

The

torque

converter

c

jng

pipes

must

be

disconnected

from

the

radiator

on

vehicles

fitted

with

automatic

transmission

S

Remove

the

COOling

fan

and

pulley

disconnect

the

fuel

pipe

from

the

fuel

pump

and

the

heater

hoses

from

the

engine

attachments

6

Disconnect

the

accelerator

control

linkage

and

the

choke

CRANKSHAFT

AND

MAIN

BEARINGS

CAMSHAFT

AND

SPROCKET

FLYWHEEL

ENGINE

Assembling

VALVE

CLEARANCES

Adjusting

ENGINE

LUBRICATION

SYSTEM

OIL

PUMP

OIL

FILTER

CHANGING

THE

ENGINE

OIL

cable

from

the

carburettor

7

Disconnect

the

wirings

from

the

starter

alternator

ignition

coil

oil

pressure

switch

and

temperature

sender

unit

8

Remove

the

clutch

slave

cylinder

Fig

A

2

and

its

return

spring

9

Disconnect

the

speedometer

cable

and

withdraw

the

plug

connector

from

the

reversing

light

switch

10

Disconnect

the

shift

rods

and

seJector

rods

and

remove

the

cross

shaft

assembly

as

described

in

the

section

Gear

box

II

Disconnect

the

front

exhaust

pipe

from

the

exhaust

manifold

disconnect

the

centre

pipe

from

the

rear

pipe

and

remove

the

front

pipe

pre

muffler

and

centre

pipe

assembly

12

Disconnect

the

propeUer

shaft

flange

from

the

companion

flange

from

the

gear

carrier

13

Jack

up

the

gearbox

slightly

and

remove

the

rear

engine

mounting

bracket

bolts

remove

the

mounting

cross

member

and

handbrake

cable

c1amp

14

Remove

the

bolts

securing

the

front

engine

mounting

brackets

to

the

crossmember

15

Attach

lifting

cable

or

chains

to

the

hooks

installed

at

the

front

and

rear

of

the

cylinder

head

Lower

the

jack

under

the

gearbox

and

carefully

lift

and

tilt

the

engine

and

gearbox

unit

Withdraw

the

engine

and

gearbox

from

the

compartment

making

sure

that

it

is

guided

past

the

accessories

installed

on

the

body

ENGINE

Dismantling

Remove

the

engine

as

previously

described

and

carefully

clean

the

exterior

surfaces

Cbeck

for

signs

of

fuel

oil

or

water

leaks

past

the

cylinder

head

and

block

Remove

the

air

cleaner

alternator

distributor

and

starter

motor

Plug

the

carburettor

air

horn

and

distributor

hole

to

prevent

the

ingress

of

foreign

matter

Remove

the

gearbox

from

the

engine

drain

the

engine

oil

and

coolant

Mount

the

engine

in

a

suitable

stand

the

special

engine

attachment

ST05260001

and

engine

ST0501SOO0

should

be

used

if

available

Fig

A

3

5

Page 18 of 171

h

W

and

connecting

rod

assemblies

Use

a

piston

ring

compressor

to

install

the

pistons

through

the

top

of

the

cylbder

bore

Make

sure

that

the

pistons

and

rings

and

the

cylinder

bores

are

lubricated

with

clean

engine

oil

The

pistons

should

be

arranged

so

that

the

F

mark

faces

to

the

front

and

with

the

piston

ring

gaps

positioned

at

1800

to

each

other

Each

piston

must

be

refitted

into

its

original

bore

NOTE

Single

inlet

valve

springs

are

used

on

the

1400

cc

engine

double

valve

springs

are

used

on

the

1600cc

and

1800

cc

engines

Screw

the

valve

rocker

pivots

with

the

locknuts

into

the

pivot

bushing

Set

the

camshaft

locating

plate

and

install

the

camshaft

in

the

cylinder

head

with

the

groove

in

the

locating

plate

directed

to

the

front

of

the

engine

Install

the

camshaft

sprocket

and

tighten

it

together

with

the

fuel

pump

earn

to

a

torque

reading

of

12

16

kgm

86

116

IbJt

a

eck

that

the

camshaft

end

play

is

within

the

specified

limits

Install

the

rocker

arms

using

a

screwdriver

to

press

down

the

valve

springs

and

fit

the

valve

rocker

springs

Gean

the

joint

faces

of

the

cylinder

block

and

head

thoroughly

before

installing

the

cylinder

head

Turn

the

crank

shaft

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

and

make

sure

that

the

camshaft

sprocket

notch

and

the

oblong

