engine DATSUN B110 1969 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: B110, Model: DATSUN B110 1969Pages: 136, PDF Size: 5.64 MB

Page 17 of 136

Bneine

Remove

the

011

pan

and

011

straIner

Remove

the

tImIng

chaIn

cover

and

the

chaIn

tenSlOner

Remove

the

crankshaft

and

camshaft

sprockets

together

WIth

the

timing

chaIn

Fig

21

Tlmmg

cham

cover

removal

I

FIg

22

PIston

and

connectmg

rod

assembly

removal

Fig

23

Rear

011

seal

removal

Rotate

the

engIne

a

quarter

turn

and

remove

the

piston

and

connectIng

rod

assembly

Take

off

the

connectIng

rod

beatings

at

the

same

tIme

and

keep

them

In

order

Rotate

the

engIne

a

quarter

turn

and

remove

the

flywheel

Remove

the

maIn

bearIng

cap

and

the

rear

011

seal

Remove

the

crankshaft

Remove

the

baffie

plate

and

the

crank

case

net

Remove

the

camshaft

after

takIng

off

the

cam

shaft

plate

Remove

the

valve

tfter

Remove

the

piston

rIngs

With

a

tlng

remover

Press

out

the

piston

pIn

With

a

piston

pin

remover

and

an

arbor

press

Remove

the

valves

USIng

a

valve

tfter

Be

careful

not

to

lose

valve

sprIng

seat

011

seal

valve

collet

and

valve

rocker

sprIng

FIg

24

Baffle

plate

and

net

removal

Fig

25

Camshaft

plate

removal

17

Page 26 of 136

BDgiDe

Fig

49

Valve

installatIon

STl

303001

EM156

Fig

50

Piston

pin

installation

FIg

51

Piston

and

connecting

rod

assembly

Assemble

the

parts

In

order

valve

sprmg

spnng

retamer

valve

collet

and

val

ve

rocker

gUIde

28

Note

Make

sure

that

the

valve

face

is

clear

from

foreign

matters

Piston

and

Connecting

Rod

Assemble

pIston

piston

pm

and

connecting

rod

assorted

accordmg

to

cyhnder

number

for

every

cylInder

Notes

a

P1ston

pin

is

press

fitted

to

the

connectmg

rod

tightly

and

fitting

force

is

from

1

to

3

tons

When

fitting

piston

pin

speCIal

tool

must

be

used

When

pressmg

the

piston

pin

into

the

con

necting

rod

apply

engine

oil

to

the

pin

and

the

small

end

of

the

connecting

rod

b

Arrange

the

connecting

