trunk DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 76 of 171

Rear

Axle

Rear

SuspensIon

DESCRIPTION

REAR

AXLE

AND

SUSPENSION

Removal

Saloons

COIL

SPRINGS

Saloons

REAR

SHOCK

ABSORBERS

Saloons

REAR

SUSPENSION

ARM

Saloons

DESCRIPTION

Saloon

models

are

fitted

with

independent

rear

suspension

with

semi

trailing

arms

suspension

arms

coil

springs

and

telescopic

hydraulic

double

acting

shock

absorbers

The

differ

ential

gear

carrier

and

suspension

member

is

mounted

directly

onto

the

body

structure

via

rubber

mountings

See

Fig

H

I

Estate

cars

and

1800

ce

Vans

are

fitted

with

a

semi

floating

rear

axle

with

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

mounted

on

rubrer

bushes

See

Fig

H

2

REAR

AXLE

AND

SUSPENSION

Removal

Saloon

models

I

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

disconnect

the

hand

brake

linkage

and

the

return

spring

Fig

H

3

3

Remove

the

exhaust

tail

pipe

and

silencer

4

Disconnect

the

brake

hoses

and

plug

the

openings

to

prevent

the

ingress

of

dirt

5

Remove

the

propeller

shaft

assembly

as

described

in

the

relevant

section

after

marking

the

propeller

rear

flange

and

differential

pinion

flange

6

Jack

up

the

suspension

ann

and

remove

the

shock

absorber

lower

mountings

taking

care

not

to

lose

the

rubber

bushings

7

Place

ajack

under

the

centre

of

the

suspension

member

and

differential

carrier

and

remove

the

nuts

securing

the

suspension

member

to

the

body

7

in

Fig

H

3

Remove

the

differential

mounting

nuts

8

8

Carefully

lower

and

remove

the

suspension

assembly

REAR

SUSPENSION

Inspection

Saloons

Examine

all

parts

for

wear

and

damage

paying

particular

attention

to

the

rubber

bushes

in

the

suspension

arms

and

the

bump

rubbers

Check

the

condition

of

the

spring

rubber

insulators

in

the

suspension

member

and

differential

mounting

memrer

The

rubber

insulators

must

be

replaced

if

the

dimension

A

in

Fig

H

4

is

less

than

5mm

0

2

in

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloons

DRNE

SHAFTS

REAR

AXLE

Removal

Estate

cars

and

Vans

REAR

SPRING

Estate

cars

and

Vans

REAR

SHOCK

ABSORBERS

Estate

cars

and

Vans

REAR

SUSPENSION

Installation

Saloons

Installation

is

a

reversal

of

the

removal

procedures

noting

the

following

points

Ensure

that

the

suspension

member

and

differential