groove

in

the

locating

plate

are

correctly

positioned

Care

should

be

taken

to

ensure

that

the

valves

are

clear

from

the

heads

of

the

pistons

The

crankshaft

and

camshaft

must

not

be

rotated

separately

or

the

valves

will

strike

the

heads

of

the

pistons

Temporarily

tighten

the

two

cylinder

head

bolts

1

and

2

in

Fig

A

37

to

a

torque

reading

of

2

kgm

14

5

lb

ft

Fit

the

crankshaft

sprocket

and

distributor

drive

gear

and

install

the

oil

thrower

Ensure

that

the

mating

marks

on

the

crankshaft

sprocket

face

towards

the

front

Install

the

timing

chain

making

sure

that

the

crankshaft

and

camshaft

keys

are

XJinting

upwards

The

marks

on

the

timing

chain

must

be

aligned

with

the

marks

on

the

right

hand

side

of

the

crankshaft

and

camshaft

sprockets

It

should

be

noted

that

three

location

holes

are

provided

in

the

camshaft

sprocket

See

Fig

A

38

The

camshaft

sprocket

being

set

to

the

No

2

location

hole

by

the

manufacturers

A

stretched

chain

will

however

affect

the

valve

timing

and

if

this

occurs

it

will

be

necessary

to

set

the

camshaft

to

the

No

3

location

hole

in

the

camshaft

sprocket

The

chain

can

be

checked

by

turning

the

engine

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

In

this

position

adjustment

will

be

required

if

the

location

notch

on

the

camshaft

sprocket

is

to

the

left

of

the

groove

on

the

camshaft

locating

plate

as

shown

in

the

illustration

The

correction

is

made

by

setting

the

camshaft

on

the

No

3

location

hole

in

the

camshaft

sprocket

the

No

3

notch

should

then

be

to

the

right

of

the

groove

and

the

valve

timing

will

have

to

be

set

using

the

No

3

timing

mark

Install

the

chain

guide

and

chain

tensioner

when

the

chain

is

located

correctly

There

should

be

no

protrusion

of

the

chain

tensioner

spindle

See

Fig

A

39

A

new

tensioner

must

be

fitted

if

the

spindle

protrudes

Press

a

new

oil

seal

into

the

timing

cover

and

fit

the

cover

into

position

using

a

new

gasket

Apply

sealing

compound

to

the

front

of

the

cylinder

block

and

to

the

gasket

and

to

the

top

of

the

timing

cover

Ensure

that

the

difference

in

height

between

the

top

of

the

timing

cover

and

the

upper

face

of

the

cylinder

block

does

not

exceed

0

15

mm

0

006

in

Two

sizes

of

timing

cover

bolts

are

used

the

size

M8

0

315

in

must

be

tightened

to

a

torque

reading

of

1

0

1

6

kgm

7

2

17

Ib

ft

and

the

size

M6

0

236

in

to

a

torque

reading

of

0

4

0

8

kgm

2

9

81b

ft

Install

the

crankshaft

pulley

and

water

pump

tighten

the

pulley

nut

to

a

torque

reading

of

12

16

kgm

86

8

115

7Ib

ft

then

set

the

No

1

piston

at

T

D

C

on

its

compression

stroke

Finally

tighten

the

cylinder

head

bolts

to

the

specified

torque

reading

in

accordance

with

the

tightening

sequence

shown

in

Fig

A

3

The

bolts

should

be

tightened

in

three

stages

as

follows

First

stage

Second

stage

Third

stage

4

kgm

28

9

lbJt

6

kgm

43

4

IbJ

t

6

5

85

kgm

47

0

61

5lb

ft

The

cylinder

head

bolts

should

be

retightened

if

necessary

after

the

engine

has

been

run

for

several

minutes

Install

the

oil

pump

and

distributor

drive

spindle

into

the

front

cover

as

described

under

Engine

Lubrication

System

r

rf

i

Install

the

fuel

pump

water

inlet

elbow

and

front

engine

slinger

Fit

the

oil

strainer

into

position

coat

the

oil

sump

gasket

with

sealing

compound

and

fit

the

gasket

and

oil

sump

to

the

cylinder

block

Tighten

the

oil

sump

bolts

in

a

diagonal

pattern

to

a

torque

reading

of

0

6

0

9

kgm

4

3

6

5

IbJt

Adjust

the

valve

clearances

to

the

specified

cold

engine

ftgures

following

the

procedures

described

under

the

appropriate

heading

Final