rod

so

that

the

oil

Jet

of

the

connecting

rod

large

end

is

directed

toward

the

right

side

of

the

cylinder

block

InstallIng

piston

rmgs

Install

the

top

and

second

rings

In

nght

pOSItIOns

so

that

the

marks

are

faced

upward

FIX

bearings

on

the

connecting

rod

and

the

connecting

rod

cap

Note

Clean

the

back

side

of

the

bearmg

carefully

Engine

Set

the

cyhnder

block

on

the

workmg

stand

WIth

the

engine

bottom

faced

upSIde

Install

the

valve

hfters

Install

the

camshaft

and

retain

by

the

camshaft

locate

plate

Locate

plate

tightemng

torque

IS

2

9

to

3

6

ft

lb

Fig

52

Installing

camshaft

locate

plate

Page 27 of 136

Bogine

Note

Set

the

locate

plate

so

as

the

LOWER

mark

comes

to

the

engine

bot

tom

side

Set

the

maIn

bearIngR

on

theIr

posItIOns

on

the

cylinder

block

Notes

a

The

center

bearmg

No

3

bearmg

is

a

flanged

type

for

thrust

force

b

Two

lOner

bearmgs

No

2

and

No

4

are

of

the

same

type

c

The

front

bearmg

No

1

IS

the

same

type

as

the

rear

bearmg

No

5

d

All

bearings

except

for

No

I

bearing

are

interchangeable

between

upper

and

lower

bearings

Apply

engIne

OIl

to

the

mam

bearIng

surfaces

on

both

sIdes

of

the

cyltnder

block

and

cap

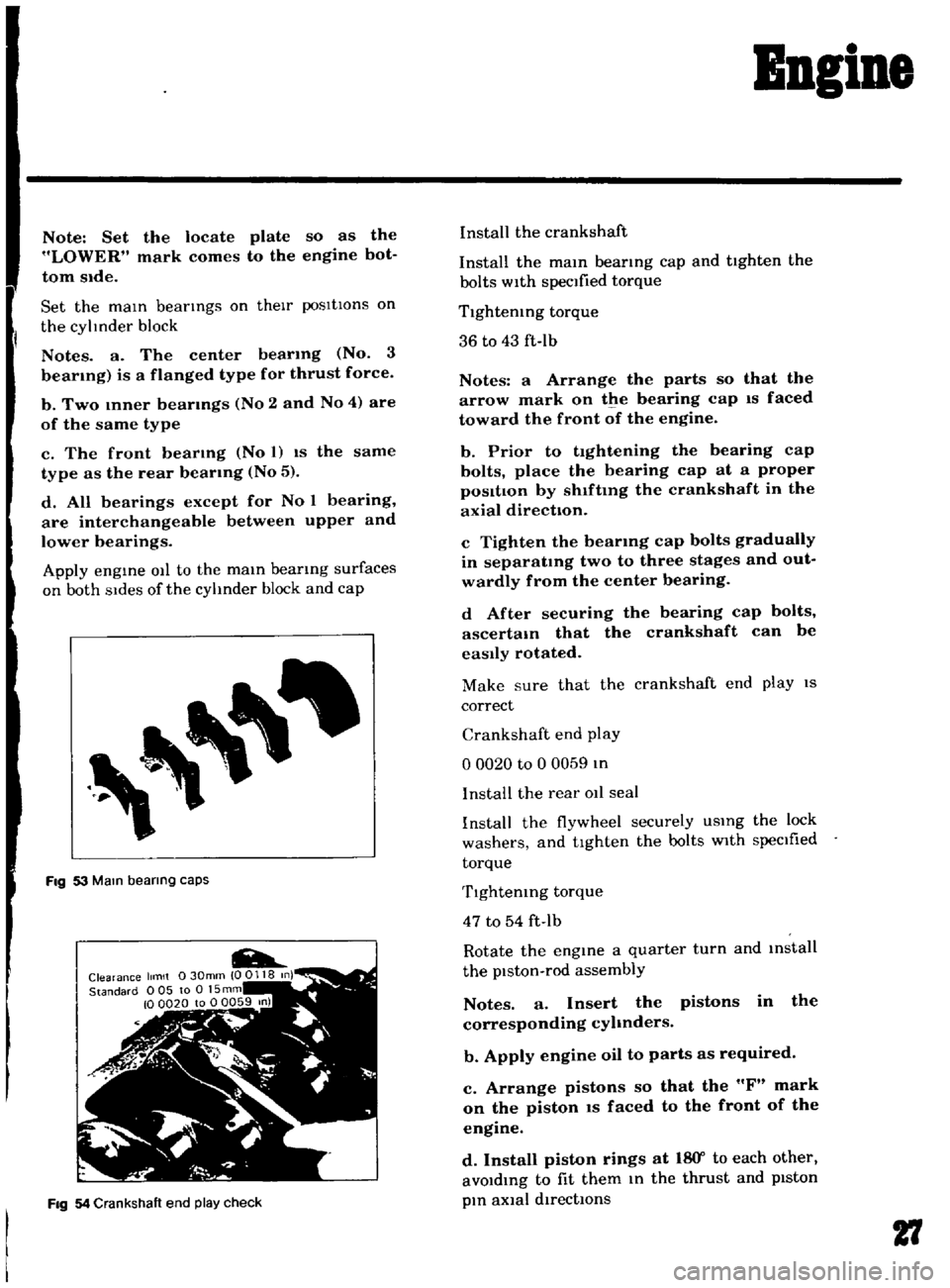

Fig

53

Mam

bearing

caps

Fig

54

Crankshaft

end

play

check

Install

the

crankshaft

Install

the

mam

bearmg

cap

and

tighten

the

bolts

with

specified

torque

Tlghtemng

torque

36

to

43

ft

Ib

Notes

a

Arrange

the

parts

so

that

the

arrow

mark

on

the

bearing

cap

IS

faced

toward

the

front

of

the

engine

b

Prior

to

tightening

the

bearing

cap

bolts

place

the

bearing

cap

at

a

proper

posItIon

by

shlftmg

the

crankshaft

in

the

axial

direction

c

Tighten

the

bearmg

cap

bolts

gradually

in

separatmg

two

to

three

stages

and

out

wardly

from

the

center

bearing

d

After

securing

the

bearing

cap

bolts

ascertam

that

the

crankshaft

can

be

easily

rotated

Make

sure

that

the

crankshaft

end

play

IS

correct