mount

ing

member

are

correctly

aligned

as

shown

in

Fig

U

5

and

insert

the

rubber

insulators

from

the

underside

of

the

vehicle

Tighten

the

differential

mounting

member

the

suspension

member

and

lower

shock

absorber

nuts

to

the

specified

tighten

ing

torques

COIL

SPRINGS

Removal

Saloons

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

and

disconnect

the

handbrake

linkage

and

return

spring

3

Remove

the

drive

shaft

flange

nuts

at

the

wheel

side

Fig

H

6

and

the

bump

rubber

securing

nuts

4

Place

ajack

under

the

suspension

ann

and

remove

the

shock

absorber

from

the

lower

mounting

bracket

Carefully

lower

the

jack

and

remove

the

coil

spring

spring

scat

and

bump

rubber

Fig

H7

COIL

SPRINGS

Installation

Saloons

Oleck

the

coil

springs

for

signs

of

deformation

or

cracks

Test

the

spring

for

its

free

length

and

height

under

load

and

compare

the

figures

obtained

with

the

information

in

Technical

Data

Inspect

all

rubber

parts

and

replace

any

which

are

damaged

or

deformed

Installation

is

a

reversal

of

the

removal

procedure

making

sure

that

the

flat

face

of

the

spring

is

at

the

top

REAR

SHOCK

ABSORBERS

Removal

and

Installation

Saloons

Remove

the

trim

in

the

boot

trunk

and

take

off

the

two

nuts

securing

the

upper

shock

absorber

mounting

See

Fig

H

S

Detach

the

shock

absorber

from

the

lower

mounting

bracket

The

shock

absorber

should

be

tested

and

the

fIgUres

com

pared

with

the

specifications

in

Technical

Data

Cbeck

for

oil

leaks

and

cracks

Make

sure

that

the

shaft

is

straight

and

that

the

rubber

bushes

are

not

damaged

or

defonned

Renew

all

unsatis

75

Page 170 of 171

Part

NanleH

and

AlternatlyeS

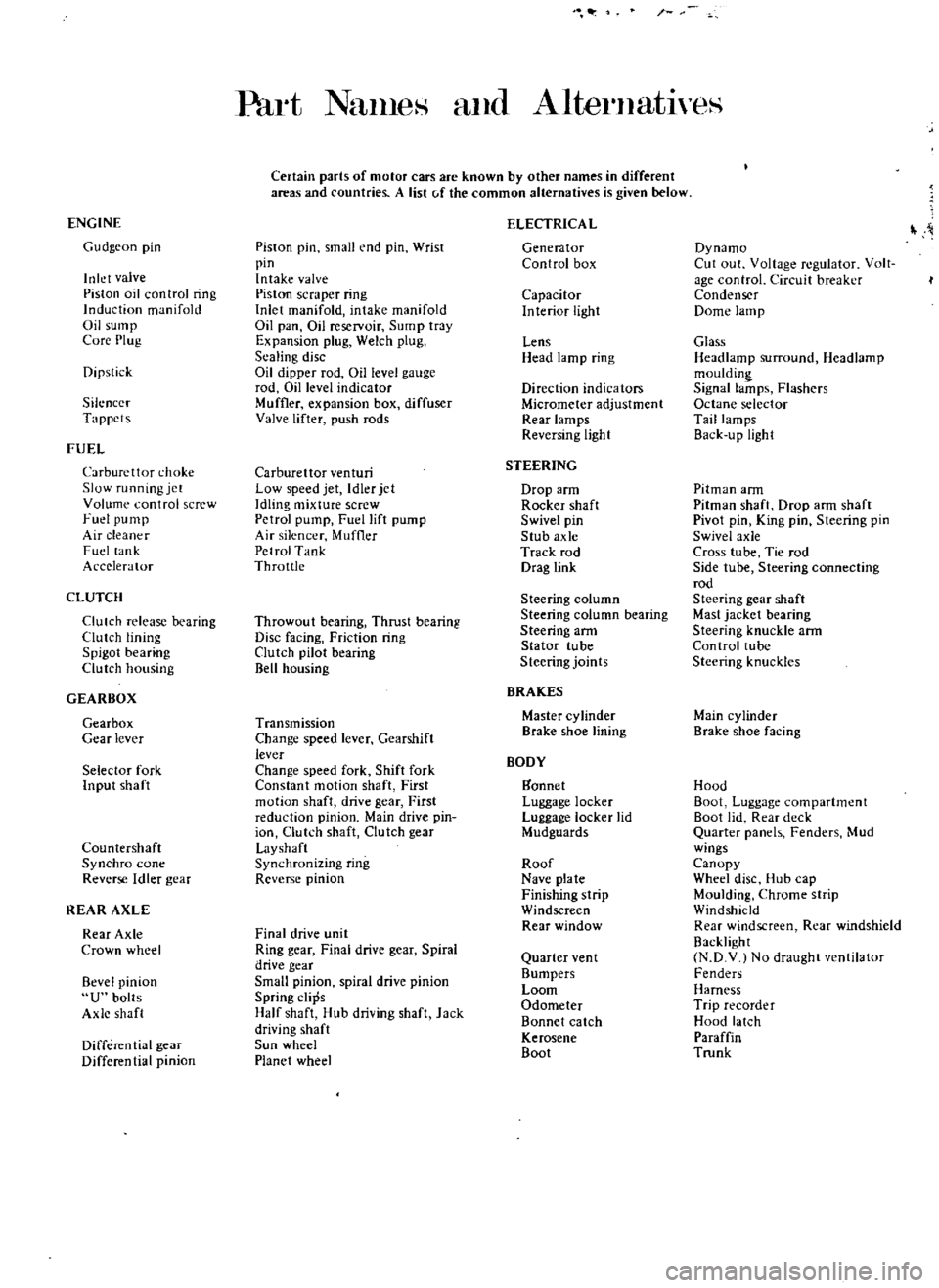

Certain

parts

of

motor

cars

are

known

by

other

names

in

different

areas

and

countries

A

list

c

f

the

common

alternatives

is

given

below

ENGINE

ELECTRICA

L

Gudgeon

pin

Piston

pin

small

end

pin

Wrist

Generator

Dynamo

pin

Control

box

Cut

out

Voltage

regulator

Volt

Inlet

valve

Intake

valve

age

control

Circuit

breaker

Piston

oil

control

ring

Piston

scraper

ring

Capacitor

Condenser

Induction

manifold

Inlet

manifold

intake

manifold

Interior

light

Dome

lamp

Oil

sump

Oil

pan

Oil

reservoir

Sump

tray

Core

Plug

Expansion

plug

Welch

plug

Lens

Glass

Sealing

disc

Head