adjustments

will

be

carried

out

after

the

engine

has

been

assembled

completely

and

warmed

up

to

its

nonnal

temperature

Install

the

rear

engine

slinger

exhaust

manifold

and

inlet

manifold

Refit

the

distributor

and

carburettor

assemblies

as

described

in

their

relevant

sections

Install

the

fuel

pipes

and

vacuum

hose

making

sure

that

they

are

securely

cl

ped

Refit

the

thermostat

housing

thermostat

and

water

outlet

together

with

the

gasket

Bond

the

rocker

cover

gasket

to

the

rocker

cover

using

sealant

and

fit

the

rocker

cover

to

the

cylinder

head

Install

the

spark

plugs

and

connect

the

high

tension

leads

Fit

the

left

hand

engine

mounting

bracket

and

install

the

clutch

assembly

using

the

alignment

tool

ST20600000

to

fit

the

clutch

to

the

flywheel

as

described

in

the

section

ClUfCR

Lift

the

engine

away

from

the

mounting

stand

and

into

the

engine

compartment

Install

the

alternator

bracket

adjusting

bar

alternator

fan

pulley

fan

and

fan

belt

in

the

order

given

Check

the

tension

of

the

fan

belt

by

depressing

the

belt

at

a

point

midw

y

between

the

pulleys

The

tension

is

correct

if

the

belt

is

deflected

by

8

12

mm

0

3

0

4

in

under

thumb

pressure

Fit

the

right

hand

engine

mounting

bracket

the

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

Take

care

not

to

overtighten

the

oil

nIter

or

leakage

will

occur

Fill

the

engine

and

gearbox

to

the

correct

levels

with

recommended

lubricant

and

refill

the

cooling

system

Adjust

the

ignition

timing

and

carburettor

as

described

in

the

appro

priate

sections

17

Page 20 of 171

VALVE

CLEARANCES

Adjusting

Incorrect

valve

clearance

will

affect

the

performance

of

the

engine

and

may

damage

the

valves

and

valve

seats

Insuf

ficient

valve

clearance

will

result

in

loss

of

power

and

may

prevent

the

valve

from

seating

properly

Excessive

clearance

causes

the

valve

to

seat

and

reduces

the

amount

of

valve

lift

This

will

result

in

noisy

operation

with

damage

to

the

valves

and

seats

Adjustment

is

made

with

the

engine

switched

off

and

should

be

carried

out

initially

with

the

engine

cold

to

allow

the

engine

to

run

Final

adjustments

are

made

after

wanning

up

the

engine

to

its

Donnal

operating

temperature

The

engine

can

be

rotated

by

removing

the

sparking

plugs

to

release

the

cylinder

compressions

then

selecting

top

gear

and

pushing

the

vehicle

backwards

and

forwards

The

cold

valve

clearances

should

be

set

to

0

20

mm

0

0079

in

for

the

inlet

valves

and

0

25

mm

0

0098

in

for

the

exhaust

valves

Check

the

clearance

between

the

valve

and

rocker

using

a

feeler

gauge

as

shown

in

Fig

A

40

Slacken

the

locknut

and

turn

the

adjusting

screw

until

the

specified

clearance

is

obtained

then

tighten

the

locknut

and

recheck

the

clearance

The

feeler

gauge

should

just

be

free

to

move

between

the

rocker

and

valve

When

the

cold

valve

clearances

have

been

set

run

the

engine

until

it

reaches

its

normal

operating

temperature

then

switch

off

and

adjust

the

valve

clearances

with

the

engine

warm

to

0

25

mm

0

0098

in

for

the

inlet

valves

and

0

30

mm

0

0118

in

for

the

exhaust

valves

ENGINE

LUBRICATION

SYSTEM

Fig

A

41

OIL

PUMP

Removal

and

Dismantling

The

rotor

type

oil

pump

is

mounted

at

the

bottom

of

the

front

timing

cover

and

driven

by

the

distributor

drive

shaft

assembly

Overhaul

of

the

pump

will

require

careful

measurement

of

the

various

clearances

to

determine

the

amount

of

wear

which

has

taken

place

If

any

part

is

found

to

be

worn

it

may

be

neces

sary

to

replace

the

entire

oil

pump

assembly

To

remove

the

oil

pump

from

the

engine

proceed

as

follows

1

Remove

the

distributor

assembly

as