Crankshaft

end

play

o

0020

to

0

0059

In

I

nstalI

the

rear

011

seal

Install

the

flywheel

securely

USIng

the

lock

washers

and

tighten

the

bolts

with

specIfied

torque

Tlghtemng

torque

47

to

54

ft

Ib

Rotate

the

engine

a

quarter

turn

and

mstall

the

piston

rod

assembly

Notes

a

Insert

the

pistons

in

the

corresponding

cyhnders

b

Apply

engine

oil

to

parts

as

required

c

Arrange

pistons

so

that

the

F

mark

on

the

piston

IS

faced

to

the

front

of

the

engine

d

Install

piston

rings

at

18

Y

to

each

other

avoIdIng

to

fit

them

In

the

thrust

and

pIston

pIn

aXial

directIOns

27

Page 30 of 136

BDgiDe

Install

the

new

011

seal

to

the

front

cover

The

front

cover

011

seal

should

be

replaced

when

the

front

cover

IS

disassembled

Install

the

front

cover

applYing

the

seahng

agent

to

both

surfaces

of

the

gasket

Tlghtemng

torque

36

to

5

1

ft

lb

Install

the

ot

strainer

and

the

011

pan

uSing

the

gasket

Apply

seahng

agent

on

both

surfaces

of

the

gasket

especIally

on

the

front

and

rear

por

tlOns

of

the

011

pan

011

pan

tlghtemng

torque

2

9

to

4

3

ft

lb

Invert

the

engine

and

Install

the

cyhnder

head

assembly

and

gasket

Note

Apply

sealing

agent

overall

the

cylinder

block

surface

Place

the

gasket

on

It

and

apply

sealing

agent

to

the

gasket

top

Tighten

the

cylinder

head

bolts

to

the

peclfied

torque

Cylmder

bloLk

Side

Stecl

heet

Sealmg

agent

not

required

Cylinder

head

Side

Jomt

sheet

Remarks

Install

WIthout

applymg

sealing

agent

Be

careful

not

to

damage

the

push

rod

Side

because

thIS

SIde

has

prevIOusly

been

provIded

WIth

sealing

agent

J

30

v

o

The

cyhnder

head

uses

two

types

of

in

stallatIOn

bolt

one

IS

for

the

center

nght

SIde

and

the

other

IS

for

all

other

posItIOns

The

bolt

for

the

center

nght

Side

has

a

I

mark

on

ItS

head

L

1

Bolt

number

hh

nlltilatlOn

rJ

Dlaml

tl

f

j

031111003189

T

T

1M

E

u

pt

lor

CD

03492

to

0

3555

ot

rhJ

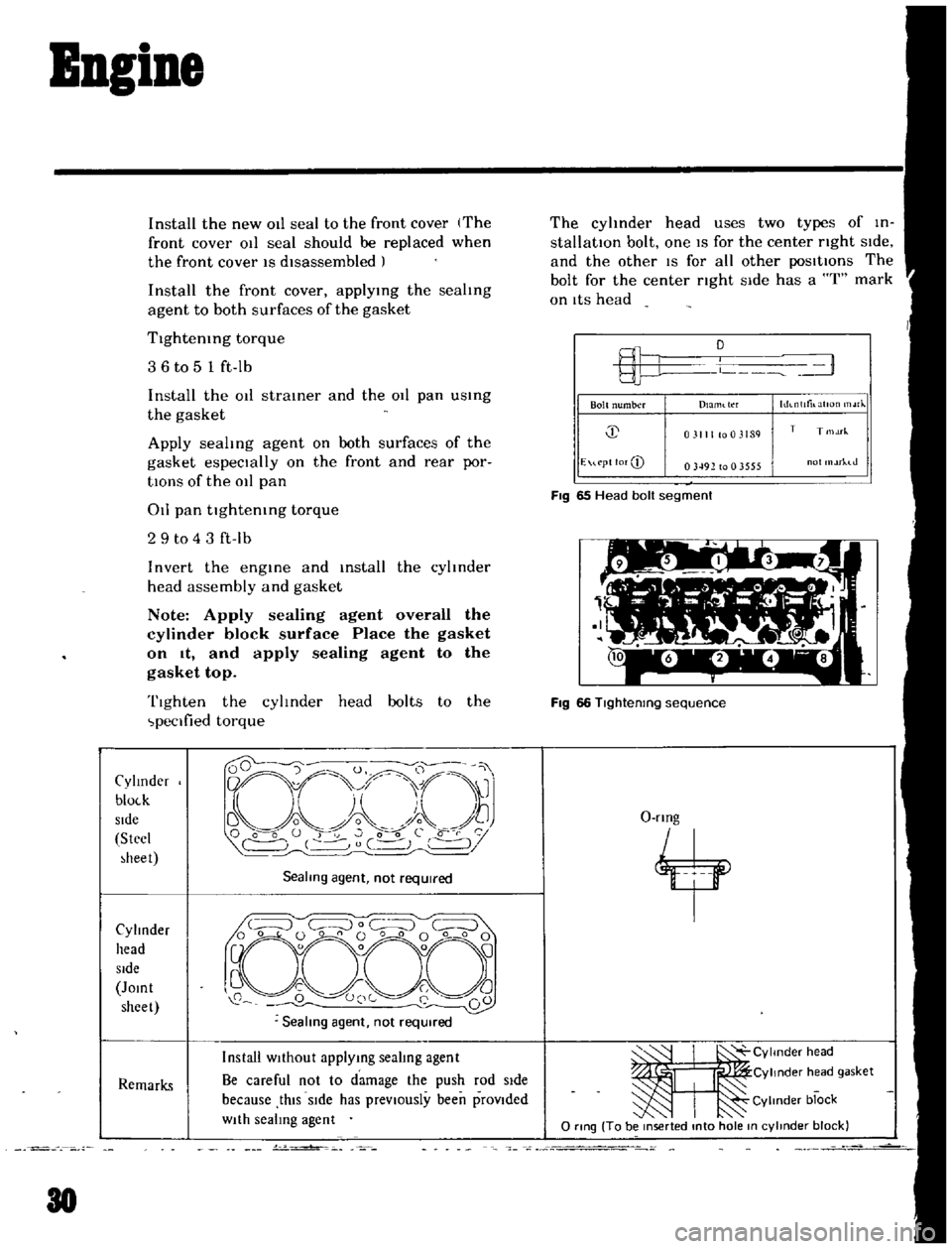