lamp

ring

Headlamp

surround

Headlamp

Dipstick

Oil

dipper

rod

Oil

level

gauge

mouldin

rod

Dillevel

indicator

Direction

indicators

Signal

lamps

Flashers

Silencer

Muffler

expansion

box

diffuser

Micrometer

adjustment

Octane

selector

Tappets

Valve

lifter

push

rods

Rear

lamps

Tail

lamps

Reversing

light

Back

u

pUgh

t

FUEL

Carburettor

choke

Carburettor

venturi

STEERING

Slow

running

jet

Low

speed

jet

Idler

jet

Drop

arm

Pitman

ann

Volume

control

screw

Idling

mixture

screw

Rocker

shaft

Pitman

shaft

Drop

ann

shaft

Fuel

pump

Petrol

pump

Fuel

lift

pump

Swivel

pin

Pivot

pin

King

pin

Steering

pin

Air

cleaner

Air

silencer

Muffler

Stub

axle

Swivel

axle

Fuel

lank

Petrol

Tank

Track

rod

Cross

tube

Tie

rod

Accelerator

Throttle

Drag

link

Side

tube

Steering

connecting

rod

CLUTCH

Steering

column

Steering

gear

shaft

Clutch

release

bearing

Throwout

bearing

Thrust

bearing

Steering

column

bearing

Mast

jacket

bearing

Clutch

lining

Disc

facing

Friction

ring

Steering

arm

Steering

knuckle

ann

Spigot

bearing

Clutch

pilot

bearing

Stator

tube

Control

tube

Clutch

housing

Bell

housing

Steering

joints

Steering

knuckles

GEARBOX

BRAKES

Gearbox

Transmission

Master

cylinder

Main

cylinder

Gear

lever

Change

speed

lever

Gearshift

Brake

shoe

lining

Brake

shoe

facing

lever

BODY

Selector

fork

Change

speed

fork

Shift

fork

Input

shaft

Constant

motion

shaft

First

gannet

Hood

motion

shaft

drive

gear

First

Luggage

locker

Boot

Luggage

compartment

reduction

pinion

Main

drive

pin

Luggage

locker

lid

Boot

lid

Rear

deck

ion

Clutch

shaft

Clutch

gear

Mudguards

Quarter

panels

Fenders

Mud

Countershaft

Layshaft

wings

Synchro

cone

Synchronizing

ring

Roof

Canopy

Reverse

Idler

gear

Reverse

pinion

Nave

plate

Wheel

disc

Hub

cap

Finishing

strip

Moulding

Chrome

strip

REAR

AXLE

Windscreen

Windshield

Rear

Axle

Final

drive

unit

Rear

window

Rear

windscreen

Rear

windshield

Crown

wheel

Ring

gear

Final

drive

gear

Spiral

Backlight

drive

gear

Quarter

ven

t

N

D

V

No

draught

ventilator

Bevel

pinion

Small

pinion

spiral

drive

pinion

Bumpers

Fenders

Loom

Harness

U

bolts

Spring

clips

Odometer

Trip

recorder

Axle

shaft

Half

shaft

Hub

driving

shaft

Jack

Bonnet

catch

Hood

latch

driving

shaft

Kerosene

Paraffin

Differential

gear

Sun

wheel

Boot

Trunk

Differential

pinion

Planet

wheel