described

in

the

section

IGNITION

SYSTEM

Remove

the

oil

sump

drain

plug

and

drain

off

the

engine

oil

See

under

the

heading

CHANGING

THE

ENGINE

OIL

2

Remove

the

front

stabiliser

and

the

splash

shield

board

3

Withdraw

the

securing

bolts

and

detach

the

oil

pump

body

together

with

the

drive

gear

spindle

Take

out

the

bolts

securing

the

pump

cover

to

the

pump

body

and

withdraw

the

rotors

and

drive

shaft

See

Fig

A

42

The

pin

securing

the

driven

shaft

and

inner

rotor

must

not

00

taken

out

as

the

shaft

is

press

fitted

to

the

rotor

and

the

pin

is

caulked

Unscrew

the

threaded

plug

and

withdraw

the

regulator

valve

and

spring

Oean

each

part

thoroughly

and

examine

for

signs

of

damage

or

wear

Use

a

feeler

gauge

to

check

the

side

clearances

between

the

outer

and

inner

rotors

the

clearances

at

the

tips

of

the

rotors

and

the

clearance

between

the

outer

rotor

and

the

pump

body

See

Technical

Data

for

the

relevant

clearances

The

clearances

can

be

checked

using

a

straight

edge

as

shown

in

Fig

A

43

OIL

PUMP

Assembly

and

Installation

Assembly

is

a

reversal

of

the

dismantling

procedure

Before

installing

the

oil

pump

in

the

engine

it

will

be

necessary

to

rotate

the

engine

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

Fill

the

pump

housing

with

engine

oil

and

align

the

punch

mark

on

the

spindle

with

the

hole

in

the

oil

pump

as

shown

in

Fig

A

44

Install

the

pump

with

a

new

gasket

and

tighten

the

securing

bolts

to

a

torque

reading

of

1

1

1

5

kgm

8

1

Ilb

ft

Replace

the

splash

shield

board

and

the

front

stabiliser

refill

the

engine

with

the

specified

amount

of

engine

oil

OIL

FILTER

The

cartridge

type

oil

filter

can

be

removed

with

the

special

tool

ST

19320000

or

a

suitable

filter

remover

Interior

cleaning

is

not

necessary

but

the

ftIter

body

and

element

must

be

repiaced

every

10

000

km

6000

miles

Be

care

ul

not

to

overtighten

the

filter

when

replacing

or

oil

leakage

may

occur

CHANGING

THE

ENGINE

OIL

After

the

fIrst

oil

change

which

should

take

place

at

1000

km

600

miles

the

oil

should

be

changed

regularly

at

5000

km

3000

miles

intervals

Draining

is

more

easily

accomplished

after

a

lengthy

run

when

the

oil

being

thoroughly

warm

will

flow

quite

freely

Stand

the

vehicle

on

level

ground

and

place

a

suitable

container

under

the

drain

plug

Remove

the

drain

plug

carefully

as

the

hot

oil

may

spurt

out

with

considerable

force

When

refIlling

the

engine

make

sure

that

the

oil

is

to

the

H

mark

on

the

dipstick

19

Page 29 of 171

inter

lW

j

@lPX

TT

Y

Gw

PRIMARY

COIL

RESISTOR

I

I

l1@

l

I

IGNITION

U

SECONDARY

COIL

COIL

IS

AK

R

POIN

i

1

1

DISTRISUTOR

I

1

J

ISI

V

nl

N

I

TO

STARTER

l

1

ROTOR

HEAD

r

SPARK

PLUG

Fig

C

t

Ignition

sys

em

circuit

diagram

i

II

@

1

1

@

J

i

9

28

l

I

i

1

I

I

@

@

G

N

7

Fig

C

2lgnition

distributor

1

Shaft

assembly

2

Collar

assembly

3

Cam

assembly

4

Governor

weights

5

Governor

spring

6

Rowr

head

7

Breaker

plate

8

Contact

set

9

Tennirtal

assembly

10

Vacuum

control

J

1

Condenser

12

Distributor

cap

13

Carbon

point

14

Plate

15

CIilmp

Page 30 of 171

IgnItIon

System

DESCRII

TION

IGNITION

TIMING

IGNITION

DISTRIBUTOR

Maintenance

ADJUSTING

THE

CONTACT

BREAKER

GAP

CENTRIFUGAL

ADVANCE

MECHANISM

VACUUM

ADVANCE

MECHANISM

IGNITION

DISTRIBUTOR

Removal

and

Dismantling

IGNITION

DISTRIBUTOR

Assembling

and

Installation

SPARKING

PLUGS

DESCRII

TION

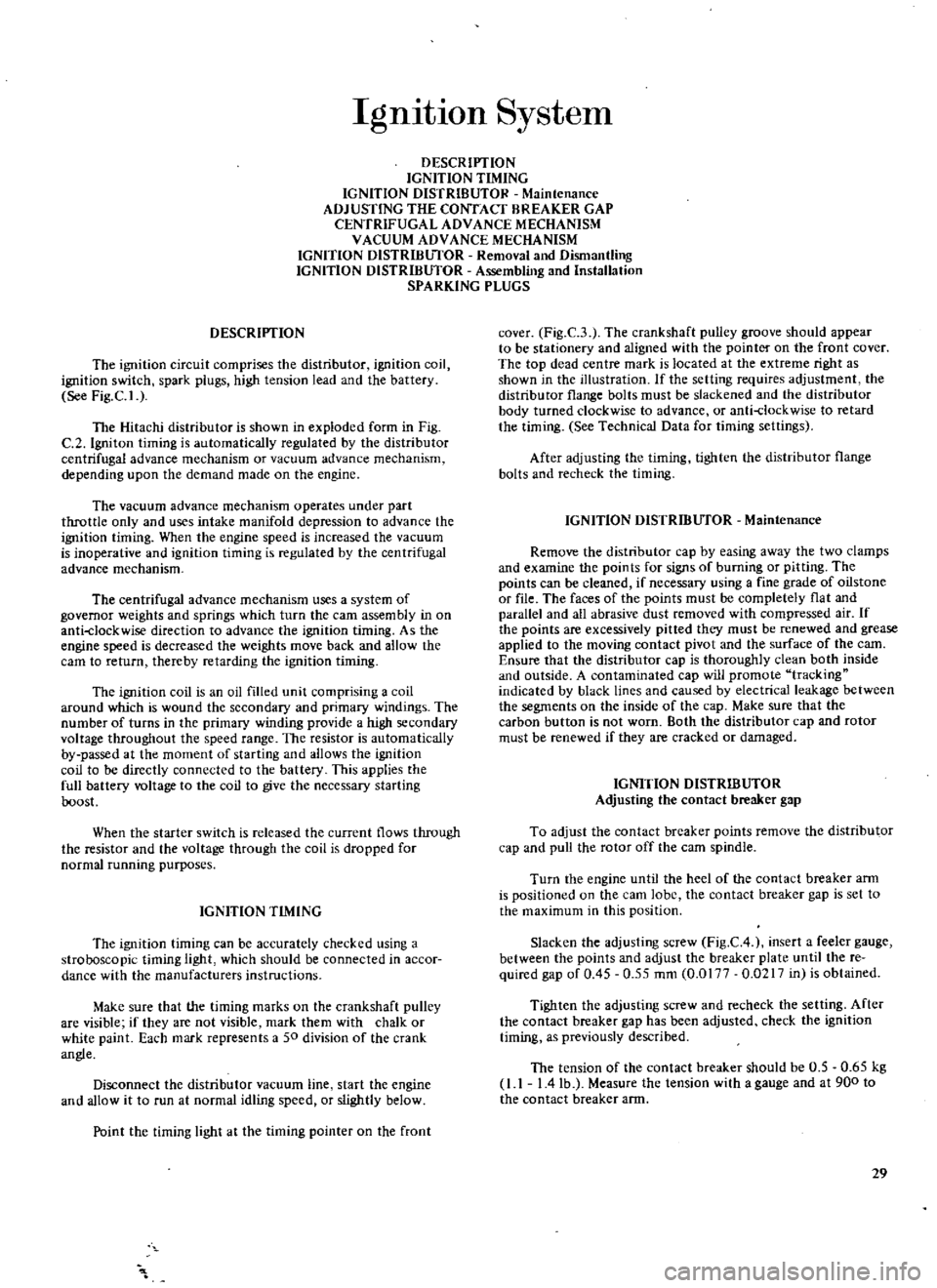

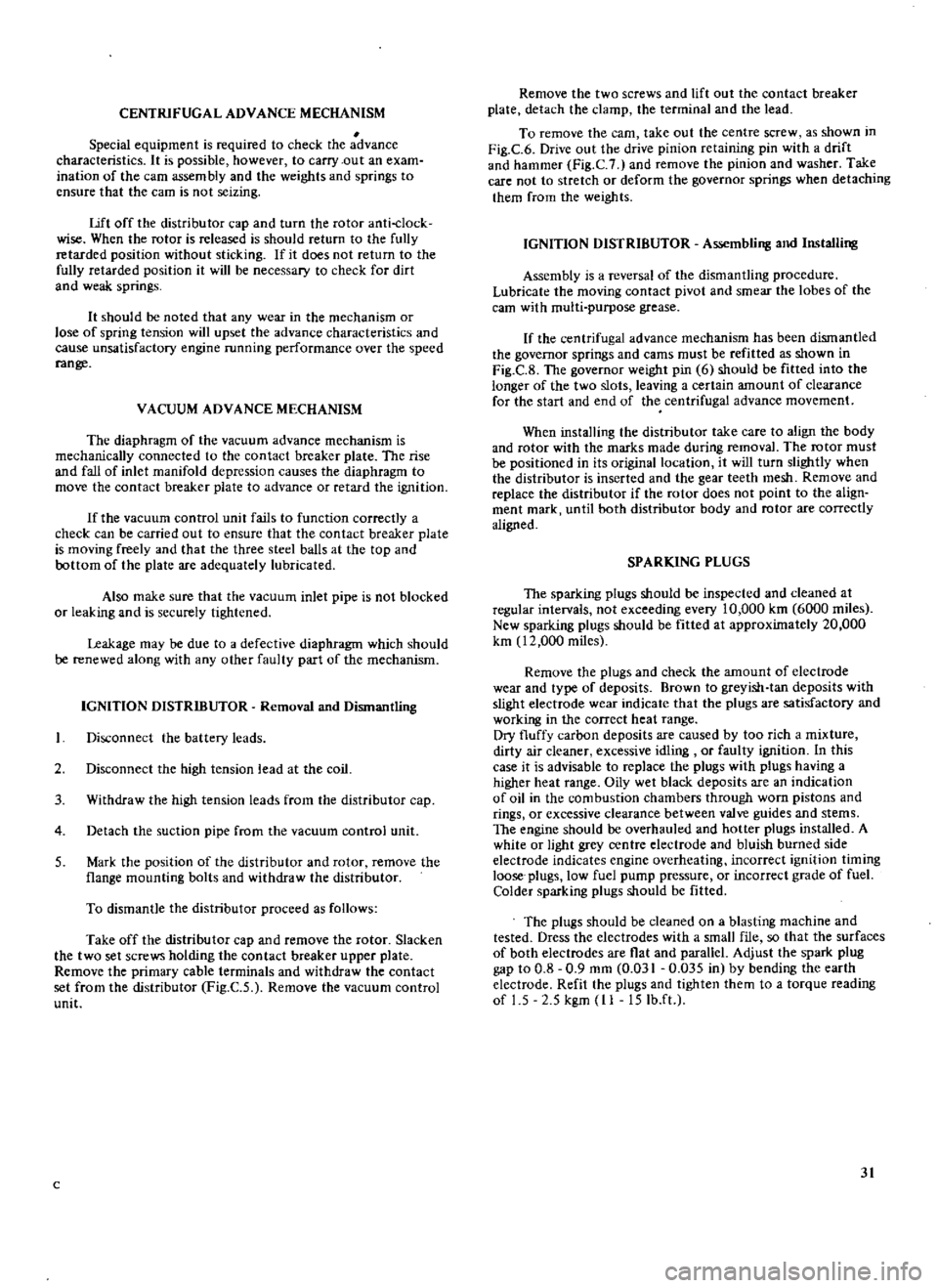

The

ignition

circuit

comprises

the

distributor

ignition

coil

ignition

switch

spark

plugs

high

tension

lead

and

the

battery

See

Fig

C

1

The

Hitachi

distributor

is

shown