FIg

65

Head

bolt

segment

Fig

66

Tlghtenmg

sequence

O

rmg

4

ItI

CYlmder

head

Cylinder

h

ad

gasket

Cylinder

block

o

rtng

To

be

mserted

mto

hole

m

cylmder

block

Page 32 of 136

BBgiBe

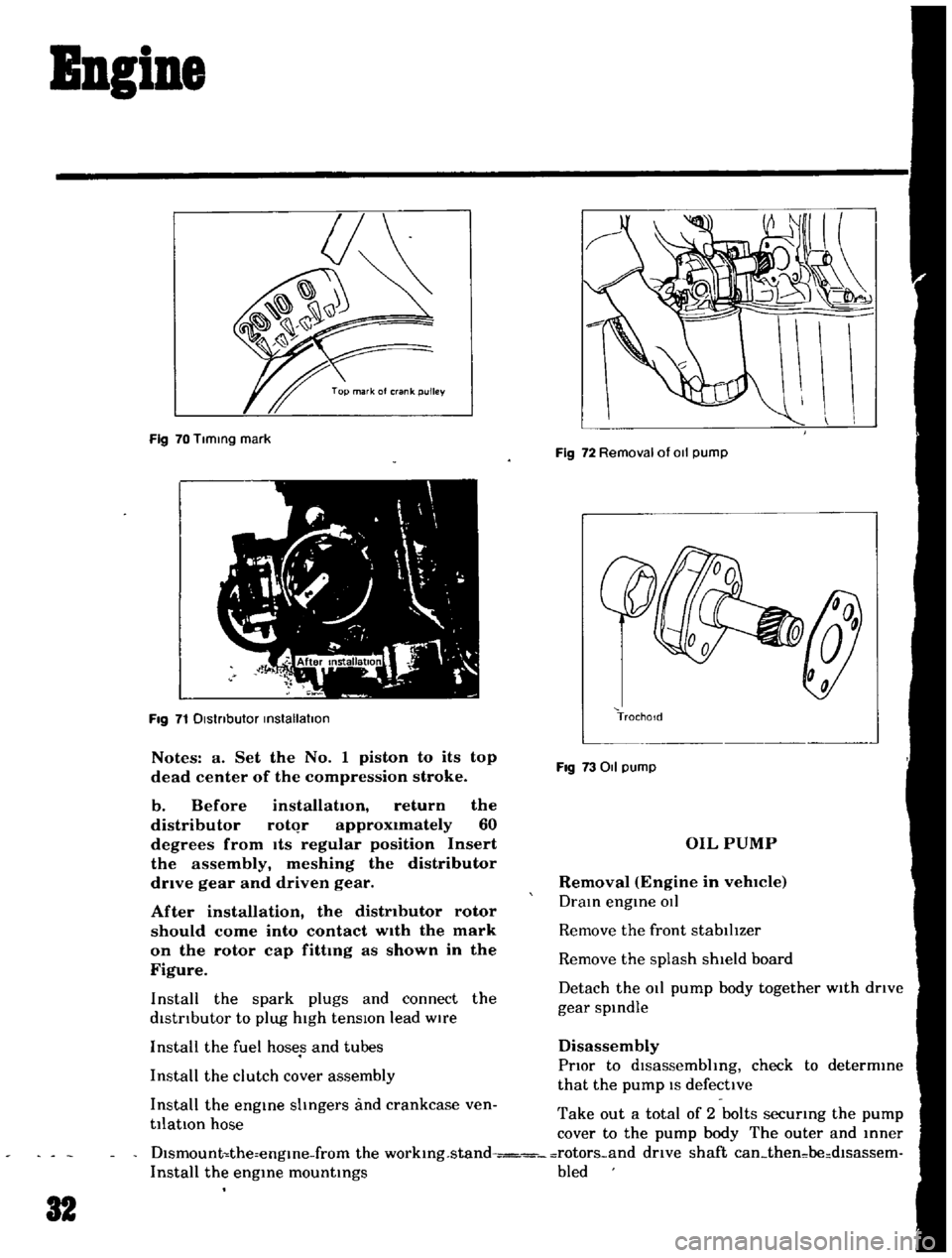

Fig

70

Tlmmg

mark

Fig

71

Dlstnbutor

mstallatlon

Notes

a

Set

the

No

1

piston

to

its

top

dead

center

of

the

compression

stroke

b

Before

installation

return

the

distributor

rotqr

approximately

60

degrees

from

Its

regular

position

Insert

the

assembly

meshing

the

distributor

drive

gear

and

driven

gear

After

installation

the

distributor

rotor

should

come

into

contact

wIth

the

mark

on

the

rotor

cap

fittmg

as

shown

in

the

Figure

Install

the

spark

plugs

and

connect

the

distrIbutor

to

plug

high

tensIOn

lead

wire

Install

the

fuel

hoses

and

tubes

Install

the

clutch

cover

assembly

Install

the

engme

shngers

and

crankcase

ven

tilatIOn

hose

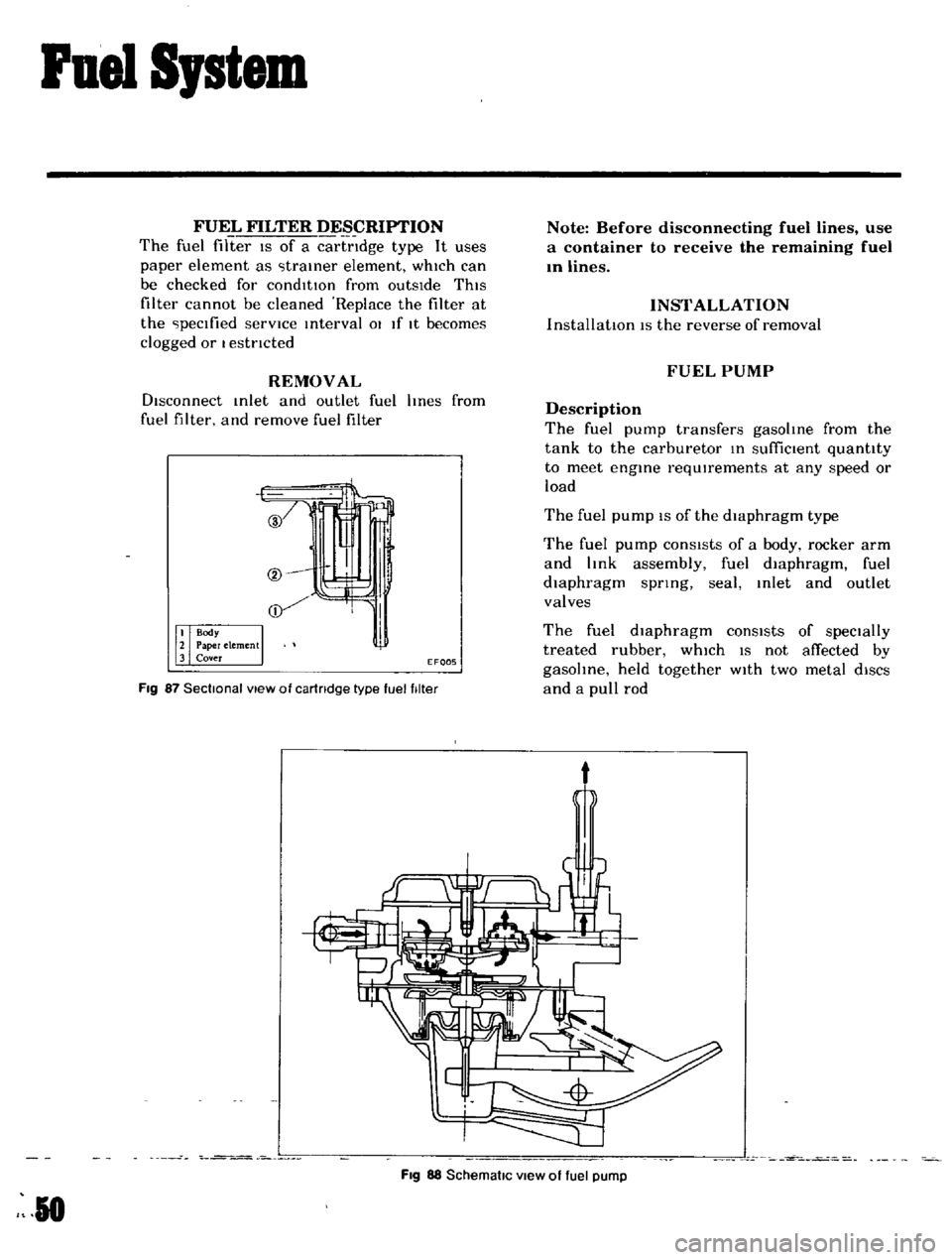

Fig

72

Removal

of

011

pump

TrochoId

Fig

73011

pump

OIL

PUMP

Removal

Engine

in

vehlCIe

Dram

engme

OIl

Remove

the

front

stabilIzer

Remove

the

splash

shield

board

Detach

the

011

pump

body

together

with

drIve

gear

spmdle

Disassembly

PrIor

to

dlsassembhng

check

to

determme

that

the

pump

IS

defective

Take

out

a

total

of

2

bolts

securmg

the

pump

cover

to

the

pump

body

The

outer

and

mner

Dlsmount

the

engme

from

the

workmg

stand

rotors

and

drive

shaft

can

then

be

dlsassem

Install

the

engme

mountmgs

bled

32

Page 47 of 136

ruel

Sptem

FUEL

FILTER

DESCRIPTION

The

fuel

filter

IS

of

a

cartndge

type

It

uses

paper

element

as

traIner

element

which

can

be

checked

for

condItIOn

from

outsIde

ThIS

filter

cannot

be

cleaned

Replace

the

filter

at

the

peclfied

servICe

Interval

01

If

It

becomes

clogged

or

I

estncted

REMOVAL

DIsconnect

Inlet

and

outlet

fuel

hnes

from

fuel

filter

and

remove

fuel

filter

if

EF005

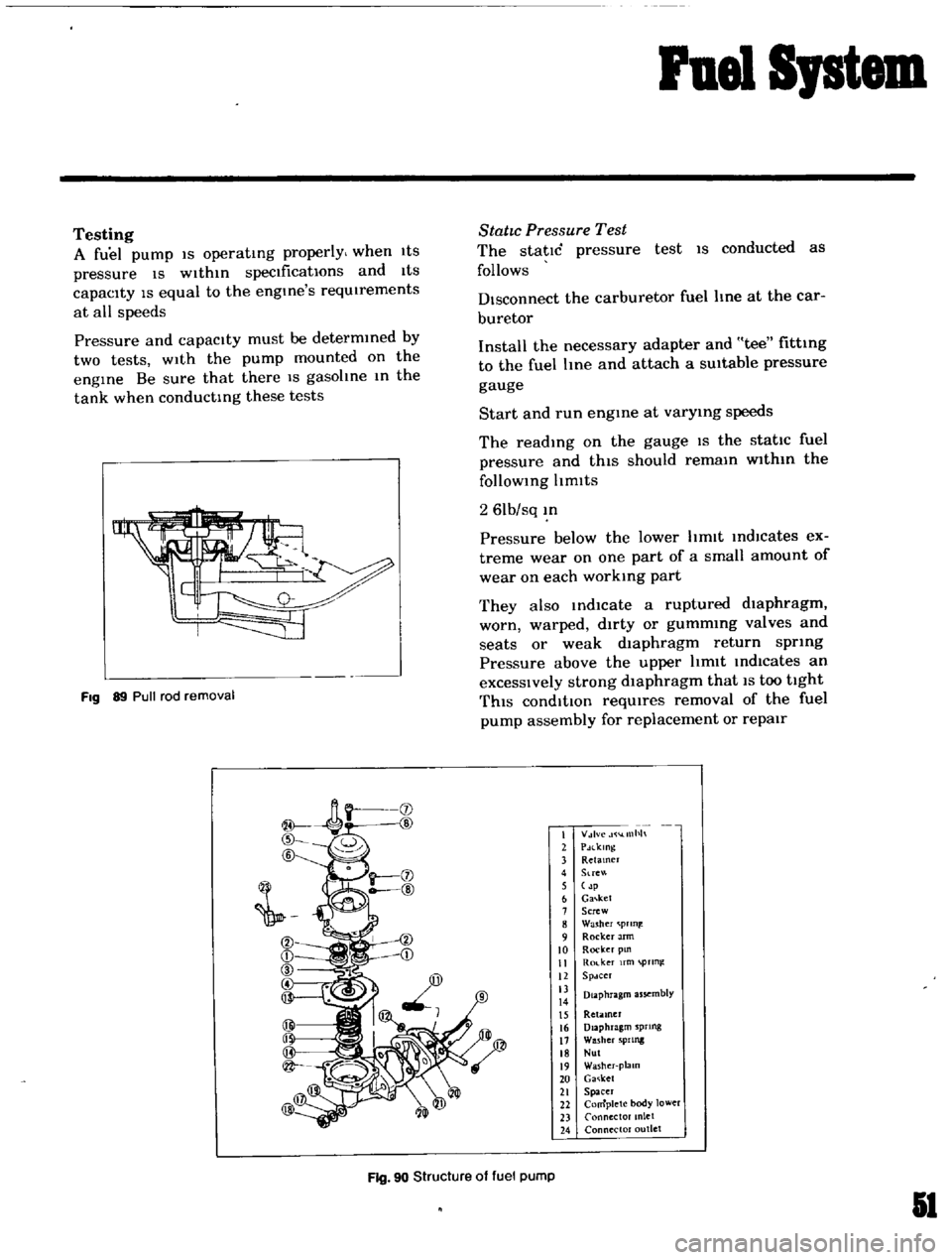

Fig

87

Sectional

view

of

cartridge

type

fuel

filter

Note

Before

disconnecting

fuel

lines

use

a

container

to

receive

the

remaining

fuel

In

lines

INSTALLATION

InstallatIOn

IS

the

reverse

of

removal

FUEL

PUMP

Description

The

fuel

pump

transfers

gasoline

from

the

tank

to

the

carburetor

In

suffiCient

quantity

to

meet

engine

requIrements

at

any

speed

or

load

The

fuel

pump

IS

of

the

diaphragm

type

The

fuel

pump

conSIsts

of

a

body

rocker

arm

and

link

assembly

fuel

diaphragm

fuel

diaphragm

spnng

seal

Inlet

and

outlet

valves

The

fuel

diaphragm

consists

of

specially

treated

rubber

whIch

IS

not

affected

by

gasohne

held

together

WIth

two

metal

diSCS

and

a

pull

rod

t

Fig

88

SchematiC

view

of

fuel

pump

R

0

Page 48 of 136

Fuel

Sptem

Testing

A

fuel

pump

IS

operatIng

properly

when

1tS

pressure

IS

Within

specifications

and

ItS

capacIty

IS

equal

to

the

engine

s

reqUIrements

at

all

speeds

Pressure

and

capacity

must

be

determined

by

two

tests

With

the

pump

mounted

on

the

engIne

Be

sure

that

there

IS

gasohne

m

the

tank

when

conductIng

these

tests

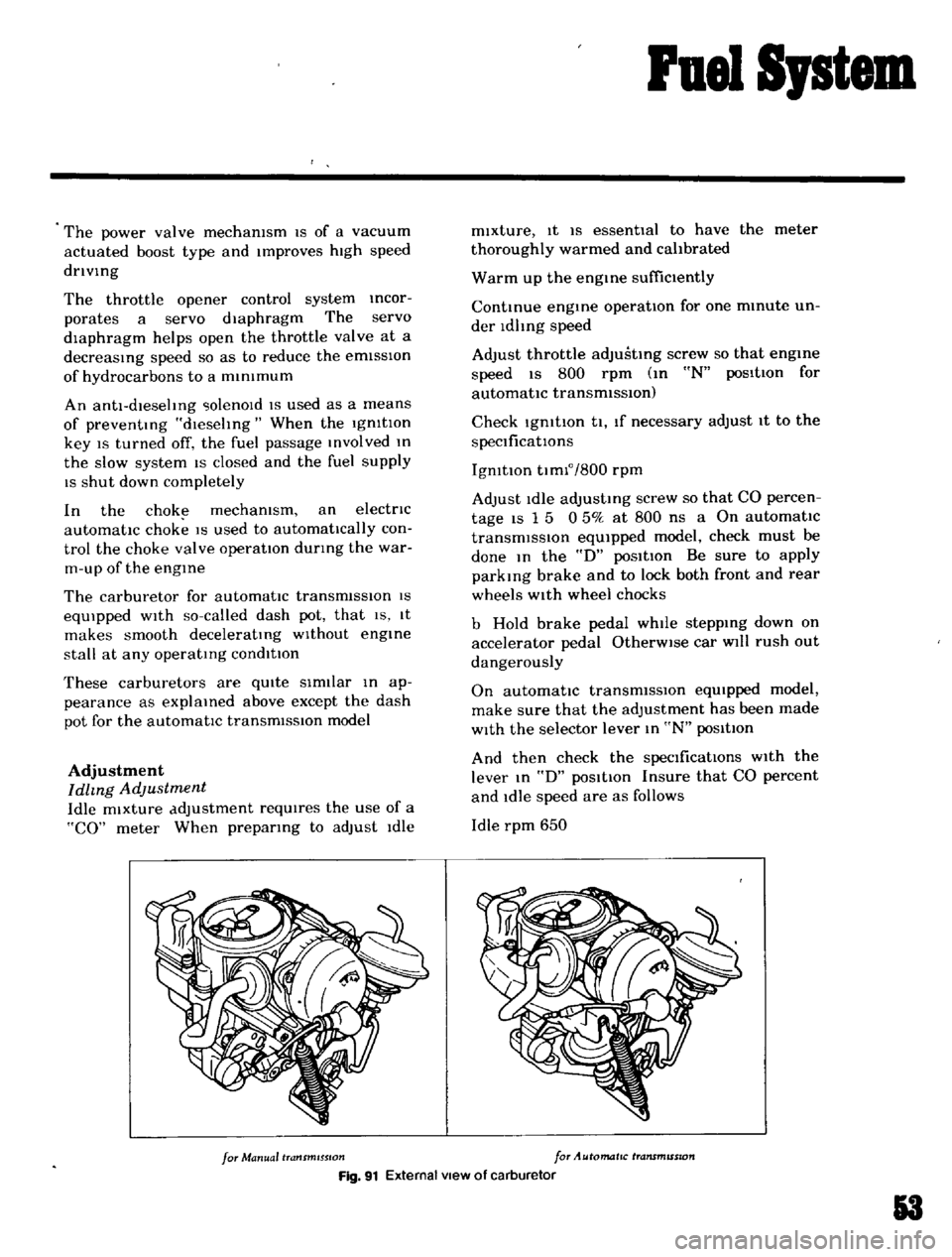

Fig

89

Pull

rod

removal

StatIc

Pressure

Test

The

static

pressure

test

IS

conducted

as

follows

Disconnect

the

carburetor

fuel

line

at

the

car

buretor

Install

the

necessary

adapter

and

tee

fitting

to

the

fuel

Ime

and

attach

a

SUitable

pressure

gauge

Start

and

run

engme

at

varymg

speeds

The

readIng

on

the

gauge

IS

the

static

fuel

pressure

and

thIS

should

remam

wlthm

the

follOWing

Itmlts

2

61b

sq

m

Pressure

below

the

lower

hmlt

IndlCates

ex

treme

wear

on

one

part

of

a

small

amount

of

wear

on

each

working

part

They

also

md1cate

a

ruptured

dIaphragm

worn

warped

dirty

or

gummmg

valves

and

seats

or

weak

dIaphragm

return

spring

Pressure

above

the

upper

hmlt

Indicates

an

excessIVely

strong

dIaphragm

that

IS

too

tight

ThIS

condItIOn

reqUIres

removal

of

the

fuel

pump

assembly

for

replacement

or

repair

I

V

lvc

llllh

2

PdlklOg

3