in

exploded

form

in

Fig

C

2

19niton

timing

is

automatically

regulated

by

the

distributor

centrifugal

advance

mechanism

or

vacuum

advance

mechanism

depending

upon

the

demand

made

on

the

engine

The

vacuum

advance

mechanism

operates

under

part

throttle

only

and

uses

intake

manifold

depression

to

advance

the

ignition

timing

When

the

engine

speed

is

increased

the

vacuum

is

inoperative

and

ignition

timing

is

regulated

by

the

centrifugal

advance

mechanism

The

centrifugal

advance

mechanism

uses

a

system

of

governor

weights

and

springs

which

turn

the

carn

assembly

in

on

anti

clockwise

direction

to

advance

the

ignition

timing

As

the

engine

speed

is

decreased

the

weights

move

back

and

allow

the

cam

to

return

thereby

retarding

the

ignition

timing

The

ignition

coil

is

an

oil

filled

unit

comprising

a

coil

around

which

is

wound

the

secondary

and

primary

windings

The

number

of

turns

in

the

primary

winding

provide

a

high

secondary

voltage

throughout

the

speed

range

The

resistor

is

automatically

by

passed

at

the

moment

of

starting

and

allows

the

ignition

coil

to

be

directly

connected

to

the

battery

This

applies

the

full

battery

voltage

to

the

coil

to

give

the

necessary

staTting

boost

When

the

starter

switch

is

released

the

current

flows

through

the

resistor

and

the

voltage

through

the

coil

is

dropped

for

normal

running

purposes

IGNITION

TIMING

The

ignition

timing

can

be

accurately

checked

using

a

stroboscopic

timing

light

which

should

be

connected

in

accor

dance

with

the

manufacturers

instructions

Make

sure

that

the

timing

marks

on

the

crankshaft

pulley

are

visible

if

they

are

not

visible

mark

them

with

chalk

or

white

paint

Each

mark

represents

a

50

division

of

the

crank

angle

Disconnect

the

distributor

vacuum

line

start

the

engine

and

allow

it

to

run

at

normal

idling

speed

or

slightly

below

Point

the

timing

light

at

the

timing

pointer

on

the

front

cover

Fig

C

3

The

crankshaft

pulley

groove

should

appear

to

be

stationery

and

aligned

with

the

pointer

on

the

front

cover

The

top

dead

centre

mark

is

located

at

the

extreme

right

as

shown

in

the

illustration

If

the

setting

requires

adjustment

the

distributor

flange

bolts

must

be

slackened

and

the

distributor

body

turned

clockwise

to

advance

or

anti

clockwise

to

retard

the

timing

See

Technical

Data

for

timing

settings

After

adjusting

the

timing

tighten

the

distributor

flange

bolts

and

recheck

the

timing

IGNITION

DISTRIBUTOR

Maintenance

Remove

the

distributor

cap

by

easing

away

the

two

clamps

and

examine

the

points

for

signs

of

burning

or

pitting

The

points

can

be

cleaned

if

necessary

using

a

fine

grade

of

oilstone

or

file

The

faces

of

the

points

must

be

completely

flat

and

parallel

and

all

abrasive

dust

removed

with

compressed

air

If

the

points

are

excessively

pitted

they

must

be

renewed

and

grease

applied

to

the

moving

contact

pivot

and

the

surface

of

the

cam

Ensure

that

the

distributor

cap

is

thoroughly

clean

both

inside

and

outside

A

contaminated

cap

will

promote

tracking

indicated

by

black

lines

and

caused

by

electrical

leakage

between

the

segments

on

the

inside

of

the

cap

Make

sure

that

the

carbon

button

is

not

worn

Both

the

distributor

cap

and

rotor

must

be

renewed

if

they

are

cracked

or

damaged

IGNITION

DISTRIBUTOR

Adjusting

the

contact

breaker

gap

To

adjust

the

contact

breaker

points

remove

the

distributor

cap

and

pull

the

rotor

off

the

cam

spindle

Turn

the

engine

until

the

heel

of

the

contact

breaker

arm

is

positioned

on

the

cam

lobe

the

contact

breaker

gap

is

set

to

the

maximum

in

this

position

Slacken

the

adjusting

screw

Fig

CA

insert

a

feeler

gauge

between

the

points

and

adjust

the

breaker

plate

until

the

re

quired

gap

of

0

45

0

55

mm

0

0177

0

0217

in

is

obtained

Tighten

the

adjusting

screw

and

recheck

the

setting

After

the

contact

breaker

gap

has

been

adjusted

check

the

ignition

timing

as

previously

described

The

tension

of

the

contact

breaker

should

be

0

5

0

65

kg

I

I

I

4

lb

Measure

the

tension

with

a

gauge

and

at

900

to

the

contact

breaker

arm

29

Page 31 of 171

inter

i

D

j

@

2l

Fig

C

3

Checking

the

ignition

timing

J

EARTH

LEAD

WIRE

SET

SCREW

OAmER

Fig

C

5

View

of

the

distributor

without

cap

Fig

C

7

Removing

the

retaining

pin

30

J

Fig

C

4

Adjusting

the

contact

points

gap

L

Fig

C

6

Removing

the

earn

2

1

1

I

7

V

J

J

1

Governor

weight

2

Oearance

for

start

and

nd

of

advanc

angle

1

Hook

4

GOllernor

spring

B

5

Com

plate

6

F7YWt

ight

pin

7

Hook

8

Goverrwrspring

A

9

Rotor

positioning

tip

@

Fig

C

8

Centrifugal

advance

mechanism

Page 32 of 171

CENTRIFUGAL

ADVANCE

MECHANISM

Special

equipment

is

required

to

check

the

advance

characteristics

It

is

possible

however

to

carry

out

an

exam

ination

of

the

caffi

assembly

and

the

weights

and

springs

to

ensure

that

the

earn

is

not

seizing

Lift

off

the

distributor

cap

and

turn

the

rotor

anti

clock

wise

When

the

rotor

is

released

is

should

return

to

the

fully

retarded

position

without

sticking

If

it

does

not

return

to

the

fully

retarded

position

it

will

be

necessary

to

check

for

dirt

and

weak

springs

It

should

be

noted

that

any

wear

in

the

mechanism

or

lose

of

spring

tension

will

upset

the

advance

characteristics

and

cause

unsatisfactory

engine

running

performance

over

the

speed

range

VACUUM

ADVANCE

MECHANISM

The

diaphragm

of

the

vacuum

advance

mechanism

is

mechanically

connected

to

the

contact

breaker

plate

The

rise

and

fall

of

inlet

manifold

depression

causes

the

diaphragm

to

move

the

contact

breaker

plate

to

advance

or

retard

the

ignition

If

the

vacuum

control

unit

fails

to

function

correctly

a

check

can

be

carried

out

to

ensure

that

the

contact

breaker

plate

is

moving

freely

and

that

the

three

steel

balls

at

the

top

and

oottom

of

the

plate

are

adequately

lubricated

Also

make

sure

that

the

vacuum

inlet

pipe

is

not

blocked

or

leaking

and

is

securely

tightened

Leakage

may

be

due

to

a

defective

diaphragm

which

should

be

renewed

along

with

any

other

faulty

part

of

the

mechanism

IGNITION

DlSTRffiUTOR

Removal

and

Dismantling

Disconnect

the

battery

leads

2

Disconnect

the

high

tension

lead

at

the

coil

3

Withdraw

the

high

tension

leads

from

the

distributor

cap

4

Detach

the

suction

pipe

from

the

vacuum

control

unit

5

Mark

the

position

of

the

distributor

and

rotor

remove

the

flange

mounting

bolts

and

withdraw

the

distributor

To

dismantle

the

distributor

proceed

as

follows

Take

off

the

distributor

cap

and

remove

the

rotor

Slacken

the

two

set

screws

holding

the

contact

breaker

upper

plate

Remove

the

primary

cable

terminals

and

withdraw

the

contact

set

from

the

distributor

Fig

C

S

Remove

the

vacuum

control

unit

c

Remove

the

two

screws

and

lift

out

the

contact

breaker

plate

detach

the

clamp

the

terminal

and

the

lead

To

remove

the

cam

take

out

the

centre

screw

as

shown

in

Fig

e

6

Drive

out

the

drive

pinion

retaining

pin

with

a

drift

and

hammer

Fig

e

and

remove

the

pinion

and

washer

Take

care

not

to

stretch

or

deform

the

governor

springs

when

detaching

them

from

the

weights

IGNITION

DISTRIBUTOR

Assembling

and

Installing

Assembly

is

a

reversal

of

the

dismantling

procedure

Lubricate

the

moving

contact

pivot

and

smear

the

lobes

of

the

cam

with

multi

purpose

grease

If

the