Retamer

4

Stre

5

p

6

Ga

ket

7

Screw

8

Washer

prln

9

Rocker

Jrm

10

Rocker

pm

II

Ro

ker

fm

pTln

12

Spdcer

13

Diaphragm

assembly

14

15

Retiuner

16

Diaphragm

sprtng

17

Washer

5PIlllg

18

Nul

19

Washer

plalO

20

Ga

ket

21

Spacer

22

Complete

body

lower

23

Connector

anlet

24

Connector

outlet

Fig

90

Structure

of

fuel

pump

51

Page 50 of 136

Fuel

Sptem

The

power

valve

mechanIsm

IS

of

a

vacuum

actuated

boost

type

and

Improves

hIgh

speed

drivIng

The

throttle

opener

control

system

Incor

porates

a

servo

diaphragm

The

servo

dIaphragm

helps

open

the

throttle

valve

at

a

decreasIng

speed

so

as

to

reduce

the

emISSIOn

of

hydrocarbons

to

a

minImum

An

antI

dlesehng

olen01d

IS

used

as

a

means

of

preventIng

dlesehng

When

the

IgnItIOn

key

IS

turned

ofT

the

fuel

passage

Involved

In

the

slow

system

IS

closed

and

the

fuel

supply

IS

shut

down

completely

In

the

chok

mechanIsm

an

electric

automatIc

choke

IS

used

to

automatically

con

trol

the

choke

valve

operatIOn

durIng

the

war

m

up

of

the

engIne

The

carburetor

for

automatic

transmiSSIOn

IS

eqUIpped

WIth

so

called

dash

pot

that

IS

It

makes

smooth

deceleratIng

WIthout

engIne

stall

at

any

operatIng

conditIOn

These

carburetors

are

qUIte

SImIlar

In

ap

pearance

as

explaIned

above

except

the

dash

pot

for

the

automatIc

transmISSion

model

Adjustment

Idhng

Adjustment

Idle

mixture

adjustment

requIres

the

use

of

a

CO

meter

When

prepatlng

to

adjust

Idle

mIxture

It

IS

essentIal

to

have

the

meter

thoroughly

warmed

and

cahbrated

Warm

up

the

engIne

suffiCiently

ContInue

engme

operatIOn

for

one

mmute

un

der

ldhng

speed

Adjust

throttle

adjustIng

screw

so

that

engme

speed

IS

800

rpm

m

N

pos1tIon

for

automatic

transmiSSIOn

Check

IgmtlOn

tl

If

necessary

adjust

It

to

the

speCificatIOns

IgnItIOn

tImlo

800

rpm

Adjust

Idle

adJustmg

screw

so

that

CO

percen

tage

IS

1

5

0

50

at

800

ns

a

On

automatIc

transmiSSIOn

eqUipped

model

check

must

be

done

In

the

D

poSItIon

Be

sure

to

apply

parkmg

brake

and

to

lock

both

front

and

rear

wheels

With

wheel

chocks

b

Hold

brake

pedal

while

steppIng

down

on

accelerator

pedal

OtherWise

car

Will

rush

out

dangerously

On

automatIc

transmiSSIOn

eqUIpped

model

make

sure

that

the

adjustment

has

been

made

With

the

selector

lever

In

N

posItIon

And

then

check

the

specificatIOns

With

the

lever

In

D

pOSitIOn

Insure

that

CO

percent

and

Idle

speed

are

as

follows

Idle

rpm

650

for

Manual

transmISSion

for

Automatic

transmISSion

Fig

91

External

view

of

carburetor

3

Page 54 of 136

Fuel

Sptem

ted

on

the

car

If

the

throttle

valve

fails

to

fully

open

the

unIoader

becomes

inoperative

resulting

in

poor

ac

celleration

after

the

engine

is

started

Note

Use

an

accurate

measuring

in

strument

such

as

a

wheatstone

bridge

B1

metal

cover

settmg

BL

metal

Settmg

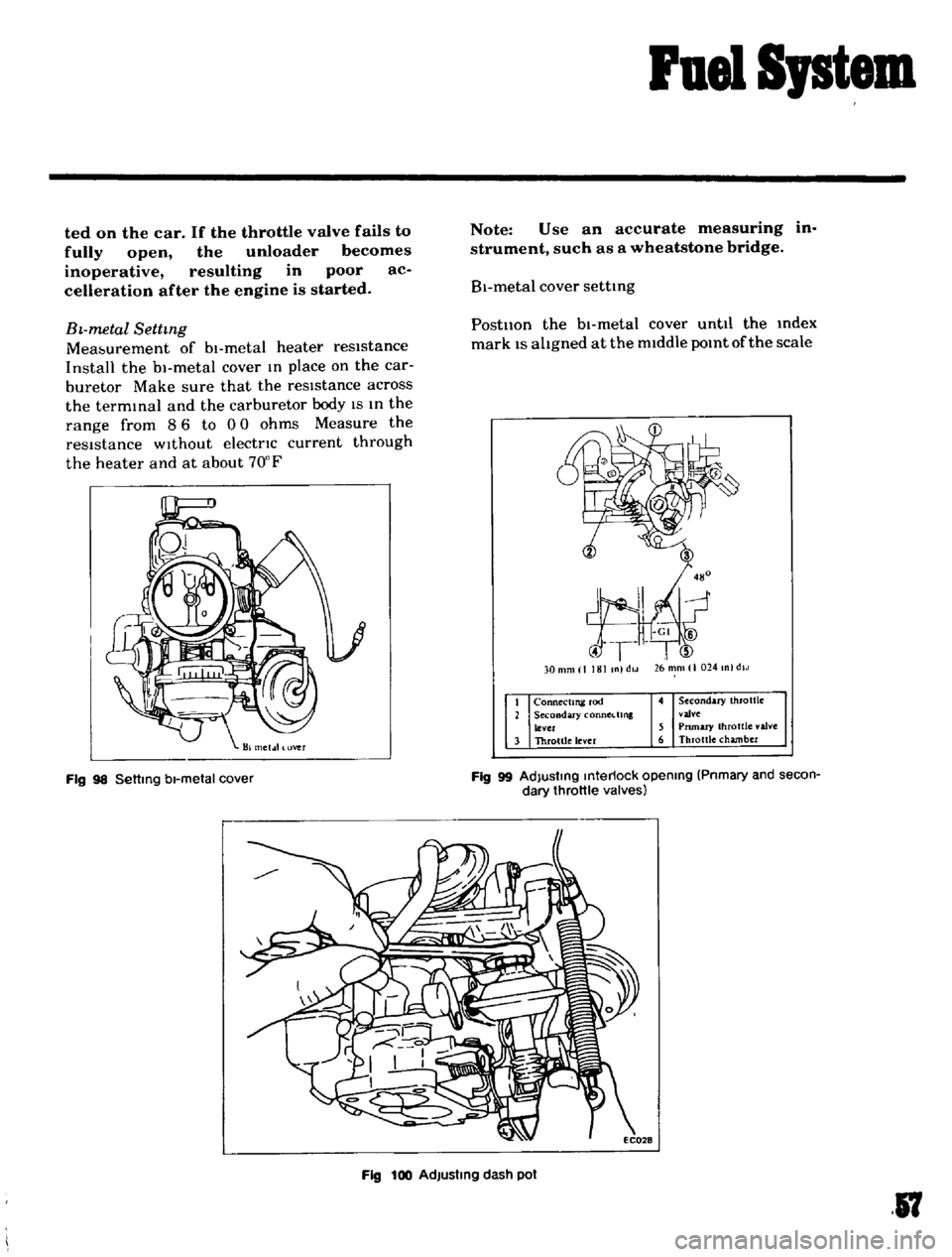

Mea

urement

of

bl

metal

heater

resistance

Install

the

bl

metal

cover

m

place

on

the

car

buretor

Make

sure

that

the

resIstance

across

the

termmal

and

the

carburetor

body

IS

m

the

range

from

8

6

to

0

0

ohms

Measure

the

resIstance

without

electnc

current

through

the

heater

and

at

about

70

F

Postllon

the

bl

metal

cover

until

the

mdex

mark

1S

altgned

at

the

middle

pomt

of

the

scale

26

mm

I

024

m

dlJ

30

m

1

181

In

dlJ

Connectml

rod

Secondary

COnnCl

lms

lever

Throltle

lever

4

Secondary

throttle

vaJve

5

Pnmary

throttle

valve

6

Throttle

chamber

Fig

98

Settmg

bl

metal

cover

Fig

99

AdJustmg

mterlock

opening

Pnmary

and

secon

dary

throttle

valves

Fig

100

AdJustmg

dash

pot

17

Page 55 of 136

ruel

S

stem

Note

When

somewhat

over

choked

set

bl

metal

cover

after

turning

it

clockwise

slightly

Adjustment

oflnterlock

Opelntng

of

Pnmary

and

Secondary

Throttle

Values

Open

the

pnmary

Side

throttle

valve

48

from

the

fully

closed

positIOn

and

measure

clearance

GIn

between

the

throttle

valve

and

throttle

chamber