centrifugal

advance

mechanism

has

been

dismantled

the

governor

springs

and

cams

must

be

refitted

as

shown

in

Fig

e

8

The

governor

weight

pin

6

should

be

fitted

into

the

longer

of

the

two

slots

leaving

a

certain

amount

of

clearance

for

the

start

and

end

of

the

centrifugal

advance

movement

When

installing

the

distributor

take

care

to

align

the

body

and

rotor

with

the

marks

made

during

removal

The

rotor

must

be

positioned

in

its

original

location

it

will

turn

slightly

when

the

distributor

is

inserted

and

the

gear

teeth

mesh

Remove

and

replace

the

distributor

if

the

rotor

does

not

point

to

the

align

ment

mark

until

both

distributor

body

and

rotor

are

correctly

aligned

SPARKING

PLUGS

The

sparking

plugs

should

be

inspected

and

cleaned

at

regular

intervals

not

exceeding

every

10

000

km

6000

miles

New

sparking

plugs

should

be

fitted

at

approximately

20

000

km

12

000

miles

Remove

the

plugs

and

check

the

amount

of

electrode

wear

and

type

of

deposits

Brown

to

greyish

tan

deposits

with

slight

electrode

wear

indicate

that

the

plugs

are

satisfactory

and

working

in

the

correct

heat

range

Dry

fluffy

carbon

deposits

are

caused

by

too

rich

a

mixture

dirty

air

cleaner

excessive

idling

or

faulty

ignition

In

this

case

it

is

advisable

to

replace

the

plugs

with

plugs

having

a

higher

heat

range

Oily

wet

black

deposits

are

an

indication

of

oil

in

the

combustion

chambers

through

worn

pistons

and

rings

or

excessive

clearance

between

valve

guides

and

stems

The

engine

should

be

overhauled

and

hotter

plugs

installed

A

white

or

light

grey

centre

electrode

and

bluish

burned

side

electrode

indicates

engine

overheating

incorrect

ignition

timing

loose

plugs

low

fuel

pump

pressure

or

incorrect

grade

of

fuel

Colder

sparking

plugs

should

be

fitted

The

plugs

should

be

cleaned

on

a

blasting

machine

and

tested

Dress

the

electrodes

with

a

small

file

so

that

the

surfaces

of

both

electrodes

are

flat

and

parallel

Adjust

the

spark

plug

gap

to

0

8

0

9

mm

0

031

0

035

in

by

bending

the

earth

electrode

Refit

the

plugs

and

tighten

them

to

a

torque

reading

of

1

5

2

5

kgm

II

15Ib

ft

31

Page 33 of 171

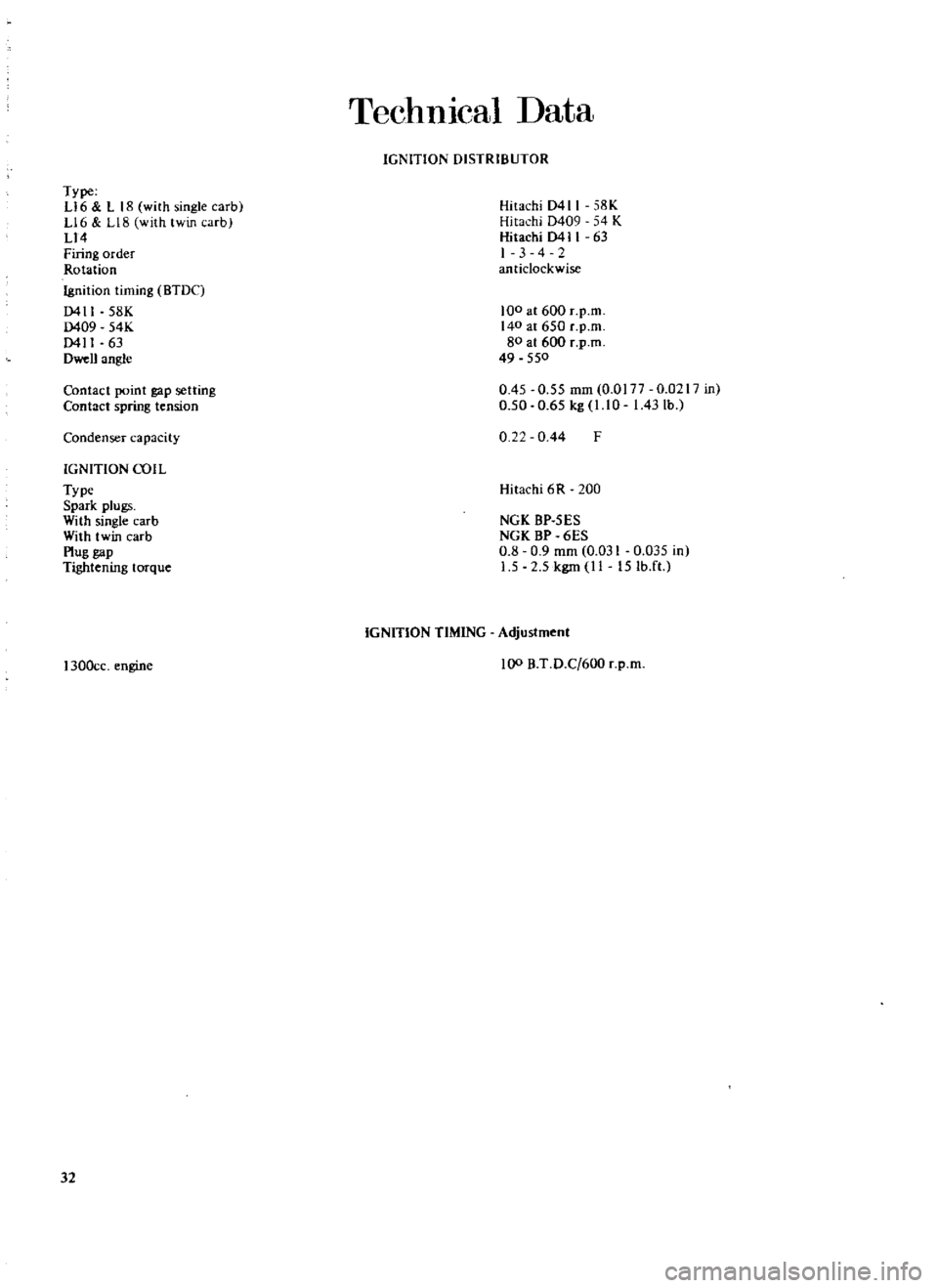

TechnIcal

Data

IGNITION

DISTRIBUTOR

Type

L16

ll8

with

single

carbl

L16

L18

with

twin

arb

L14

Firing

order

Rotation

Ignition

timing

BTDC

0411

58K

0409

54K

0411

63

Dwen

angle

Hitachi

D411

58K

Hitachi

D409

54

K

Hitachi

0411

63

I

3

4

2

anticlockwise

100

at

600

r

p

m

140

at

650

c

p

m

80

at

600

r

p

m

49

550

Contact

point

gap

setting

Contact

spring

tension

0

45

0

55

mm

O

OI77

0

0217

in

0

50

0

65

kg

l

l

0

I

43

lb

Condenser

capacity

0

22

0

44

F

IGNITION

COil

Type

Spark

plugs

With

single

carb

With

twin

carb

Plug

gap

Tightening

torque

Hitachi

6

R

200

NGK

BP

5ES

NGK

BP

6ES

0

8

0

9

mm

0

031

0

035

in

1

5

2

5

kgm

II

15Ib

ft

1300cc

engine

IGNITION

TIMING

Adjustment

100

B

T

D

C

600

r

p

m

32

Page 36 of 171

and

seats

or

a

weak

diaphragm

return

spring

A

pressure

above

the

specified

figure

may

be

due

to

an

excessively

strong

and

tight

diaphragm

Capacity

test

The

capacity

test

can

be

carried

out

when

the

static

pressure

has

been

tested

and

conforms

with

the

specified

figure

of

0

18

kg

sq

cm

2

6Ib

sq

inJ

Disconnect

the

fuel

line

at

the

carburettor

and

place

a

container

under

the

end

of

the

pipe

to

act

as

a

fuel

sump

Start

the

engine

and

run

it

at

a

speed

of

1000

Lp

m

The

amount

of

fuel

delivered

from

the

pump

in

one

minutc

should

be

1000

cc

2

1

US

pt

If

petrol

does

not

flow

from

the

opcned

end

of

the

pipe

at

the

correct

rate

then

either

the

fuel

pipe

is

clogged