mSlde

wall

as

shown

m

Figure

99

GIn

0

228

m

WIthout

dlsturbmg

the

above

settmg

bend

connectmg

rod

as

necessary

so

that

secoridary

throttle

valve

IS

about

to

open

Upon

com

pletIOn

of

the

adjustment

make

sure

that

the

hnk

system

operates

smoothly

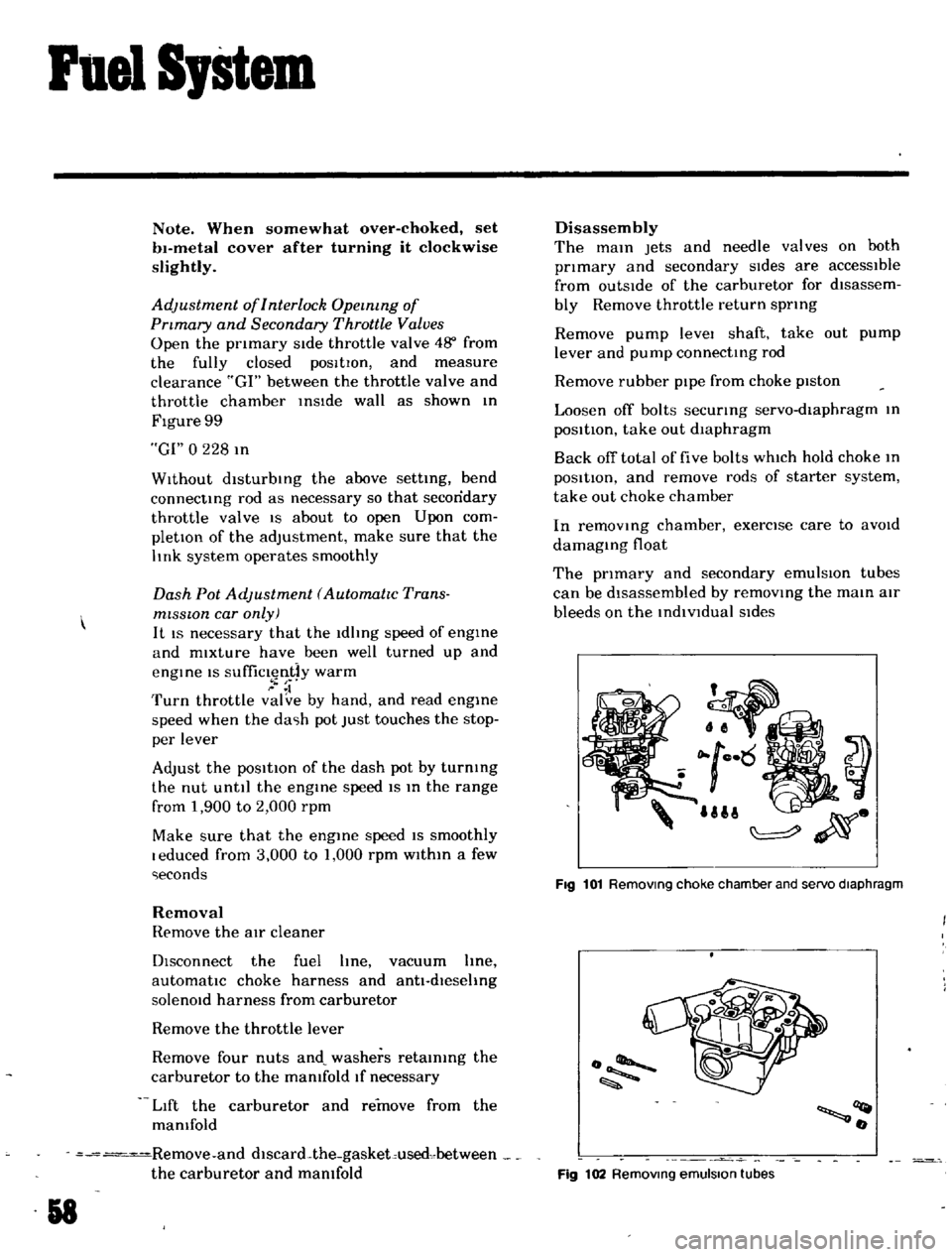

Dash

Pot

Adjustment

AutomatIC

Trans

mlsszon

car

only

It

IS

necessary

that

the

Idhng

speed

of

engme

and

mIxture

have

been

well

turned

up

and

engme

IS

suffiC1

n

y

warm

1

Turn

throttle

valve

by

hand

and

read

engme

speed

when

the

da

h

pot

Just

touches

the

stop

per

lever

Adjust

the

pOSitIOn

of

the

dash

pot

by

turnmg

the

nut

until

the

engine

speed

IS

In

the

range

from

1

900

to

2

000

rpm

Make

sure

that

the

engine

speed

IS

smoothly

leduced

from

3

000

to

1

000

rpm

within

a

few

econds

Removal

Remove

the

aIr

cleaner

DIsconnect

the

fuel

line

vacuum

line

automatic

choke

harness

and

antl

dlesehng

solenOId

harness

from

carburetor

Remove

the

throttle

lever

Remove

four

nuts

and

washers

retaining

the

carburetor

to

the

mamfold

If

necessary

LIft

the

carburetor

and

remove

from

the

mamfold

Remove

and

dlscard

the

gasketcused

between

the

carburetor

and

mamfold

8

Disassembly

The

main

Jets

and

needle

valves

on

both

primary

and

secondary

Sides

are

accessible

from

outSIde

of

the

carburetor

for

disassem

bly

Remove

throttle

return

sprmg

Remove

pump

level

shaft

take

out

pump

lever

and

pump

connectmg

rod

Remove

rubber

pipe

from

choke

piston

Loosen

off

bolts

secutlng

servo

diaphragm

In

positIOn

take

out

dIaphragm

Back

off

total

of

five

bolts

which

hold

choke

In

posItion

and

remove

rods

of

starter

system

take

out

choke

chamber

In

removmg

chamber

exercise

care

to

aVOId

damaging

float

The

pnmary

and

secondary

emulsIOn

tubes

can

be

disassembled

by

removmg

the

main

air

bleeds

on

the

indiVidual

SIdes

UII

ij

Fig

101

Removmg

choke

chamber

and

servo

diaphragm

o

llQt

o

Fig

102

Removmg

emulsion

tubes