or

the

pump

is

not

operating

correctly

If

the

latter

cause

is

suspected

the

pump

must

be

removed

and

inspected

as

described

below

FUEL

PUMP

Removing

and

Dismantling

Before

removing

the

pump

take

off

the

petrol

tank

cap

and

disconnect

the

pump

inlet

and

outlet

pipes

Blow

through

the

pipes

with

compressed

air

to

make

sure

that

they

are

not

clogged

Remove

the

pump

retaining

nuts

withdraw

the

pump

and

dismantle

it

in

the

following

order

Referring

to

Fig

D

l

Take

out

the

screws

holding

the

two

body

halves

together

and

scparate

the

upper

body

from

the

lower

body

2

Remove

the

cap

and

cap

gasket

3

Unscrew

the

eI

bow

and

connector

4

Take

off

the

valve

retainer

and

remove

the

two

valves

5

To

remove

the

diaphragm

diaphragm

spring

and

lower

body

sealing

washer

press

the

diaphragm

down

against

the

force

of

the

spring

and

tilt

the

diaphragm

at

the

same

time

so

that

the

pull

rod

can

be

unhooked

from

the

rocker

arm

link

Fig

D

7

The

rocker

arm

pin

can

be

driven

out

with

a

suitable

drift

FUEL

PUMP

Inspection

and

Assembly

Check

the

uppcr

and

lower

body

halves

for

cracks

Inspect

the

valve

and

valve

spring

assembly

for

signs

of

wear

and

make

sure

that

the

diaphragm

is

not

holed

or

cracked

also

make

sure

that

the

rocker

arm

is

not

worn

at

the

point

of

contact

with

the

camshaft

The

rocker

arm

pin

may

cause

oil

leakage

if

worn

and

should

be

renewed

Assembly

is

a

reversal

of

the

dismantling

procedure

noting

the

following

points

Fit

new

gaskets

and

lubricate

the

rocker

arm

link

and

the

rocker

arm

pin

before

installing

The

pump

can

be

tested

by

holding

it

approximately

I

metre

3

feet

above

the

level

of

fuel

and

with

a

pipe

connected

between

the

pump

and

fuel

strainer

Operate

the

rocker

ann

by

hand

the

pump

is

operating

correctly

if

fuel

is

drawn

up

soon

after

the

rocker

ann

is

released

CARBURETTOR

IDLING

ADJUSTMENT

The

idling

speed

cannot

be

adjusted

satisfactorily

if

the

ignition

timing

is

incorrect

if

the

spark

plugs

are

dirty

or

if

the

valve

clearances

are

not

correctly

adjusted

Before

adjusting

the

idling

speed

set

the

hot

valve

clearances

t

o

0

25

mm

0

0098

in

for

the

intake

valves

and

0

30

mm

0

0118

in

for

the

exhaust

valves

as

described

in

the

ENGINE

section

Idling

adjustment

is

carried

out

with

the

throttle

stop

screw

in

conjunction

with

the

idling

adjustment

screw

See

Fig

D

8

Run

the

engine

until

it

attains

its

normal

operating

temperature

and

then

switch

off

Starting

from

the

fully

closed

position

unscrew

the

idling

adjustment

screw

by

approximately

three

turns

Screw

the

throttle

stop

screw

in

by

two

or

tftr

e

turns

and

start

th

engine

Unscrew

the

throttle

stop

screw

until

the

engine

commences

to

run

unevenly

then

screw

in

the

idling

adjustment

screw

so

that

the

engine

runs

smoothly

at

the

highest

speed

Readjust

the

throttle

stop

screw

to

drop

the

engine

speed

of

approximately

600

r

p

m

is

obtained

WARNING

Do

not

attempt

to

screw

the

idling

adjustment

screw

down

completely

or

the

tip

of

the

screw

may

be

damaged

FAST

IDLE

OPENING

ADJUSTMENT

The

choke

valve

is

synchronized

with

the

throttle

valve

and

connected

to

it

by

levers

as

shown

in

Fig

D

9

The

fast

idle

opening

can

be

check

by

fully

closing

the

choke

valve

and

measuring

the

clearance

between

the

primary

throttle

valve

and

the

wall

of

the

throttle

chamber

This

clearance

being

shown

as

A

in

the

illustration

The

clearance

for

the

carburettor

types

is

as

follows

Carburettor

type

Throttle

opening

angle

180

180

190

Dimension

A

213304

361

13304

4

I

13282

331

1

55mm

0

06lin

1

55mm

0

06Iin

1

3

mm

0

051

in

35